Pipe pile construction method and pile tip bearing capacity reinforcement equipment

A technology of pile end bearing capacity and construction method, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of weakening pile end bearing capacity, re-extrusion of soil plug in pipe pile, etc. force, improve the quality of piles, and reduce the effect of settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

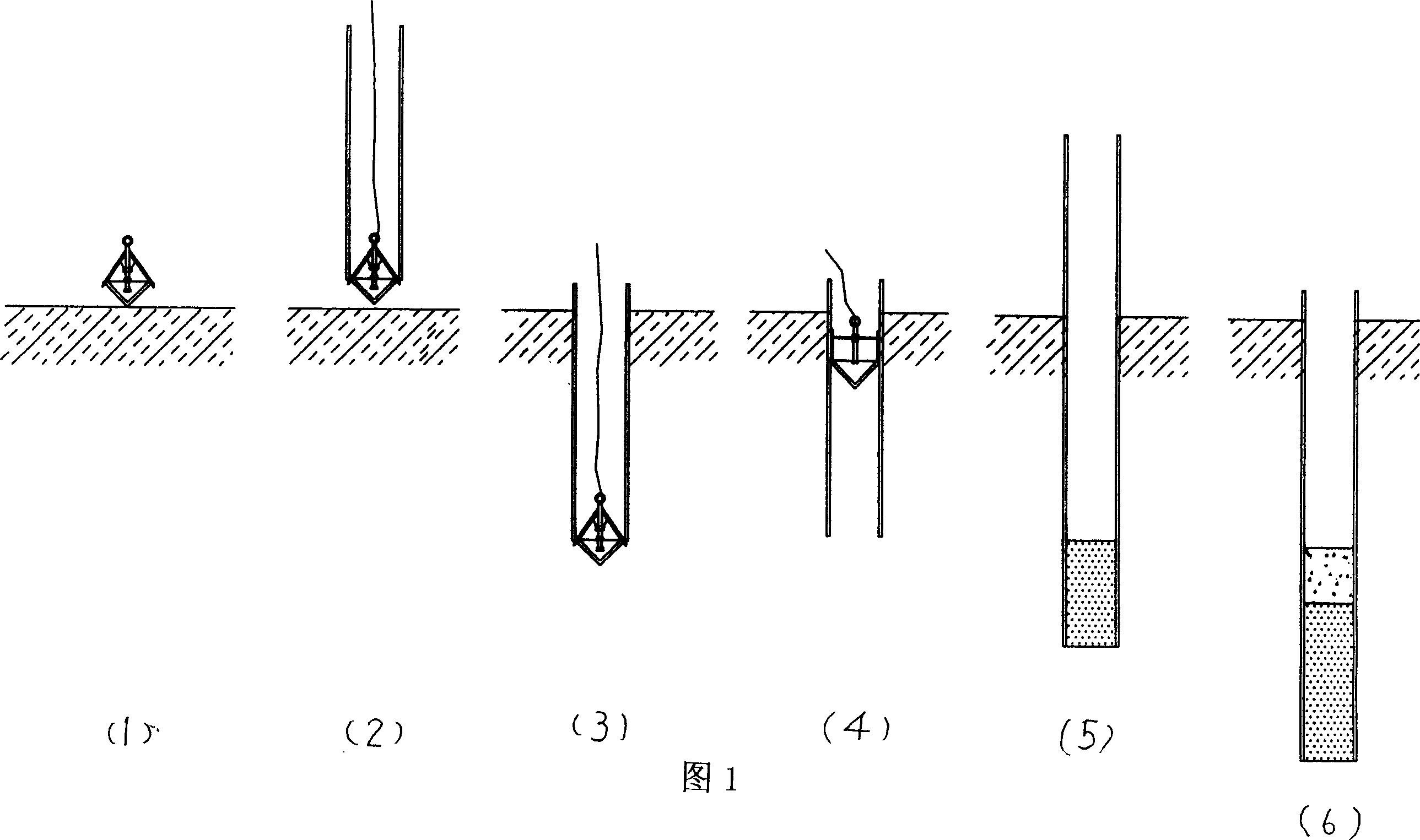

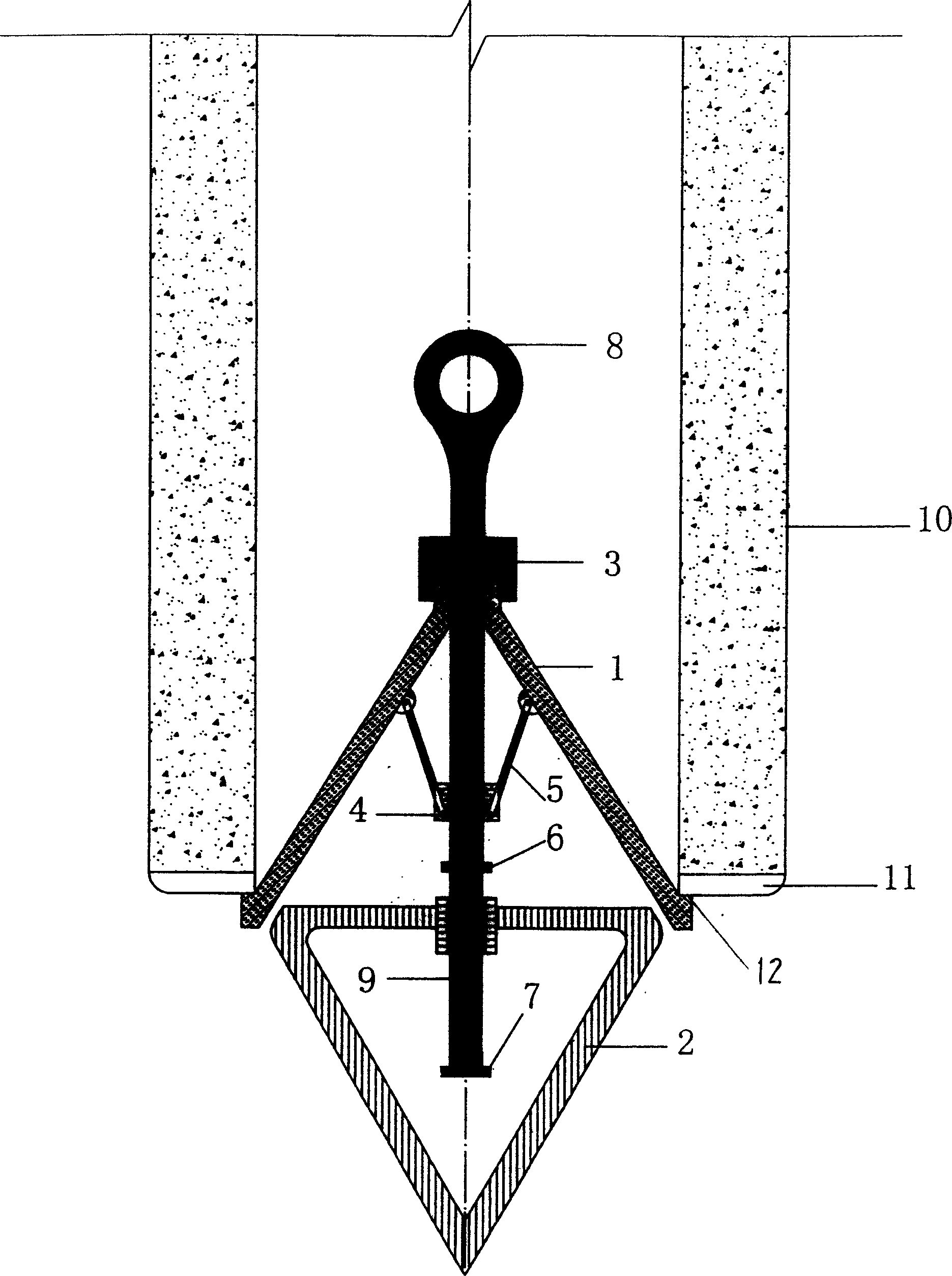

[0058] Embodiment: The pipe pile construction technique is as shown in Figure 1:

[0059] Step (1): Install a pile end bearing capacity enhancer at the anchor point of the pile foundation;

[0060] Step (2): The pile driver is in place, so that the pile ends of the pipe piles are aligned with the pile shoes, and the verticality is ensured;

