Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Stable current output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

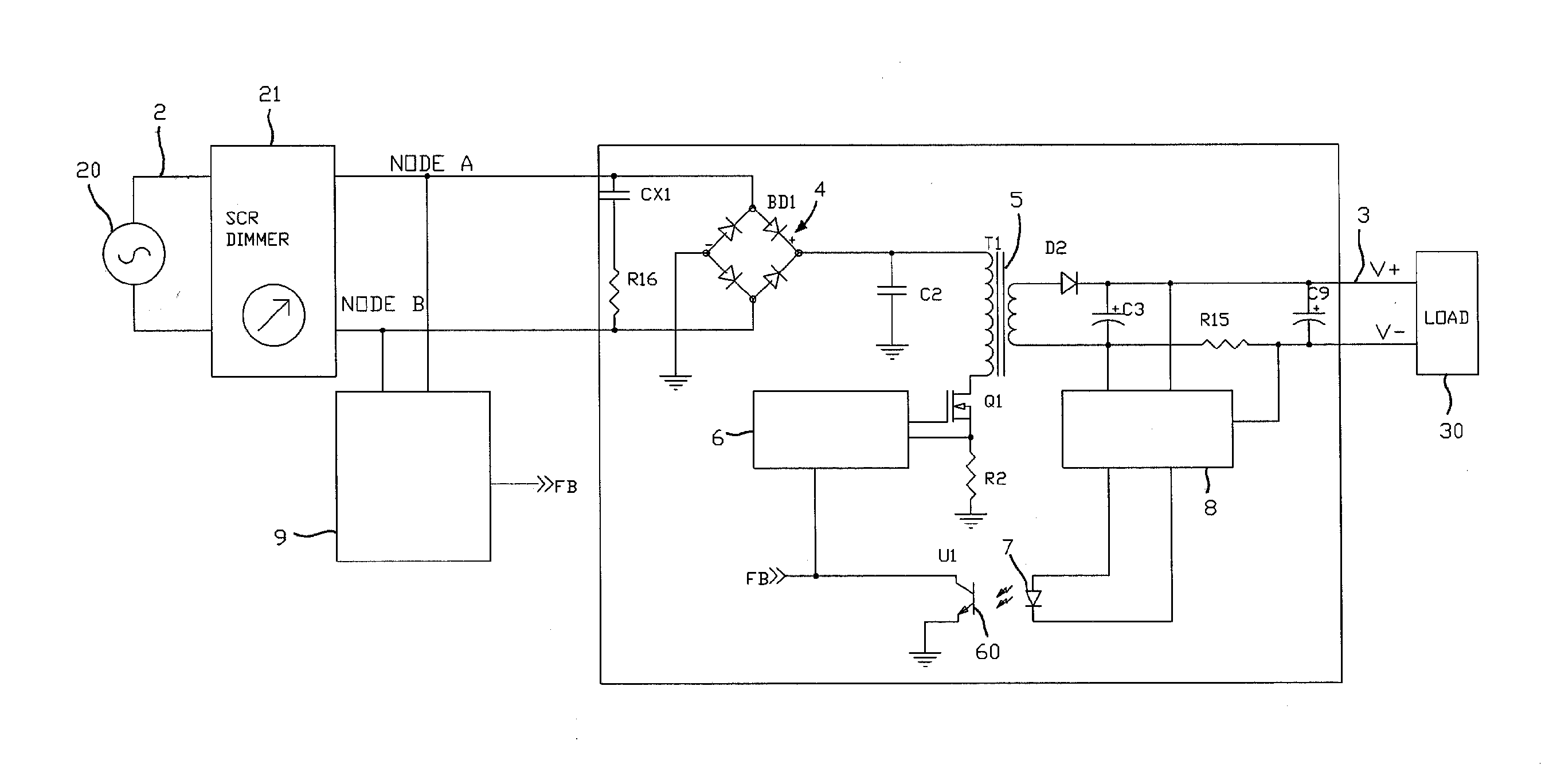

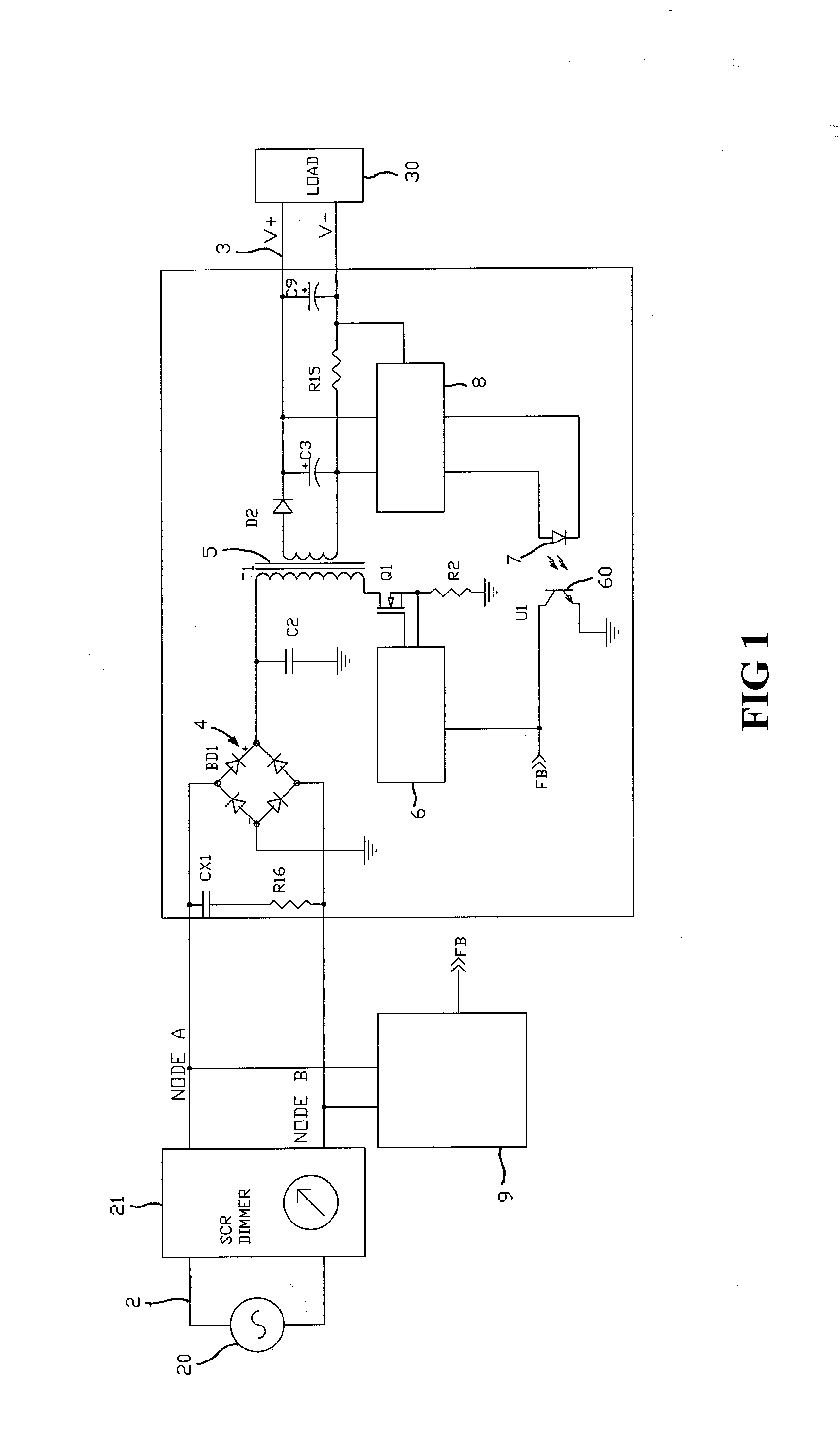

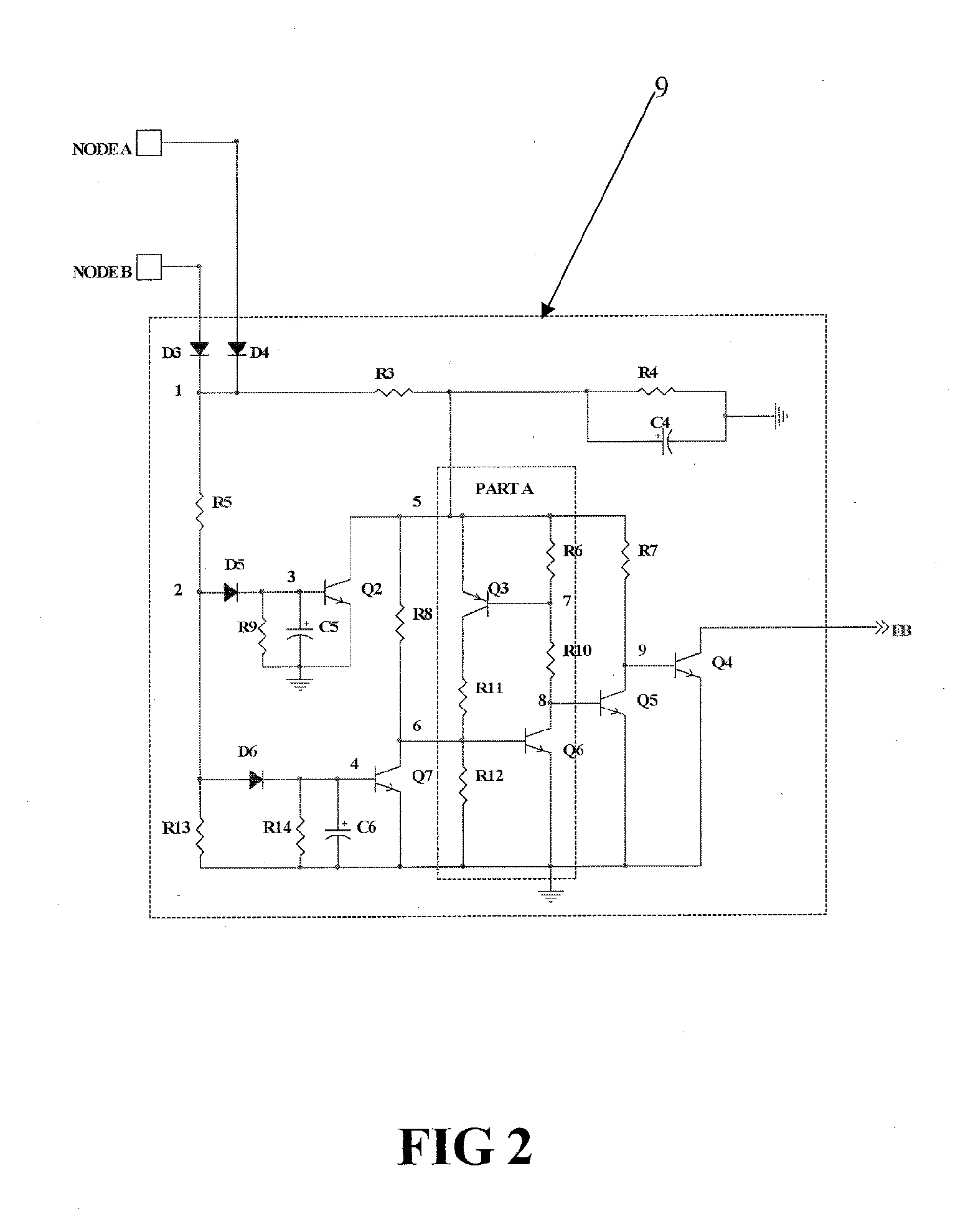

Driving and Dimming Control Device for Illuminator

InactiveUS20100123410A1Stable current outputStable outputElectrical apparatusElectroluminescent light sourcesLow voltageTransformer

The driving and dimming control device for illuminator includes an AC power input end connecting to a phase dimmer, a DC power output end for connecting to a lighting load, a rectifier connecting to the AC power input end, a pulse width modulator connecting to a transformer, a voltage / current detector, a photo-coupler connecting between the voltage / current detector and pulse width modulator, and a low-voltage-input locking circuit connecting between an output terminal of the phase dimmer and pulse width modulator. The low-voltage-input locking circuit includes a locking switch and a reset switch. The signals input to the pulse width modulator are locked by the locking switch to prohibit the pulse width modulator from hiccupping. Thus the DC output power can be stabilized.

Owner:LINKCOM MFG

Local shadow photovoltaic array MPPT control method based on optimization algorithm of molecular kinetic theory

InactiveCN107193320AReal-time efficient iterative searchImprove power generation efficiencyPhotovoltaic energy generationElectric variable regulationKinetic theorySteady state oscillation

The invention discloses a local shadow photovoltaic array MPPT control method based on an optimization algorithm of the molecular kinetic theory. Output current of a photovoltaic array serves as particles of the algorithm, the power of the photovoltaic array serves as an algorithm fitness function, and through the novel and rapid overall search technology, namely the optimization algorithm of the molecular kinetic theory, the maximum power point of the overall photovoltaic array is efficiently and accurately found out, the voltage of the maximum power point is output through the algorithm, the difference value between the voltage of the maximum power point and the actual output voltage of the photovoltaic array is obtained, a Boost circuit is controlled through a PWM module, and tracking of the maximum power point is achieved. The problem that under the local shadow condition, the photovoltaic array MPPT control having multi-peak output characteristics is easy to fall into interference of local maximum power points, the overall maximum power point can be accurately found out, tracking speed is high, and steady-state oscillation is small.

Owner:XIANGTAN UNIV

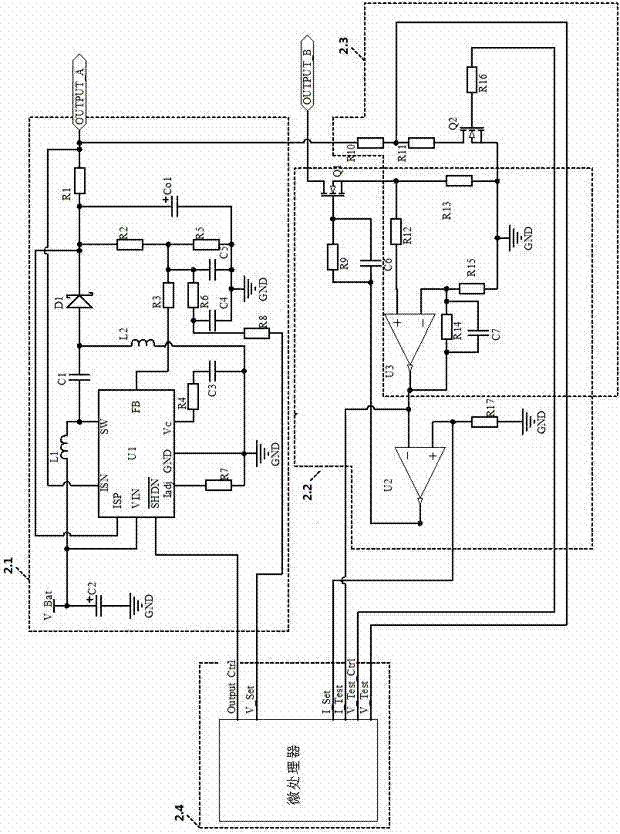

Current pulse circuit embedded with nerve stimulator

ActiveCN102727995AStable current outputEasy to controlArtificial respirationElectrical currentNerve stimulators

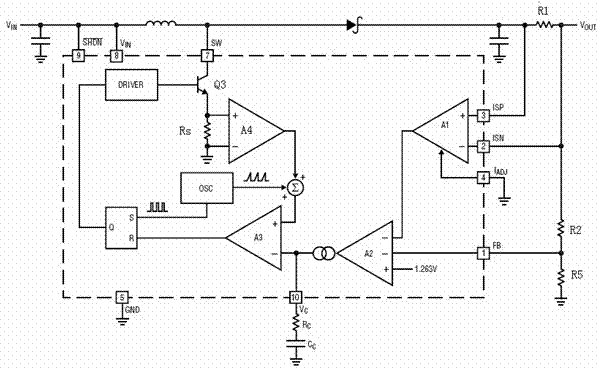

The invention discloses a current pulse circuit embedded with a nerve stimulator. The current pulse circuit comprises a microprocessor, a first inductor, a first diode, a second resistor, a fifth resistor, a filter capacitor, a boost-buck DC-DC (direct-current-direct-current) chip, a first circuit output terminal and a second circuit output terminal, wherein the first circuit output terminal is grounded through the second resistor and the fifth resistor; the boost-buck DC-DC chip comprises an error amplifier, a PWM (pulse-width modulation) comparator, a switching tube, an SR trigger and an oscillator; the common terminal of the second resistor and the fifth resistor is connected into the first inverting input terminal of the error amplifier; the non-inverting input and output terminals of the error amplifier are respectively connected with reference voltage and the inverting input terminal of the PWM comparator; the oscillation output of the oscillator is connected with the non-inverting input terminal of the PWM comparator; the oscillator outputs a switching signal to the terminal S of the SR trigger; the output terminal of the PWM comparator is connected with the terminal R of the SR trigger; and the output terminal Q of the SR trigger is connected with the control terminal of the switching tube.

