Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179results about How to "Solving automation problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

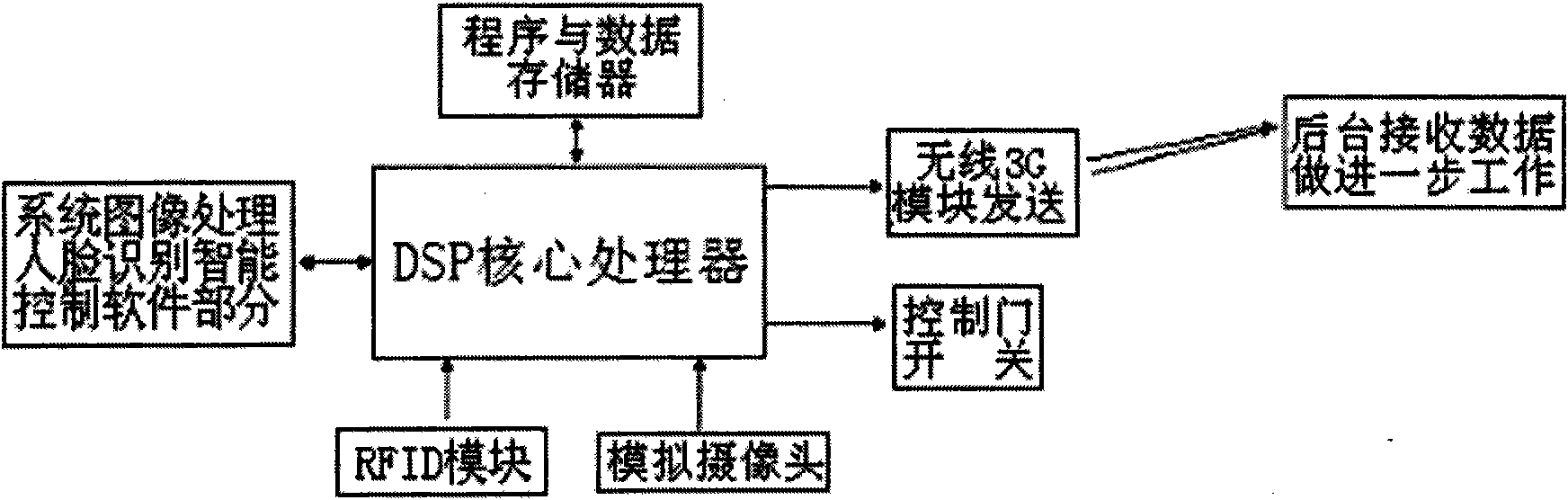

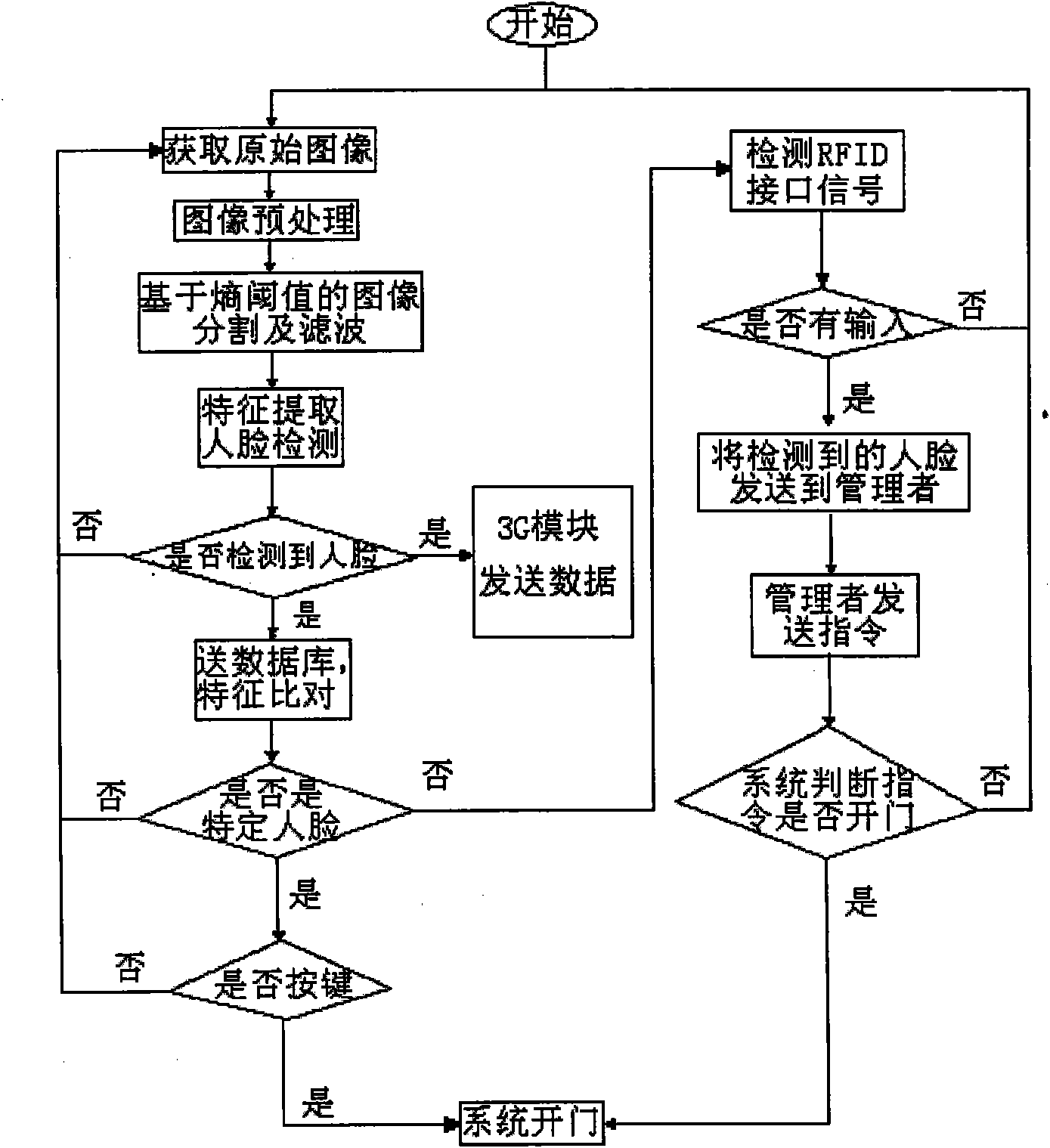

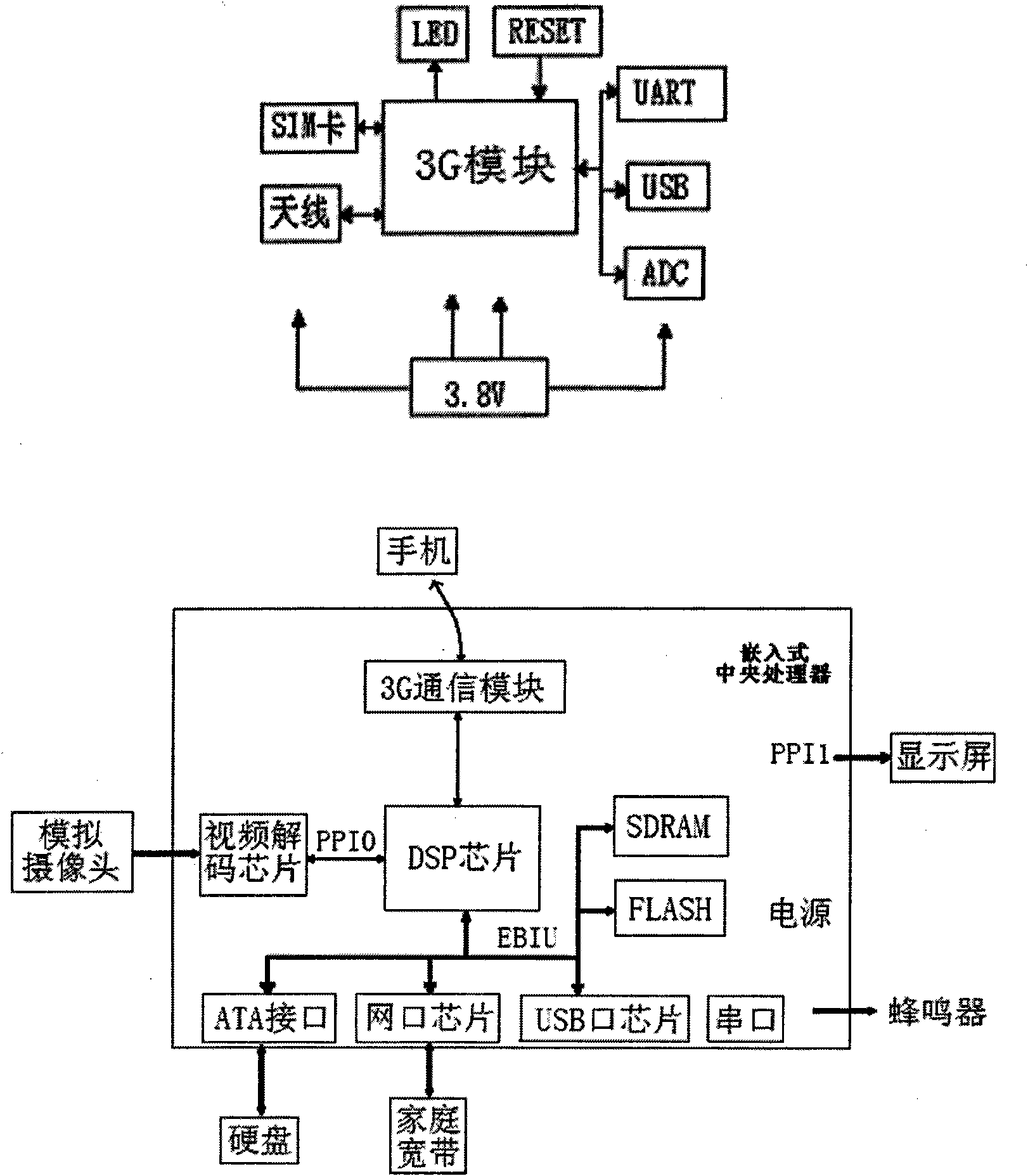

Face identification and 3G communication-based intelligent household access control system

