Intermediate frequency high-power components for resistance welding machines

A resistance welding machine, high-power technology, applied in the direction of resistance welding equipment, welding power supply, welding equipment, etc., can solve the problems that affect production efficiency, cannot be replaced quickly, and heat generation is not enough, so as to avoid heating problems, heat generation is small, Even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

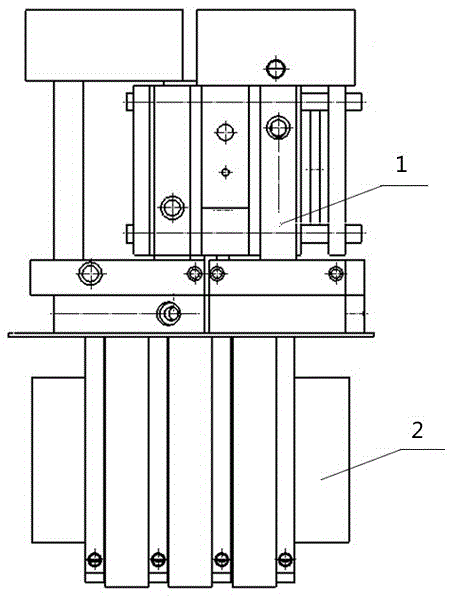

[0034] Such as figure 1 As shown, the present invention includes an FRD diode part 1 and an intermediate frequency transformer part 2, and the FRD diode rectification part 1 and the intermediate frequency transformer part 2 are connected by screws.

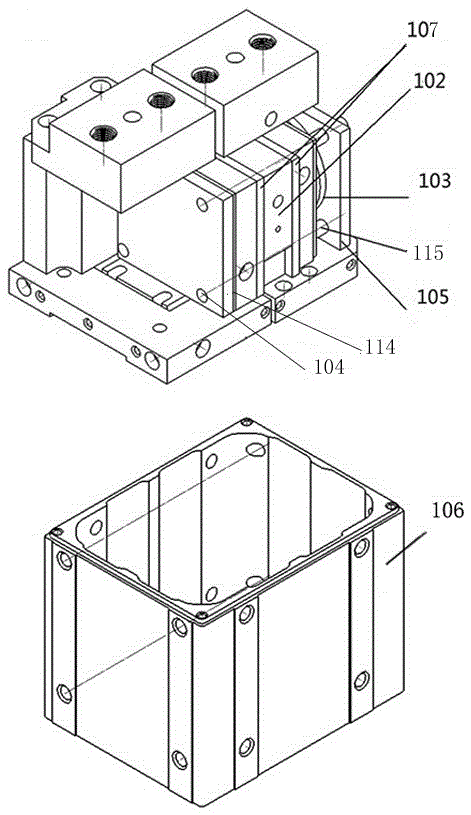

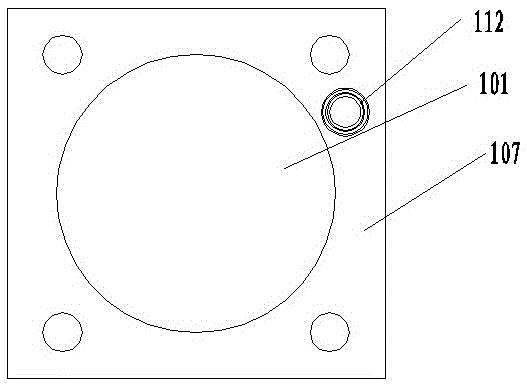

[0035] Such as figure 2 image 3 As shown, the FRD diode part 1 is composed of two FRD diodes 101, a sealing ring 107, a conductor 102, a spring 103, a connecting screw 104, a pressing plate 105, and an outer cover 106 arranged on the conductor 102. On the connecting screw 104 An insulating sleeve 115 is provided to insulate the connecting screw and the conductor 105 through the insulating sleeve 115 . The outer cover 106 is made of SMC material, and the protective function is realized by the outer cover 106 made of SMC material with insulation and flame retardancy. A sealing ring 107 is provided on the outer peripheral surface of the FRD diode 101 , and the FRD diode 101 is embedded in the inner ring of the sealing ring 107 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com