Owner:CHANGZHOU RUISHENAN MEDICAL DEVICES

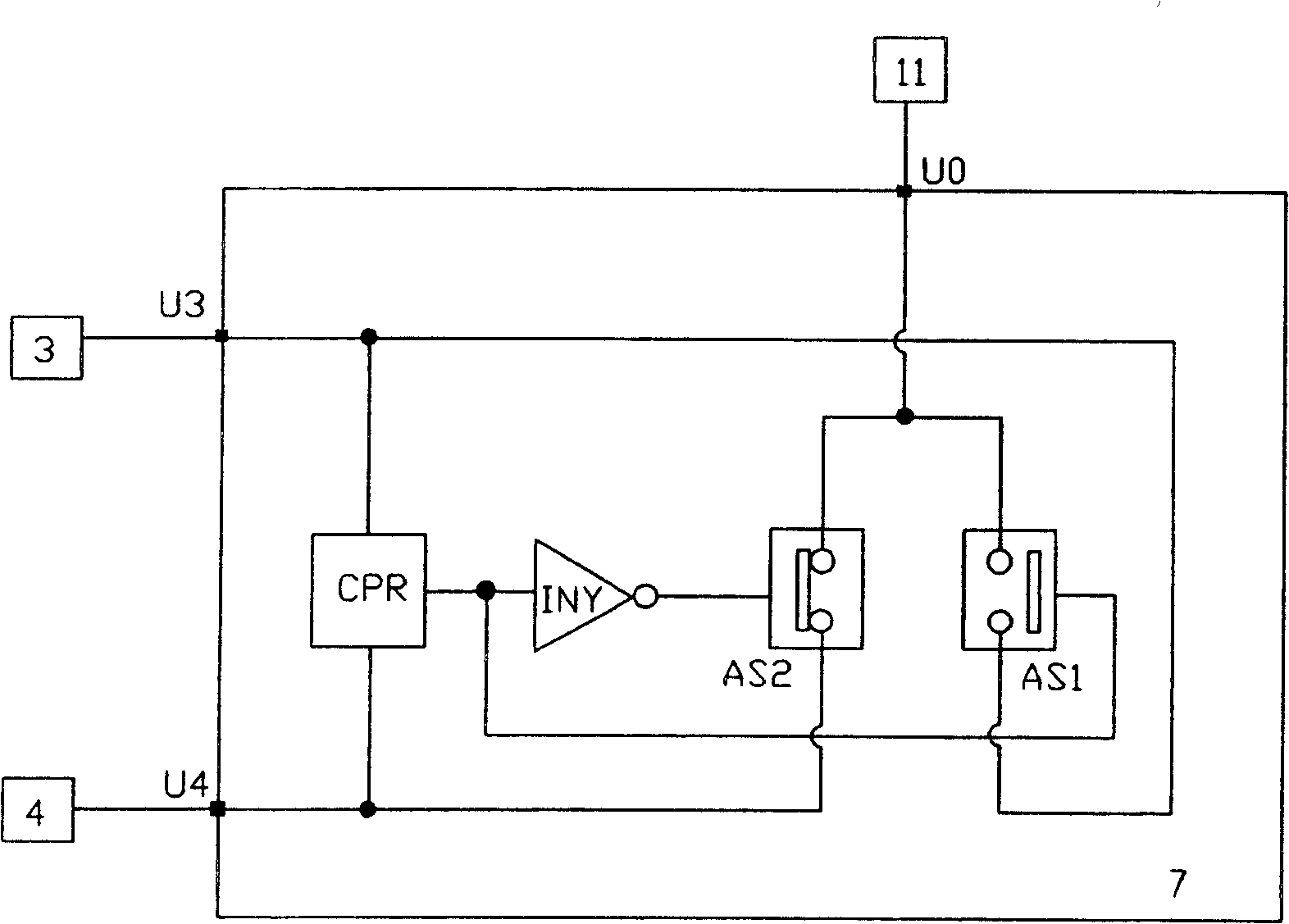

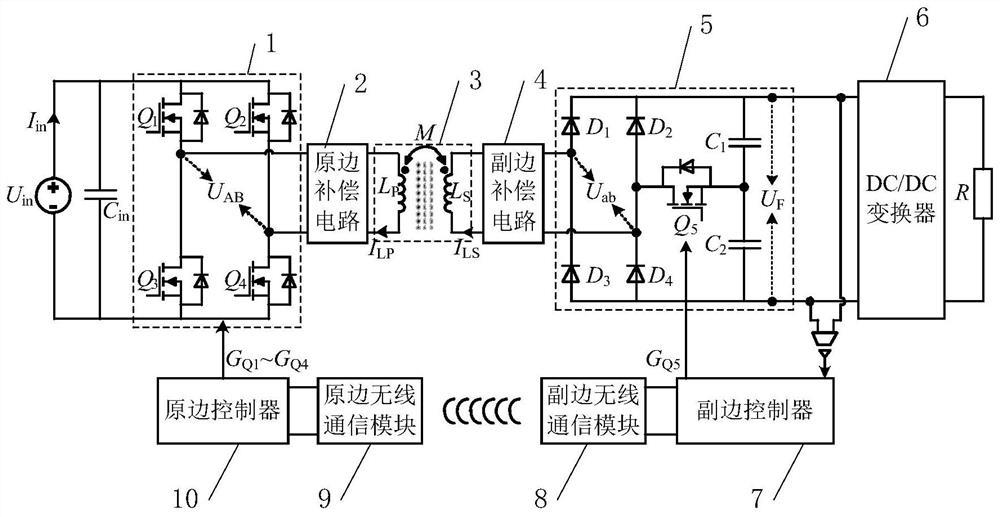

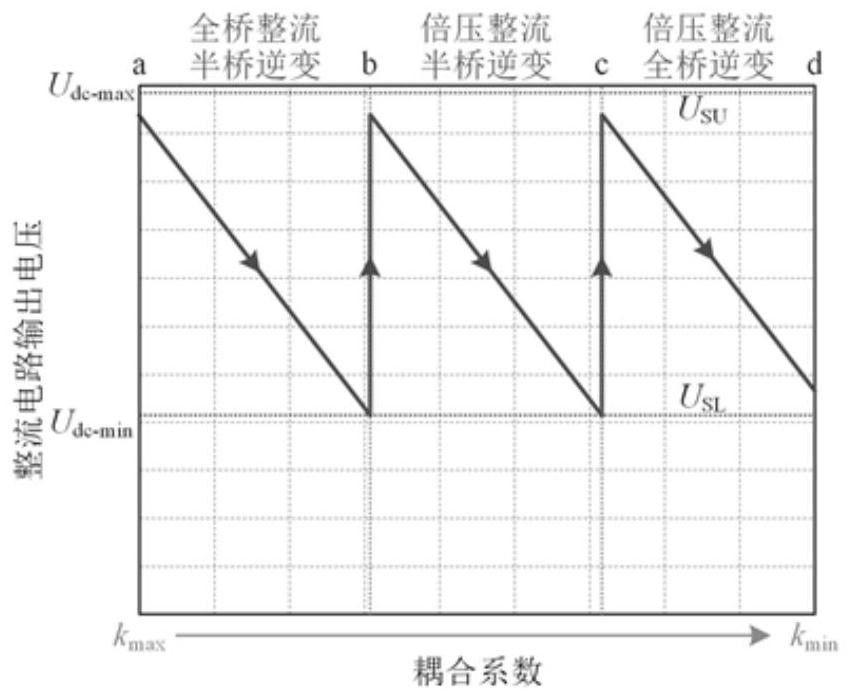

Strong anti-offset wireless power transmission system based on mode switching

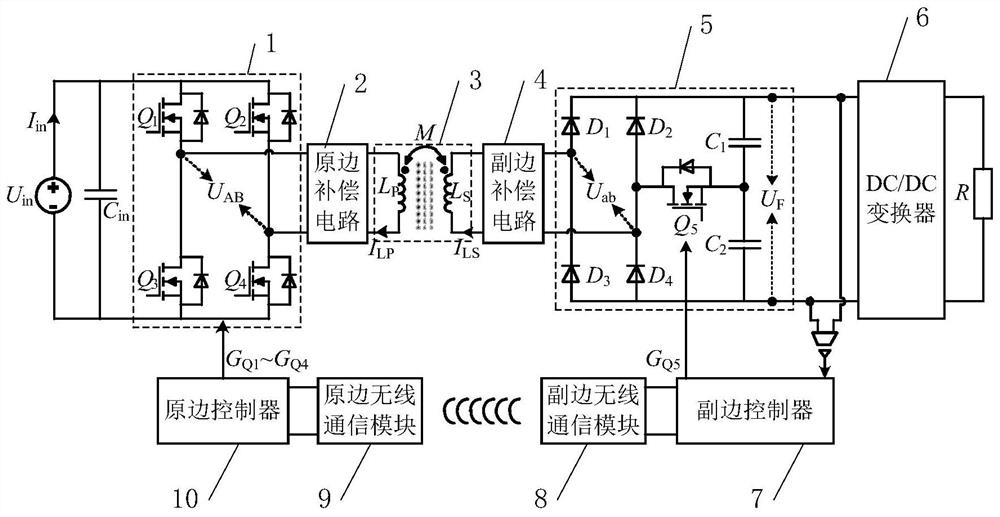

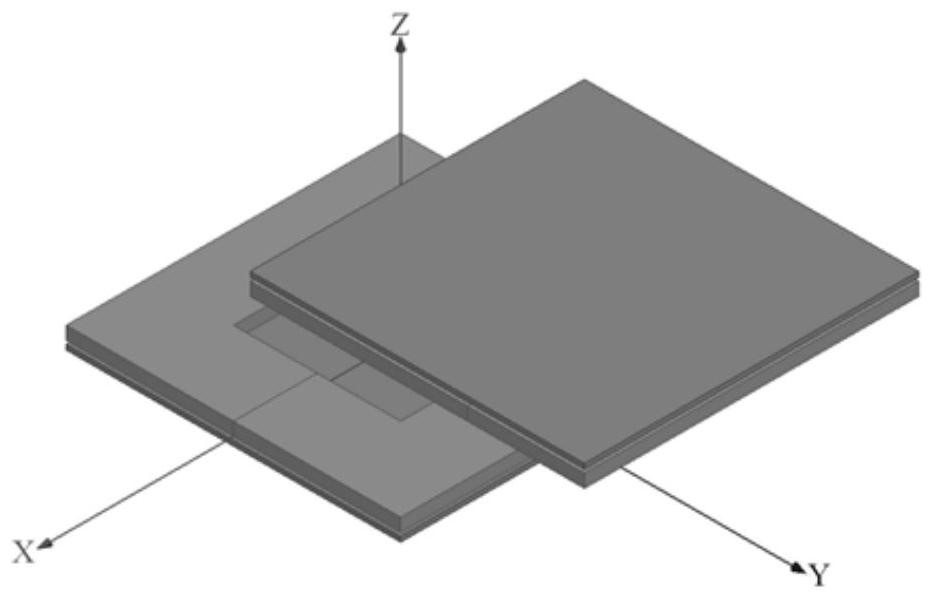

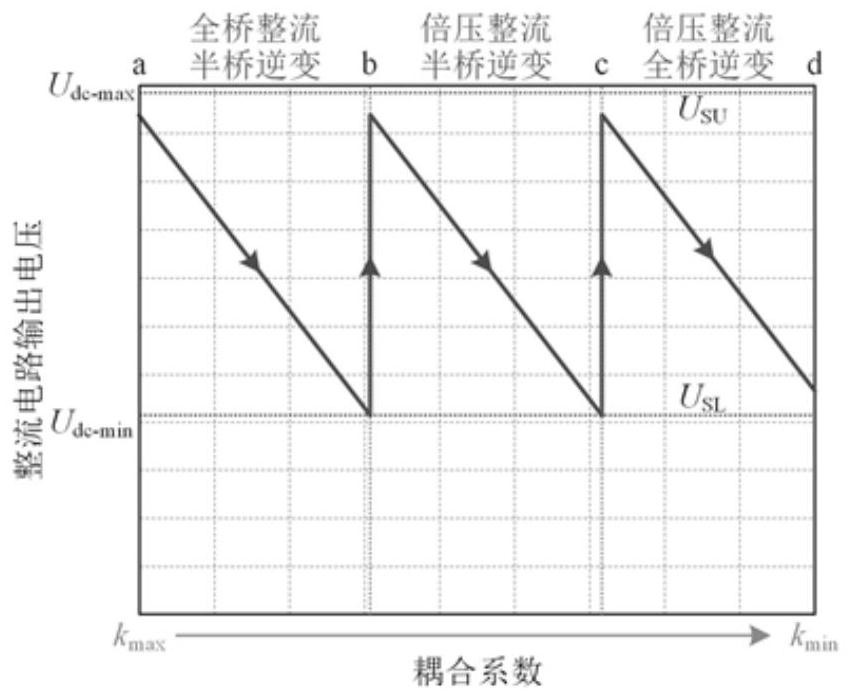

ActiveCN112994260AIncrease the output voltageReduce output voltageCircuit arrangementsAc-dc conversionTelecommunicationsLoop control

The invention discloses a strong anti-offset wireless power transmission system based on mode switching, belongs to the technical field of wireless power transmission, and particularly relates to the strong anti-offset wireless power transmission system based on mode switching. According to the invention, the problems of a large size, high cost and low efficiency of a post-stage closed-loop control DC / DC converter caused by a large offset of a primary and secondary side coupling mechanism of an existing wireless power transmission system are solved. A secondary side controller outputs a rectification switching instruction to a control signal input end of a rectification switching circuit according to an upper limit and a lower limit of an output voltage of the rectification switching circuit and an input voltage of a DC / DC converter; the secondary side controller also transmits the inversion switching instruction to the secondary side wireless communication module through the secondary side wireless communication module; and a primary side wireless communication module receives the inversion switching instruction and transmits the inversion switching instruction to a primary side controller, and the primary side controller receives the inversion switching instruction and sends a state switching control signal to the inversion switching circuit. The system is suitable for the technical field of wireless power transmission.

Owner:HARBIN INST OF TECH

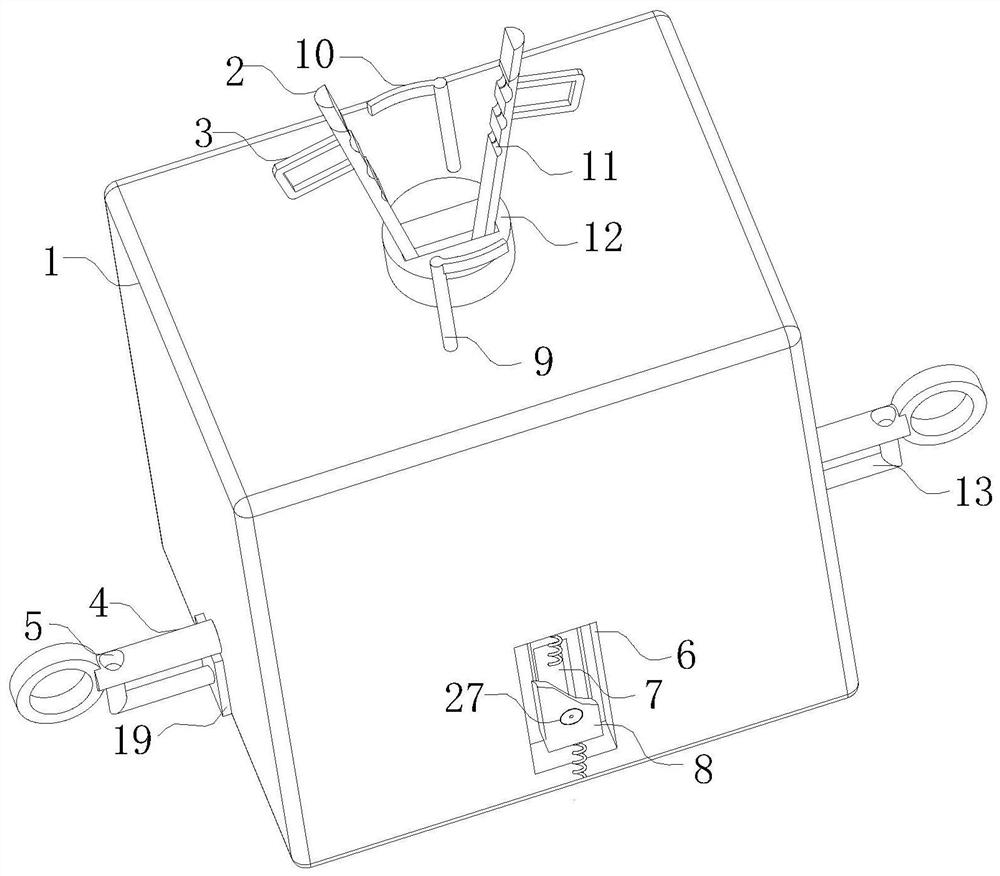

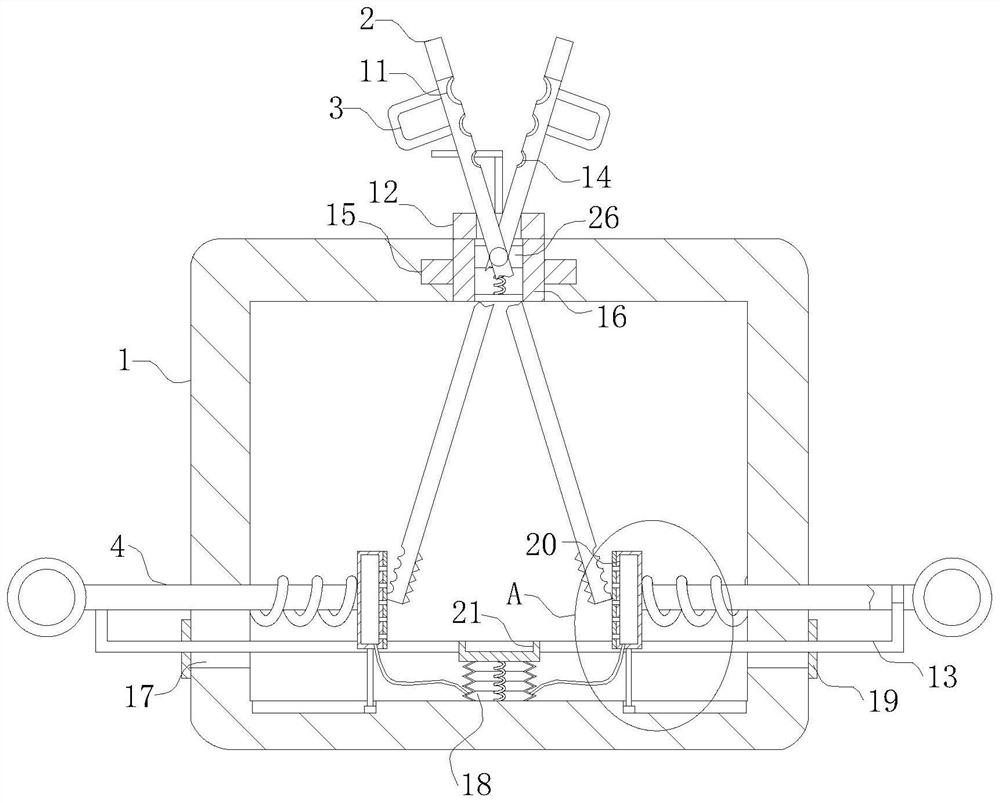

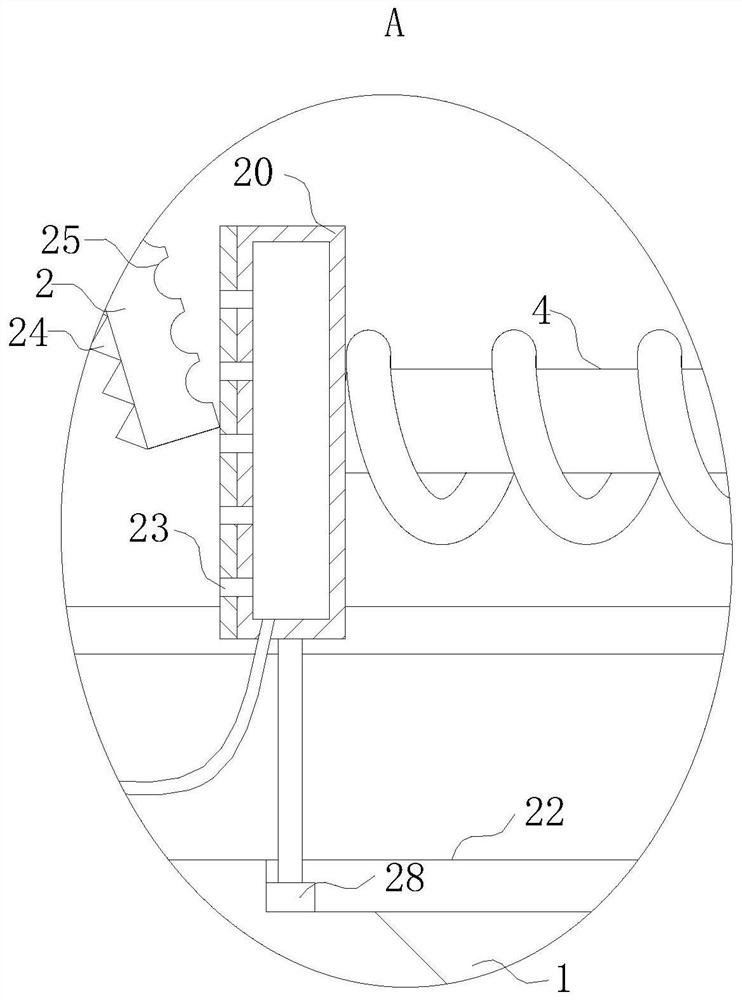

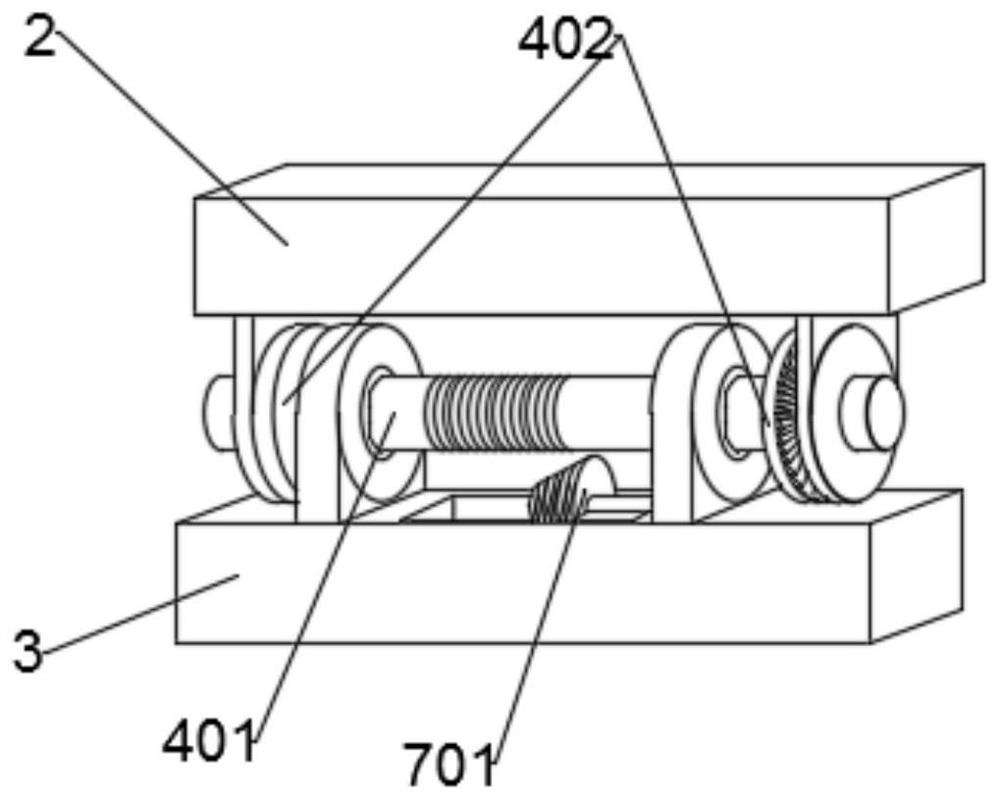

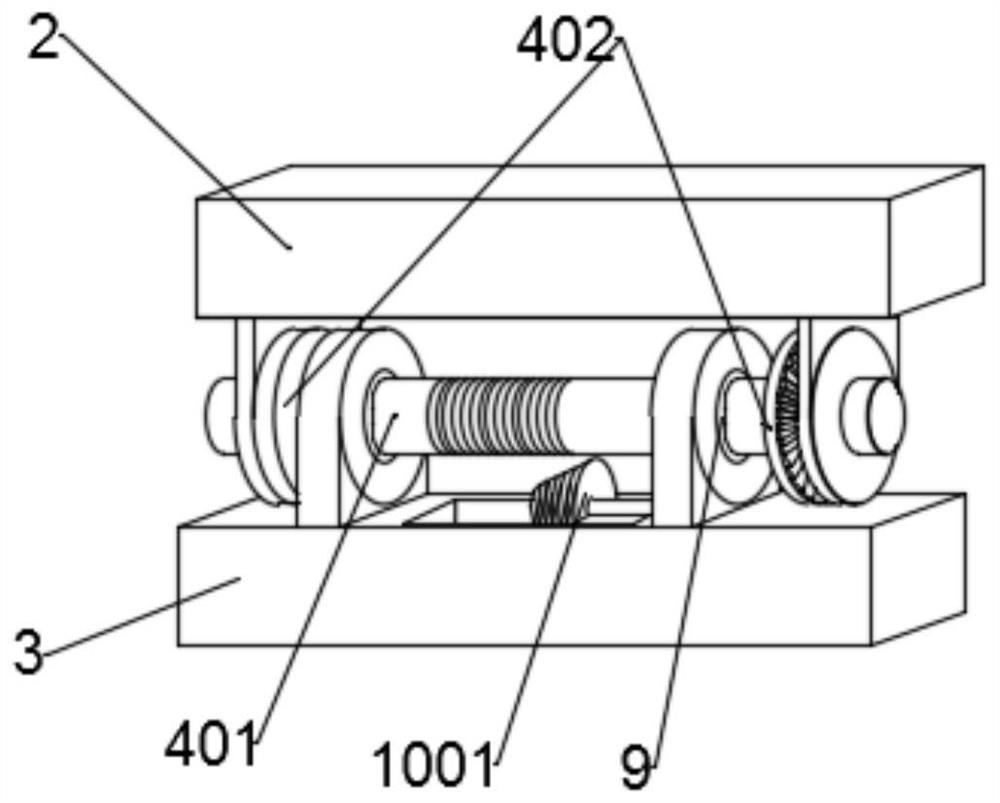

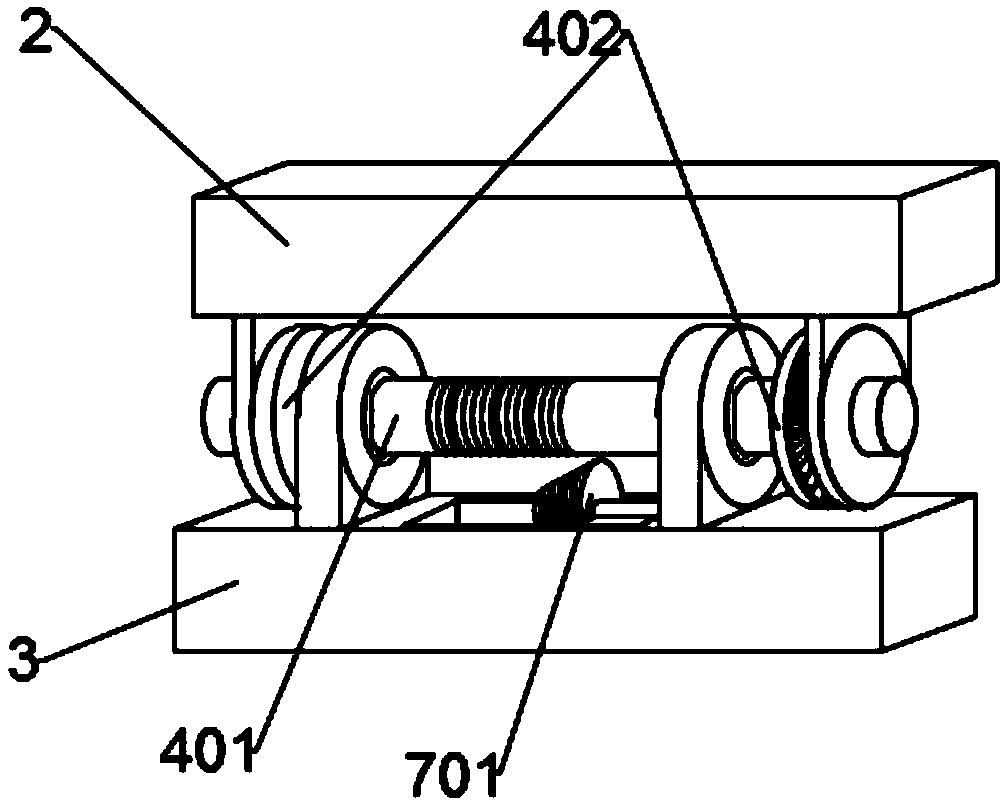

Wiring terminal

ActiveCN111628299AFirmly connectedStable current outputLine/current collector detailsConnections effected by permanent deformationSlide plateElectrical current

The invention belongs to the technical field of wiring terminals, and particularly relates to a wiring terminal which comprises a shell, an output rod, a lantern ring, a mounting pipe and a clamping device. The mounting pipe is arranged in a circular through hole in the center of the top of the shell; an annular sliding plate fixedly arranged at the outer edge of the mounting pipe is in sliding connection with an annular sliding groove in the inner wall of the circular through hole. A rectangular through hole is formed in the mounting pipe; a rectangular sliding groove is formed in the inner wall of the mounting pipe; the bottom of a rectangular sliding block is fixedly connected with the bottom of the rectangular sliding groove through a spring. A pin shaft is fixedly arranged on the rectangular sliding block; two output rods which are mutually symmetrical and crossed are movably arranged on the pin shaft through torsional springs; the two output rods are of semi-cylindrical structures respectively, and the curved surfaces of the two output rods deviate from each other. The top end of each output rod extends out of the top of the shell; and a handle is fixedly arranged at the edgeof the output rod and located above the lantern ring. Connection between the cable and the output rods is quite firm, current output is more stable, and meanwhile a cable insulating sleeve can be cut.

