Method for preparing composite section bar with metal and/or plastic surface having wood layer thereon

A technology of surface bonding and composite profiles, applied in the direction of wood layered products, chemical instruments and methods, layered products, etc., can solve problems such as complex structure, difficult connection, rough outer surface of anti-theft door fire door profiles, etc., to achieve overall Good performance, solve the effect of easy deformation, bright and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

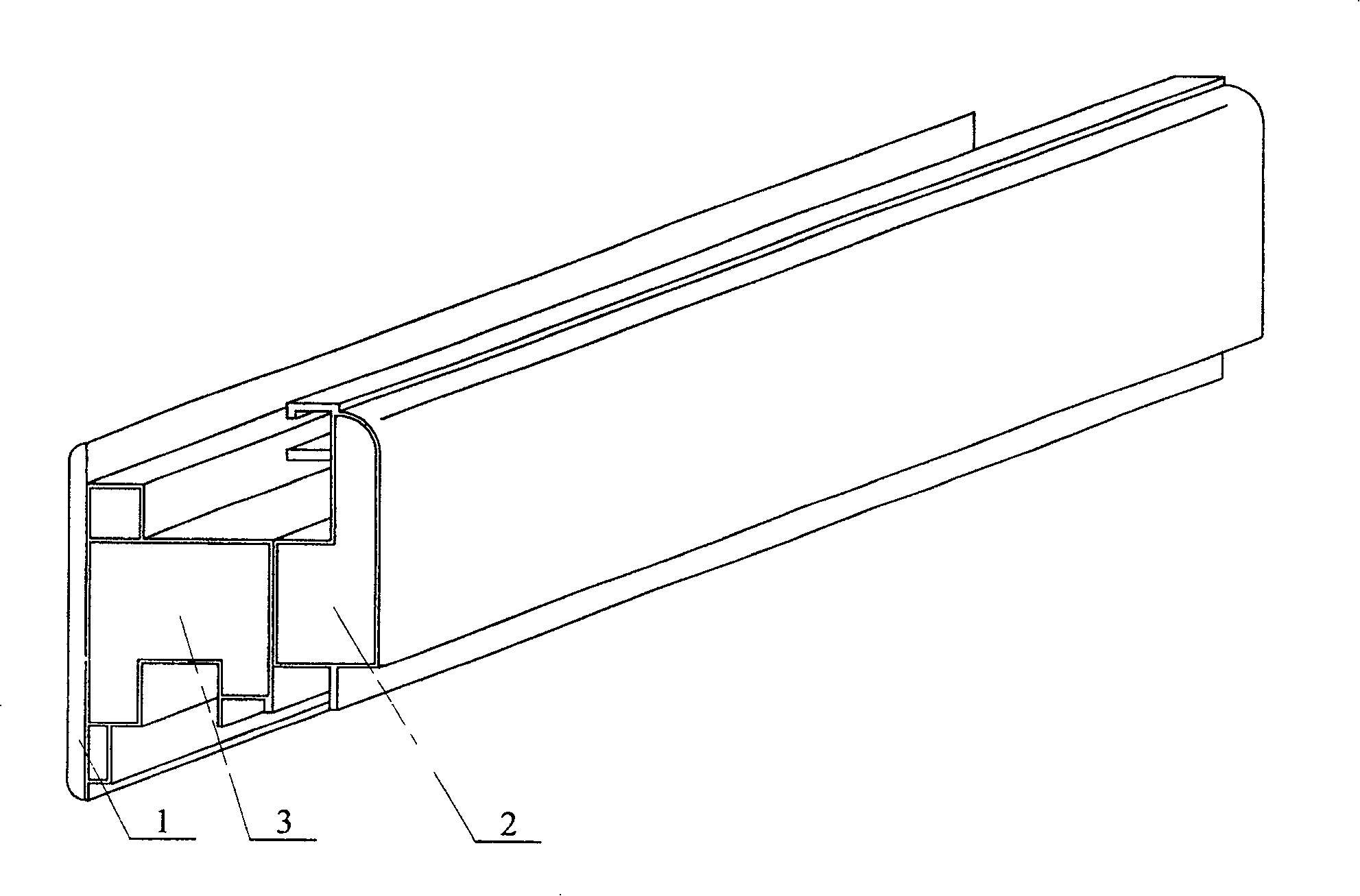

[0010] Specific implementation mode one: the preparation method of the composite profile with the wood layer bonded to the metal or / and plastic surface of this embodiment adopts the following steps:

[0011] Step 1, decontamination and cleaning the outer surface of the metal or / and plastic profile;

[0012] Step 2. Apply liquid glue evenly on the outer surface of the metal or / and plastic profiles treated in step 1. The temperature of the applied liquid glue is 10°C to 30°C, and then apply the liquid glue with a thickness of 0.3 mm to 30 mm. The inner surface of the wooden layer 1, which has been polished by a sander or sandpaper, is pasted together with the outer surface of the metal or / and plastic profile coated with liquid glue, and then placed on the extruder with a pressure of 5-50T. Squeeze for 0.5 to 4 hours;

[0013] Step 3, after the liquid glue in step 2 dries, the outer surface of the wooden layer 1 is polished with a sander or sandpaper, and the primer is first spr...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 4 is that the temperature of the liquid glue applied in step 2 is 10° C. to 20° C.; the extrusion machine extrudes for 2 to 4 hours at a pressure of 5 to 30 T.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 4 is that the temperature of the liquid glue applied in step 2 is 21° C. to 30° C.; the extruder extrudes for 0.5 to 2 hours at a pressure of 31 to 50 T.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com