A car brake disc capable of rapidly cooling down

A technology of automobile brakes and brake discs, which is applied in the direction of brake parts, brake types, brake parts, etc., can solve the problems of poor heat dissipation, high heat of brake pads, and inability to dissipate heat, so as to achieve good heat dissipation and Large moving area and good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

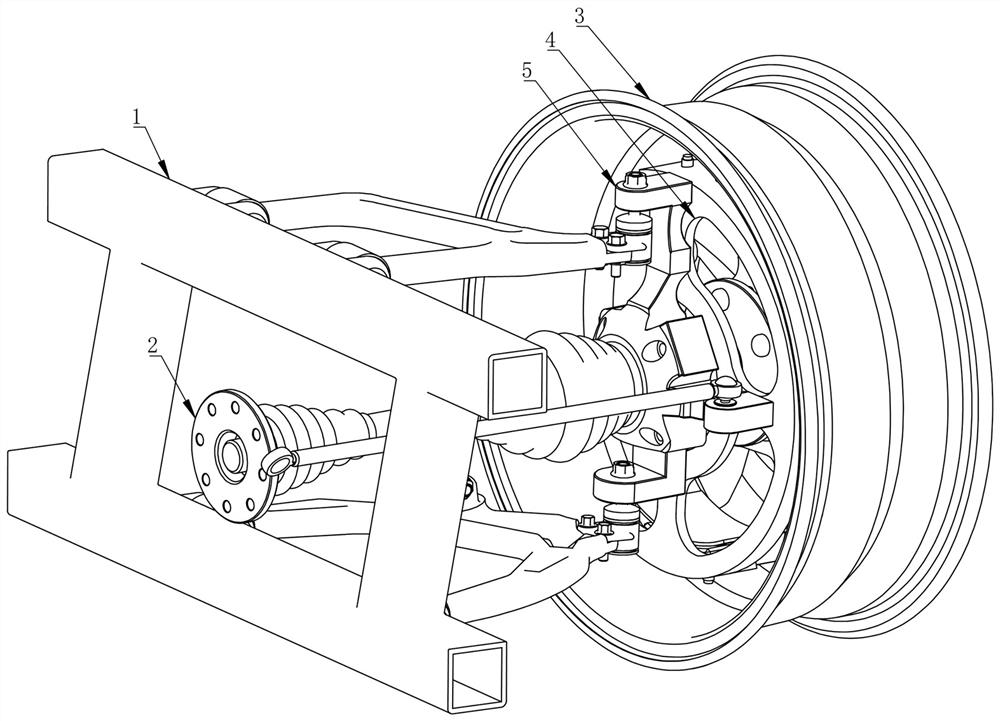

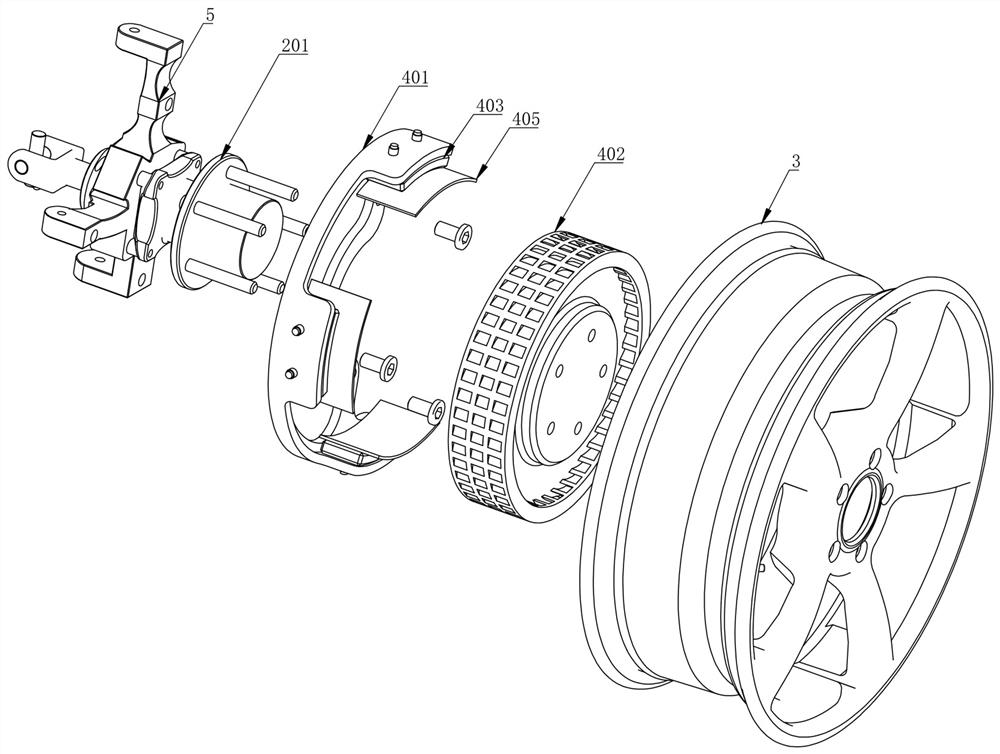

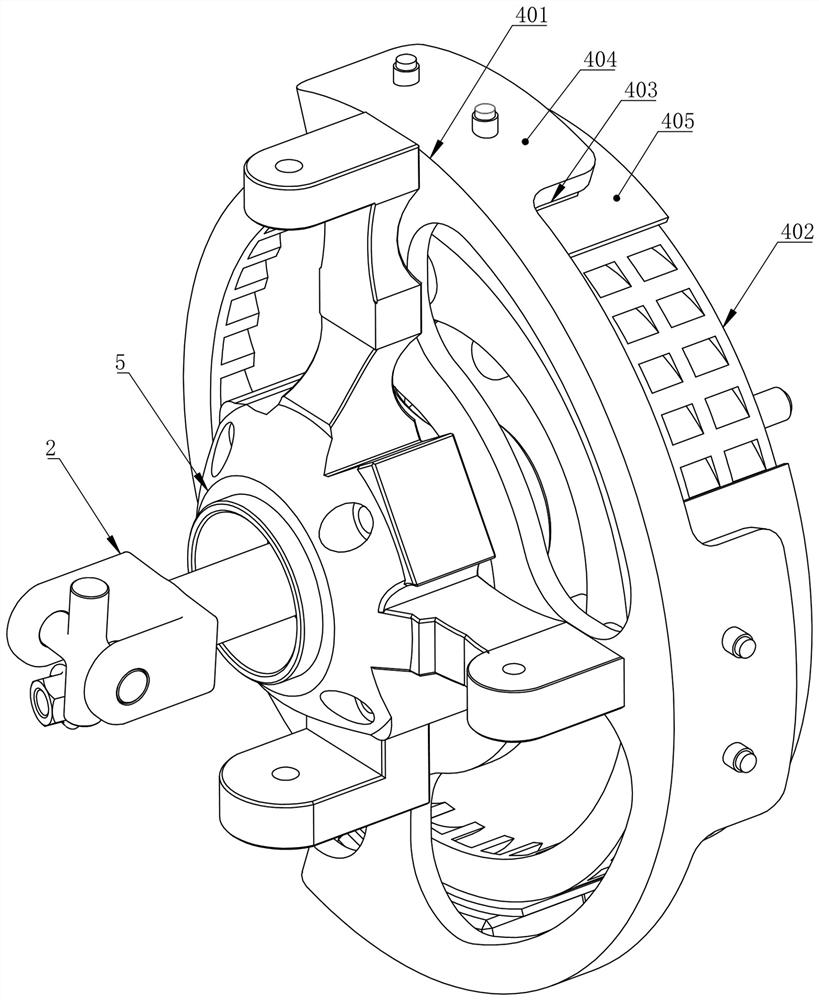

[0019] Specific implementation mode one: combine Figure 1-6 As shown, an automobile brake disc that can cool down quickly is characterized in that: it includes a main bridge frame 1, a transmission shaft 2, a wheel hub 3 and a ring-disk type powerful brake cooling device 4; a support frame 5 is installed on the right side of the main bridge frame 1; The transmission shaft 2 is connected to the middle part of the support frame 5 through the bearing; the right end of the transmission shaft 2 is provided with a connection plate 201; the ring-disk type powerful brake heat dissipation device 4 is installed on the right end of the connection plate 201; the wheel hub 3 is installed on the ring-disk type strong brake heat dissipation device 4. The right end; the ring-disc type powerful brake cooling device 4 includes a brake chassis 401, a brake disc 402 and a hydraulic cylinder 403; the connection disc 201, the brake disc 402 and the wheel hub 3 are fixed and locked by bolts; Fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com