Owner:北京北科集源电子科技有限公司

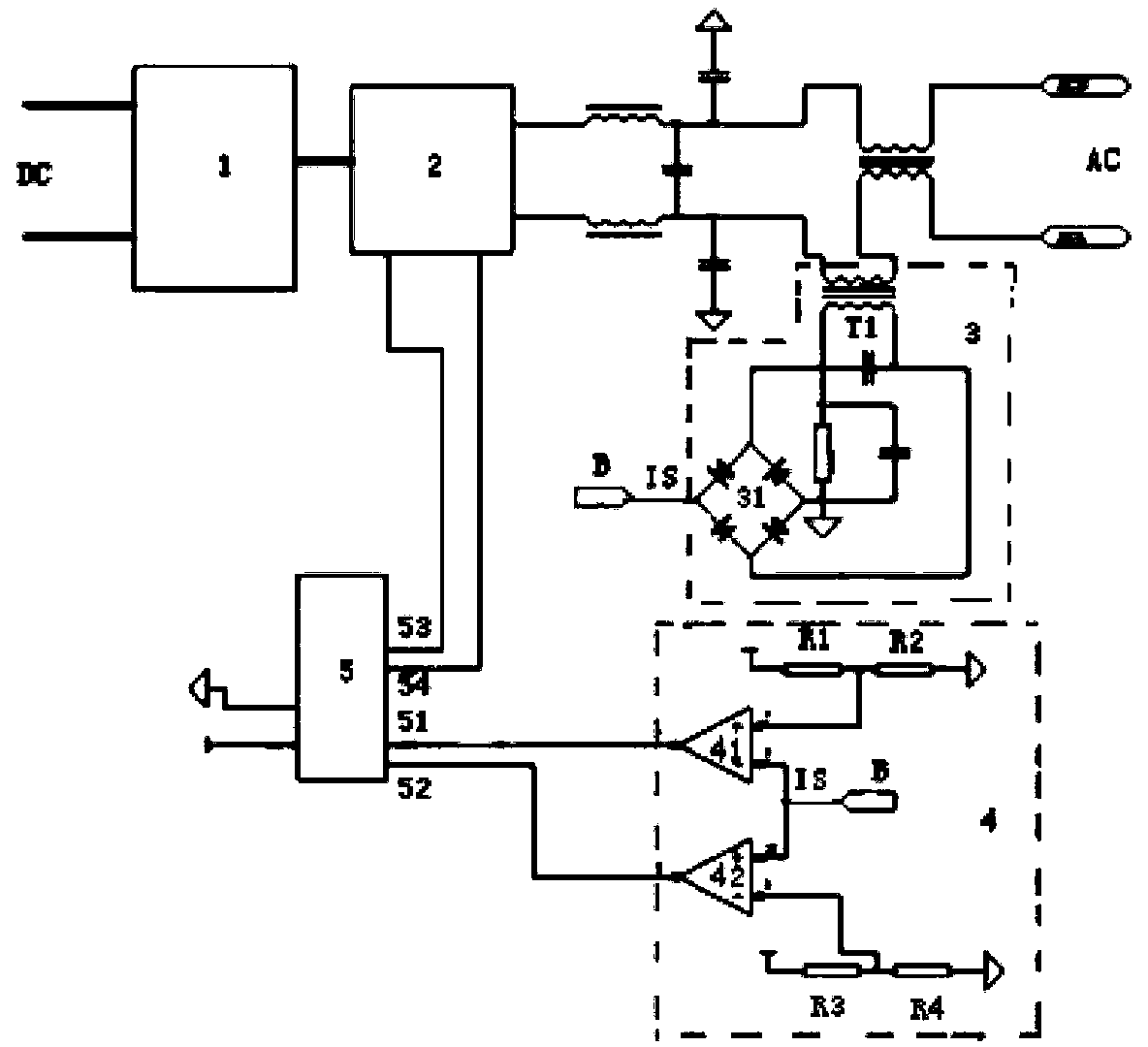

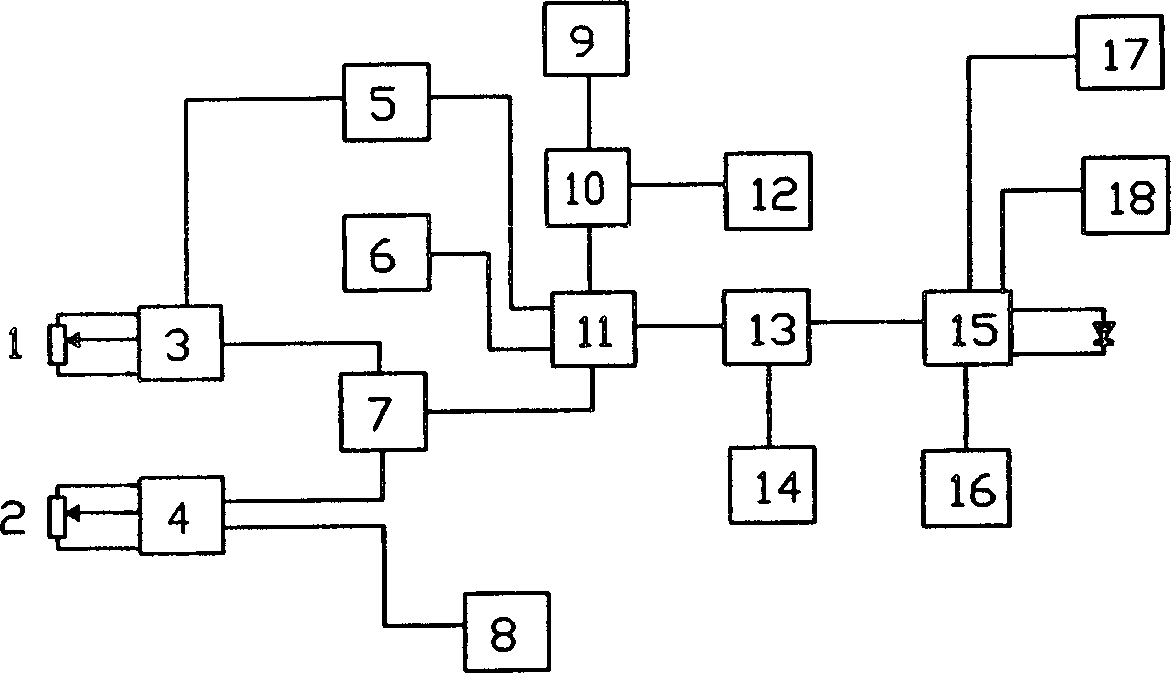

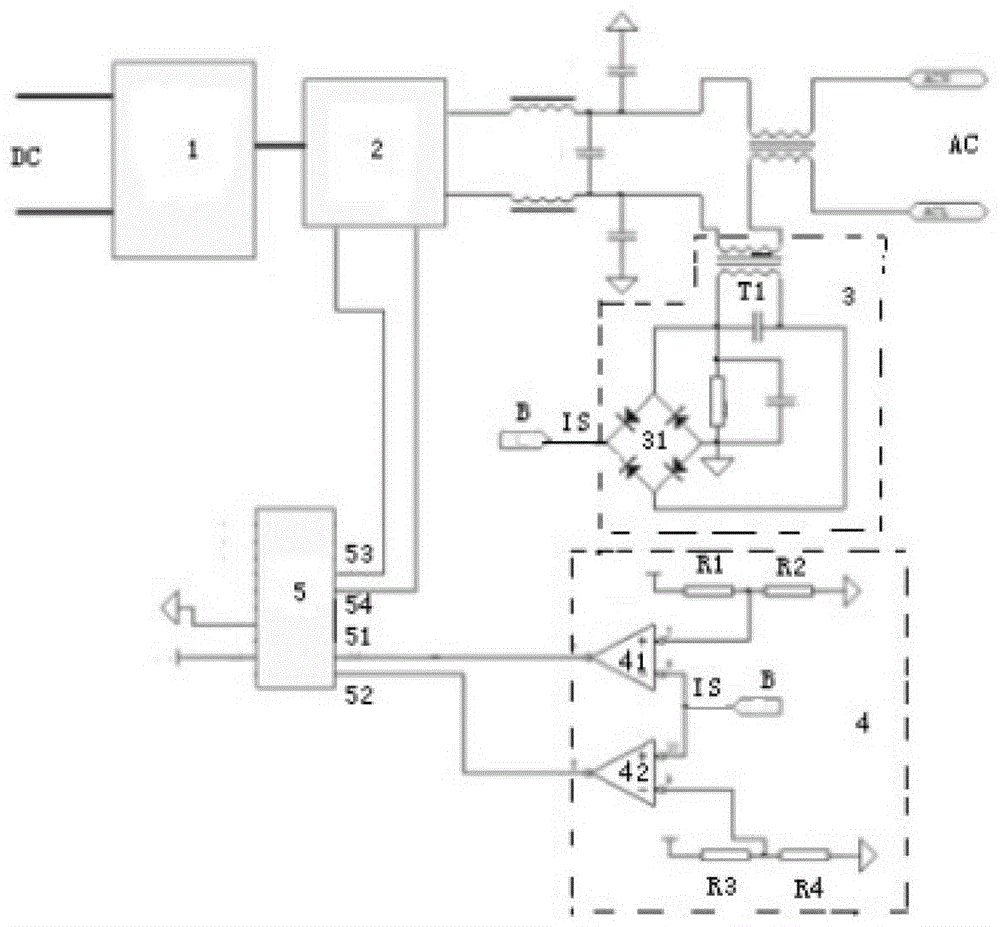

Constant-current current-limiting inverter

ActiveCN104242703AOptimal control methodConditions that affect the ability to startEmergency protective circuit arrangementsDc-ac conversion without reversalCurrent limitingComputer module

The invention discloses a constant-current current-limiting inverter. The constant-current current-limiting inverter comprises a voltage booster, an H-bridge circuit, a sampling module, a comparison module and an MCU. The voltage booster is used for increasing the voltage of direct current. The H-bridge circuit is provided with a rectifier filter device and used for converting the direct current output by the voltage booster into alternating current. The sampling module is used for conducting current sampling on the alternating current output by the H-bridge circuit and rectifying the alternating current into a voltage value signal IS which corresponds to voltage of the output end of the H-bridge circuit and is constant in direction. A maximum threshold value and a minimum threshold value are set for the comparison module, and the comparison module judges whether the voltage output by the H-bridge circuit is between the maximum threshold value and the minimum threshold value according to the voltage value signal IS. The MCU controls the H-bridge circuit to be on or off according to output of the comparison module. The constant-current current-limiting inverter has the advantages that the situation that starting power of the H-bridge circuit is affected due to changes in performance of short-circuit protection and overload protection is avoided, the structure is simple, the cost is low, the development cycle is short, the current output is stable, and the constant-current current-limiting inverter can be applied to high-power electrical appliances.

Owner:NEW FOCUS LIGHTING & POWER TECH

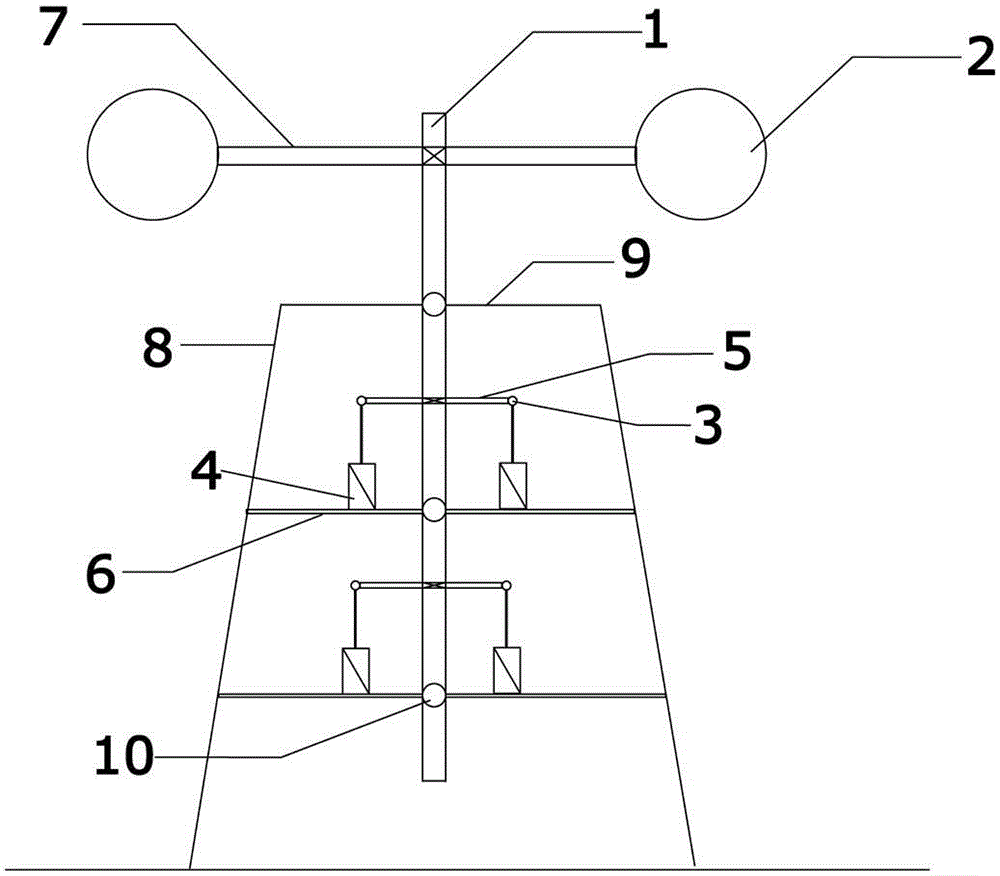

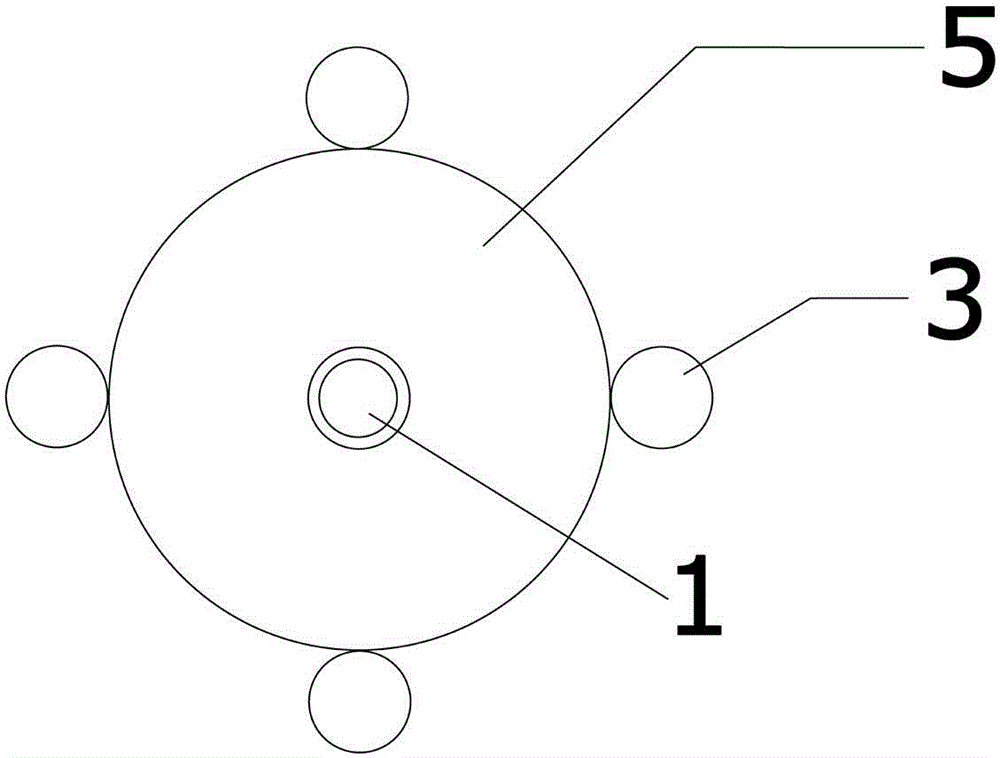

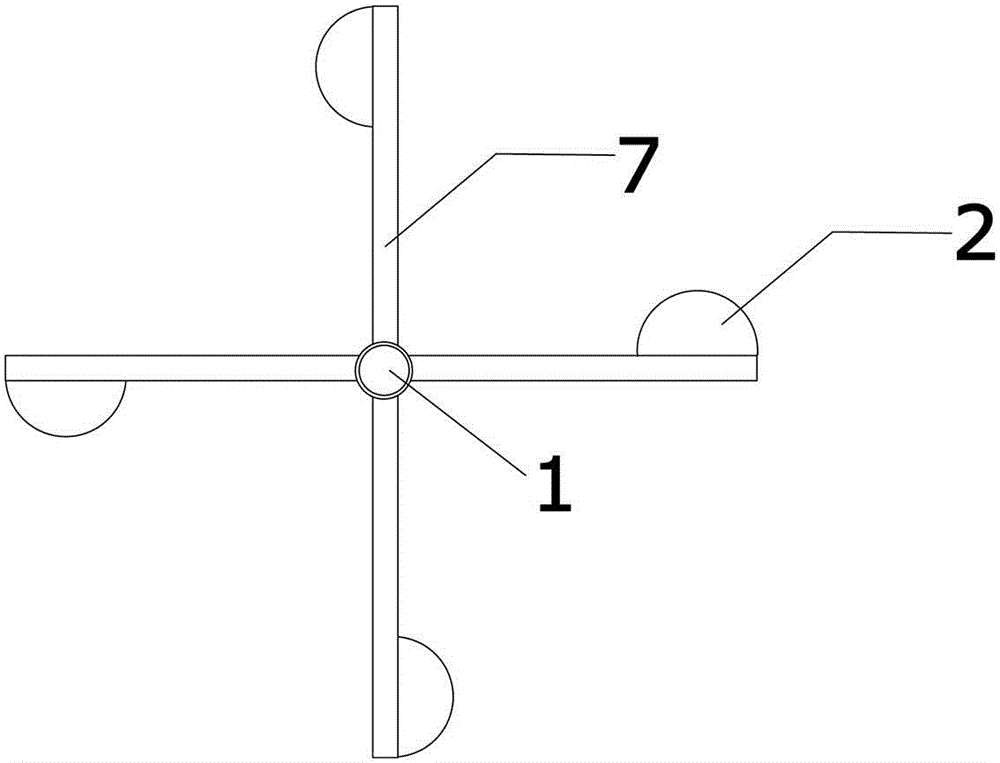

Parallel type wind driven generator device

InactiveCN105179172AReduce wear rateImprove power generation efficiencySingle network parallel feeding arrangementsMachines/enginesWind drivenMechanical energy

The invention discloses a parallel type wind driven generator device. The parallel type wind driven generator device comprises a fan blade, a central shaft and a power generator which are arranged in parallel, and further comprises a first bracket for supporting the central shaft and a second bracket for supporting the power generator, wherein the fan blade is connected with the central shaft through a fan blade connecting rod; while rotating around the central shaft, the fan blade drives the central shaft to rotate together; a fixed drive gear is mounted on the central shaft; a driven gear is mounted on the power generator; the drive gear and the driven gear are arranged tangentially; the driven gear can rotate along with the rotation of the drive gear, so that mechanical energy is input to the power generator connected with the driven gear. The wind driven generator device disclosed by the invention is not affected by wind direction change, and capable of realizing stable and uninterrupted current output. Meanwhile, compared with current similar devices, the device is obviously improved in integral stability, obviously improved in power generating efficiency, and has prominent advantages.

