Liquid metal alloy tooth-filling material and preparation method thereof and injection molding machine

A technology of liquid metal alloys and dental filling materials, which is applied in dental preparations, dentistry, mold cups, etc., can solve the problems of amalgam health hazards, operator and environmental hazards, and easy wear and tear of composite resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

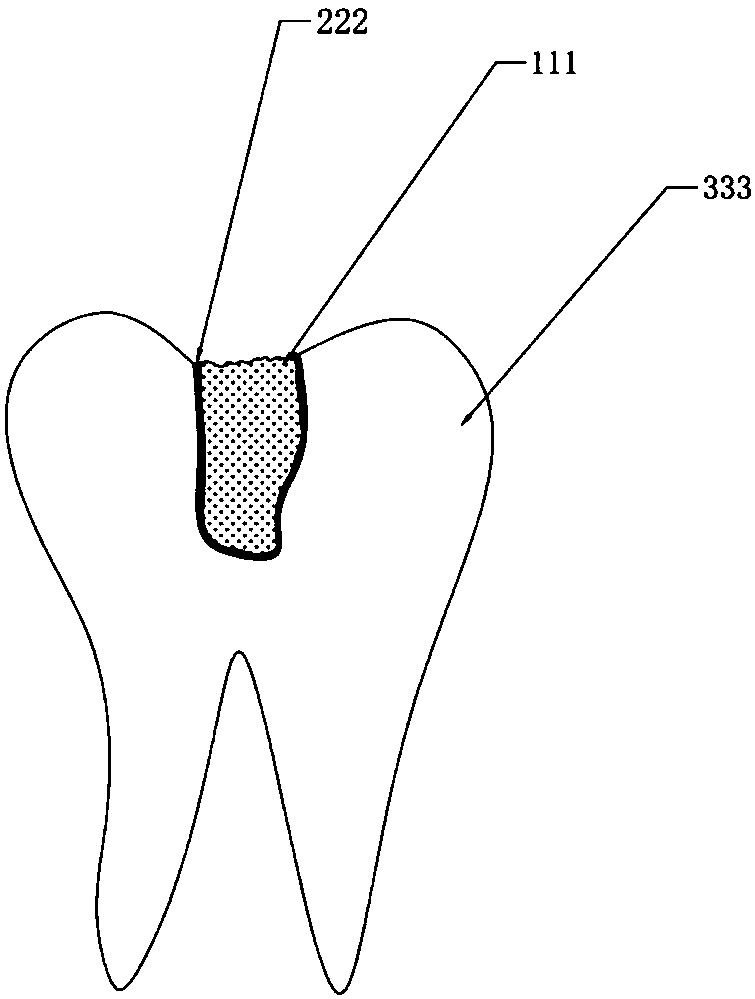

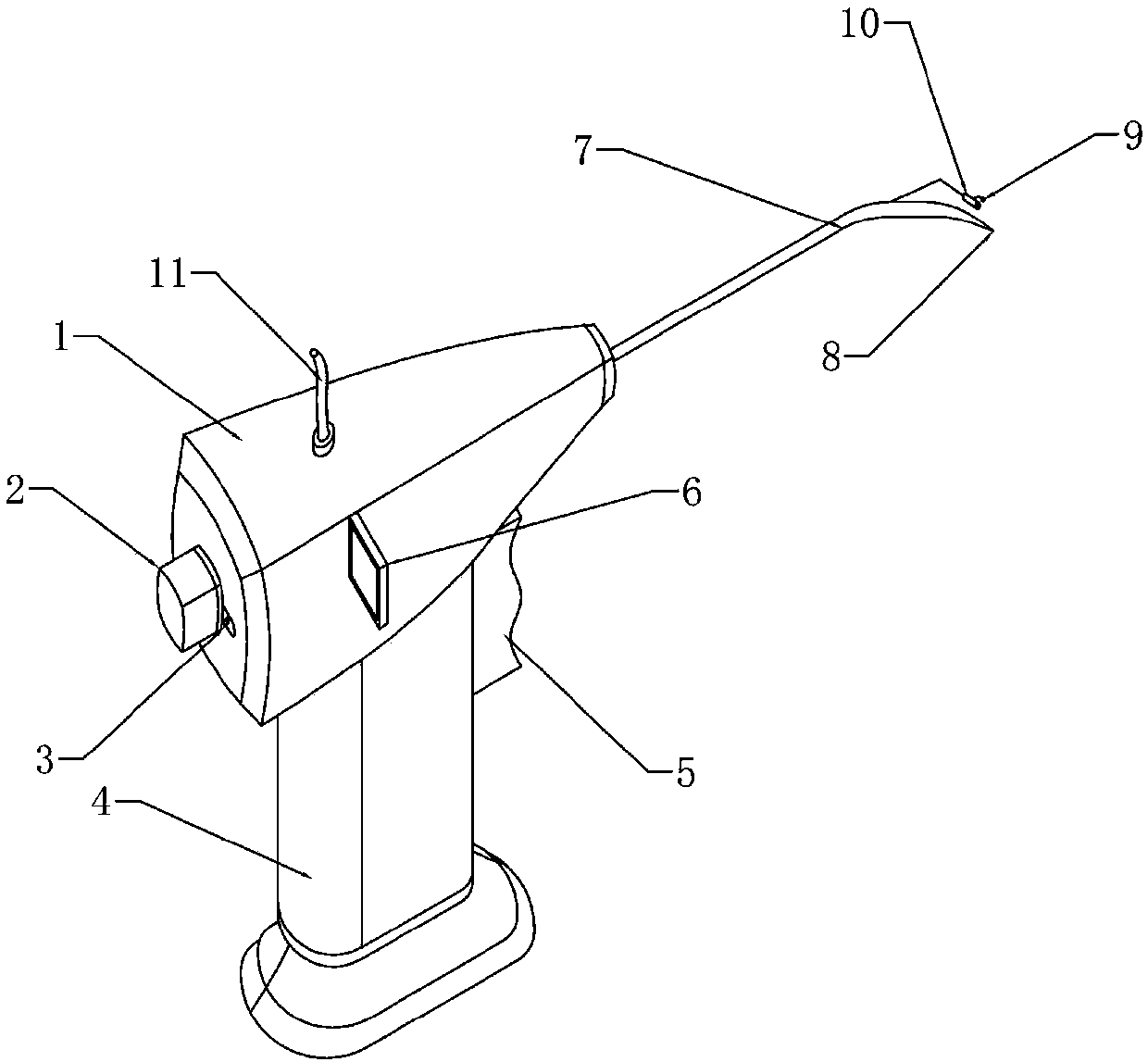

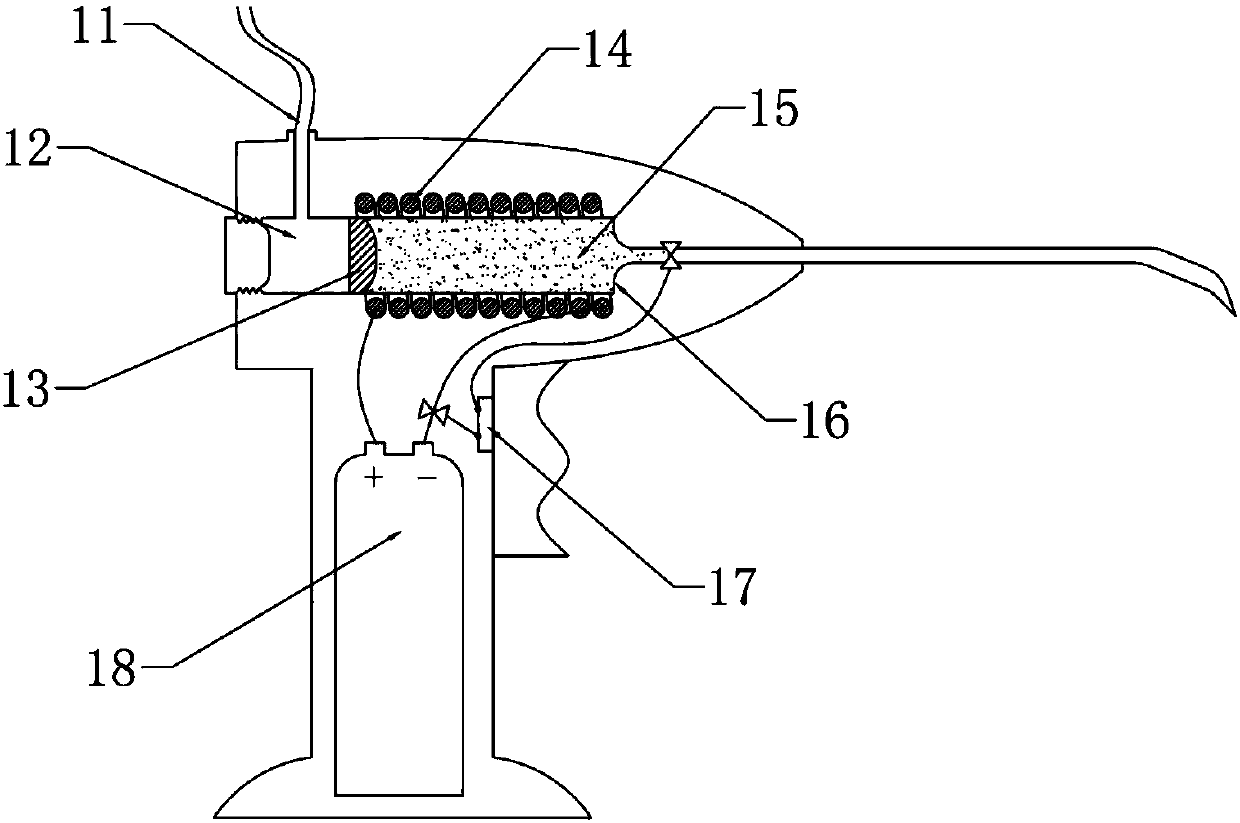

[0033] On the one hand, the embodiment of the present invention provides a liquid metal alloy tooth filling material, comprising the following components in terms of mass fractions: 32-60 parts of Bi, 4-20 parts of Al, 28-48 parts of Zn, 7-48 parts of Sn, 1 to 12 parts of Nb. Wherein, Bi is bismuth, Al is aluminum, Zn is zinc, Sn is tin, and Nb is niobium. Specifically, the ratio ranges of the above five components can be selected according to actual implementation conditions. The bismuth-based eutectic alloy prepared by using the above five substances is used as a tooth filling material. Because of the bismuth element, the tooth filling material