Novel industrial combined toilet

A combined, toilet technology, applied in small buildings, building components, walls, etc., can solve the problems of physical health hazards of installation workers, the impact of high-rise building structure stability, and the burden of high-rise building load-bearing capacity, so as to reduce construction waste and construction waste. Noise, enabling rapid mass production installation, good versatility and structural realizability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

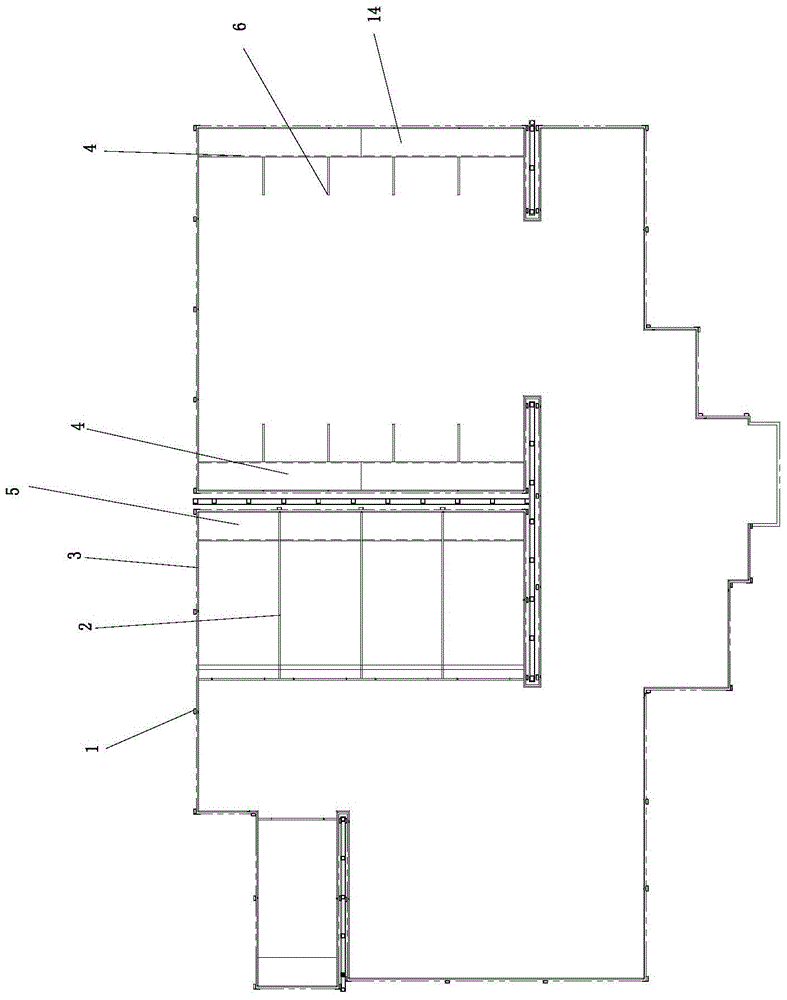

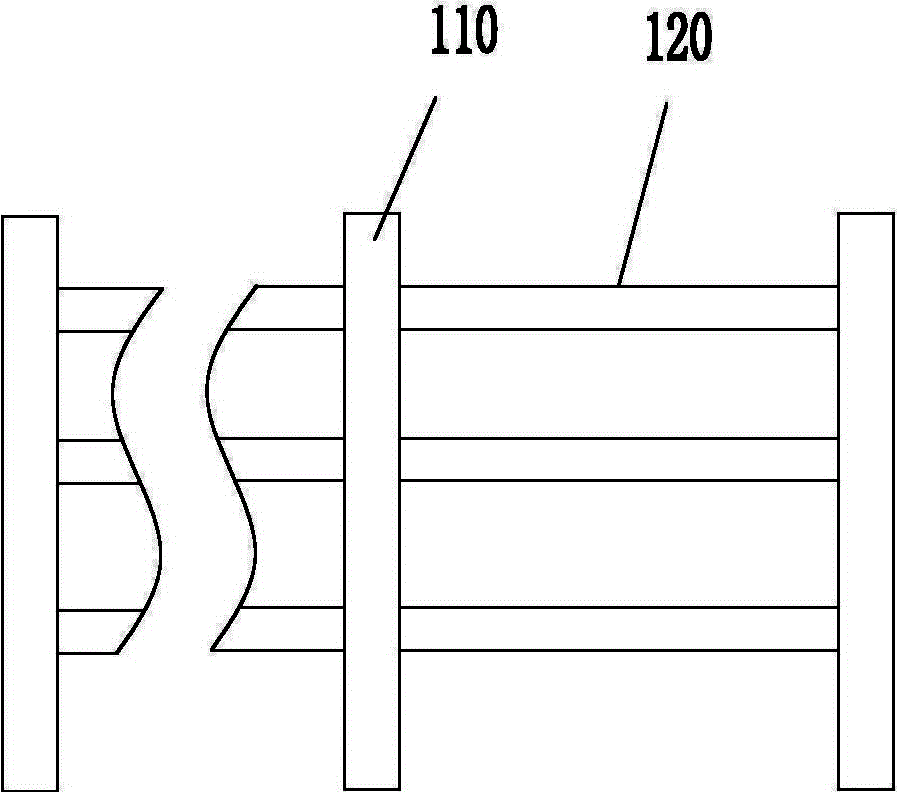

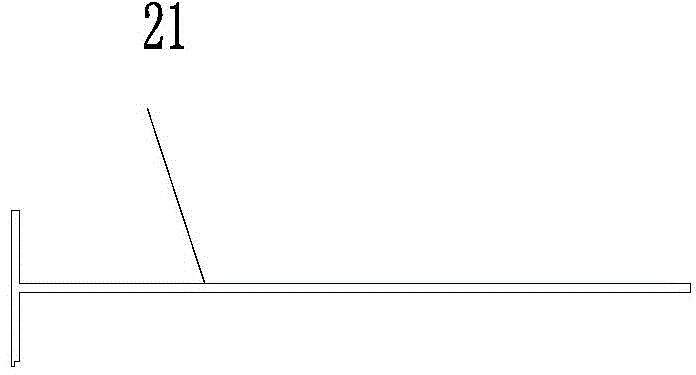

[0029] Such as figure 1 The new industrial combined toilet shown is characterized in that it includes a frame 1 fixedly connected to the wall, and a wall panel 3 hung on the frame 1, and the wall panel 3 is connected with a toilet partition unit 2 And the urinal partition unit 5, the toilet partition unit 2 includes a plurality of T-shaped partitions 21 vertically arranged on the ground, the lower ends of the T-shaped partitions 21 are fixed on the ground by supports, and the T-shaped partitions The strip edge of 21 is plugged on the wallboard 3, and a mechanism 5 for shielding and sealing the toilet is arranged between adjacent T-shaped partitions 21; the urinal partition unit includes two ends fixed on the wall The connecting crossbeam 52, the connecting crossbeam 52 is hung with a rib 7, the surface of the rib 7 is extended outward and evenly distributed with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com