Five-level multi-bridge-arm switching power amplifier circuit

A power amplifier circuit and multi-arm technology, applied in the field of magnetic bearings, can solve the problems of non-adjustable bus voltage, single, control current fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

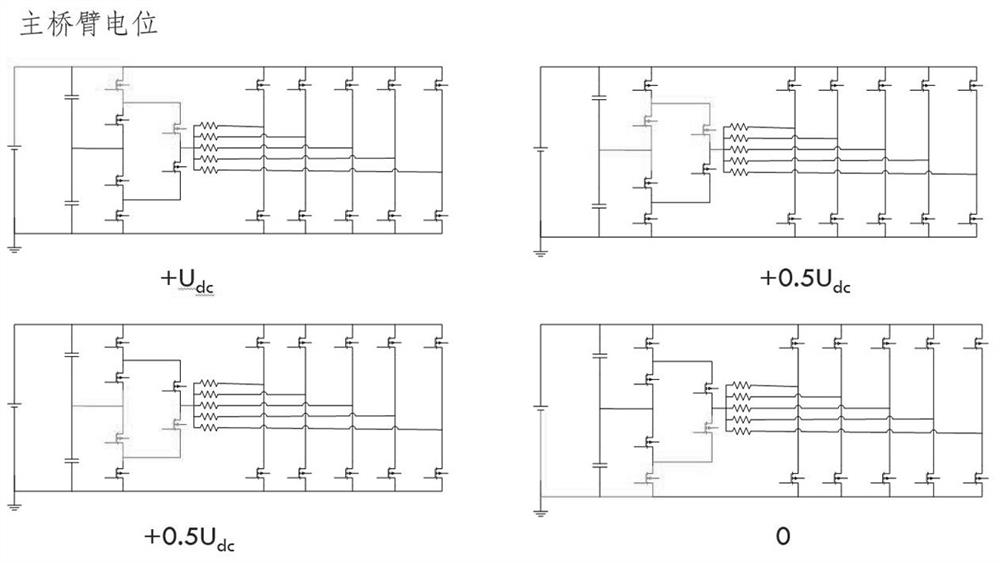

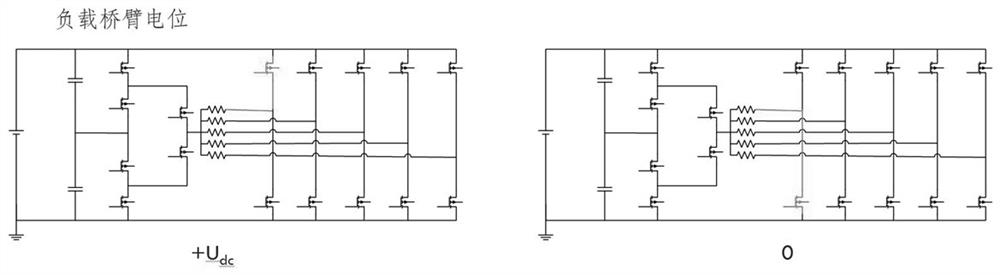

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

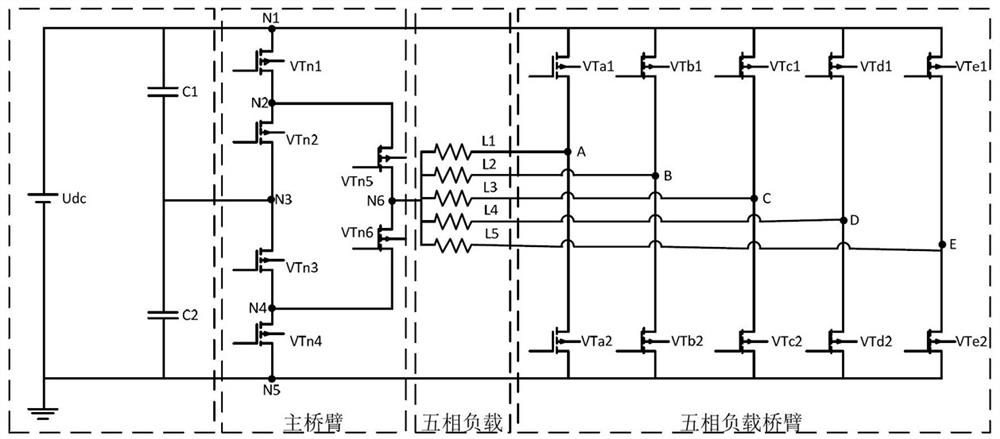

[0020] Such as figure 1 A five-level multi-bridge switch power amplifier circuit shown is composed of an active neutral point clamp power supply, a main bridge arm, a five-phase load, and a load bridge arm. The active neutral point clamp power supply, the main bridge arm , five-phase load, and load bridge arms are electrically connected together in sequence;

[0021] The active neutral point clamp power supply is composed of a DC voltage source Udc, a voltage stabilizing capacitor C1 and a voltage stabilizing capacitor C2: the voltage stabilizing capacitor C1 and the voltage stabilizing capacitor C2 are connected in series and connected to both ends of the power supply Udc, the voltage stabilizing capacitor C1 and the voltage stabilizing capacitor The midpoint of the capacitor C2 is connected to the midpoint N3 of the main bridge arm;

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com