has the advantages of wear resistance and compressive strength, and has a long service life; at the same time, the liquid metal alloy tooth filling The material is healthy and non-toxic, and the curing and setting time is fast, which is beneficial to reduce the working time of tooth restoration; after filling, the volume remains uncha...

Embodiment 2

[0056] An embodiment of the present invention provides a liquid metal alloy tooth filling material, comprising the following components in terms of mass fractions: 40-50 parts of Bi, 10-15 parts of Al, 20-30 parts of Zn, 20-30 parts of Sn, 2-30 parts of Nb 5 parts, and the reasonable ratio of each component can be selected according to the actual implementation conditions. The bismuth-based eutectic alloy containing the above components is used as a dental filling material, which is healthy and non-toxic, and has a fast curing and setting time; the volume remains unchanged after filling, and the effect of sealing with the cavity is good, which effectively improves the dental restoration effect; at the same time, the liquid metal alloy The dental filling material is bright white and beautiful in appearance, has strong corrosion resistance, and is not easily corroded or dissolved by saliva; in addition, because of the bismuth element, the dental filling material has the advantage...

Embodiment 3

[0059] The embodiment of the present invention provides a liquid metal alloy tooth filling material, comprising the following components in terms of mass fractions: 46 parts of Bi, 10.6 parts of Al, 8.8 parts of Zn, 29.2 parts of Sn, and 5.4 parts of Nb. The liquid metal alloy dental filling material prepared in this example is tested, and its performance parameter values are specifically referred to in Table 1, wherein the compressive strength is 22Mpa, and the tensile strength is 20Mpa. The dental filling material is more wear-resistant and compressive. Advantages, and has good physical properties, which is beneficial to prolong the service life.

[0060] Table 1 Performance parameter values of dental filling materials

[0061]

[0062] Other technical solutions are the same as those in Embodiment 1, and will not be described again to avoid repetition.

[0063] To sum up, the present invention provides a liquid metal alloy tooth filling material, specifically, the to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com