Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about How to "Strong capillary force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

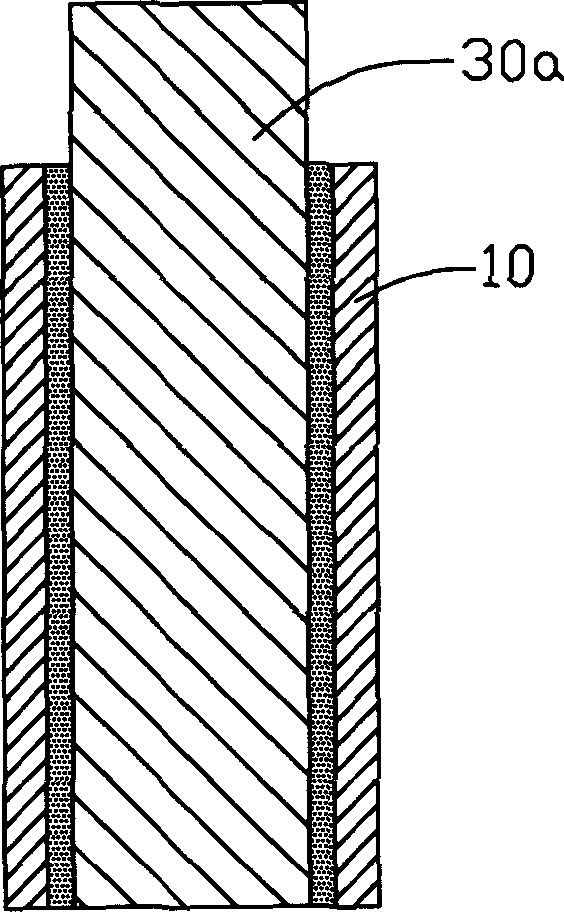

Gas diffusion layer for low temp fuel cell and preparing process thereof

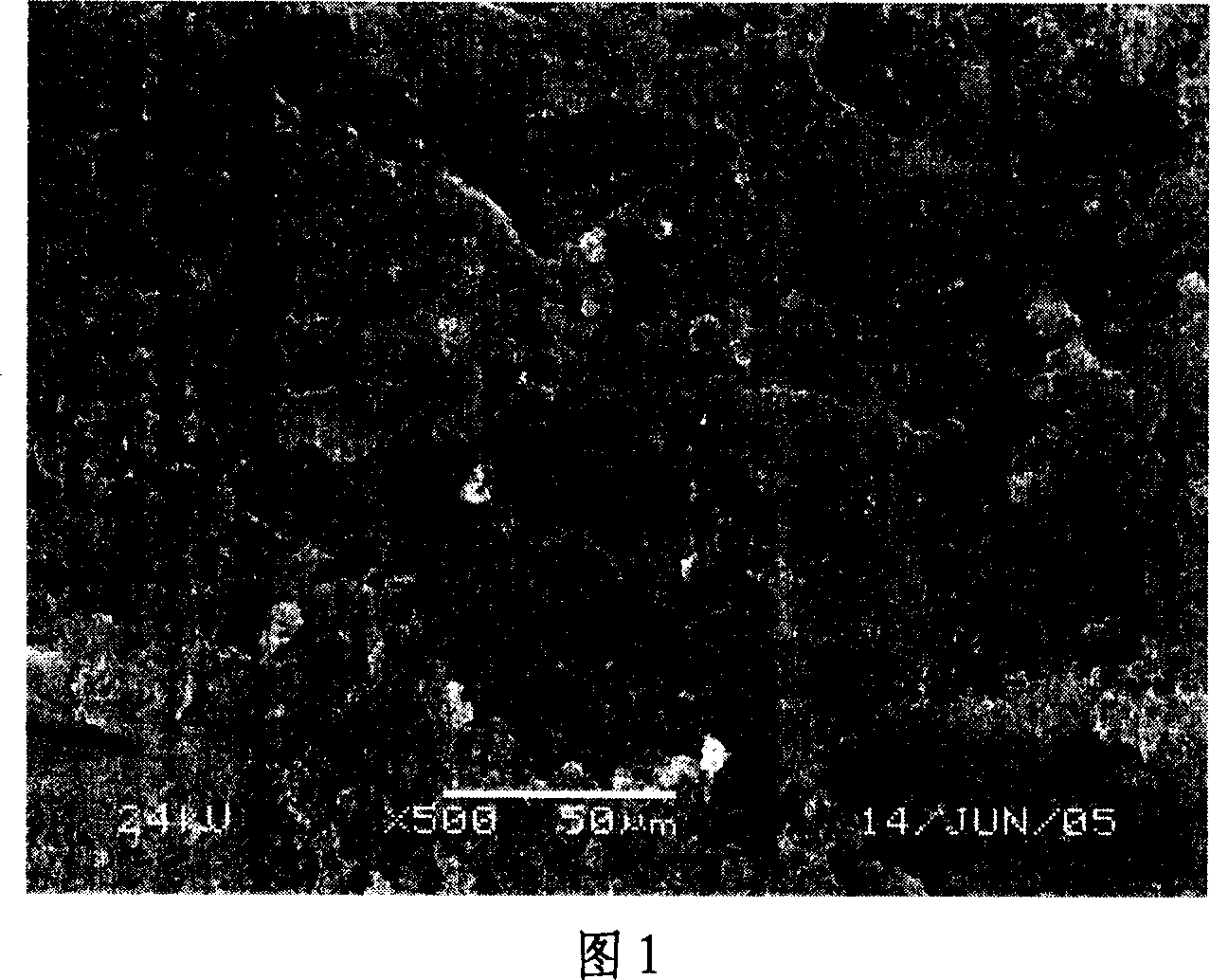

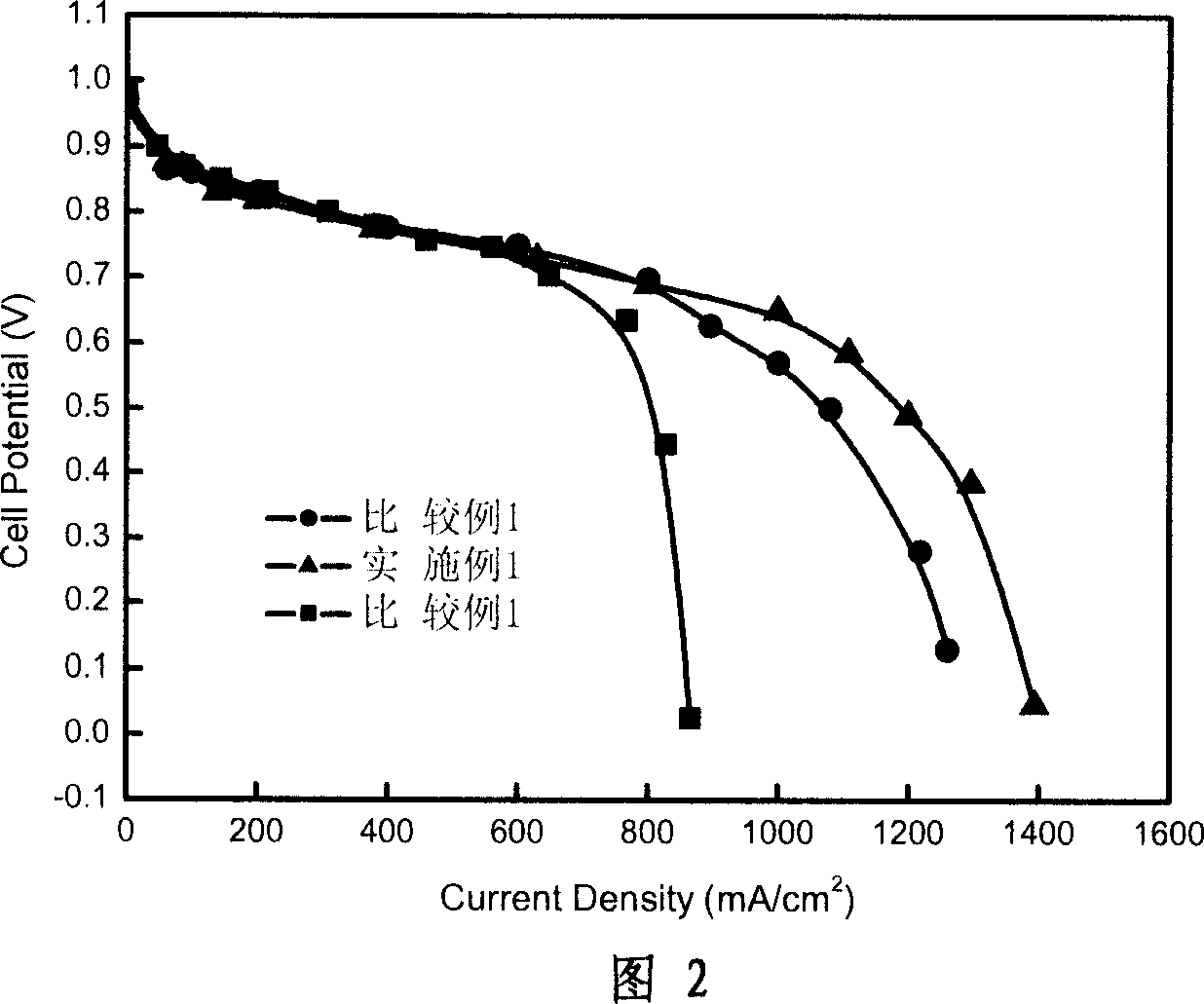

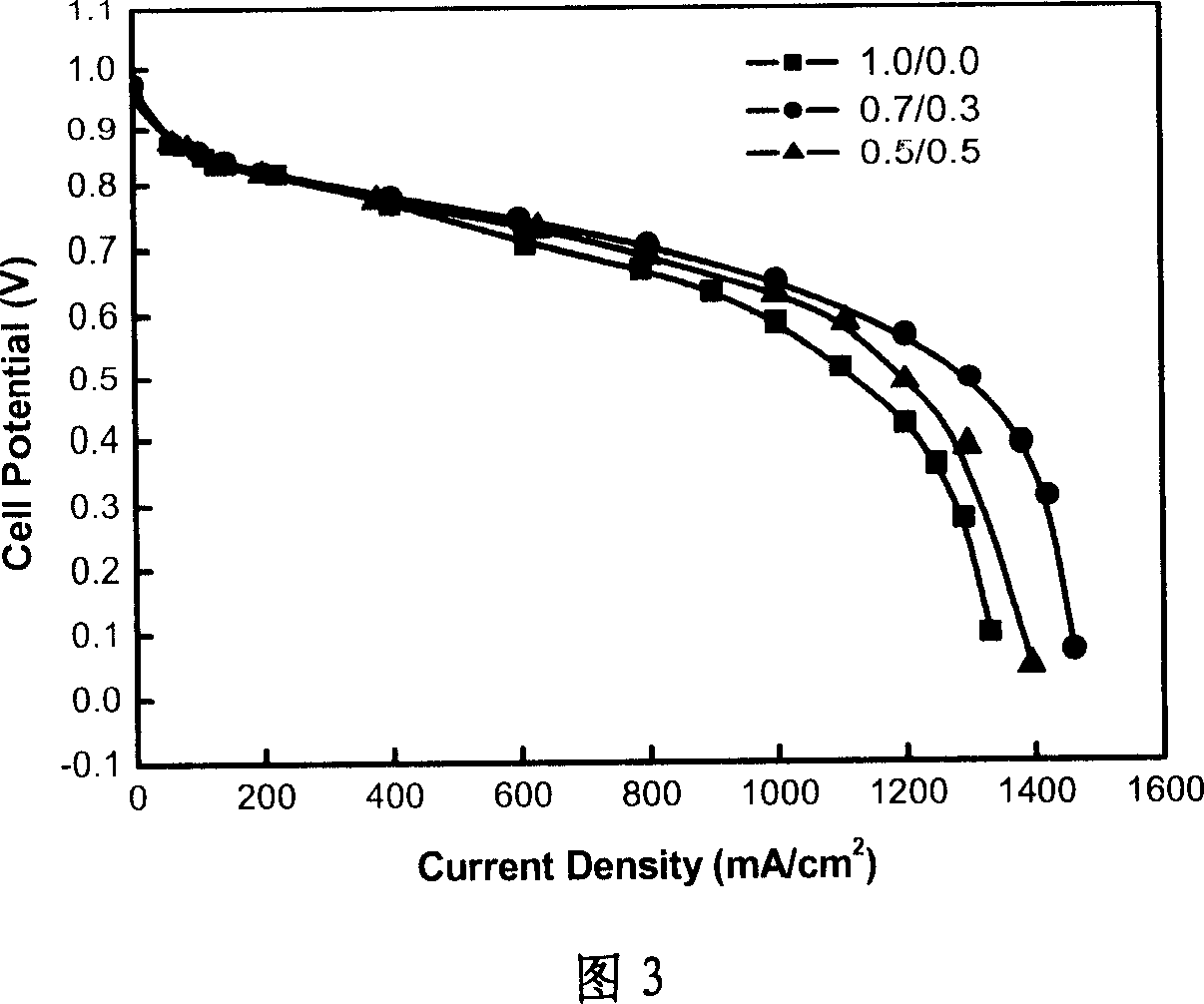

ActiveCN1949570AImprove mass transfer effectNot easy to coagulateCell electrodesFuel cell detailsFuel cellsLiquid water

The invention relates to a low-temperature fuel cell, concretely a gas diffusion layer for low-temperature fuel cell and the preparing method thereof, where the gas diffusion layer is composed of substrate layer and microporous laye, and the microporous layer is mixed of two or more conductive carbon materials. And the preparing method: taking and mixing two or more conductive carbon materials in proportion into composite conductive material, uniformly diffusing the composite condutive material and hydrophobic agent in solvent to form plup; uniformly arranging the pulp on one or two sides of a hydrophobic processed porous conductive substrate; finally forming the gas diffusion layer by thermal treatment. Because of preparing microporous layer by compositive conductive material, it forms a double-function hole structure beneficial to reacting gas transmission and liquid water transmission, improving battery performances.

Owner:SUNRISE POWER CO LTD

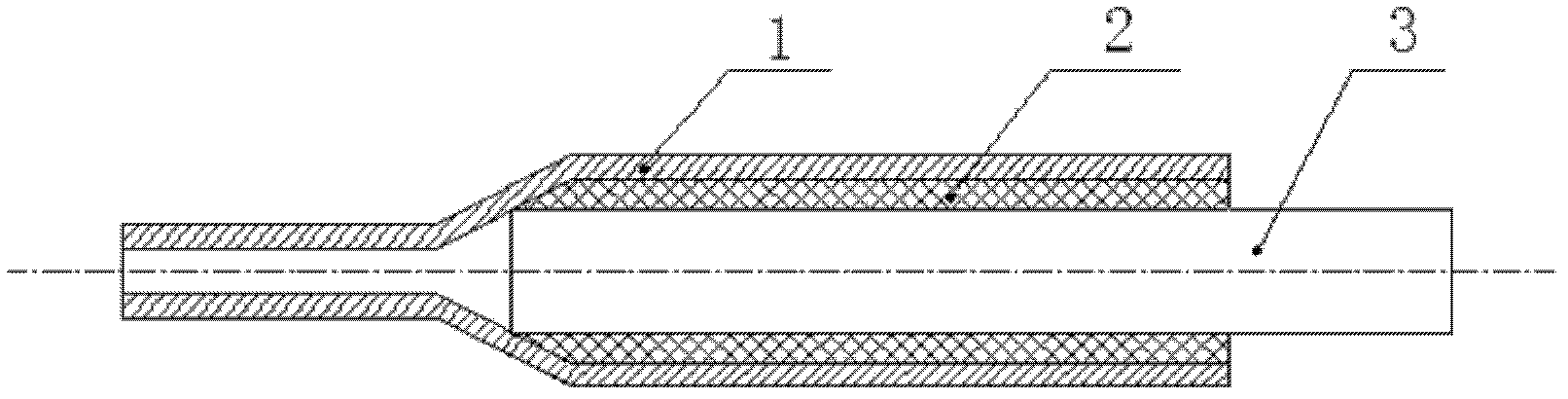

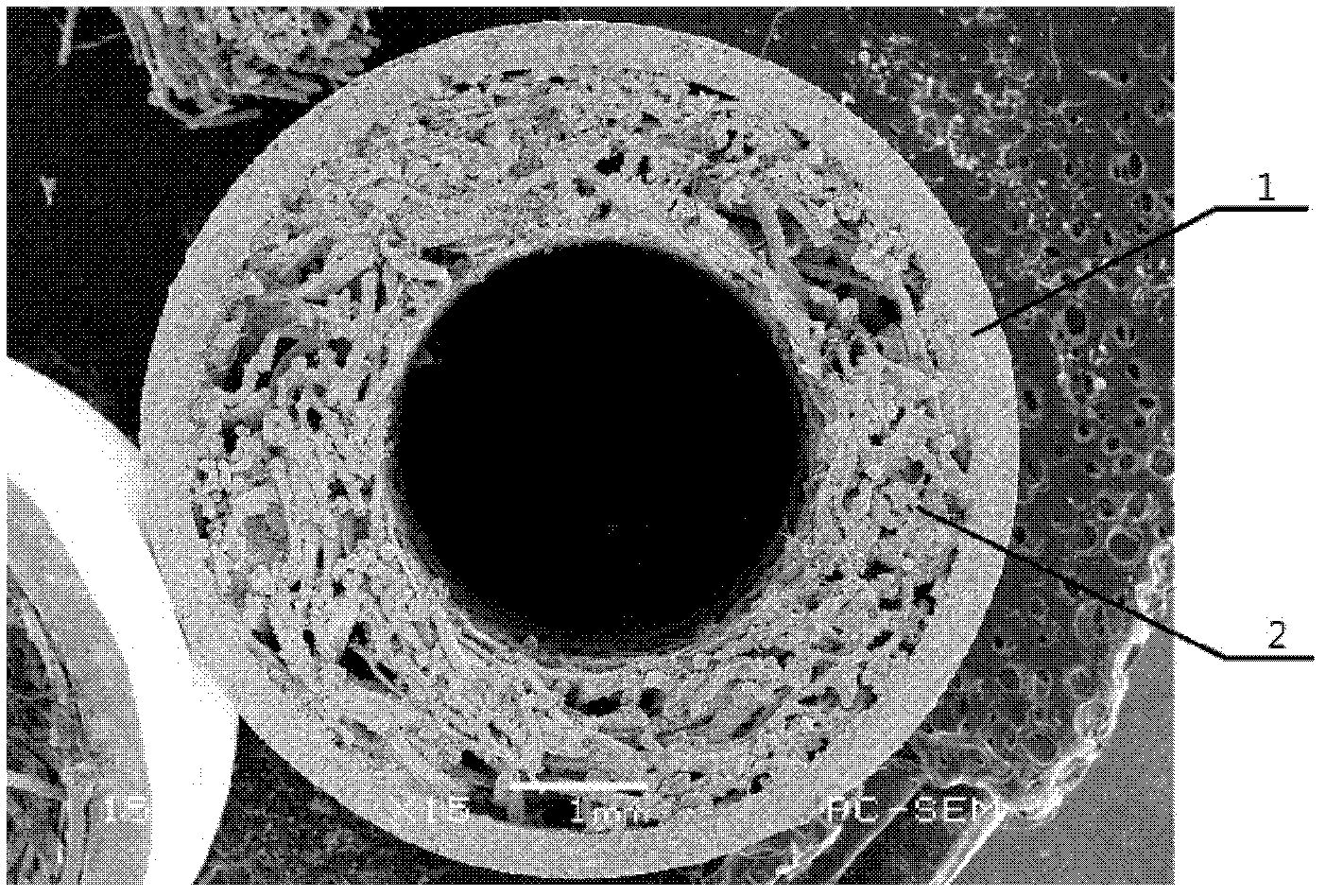

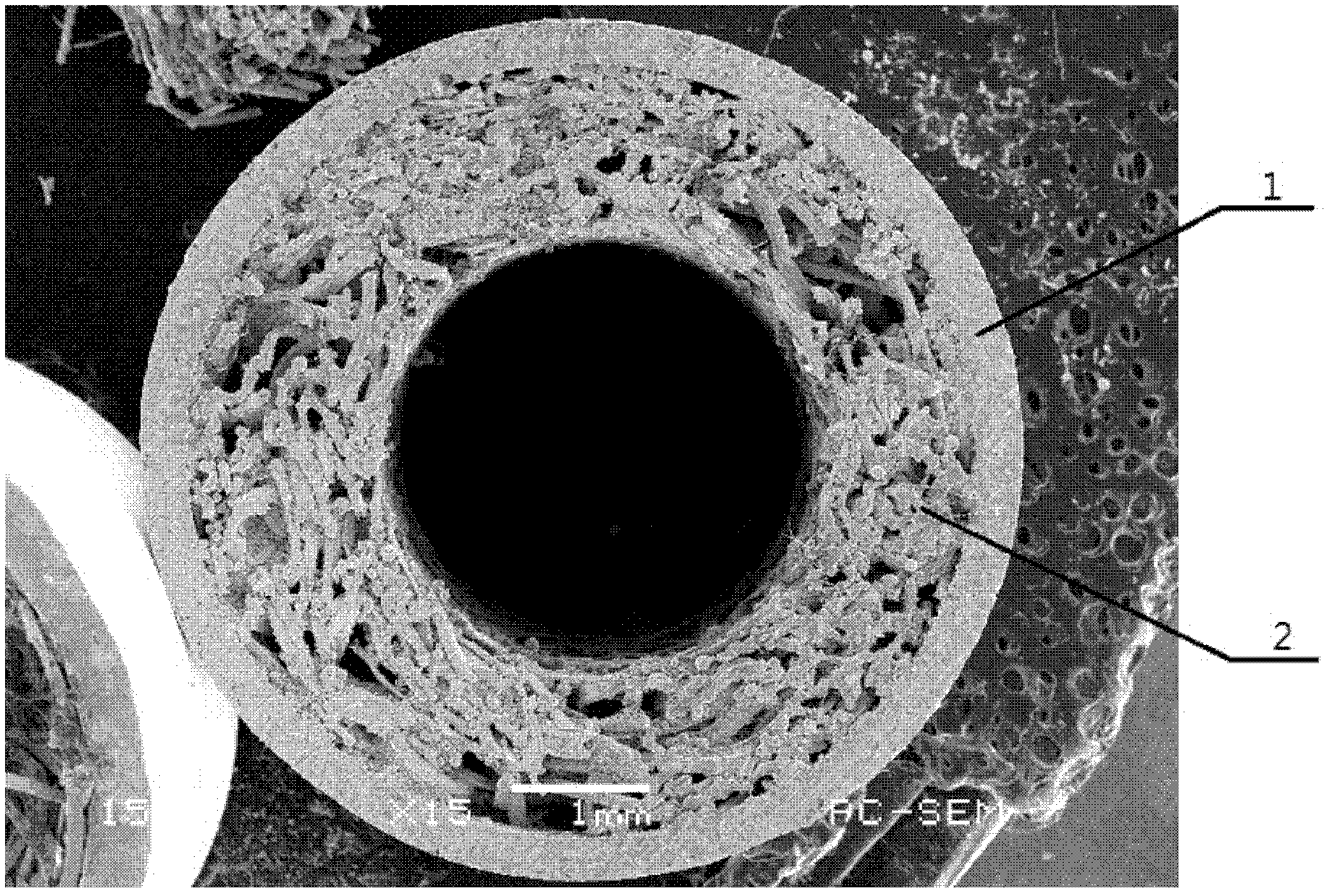

Fiber sintering type micro heat pipe and manufacturing method thereof

InactiveCN102305564ARich multi/microscale surface structuresIncrease contact areaIndirect heat exchangersPorosityMetal fiber

The invention discloses a fiber sintering type micro heat pipe and a manufacturing method thereof. The fiber sintering type micro heat pipe consists of a base pipe, a liquid suction core and a liquid working medium, wherein the liquid suction core is formed by solid-phase sintering for metal fibers. The manufacturing method for the fiber sintering type micro heat pipe mainly comprises four steps, namely preparation for the base pipe, processing of the metal fibers, manufacturing of the liquid suction core and precise encapsulation for the liquid suction core. After the metal fibers are sintered, metallurgical bonding is realized among the fibers and a large quantity of multi-scale pore structures are formed. The fiber sintering type micro heat pipe manufactured by using the method has the advantages of simple process, low cost, high porosity and controllability of the liquid suction core, high permeability, small liquid reflux resistance, large specific surface area of a metal fiber sintering layer, high capillary force and the like, and a stable three-dimensional meshed porous structure is formed among the fibers, so the fiber sintering type micro heat pipe is difficult to damage.