Owner:郝克强

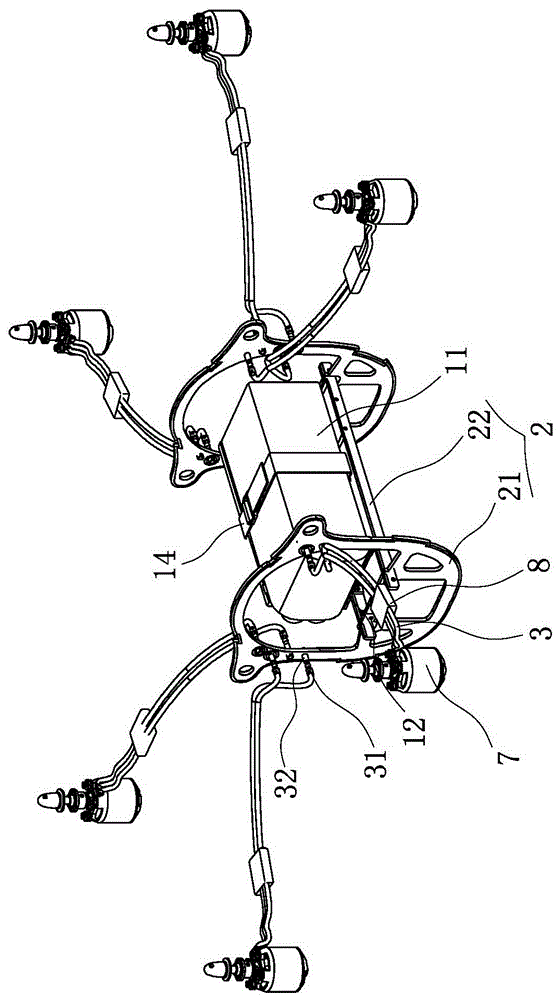

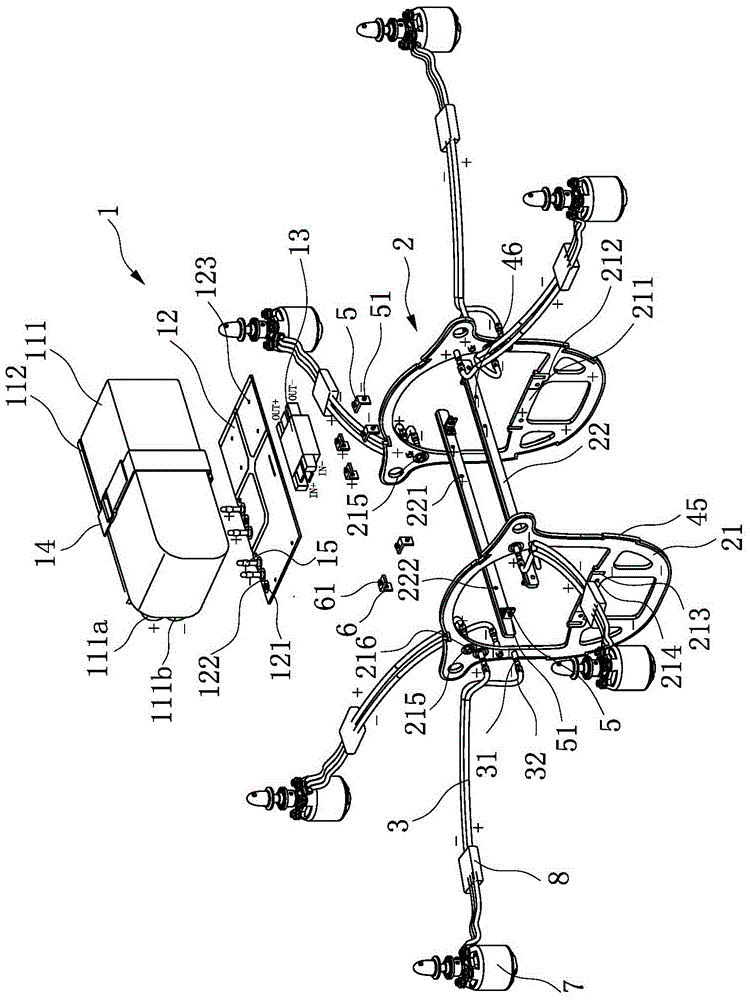

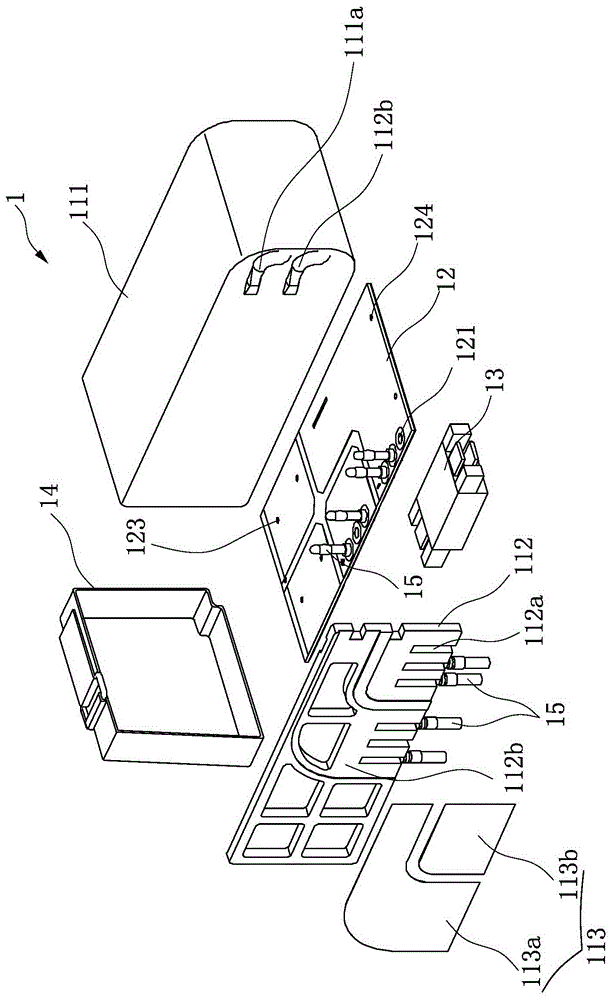

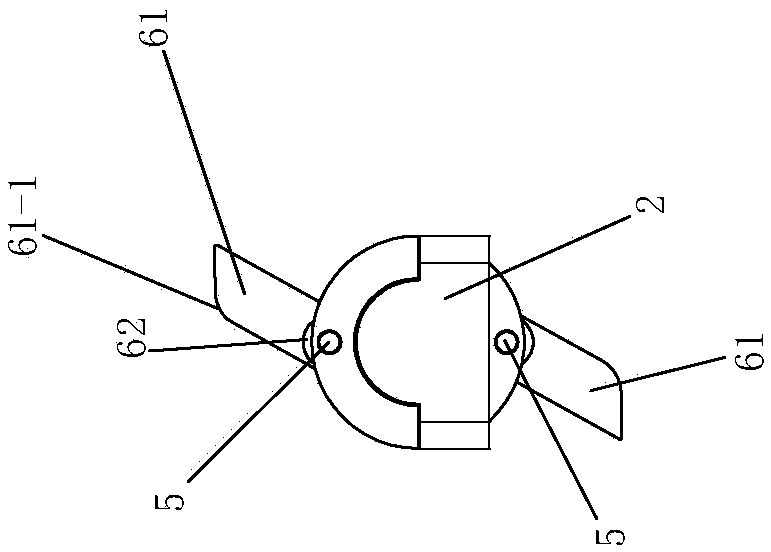

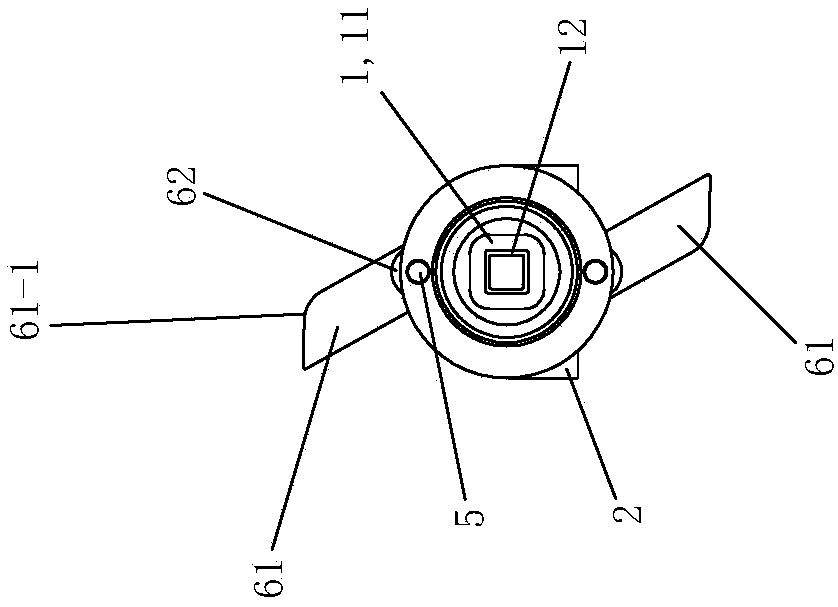

Fuselage conductive structure of unmanned aerial vehicle and manufacturing method of fuselage frames

ActiveCN106516073AEasy to replaceStable current outputFuselage framesWeight reductionEngineeringMechanical construction

The invention discloses a fuselage conductive structure of an unmanned aerial vehicle and a manufacturing method of fuselage frames, the fuselage conductive structure comprises a battery pack, a fuselage assembly and blade motor power supply wires; the battery pack includes a lithium battery pack body and a power supply circuit board, the fuselage assembly includes two fuselage frames and two fuselage cross beams, the fuselage frames and the fuselage cross beams are respectively prepared from a thickening-type double-sided copper clad plate which is double-sided printed with conductive layers, the fuselage frames are respectively arranged at trisection cross sections in a fuselage cabin, PI shaped supporting structures are formed on the fuselage frames, two ends of the fuselage cross beams are respectively fixed on the PI shaped supporting structures of the two fuselage frames, the two fuselage frames are also provided with banana jacks, and a plurality of groups of blade motor power supply wires are in plug connection with the power supply banana jacks of the fuselage frames. The fuselage conductive structure has the advantages of simple structure, light weight and compact structure, and solves the problems of a complex fuselage mechanical structure and many electrical circuits of a traditional multi-rotor unmanned aerial vehicle, the weight of the fuselage structure is reduced, meanwhile a stable large current output is realized, and time of endurance is improved.

Owner:XIAMEN HANHANG PRECISION TECH CO LTD

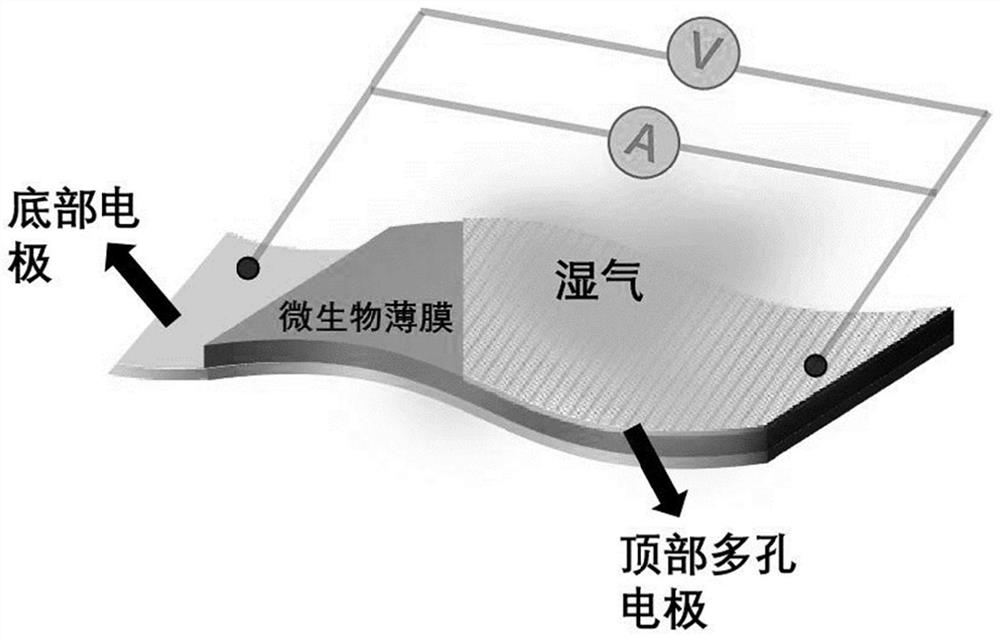

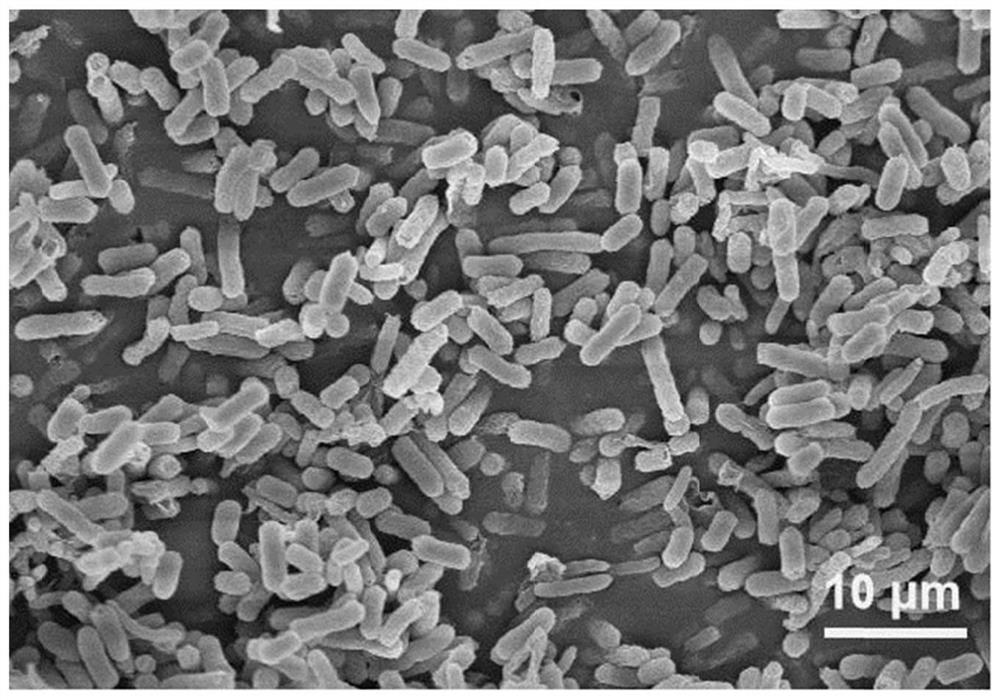

Flexible moisture power generation device and application thereof

PendingCN114350545AEasy accessThe preparation method is simple and quickBacteriaMicroorganism based processesChemistryElectrical and Electronics engineering

The invention discloses a flexible moisture power generation device and application thereof. The invention relates to a microbial film which is prepared by drying electroactive bacteria, the electroactive bacteria comprise escherichia coli. The flexible moisture power generation device comprises a microbial film, a bottom electrode and a top electrode, one side surface of the microbial film is in fit connection with the top electrode, and the other side surface of the microbial film is in fit connection with the bottom electrode. After escherichia coli forms a film, the surface is smooth, a large number of hydrophilic groups are contained in the film, the self-healing property is high, and the film can be used as an ideal moisture absorption material. The Escherichia coli microbial film can serve as a core component of a moisture power generation device, and compared with an existing core component of the moisture power generation device, the Escherichia coli microbial film is simpler in preparation process, lower in cost and higher in power generation efficiency.

Owner:FUJIAN AGRI & FORESTRY UNIV

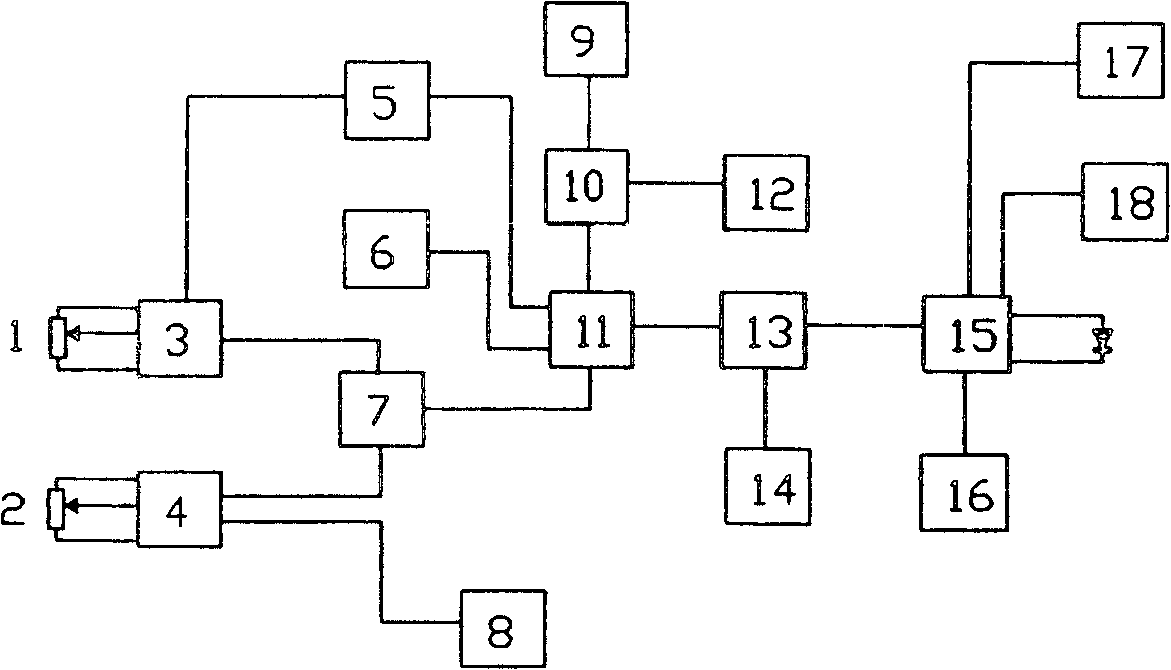

Actuator power-supply for driving laser diode

InactiveCN1897373AImprove machine efficiencyPrevent overcurrentLaser detailsSemiconductor lasersAudio power amplifierPower factor

A switch power for driving laser light emitting diode, including: the adjusting operating current multi-circle potentiometer and the operating current amplifier that connect with each other, the setting most current multi-circle potentiometer and the setting current amplifier that connect with each other, the operating current amplifier and the setting current amplifier connect with the current value comparison selecting gate, the output of the current value comparison selecting gate connects with the outputting current controller, the outputting current controller connects with the laser by the big current power module. The invention is: high stability power, settable most operating current, forcible zero startup function, high power factor and high power efficiency.

