Micro-channel single phase convection and capillary groove phase inversion heat combined cooling method and device

A technology of phase change heat and cooling method, applied in the cooling of instruments, cooling/ventilation/heating renovation, instruments, etc., can solve the problems of large total heat dissipation capacity, high heat dissipation heat flow density, small heat dissipation area, etc., to achieve good cooling The effect of heat dissipation, high strength and high convection heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

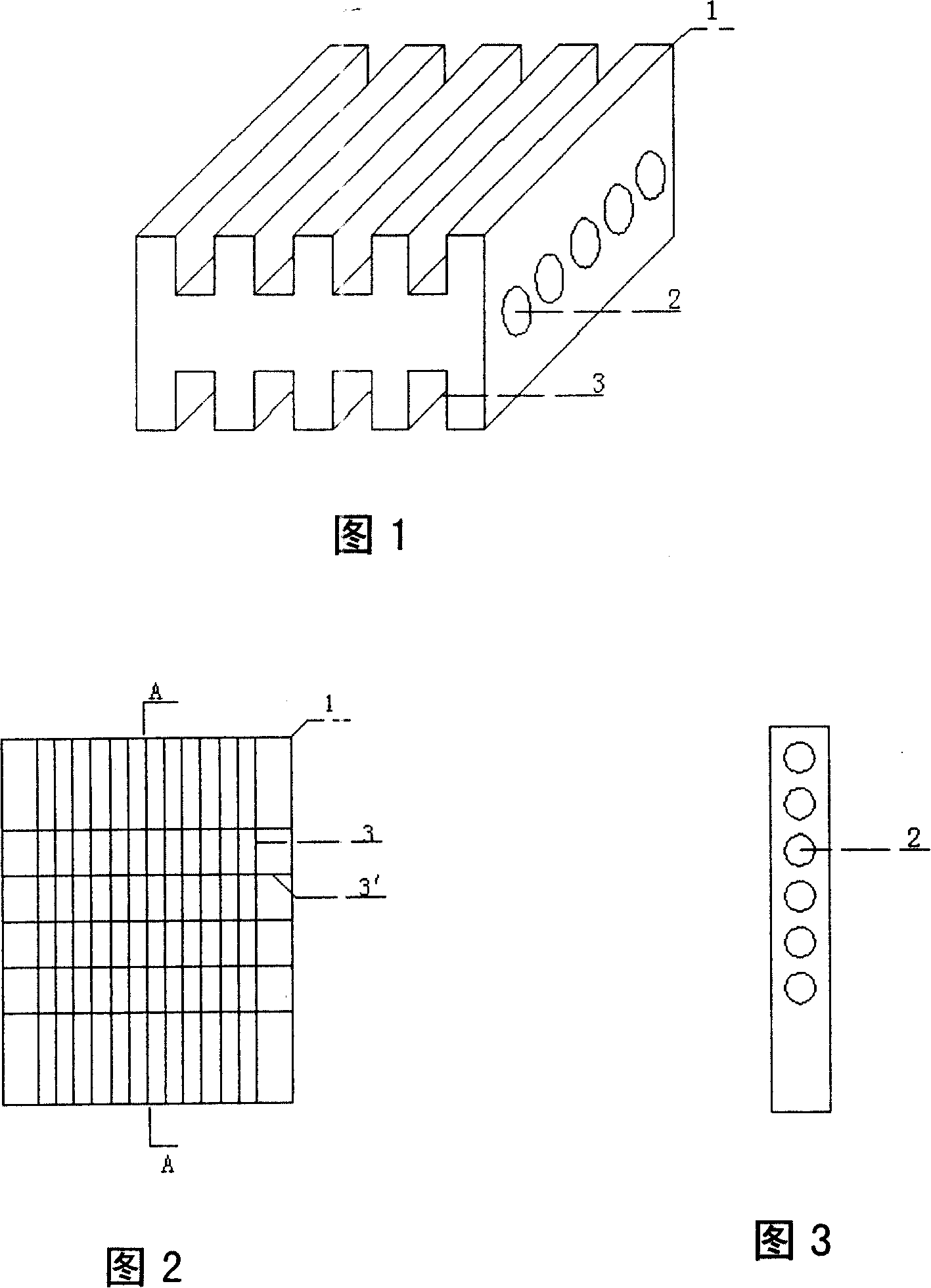

[0023] Embodiment 1: see Fig. 1, a lot of circular microchannels 2 are set inside metal plate or other heat-conducting materials 1, form microchannel group, and many rectangular capillary microgrooves 3 are set on the outer surface, form capillary microgroove group, this band A heat exchange structure with microchannels and capillary grooves is called a heat sink. As shown in Fig. 1 and Fig. 3, the microchannels 2 are densely arranged horizontally inside the heat-conducting material 1, and as shown in Fig. 1 and Fig. 2, the capillary microgrooves 3 are densely arranged longitudinally. The diameter of the microchannel 2 is in the range of 0.05-1mm, the distance between the microchannels is in the range of 0.05-5mm, the length of each microchannel is in the range of 5-50mm, and the cross-section of the microchannel is circular, and the capillary microgroove 3 The channel is a rectangular micro channel, its width and channel depth are in the range of 0.05-2mm, and the distance be...