Owner:SOUTH CHINA UNIV OF TECH

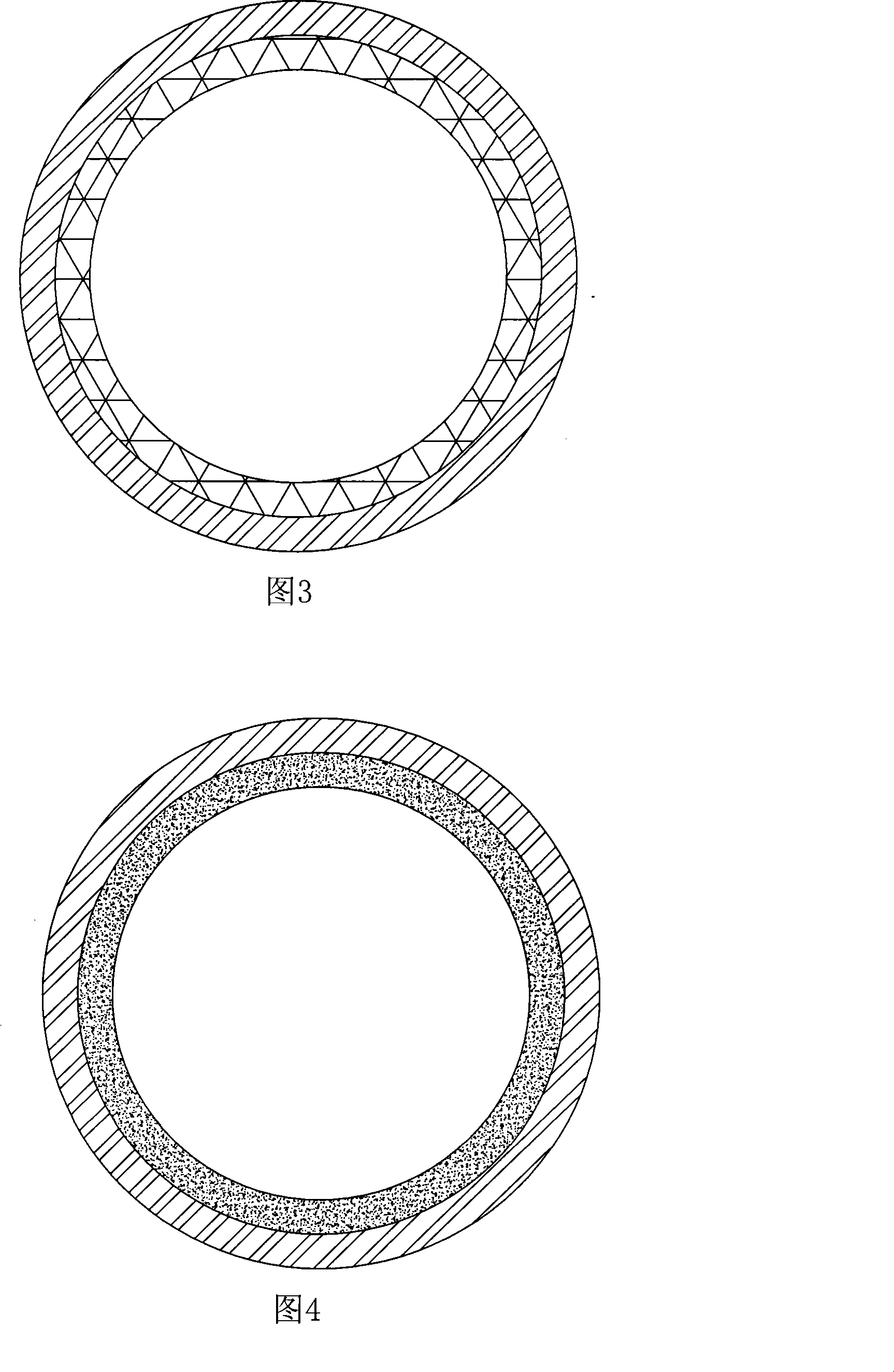

Sintered heat pipe and its manufacturing method

InactiveCN1815130AReduce resistanceStrong capillary forceIndirect heat exchangersWorking fluidLayer thickness

Present invention discloses a sintering type heat tube and manufacturing method. Said method includes 1, providing a metallic shell and at least three kinds of metal powder with different particle size, 2, in turn filling above-mentioned metal powder in particle size scaling up or degressive sequence, each time using a cored bar as structure layer thickness control and rapid sintering,3, whole sintering after all metal powder filling-in, pulling out cored bar after completing sintering, 4, filling working fluid in shell cavity and enclosing said shell, to obtain sintering type heat tube with mutually complicated multiwall capillary structure in inner wall and distributed according to particle size scaling up or degressive sequence.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

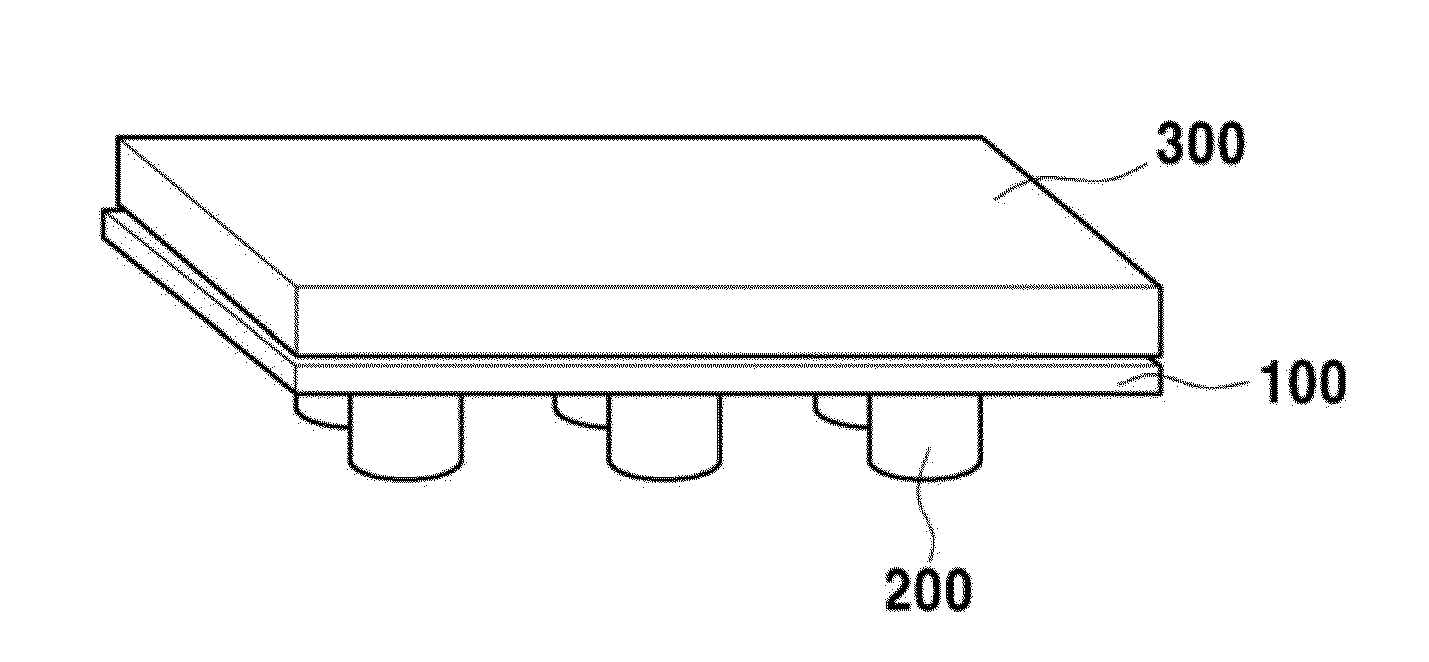

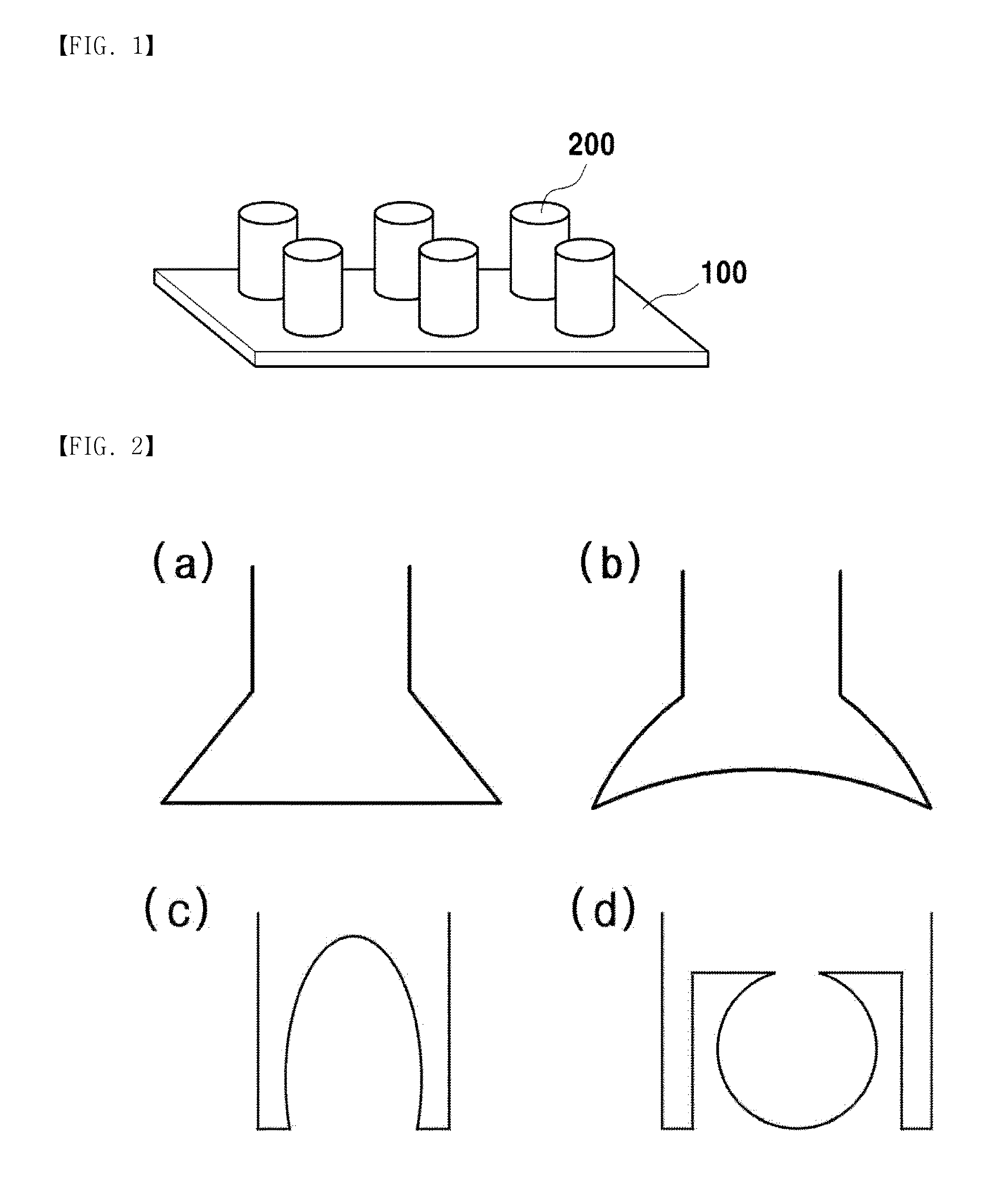

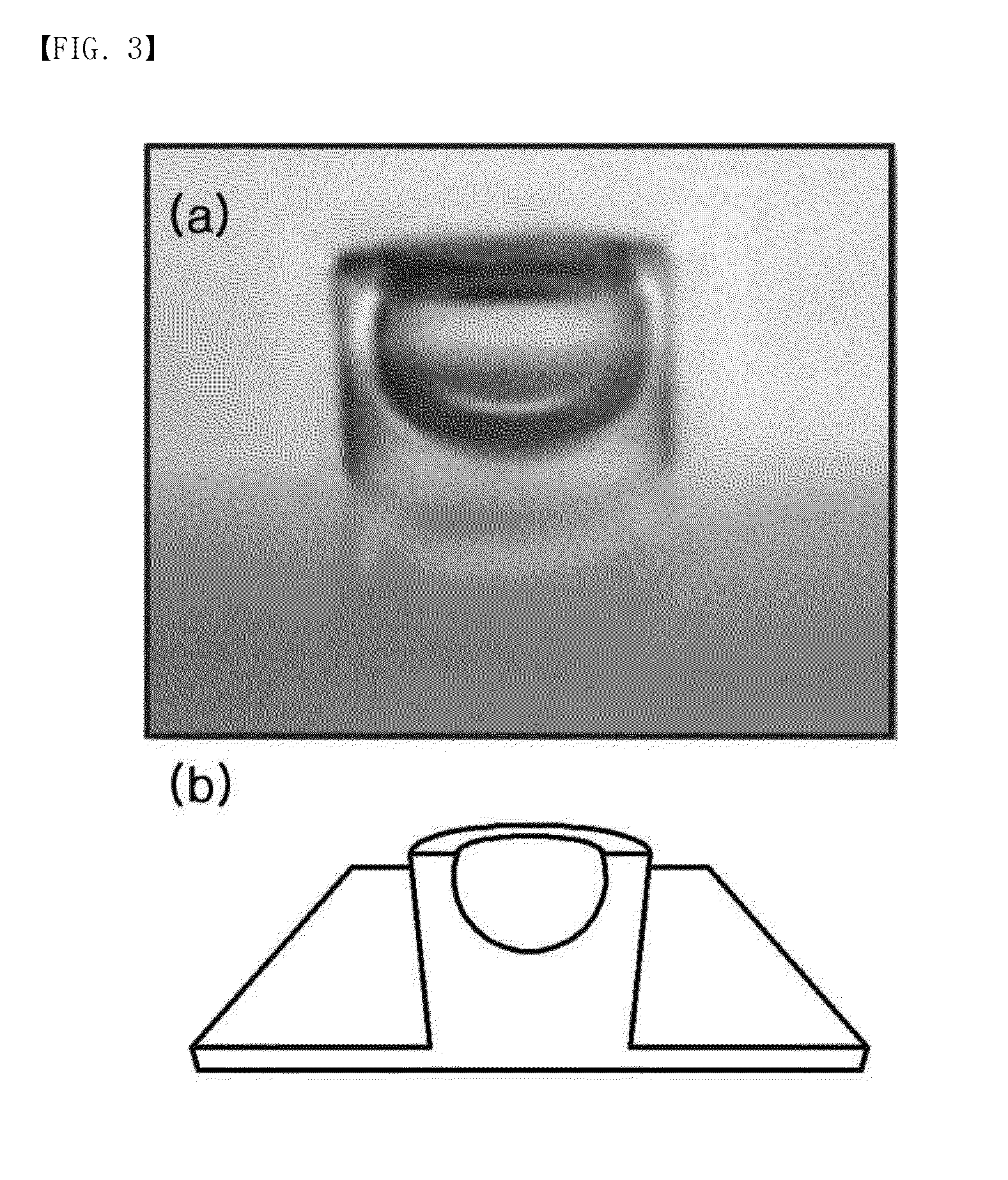

Dry bonding system and wearable device for skin bonding including the same

ActiveUS20160206243A1Sufficient adhesion forceSuperiority in repeated attachmentLayered productsAdhesive dressingsBiomedical engineering

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Loop soaking plate

InactiveCN106949764AAccelerate evaporationRelieve heat loadIndirect heat exchangersLiquid stateEvaporation

The invention discloses a loop soaking plate, and aims to provide the loop soaking plate with simple structure, low cost and higher generality and particularly suitable for high-heat-flux places. The loop soaking plate comprises a cover plate and a baseplate; the cover plate is fixed on the baseplate; a closed vacuum plate shell is formed between the cover plate and the baseplate; a first capillary structure layer and a second capillary structure layer are arranged in the plate shell; an evaporation cavity is formed between the first capillary structure layer and the second capillary structure layer; multiple support structures are vertically arranged between the first capillary structure layer and the second capillary structure layer; the first capillary structure layer is permeated with a liquid-state working medium; the plate shell is provided with at least one loop module for accommodating the working medium to flow; and the loop module communicates with the evaporation cavity.

Owner:GUANGZHOU HUAZUAN ELECTRONICS TECH

Flat and thin type heat pipe

InactiveCN101900507AImprove cooling effectWon't clogIndirect heat exchangersInterior spaceSolid structure

Owner:FURUI PRECISE COMPONENT (KUNSHAN) CO LTD +1

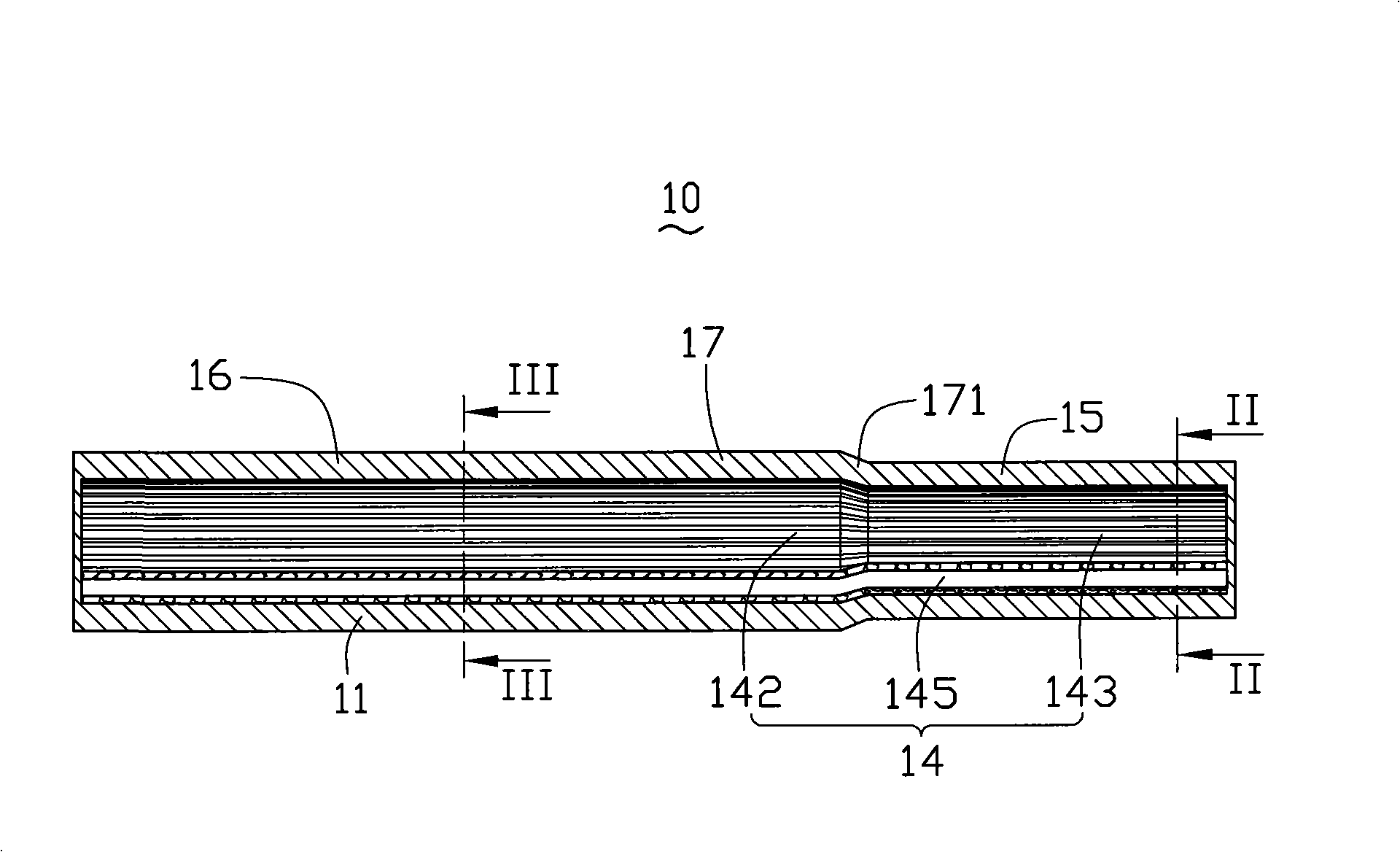

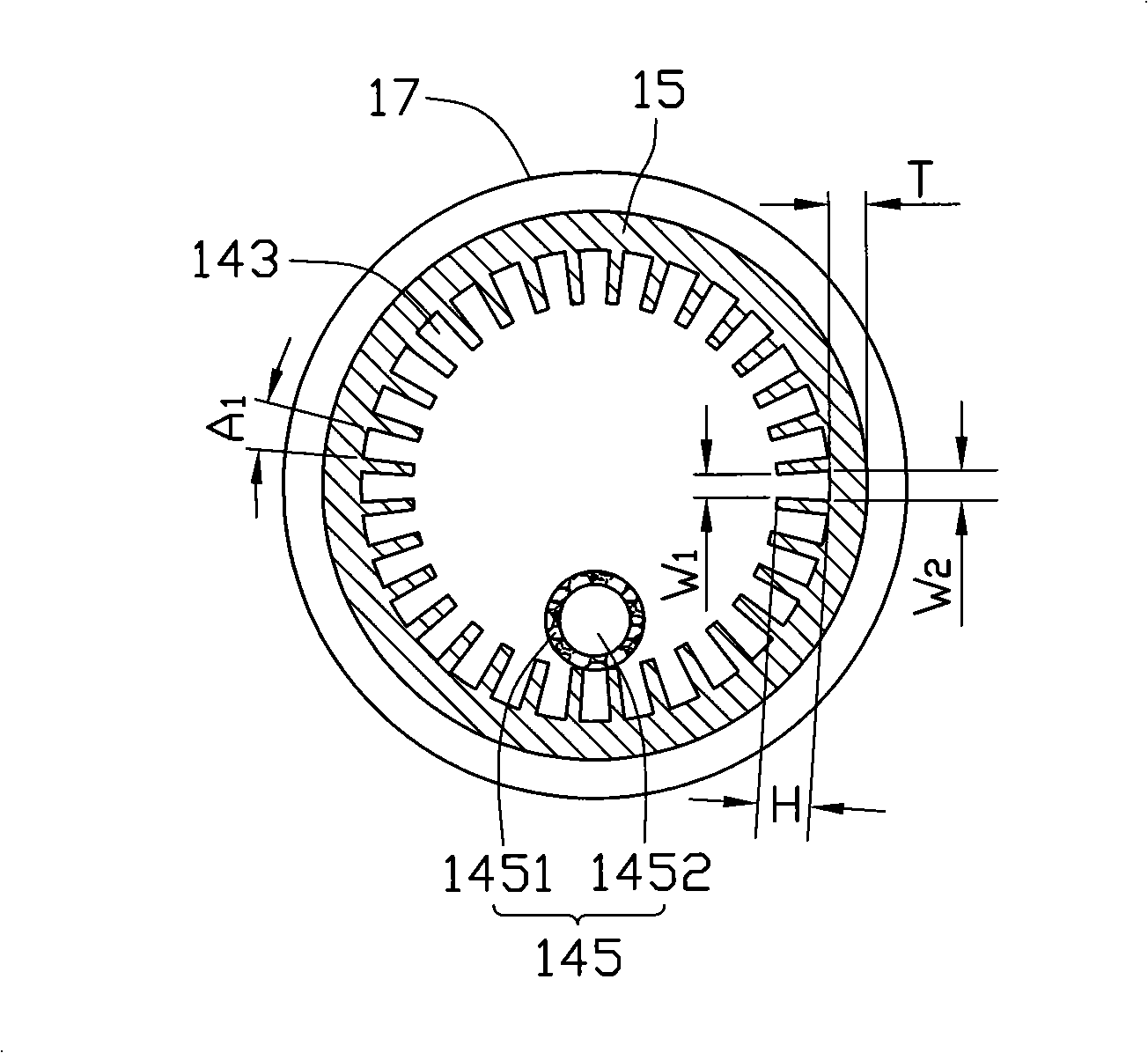

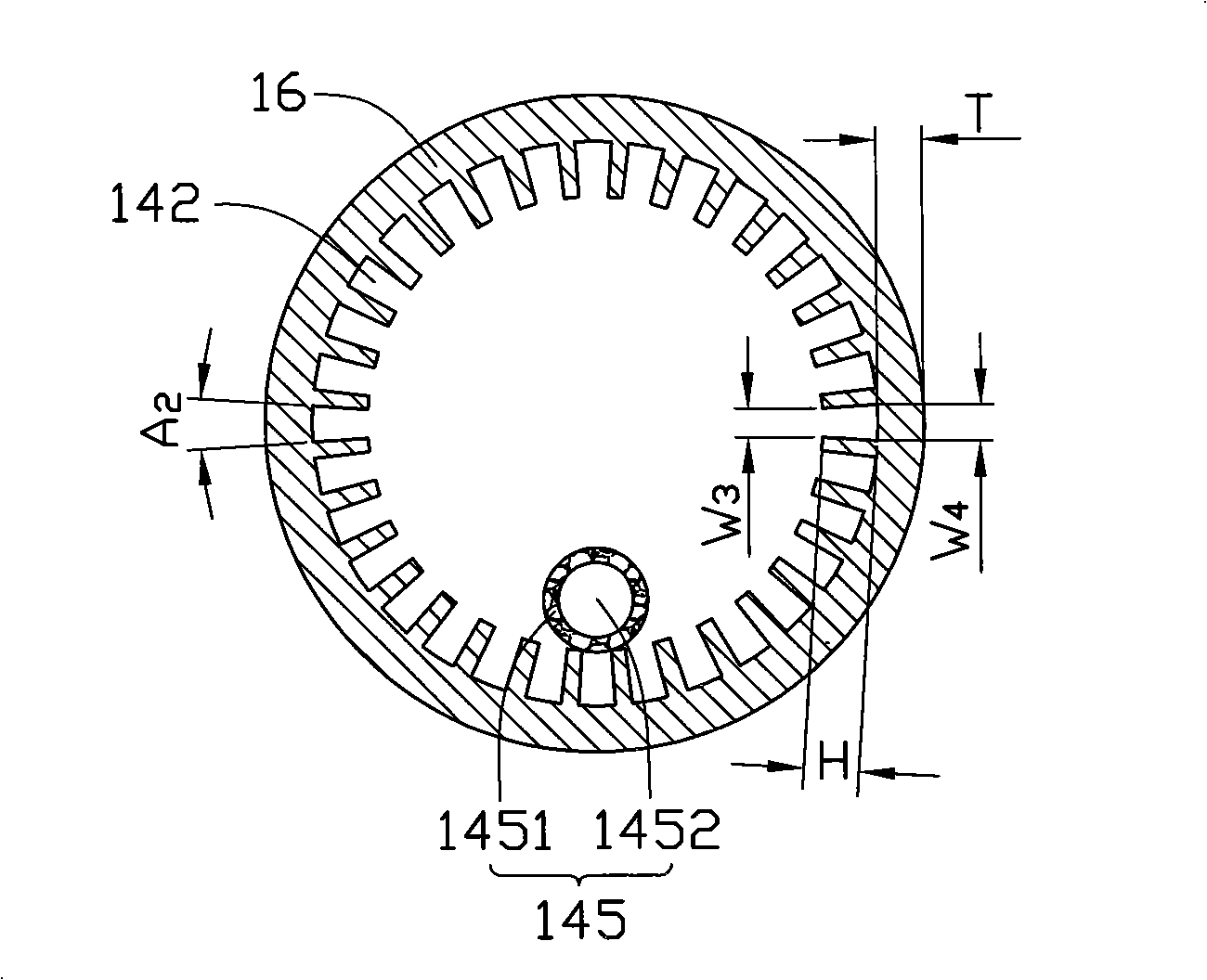

Hot pipe

InactiveCN101349519AImprove heat transfer performanceSmall apertureIndirect heat exchangersWorking fluidEngineering

A heat pipe comprises a pipe body, a capillary structure in the pipe body and working fluid which is filled in the pipe body, wherein the heat pipe comprises an evaporating section and a condensing section along the pipe body direction, the capillary structure comprises a main capillary structure and an auxiliary capillary structure, wherein the main capillary structure is attached on the inner walls of the pipe body, the main capillary structure of the evaporating section has stronger capillary force than the main capillary structure of the condensing section, the auxiliary capillary structure comprises at least a haemal tube in hollow tube structure, wherein the haemal tube is extended between the evaporating section and the condensing section, a plurality of tiny pores are formed on the walls of the haemal tube, and one side of the haemal tube is contacted with the main capillary structure, thereby facilitating the capillary structure of the heat pipe to provide stronger capillary acting force and to have small liquid reflux resistance, and increasing the heat transfer property of the heat pipe.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