InactiveCN101980305ASmall and easyReduce power consumptionCharacter and pattern recognitionIndividual entry/exit registersData transmissionSystem administrator

The invention relates to a face identification and 3G communication-based intelligent household access control system. The system processes a dynamic video image, detects a face, compares the detected face with stored specific face features, judges whether the face is a specific face or not, and judges whether to automatically open a door according to the judgment; meanwhile, the system sends the detected face image to a mobile phone of a system administrator through a 3G module and is convenient for the administrator to process; and the administrator can monitor the situations in front of the door in real time through the 3G, and can send instructions through the 3G to complete corresponding operation. The system has the auxiliary functions of identifying the face and intelligently opening doors through a radio frequency identification devices (RFID) identification magnetic card. The system consists of an image acquisition part for photographing the image by using an analog camera, an information processing part which uses a digital signal processor (DSP) processor, an RFID module which is connected with the processor through a serial port, and a data transmission part for receiving and sending data by using a wireless 3G module. The system realizes data collection, data processing and data transmission control on the basis of Linux programming.

Owner:QINGDAO UNIV OF SCI & TECH

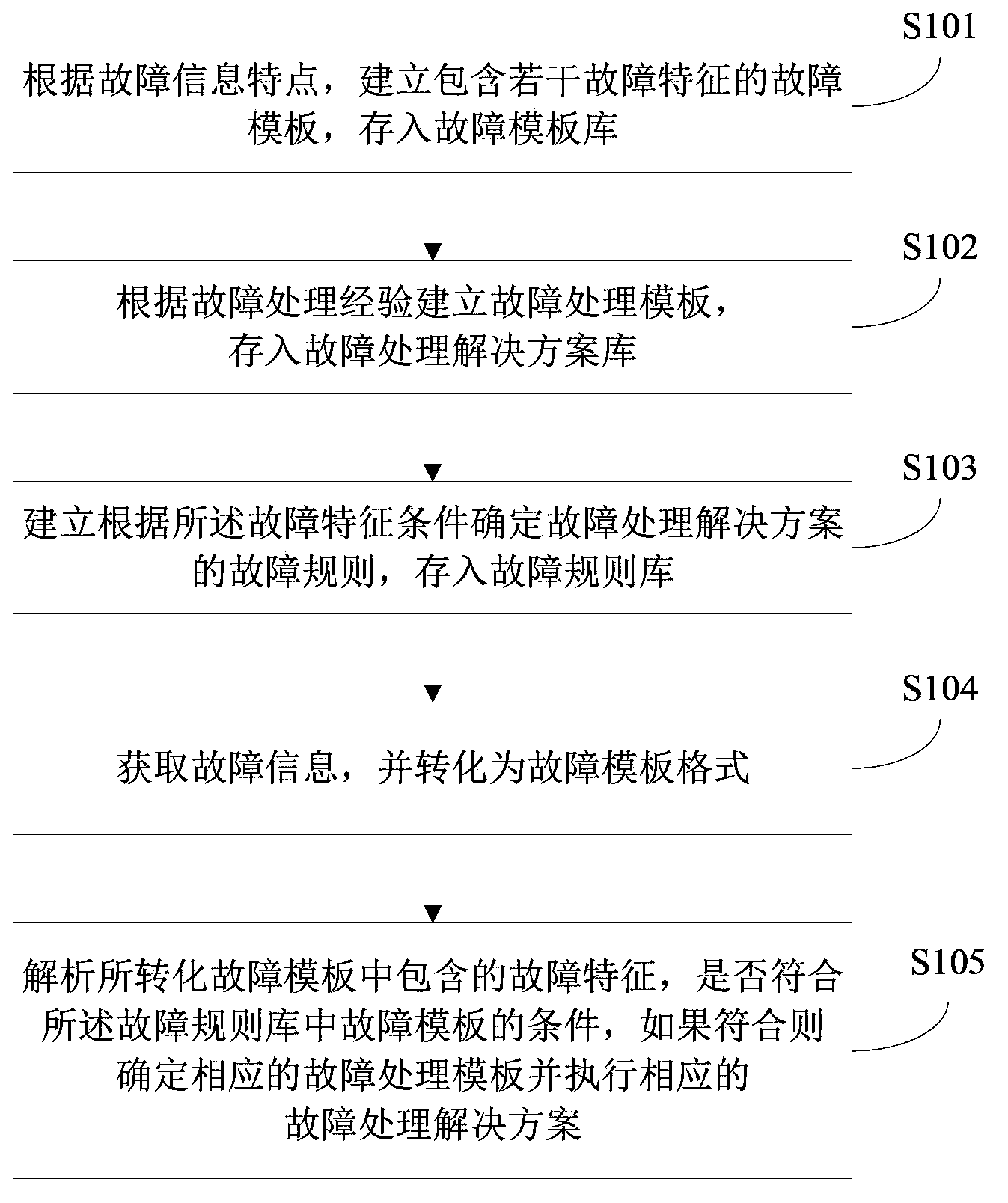

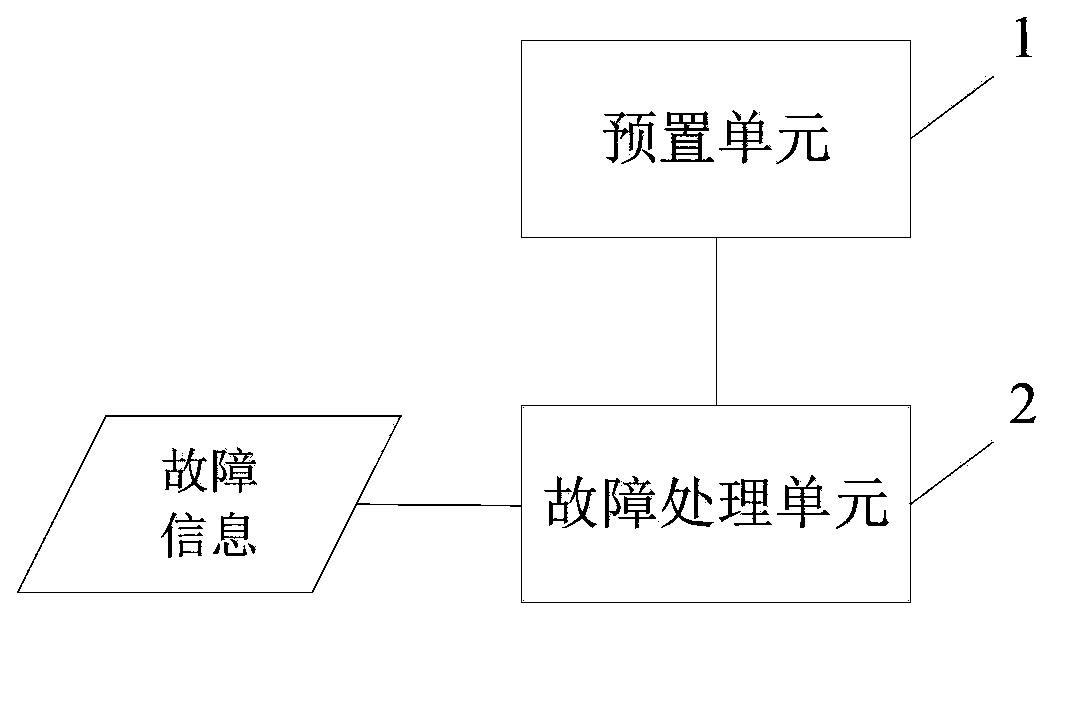

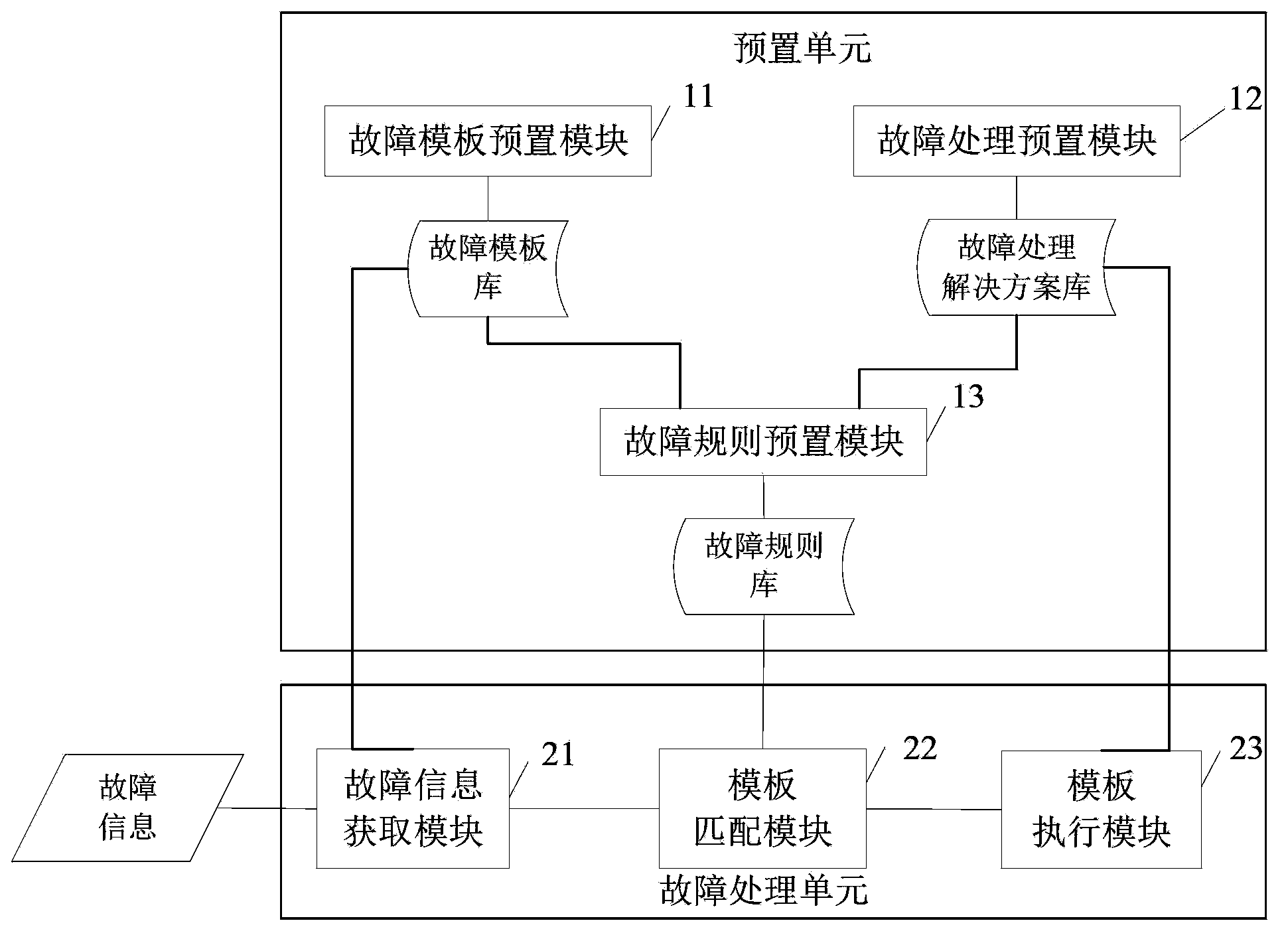

Method and device for processing faults of telecommunication equipment

ActiveCN103684828ASolving automation problemsImprove work efficiencyData switching networksFault handlingComputer science

The embodiment of the invention discloses a method and a device for processing faults of telecommunication equipment. The method comprises the following steps: constructing a fault template library comprising fault features according to fault information characteristics; constructing a fault processing solution library according to the fault processing experience, and describing a solution for positioning and solving equipment problems through a fault processing template; constructing a fault rule library for determining the fault processing template according to a fault