Owner:GUANGZHOU IND DEV GRP

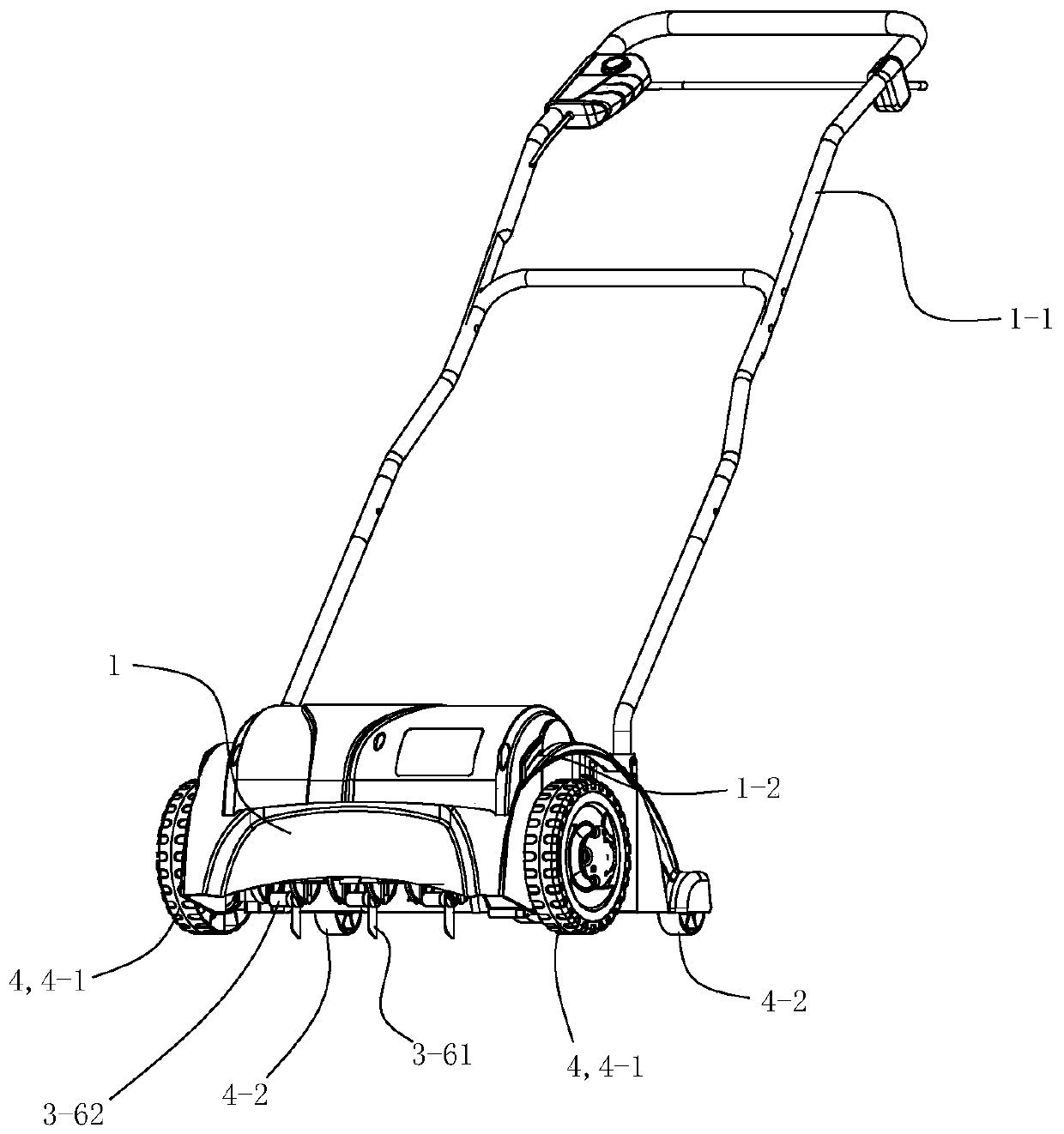

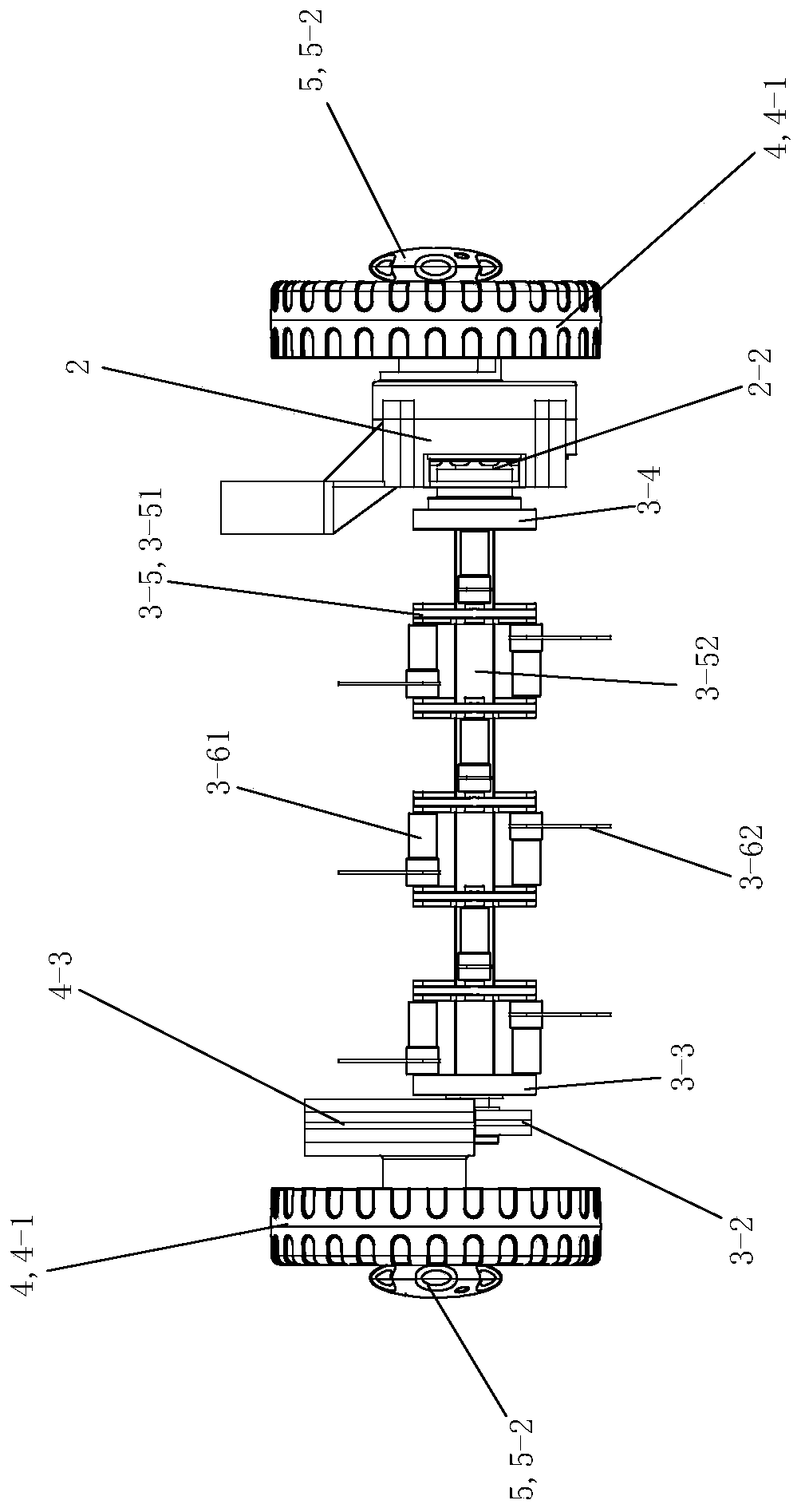

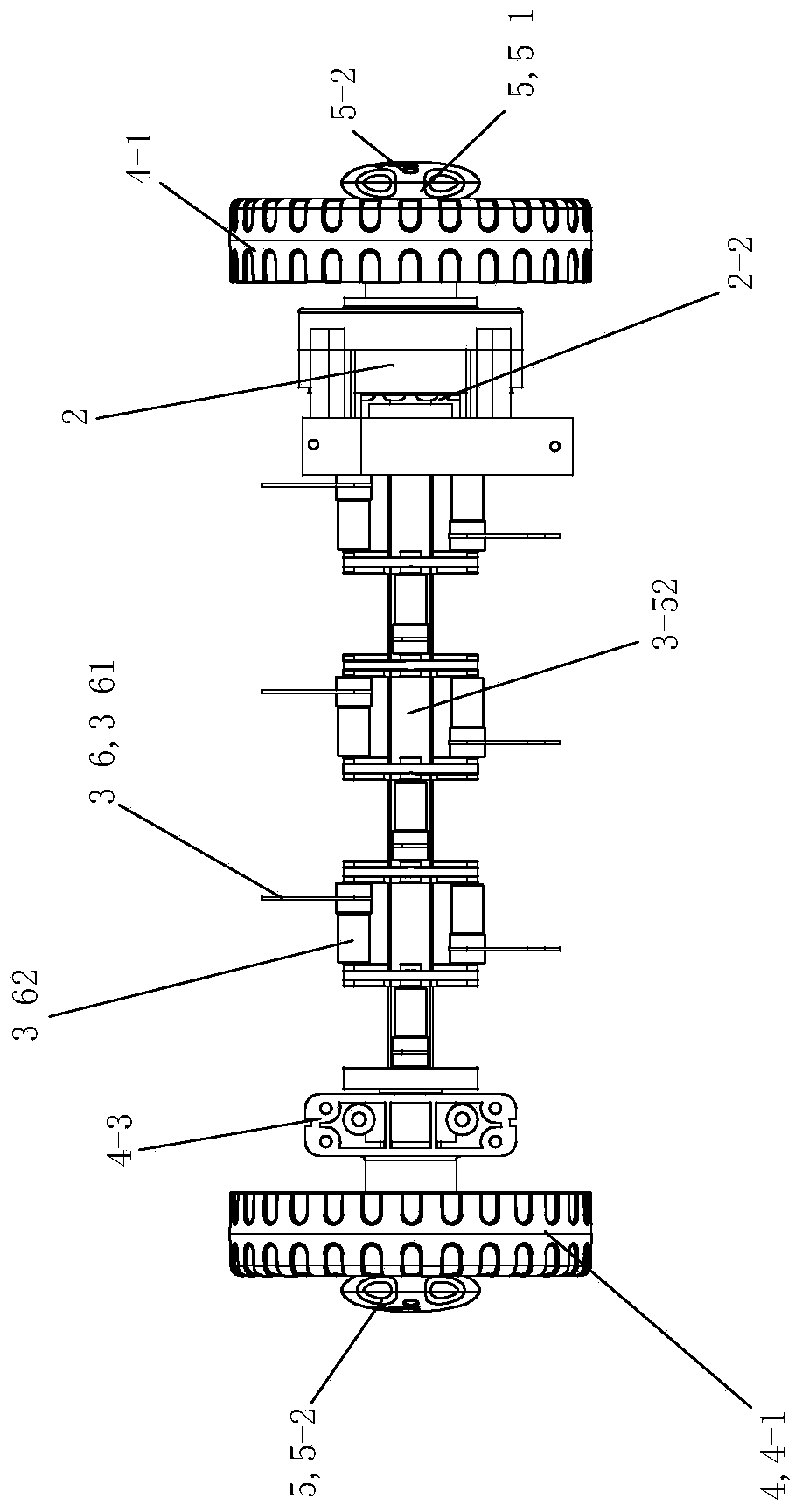

Cutter for lawn ventilator

The invention discloses a cutter for a lawn ventilator. The main points of the cutter provided by the invention are as follows: the cutter comprises a rotating shaft, a hitching leg support, mountingdisks, supporting disks, cutter shafts and blade assemblies; the left end of a short axis of the rotating shaft is rotatably arranged in the hitching leg support through a corresponding bearing; two mounting disks are respectively and fixedly arranged at the left and right ends of a square-tube long axis of the rotating shaft; the supporting disks are arranged on the square-tube long axis of the rotating shaft in a uniformly-spaced manner from left to right; the cutter shafts are arranged on the mounting disks and the supporting disks; each blade assembly comprises a blade and a connecting sleeve; each blade is fixedly embedded on a connecting sleeve; blades are rotatably arranged on the cutter shafts through connecting sleeves; and the blades are spirally arranged in the axial direction of the square-tube long axis of the rotating shaft.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

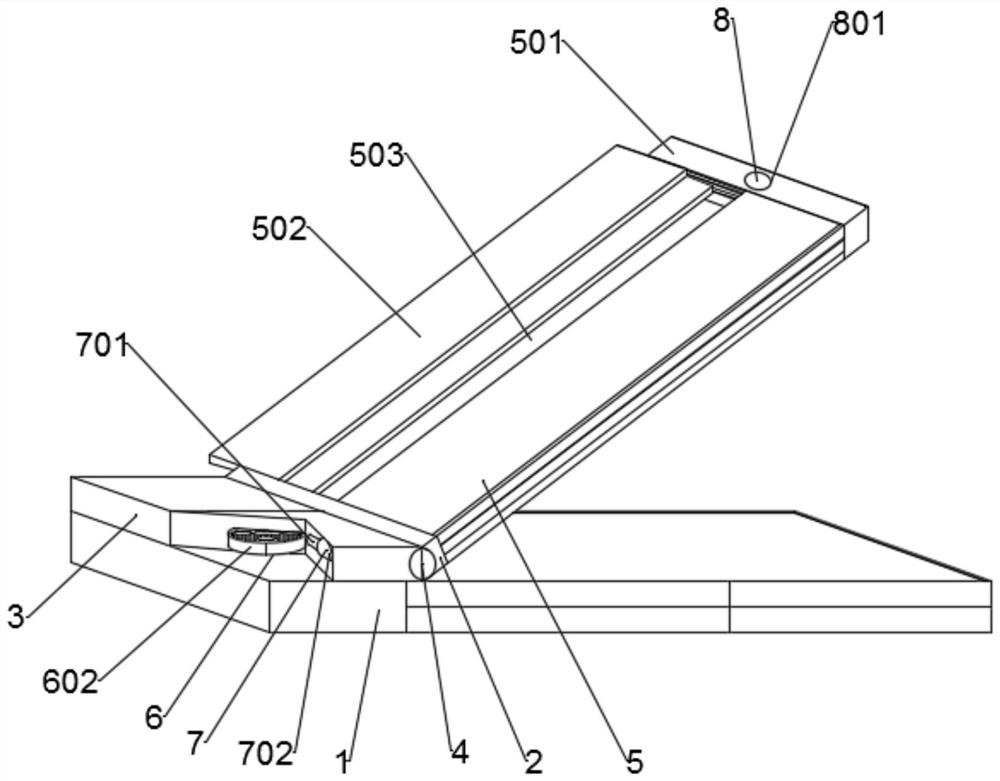

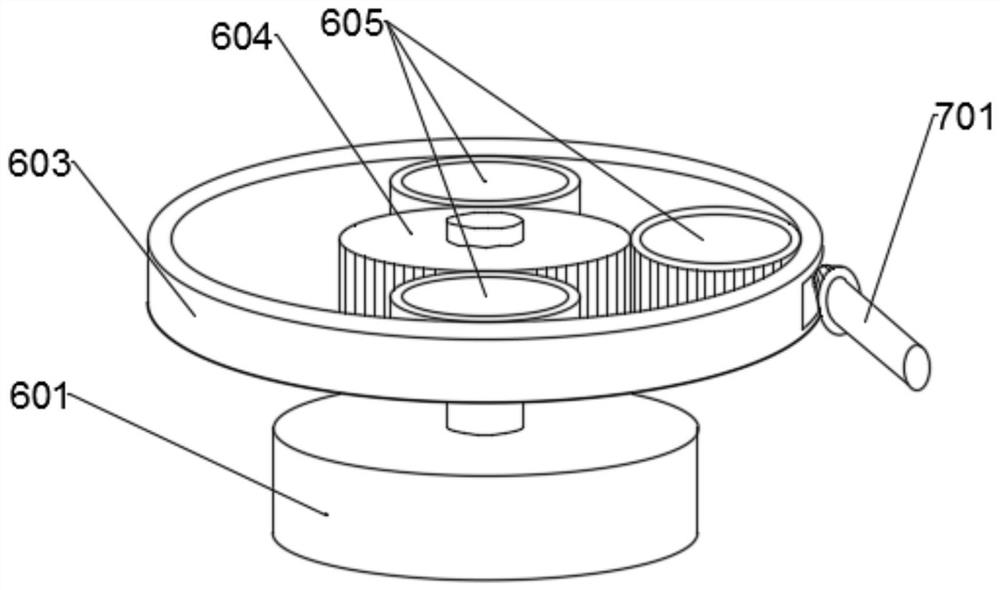

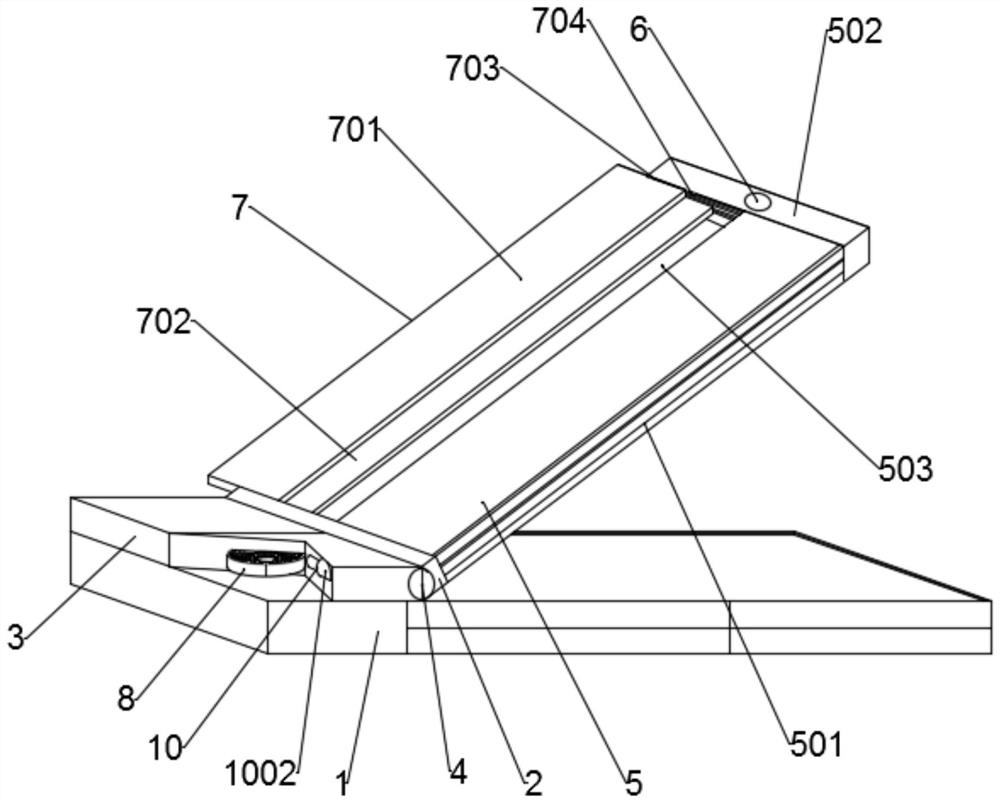

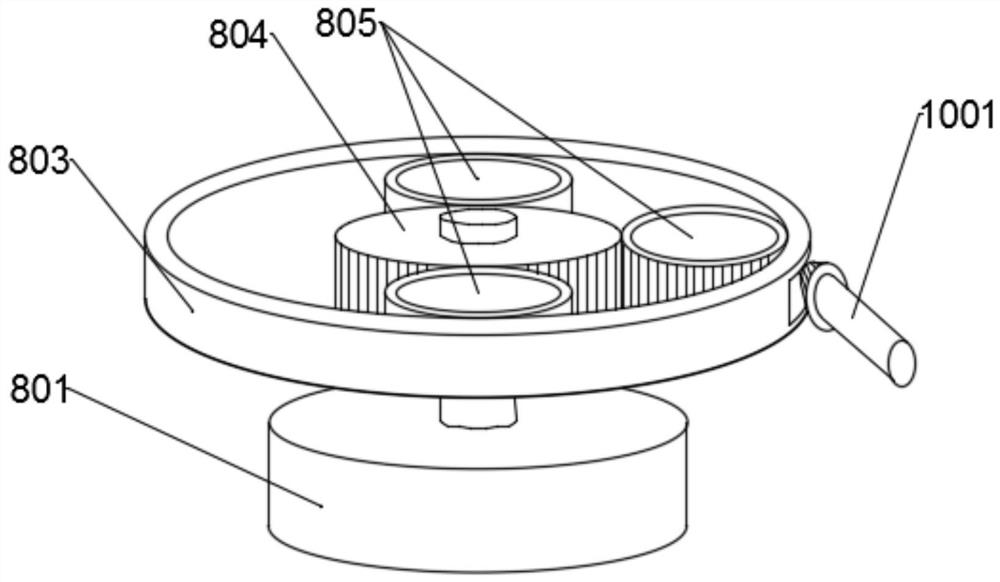

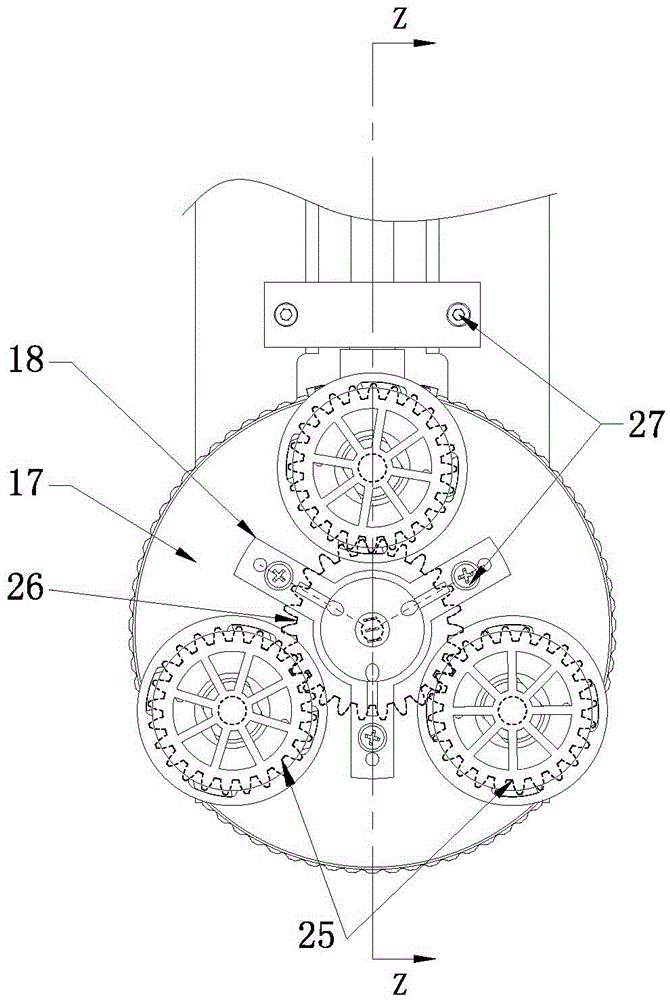

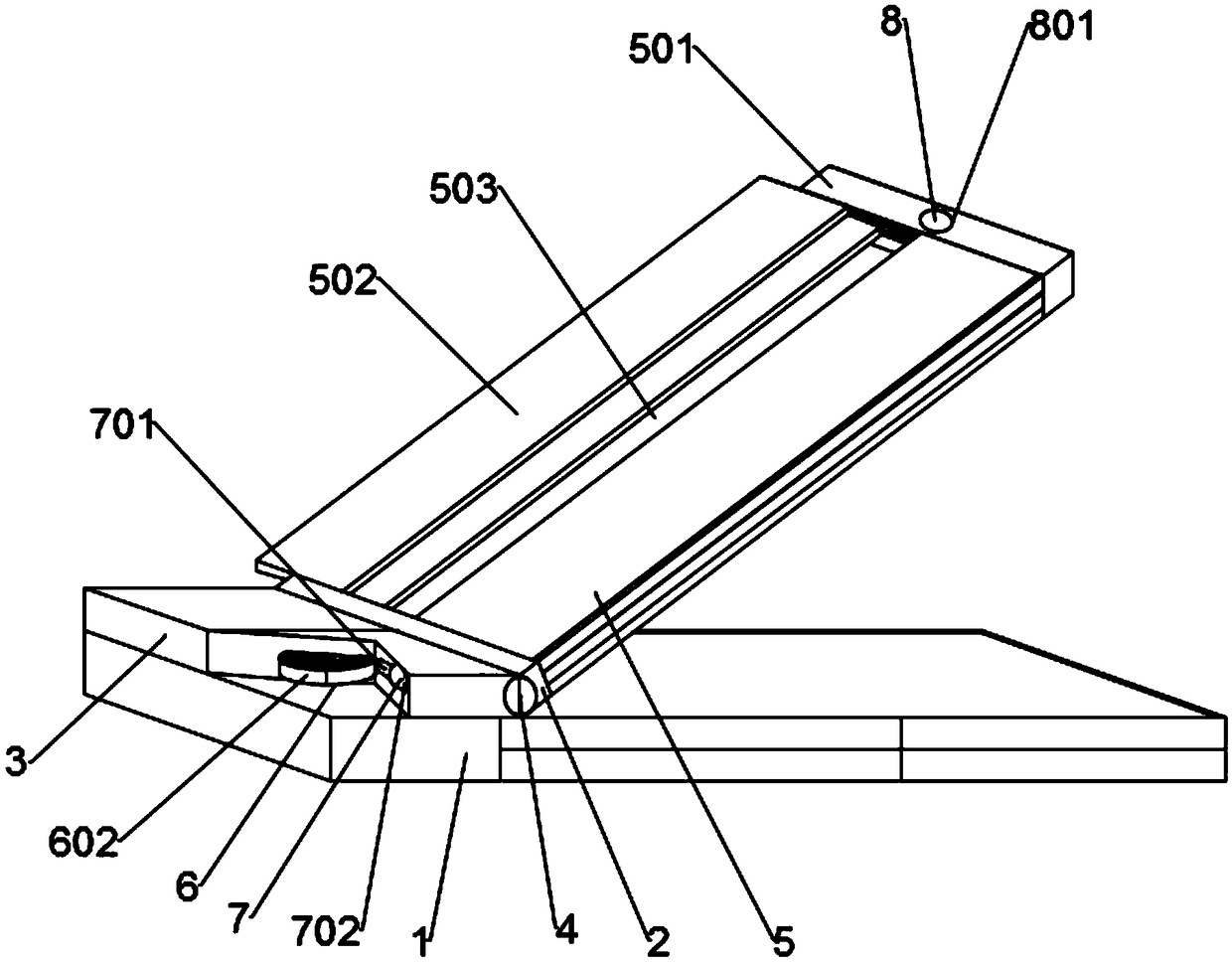

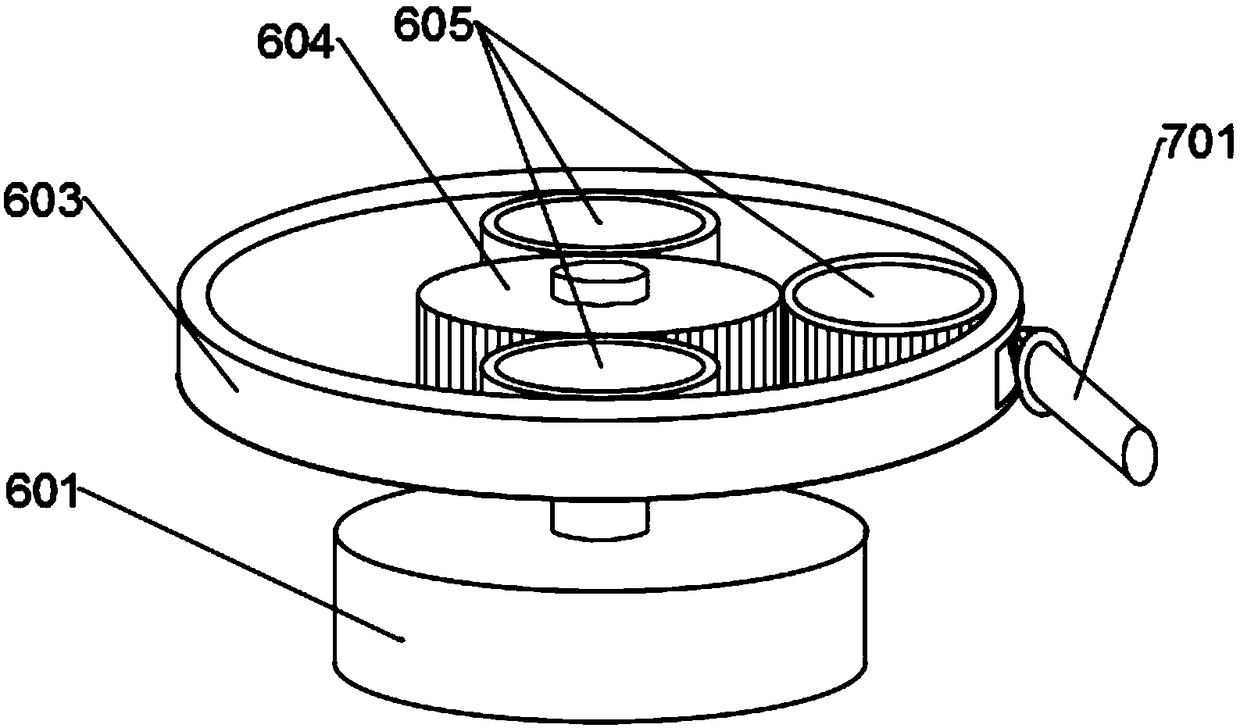

A portable solar charging treasure with ray tracing and its charging method

ActiveCN109193898BIncrease the receiving areaAvoid fixed receiving surfacesPhotovoltaic supportsElectric powerElectric machineryDrive motor

The invention discloses a portable solar charging treasure with ray tracing. There is a corner device in the middle of the contact surface between the plate and the battery bottom plate. The corner device includes a micro-drive motor installed in the battery bottom plate. The motor shaft of the micro-drive motor is connected to a reducer. Rack ring, the center of the double-sided rack ring is provided with a sun gear connected to the output shaft of the micro drive motor, and there are three star gears evenly meshed between the sun gear and the double-sided rack ring, the double-sided rack ring and the hinge shaft There is a clutch wheel device between them, and a ray tracing device is installed on the top of the battery panel assembly, which realizes the structure of the solar power bank is simple and portable, and at the same time can provide stable power output and improve the charging efficiency of the solar power bank.