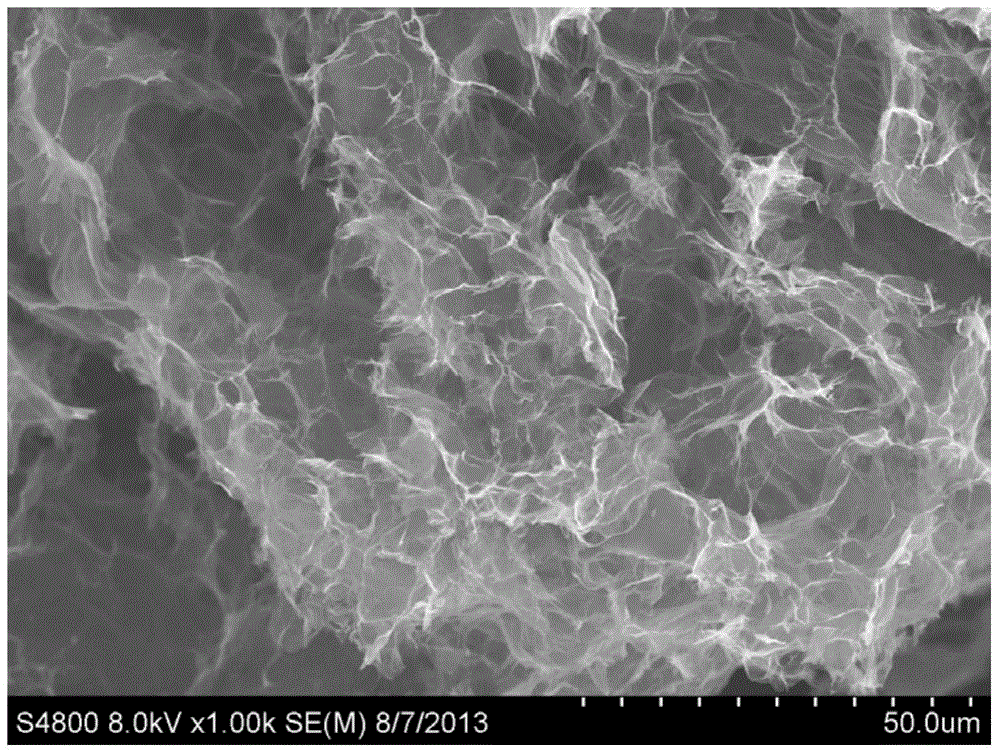

Graphene powder and preparation method thereof

ActiveCN104787751ALower decomposition temperatureConducive to the degree of oxidationState of artCvd graphene

The present invention provides a graphene powder preparation method, which comprises: a, carrying out a reaction of graphite oxide and a dispersant to obtain an intermediate product, wherein the dispersant comprises an ammonium salt; and b, carrying out a heat treatment on the intermediate product to obtain the graphene powder. According to the present invention, the close contact degree of the graphite oxide sheet layers can be weakened through the dispersant, such that the obtained graphene powder of the present invention has characteristics of low agglomeration degree and good dispersion property; the dispersant is subjected to thermal decomposition to produces gas during the heat treatment process and the gas makes the graphite oxide be peeled, such that the agglomeration degree of the obtained graphene powder of the present invention is further weakened so as to obtain the graphene powder having the good dispersion property; and the graphene powder having the good dispersion property can be obtained without the spray drying compared with the method in the prior art, such that the graphene powder preparation method of the present invention has characteristics of high efficiency and low energy consumption, and can be used for large-scale production of the graphene powder.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

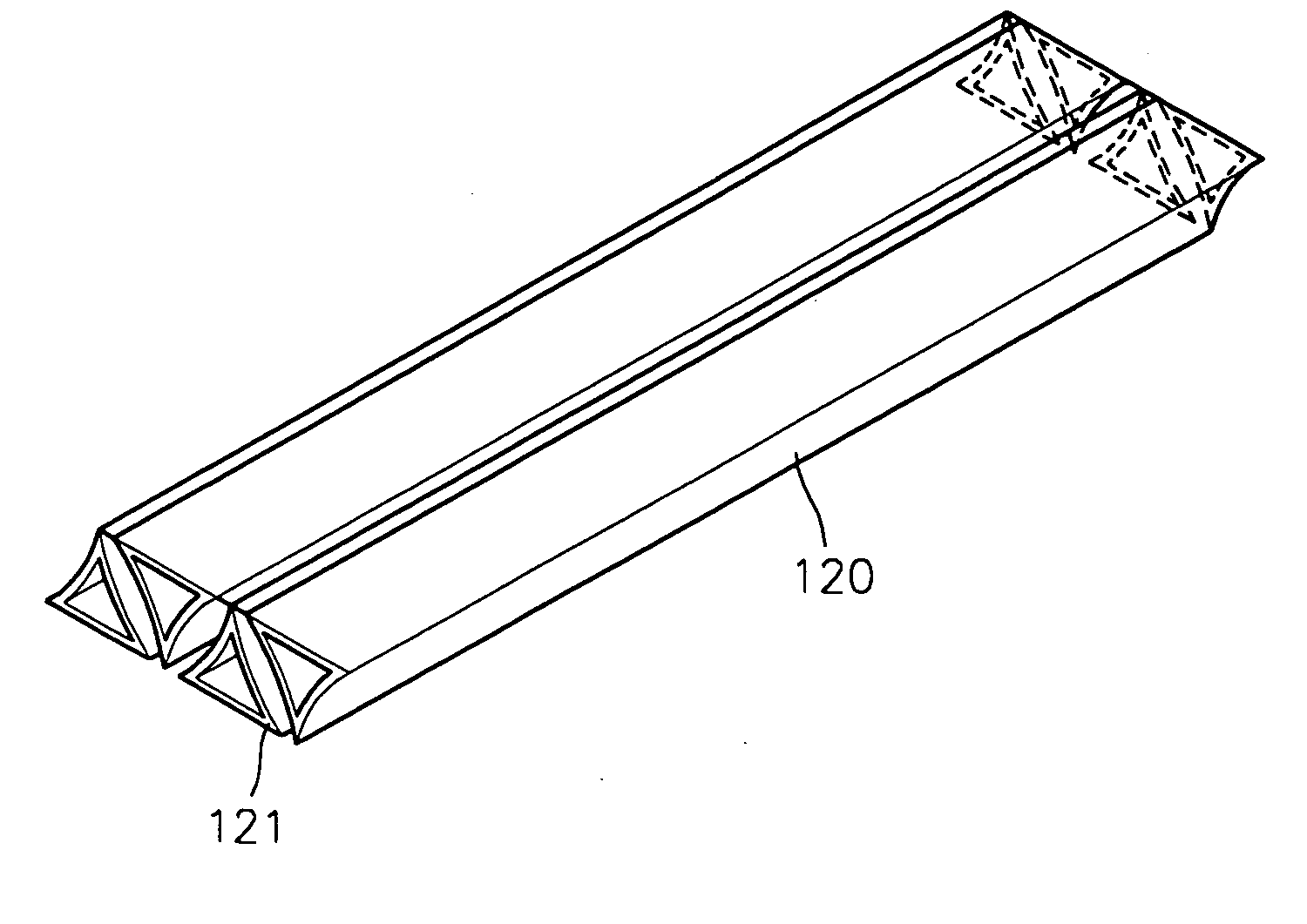

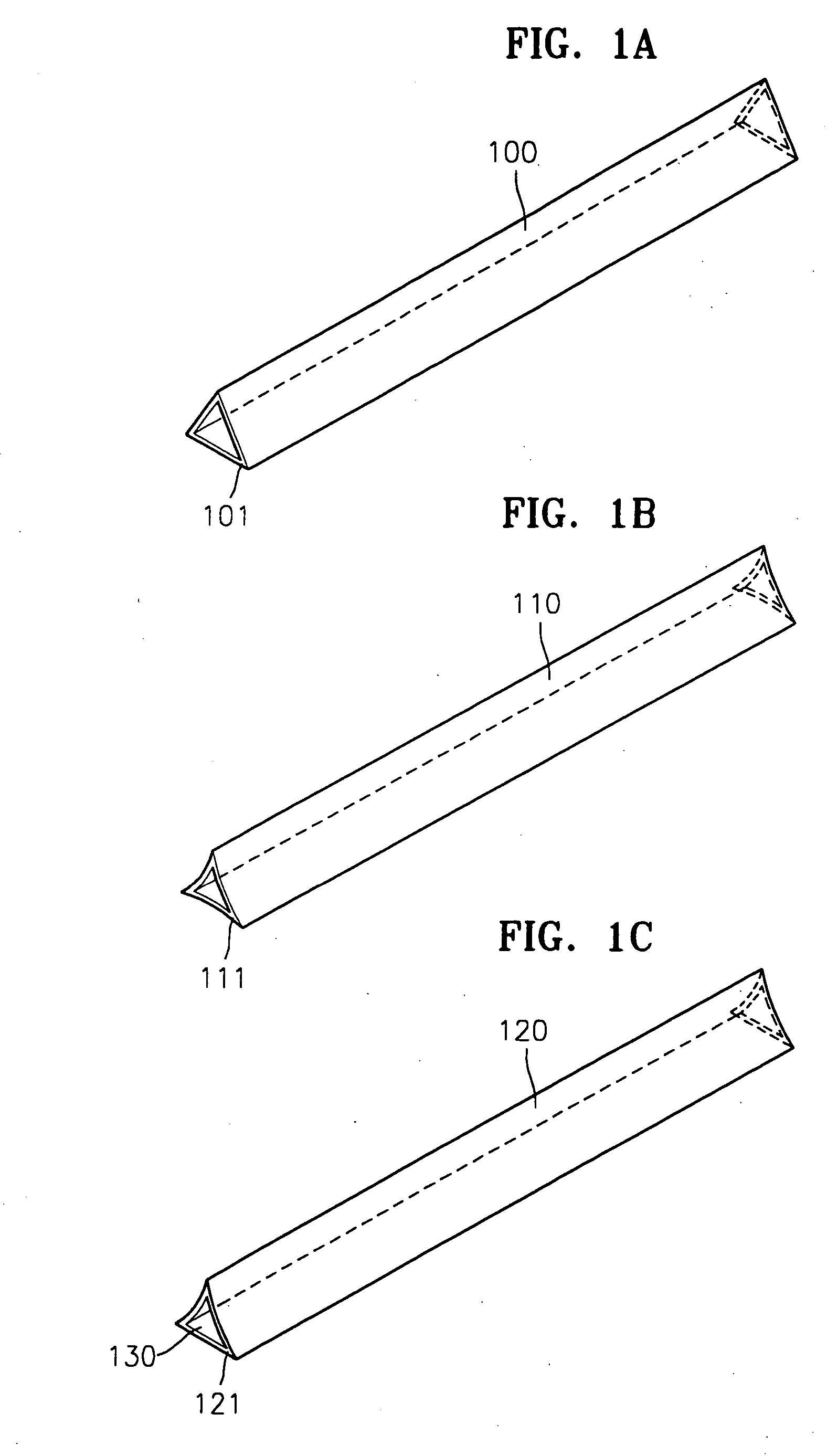

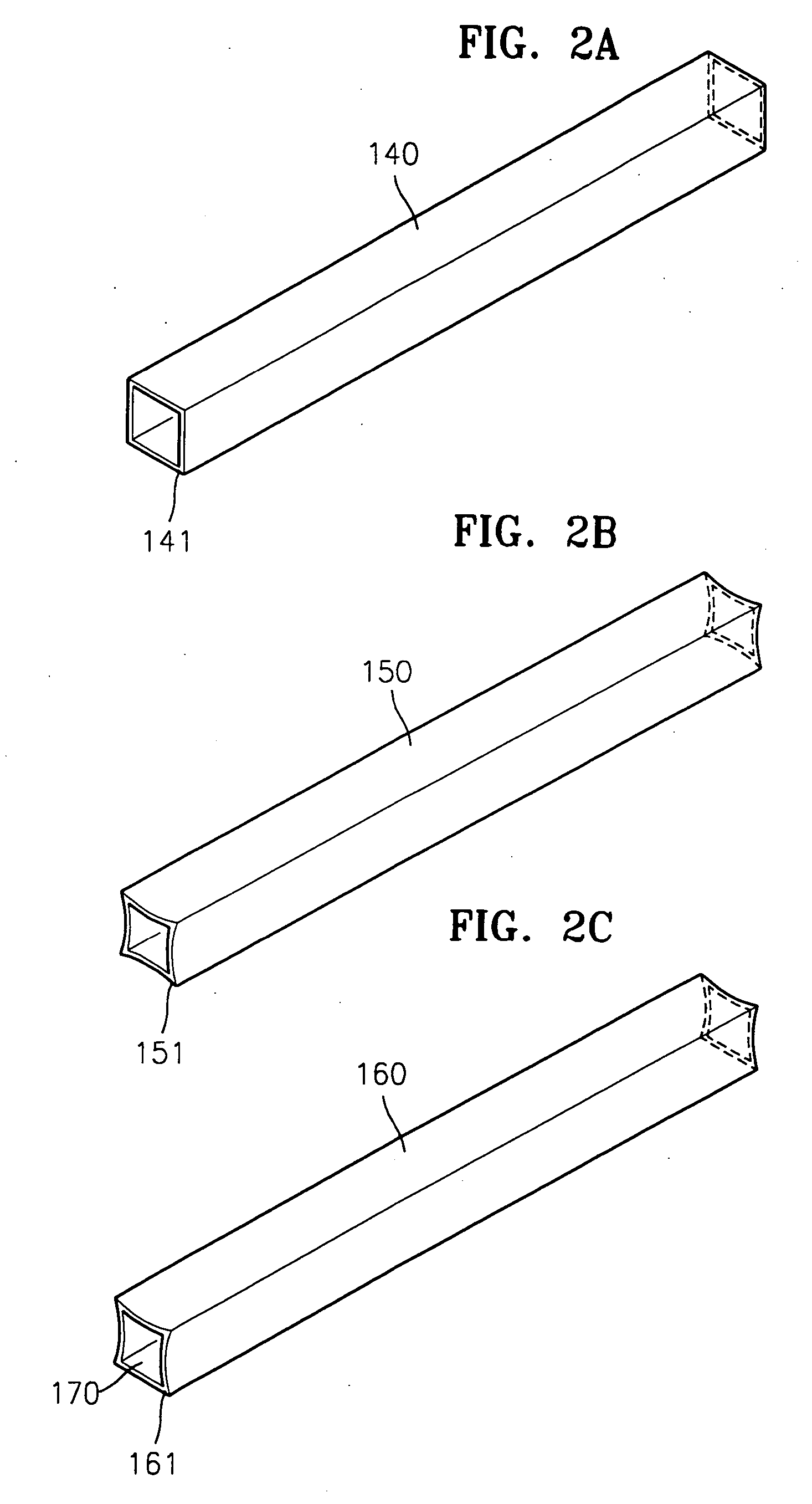

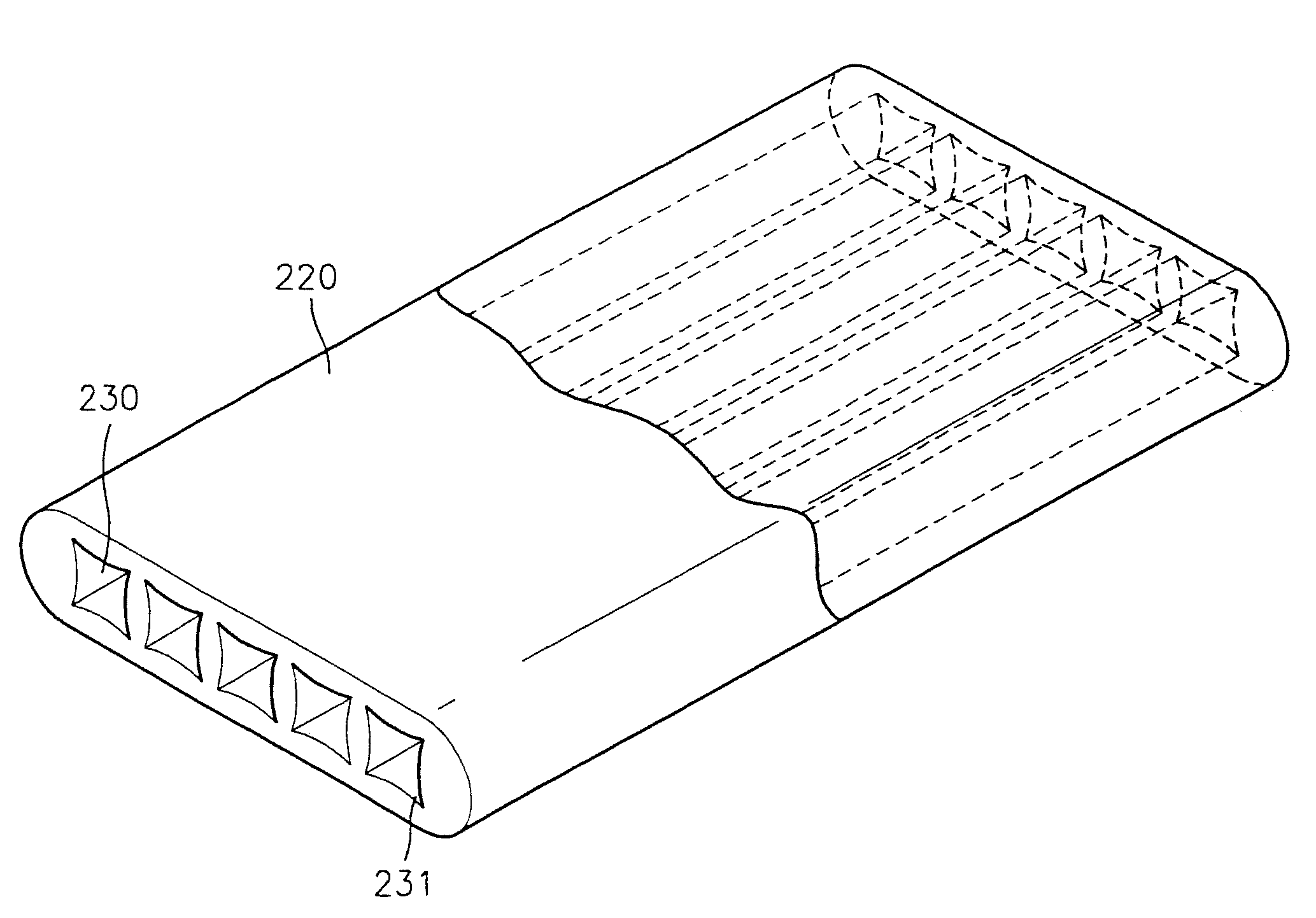

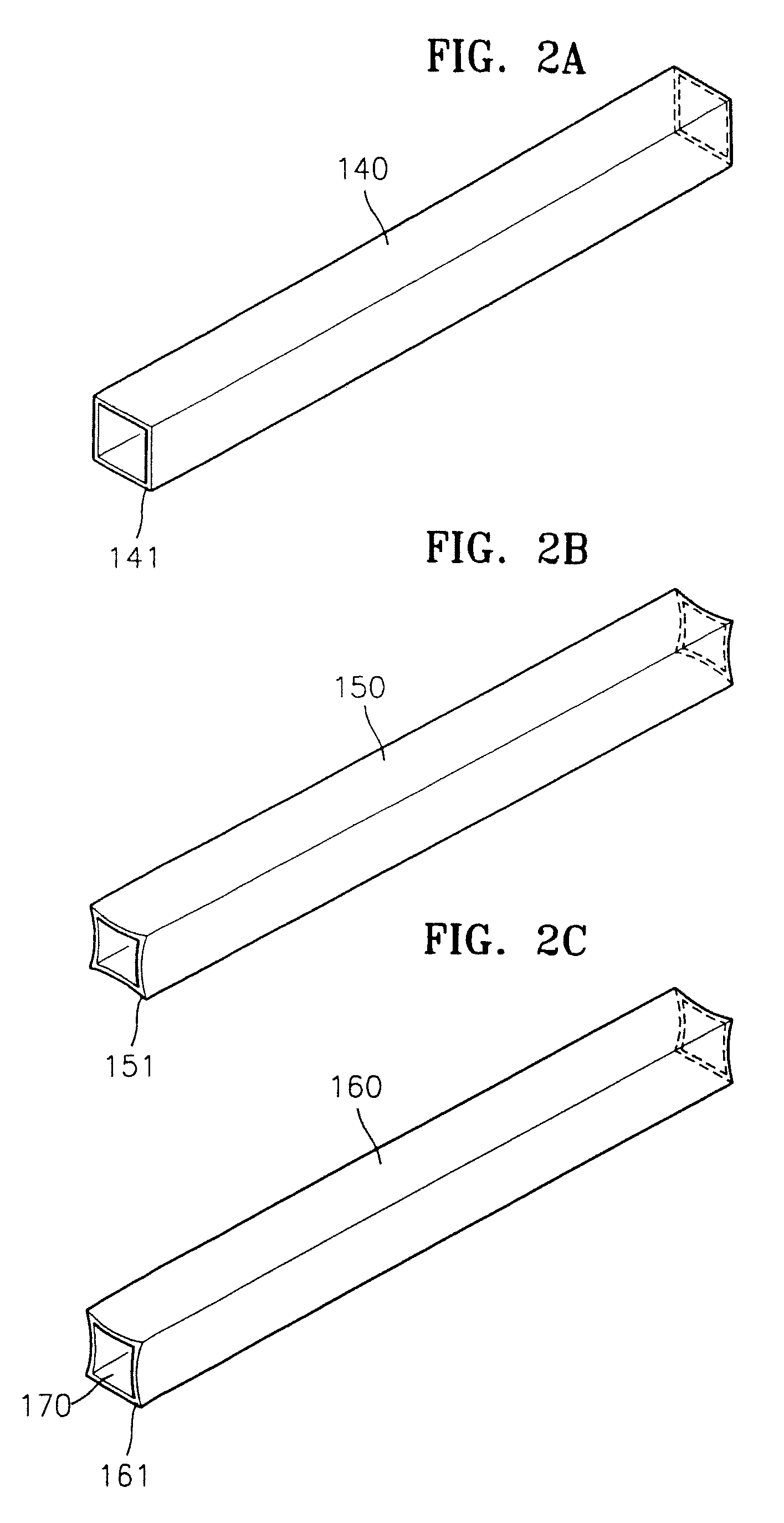

Micro heat pipe with poligonal cross-section manufactured via extrusion or drawing

InactiveUS20060157228A1Easy to manufactureStrong capillary forceIndirect heat exchangersTubular elementsWorking fluidEngineering

A method for fabricating a metal micro heat pipe with a polygonal cross-section including at least two concave sides to allow working fluid to flow by capillary force generated at the edges of the micro heat pipe. The concave sides are each formed of a single metal layer via a single drawing process. The polygonal cross-section is triangular, and the micro heat pipe is formed of a single metal plate.

