Production technology of high-tooth fin copper heat tube

A high-tooth fin copper and production process technology, applied in the field of heat pipes, can solve the problems of low heat dissipation efficiency and high manufacturing cost, and achieve the effects of beautiful appearance, good air tightness and good shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

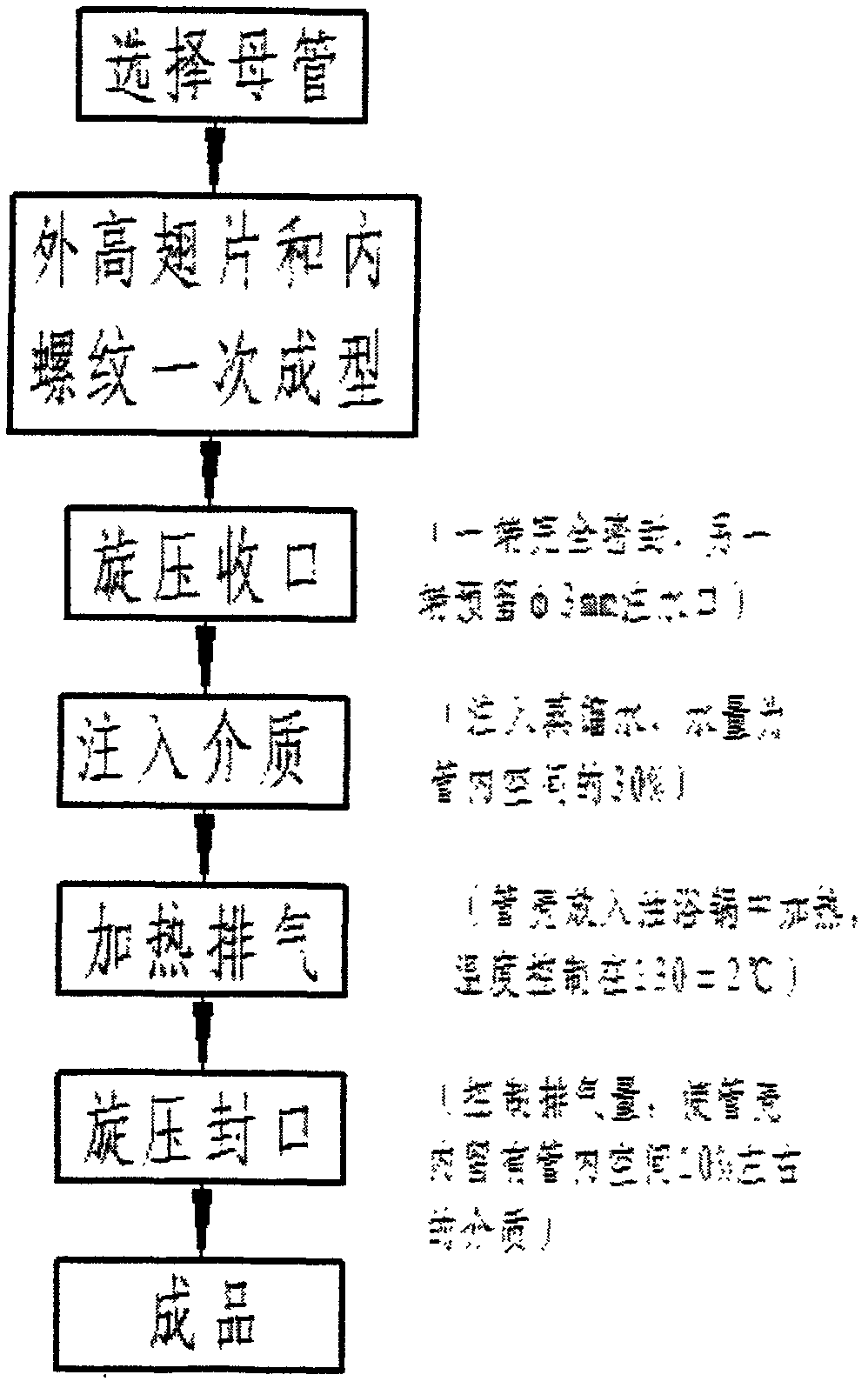

[0024] As shown in the figure, the production process of the product of the present invention is mainly composed of selecting the mother tube - forming the outer high fins and inner grooves - spinning and closing - injecting medium - heating and exhausting - spinning and sealing - finished products seven steps composed of processes. Among them, the second process adopts special processing technology to form high-toothed fins on the outer surface of high-quality seamless copper tubes and grooves on the inner wall, and the high-toothed fins and grooves are formed at the same time. The third process and the sixth process adopt the special processing technology independently developed, and use the spinning method to shrink the diameter of the two ends of the copper tube until they are welded together to achieve the effect of closing and sealing.

[0025] The invention is applicable to the fields of electric power, energy, chemical industry, transportation and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com