feature condition in a fault template; acquiring fault information, and converting the fault information into a fault template format; resolving the fault feature comprised in the fault information, judging whether the fault feature conforms to the fault feature condition of the fault template in the fault rule library, if the fault feature conforms to the fault feature condition of the fault template in the fault rule library, determining the corresponding fault processing template, and executing the corresponding fault processing solution. According to the embodiment of the invention, the automation degree of the fault processing flow is increased, the working efficiency of a client processing the fault is improved, the process that a worker participates into processing of a work order is reduced, and the cost investment of the client is effectively optimized.

Owner:长春亿阳计算机开发有限公司

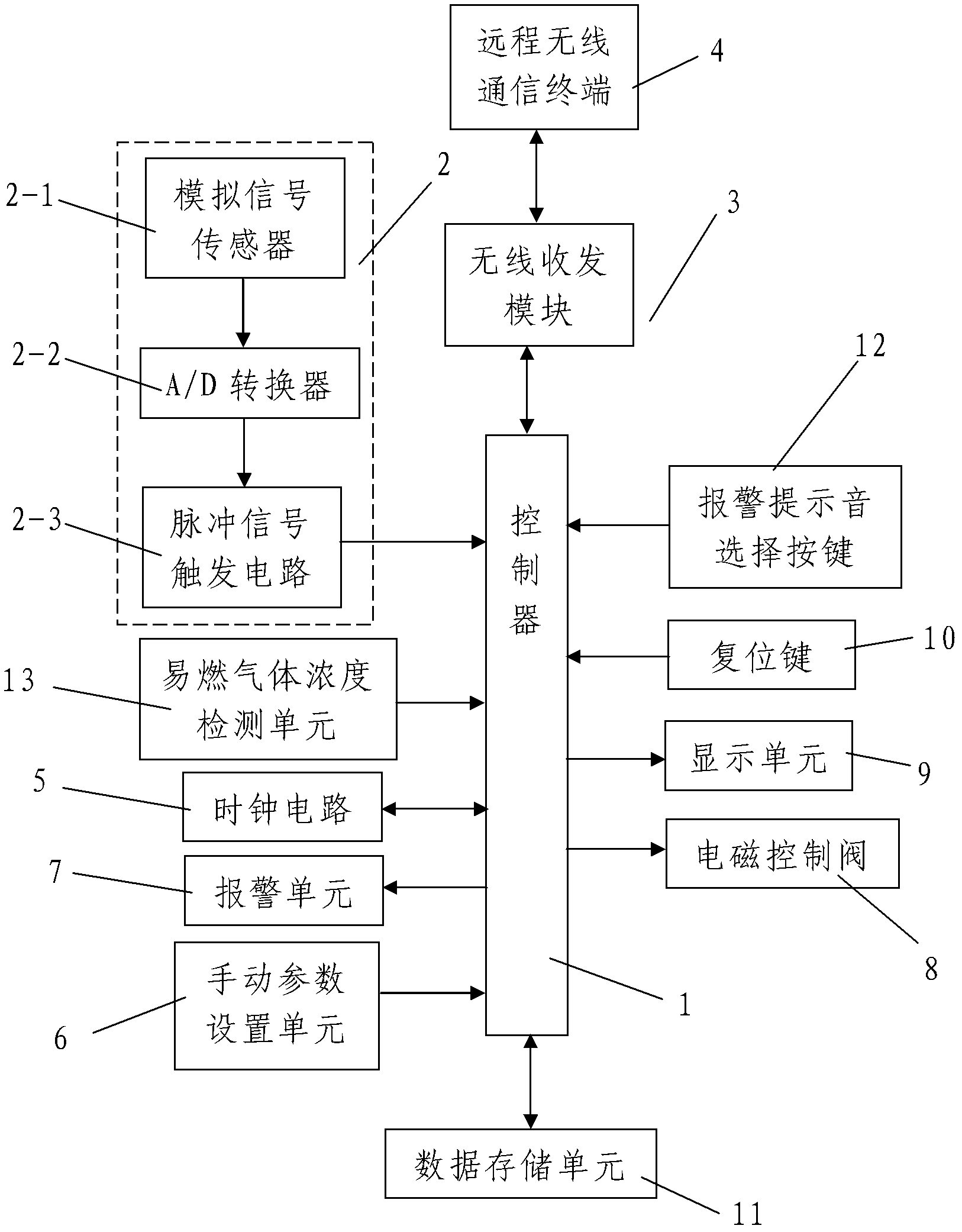

Household gas cooker wireless monitoring system

InactiveCN103134088ASimple structureEasy wiringDomestic stoves or rangesLighting and heating apparatusWireless transceiverMonitoring system

The invention discloses a household gas cooker wireless monitoring system which comprises a controller, a wireless transceiver module, a gas cooker ON-state detection unit for real-time detection of the ON state of a gas cooker, an inflammable gas concentration detection unit for real-time detection of the concentration of inflammable gas around the gas cooker, a remote wireless communication terminal for bidirectional communication through the wireless transceiver module and the controller, a clock circuit for automatic statistics of continuous working time of the gas cooker, a hand-operated parameter setting unit, an alarm unit, a solenoid electric valve, and a display unit; the solenoid electric valve is mounted at a gas supply pipe mounted at a gas inlet of the monitored gas cooker, and both the ON / OFF state and the opening degree of the solenoid electric valve are controlled by the controller. The invention is simple in structure, convenient for wiring, simple in operation, high in intelligentization degree, and good in application effect, and can solve the defects of low automation and intelligentization degrees, inconvenient usage and operation, indispensability of personal on-site hand-operated control by users, incapability of realizing remote intelligent monitoring, and the like for current gas cookers.

