Sewing machine and its control method

A control method and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve the problems of time-consuming and labor-intensive repairing of broken threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

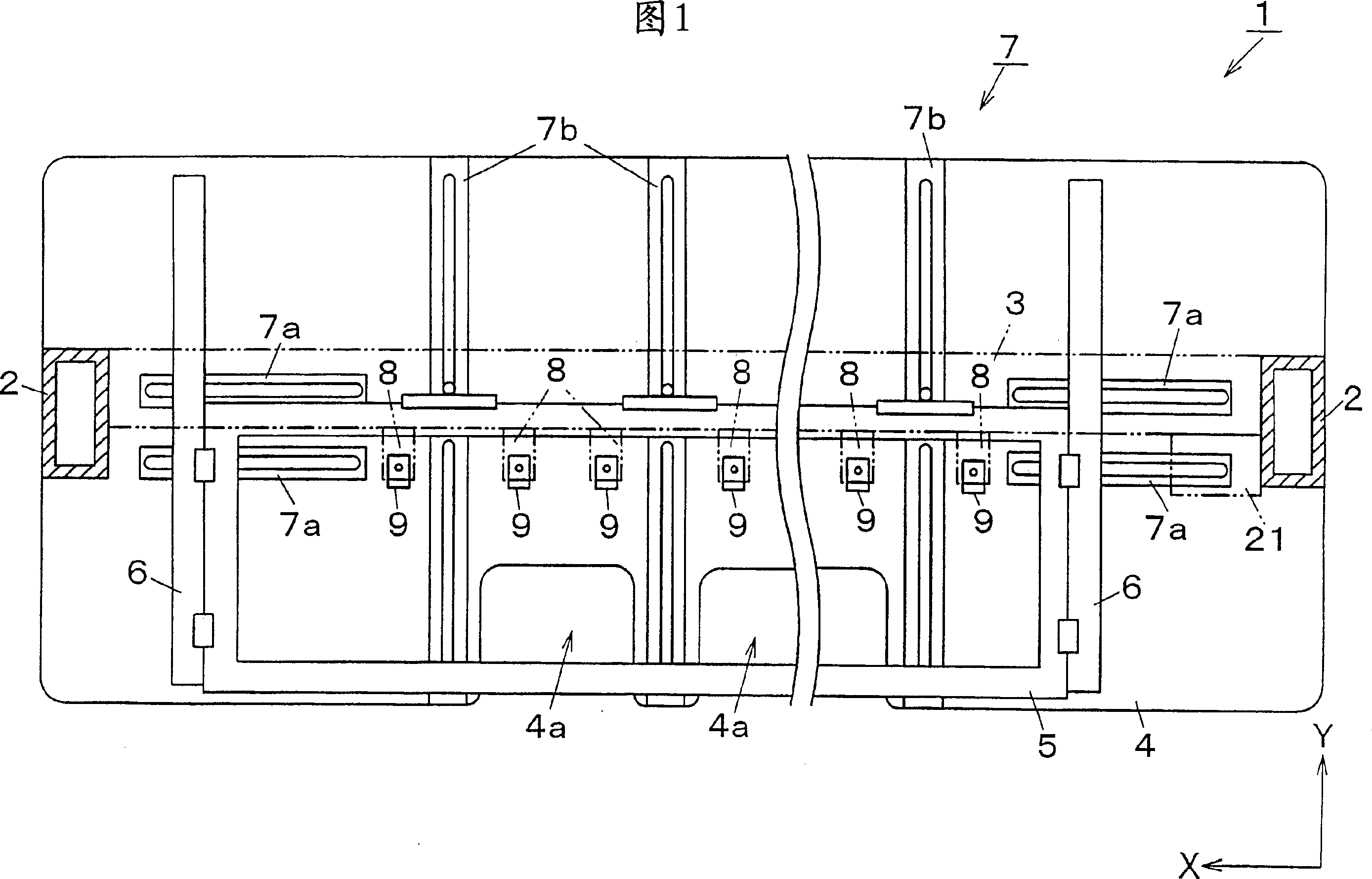

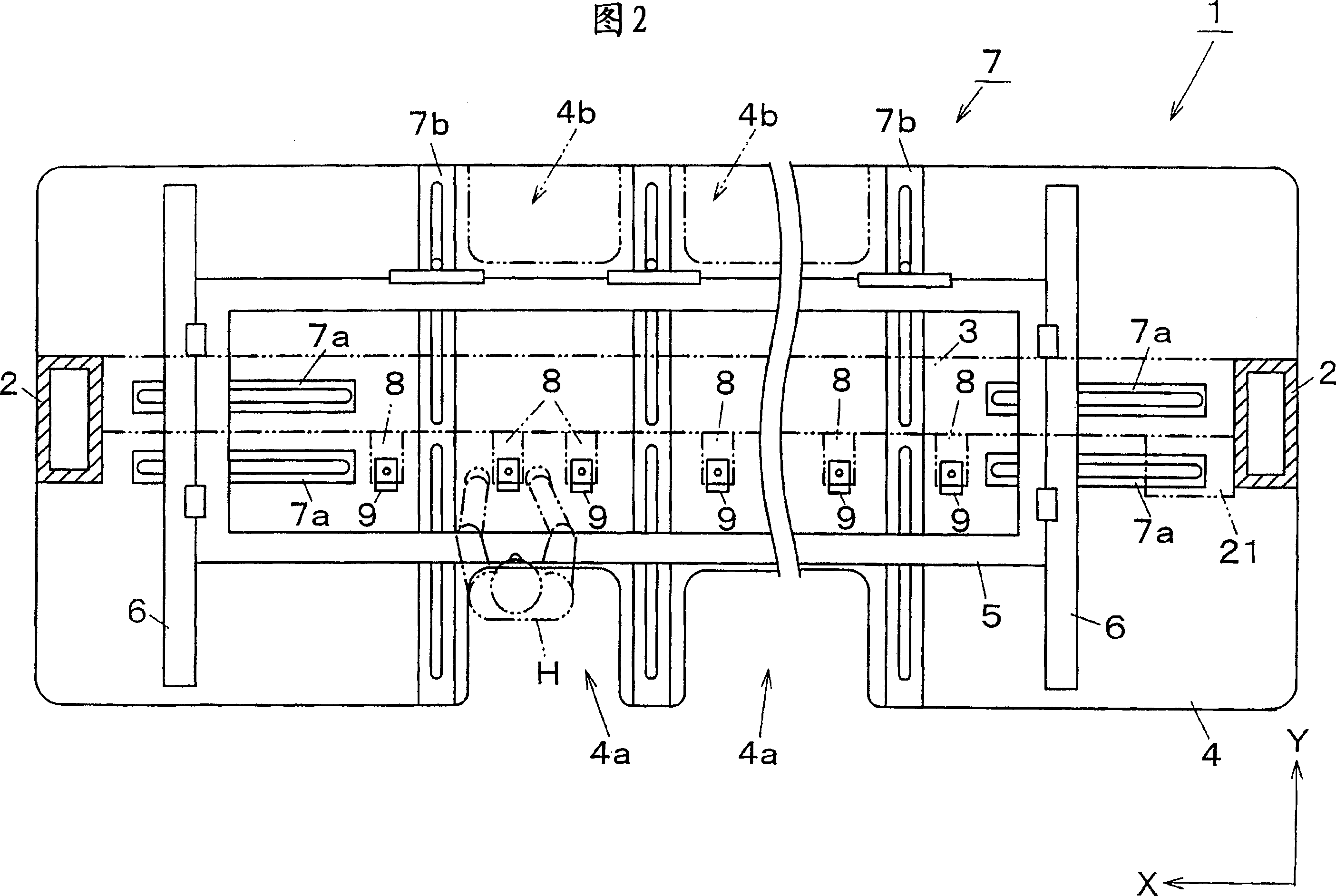

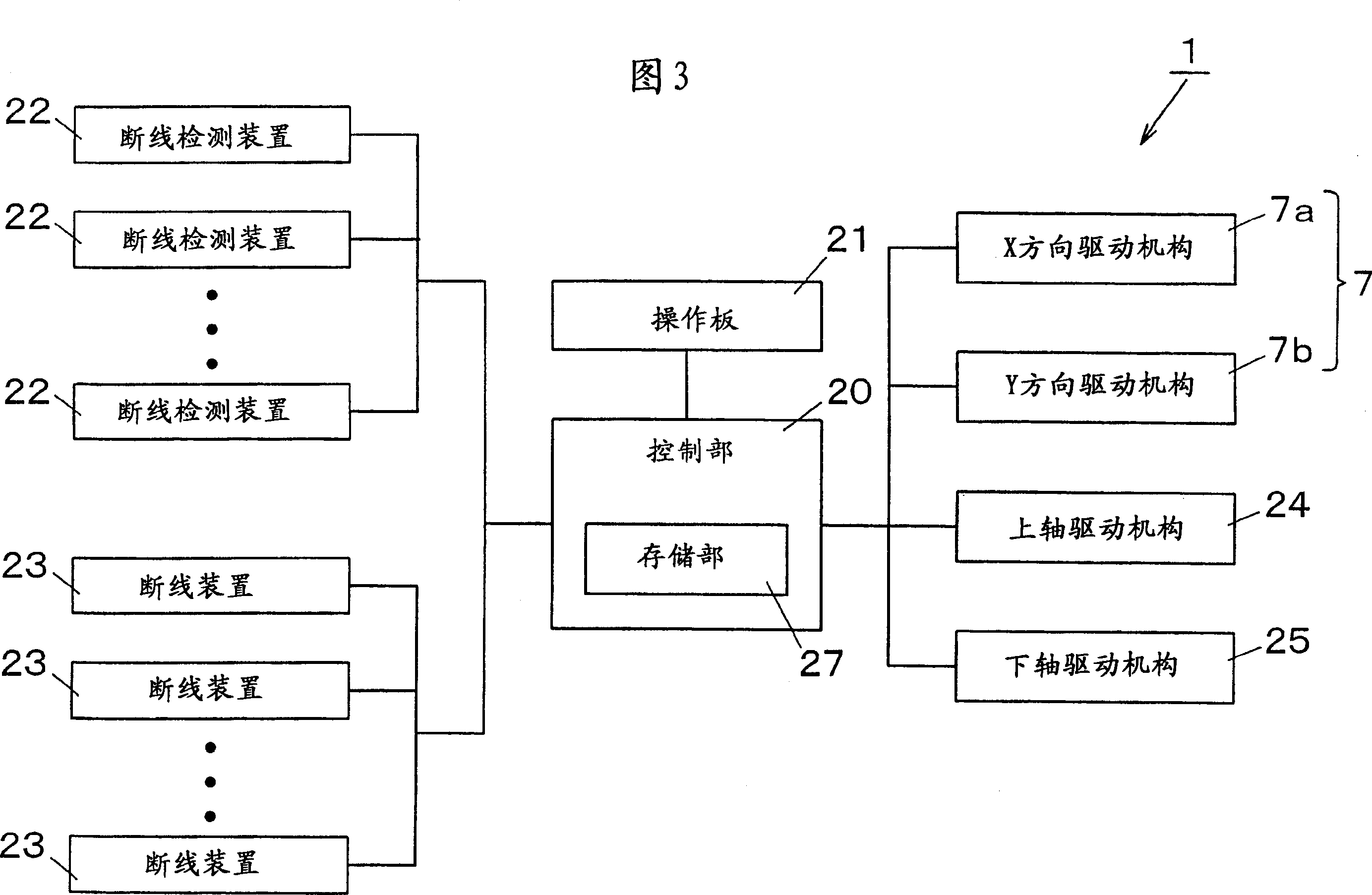

[0025] A sewing machine embodying an embodiment of the present invention and a control method thereof will now be described with reference to the accompanying drawings. First, FIGS. 1 and 2 are plan views showing a multi-head embroidery sewing machine 1 using the control method of the present invention. This embroidery sewing machine 1 has: a pair of left and right pillars 2 erected on the table, and a lower frame (not shown) and an upper frame 3 respectively extending to the left and right directions supported between the lower parts and the upper parts of the two pillars 2. frame, the aforementioned lower frame supports the table top 4 slightly horizontally. A planar, horizontally long rectangular frame-shaped sewing frame 5 is placed on the table 4 , and the short sides of the left and right sides of the sewing frame 5 are connected with respective driving bodies 6 . Like this, when the X-direction drive mechanism 7a of the frame drive mechanism 7 that is provided with fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com