Liquid heating vessel, heating tool and method for processing liquid heating vessel

A liquid heating container and container body technology, which is applied to water-boiling utensils, heating devices, cooking utensils, etc., can solve the problems of reduced service life of heating containers, complicated processing and installation processes, and low detection accuracy, etc. The effect of reducing the loss, facilitating mass production, and simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

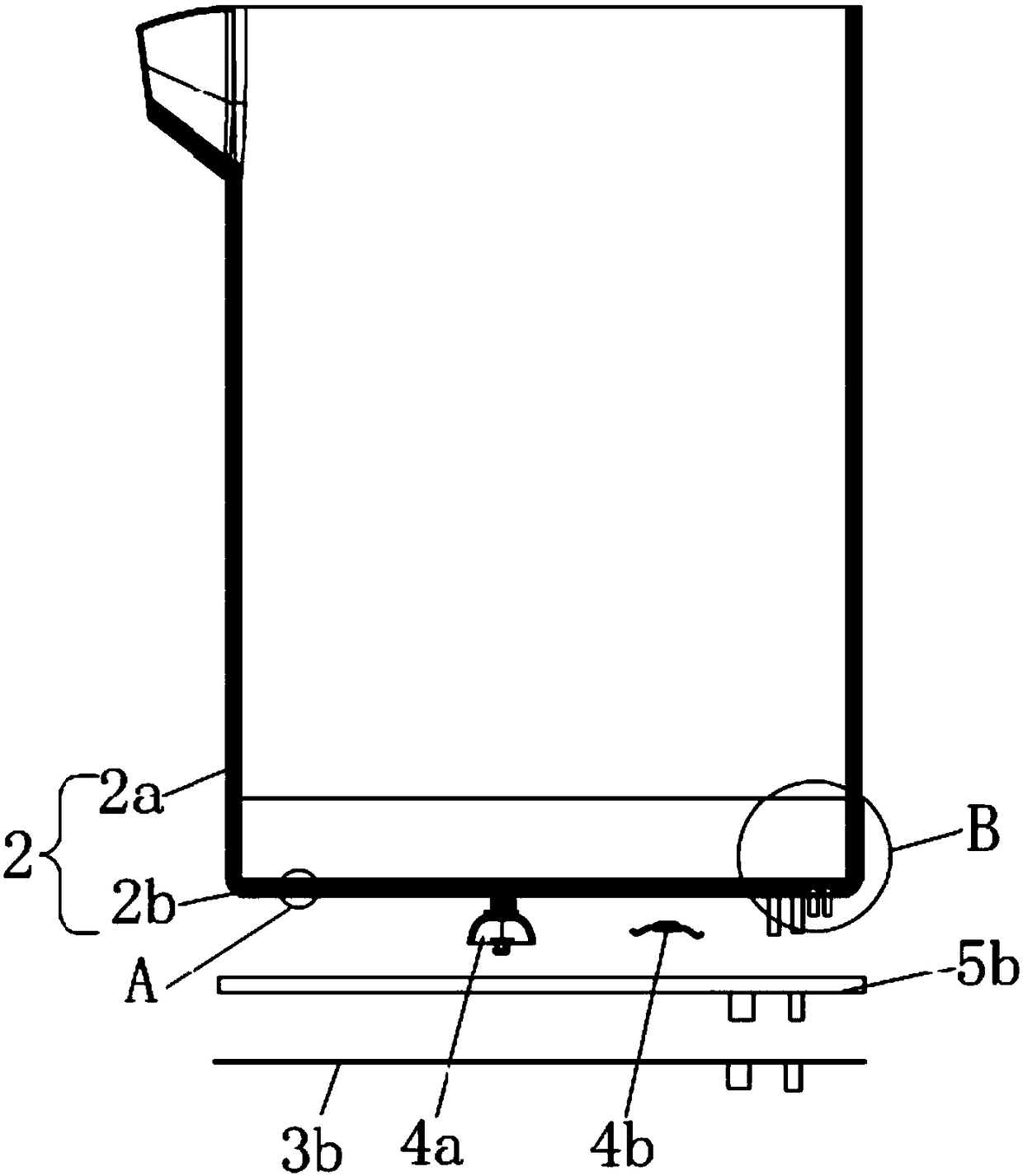

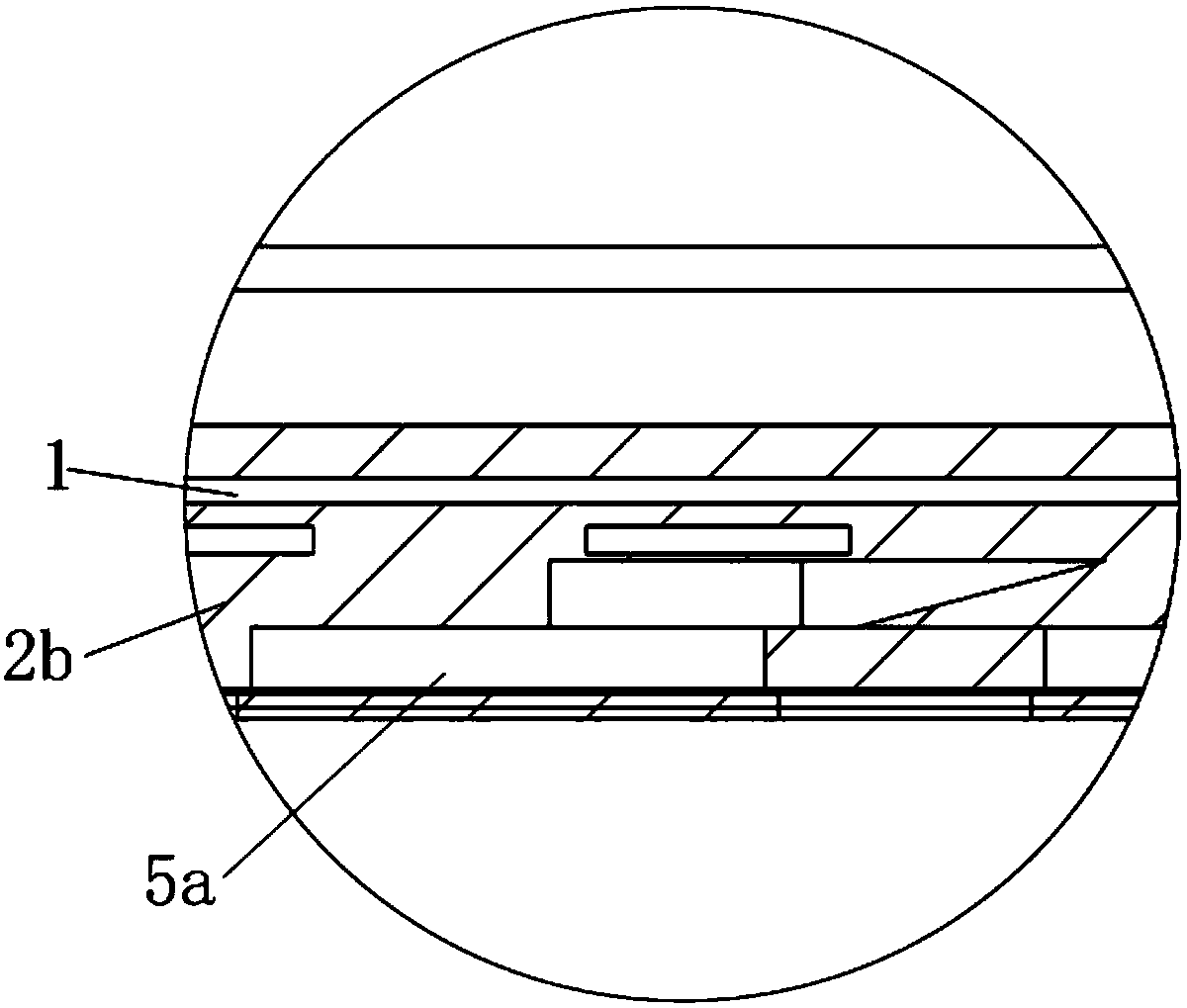

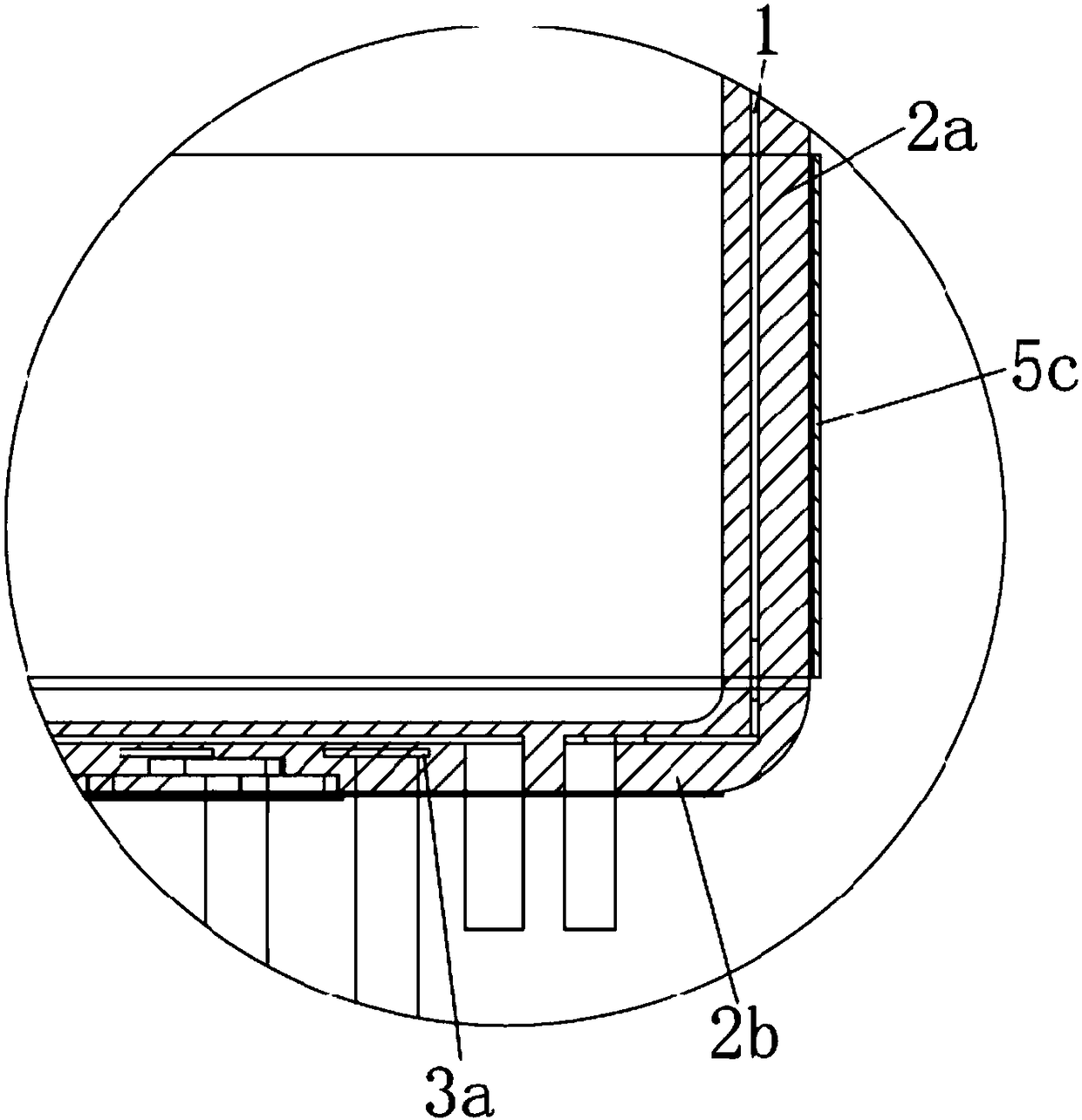

[0056] See attached figure 1 To attach Figure 4 , the invention discloses a liquid heating container, comprising a container body 2 and a heating element 1, the container body 2 is used to contain the liquid to be heated, the container body 2 is made of non-metallic insulating material, the heating element The body 1 is pre-embedded in the bottom and / or side wall of the container body 2 . Wherein, the container body 2 is made of temperature-resistant material, so as to ensure the normal operation of the container body. In the present invention, the heating element 1 is pre-embedded