Method for repairing high Cr cast iron dredge pump impeller

A high-chromium cast iron and repair method technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems that the welding repair process is difficult to meet its requirements, affect the dredging efficiency of ships, and replace spare parts. The effect of repairing working time, saving manpower and material resources, and reducing equipment wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

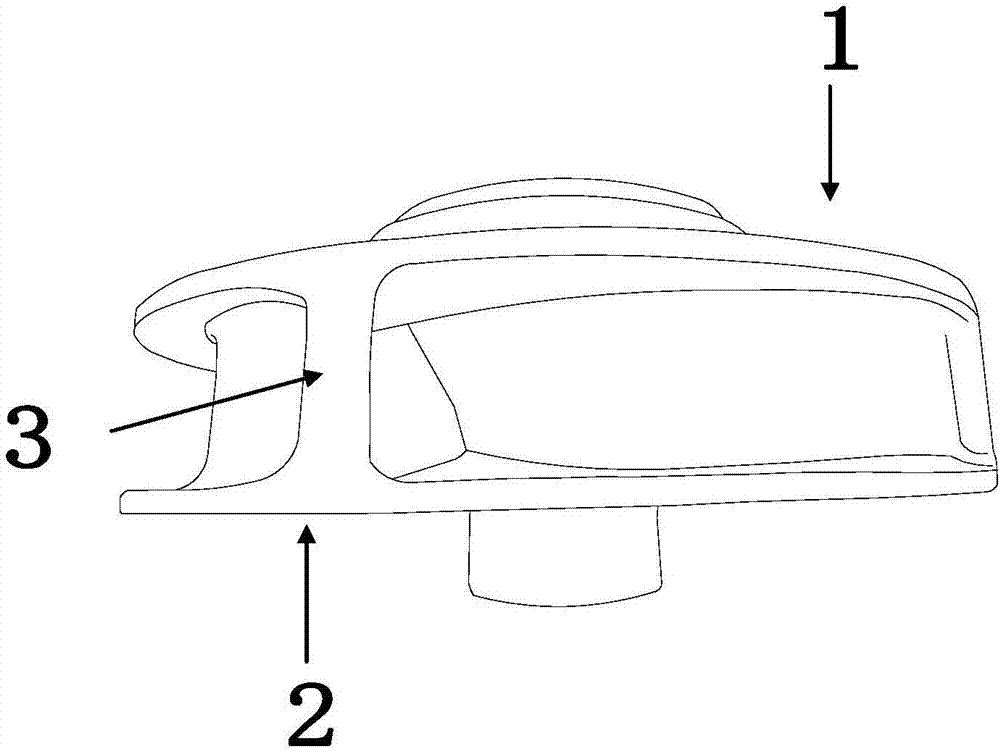

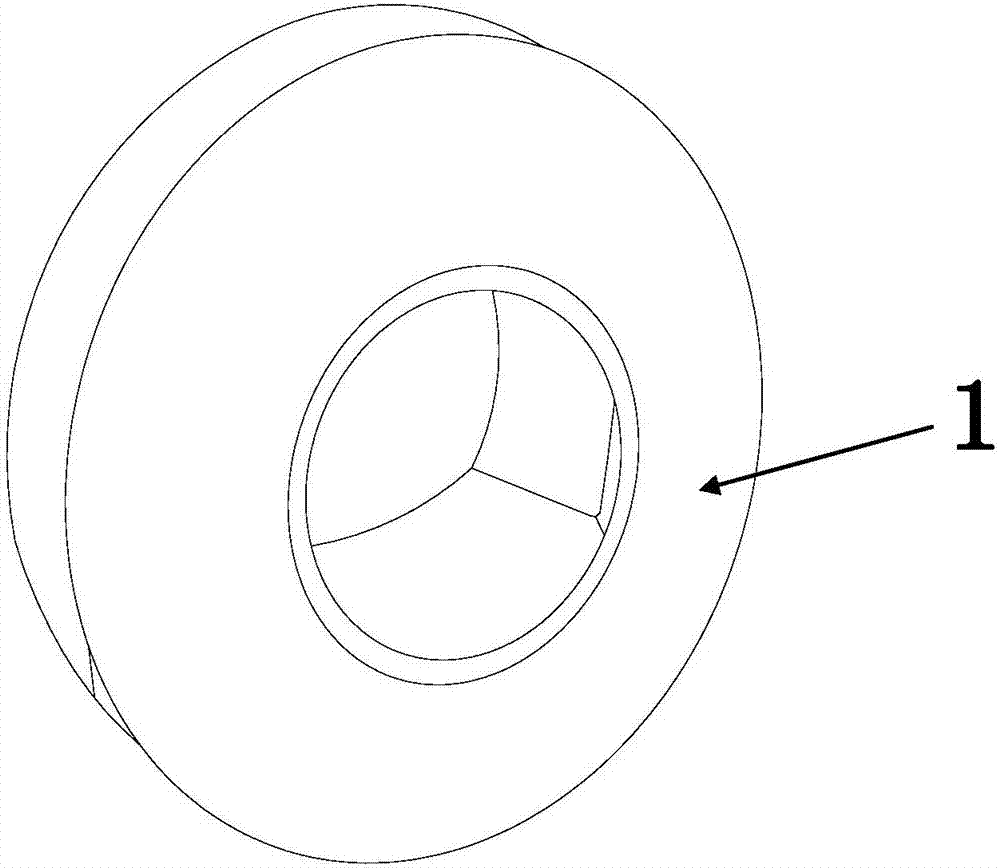

[0025] The invention discloses a method for repairing the impeller of a mud pump made of high chromium cast iron. According to the structural characteristics of the impeller of the mud pump made of high chromium cast iron, comprehensive treatment is carried out by relatively