Owner:韶关市诚湃新能源科技有限公司

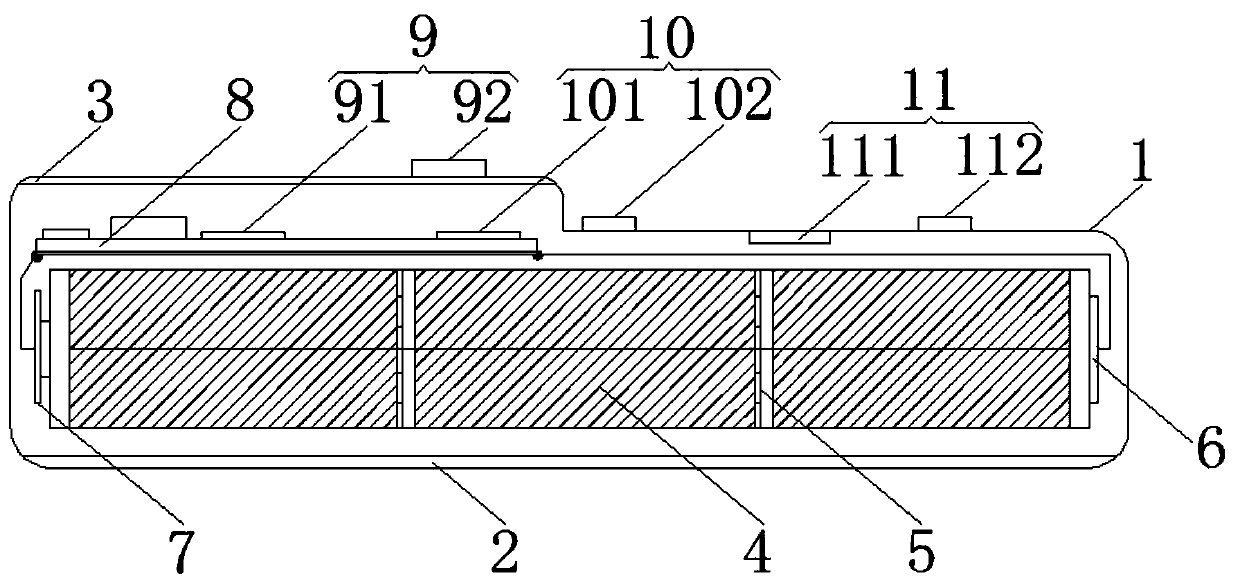

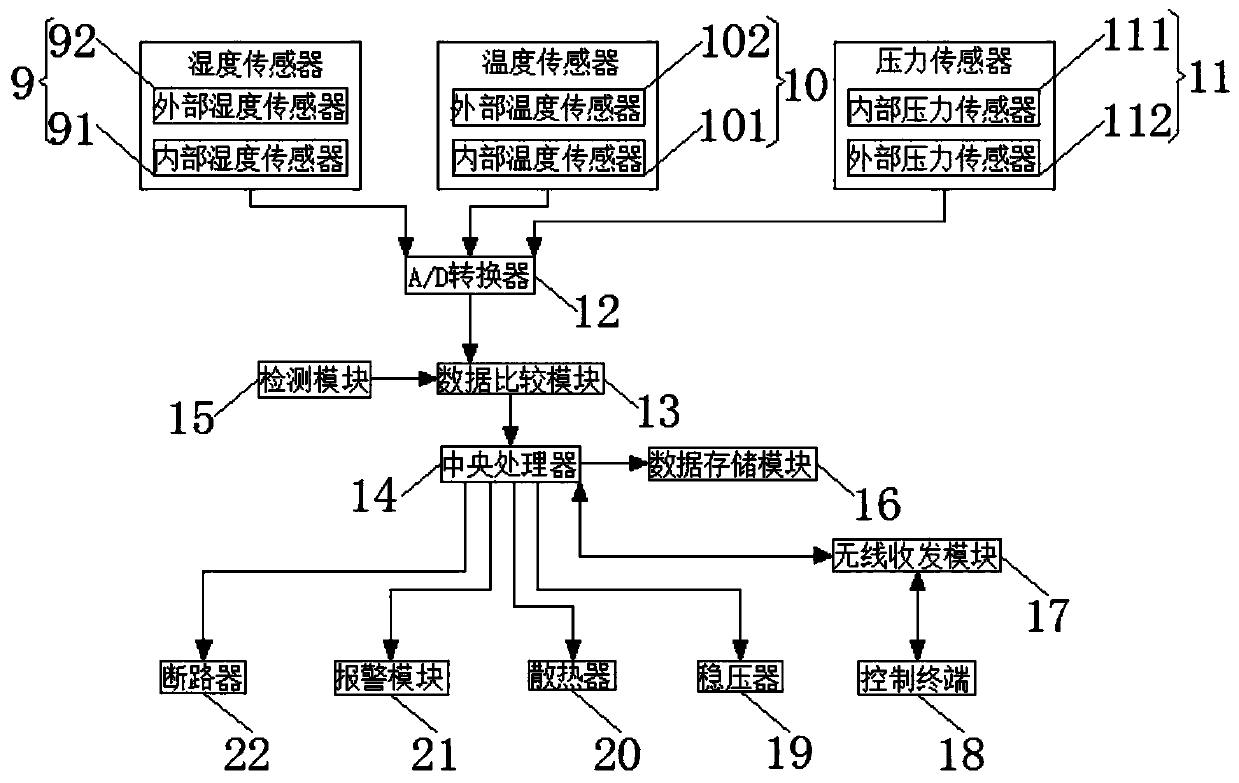

An intelligent computer storage power supply

ActiveCN106648006BImprove buffering effectAvoid using effectsVolume/mass flow measurementPower supply for data processingElectrical batteryEngineering

The invention discloses an intelligent computer storage power source, and relates to the technical field of computer accessories. The intelligent computer storage power source comprises a battery box, a lower protection edge is fixedly installed at the bottom of the inner cavity of the battery box, an upper protection edge is fixedly installed at the top of the inner cavity of the battery box, a battery pack is fixedly installed in the inner cavity of the battery box, a series connection chip located in the inner cavity of the battery box is fixedly installed at the inner side of the battery pack, a negative pole contact chip located in the inner cavity of the battery box is fixedly installed at the right side of the battery pack, a positive pole contact chip located in the inner cavity of the battery box is fixedly installed at the left side of the battery pack, and a mainboard located in the inner cavity of the battery box is fixedly installed above the battery pack. According to the intelligent computer storage power source, the unstable voltage and received overlarge pressure, temperature and humidity of the storage power source can be effectively prevented, the service life of the storage power source is prolonged, and the using safety of the storage power source is enhanced.

Owner:XINXIANG UNIV

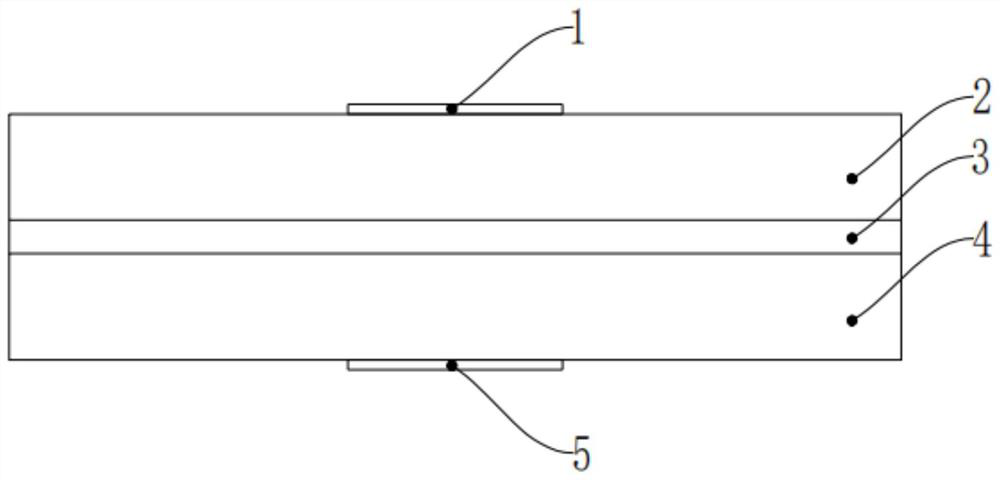

Environment-friendly geopolymer battery and preparation method thereof

ActiveCN112652782BGood compatibilityClosely connectedCell electrodesDry cellsElectrical batteryGeopolymer

The invention discloses an environment-friendly geopolymer battery, which comprises a first metal patch, a positive electrode layer, an electrolyte layer, a negative electrode layer and a second metal patch from top to bottom; The raw materials include 40 to 50 parts of geopolymer powder, 20 to 30 parts of potassium base activator, 15 to 25 parts of manganese dioxide powder and 2 to 3 parts of graphite powder; the raw materials of the electrolyte layer include 4 to 5 parts of earth polymer powder and 4-5 parts of potassium-based base activator; the raw materials of the negative electrode layer include 40-50 parts of geopolymer powder, 20-30 parts of potassium-based base activator and 10-20 parts of zinc powder. The environmentally friendly geopolymer battery proposed in the technical solution has a stable current output, can effectively improve the metal utilization rate of the battery and reduce its recycling cost, and has little impact on the environment. Furthermore, a method for preparing the above-mentioned environment-friendly geopolymer battery is proposed, which has a simple process and strong operability, and is beneficial to ensure the stable current output of the geopolymer battery.

Owner:广东至道先进土木工程材料技术研究有限公司

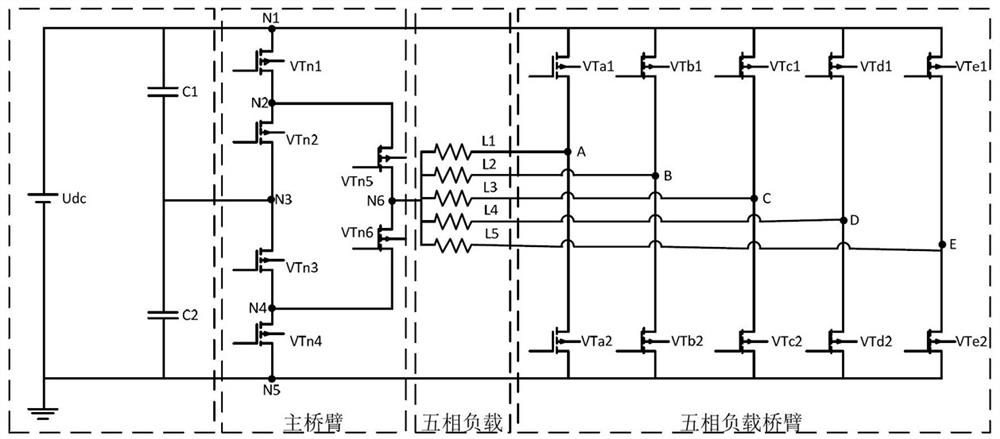

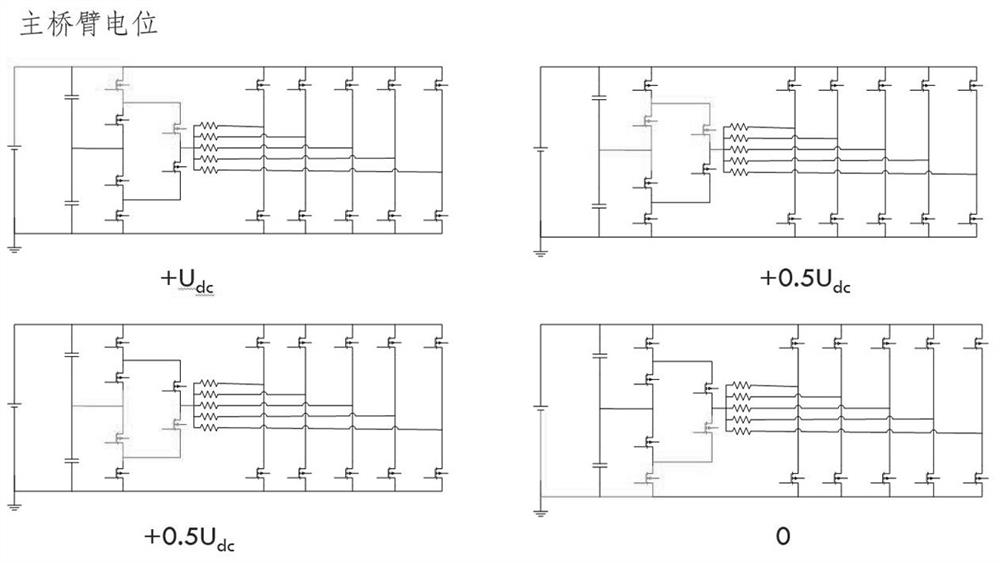

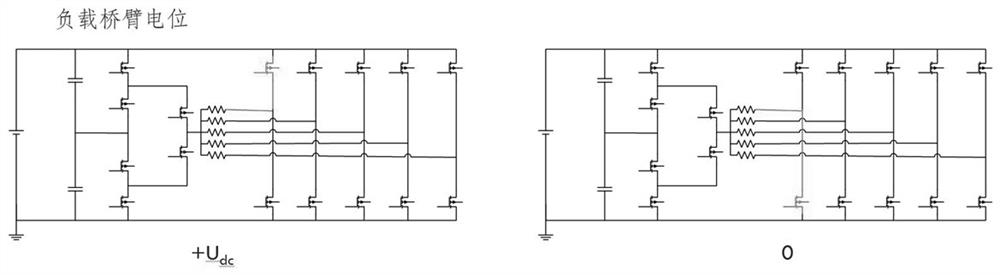

Five-level multi-bridge-arm switching power amplifier circuit

PendingCN112491375AStable current outputStrong current stiffnessPower amplifiersAc-dc conversionHemt circuitsSwitching power

The invention provides a five-level multi-bridge-arm switching power amplifier circuit which is composed of an active midpoint clamping power supply, a main bridge arm, a five-phase load and a load bridge arm, wherein the active midpoint clamping power supply, the main bridge arm, the five-phase load and the load bridge arm are electrically connected together in sequence. Through the design of thecircuit topology, the circuit can provide five levels, two of the five levels are forward half-voltage conduction and reverse half-voltage conduction, so that output waveform ripples are smaller whenthe power amplifier tracks more stable signals, and the power amplifier can be used in a magnetic suspension bearing.

Owner:NANJING UNIV OF POSTS & TELECOMM

A Constant Current Limiting Inverter

ActiveCN104242703BOptimal control methodConditions that affect the ability to startAc-dc conversionEmergency protective circuit arrangementsCurrent limitingComputer module

The invention discloses a constant-current current-limiting inverter. The constant-current current-limiting inverter comprises a voltage booster, an H-bridge circuit, a sampling module, a comparison module and an MCU. The voltage booster is used for increasing the voltage of direct current. The H-bridge circuit is provided with a rectifier filter device and used for converting the direct current output by the voltage booster into alternating current. The sampling module is used for conducting current sampling on the alternating current output by the H-bridge circuit and rectifying the alternating current into a voltage value signal IS which corresponds to voltage of the output end of the H-bridge circuit and is constant in direction. A maximum threshold value and a minimum threshold value are set for the comparison module, and the comparison module judges whether the voltage output by the H-bridge circuit is between the maximum threshold value and the minimum threshold value according to the voltage value signal IS. The MCU controls the H-bridge circuit to be on or off according to output of the comparison module. The constant-current current-limiting inverter has the advantages that the situation that starting power of the H-bridge circuit is affected due to changes in performance of short-circuit protection and overload protection is avoided, the structure is simple, the cost is low, the development cycle is short, the current output is stable, and the constant-current current-limiting inverter can be applied to high-power electrical appliances.

Owner:NEW FOCUS LIGHTING & POWER TECH

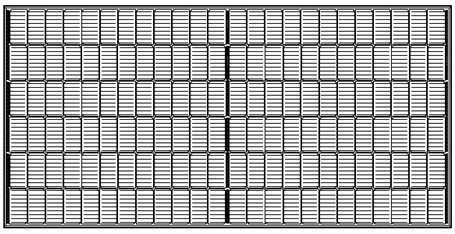

A portable solar charging treasure with multiple folding surfaces and its charging method

ActiveCN109245699BImprove unityIncrease the receiving areaPhotovoltaic supportsSolar heating energyElectrical batterySolar battery

The invention discloses a portable solar power charging treasure with multiple folding surfaces, which comprises a battery bottom plate, on which a solar battery panel is arranged, the solar battery panel includes a supporting rotating plate, and the supporting rotating plate is connected with a battery panel assembly through a hinge shaft, and the battery The top of the board assembly is provided with a ray tracing device. The battery board assembly includes a main body and a rail baffle set on the top of the main body. There are two push-pull battery board groups symmetrically arranged on the main body, and the main body surface of the push-pull battery board group An integrated battery board is provided, and the push-pull battery board group includes a first battery board and a second battery board, and translation components are provided on the sides of the first battery board and the second battery board, relative to the first battery board and the second battery board of the translation assembly There is a U-shaped groove on the second battery board, and a concentrator is hinged on one side of the first battery board along the length direction, which realizes the simple and portable structure of the solar power bank, and at the same time can provide stable power output and improve the performance of the solar power bank. Charging efficiency.