Owner:MOON SEOK HWAN +6

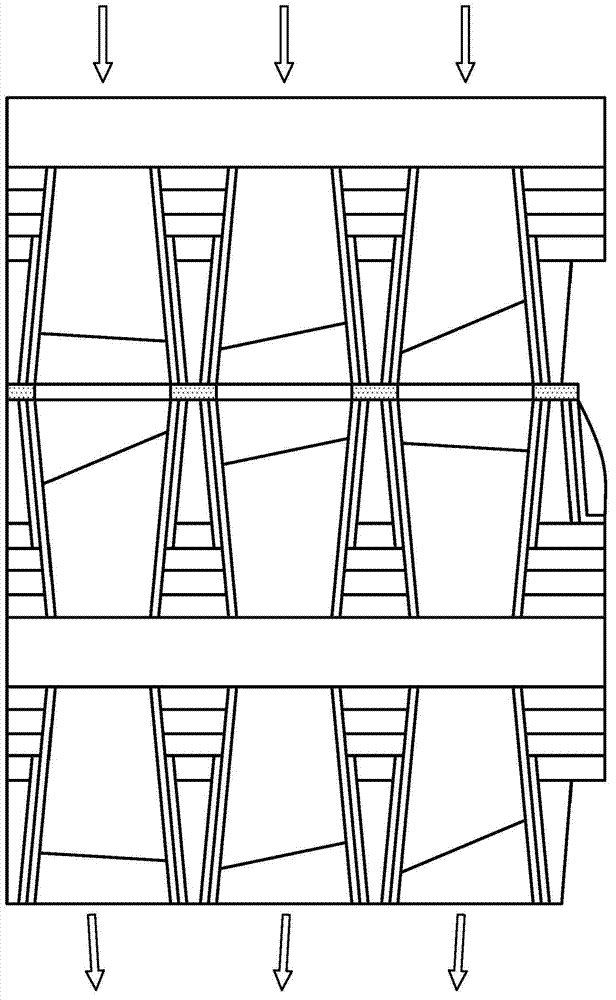

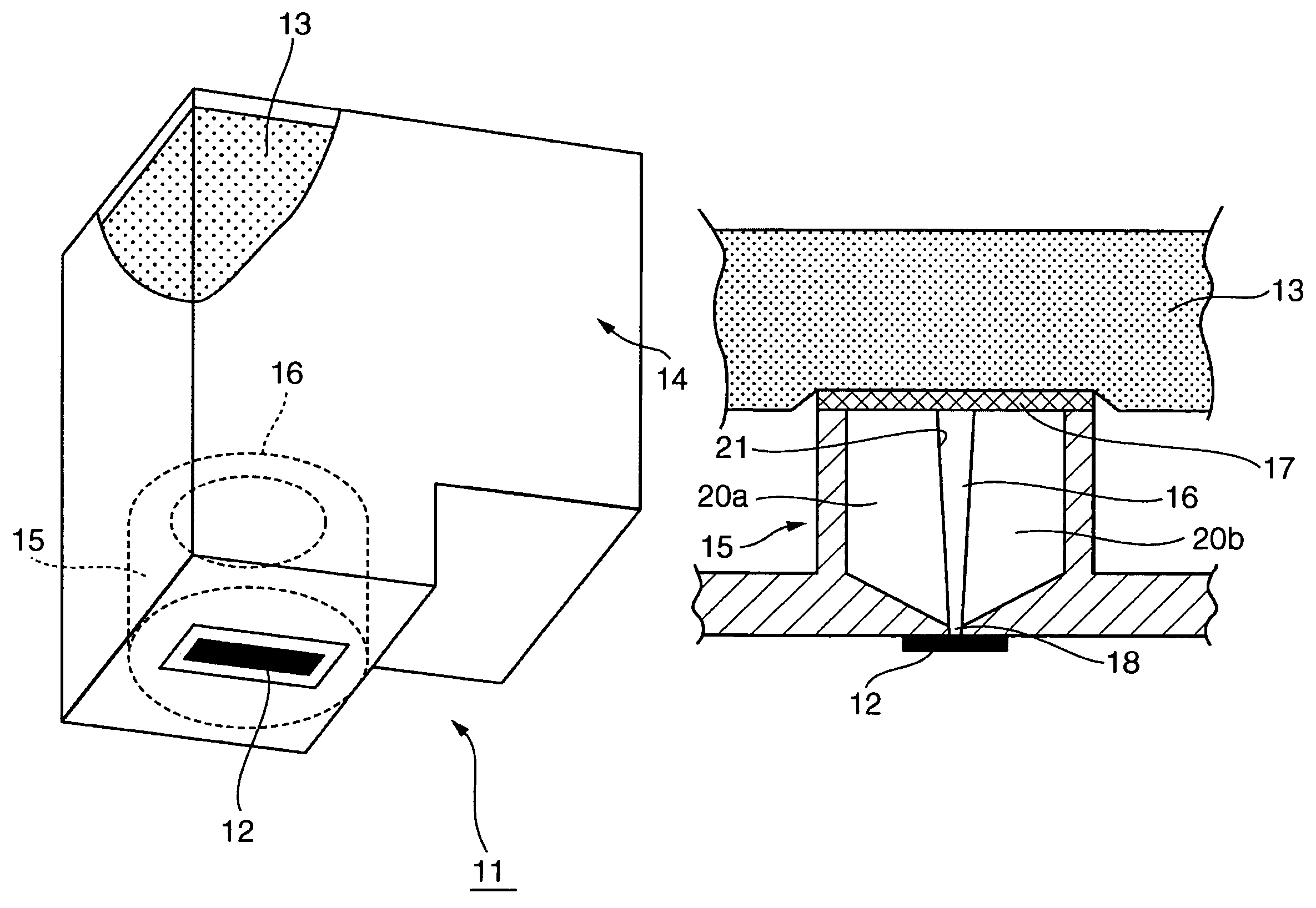

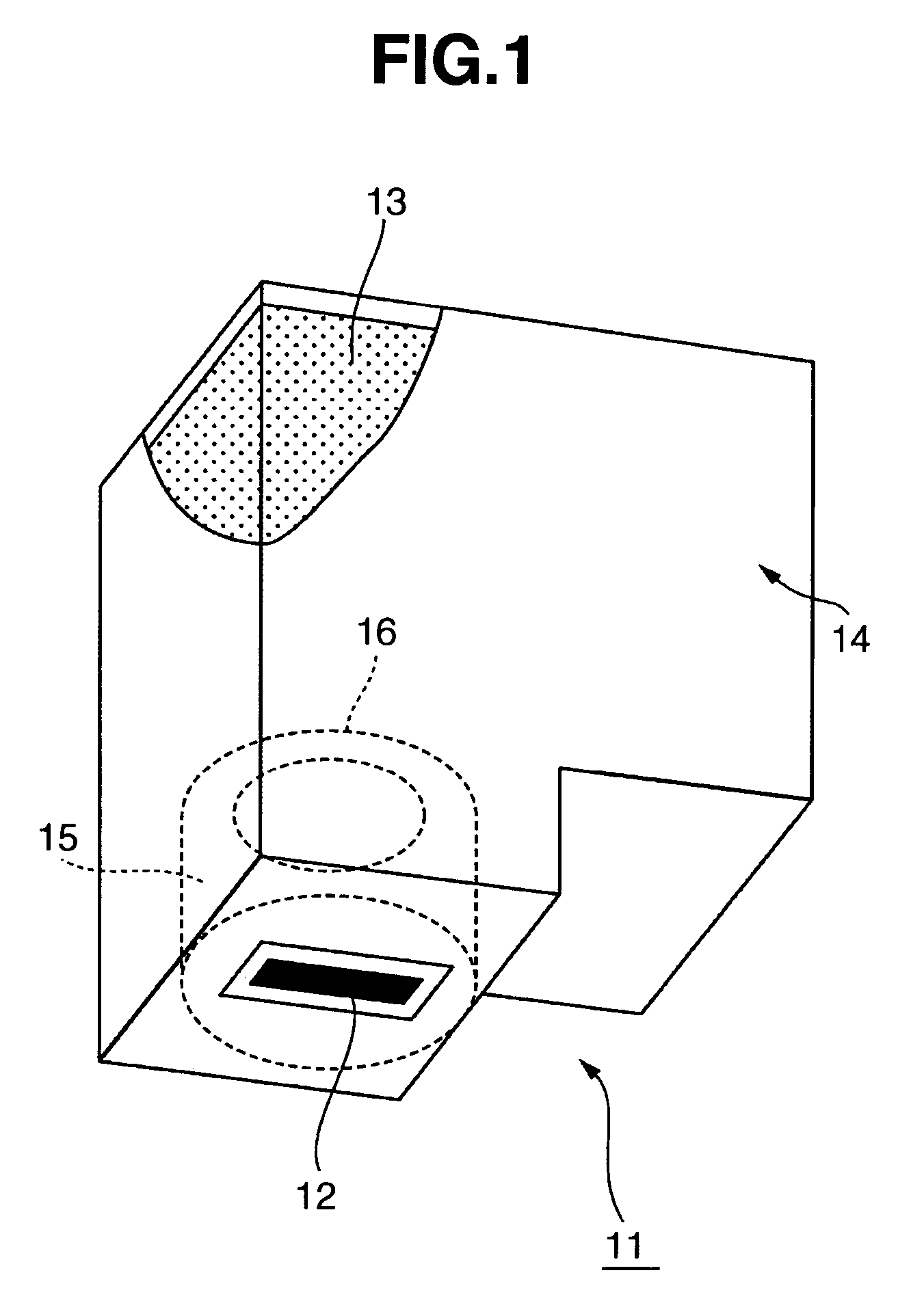

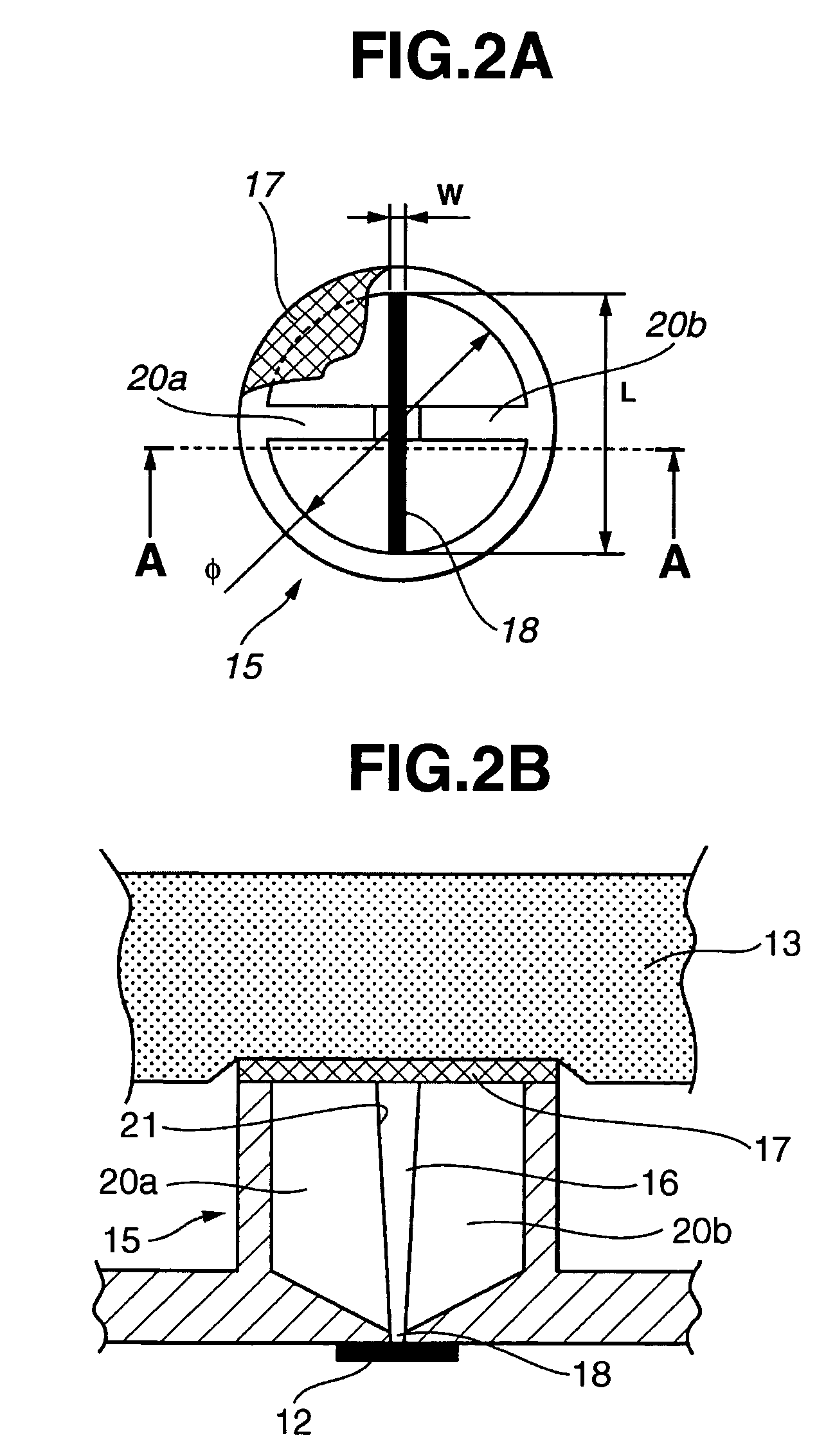

Three-dimensional display device

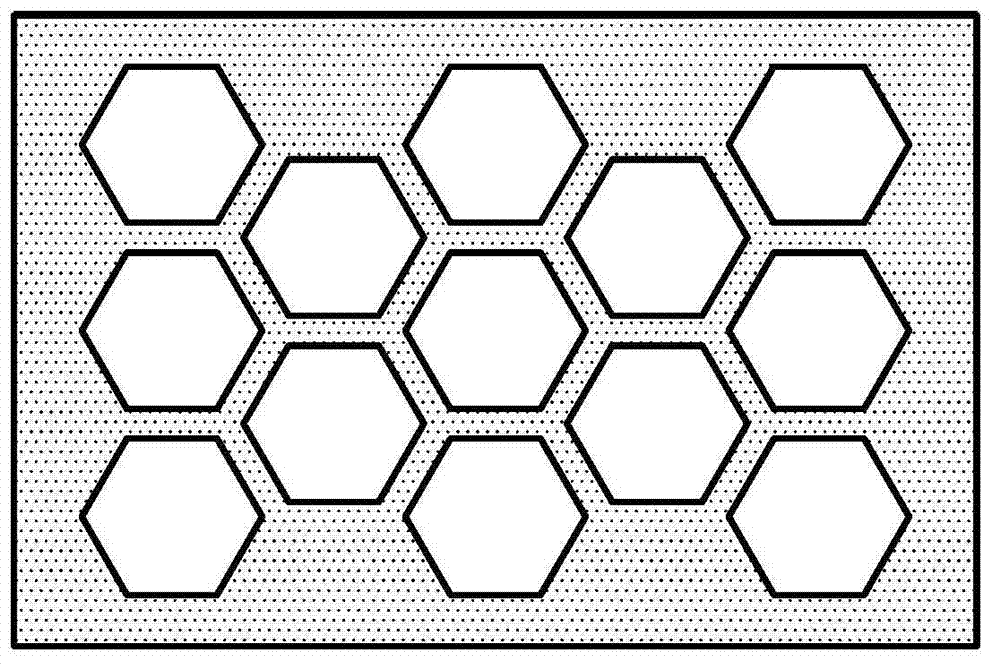

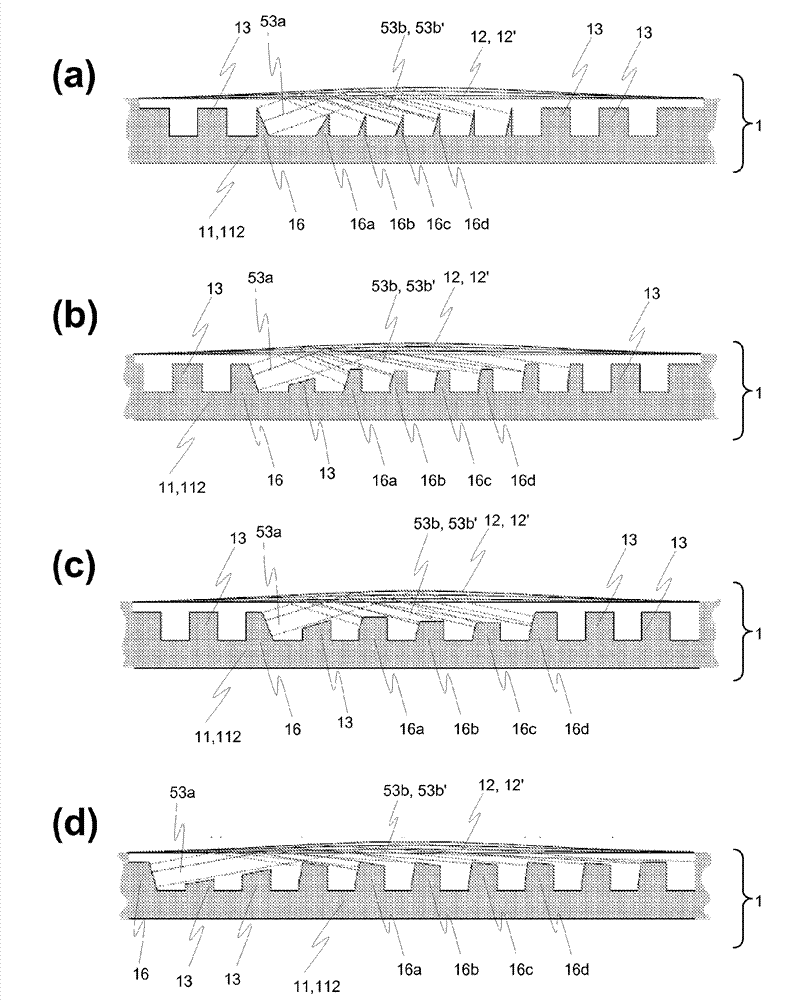

InactiveCN102967932AEnhance homing abilityStrong capillary forceSteroscopic systemsOptical elementsElectricity3d image

A 3D image display device with high resolution is disclosed. The device may deflect left and right eye images to a left and right eye of a viewer, respectively. As such, the viewer may see 3D images. The 3D image display device includes a plurality of electrically switchable light modulating cells containing two incompatible light modulating mediums. When a voltage is applied to electrodes of the electrically switchable light modulating cell, the interface between the incompatible light modulating mediums non-horizontally deforms corresponding to the electrowetting or electrostatic concept. The geometrical shape, size, and material of partition walls in the electrically switchable light modulating cells may reduce or eliminate misplacement of incompatible light modulating mediums while voltages are applied thereto. In addition, the method of manufacturing the 3D image display device is also disclosed.

Owner:DELTA ELECTRONICS INC

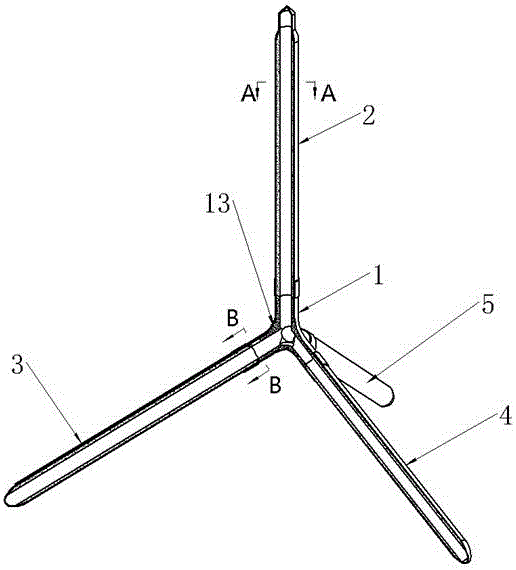

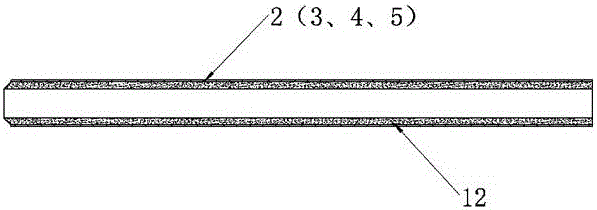

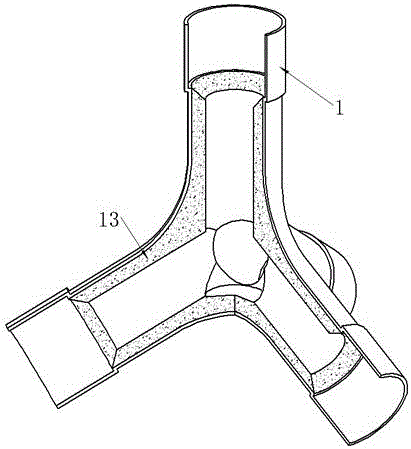

Splitting type spatial multi-branch distribution heat pipe and preparation method thereof

ActiveCN106482562AMeet the needs of common heat dissipationImprove heat transfer performanceIndirect heat exchangersHeat exchanger casingsEngineeringSpace requirements

The invention discloses a splitting type spatial multi-branch distribution heat pipe and a preparation method thereof. The splitting type spatial multi-branch distribution heat pipe comprises a spatial multi-channel pipe joint (1), a first branch pipe housing (2), a second branch pipe housing (3), a third branch pipe housing (4) and a fourth branch pipe housing (5). According to the splitting type spatial multi-branch distribution heat pipe, a spatial connecting type sintering multi-pore capillary layer is arranged inside, so that the heat transfer performance is outstanding; meanwhile, the angle of each port of the spatial multi-channel joint can be selected in advance, so as to flexibly change the bifurcation shape of the spatial multi-branch pipe to meet different heat dissipating space requirements, and a flexible, reliable and stable heat dissipating environment is provided to the miniaturized multi-chip integral development of electronic equipment; branches and joints are separately manufactured and then split during the preparation process, so that the manufacturing is simple, the cost is low, and the industrial production demand is met.