Owner:XIAN KUOLI MACHANICAL & ELECTRICAL TECH

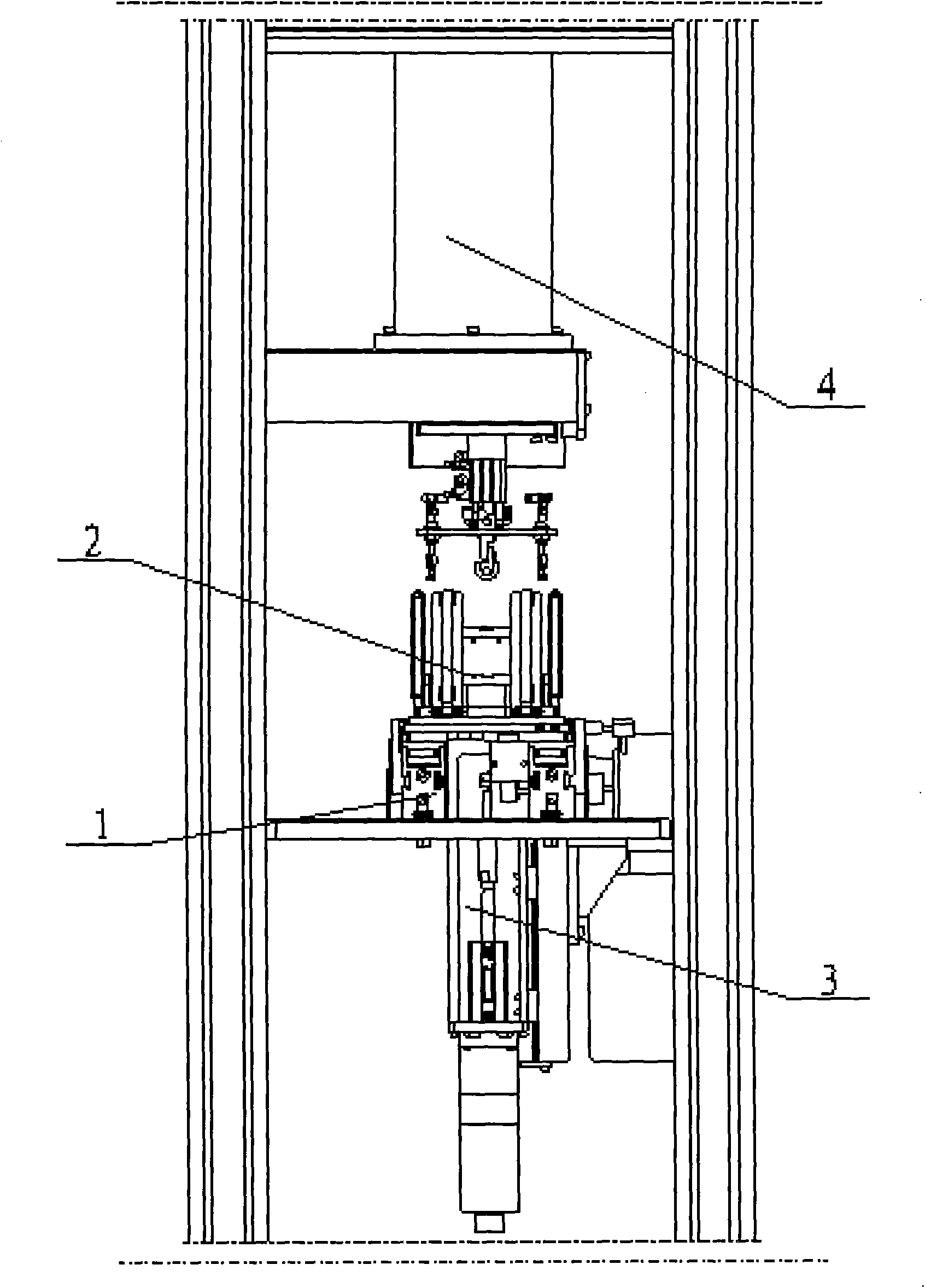

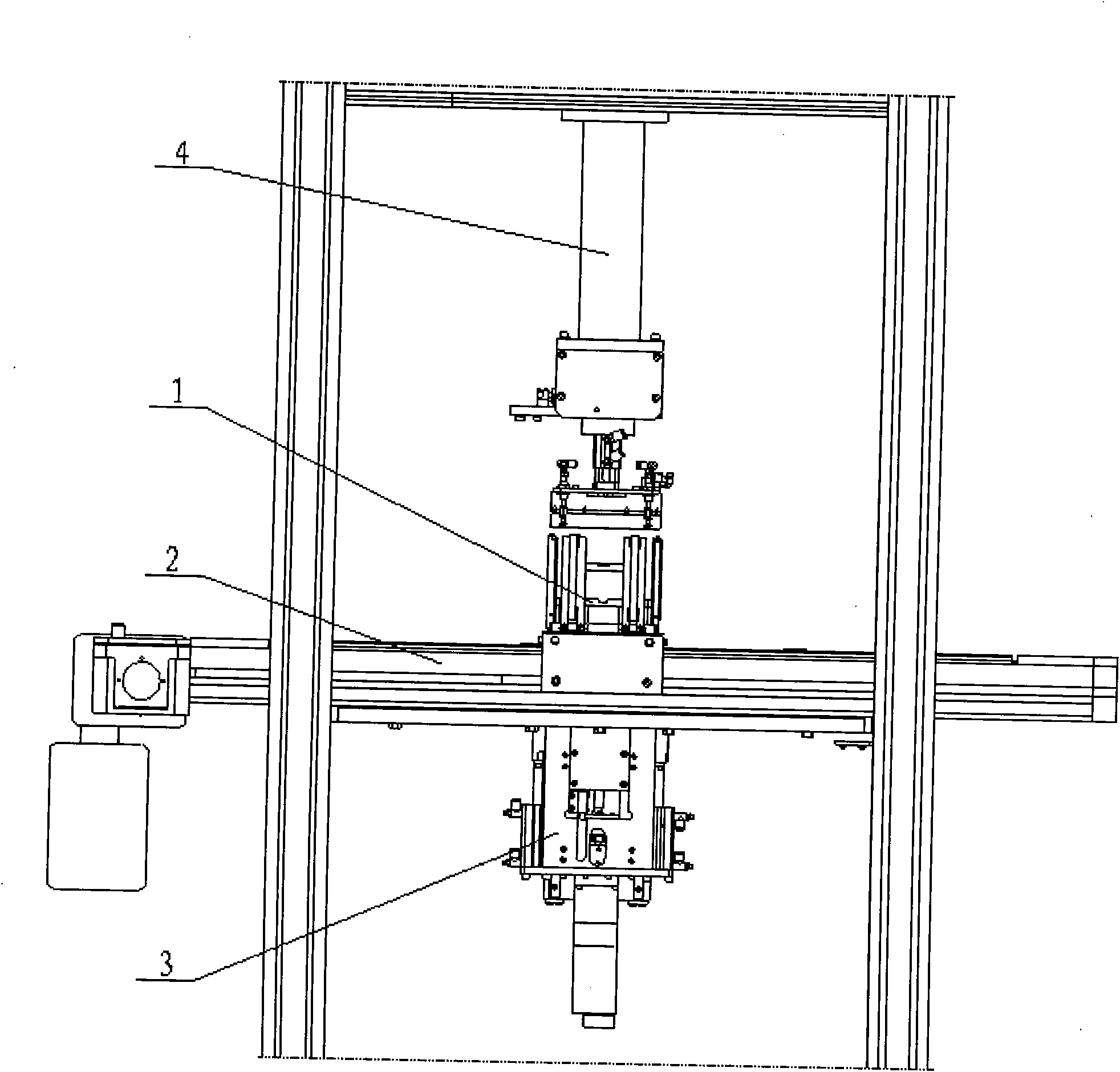

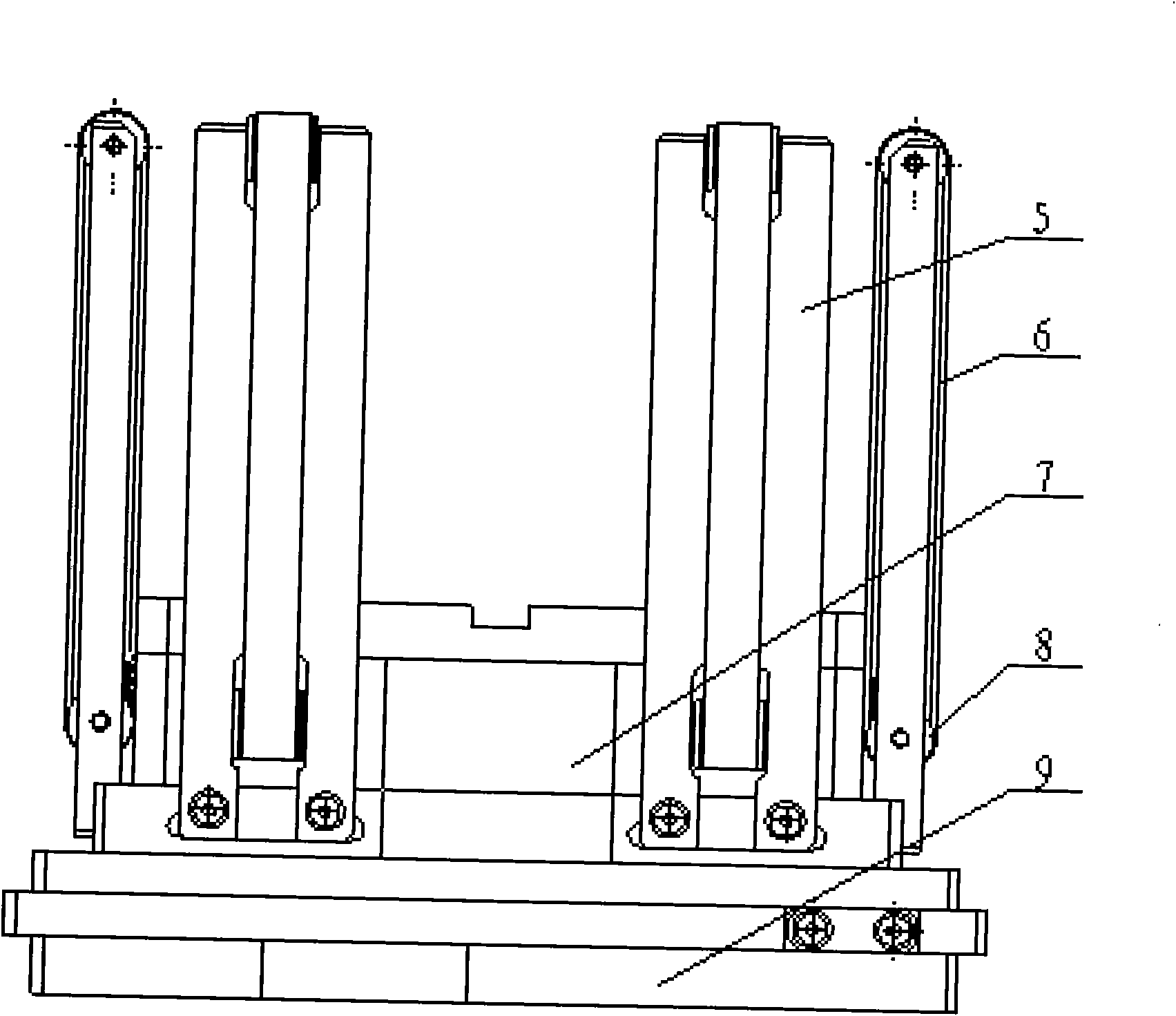

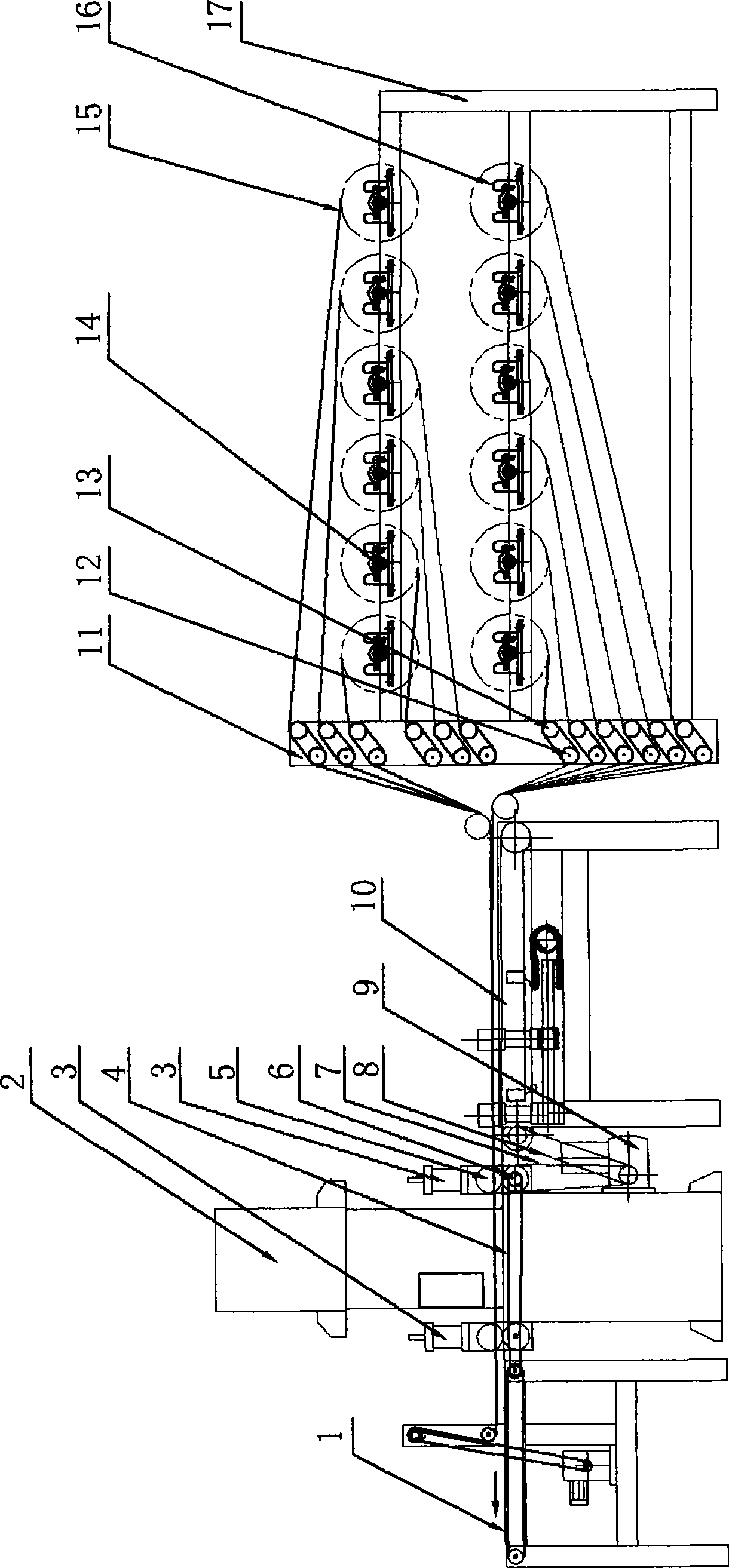

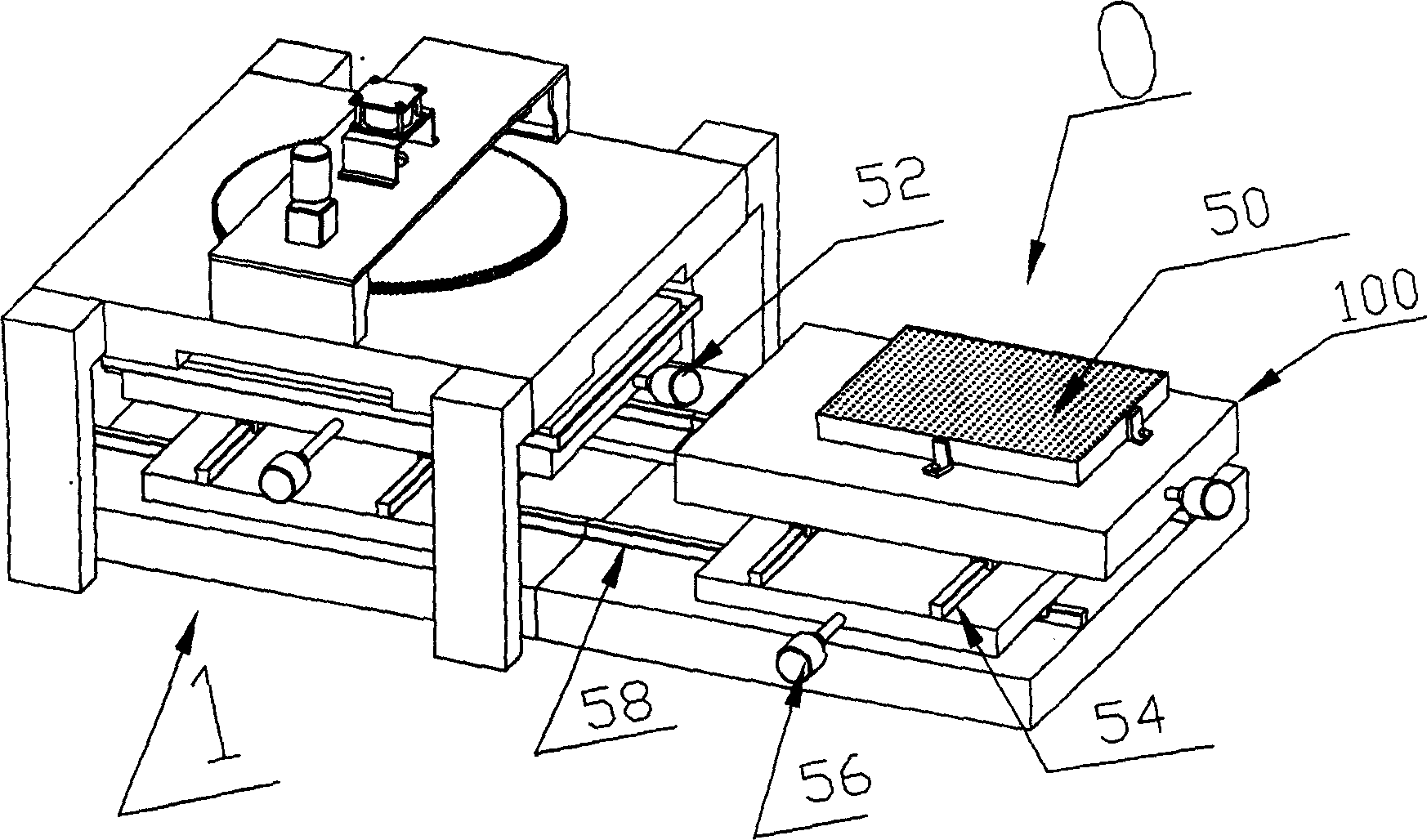

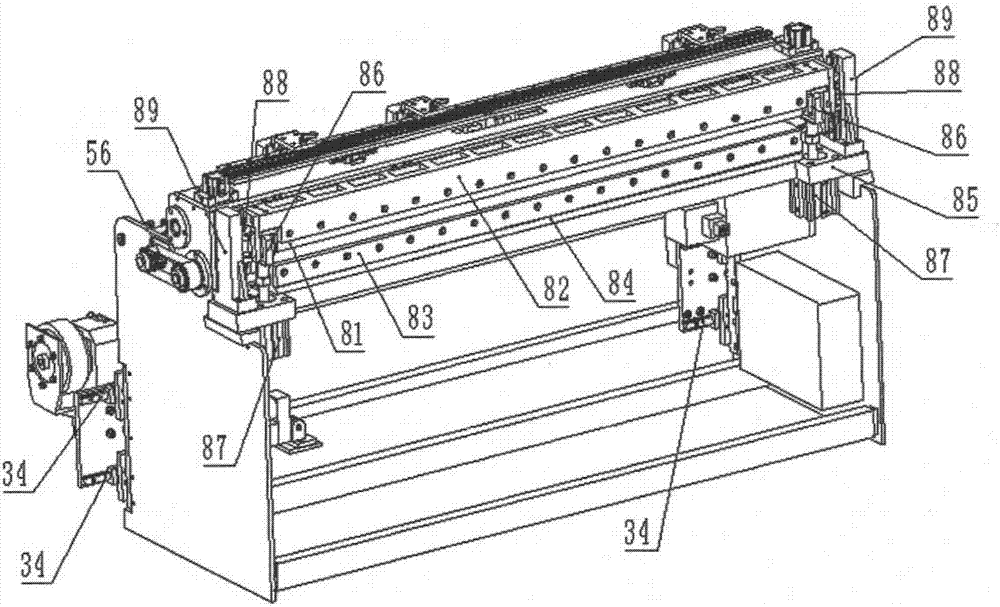

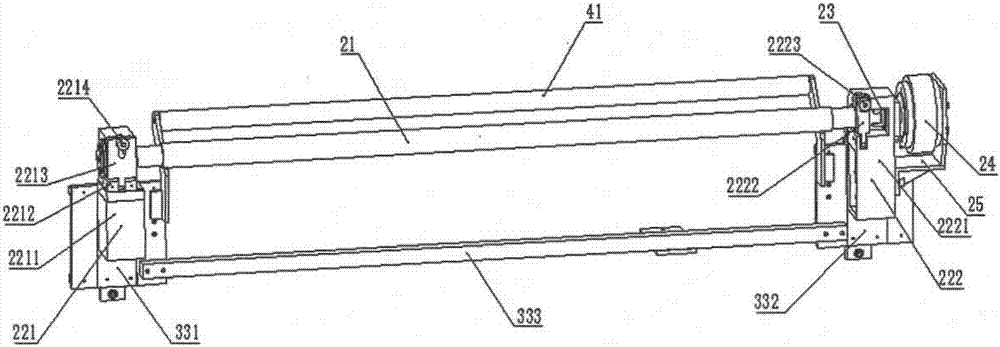

Automatic loading system suitable for stacking silicon chips in automatic equipment

InactiveCN101901773AIncrease productivityOverall reliable operationFinal product manufactureConveyor partsSilicon chipManipulator

The invention relates to automatic loading equipment suitable for silicon chips or similar silicon chips such as printed circuit board (PCB) and the like, in particular to an automatic loading system suitable for stacking silicon chips on an automatic solar cell printing production line and belongs to automatic equipment. The system comprises a material box, an automatic transmission mechanism, apre-loading position, a loading position and an unloading position, wherein the pre-loading position, the loading position and the unloading position are arranged along the automatic transmission mechanism in turn; an automatic blocking mechanism for blocking the material box is arranged at the pre-loading position; and an automatic blocking mechanism, a material box elevating mechanism for positioning the material box and elevating the silicon chips and a transverse transmission manipulator for gripping the silicon chips and delivering the silicon chips to a next procedure are arranged at the loading position. The fully-automatic loading equipment has the advantages of capability of realizing automatic transmission during loading, automatic positioning and locking, automatic ascending ofthe silicon chips and automatic gripping of the manipulator, simpleness, reliability, reasonable design, wide application in automatic loading of electronic equipment or solar cell production equipment and the realization of high-efficiency production of products.