Owner:ZHONGSHAN PINNENG BATTERY CO LTD

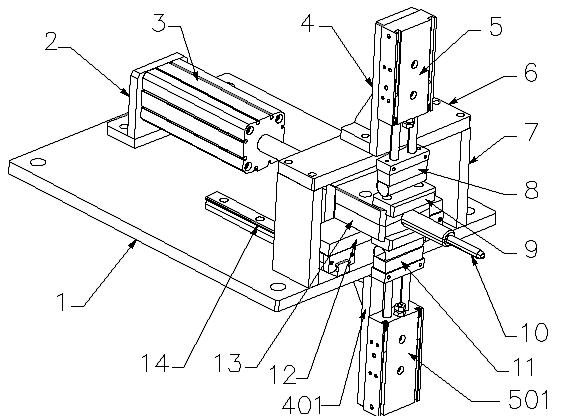

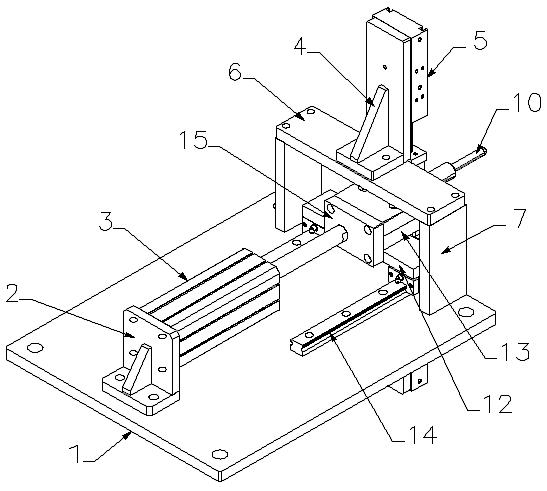

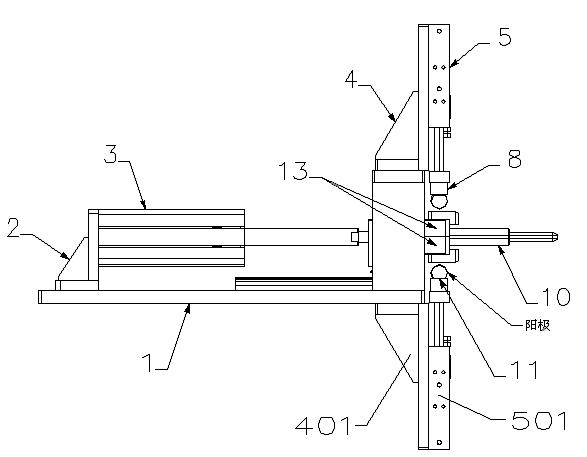

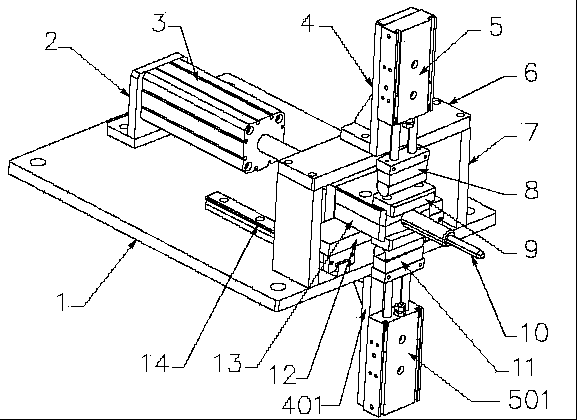

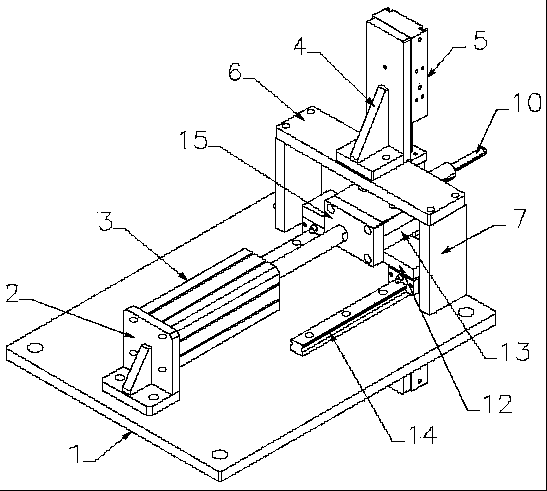

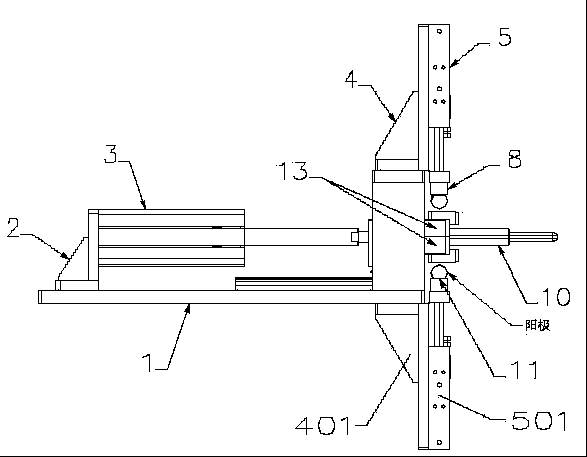

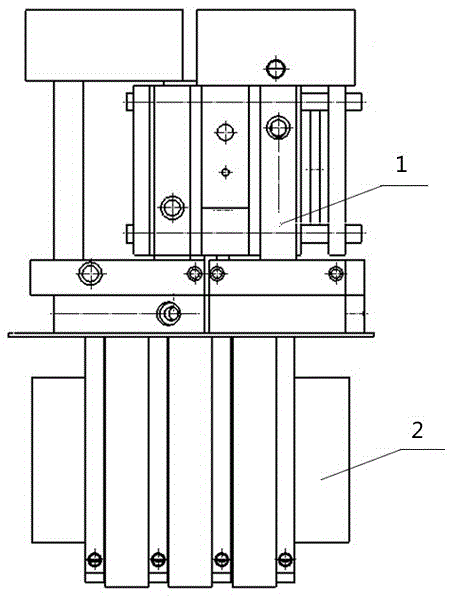

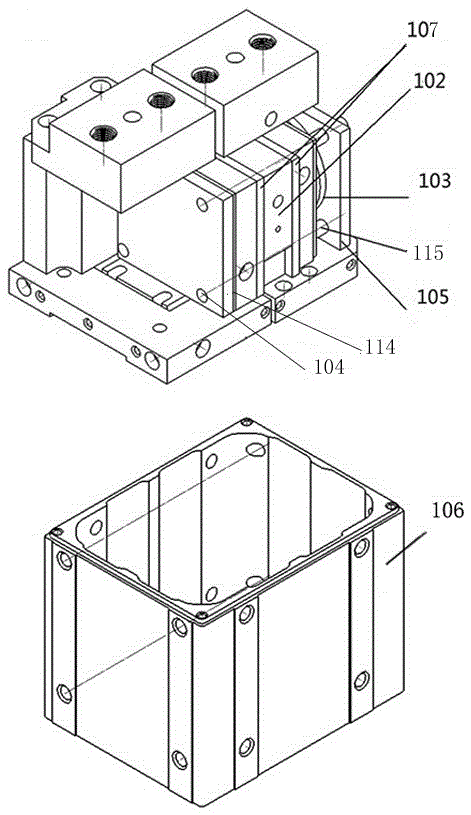

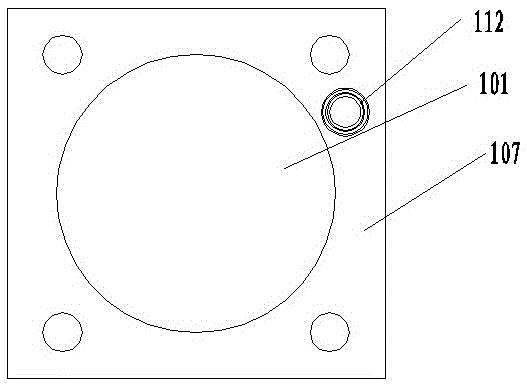

High frequency current commutation device for medical bag production

The invention discloses a high frequency current commutation device for medical bag production. The device comprises a bottom plate that is connected to two side plates, over which a mounting plate is fixed. The mounting plate is in connection with a first support, where a first double-rod cylinder is fixed. And the lower part of the first double-rod cylinder is connected to a first electrode. The bottom of the bottom plate is in connection with a second support, where a second double-rod cylinder is fixed. And the second double-rod cylinder is in connection with a second electrode. The bottom plate is provided with two linear guide tracks connected to a slider mounting plate, which is in connection with two vertically overlapped insulation plates. A conductive rod is arranged between theinsulation plates, the top and bottom of which are connected to brass plates. The bottom plate is also equipped with a cylinder support connected to a cylinder. And the cylinder piston is in connection with a cylinder connection plate that is connected to the insulation plates and the slider mounting plate. The invention provides a high frequency welding machine used for medical bag production and processing.

Owner:SUZHOU HUARI JINLING MACHINERY

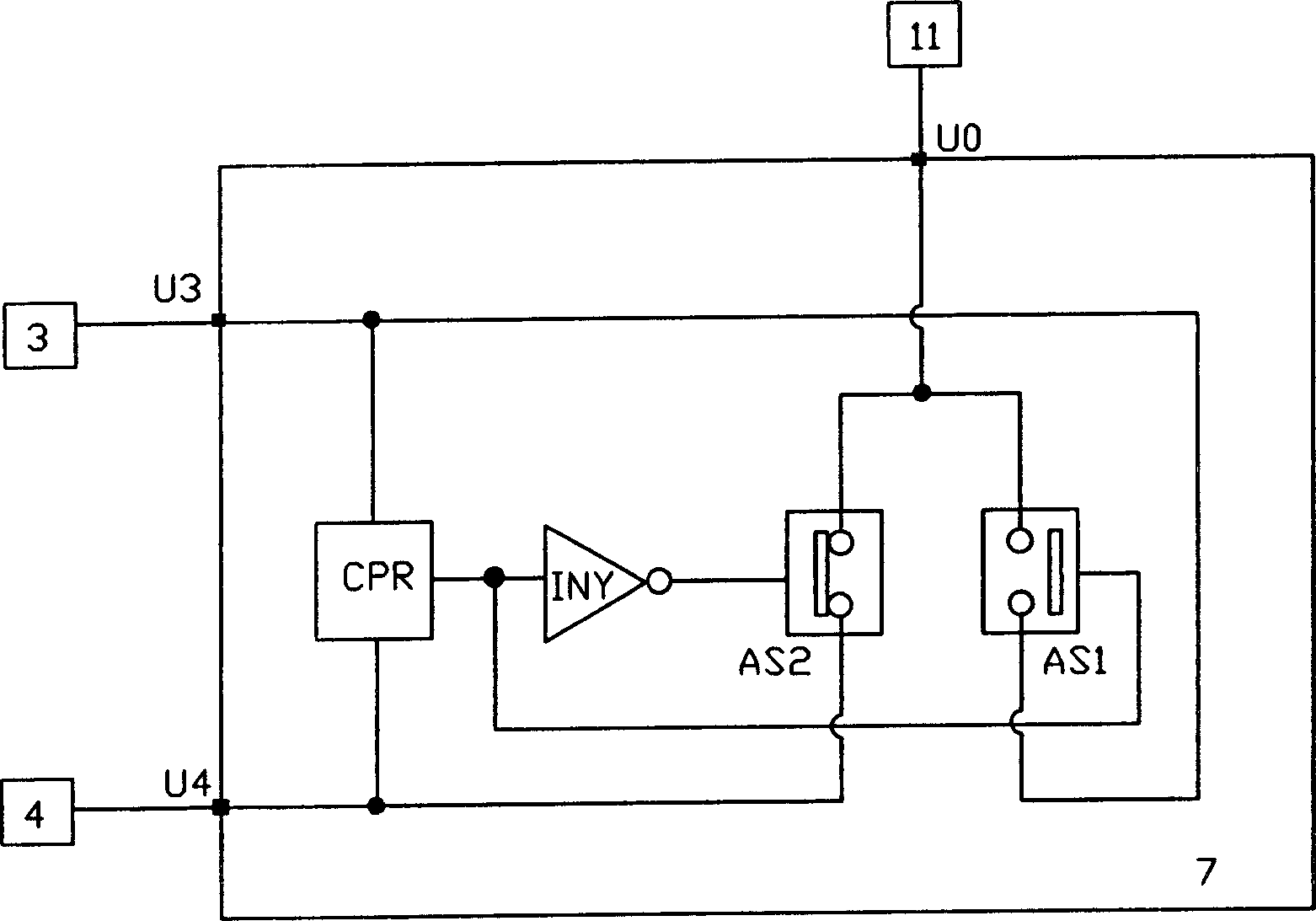

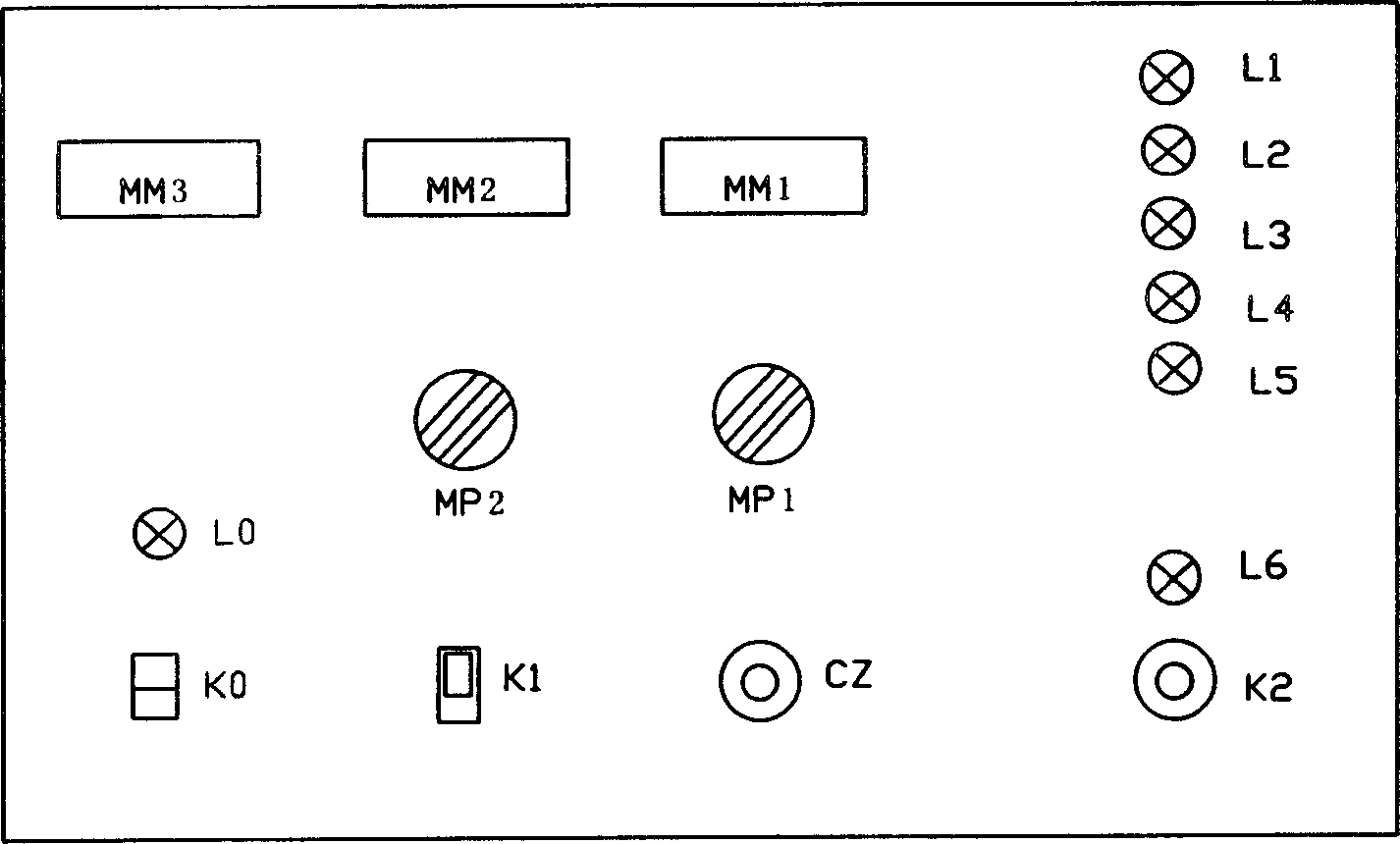

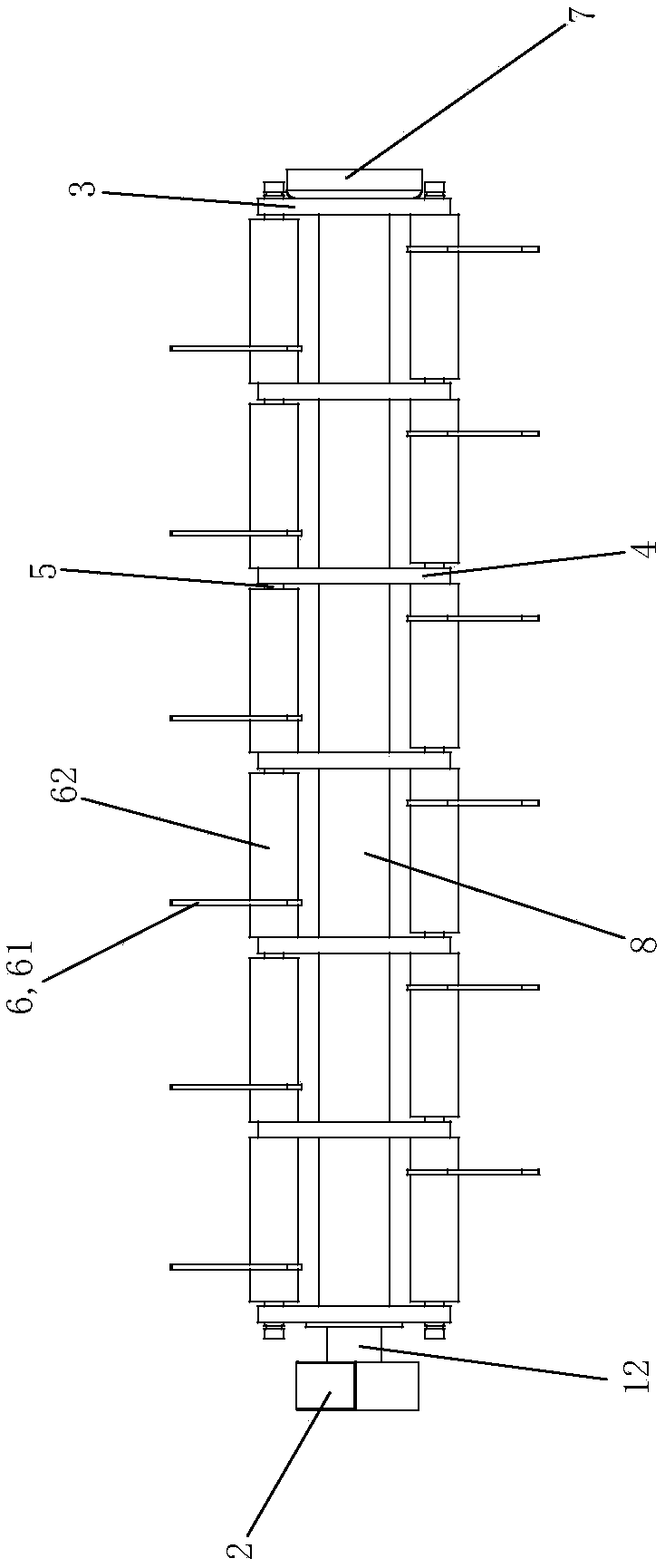

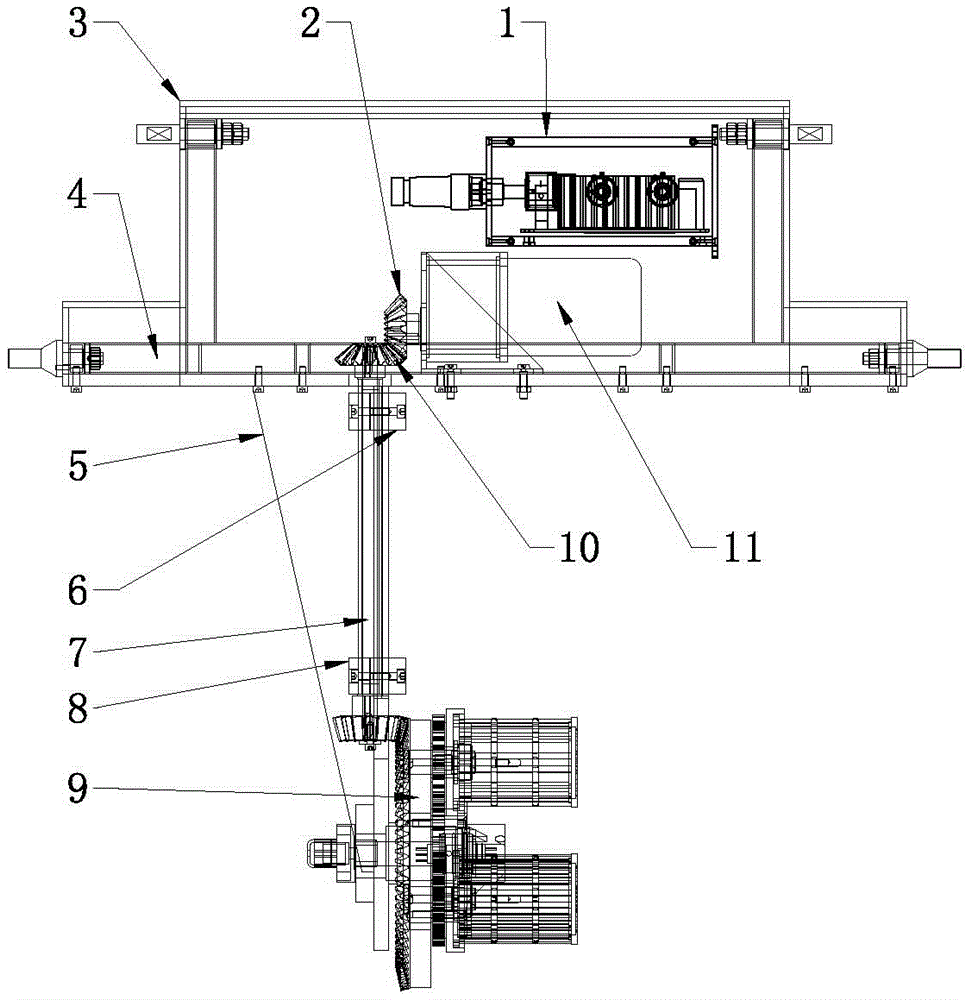

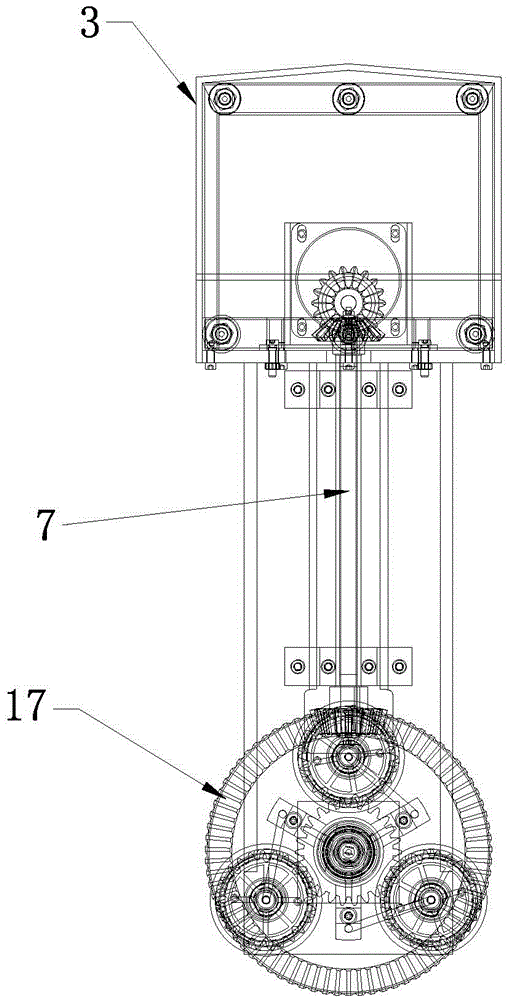

A planetary barrel plating machine

ActiveCN104611758BImprove work efficiencyImprove the quality of plated partsElectrolysis componentsDrive shaftEngineering

The invention relates to the technical field of workpiece barrel plating equipment in the electroplating industry and particularly relates to a planetary barrel plating machine. The planetary barrel plating machine comprises a controller, a first bevel gear, an outer cover, a rack, a roller mounting frame, a first bearing support, a transmission shaft, a second bearing support, a planetary roller mechanism, a second bevel gear, a motor and a third bevel gear; the controller is installed in the rack and is used for supplying power to the motor and controlling the speed of the motor; the motor is fixed on the rack, the motor is connected with the first bevel gear, the first bevel gear is engaged with the second bevel gear, and the second bevel gear and the third bevel gear are respectively installed at the upper and lower ends of the transmission shaft; the transmission shaft is installed on the roller mounting frame through the first bearing support and the second bearing support, and the roller mounting frame is fixedly connected with the rack through a screw; the outer cover is fixedly arranged on the rack and covers the controller and the motor; the working efficiency of the planetary barrel plating machine is much higher than that of a common single-roller barrel plating machine, the plated part quality is relatively higher and the electroplating reaction time is shorter.