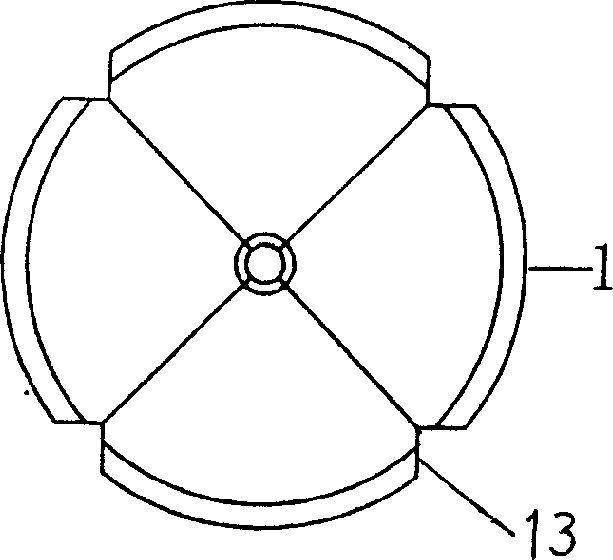

[0061] Step (3): Sink the pile by static pressure, hammering, etc., according to the design requirements, connect the pile or not connect the pile, and suspend the pile sinking when the pipe pile passes through the bad soil layer or enters the bearing layer at the pile end; pile sinking When the spud shoe squeezes the brace steel plate, the lower end of the brace steel plate expands to the surroundings, relying on the top cap, the pile end steel plate and the pipe pile wall to bear the transmitted pressure.

[0062] Step (4): Take out the pile end bearing capacity enhancer from the pipe pile, first pull the rope from the top of the pile t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com