Owner:SOUTH CHINA UNIV OF TECH

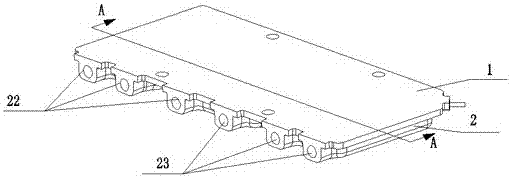

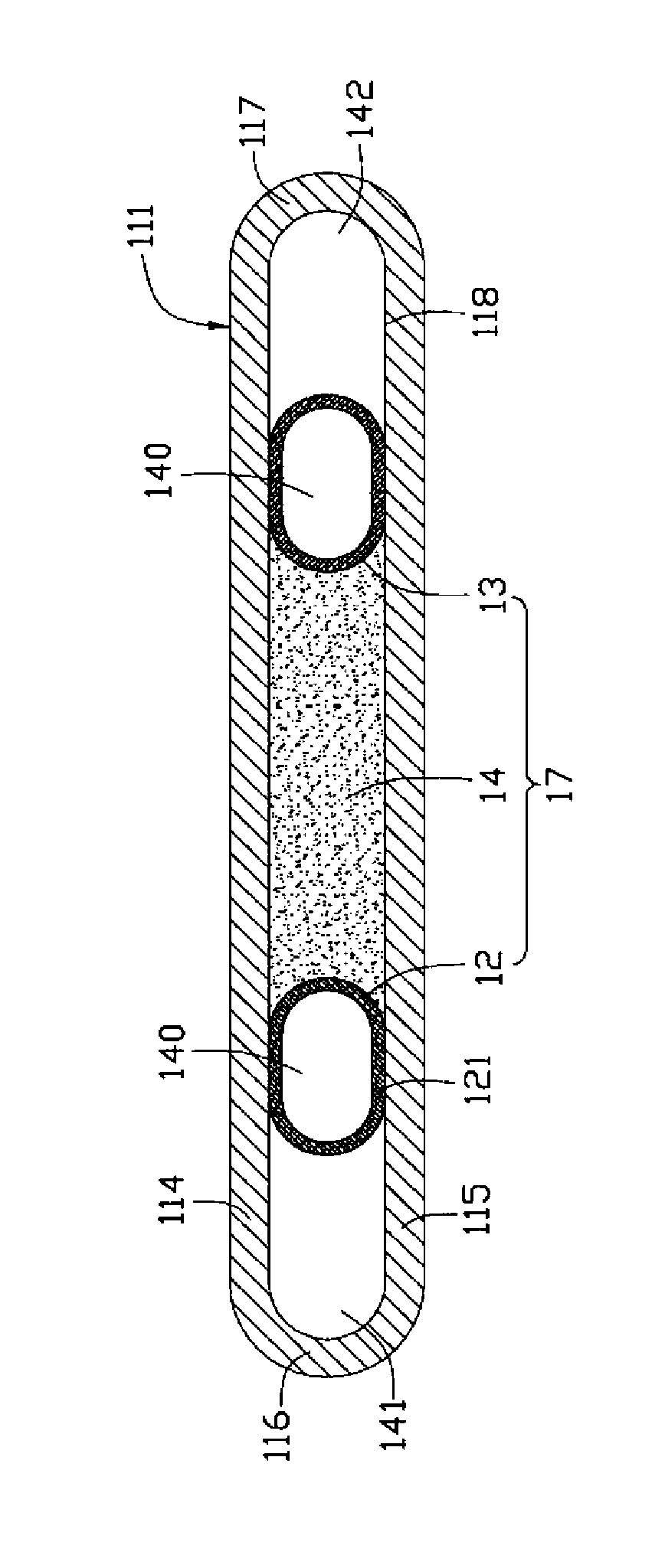

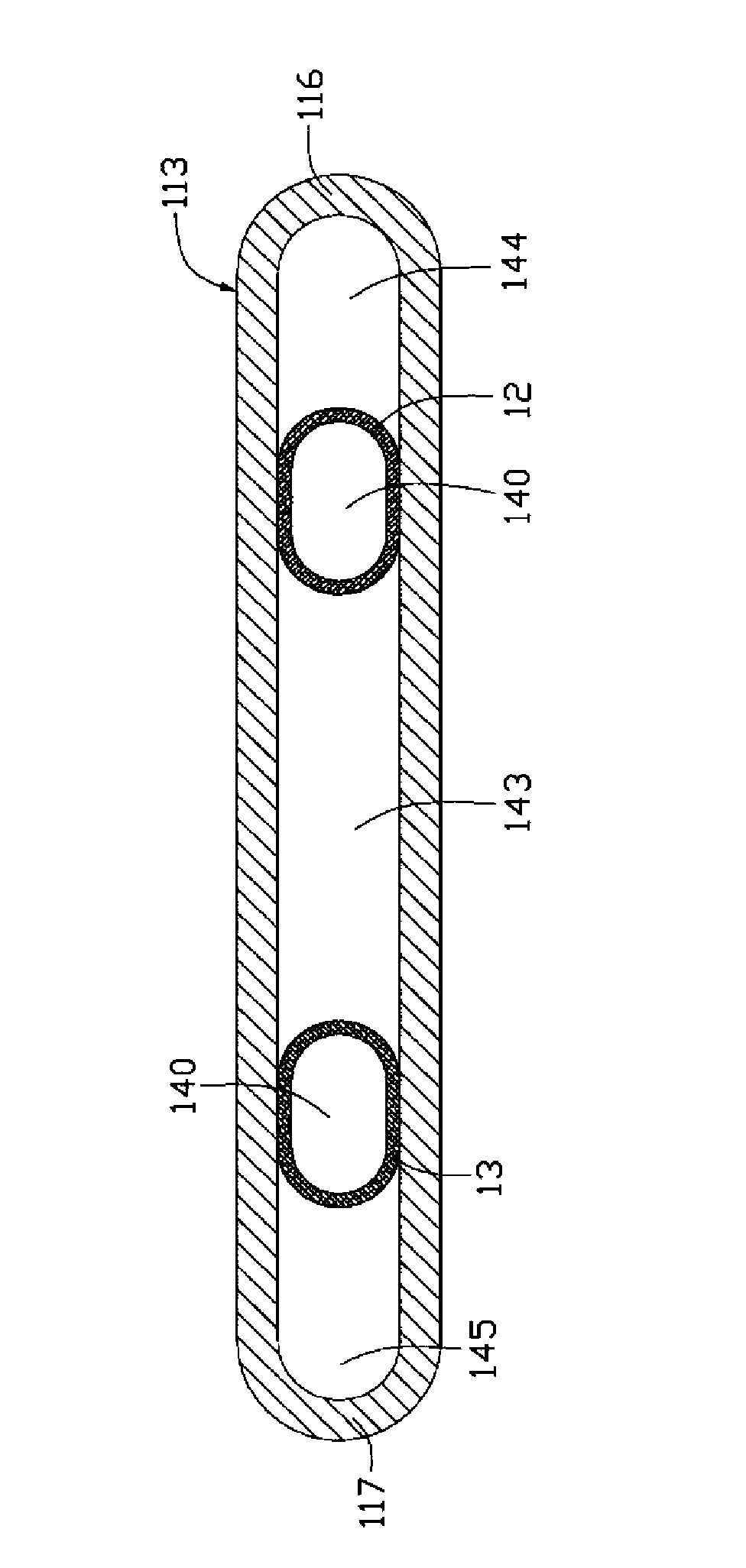

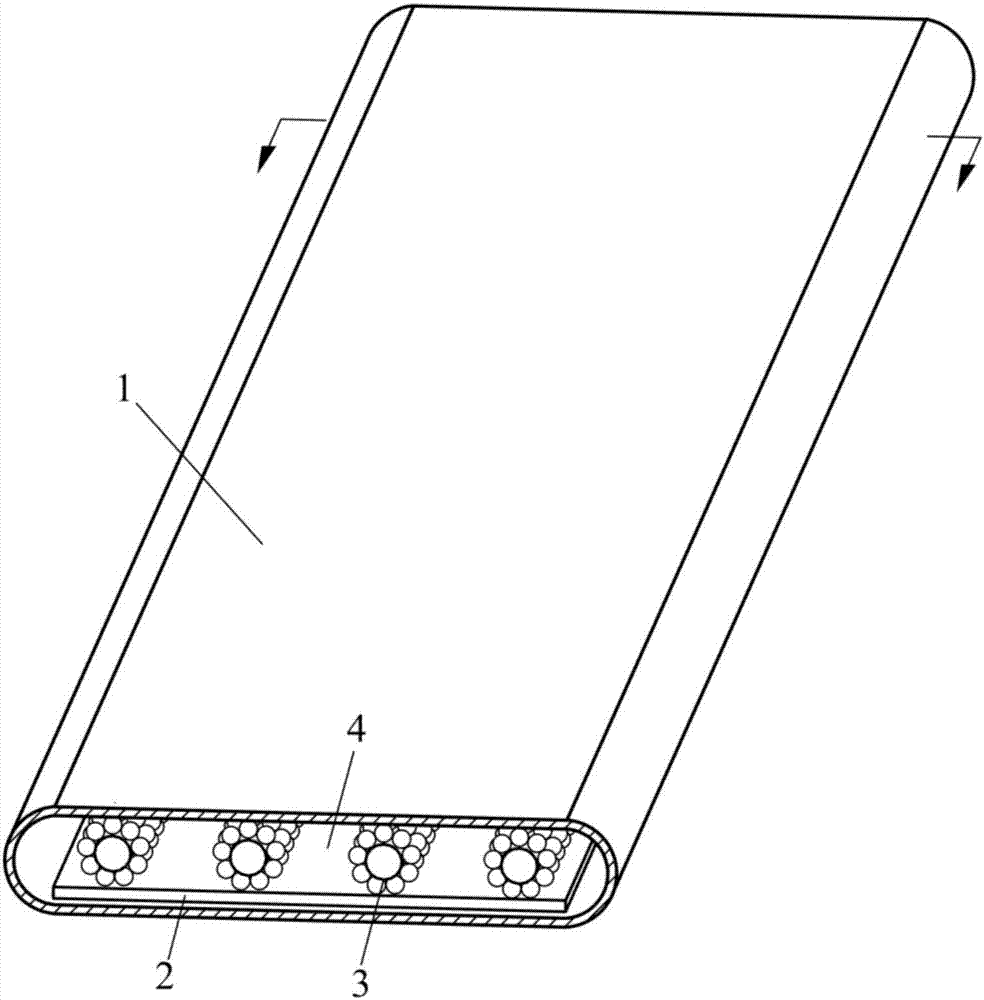

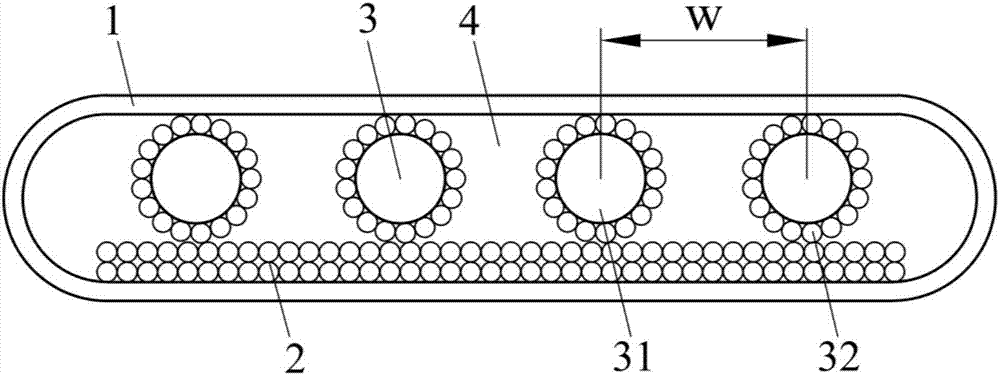

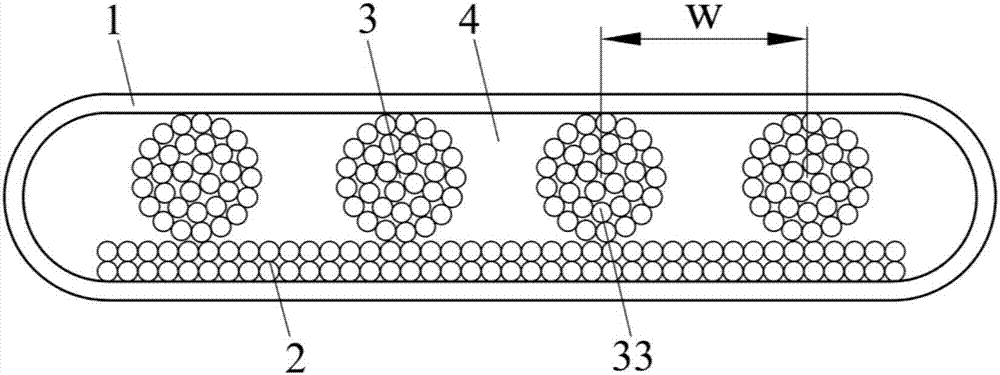

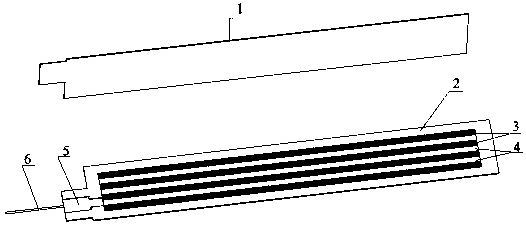

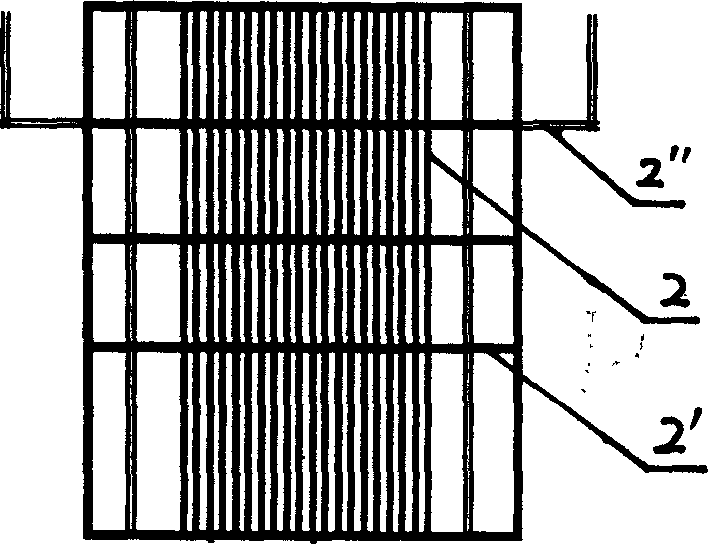

Ultra-thin flat panel heat pipe and manufacturing method thereof

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

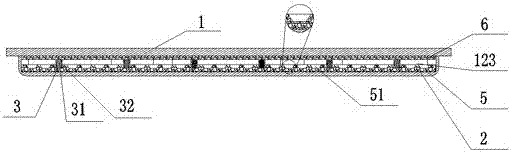

Ultra-thin flat heat pipe and manufacturing process thereof

ActiveCN109443060AIncrease heat transfer limitPrevent collapseIndirect heat exchangersMiniaturizationProcess engineering

The invention relates to the technical field of heat dissipating devices, in particular to an ultra-thin flat heat pipe and a manufacturing process thereof. A bottom plate and a cover plate which arebuckled and packaged are included, the bottom plate is provided with a cavity internally provided with a plurality of capillary structures arranged in parallel, gas flow channels for a heat pipe working medium to flow therein is formed between the adjacent capillary structures, and each capillary structure includes a plurality of liquid flow channels arranged in parallel. A gas working medium flows in the gas flow channels, and a liquid working medium flows in the capillary structures, so that gas-liquid separation of the working media is achieved, the flow resistance is reduced, and the heattransfer limit of the heat pipe is increased; and the ultra-thin flat heat pipe is simple in structure and easy to manufacture, can realize industrial production line production, has strong heat transfer capacity, is small in thickness of heat pipe, can meet the requirement for heat dissipation of electronic devices in a narrow space, meets the needs of integration and miniaturization of electronic components, and has good practicability and applicability .

Owner:GUANGDONG UNIV OF TECH

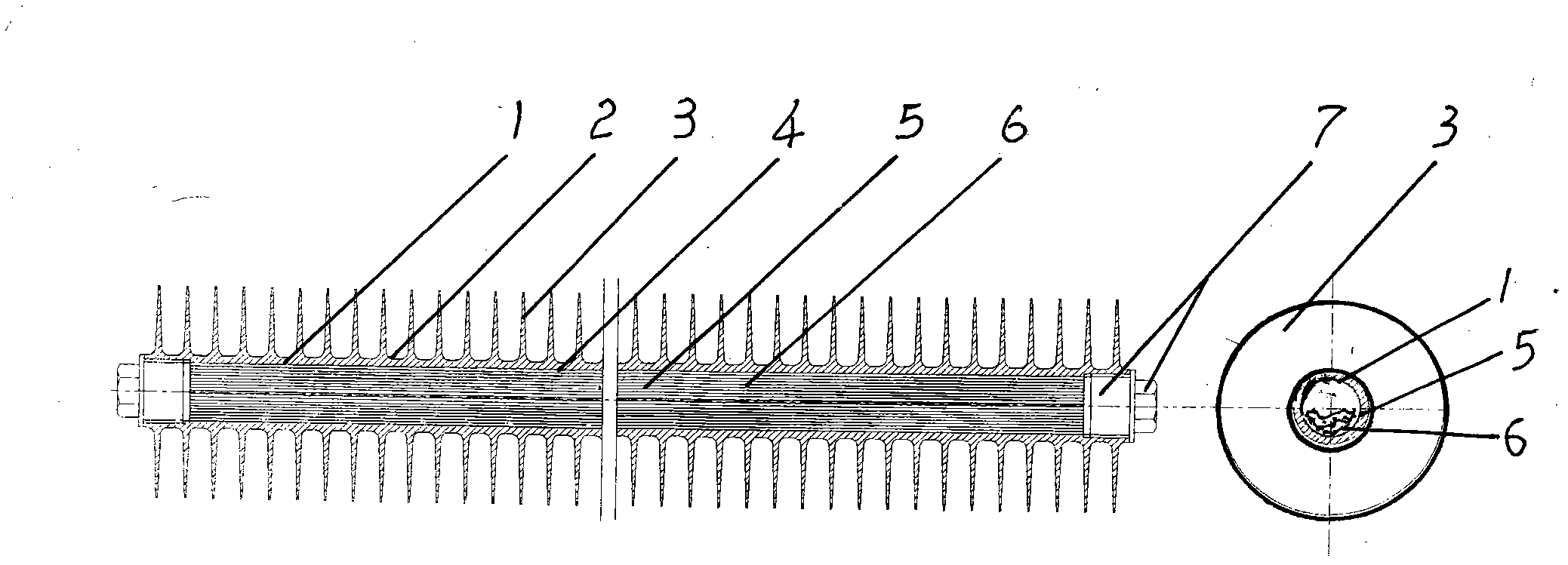

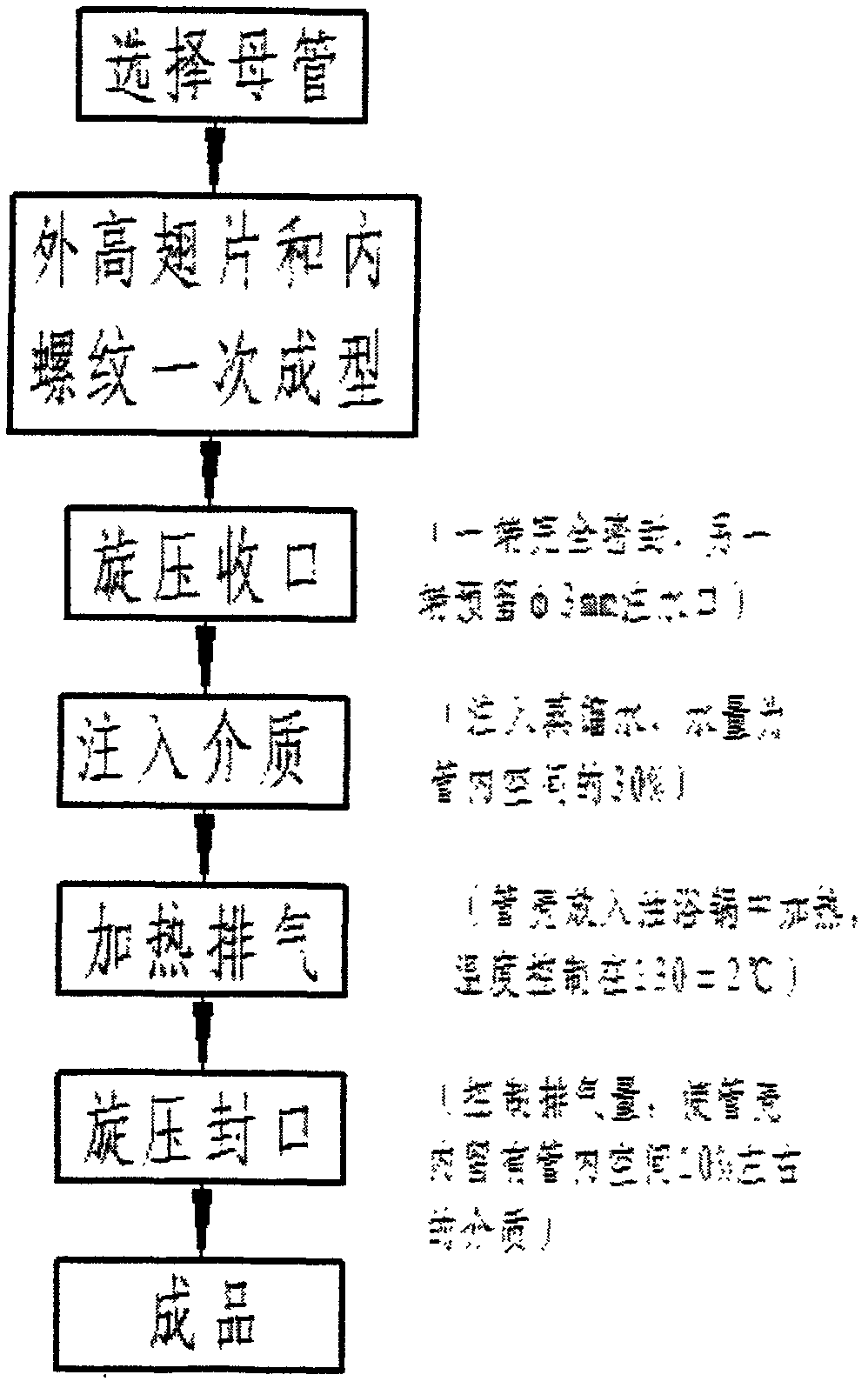

Copper heat tube with high-tooth fins and production technology of copper heat tube

InactiveCN102581583AImprove heat exchange efficiencyStrong capillary forceIndirect heat exchangersDistilled waterElectric power

The invention discloses a copper heat tube with high-tooth fins and production technology of the copper heat tube. The copper heat tube comprises a copper and copper alloy seamless tube, the high-tooth fins which are spirally wound around a tube body are arranged on the periphery of the seamless base tube and are structurally integrated with the seamless base tube, a plurality of regular grooves which are parallel to the tube are arranged on the inner wall of each high-tooth fin, two ends of the copper tube are sealed by nuts, the inside of the copper tube is vacuum, and a certain quantity of liquid (distilled water) is filled into the tube. The technological process includes selecting the base tube; simultaneously molding the high-tooth fins and internal threads; vacuumizing and filling the liquid into the tube; sealing the copper tube by the nuts; and obtaining a finished product. The copper heat tube and the production process are applicable to the fields of electric power, energy resources, chemical engineering, transportation and the like.

Owner:浙江宏天铜业有限公司

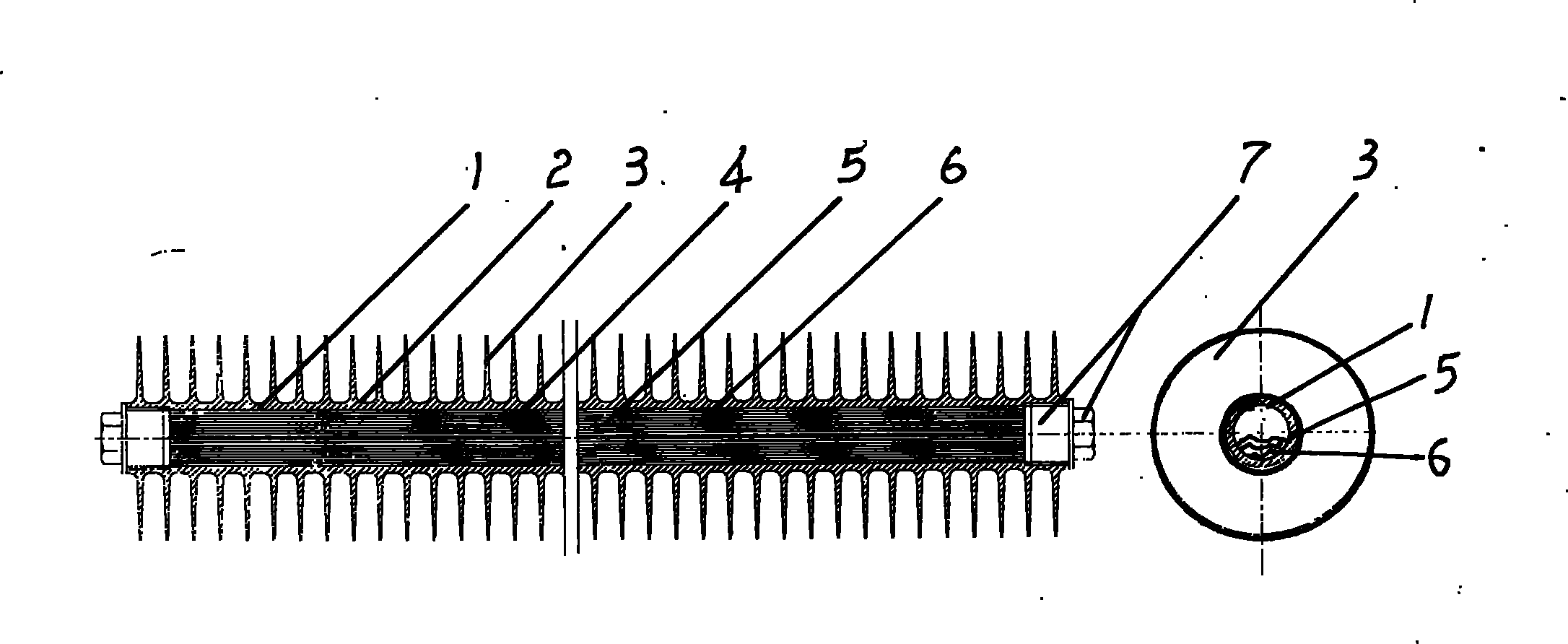

Production technology of high-tooth fin copper heat tube

InactiveCN103157965AImprove heat exchange efficiencyStrong capillary forceChemical industryLiquid medium

The invention discloses a production technology of a high-tooth fin copper heat tube. A product produced by the production technology is composed of copper and copper alloy seamless tubes. High-tooth fins are arranged on the periphery of a main seamless tube, and the high-tooth fins and the main seamless tube are formed in an integral mode. A plurality of regular grooves parallel to a high-tooth fin tube are formed in the inner wall of the high-tooth fin tube. Two ends of the high-tooth fin tube are sealed in a spinning mode. The high negative pressure state is maintained in the high-tooth fin tube. A certain amount of liquid media (distilled water) is poured into the high-tooth fin tube. The technological process of the production technology of the high-tooth fin copper heat tube includes choosing the main seamless tube, one-time forming of the high-tooth fins and the inner wall grooves, sealing the two ends in a spinning mode, pouring the media, heating up and exhausting air, sealing openings in a spinning mode and finishing a product. The production technology of the high-tooth fin copper heat tube is suitable for the field of electric power, energy sources, chemical industry, communication and transportation and the like.

Owner:浙江宏天铜业有限公司

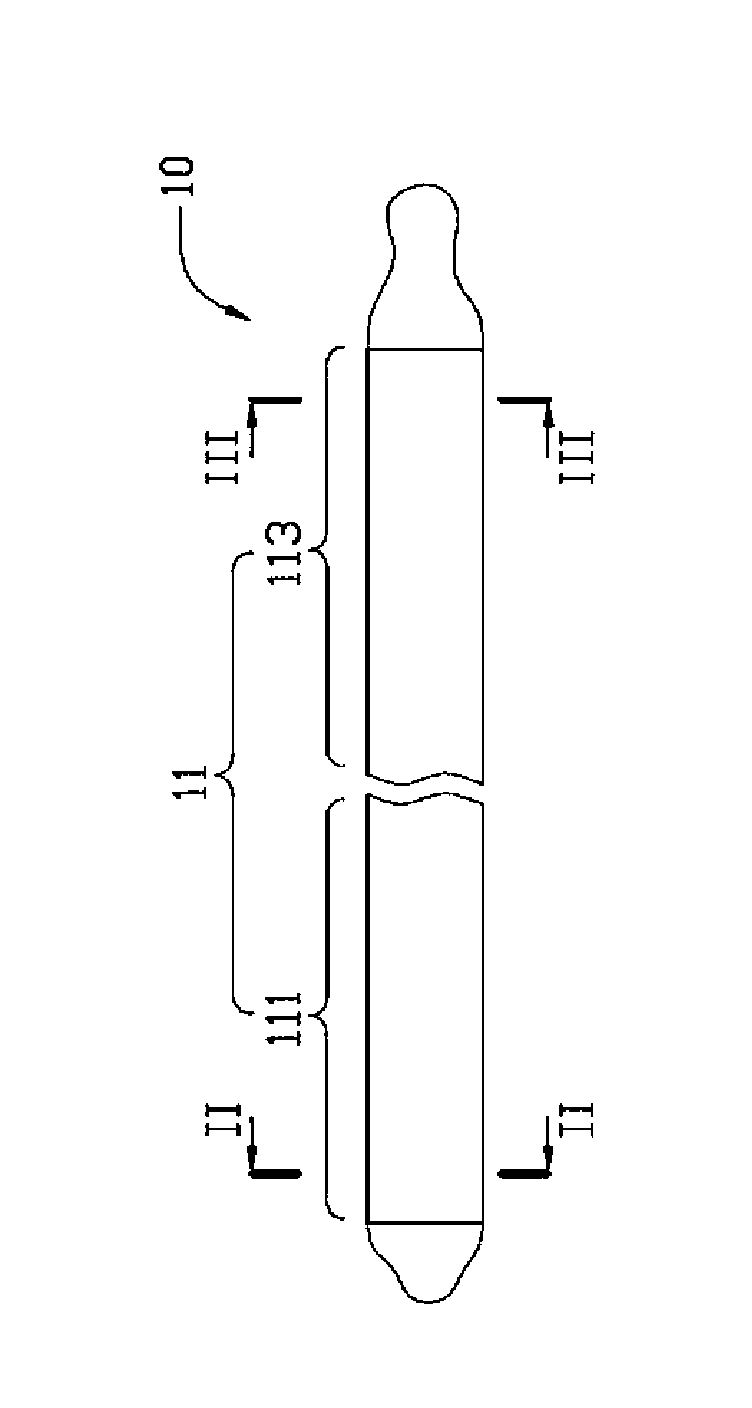

Ultrathin heat pipe and manufacturing method thereof

PendingCN107289802ACompact structureStrong capillary forceIndirect heat exchangersMetal powderHeat pipe

The invention discloses an ultrathin heat pipe. The ultrathin heat pipe comprises a metal pipe body, a liquid sucking core and a working medium; the wall thickness of the metal pipe body is 0.03-0.10 mm; the tail part and the head part of the metal pipe body are both sealing ends; the metal pipe body is a flat metal pipe body with a closed inner cavity; the liquid sucking core is arranged in the closed inner cavity of the metal pipe body; the liquid sucking core is a metal powder sintering capillary layer formed by bonding metal powder on the inner wall of the metal pipe body after high-temperature sintering; and the closed inner cavity of the metal pipe body is filled with the working medium. The invention further discloses a manufacturing method of the ultrathin heat pipe. The ultrathin heat pipe has the characteristics of smooth gas-liquid channel separation, good heat transfer performance, high capillary force and low backflow resistance of the working medium. The manufacturing method has the characteristics of convenience in operation of process steps, high production efficiency and adaption to large-batch production, and can effectively prevent drapes and recesses formed in the manufacturing process of the ultrathin heat pipe.