Owner:广东保盈环保电镀设备有限公司

High frequency current commutation device for medical bag production

The invention discloses a high frequency current commutation device for medical bag production. The device comprises a bottom plate that is connected to two side plates, over which a mounting plate is fixed. The mounting plate is in connection with a first support, where a first double-rod cylinder is fixed. And the lower part of the first double-rod cylinder is connected to a first electrode. The bottom of the bottom plate is in connection with a second support, where a second double-rod cylinder is fixed. And the second double-rod cylinder is in connection with a second electrode. The bottom plate is provided with two linear guide tracks connected to a slider mounting plate, which is in connection with two vertically overlapped insulation plates. A conductive rod is arranged between the insulation plates, the top and bottom of which are connected to brass plates. The bottom plate is also equipped with a cylinder support connected to a cylinder. And the cylinder piston is in connection with a cylinder connection plate that is connected to the insulation plates and the slider mounting plate. The invention provides a high frequency welding machine used for medical bag production and processing.

Owner:SUZHOU HUARI JINLING MACHINERY

Lawn ventilator

PendingCN109845431ASimple structureReduce transmission structureAgricultural machinesAdjusting devicesEngineeringCentrifugal force

The invention discloses a lawn ventilator which comprises an enclosure, a motor, a soil loosening tool and a walking mechanism. The walking mechanism is arranged on the enclosure; a hand rail is arranged on the enclosure; an operation switch is arranged on the upper portion of the hand rail; the technical scheme includes that the soil loosening tool includes a rotating shaft rotatably arranged onthe enclosure and blades movably arranged on the rotating shaft. The motor shaft of the motor is in direct transmission connection with the rotating shaft of the soil loosening tool to drive the rotating shaft of the soil loosening tool to rotate to enable the blades on the rotating shaft to be swung out under the action of centrifugal force to conduct lawn loosening and aeration.

Owner:CHANGZHOU CREATE ELECTRIC APPLIANCE

Actuator power-supply for driving laser diode

InactiveCN100426604CImprove machine efficiencyPrevent overcurrentLaser detailsSemiconductor lasersAudio power amplifierPower factor

A switch power for driving laser light emitting diode, including: the adjusting operating current multi-circle potentiometer and the operating current amplifier that connect with each other, the setting most current multi-circle potentiometer and the setting current amplifier that connect with each other, the operating current amplifier and the setting current amplifier connect with the current value comparison selecting gate, the output of the current value comparison selecting gate connects with the outputting current controller, the outputting current controller connects with the laser by the big current power module. The invention is: high stability power, settable most operating current, forcible zero startup function, high power factor and high power efficiency.

Owner:GUANGZHOU IND DEV GRP

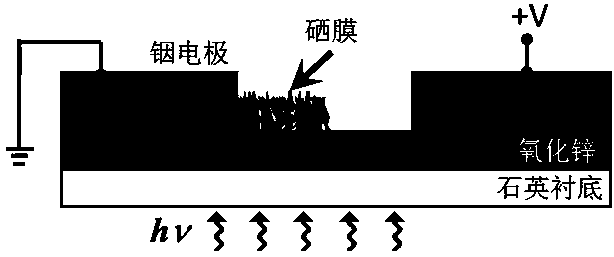

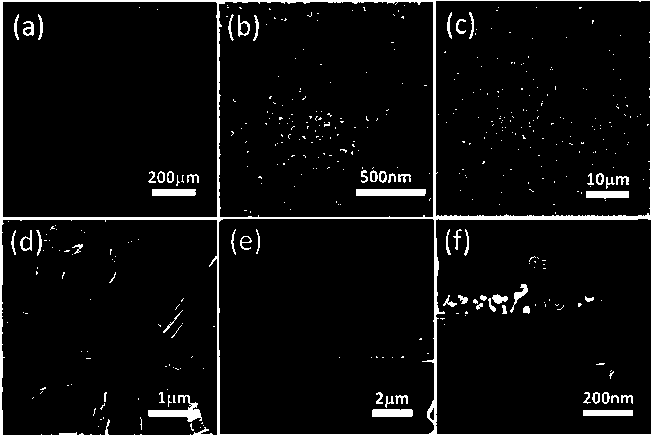

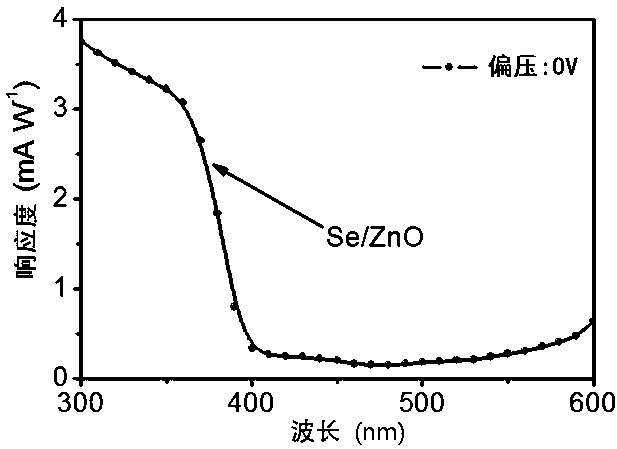

A self-driven se/zno heterojunction ultraviolet photodetector and its preparation method

InactiveCN106252455BSelf-drivingStable current outputFinal product manufactureSemiconductor devicesHeterojunctionPhotodetector

The invention belongs to the technical field of a photoelectric device and particularly relates to a self-driven Se / ZnO heterojunction ultraviolet photoelectric detector and a manufacturing method thereof. According to the method, a spin coating-high temperature annealing method is employed, and a large-scale ZnO nanometer particle film with thickness in a range of 50-200nm and having an excellent crystallization degree is manufactured; a heat evaporation transfer method is then employed, a Se film with thickness in a range of 1-2mum is deposited on the ZnO nanometer film; the Se / ZnO heterojunctio dual-layer film is utilized to construct a photoelectric detector. The Se / ZnO heterojunction photoelectric detector working under a zero bias voltage has self-driven characteristics, excellent ultraviolet light selectivity and millisecond-level response time, a problem of slow response speed existing in a traditional ZnO-based ultraviolet photoelectric detector is solved, the manufacturing process is simple, and the method is applicable to ultraviolet light detection and the related field.

Owner:FUDAN UNIV

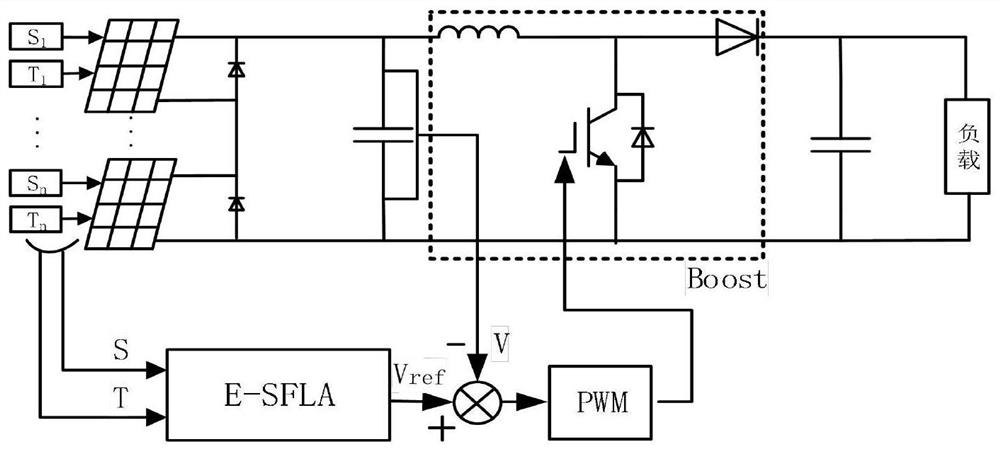

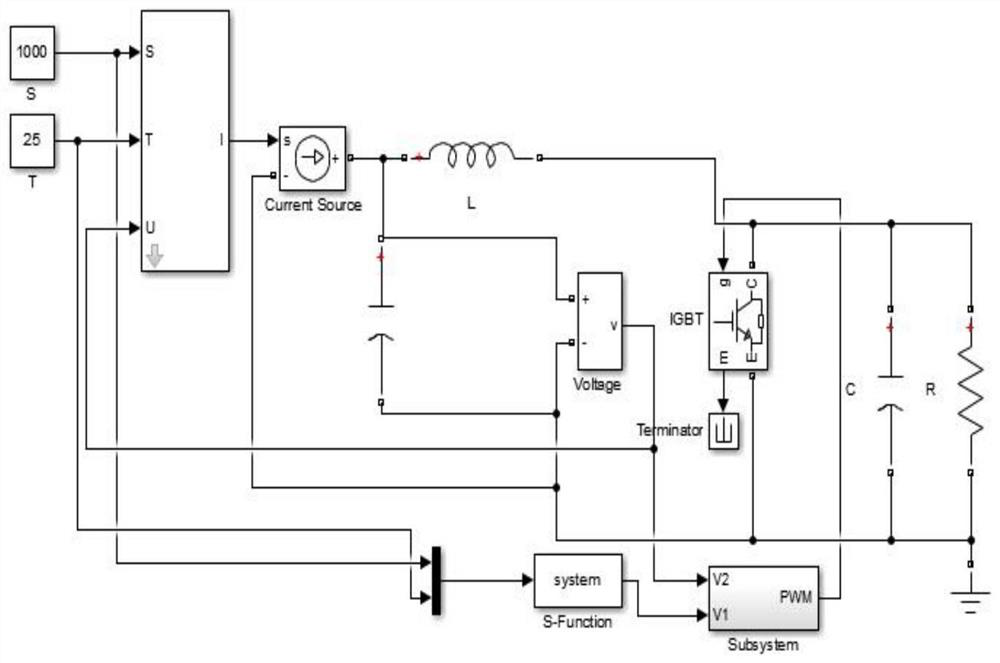

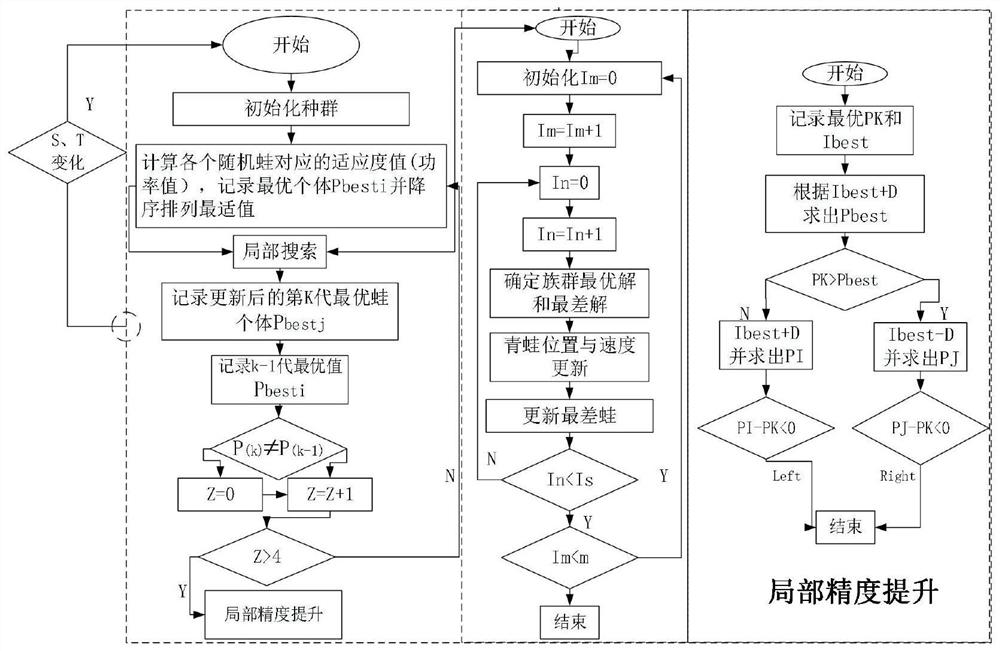

A mppt control of partially shadowed photovoltaic array based on random leapfrog global search algorithm

ActiveCN108594927BReal-time efficient iterative searchGuaranteed uptimePhotovoltaic energy generationElectric variable regulationPhotovoltaic arraysControl theory

The invention discloses a local shadow photovoltaic array multi-peak Maximum Power Point Tracking (MPPT) control method based on a random leapfrog global search algorithm. The output current of the photovoltaic array is used as the particle of the algorithm, and the power of the photovoltaic array is As the fitness function of the algorithm, the global maximum power point of the photovoltaic array can be found efficiently and accurately through the new fast and global search technology of the random leapfrog global search algorithm, and then the maximum power can be achieved by controlling the Boost circuit through the PWM duty cycle Points to track. This algorithm can solve the problem that the MPPT control of photovoltaic arrays with multi-peak output characteristics under local shadows is easy to fall into the local maximum power point. It can accurately find the global maximum power point, and has strong optimization ability, high search accuracy, and easy programming.

Owner:XIANGTAN UNIV

Intermediate frequency high-power components for resistance welding machines

ActiveCN103949766BSolve fever problemEvenly heatedWelding electric supplyElectrical resistance and conductanceElectrical conductor

Owner:JINZHOU SHENGHE POWER ELECTRONICS +1

Mode Switching Based Strong Offset Resistance Wireless Power Transfer System

ActiveCN112994260BIncrease the output voltageReduce output voltageCircuit arrangementsAc-dc conversionTelecommunicationsLoop control

A strong offset-resistant wireless power transmission system based on mode switching belongs to the technical field of wireless power transmission, and specifically relates to a strong offset-resistant wireless power transmission system based on mode switching. The present invention solves the problems of large volume, high cost and low efficiency of the rear-stage closed-loop control DC / DC converter due to the relatively large deviation of the primary and secondary side coupling mechanisms of the existing wireless power transmission system. According to the output voltage of the rectification switching circuit and the upper limit and lower limit of the input voltage of the DC / DC converter, the secondary side controller of the present invention outputs the rectification switching command to the control signal input end of the rectification switching circuit; the secondary side controller also outputs the inverter switching command The secondary side wireless communication module transmits to the secondary side wireless communication module; the primary side wireless communication module receives the inverter switching command and transmits it to the primary side controller, and the primary side controller receives the inverter switching command and sends it to the inverter switching circuit State switching control signal. The invention is applicable to the technical field of wireless power transmission.

Owner:HARBIN INST OF TECH

Flexible pressure sensor based on shaddock peel carbon and preparation method and application thereof

PendingCN113295305AHigh mechanical strengthImprove mechanical propertiesForce measurement using piezo-electric devicesDiagnostic recording/measuringElastomerCellulose

The invention provides a flexible pressure sensor based on shaddock peel carbon and a preparation method and application thereof, and relates to the technical field of biomass material processing materials. According to the preparation method, the shaddock peel is subjected to hydrothermal reaction, and part of organic matters such as saccharides and hemicellulose can be removed in the process; the shaddock peel hydrogel is carbonized to obtain the 3D porous carbon aerogel, the 3D structure of the carbon aerogel can be fully reserved in the process, and when the flexible pressure sensor is prepared from the 3D porous carbon aerogel, on one hand, the mechanical property of the pressure sensor can be improved; on the other hand, sensitivity and response time of the pressure sensor can be improved; the 3D porous carbon aerogel is mixed with the flexible polymer, the flexible polymer can be filled in the 3D porous carbon aerogel, and a flexible elastomer is formed through a curing reaction, so that the prepared flexible pressure sensor has excellent stability and mechanical performance and good sensing performance.

Owner:GUANGXI UNIV

A portable solar power bank with light tracing and a charging method

ActiveCN109193898AIncrease the receiving areaWiden reception anglePhotovoltaic supportsElectric powerReduction driveDrive motor

The invention discloses a portable solar power bank with light tracing, including a battery backplane, a solar panel is arranged on the battery bottom plate, a solar panel includes a support rotary panel, a support rotary plate is connected with a battery panel assembly through an articulated shaft, a corn device is arranged in the middle of the contact surface of the support rotating plate and the battery bottom plate, the corner device includes a micro drive motor mounted in a battery chassis, the motor shaft of the micro drive motor is connected with a speed reducer, the speed reducer comprises a double-sided rack ring fixedly mounted on the bottom of the supporting rotary plate, the center of the double-sided rack ring is provided with a sun gear connected with the output shaft of themicro drive motor, Between that sun gear and the double-sided rack re, a clutch wheel device is arranged between the double-sided rack ring and the articulated shaft, and a light tracing device is arranged on the top of the battery panel assembly, so that the structure of the solar energy power bank is simple and portable, the stable power output can be provided, and the charging efficiency of thesolar energy power bank can be improved.

Owner:韶关市诚湃新能源科技有限公司

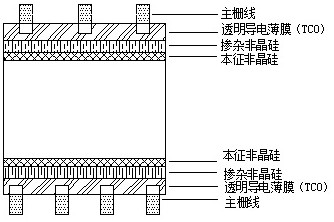

Photovoltaic module, and processing device and processing technology of photovoltaic module

PendingCN113659043AIncrease powerEliminate the effects of efficiency deteriorationLamination ancillary operationsFinal product manufactureHeterojunctionThermodynamics

The invention discloses a photovoltaic module and a processing device and processing technology thereof, and the processing device comprises a power supply device which is used for outputting a direct current and is provided with at least one group of positive and negative electrodes; at least two conductive wires which are used for connecting a power supply device and a to-be-processed component, wherein each conductive wire is connected with the positive electrode and the negative electrode respectively; and a temperature sensing control module which is used for detecting the temperature of the to-be-processed component and the temperature of the power supply device and comparing the detected temperature with a set temperature so as to adjust the current of the power supply device. Through the processing device, the photovoltaic module can be subjected to electric injection in the lamination process, and the current of the power supply device is adjusted by detecting the temperature in the lamination process, so the attenuation problem in the lamination process can be effectively solved, and the attenuation problem in the cooling period after the photovoltaic module is laminated is also solved; and the influence of a high-temperature dark state on the efficiency deterioration of the heterojunction cell is eliminated.

Owner:南京和洪智能设备有限公司

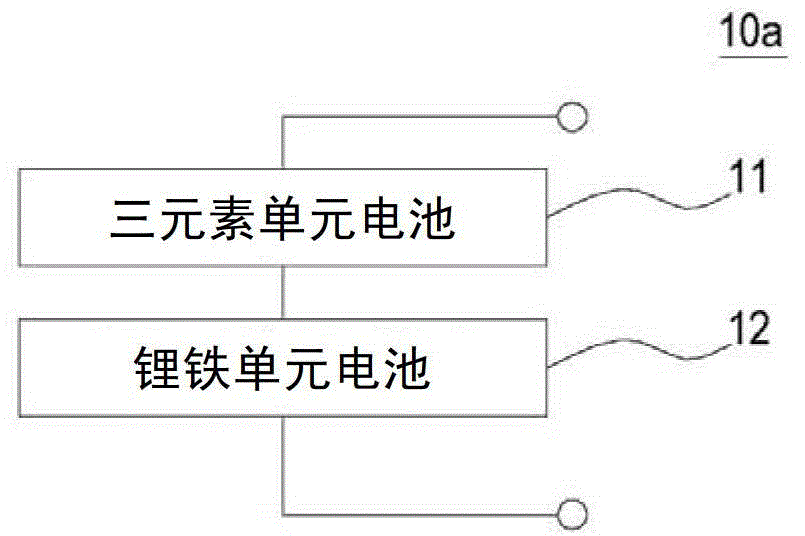

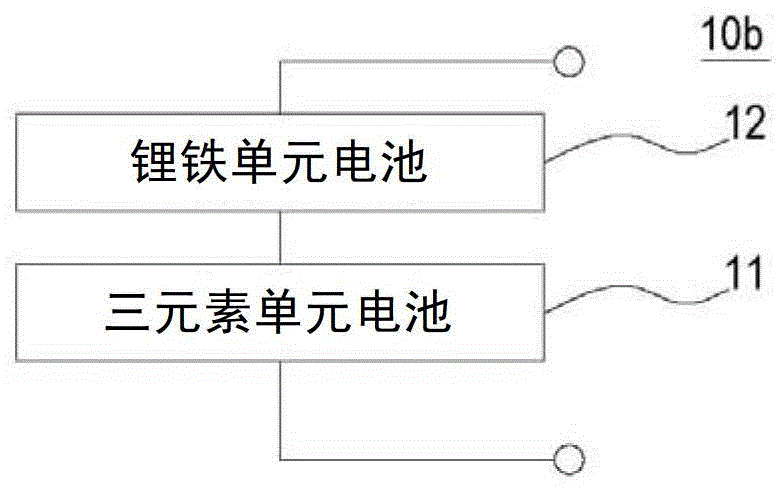

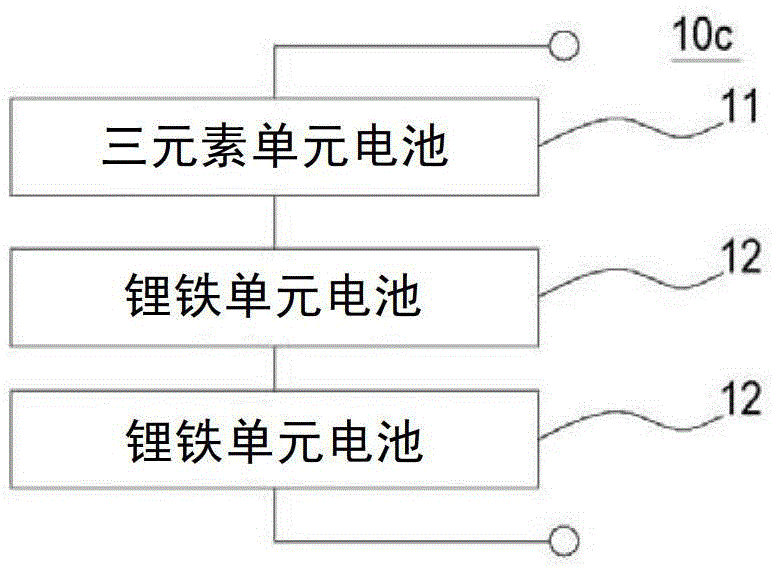

How to measure battery capacity

InactiveCN103389465BThe curve changes clearlyStable current outputElectrical testingLithiumElectrical battery

The invention discloses a method for measuring electric quantity of a battery, and the method is suitable for a battery structure. The battery structure comprises a three-element unit battery and at least one lithium iron unit battery. The method for measuring the electric quantity comprises the first step of measuring the voltage or a current of the three-element unit battery to work out the remaining electric quantity of the three-element unit battery, and the second step of working out the current remaining electric quantity of the battery structure according to the remaining electric quantity of the three-element unit battery.

Owner:KYMCO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com