Hot pipe and manufacturing method thereof

A manufacturing method and technology of heat pipes, applied in cooling/ventilation/heating transformation, indirect heat exchangers, lighting and heating equipment, etc., can solve problems such as heat pipe process difficulties, difficult mass production implementation, and reduced liquid delivery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

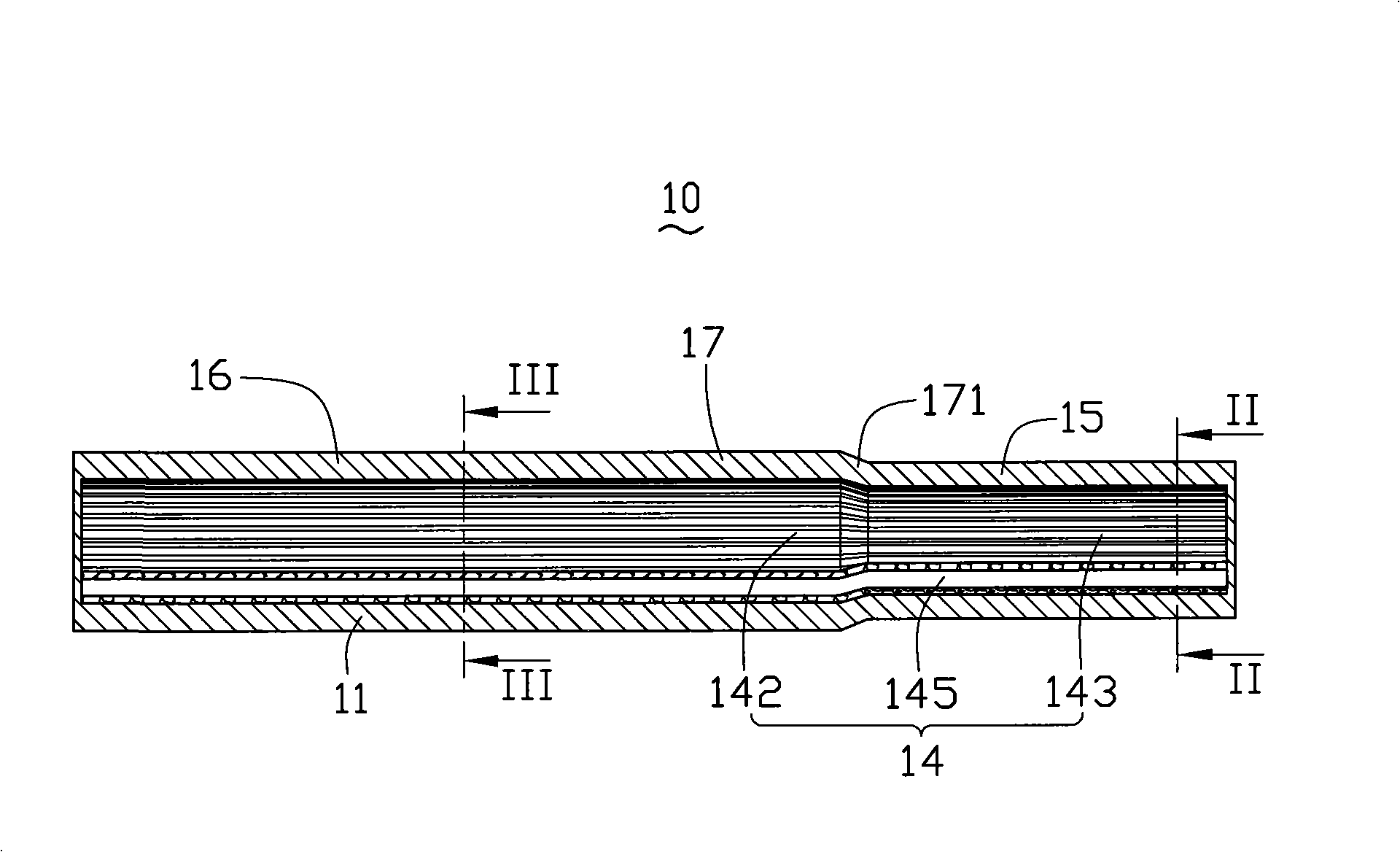

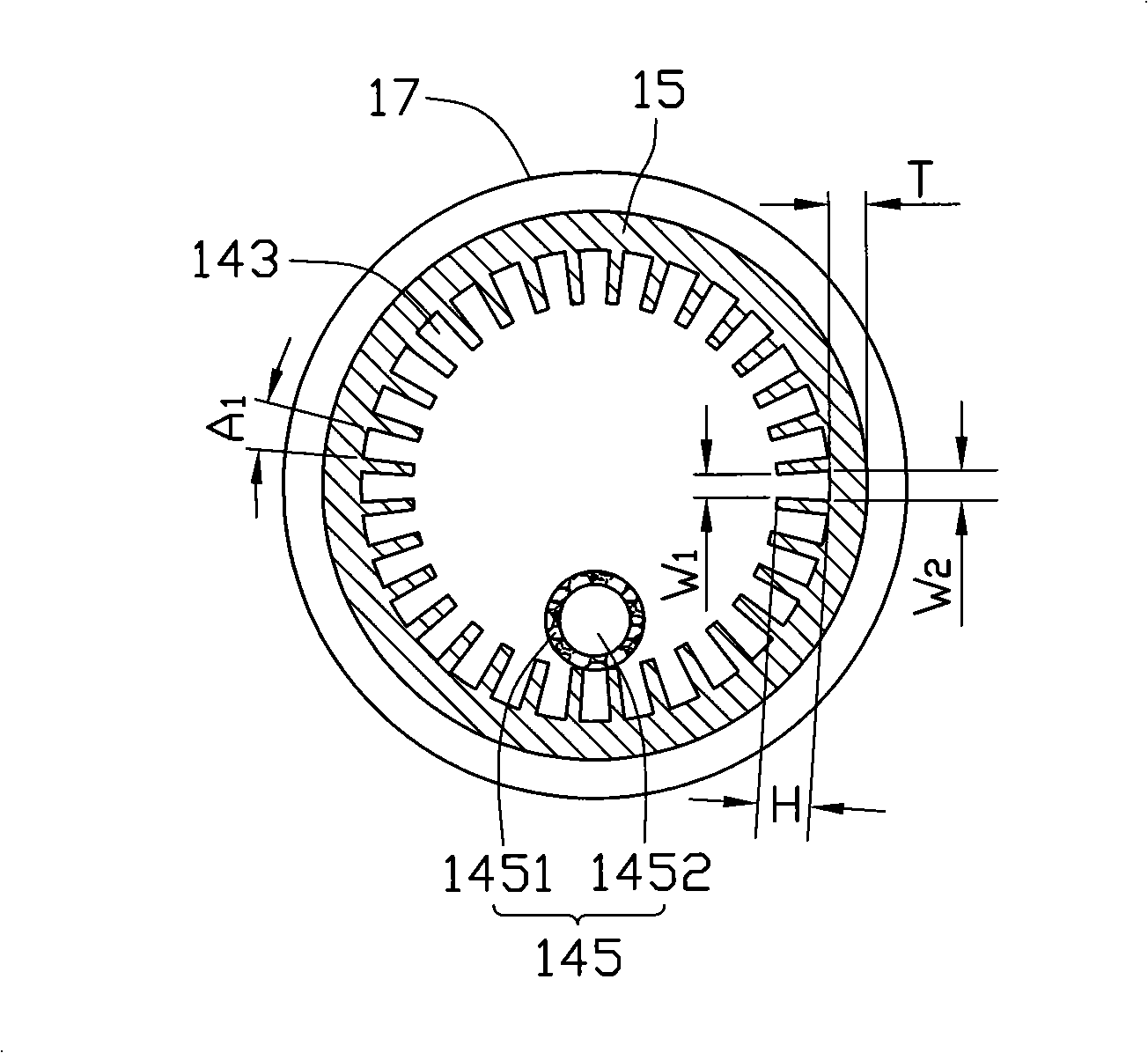