Owner:杭州瀚亨实业有限公司

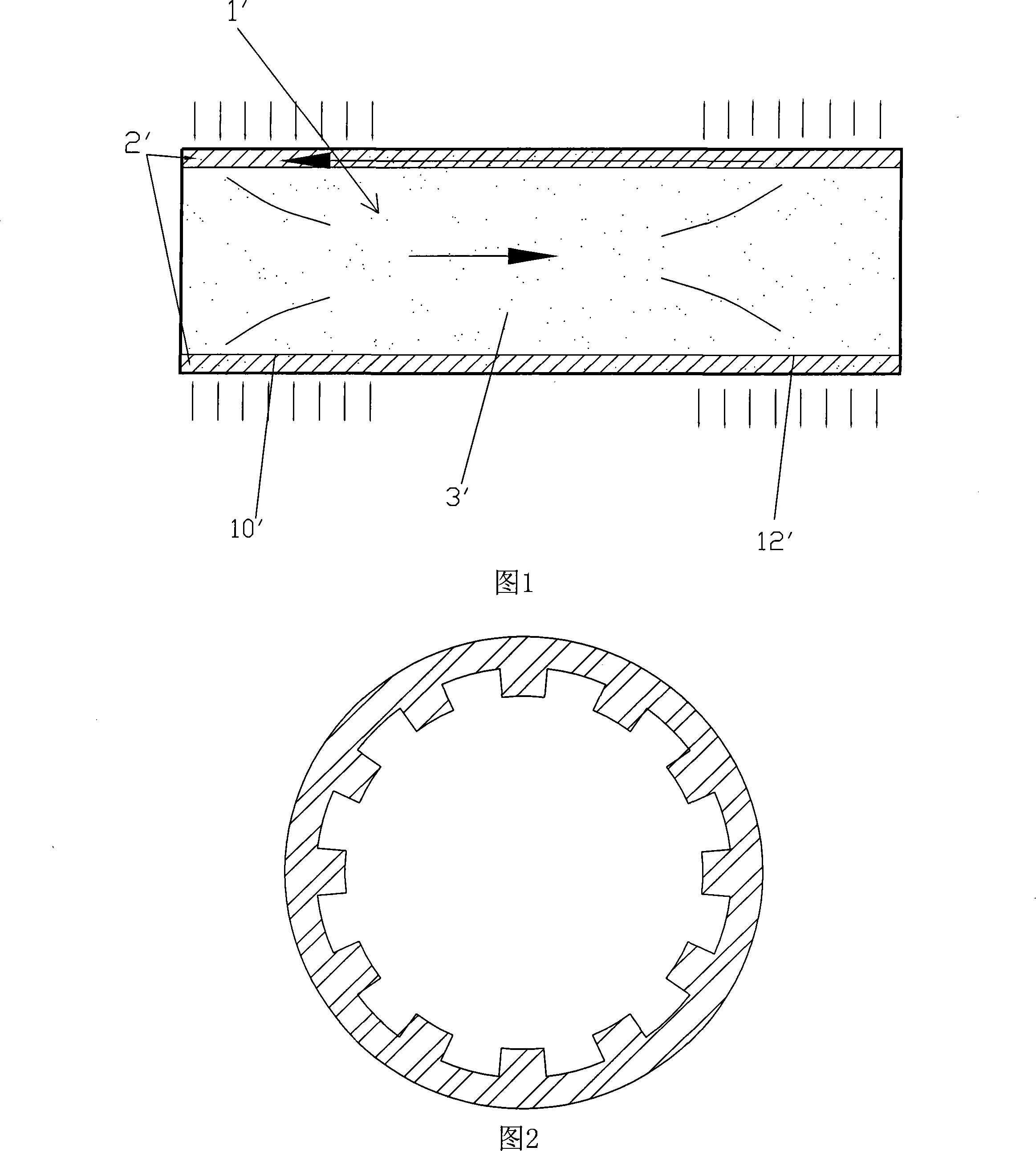

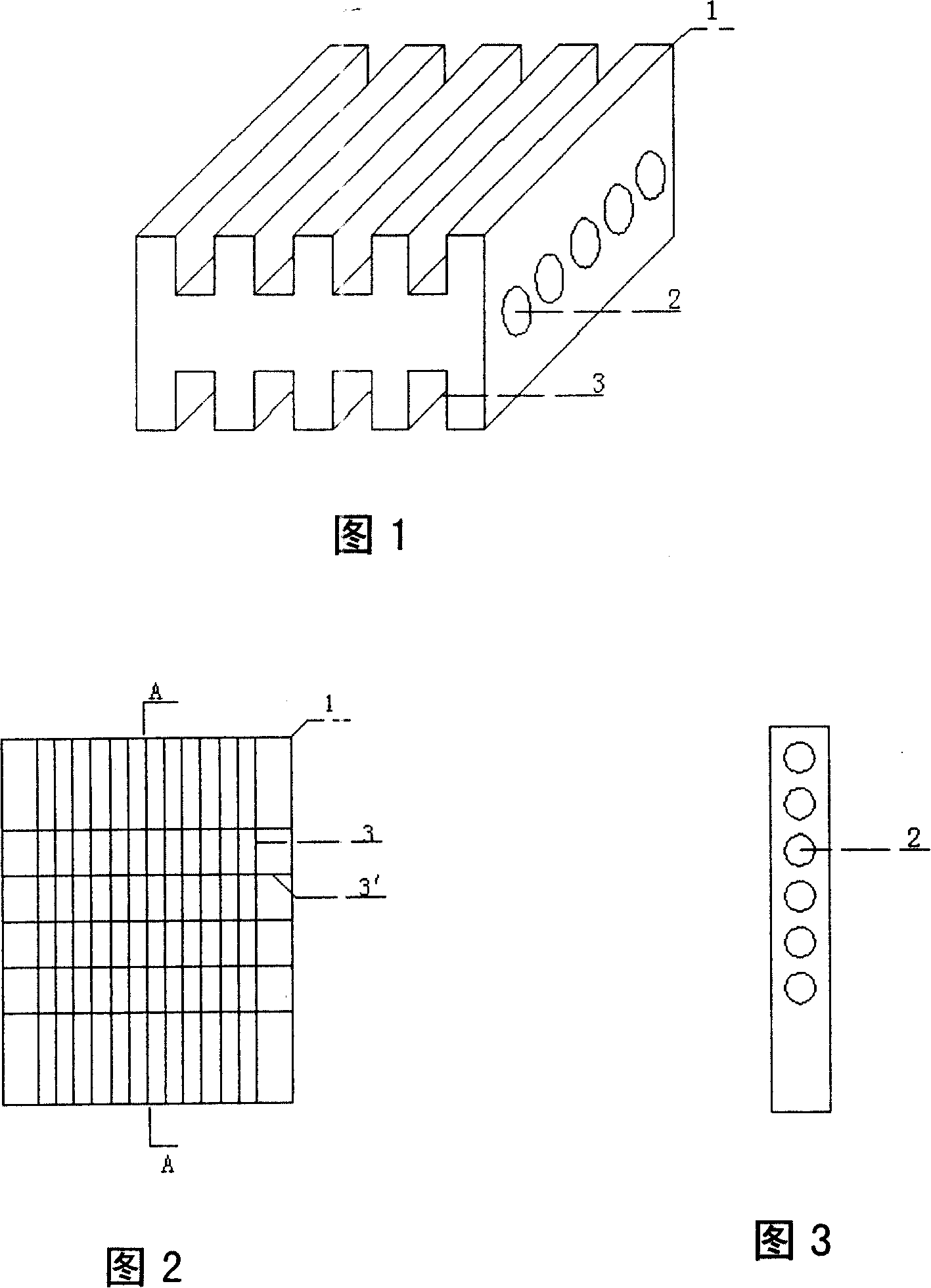

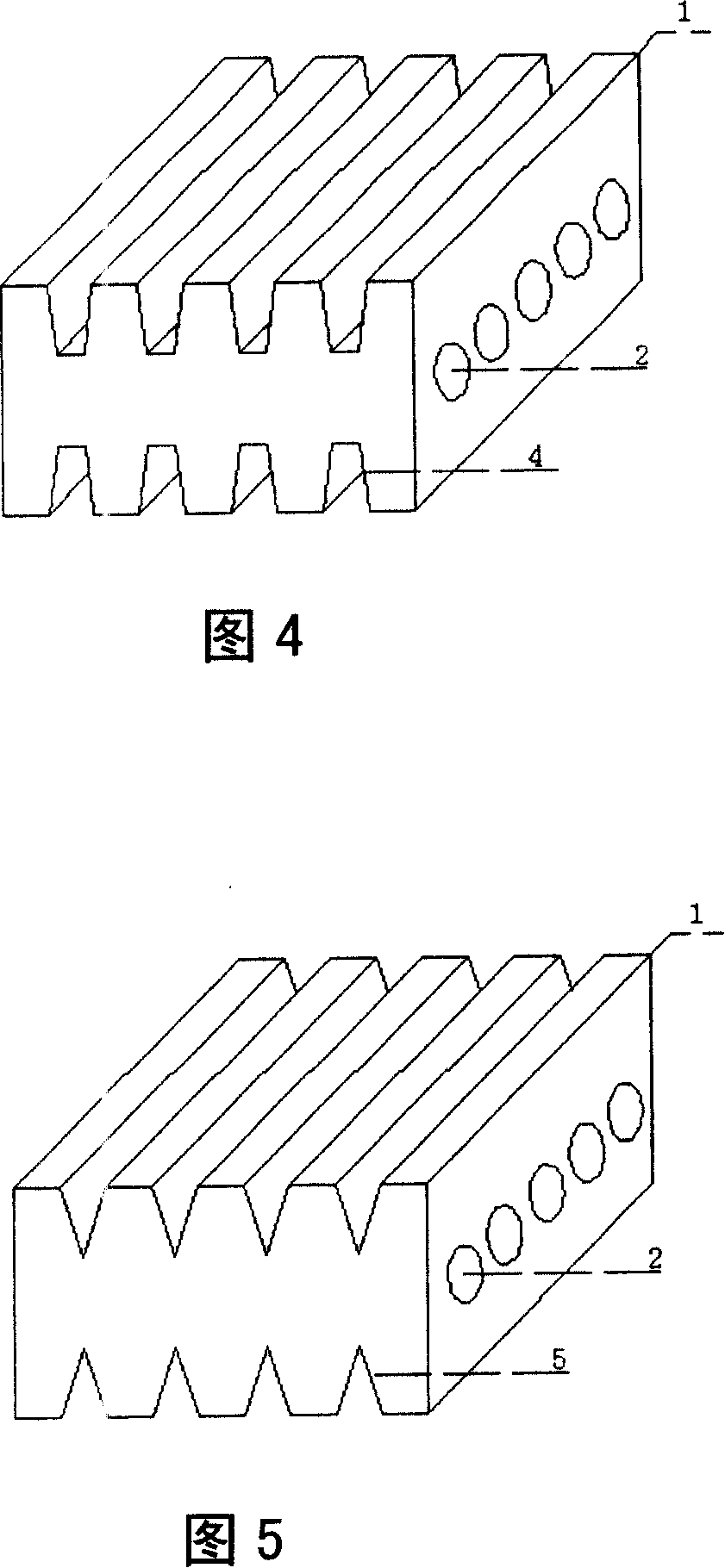

Microflute evaporating and cooling method and apparatus using same

InactiveCN1482523AReduce and control operating temperatureHigh strengthEnergy efficient ICTDigital data processing detailsHeat flowEvaporation

A microflute group heat-sink cooling method characterized by that, a plurality of microflutes are arranged at the radiating region near the external surface of the heater forming a microflute group, the liquid actuating medium in the microflutes can form high-intensity evaporation at the heated region for removing heat produced by the heater, thus cooling the heater through evaporation. The advantages of the invention are no power consumption, small heat dissipation area, high heat dissipation flow density and high intensity of heat.

Owner:SINO TECH INVESTMENT HLDG

Micro heat pipe with poligonal cross-section manufactured via extrusion or drawing

InactiveUS20090188110A1Easy to manufactureSimplify the drawing processSemiconductor/solid-state device detailsSolid-state devicesMicro-loop heat pipeMetal

Owner:MOON SEOK HWAN +6

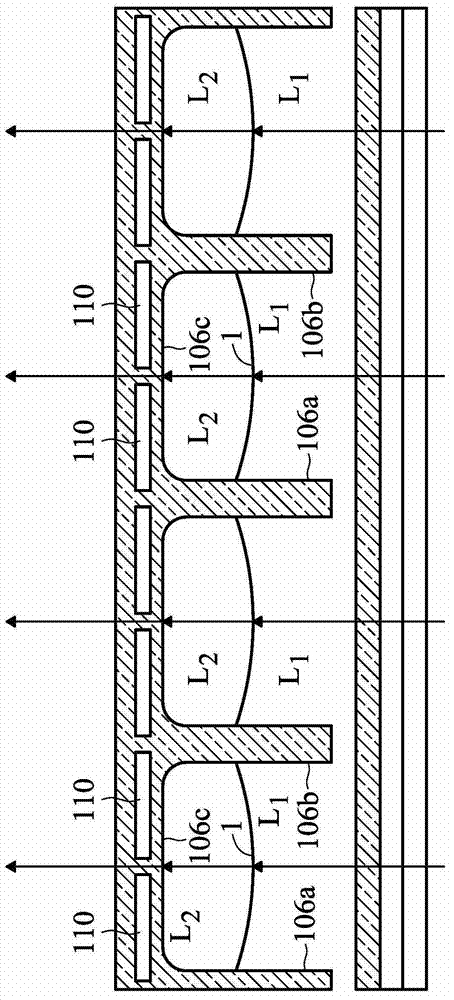

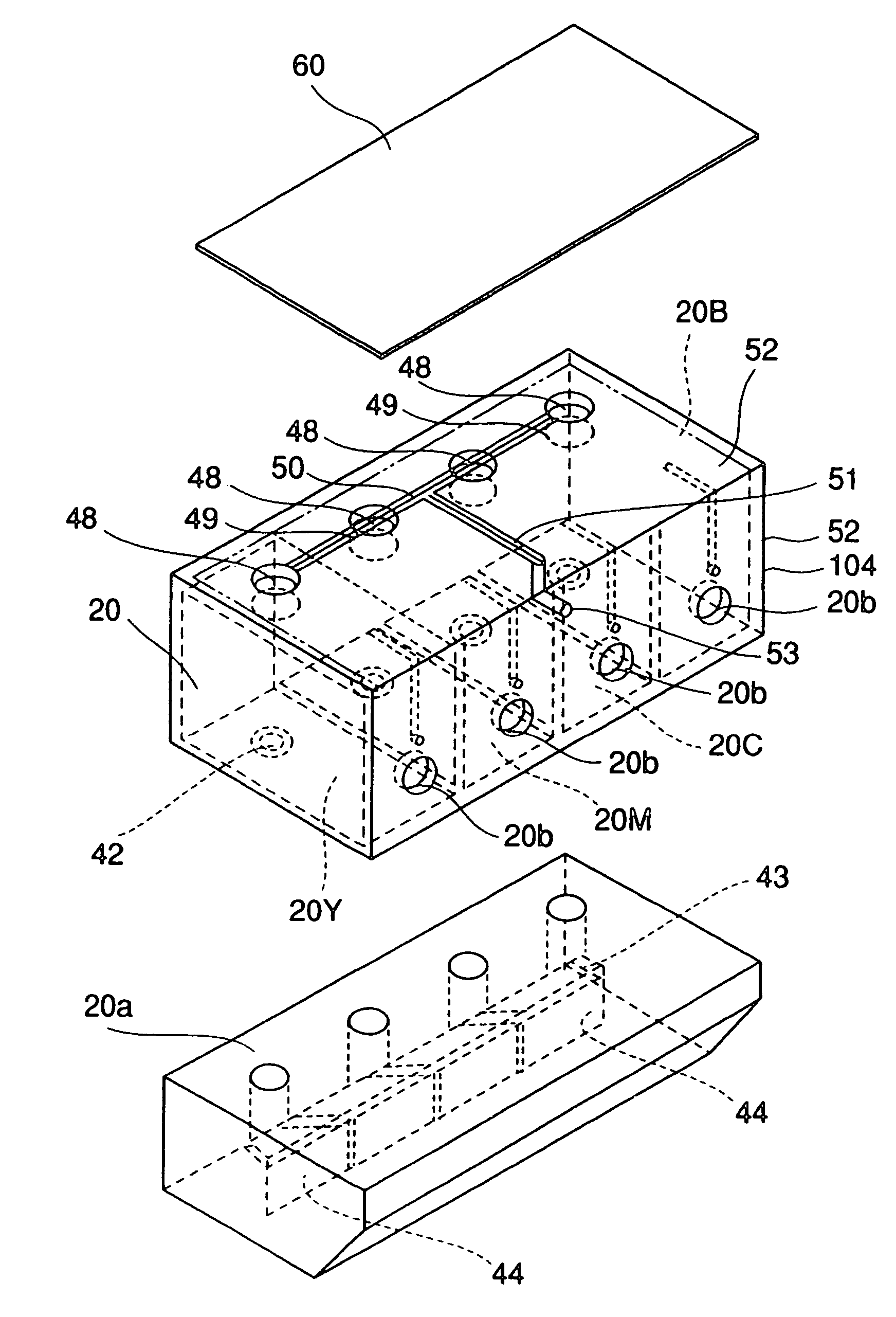

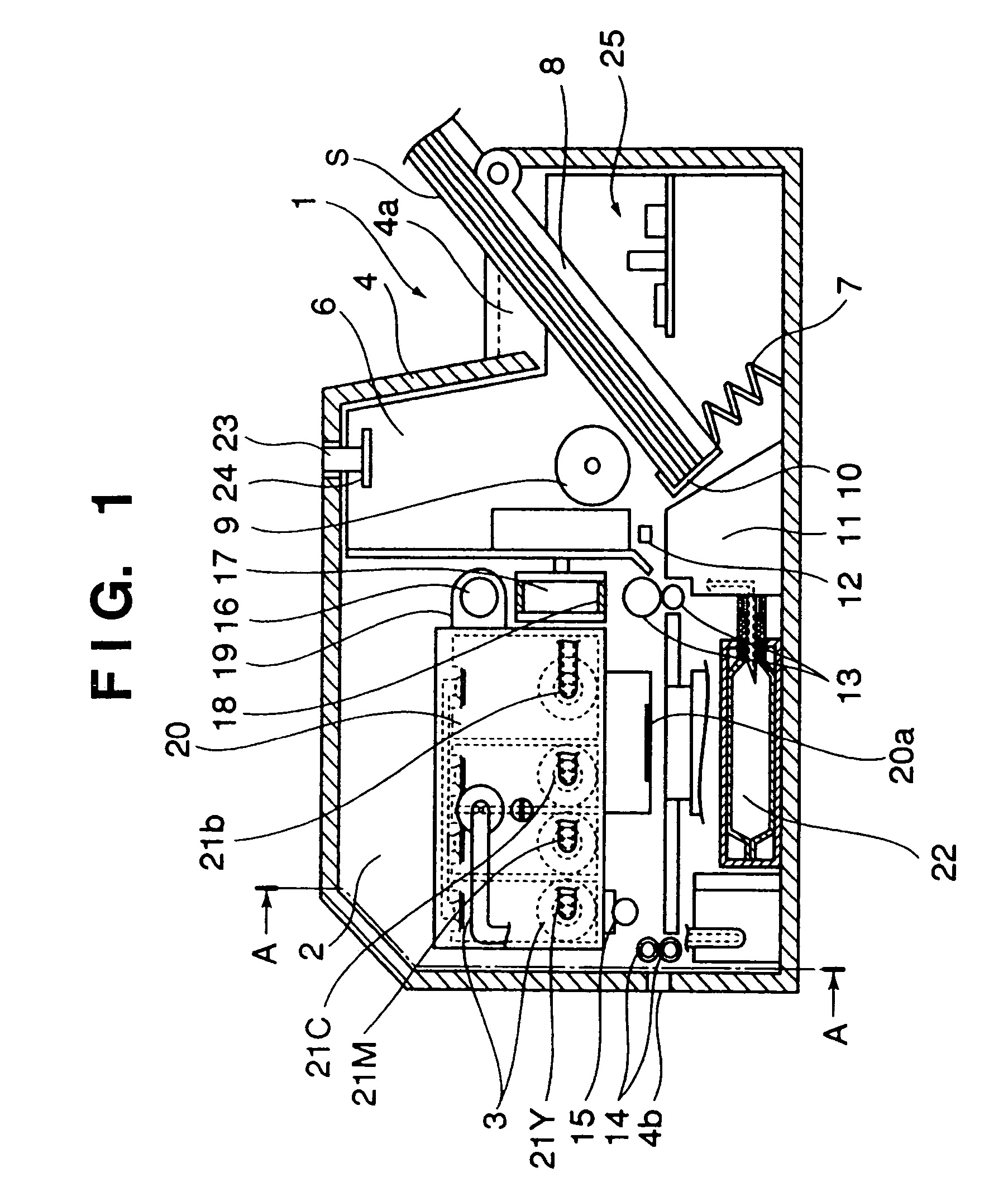

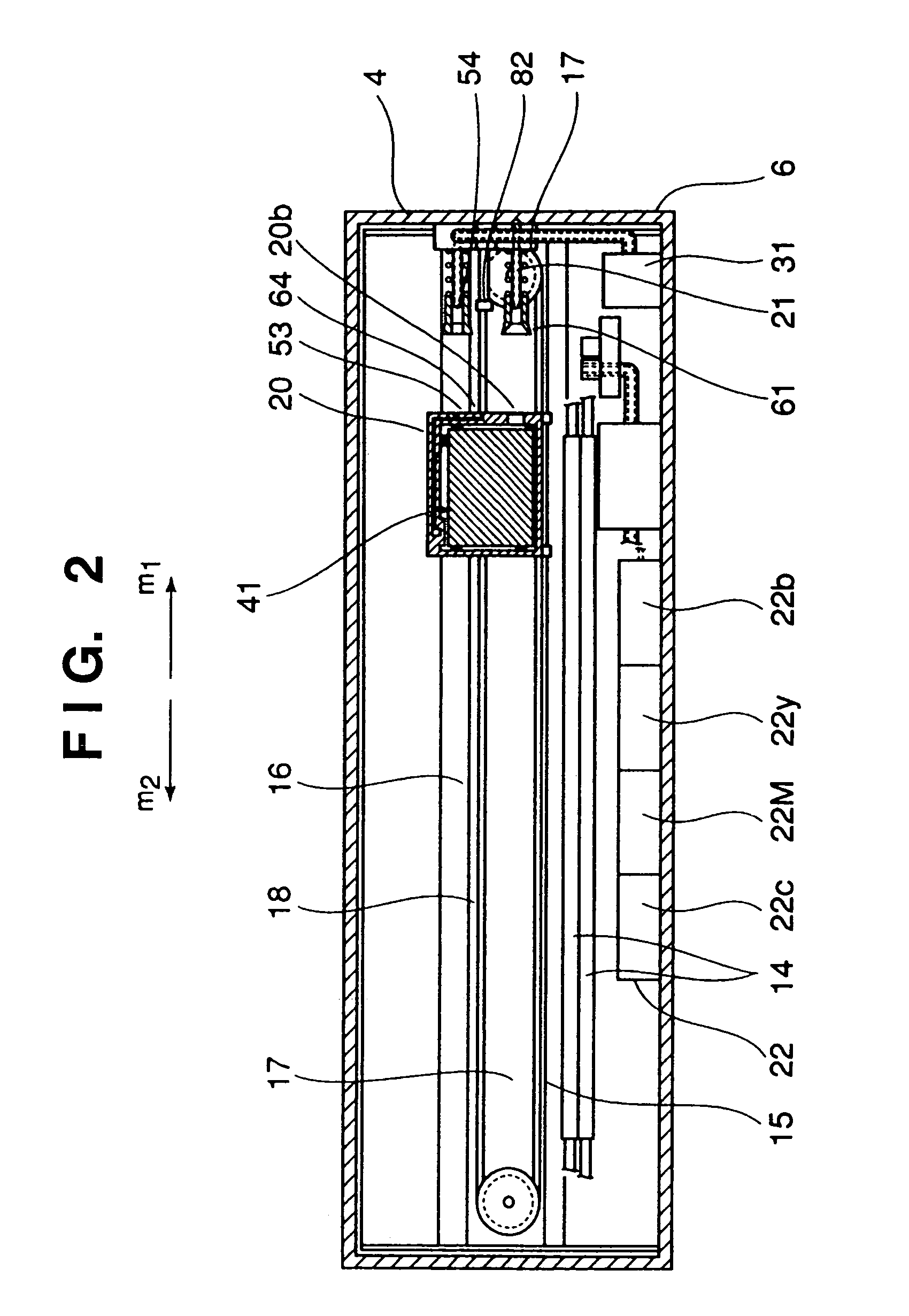

Liquid discharge head cartridge

ActiveUS7055942B2Excellent recording characteristicImprove featuresPrintingEngineeringMechanical engineering

A liquid discharge head cartridge can assuredly supply a liquid discharge head with a liquid even when a bubble is generated within a liquid channel, and maintain excellent recording characteristics even in a configuration in which light recovery or no recovery is adopted. The cartridge includes a slit-shaped opening provided at an ink channel facing an ink-jet recording head, a filter provided at an ink introducing unit so as to contact an ink absorber, and ribs for supporting the filter that extend from an inner wall of the ink introducing unit to a substantially central portion of the filter.