complete repairing methods. The surfacing method is used to restore the size of the sealing water belt of the impeller of the high-chromium cast iron mud pump, so as to ensure the restoration of the original gap between the sealing water belt and the liner, and realize the pumping efficiency of the mud pump.

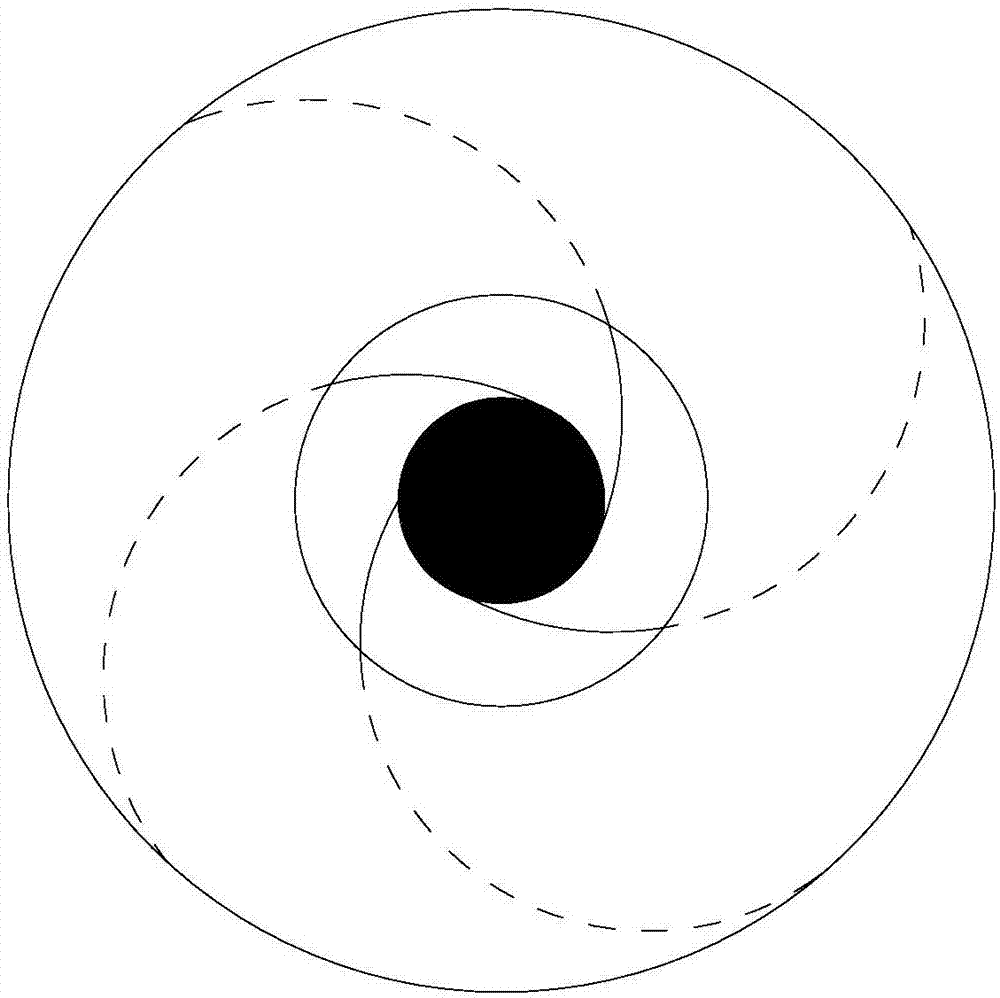

[0026] The surfacing welding method adopts the welding wire open arc surfacing method, and the gap between the front lining board and the back lining board is 30mm and 40mm after restoring the size. During the surfacing repair process, the long welding thickness of the front and rear impeller blade wall sealing water belts is 10mm.

[0027] Welding wire open arc surfacing method adopts JDR17 self-shi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com