Owner:THE 45TH RES INST OF CETC

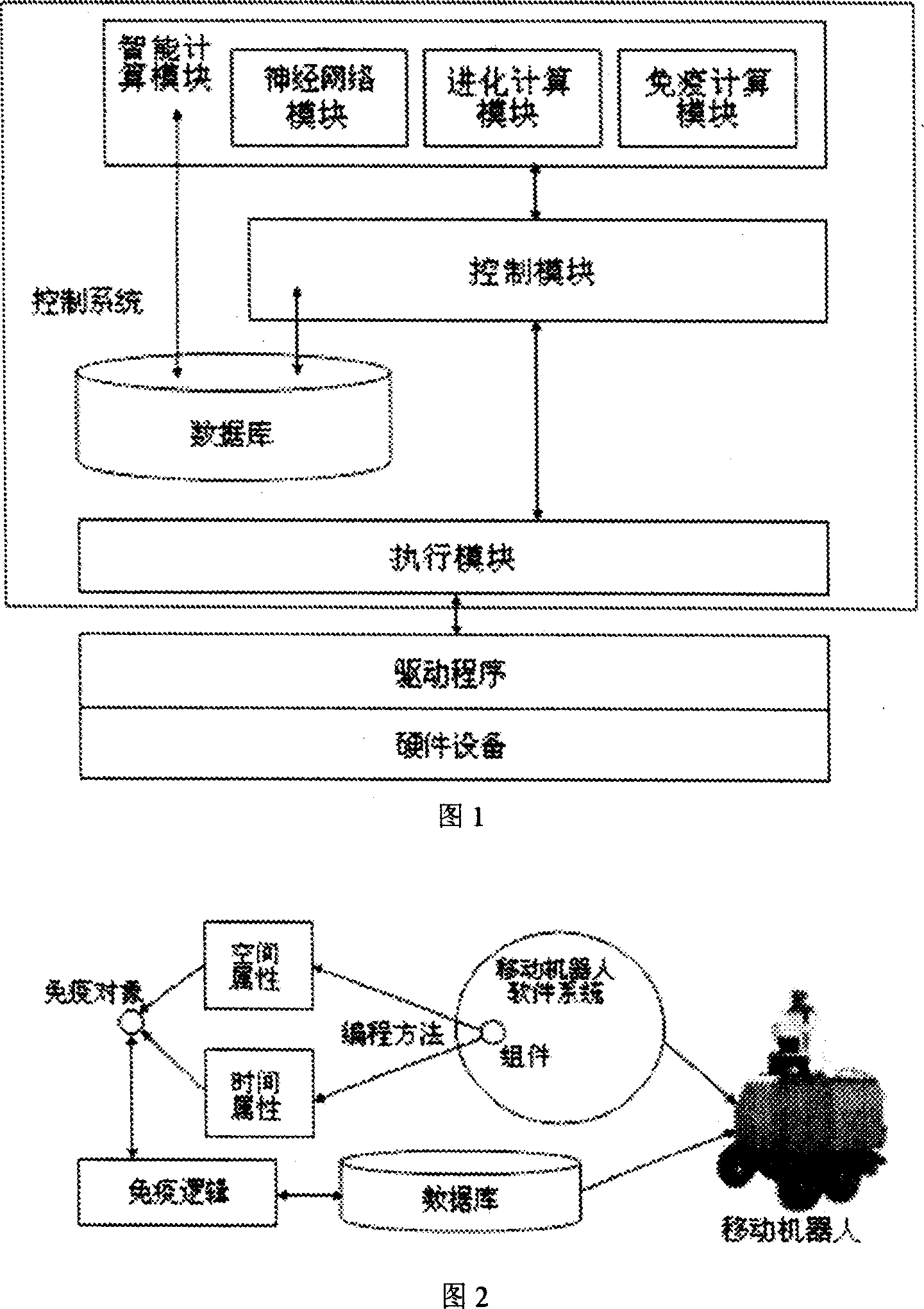

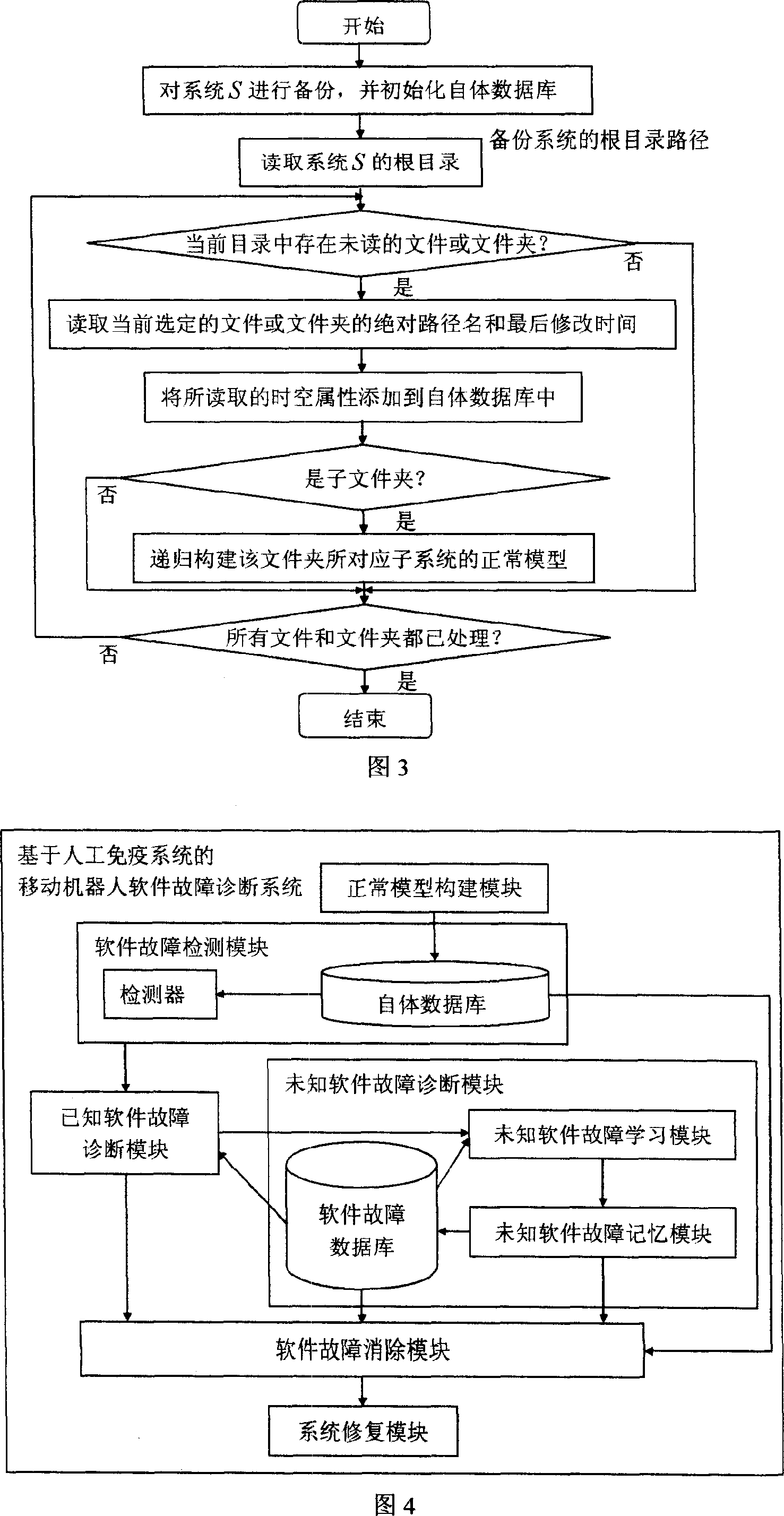

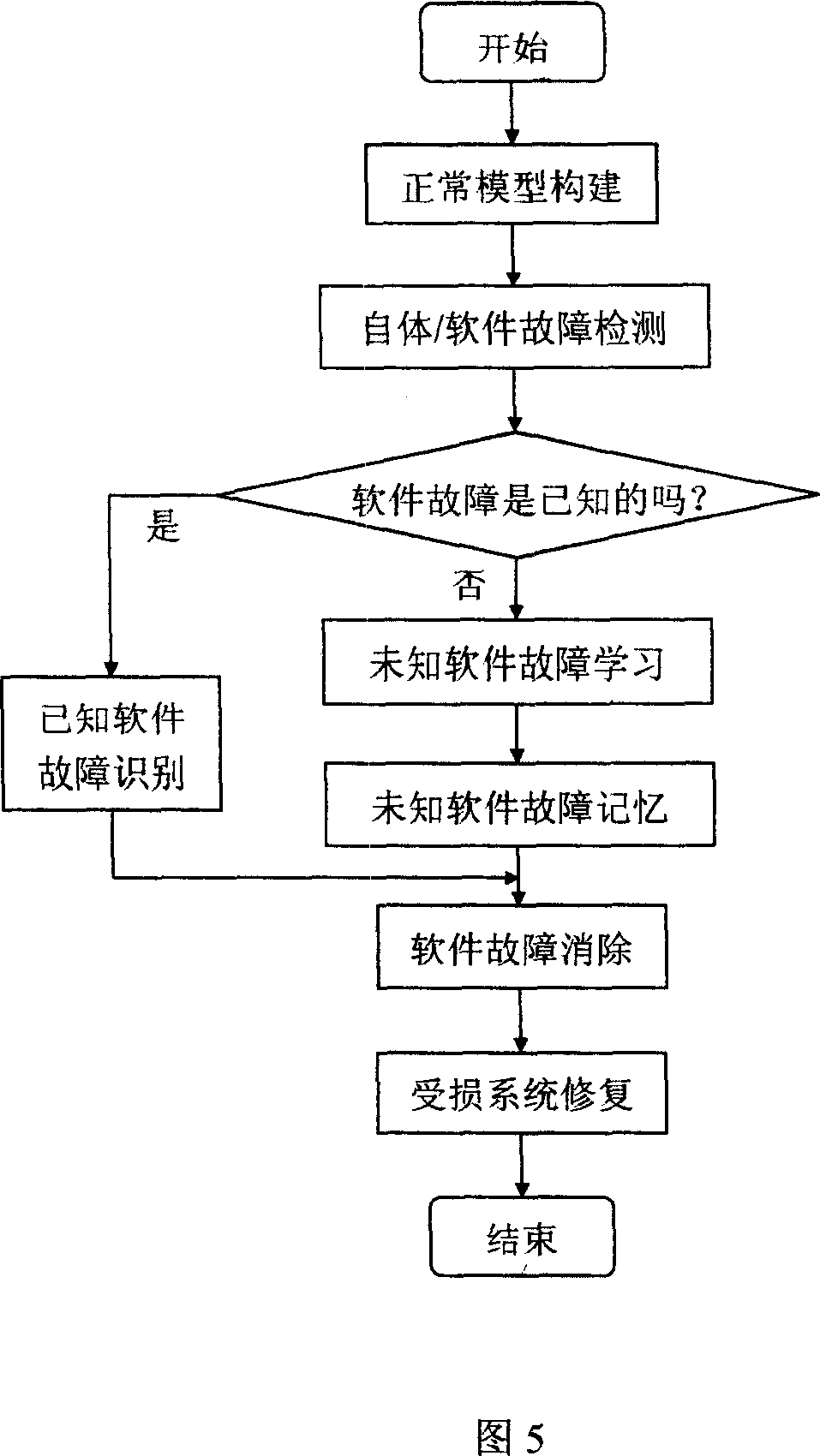

Fault diagnostic system of mobile robot software based on artificial immune system

InactiveCN101008917ASolving automation problemsSoftware testing/debuggingSpecial data processing applicationsArtificial immune systemNerve network

This invention relates to mobile robot software fault dialogue system based on human immune system, which comprises normal module form module, software fault test module, known software fault dialogue module, unknown software dialogue module, software remove module and system restore module, wherein, the normal mode form uses mobile robot software system to establish database; the software fault test module is to test whole software fault; normal mode is determined by all abnormal time and space property.

Owner:CENT SOUTH UNIV

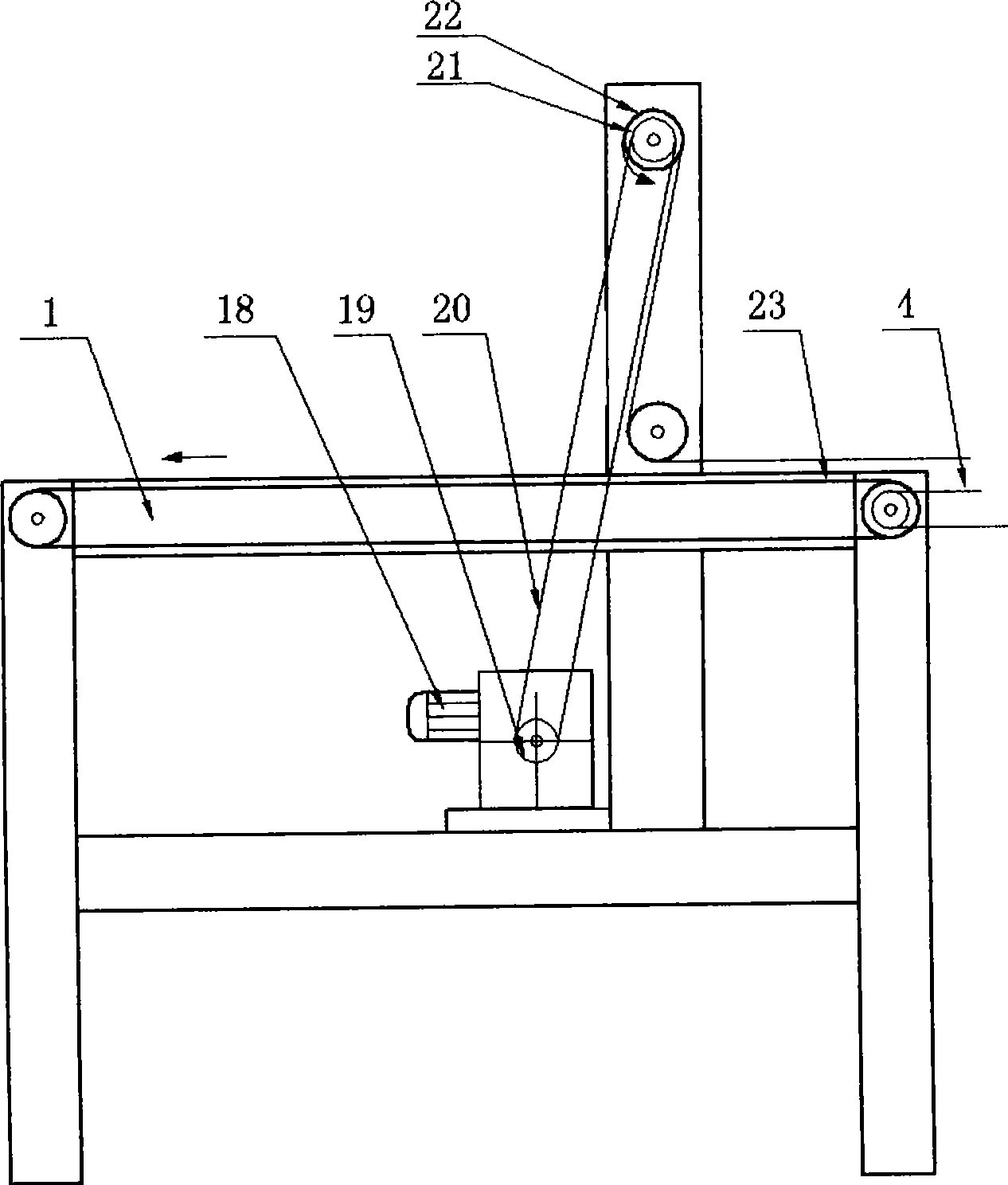

Full automatic coiled sheet material energy-saving blanking machine

InactiveCN101468476AIncrease productivityGuarantee product qualityShoemaking devicesSevering textilesWaste materialTextile industry

The invention relates to a fully-automatic rolled sheet energy saving blanking machine, which is suitable for shoe making industry, embroidery industry, textile industry, paper industry and so on. A discharge worktable of the machine is connected with a host machine through a conveyer belt chain, the host machine is connected with a material feeding worktable frame which is connected with a rolled material feeder, a cylinder outlet pipeline is connected with a press roller, and two oil path pipes of a hydraulic device are connected with a hydraulic mechanism of a moving head device main body. An integrated control circuit is arranged in a computer program controller so as to input a required mechanical action program into a computer and the mechanical action program is displayed on a human-computer interface in full Chinese and English. Circuits of the computer program controller are connected with a discharge worktable device, the material feeding worktable device, the moving head device, a pneumatic device and a hydraulic device respectively. A waste material recovery mechanism is arranged on the discharge worktable, so as to solve the technical difficult problem that a finished product and a waste rolled material are mixed together and need to be selected by manpower for a long time. A plurality of rolled materials or sheets are conveyed onto the surface of the worktable through a convey roller, and the material convey speed is controlled by the computer program controller, so the material convey automation is realized. A magnetic suction disc is arranged below the moving head so as to suck a plurality of cutter heads. One machine is provided with a plurality of molds for blanking and punching so as to ensure the assembly and disassembly of the cutter molds are fast and convenient, and save time and labor.

