Automobile brake drum with heat resistance and wear resistance

A technology of automobile braking and brake drum, applied in the direction of brake drum, brake type, brake components, etc., can solve the problems of good heat dissipation effect, small braking area, poor heat dissipation effect, etc. Large moving area and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

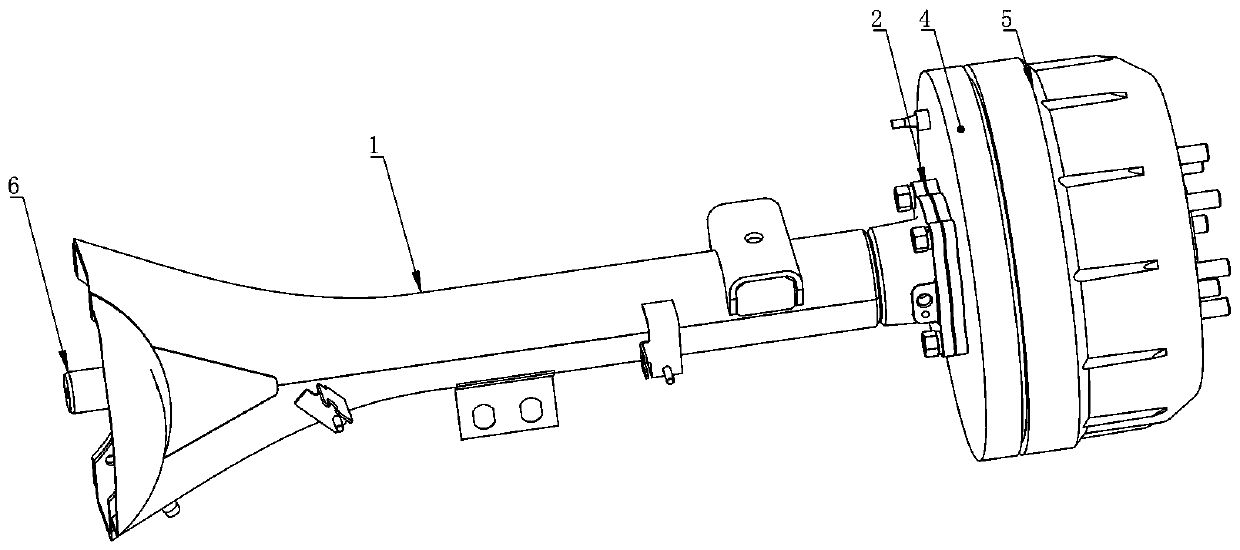

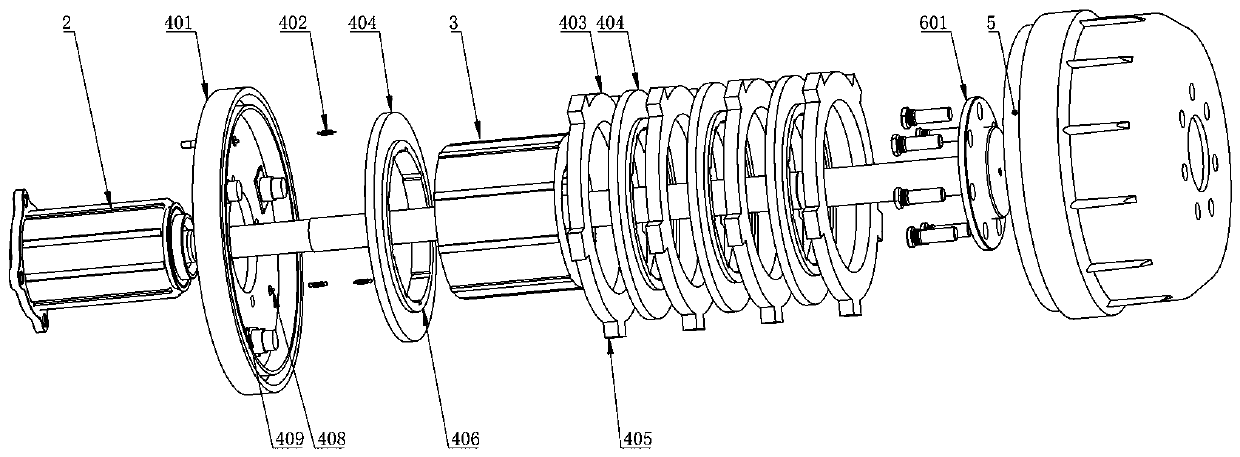

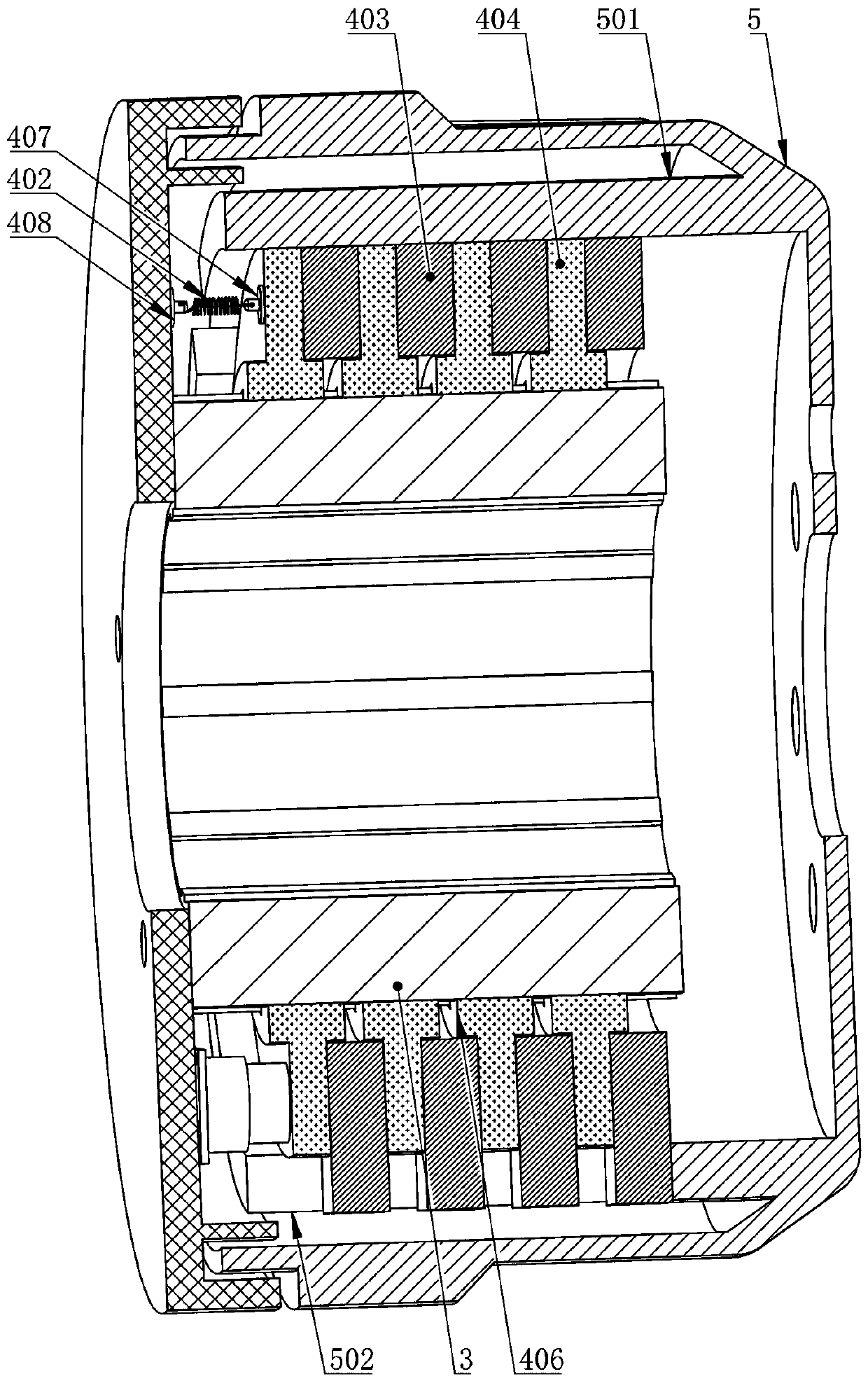

[0017] Specific implementation mode one: combine Figure 1-4 As shown, an automobile brake drum with heat-resistant and anti-wear properties is characterized in that it includes a main bridge frame 1, a bearing seat 2, a spacer sleeve 3, an axial multi-spacer braking device 4 and a brake drum 5; the bearing seat 2. It is fixedly installed at one end of the main bridge frame 1; the middle part of the main bridge frame 1 and the bearing seat 2 is connected with a transmission shaft 6 through the bearing; the right end of the transmission shaft 6 is provided with a fixed disc 601; The spacer brake device 4 is installed between the bearing housing 2 and the fixed disc 601; the axial multi-spacer brake device 4 includes a brake chassis 401, a return tension spring 402, a brake pad 403 and a brake pad 404; the brake chassis 401 is fixedly installed on the right end of the bearing seat 2; the inside of the brake drum 5 is provided with a sleeve 501 in the length direction; the brake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com