A kind of preparation method of foam board filler

A foamed sheet and filler technology, which is applied in the field of preparation of foamed sheet fillers, can solve problems such as resource consumption and environmental pollution, and achieve the effects of good air permeability, resource saving, and extensive practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

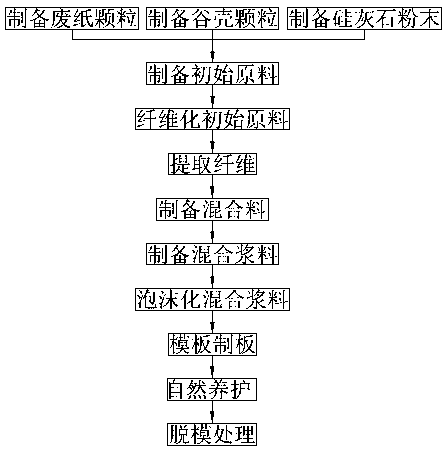

[0041] Such as Figure 1-4 As shown, this embodiment provides a method for preparing foamed board filler, the cement used is P.042.5, including the following steps:

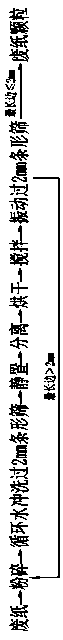

[0042] Step 1: Prepare waste paper granules; prepare waste paper into granules, and the treated waste paper is rich in short fibers, which disperse quickly and are not easy to agglomerate, leaving more gaps in the prepared filler. It has good air permeability, and can quickly discharge the water vapor in it during the drying process, reducing the drying time. At the same time, due to the dense presence of short fibers in the filler, the board made by the filler is not easy to produce Burst phenomenon.

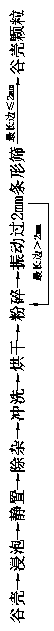

[0043] Step 2: Prepare chaff granules; treat the chaff into granules, and the treated chaff is also rich in cellulose, lignin, and silica, which can further increase the fiber of the filler and the short fiber of waste paper Together, they can maintain the bulkiness of the filler to the greatest extent and impro...

Embodiment 2

[0062] As the preparation method of embodiment 1:

[0063] In step 4, waste paper particles, chaff particles and wollastonite powder are mixed in a weight ratio of 1.1:1.1:0.15.

[0064] In step 5, the concentration of the sodium hydroxide solution is 0.8mol / L, the reaction time is about 50min, the soaking temperature is about 85°C, and the weight ratio of the initial raw material to the sodium hydroxide solution is about 1.05:30.5.

[0065] In step 7, the weights of the fibrous raw material, slag powder and fly ash are respectively 65%, 30% and 20% of the weight of the cement.

[0066] In step 8, the weight of the water is 55% of the total water consumption.

[0067] In step 9, the weights of the sodium silicate, sodium carbonate, sodium sulfate, and hydrogen peroxide are respectively 1%, 1.8%, 1.8%, and 10.5% of the cement weight used in step 7, and the weight of the water is the total water consumption 45%.

[0068] Preferably, the weight of the total water consumption i...

Embodiment 3

[0071] As the preparation method of embodiment 2:

[0072] In step 4, waste paper particles, chaff particles and wollastonite powder are mixed in a weight ratio of 1:1:0.1.

[0073] In step 5, the concentration of the sodium hydroxide solution is 0.8mol / L, the reaction time is about 45min, the soaking temperature is about 80°C, and the weight ratio of the initial raw material to the sodium hydroxide solution is about 1:30.

[0074] In step 7, the weights of the fibrous raw material, slag powder, and fly ash are respectively 58%, 27%, and 18% of the weight of the cement.

[0075] In step 8, the weight of the water is about 50% of the total water consumption.

[0076] In step 9, the weights of the sodium silicate, sodium carbonate, sodium sulfate, and hydrogen peroxide are respectively 0.8%, 1.6%, 1.6%, and 10% of the cement weight used in step 7, and the weight of the water is the total water consumption 50% of.

[0077] Preferably, the weight of the total water consumption ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com