in the container body 2. At this time, the heating element 1 is isolated from the outside, which can reduce the probability of the heating element 1 being oxidized, thereby improving the service life of the heating element 1. In addition, when the heating element 1 is pre-installed When buried in the container body 2, the heat dissipated by the heating element 1 is not easily lost, and more heat ...

Embodiment 2

[0089] See attached Figure 5 , this embodiment discloses a heating appliance, which includes the liquid heating container described in Embodiment 1 and the base 6 adapted to the liquid heating container.

[0090] In addition, the heating device further includes a temperature control unit, an anti-dry heating unit and / or an anti-leakage protection unit.

[0091] Wherein, the temperature control unit includes a temperature sensing component 3 and a temperature control component, the temperature sensing component is used to sense the temperature of the container body 2, and the temperature control component controls the operation of the heating element 1 according to the temperature sensed by the temperature sensing component.

[0092] The anti-dry heating unit includes several temperature controllers 4, and the temperature controllers 4 are used to detect the temperature of the container body 2. When the temperature detected by the temperature controller reaches the anti-dry he...

Embodiment 3

[0097] This embodiment discloses a method for processing the liquid heating container described in Embodiment 1. This embodiment is aimed at when the container body 2 has an integrated structure, that is, when the container body 2 is a bottomless container body 2, Method for processing liquid heating vessels.

[0098] Specifically, the method for processing a liquid heating container includes the following steps:

[0099] S11, placing the heating element 1 in a forming mold compatible with the container body 2;

[0100] S12, passing the slurry for forming the container body 2 into the forming mold, and burying the heating element 1 in the slurry;

[0101] S13. The container body 2 is obtained after molding the slurry, and the heating element 1 is embedded in the bottom and / or sidewall of the container body 2 .

[0102] Wherein, the container body 2 is preferably molded through a die-casting process, a pouring process, a pouring process or a pressing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com