Photovoltaic module, and processing device and processing technology of photovoltaic module

A technology for photovoltaic modules and processing devices, applied in photovoltaic power generation, sustainable manufacturing/processing, electrical components, etc., can solve problems such as efficiency attenuation, and achieve the effect of eliminating the impact of efficiency deterioration, strong operability, and simple transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to a method for processing a photovoltaic module, comprising the following steps:

[0041] 1) First prepare heterojunction solar cells

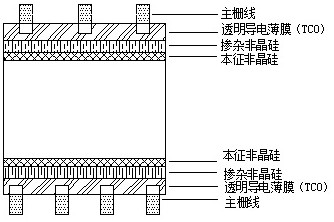

[0042] Using 166-size N-type monocrystalline silicon wafers as substrates, prepare back-emitting heterojunction solar cells. The front side is n-type, and the back side is p-type. Oxide (TCO) layer, N-type amorphous silicon layer (n-Si: H), intrinsic amorphous silicon layer (i-Si: H), N-type crystalline silicon (c-Si), intrinsic amorphous silicon layer (i-Si:H), P-type amorphous silicon layer (p-Si:H), transparent conductive oxide (TCO) layer, back metal grid electrode, battery structure see figure 1 . The obtained silicon heterojunction solar cell is subjected to light injection treatment, and this step can improve the conversion efficiency of the cell sheet.

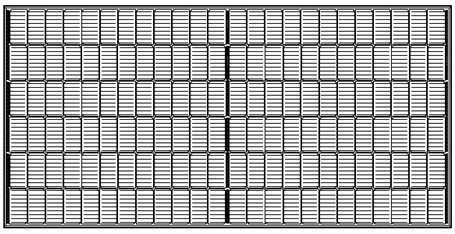

[0043] 2) Connect silicon heterojunction solar cells in series and parallel to form silicon heterojunction solar cell strings: cut the heterojunction...

Embodiment 2

[0050] This embodiment relates to a method for processing a photovoltaic module. The difference between this embodiment and Embodiment 1 is that in step 1), the heterojunction solar cells are not subjected to light injection treatment. According to this process, 5 components were processed, and the power data of the obtained components were measured. The experimentally measured data are shown in Table 1.

Embodiment 3

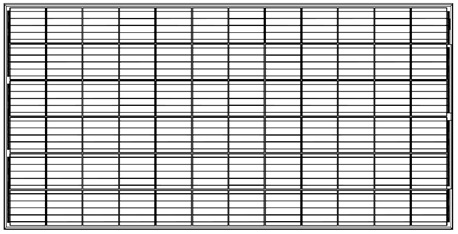

[0052] The difference between this embodiment and embodiment 1 is that in step 2), the heterojunction solar cells are not sliced, and the whole cell is connected in series, and the shape of the components is as follows: image 3 shown. According to this process, 5 components were processed, and the power data of the obtained components were measured. The experimentally measured data are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com