Owner:CANON KK

Liquid reservoir apparatus

Owner:CANON KK

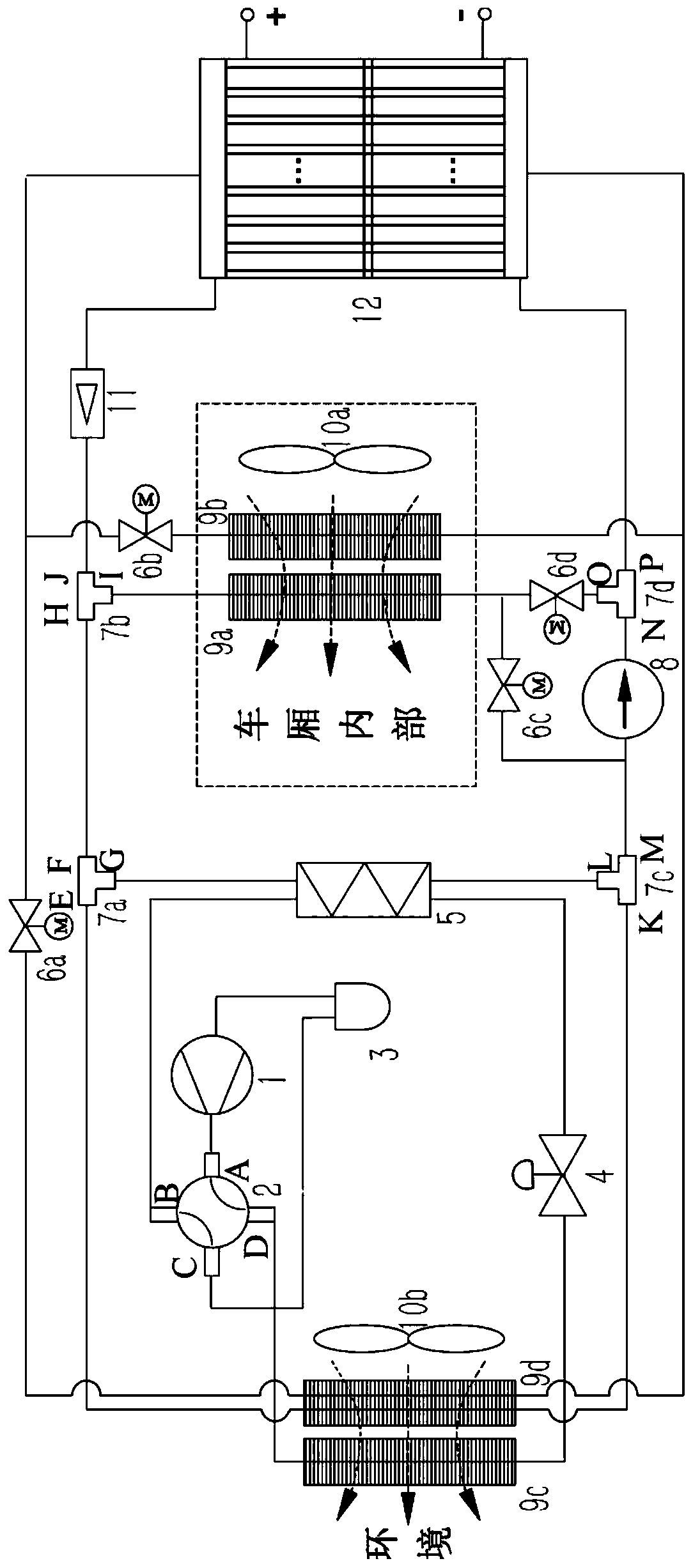

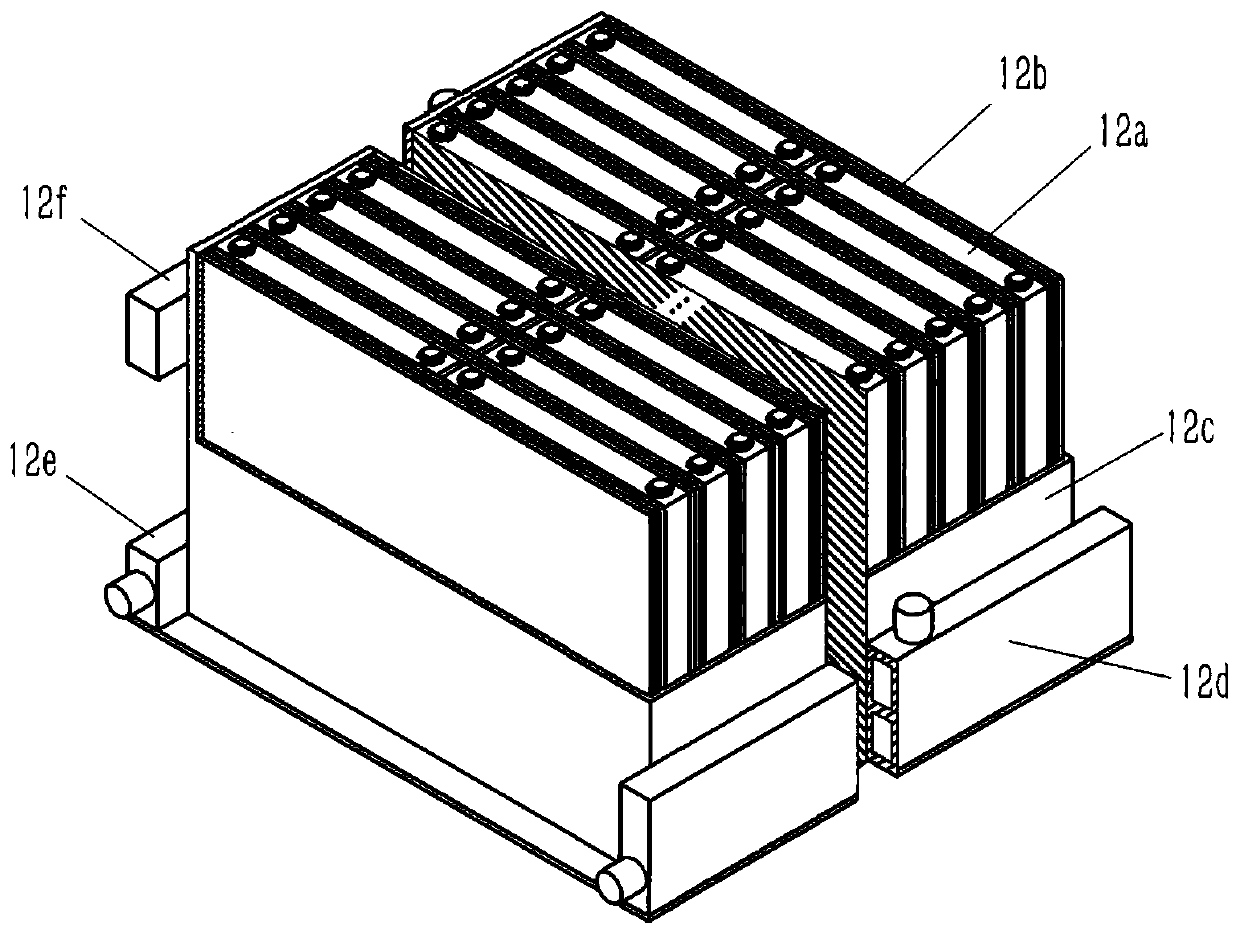

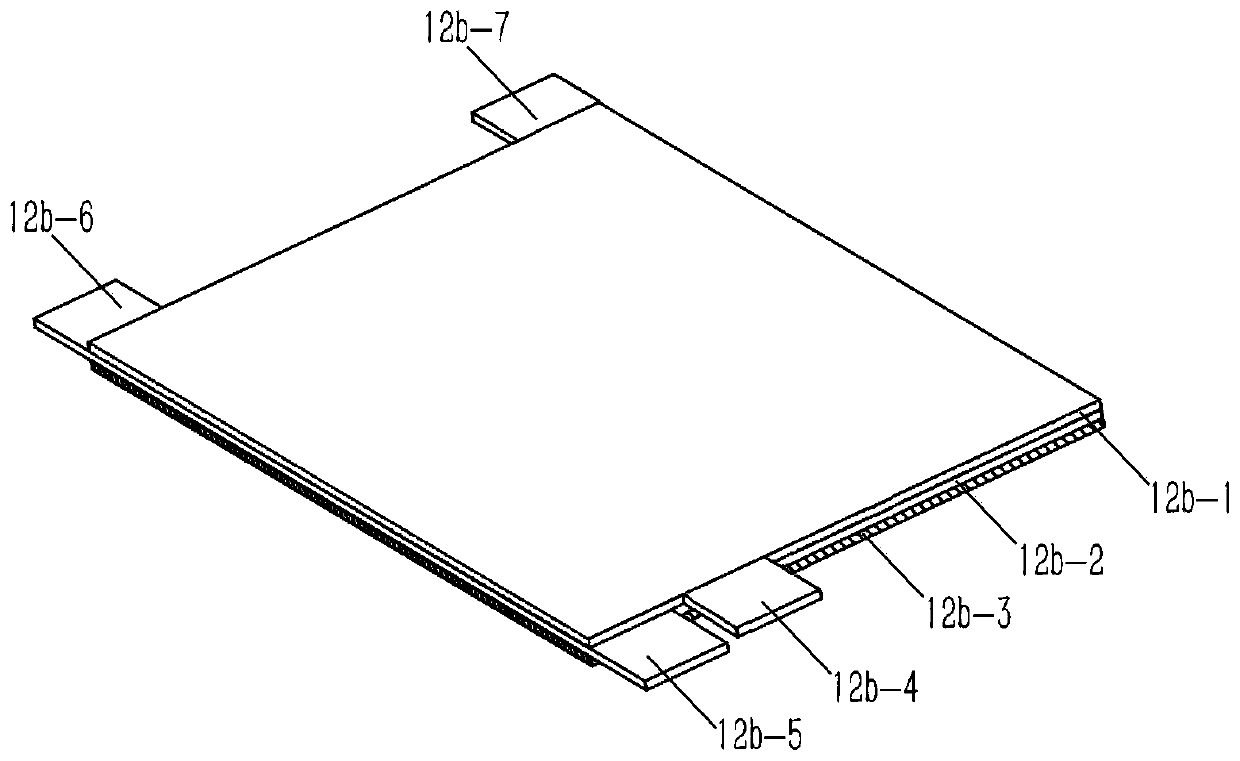

New energy electric vehicle thermal management system with all-weather multi-mode switching function

ActiveCN111391605AMeet comfortMeet temperature control needsAir-treating devicesSecondary cellsElectrical batteryNew energy

The invention discloses a new energy electric vehicle thermal management system with an all-weather multi-mode switching function. The new energy electric vehicle thermal management system comprises arefrigerating / heating system with the all-weather multi-mode switching function and a battery pack. The refrigerating / heating system comprises an air compressor, a four-way reversing valve, a gas-liquid separator, an expansion valve, a heat exchanger, a circulating pump, an electromagnetic valve set, a three-way valve set and a fin heat exchanger set. The battery pack comprises a battery box body, a voltage-sharing and shunting recombiner, a voltage equalizer and a junction station; the battery box body comprises a plurality of single batteries internally, and a heat accumulating type active / passive combined liquid temperature control unit is arranged between every two single batteries. The new energy electric vehicle thermal management system has multiple working modes, switching can beconveniently conducted under different weather conditions such as hot weather and cold weather, the multiple advantages of single-phase forced convection heat exchange, solid-liquid phase change heatexchange and gas-liquid phase change heat exchange are reasonably combined, and the requirements for compartment internal temperature adjustment and power battery temperature control and temperature equalization are met.

Owner:CHINA UNIV OF MINING & TECH +1

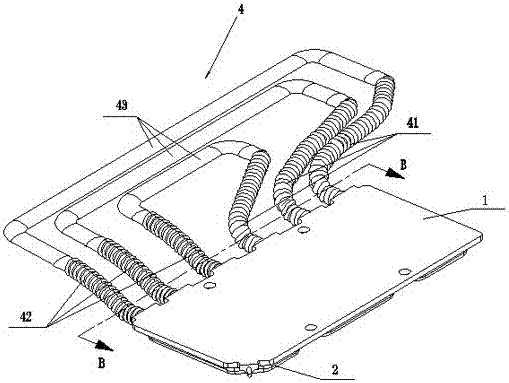

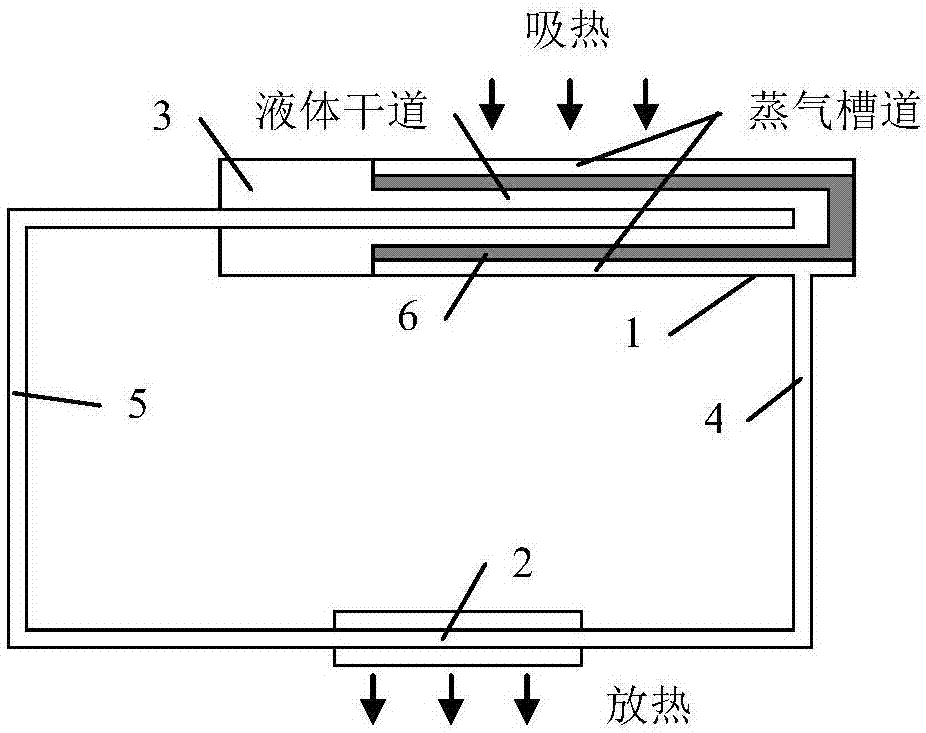

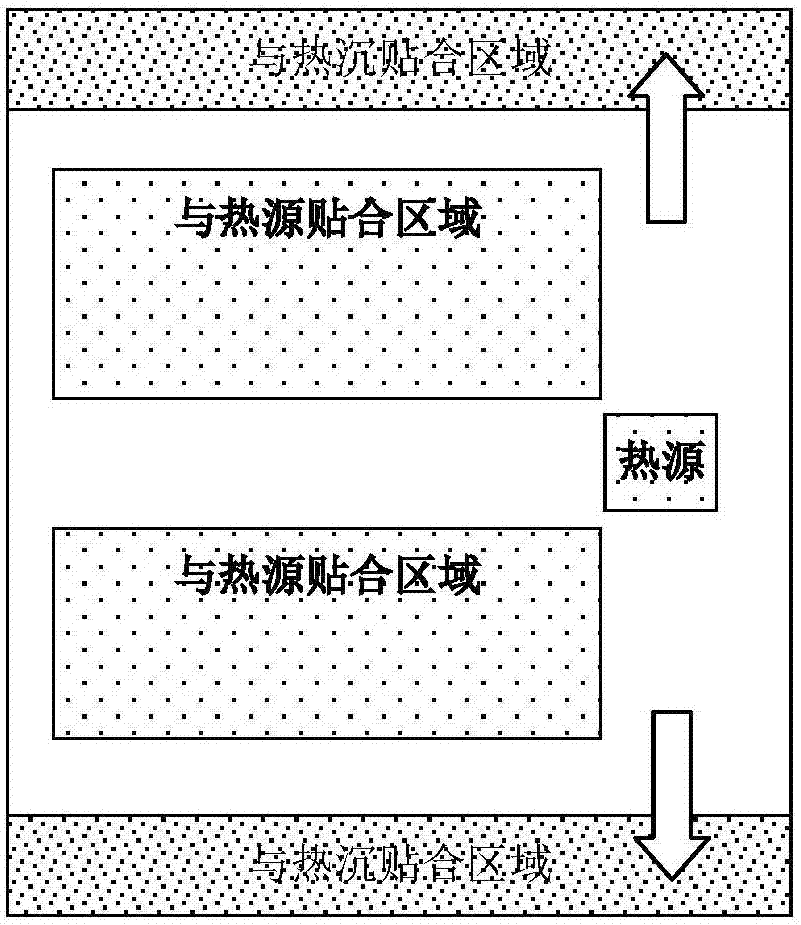

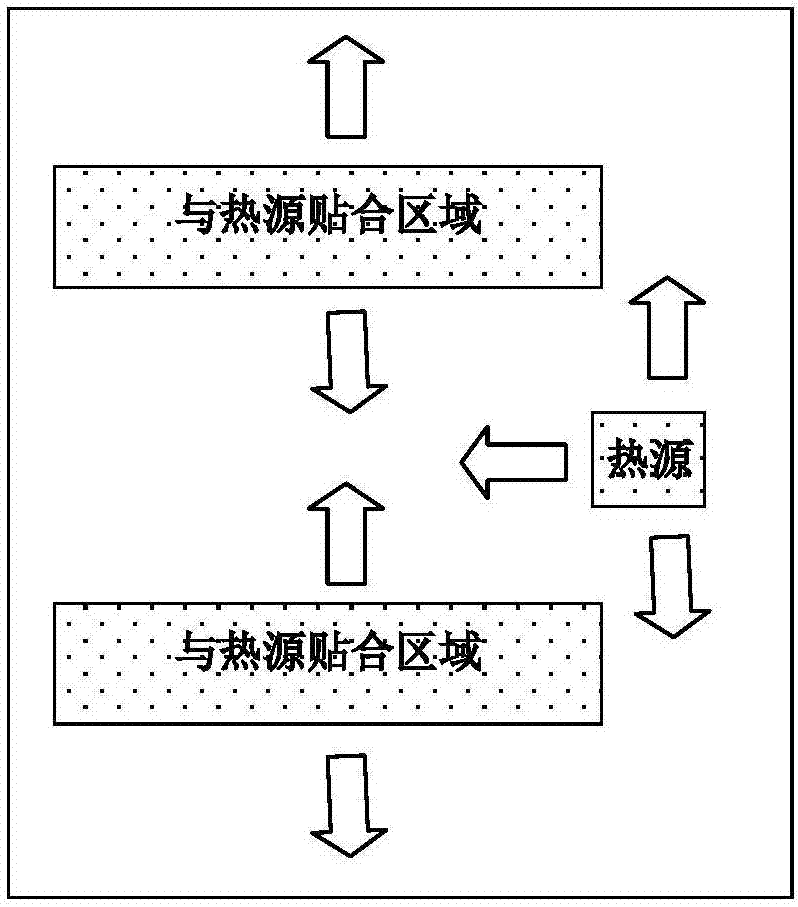

Vapor chamber based on flat-plate loop heat pipe

ActiveCN107131784ALow flow resistanceImprove heat transfer capacitySemiconductor/solid-state device detailsIndirect heat exchangersPerformance improvementHeat sink

The invention discloses a vapor chamber based on a flat-plate loop heat pipe. The heat transfer capability, the limiting heat flow density heat dissipation capability, the anti-overloading and inverse gravity capability of the vapor chamber are improved. The size of the vapor chamber is increased. The thickness of the vapor chamber is reduced. The conflicting requirements of performance improvement of the vapor chamber for both large pore size of capillary wick and small pore size of the capillary wick are met. The flat-plate loop heat pipe composed of an evaporator, a liquid accumulator and a gas / liquid pipe is pre-embedded in an aluminum alloy plate to form the vapor chamber based on the flat-plate loop heat pipe. The evaporator of the flat-plate loop heat pipe is arranged in the region, which is attached to a biggest heat source of a chip to be cooled, of the vapor chamber. The side, provided with a vapor channel, of the evaporator is attached to the biggest heat source. The vapor chamber is provided with a heat sink attached region and a heat source attached region. The gas / liquid pipe is led out of an outlet of the evaporator and is arranged in the heat sink attached region and the heat source attached region in a reciprocating mode, finally passes the heat sink attached region and returns to the liquid accumulator of the flat-plate loop heat pipe.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

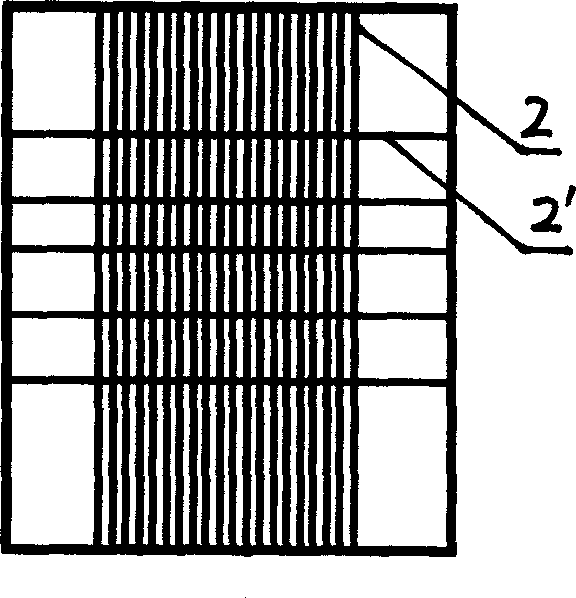

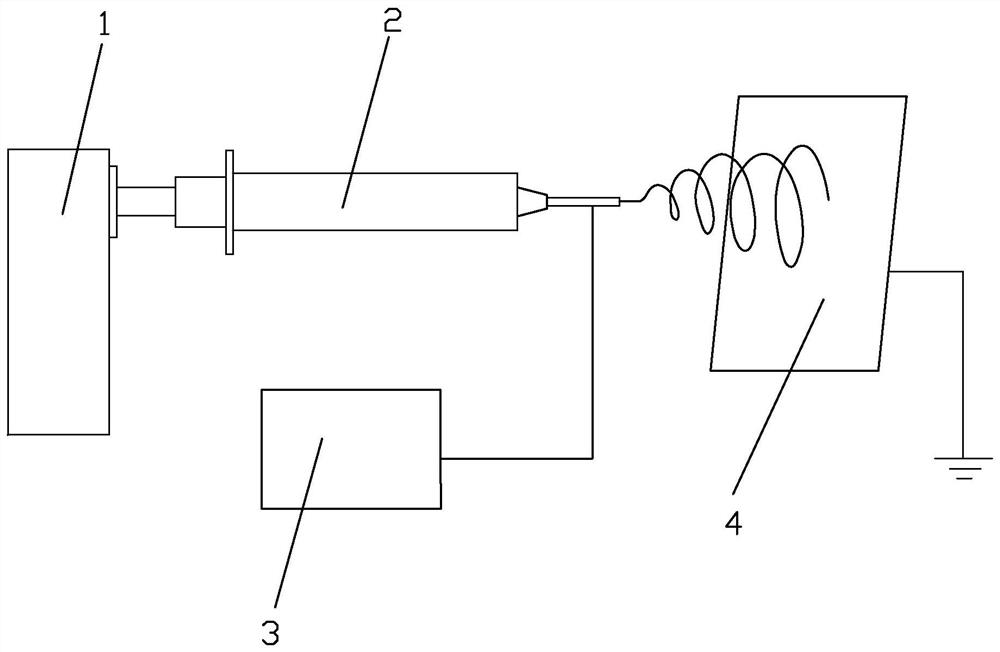

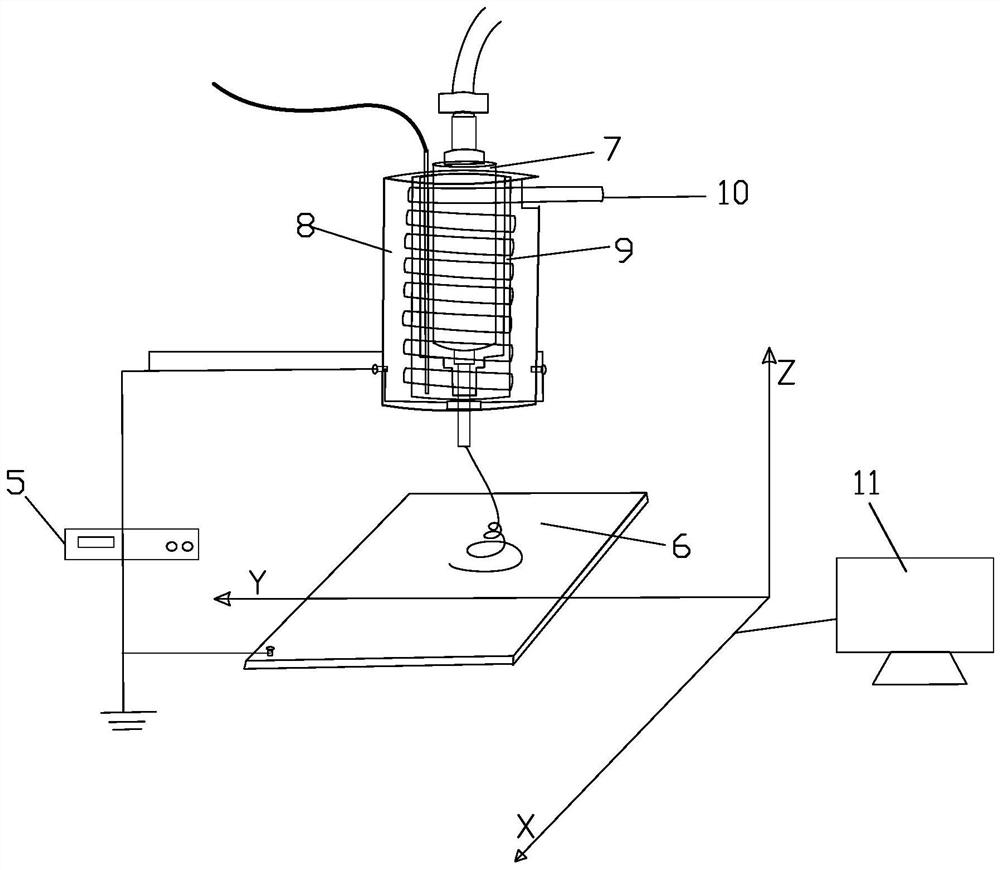

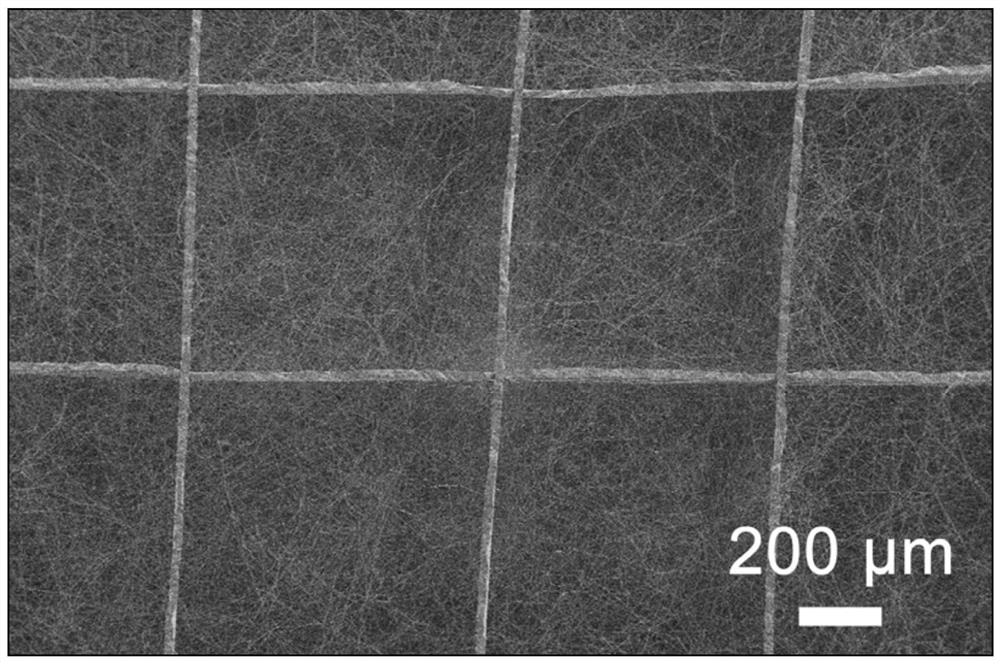

Preparation method of double-layer one-way moisture-conducting micro-nano fiber membrane based on near-field direct writing and solution electrospinning technology

ActiveCN113249875AFast evaporationThin diameterAdditive manufacturing apparatusElectro-spinningMicro nanoPolymer science

The invention discloses a preparation method of a double-layer one-way moisture-conducting micro-nano fiber membrane based on a near-field direct writing and solution electrospinning technology. The preparation method comprises the following steps of (1) preparing a layer of disordered hydrophilic micro-nano fiber membrane A through a solution electrospinning method; and (2) carrying out melt spinning by using melt direct writing equipment, and preparing an inner-layer hydrophobic micro-nano fiber membrane B on the hydrophilic micro-nano fiber membrane A. On the basis of solution electrostatic spinning, melt direct-writing spinning is added, so that accurate control over the pore size of the fiber membranes is facilitated, the topological structures of the fiber membranes can be constructed by printing preset grid patterns, then the requirement for permeation of liquid drops with different diameters is met, and the moisture absorption efficiency is improved. The micro-nanofiber membrane with an excellent one-way moisture guiding function can be prepared by combining the solution electrostatic spinning and the melt direct-writing spinning, the moisture absorption rate is adjusted, and the one-way moisture guiding performance of the micro-nano fiber membrane is further improved. The composite fiber membrane has a huge application prospect in the aspects of sportswear, paper diapers and medical dressings.