Embodiment 2

[0025] Embodiment 2: As shown in Fig. 2, the heat sink of this embodiment has a plurality of capillary microgrooves 3 densely arranged vertically, and a plurality of transverse capillary microgrooves 3' are arranged crosswise on the densely arranged longitudinal capillary microgrooves 3. The capillary microchannels 3' arranged horizontally can ensure the capillary driving force of the liquid working medium flowing along the longitudinal capillary microchannels 3 under ultra-high heat load, so that the liquid working medium evaporated in the heated area can be replenished in time, thereby improving the cooling efficiency. In this embodiment, the groove width of the capillary micro-channel 3 is 0.2mm, the groove depth is 0.5mm, and the groove spacing is 0.2mm, and the groove width of the transverse capillary micro-channel 3' is 0.4mm, the groove depth is 0.8mm, and the groove spacing is 5mm.

Embodiment 3

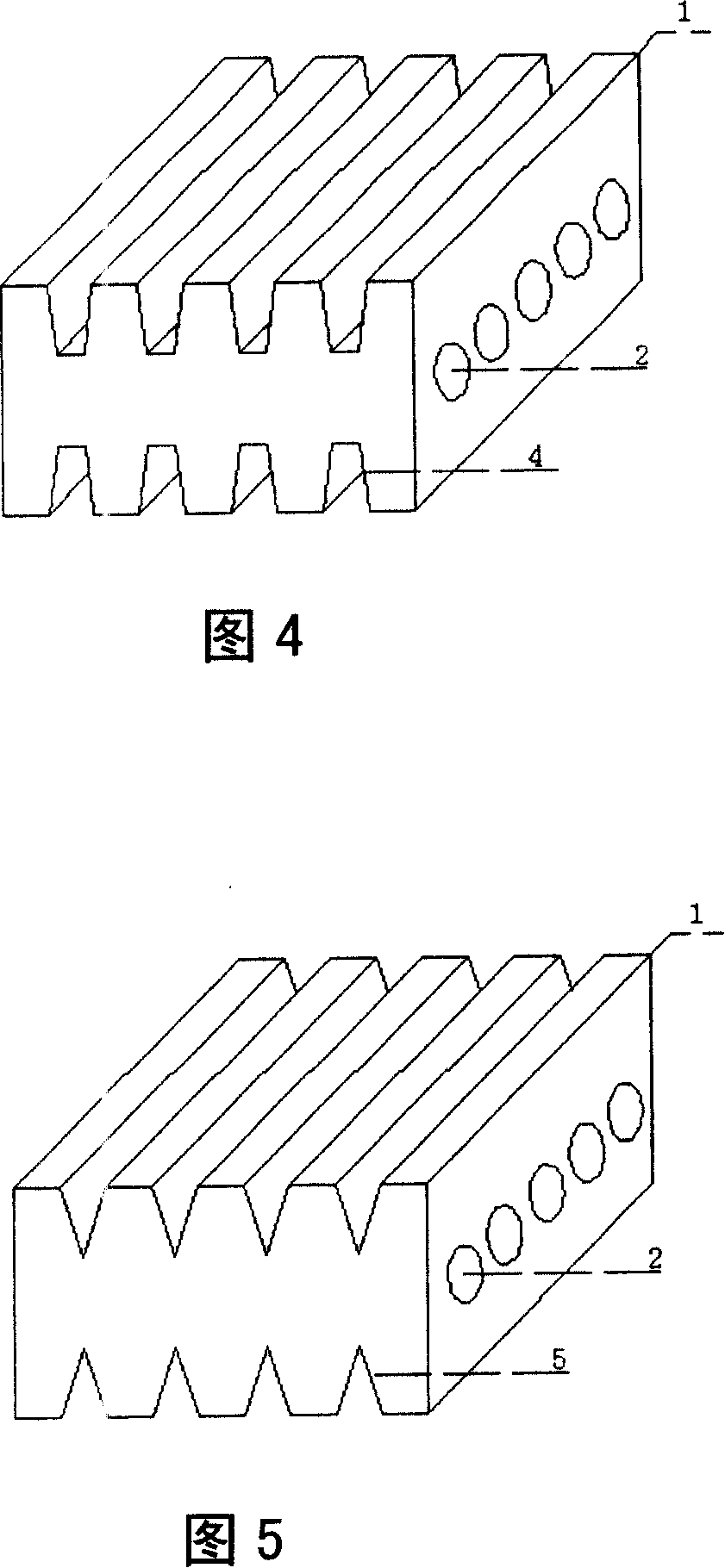

[0026] Embodiment 3: See Fig. 4, the plurality of capillary grooves 4 of the heat sink of this embodiment are vertically densely arranged, and its cross section is trapezoidal, the length of the upper base of the trapezoid is 0.2 mm, the length of the lower base is 0.4 mm, and the groove depth is 0.8mm, the spacing is 0.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com