Non-woven fabric cutting device

A technology of non-woven fabrics and fabric guide rollers, which is applied in textiles, papermaking, and textile material cutting, etc. and other problems, to achieve the effect of simple structure, improved production efficiency and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

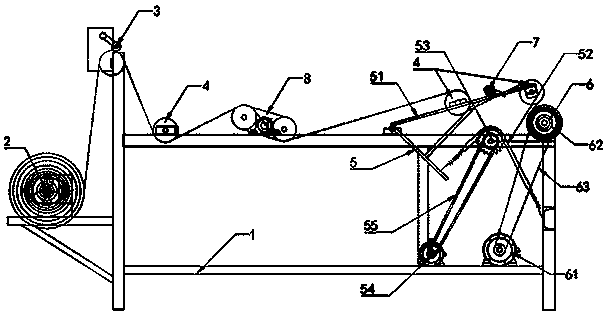

[0009] Depend on figure 1 Known, a non-woven fabric cutting device, including a frame 1, is characterized in that: the frame 1 is provided with an unwinding mechanism 2, a meter counter 3, a cloth guide roller 4, and a lifting mechanism from left to right. Slitting assembly 5, winding mechanism 6; described liftable slitting assembly 5 is made up of tripod 51, chain belt 52, double gear shaft 53, lifting drive device 54, transmission chain belt 55, and described tripod 51 The left end of bottom edge is movably connected on the frame 1 by pin shaft, is provided with cutting blade 7 on the tripod 51, and is provided with cloth guide roller 4 on both sides of cutting blade 7; Described chain belt 52 and double gear Axle 53 is connected, and chain belt 52 two ends are provided with spring, is connected with the right end of tripod 51 bottoms by the spring of left end, is connected with frame 1 by the spring of right end; The double gear shaft 53 rotates forward or reversely, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com