Owner:ZHEJIANG SCI-TECH UNIV

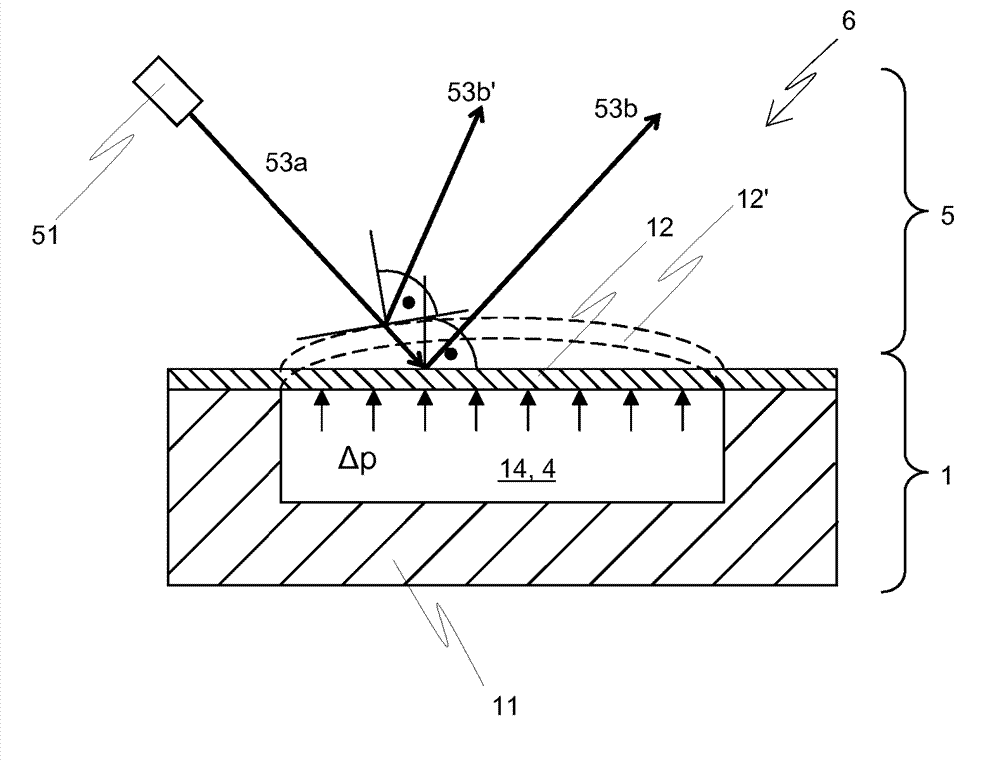

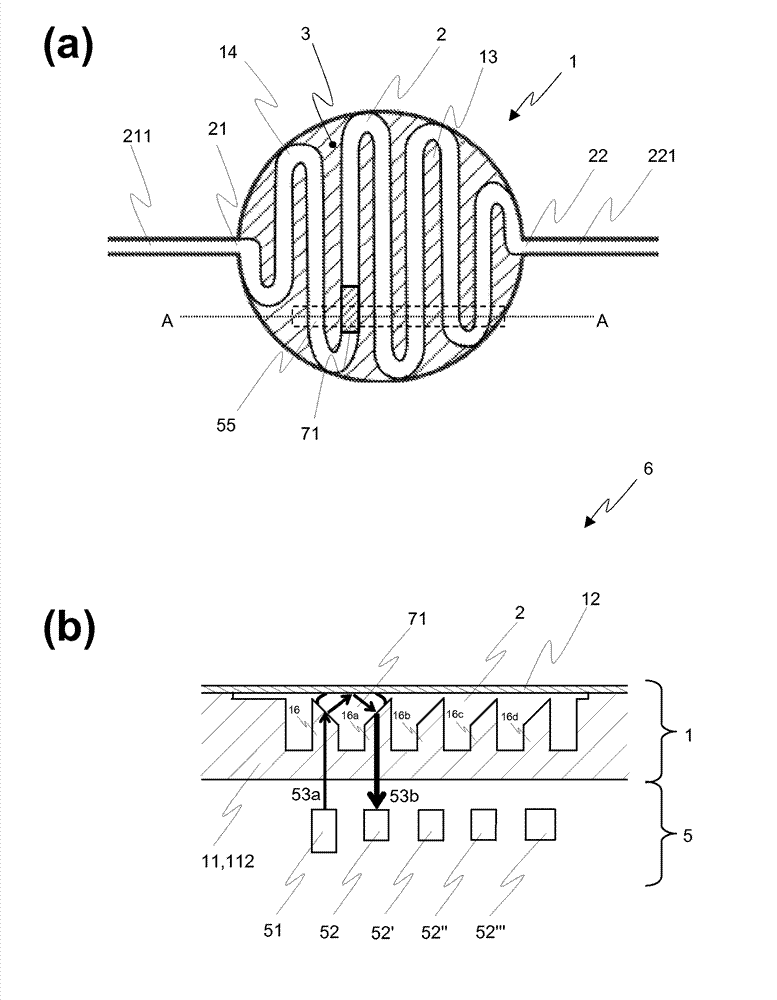

Sensor for use in liquid medicament delivery systems

InactiveCN102958549ALight signal decreaseLow costInvestigating moving fluids/granular solidsScattering properties measurementsLight beamEngineering

A sensor device (6) for use in a liquid medicament delivery system has a micro-fluidic chamber (1) comprising a rigid bottom substrate (11) and a cover (12), and an optical detection system (5) that is arranged to emit one or more light beams (53a) toward the cover membrane (12) and to observe the one or more light beams (53b) reflected from the cover membrane (12). The optical detection system (5) is arranged on a side of the bottom substrate (11) opposite to the cover membrane (12).

Owner:F HOFFMANN LA ROCHE & CO AG

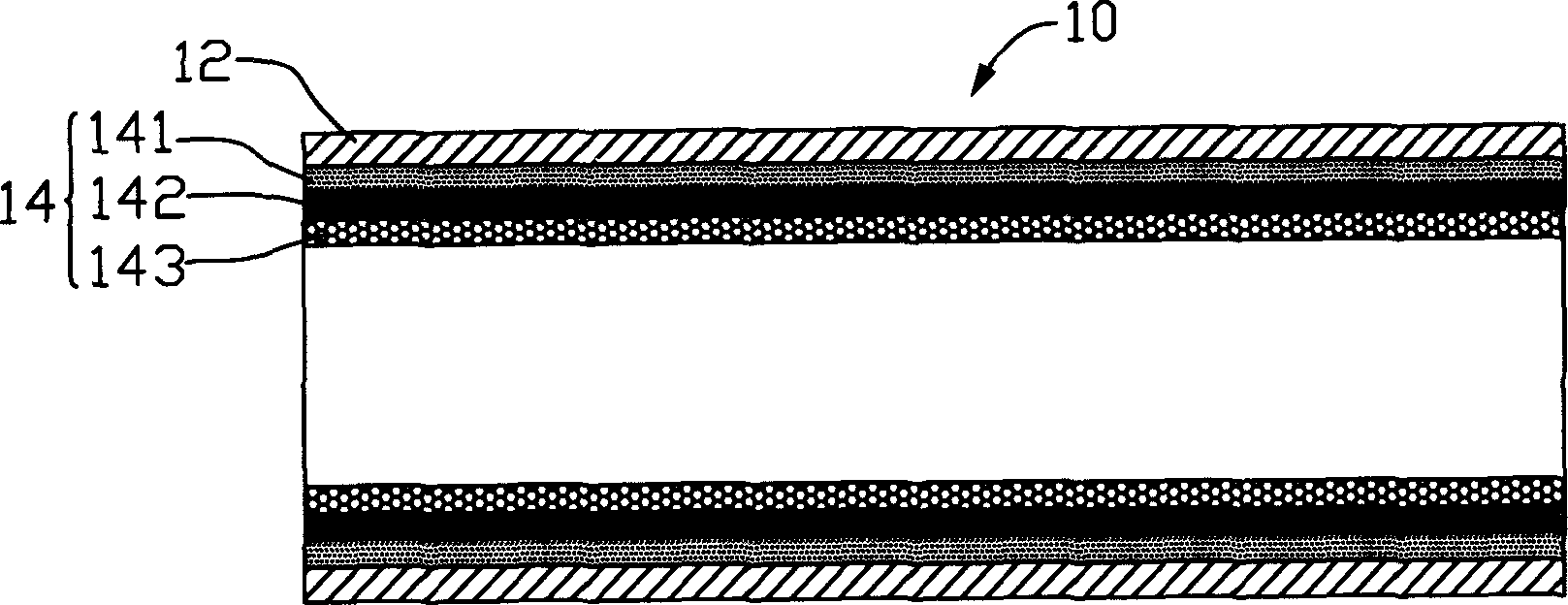

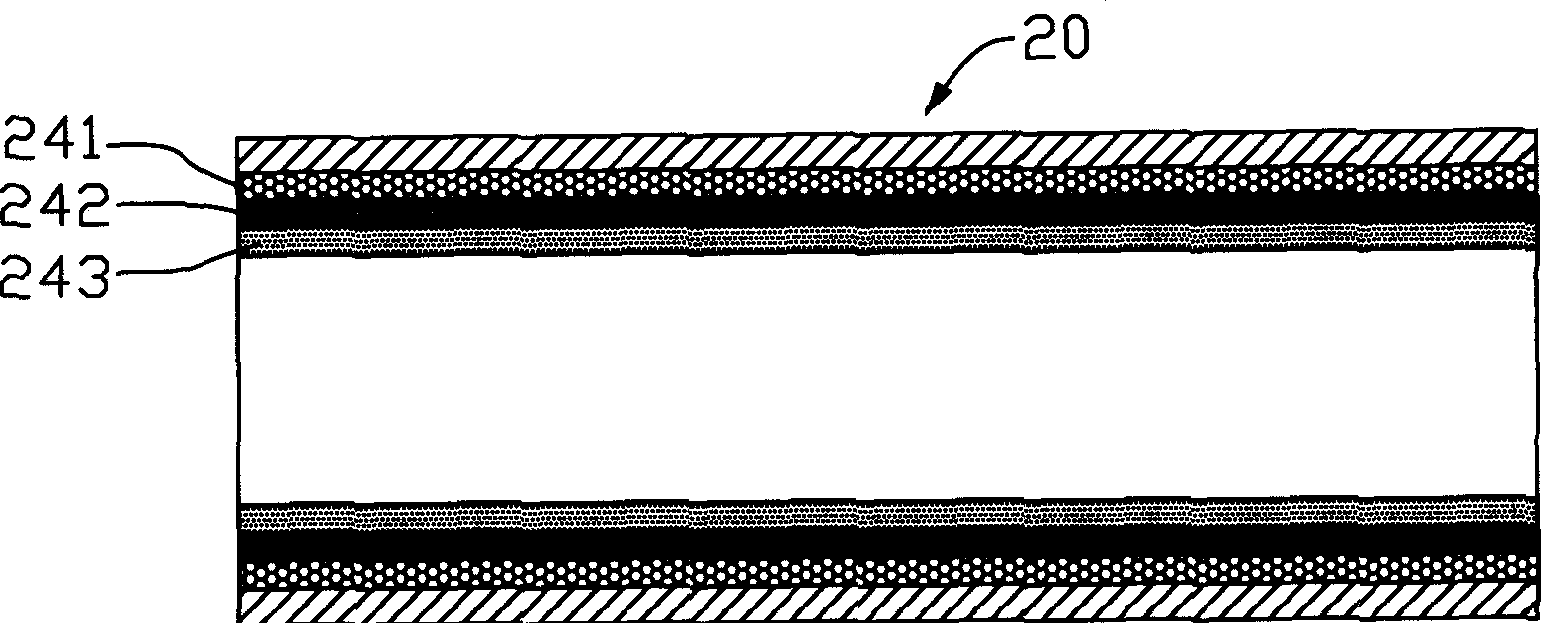

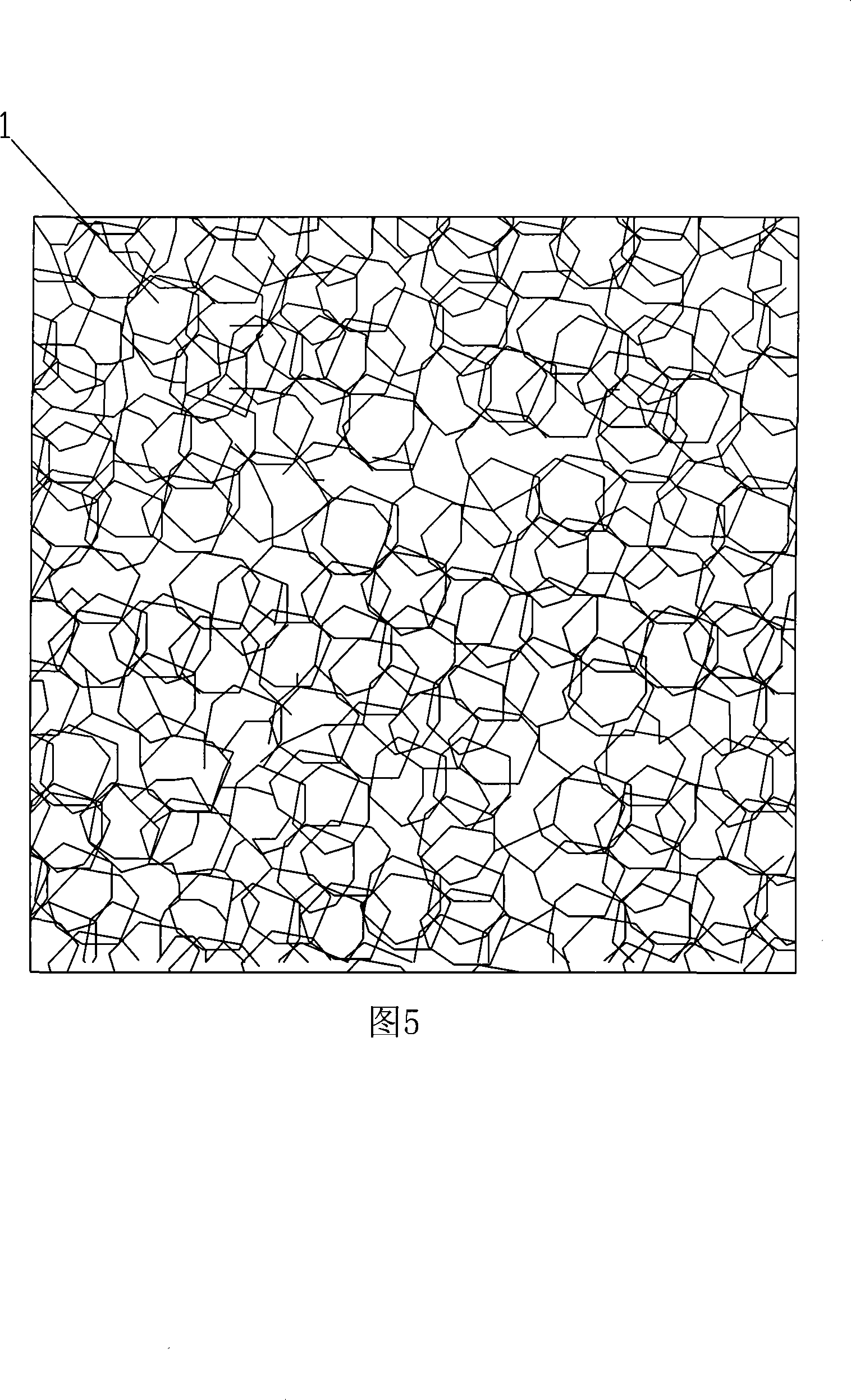

Heat radiating capillary structure, heat conducting component and method for making the heat radiating capillary structure

InactiveCN101163388AGood heat transfer performanceComplete network cross-linked structureSemiconductor/solid-state device detailsSolid-state devicesCross-linkageSolid shape

The invention provides a heat dissipating capillary structure which is a metal capillary structure, and the metal capillary structure is a three-dimensional reticular cross-linkage structure. The heat dissipating capillary structure is the three-dimensional reticular cross-linkage structure which has the three-dimensional solid shape and complete reticular cross-linkage structure and larger gap rate and also has larger capillary force. The invention also provides a heat conducting component which uses the heat dissipating capillary structure and the method for manufacturing the heat dissipating capillary structure. The heat conducting component has good performance of heat conduction, and the method for manufacturing the heat dissipating capillary structure is simple.

Owner:艾建华

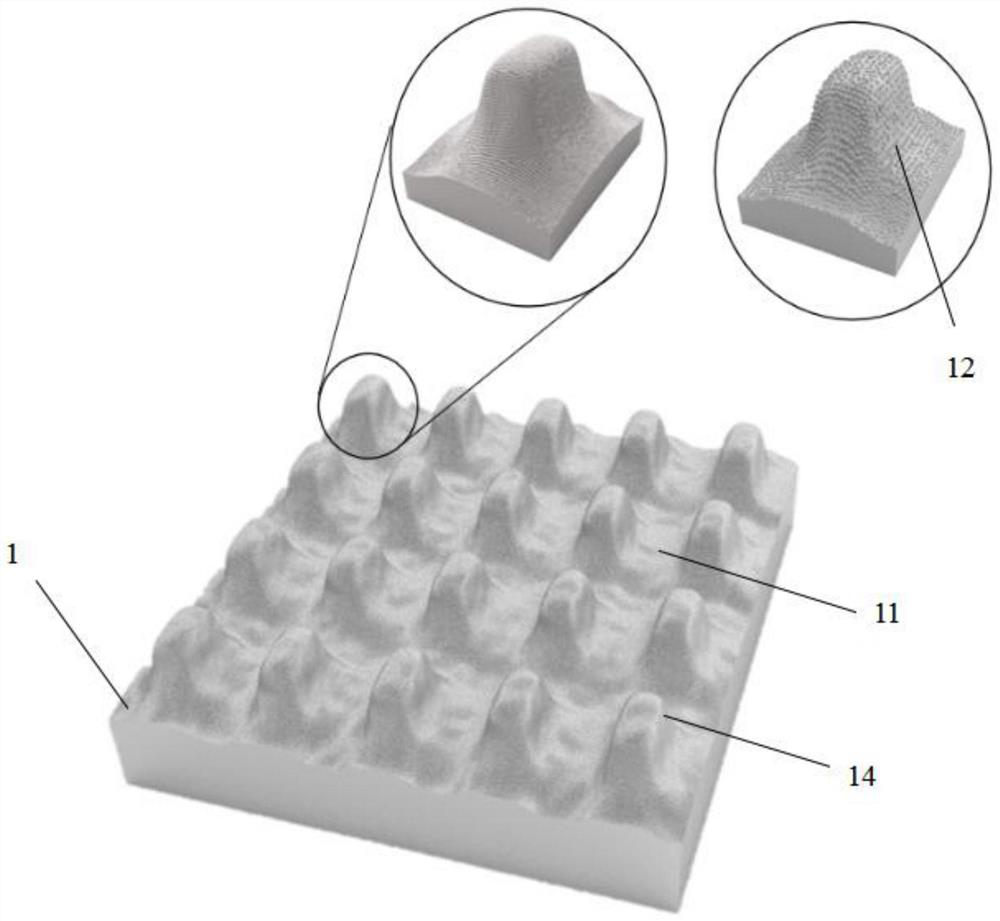

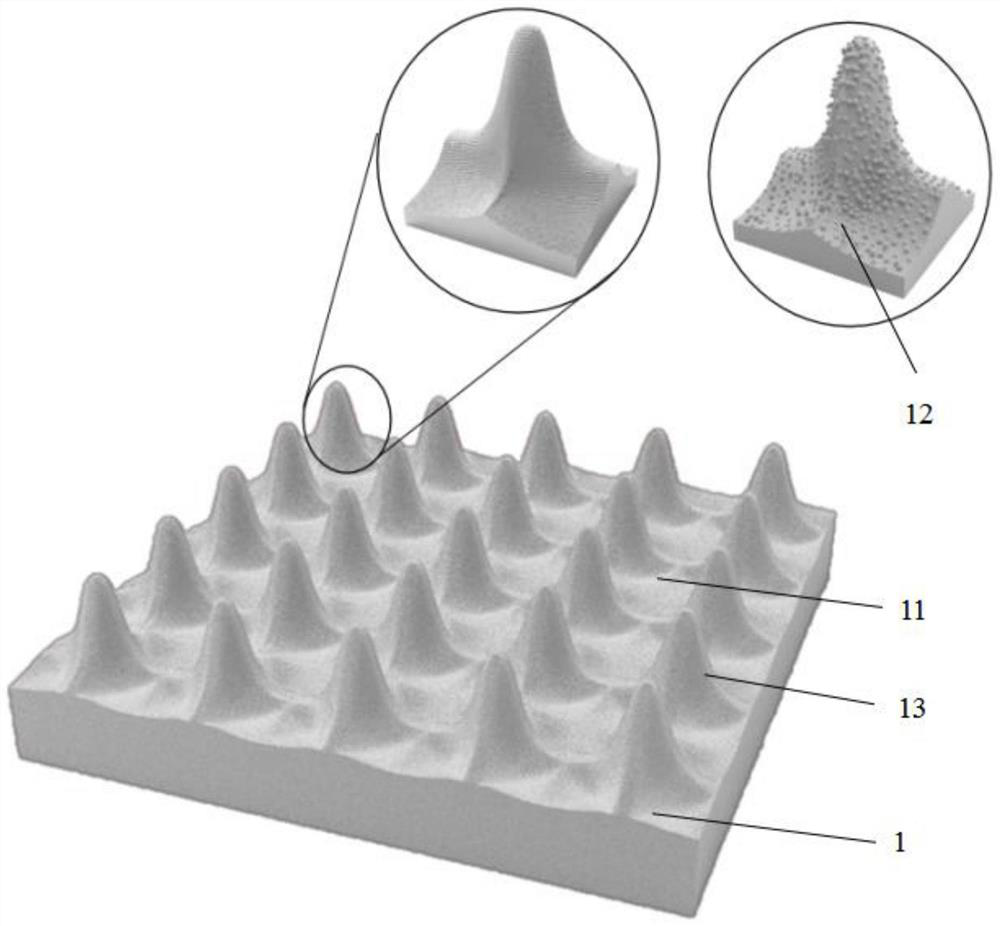

Ultrathin soaking plate super-hydrophilic micro-nano-structure liquid absorbing core and preparation method

PendingCN111735331AAvoid Directional Inadequate AspirationGuaranteed cooling effectIndirect heat exchangersMicro nanoHigh surface

The invention discloses an ultrathin soaking plate super-hydrophilic micro-nano-structure liquid absorbing core. The ultrathin soaking plate super-hydrophilic micro-nano-structure liquid absorbing core comprises a liquid absorbing core body and a soaking plate cover plate. The liquid absorbing core body is directly prepared on the soaking plate cover plate. The liquid absorbing core body is formedby periodically-distributed micro-arrays and passageways around the micro-arrays. Nano-scale sub-structures are densely distributed on the surfaces of the micro-arrays and the surfaces of the passageways around the micro-arrays, and a micro-nano full-coverage structure containing rich micro-cavities is formed by the micro-arrays, the passageways and the nano-scale sub-structures. A high-surface-energy oxide coating is arranged on the surface of the micro-nano full-coverage structure. Compared with powder spraying sintering of an existing liquid absorbing core and a traditional preparation method of a red copper silk screen liquid absorbing core, the steps of the process of preparing the liquid absorbing core with a laser method are fewer, the flow path is short, the efficiency is high, the structural consistency is good, the stability is high, the comprehensive performance is good, and a lowest heat pipe thickness and an optimal heat dissipation effect can be achieved.

Owner:绍兴镭纳激光科技有限公司

Hot pipe and manufacturing method thereof

InactiveCN101349520AImprove heat transfer performanceStrong capillary forceIndirect heat exchangersCooling/ventilation/heating modificationsWorking fluidEngineering

A heat pipe comprises a pipe body, a capillary structure in the pipe body and working fluid which is filled in the pipe body, wherein the heat pipe is provided with an evaporating section and a condensing section, the capillary structure comprises a plurality of superfine slots which are arranged on the inner walls of the pipe body, the pipe diameter of the evaporating section is smaller than the pipe diameter of the condensing section, the width of the slot on the evaporating section is smaller than the width of the slot on the condensing section, and the capillary structure further comprises at least a haemal tube which is attached on the inner walls of the pipe body, and a plurality of tiny holes are formed on the walls of the haemal tube, wherein one side of the haemal tube is contacted with the slots, the capillary structure of the heat pipe can provide stronger capillary acting force, and has small liquid reflux resistance, thereby increasing the heat transfer property of the heat pipe. The invention further provides a process for producing the heat pipe, which is convenient for quantity production and application.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Anode of lithium-ion battery and lithium-ion battery prepared from same

InactiveCN105185938AImprove high temperature resistanceImprove securityCell seperators/membranes/diaphragms/spacersSecondary cellsUltimate tensile strengthMaterials science

The invention relates to an anode of a lithium-ion battery and a lithium-ion battery prepared from the same. The anode of the lithium-ion battery comprises an anode base material layer, an anode active substance layer, and an aluminum oxide micro-pore coating which can replace traditional lithium-ion battery PP and PE isolating membranes. The aluminum oxide micro-pore coating on the surface of the anode of the lithium-ion battery not only has relatively high mechanical intensity, but also has good electrolyte-keeping capability, avoids the phenomenon of closing holes at a high temperature, furthermore guarantees a battery to have better high-temperature adaptability in a temperature application scope, and is applicable for a high-power lithium-ion battery.

Owner:DALIAN CBAK POWER BATTERY CO LTD

Micro-channel single phase convection and capillary groove phase inversion heat combined cooling method and device

InactiveCN101155495ATo achieve the purpose of coolingHigh strengthInstrumental cooling apparatusCooling/ventilation/heating modificationsSingle phaseBoiling point

The invention, relates to a cooling method, using the combination of micorchannel single-phase convection and remoteness groove phase transforming heat, and a device thereof, special components and a method of heat dissipation. The process is: high boiling point working liquid flows through the surface of a heating body, enters a plurality of micor-channels arranged inside heat conducting material after absorping heat; another low boiling point liquid in the remoteness grooves is inhaled by the capillary force produced by a plurality of remoteness grooves arranged on the outer surface of heat conducting material; heat is transferred by the high boiling working liquid in the micro-channels through heat exchanging of high intensity microscale singlephase convection to heat conducting material. The heat of a heating body is taken away by another low boiling point working liquid, which generates evaporation and boiling of high intensity when the working liquid is heated, in the remoteness grooves arranged on outer surface of heat conducting material. The heat exchanging element of remoteness grooves arranged on outer surface of heat conducting material has micro-channels inside is special device of the invention.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

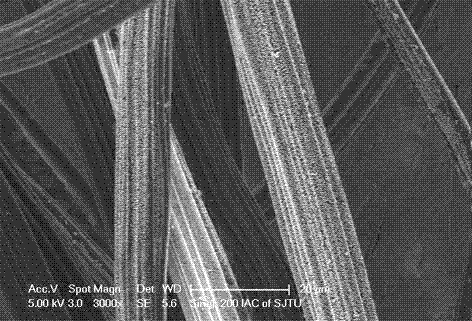

Calcium chloride-active carbon fibrofelt solid composite adsorbent and preparation method thereof

InactiveCN104772112AHigh adsorption rateMaximum adsorptionOther chemical processesActivated carbonFiber

The invention discloses a calcium chloride-active carbon fibrofelt solid composite adsorbent and a preparation method thereof. The calcium chloride-active carbon fibrofelt solid composite adsorbent is composed of calcium chloride and active carbon fibrofelt, wherein the fiber surface of the active carbon fibrofelt is uniformly covered with calcium chloride. The calcium chloride-active carbon fibrofelt solid composite adsorbent is prepared by using a hanging adsorption method which allows a calcium chloride solution to be uniformly distributed on the fine fiber of the active carbon fibrofelt. The calcium chloride-active carbon fibrofelt solid composite adsorbent prepared in the invention has better adsorptivity and stronger heat and mass transfer capability compared with a traditional silica gel-based composite adsorbent and is a composite adsorbent with the advantages of exemption from lyolysis and damage and a low price.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com