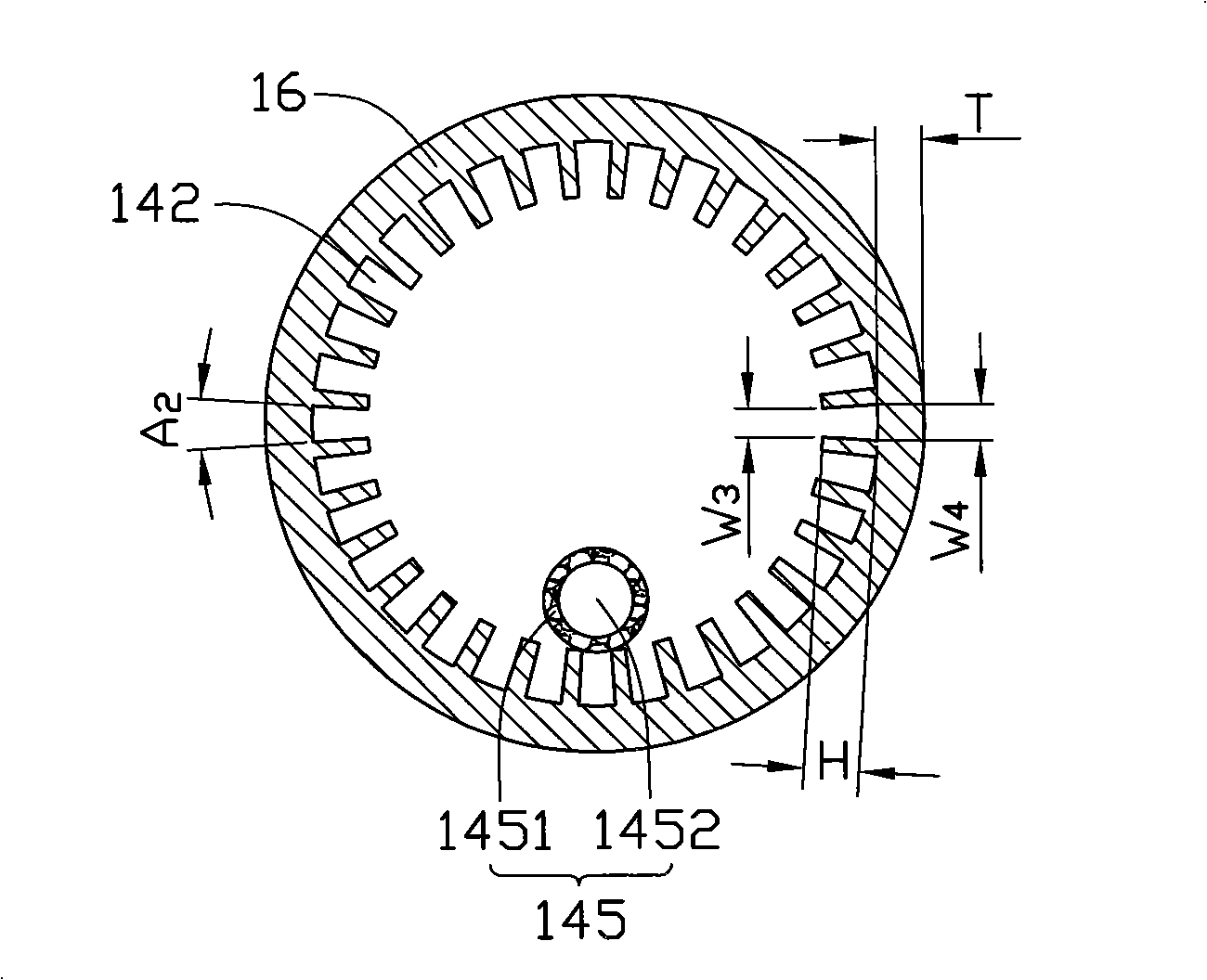

[0018] Figure 1 to Figure 3 Shown is a preferred embodiment of the heat pipe 10 of the present invention, the heat pipe 10 includes a pipe body 11, a capillary structure 14 disposed in the pipe body 11, and an appropriate amount of working fluid (not shown) filled in the pipe body 11 .

[0019] The tube body 11 is a closed hollow metal tube made of copper, aluminum and other materials with good thermal conductivity. The cross section of the tube body 11 is a ring, and its thickness T remains constant Change. The tube body 11 includes an evaporating section 15 and a condensing section 16 located at both ends of the tube body 11 in the axial direction, and an adiabatic section 17 connected between the evaporating section 15 and the condensing section 16 . The pipe diameter (inner diameter and outer diameter) of the evaporating sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com