A production process of needle selection presser foot for flat knitting machine

A production process and needle selection technology, which is applied in the field of flat knitting machine needle selection presser foot production technology, can solve the problems of short service life, poor toughness of needle selection presser foot, poor controllability of external dimensions, etc., and achieve good toughness and long service life , the effect of bright and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

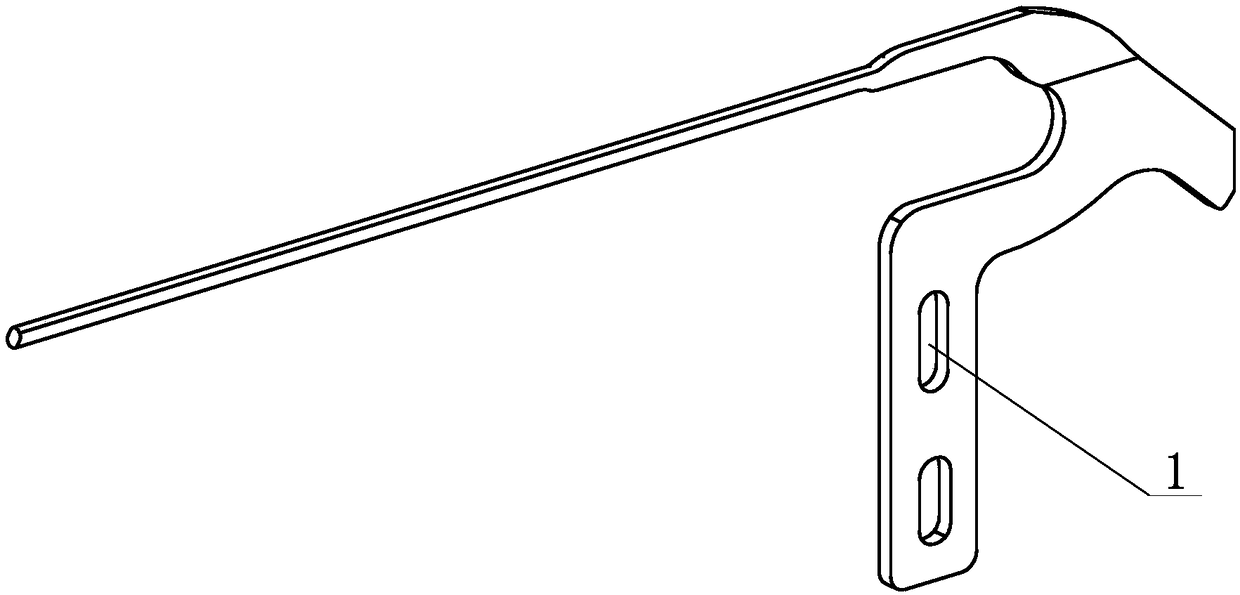

[0018] Such as figure 1 Shown, the present invention comprises the following steps:

[0019] 1) Blank forging: the blank is stamped and formed by a high-speed punch, and the width of the working part of the needle selection presser foot is guaranteed to be 8mm plus or minus 0.1mm;

[0020] 2) Drilling: Drill two fixed installation holes 1 on the drilling mold for the blank formed by stamping in step 1. The drilling is one-time forming, and the absolute error of the hole distance after drilling is ±0.04mm;

[0021] 3) Stamping and bending: in step 2), the processed blank is placed on the bending die for stamping angle bending treatment, ensuring that the bending angle is 30°±1°;

[0022] 4) Heat treatment: First clamp and fix the stamped and bent blank, then preheat the fixed blank, raise the temperature of the blank to 780°C and keep it warm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com