A kind of manufacturing method of glass for glaze carving porcelain

A manufacturing method and glass technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., to achieve the effects of improving crack resistance, hardness, and high glass network connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Color material layer chemical composition mass percent (wt%) is:

[0032] ,

[0033] Add 0.1wt% Cr 2 o 3 .

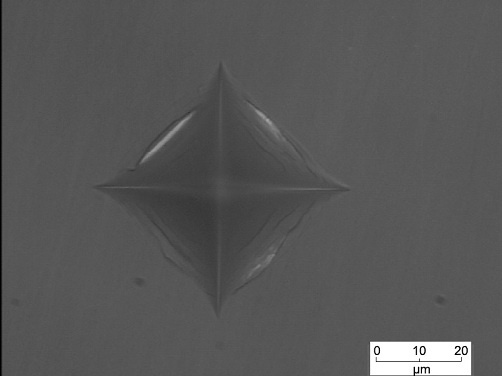

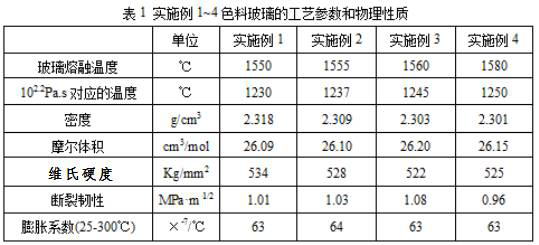

[0034]The raw materials used consist of 78.89 parts by weight of quartz sand, 1.55 parts of aluminum hydroxide, 9.28 parts of boric acid, 18.31 parts of soda ash, 2.61 parts of magnesium oxide, 2.24 parts of potassium carbonate, 1.83 parts of calcite and 0.1 part of dichromium trioxide. The appearance of the obtained product is cyan, wherein the thickness of the clear material layer is 1.6mm, the thickness of the white material layer is 1.85mm, and the thickness of the color material layer is 1.80mm. The expansion coefficient of clear layer glass is 63×10 -7 / °C, the expansion coefficient of the white layer glass is 65×10 -7 / °C, in the Vickers hardness test of the pigment layer glass, there is no crack growth at the tip of the indentation after holding a load of 1 kg for 10 seconds. Other process parameters and physical properties are shown in Table 1.

Embodiment 2

[0036] Color material layer chemical composition mass percent (wt%) is:

[0037] ,

[0038] Add 0.02wt% CoO.

[0039] The raw materials used consist of 79.80 parts by weight of quartz sand, 0.93 parts of aluminum hydroxide, 8.93 parts of boric acid, 17.62 parts of soda ash, 2.71 parts of magnesium oxide, 1.94 parts of potassium carbonate, 2.19 parts of calcite and 0.02 parts of cobalt oxide. The appearance of the obtained product is blue, wherein the thickness of the clear material layer is 1.5 mm, the thickness of the white material layer is 1.7 mm, and the thickness of the color material layer is 1.5 mm. The expansion coefficient of clear layer glass is 64×10 -7 / °C, the expansion coefficient of the white layer glass is 67×10 -7 / °C, in the Vickers hardness test of the pigment layer glass, there is no crack growth at the tip of the indentation after holding a load of 1 kg for 10 seconds. Other process parameters and physical properties are shown in Table 1.

Embodiment 3

[0041] Color material layer chemical composition mass percent (wt%) is:

[0042] ,

[0043] Add 0.03wt% CoO, 1.5wt% NiO and 0.1wt% Cr 2 o 3 .

[0044] The raw materials used are composed of 80.30 parts by weight of quartz sand, 1.24 parts of aluminum hydroxide, 8.75 parts of boric acid, 17.79 parts of soda ash, 2.51 parts of magnesium oxide, 1.64 parts of potassium carbonate, 1.64 parts of calcite, 0.03 parts of cobalt oxide, and 1.5 parts of nickel oxide and 0.1 part of chromium trioxide. The obtained product was black in appearance, wherein the thickness of the clear material layer was 1.8 mm, the thickness of the white material layer was 2.2 mm, and the thickness of the color material layer was 2.0 mm. The expansion coefficient of clear layer glass is 65×10 -7 / °C, the expansion coefficient of the white layer glass is 64×10 -7 / °C, in the Vickers hardness test of the color material layer glass, there is no crack growth at the tip of the indentation after a load of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com