Wall-mounted solar water heater and manufacturing method of solar heat accumulator

A technology for solar water heaters and solar heat collectors, which is applied to solar heat collectors, solar thermal energy, and solar heat collectors using working fluids, etc. It can solve the problem that vacuum glass tubes cannot be used in series and the insulation effect of solar heat collectors is poor And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

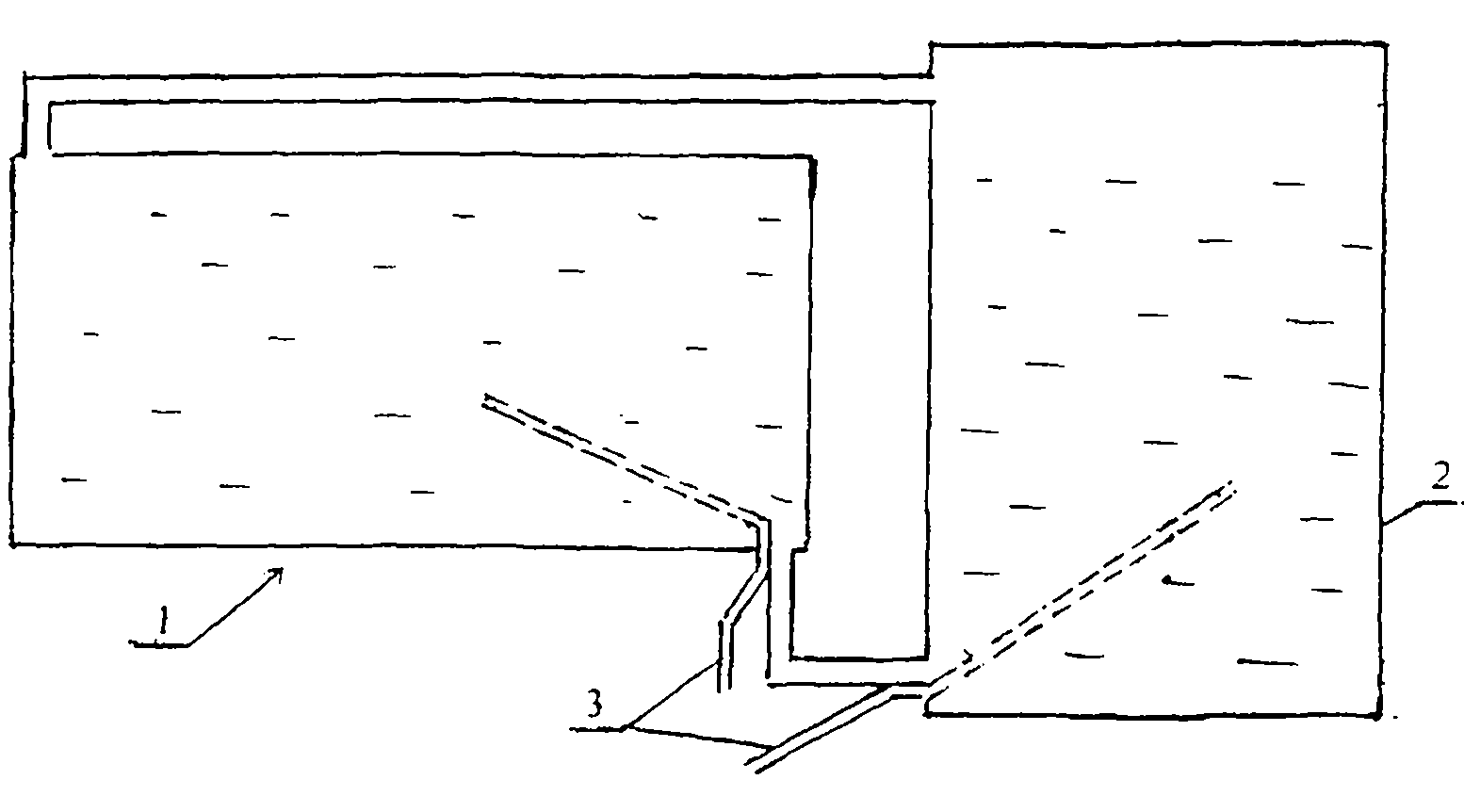

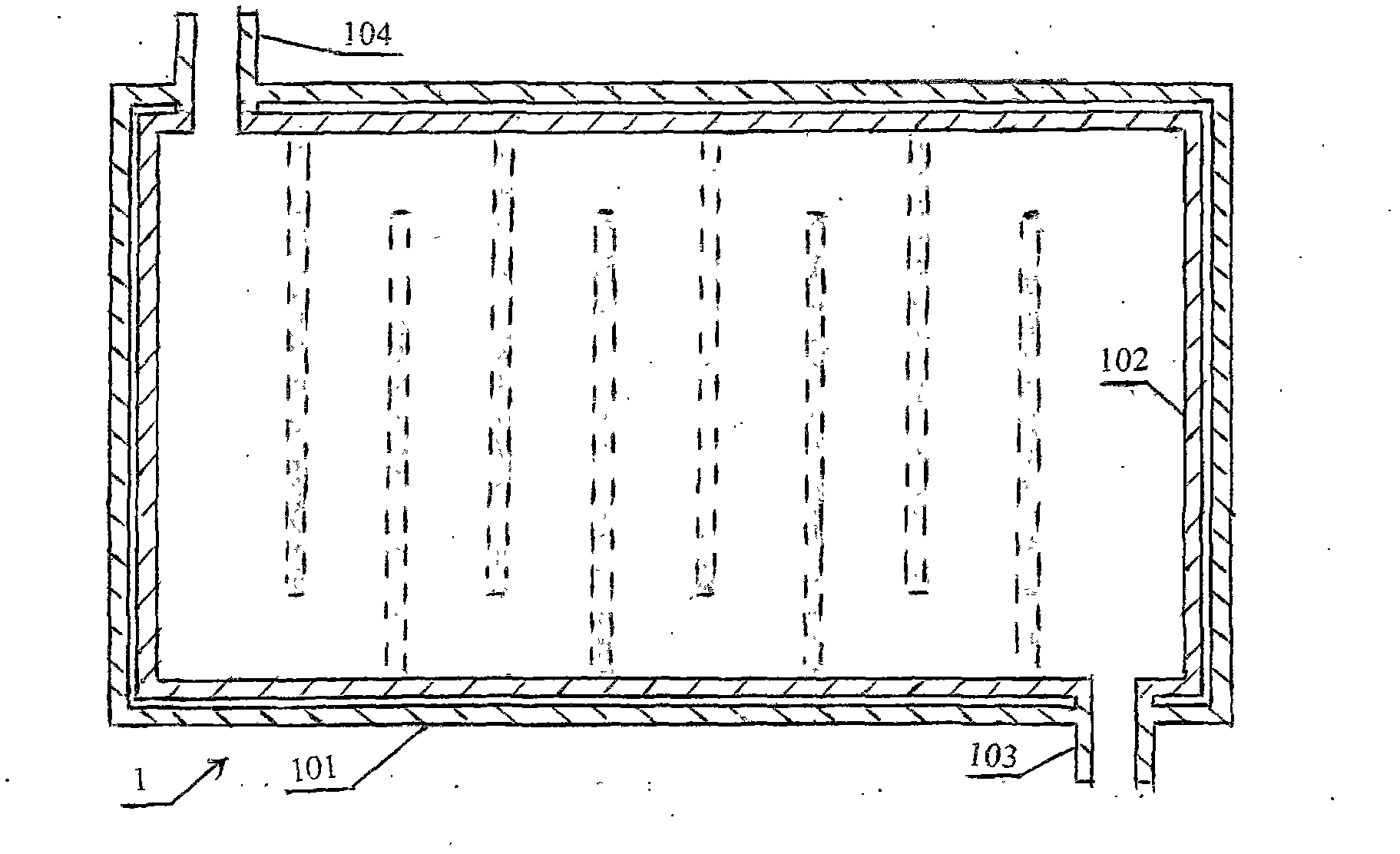

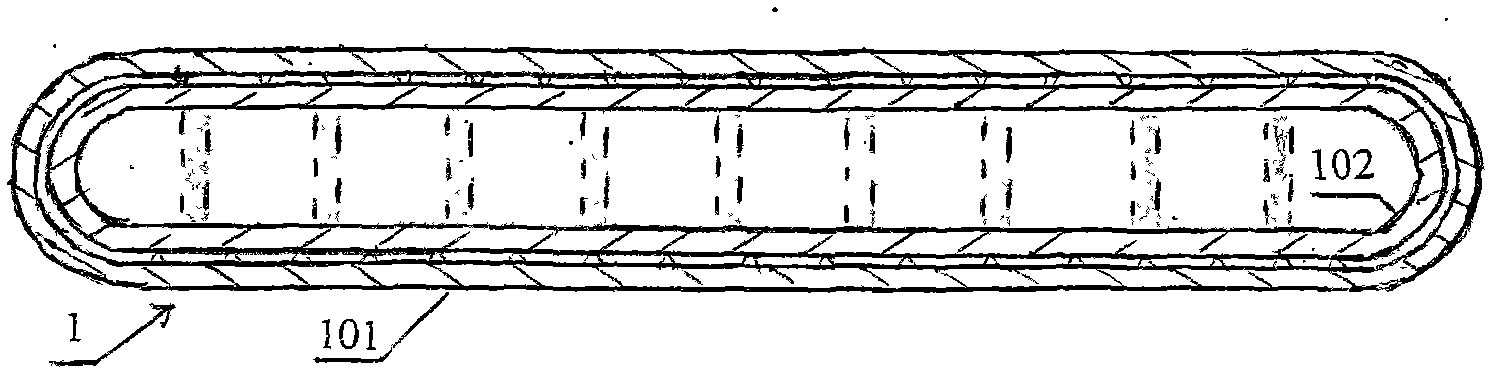

[0012] figure 1 , figure 2 , image 3As shown, the wall-mounted solar water heater of the present invention has the basic structure of a traditional split cycle solar water heater, and the water tank 2 is packaged with an insulating layer, and the flat glass solar collector 1 it uses is divided into a pressure-bearing flat glass solar collector 1 and unpressurized flat glass solar collectors1. The inside of the pressure-bearing flat glass solar collector 1 glass inner box 102 is isolated into several pipes, and the shape of the pipes connected in series is like an electromagnetic square wave. The inside of the glass inner box 102 of the non-pressurized flat glass solar collector 1 is empty. The outer surface of the glass inner box 102 of the flat glass solar collector 1 is flat and smooth, and the inner surface of the front panel and the back panel of the glass shell 101 is evenly distributed with many equal-height conical protrusions as support points. The glass shell 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com