Owner:郑书龙 +1

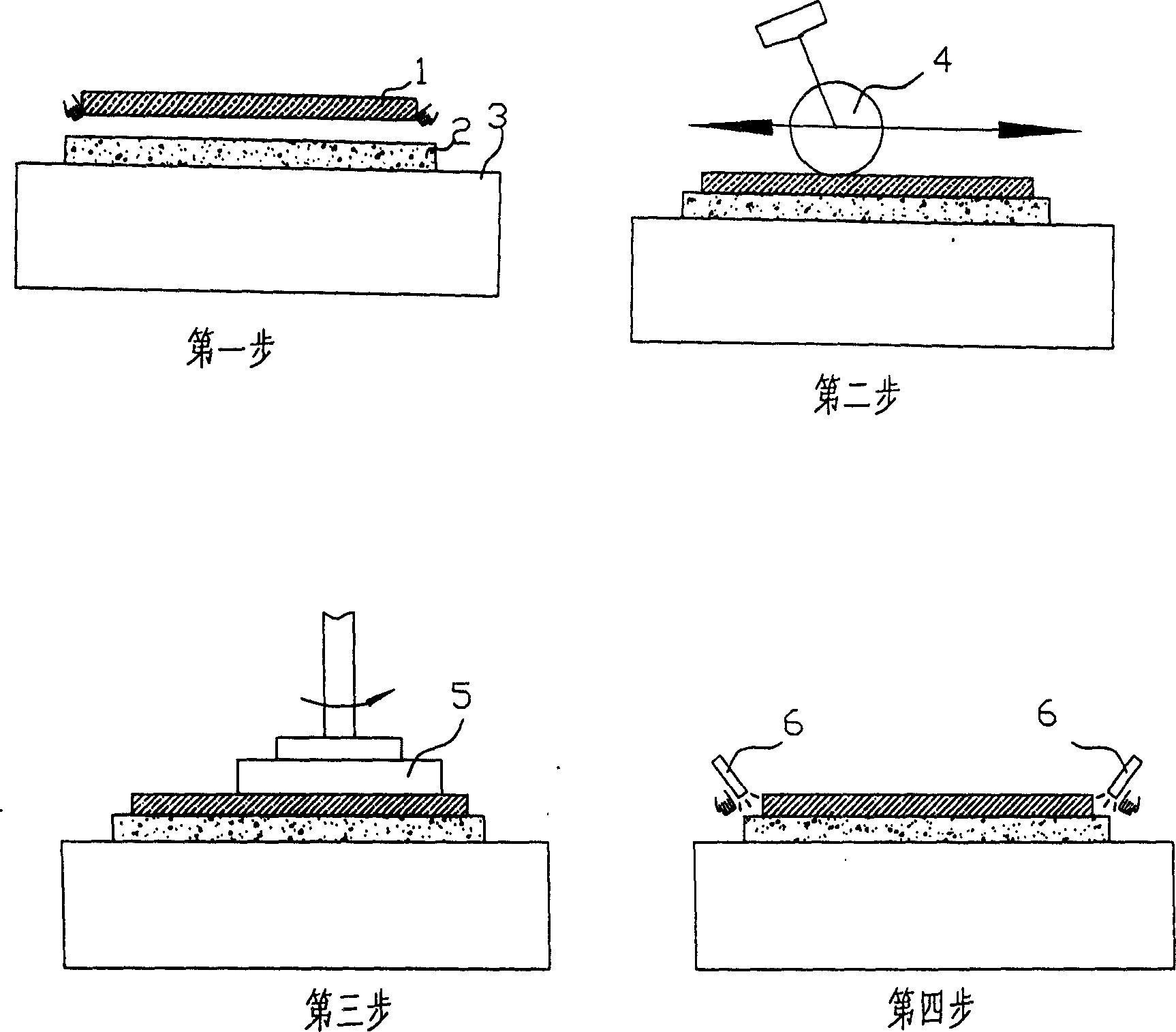

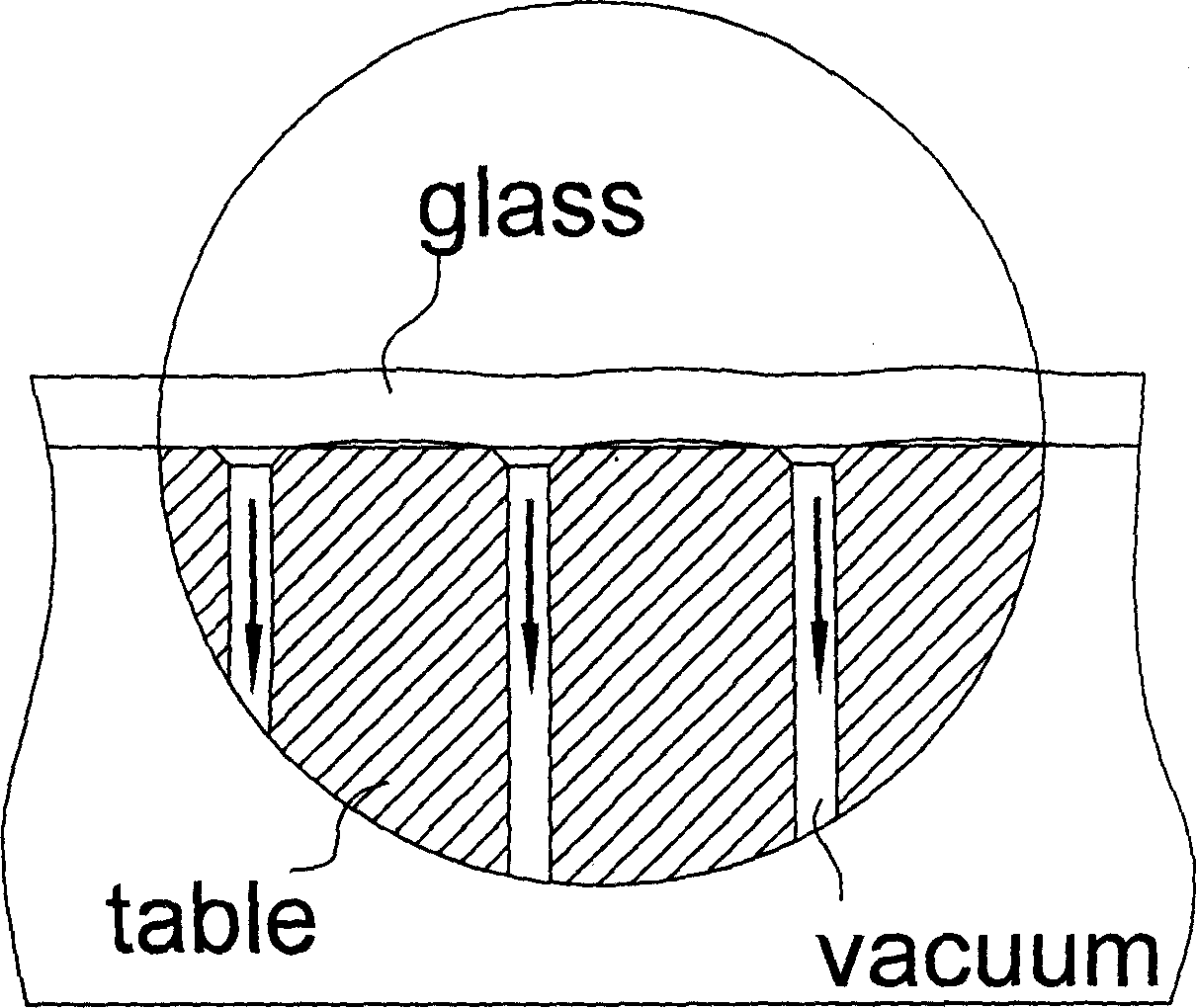

Loading and unloading device and method for ultrathin plate glass grinding step

InactiveCN1857867AAdhesive printingImprove thermal stabilityGrinding machine componentsOptical surface grinding machinesFlat glassEngineering

The present invention relates to loading and unloading device and method for ultrathin plate glass grinding step. The loading and unloading device includes one bench mechanism with surface pores for vacuum adsorption and air pressure suspending of plate glass, and one servo motor mechanism for driving the bench mechanism to load or unload plate glass. The bench mechanism has cushion of rigid porous ceramic material for bearing the plate glass. The present invention can realize automatic loading and unloading of plate glass automatically in high work efficiency.

Owner:HENAN ANCAI HI-TECH +1

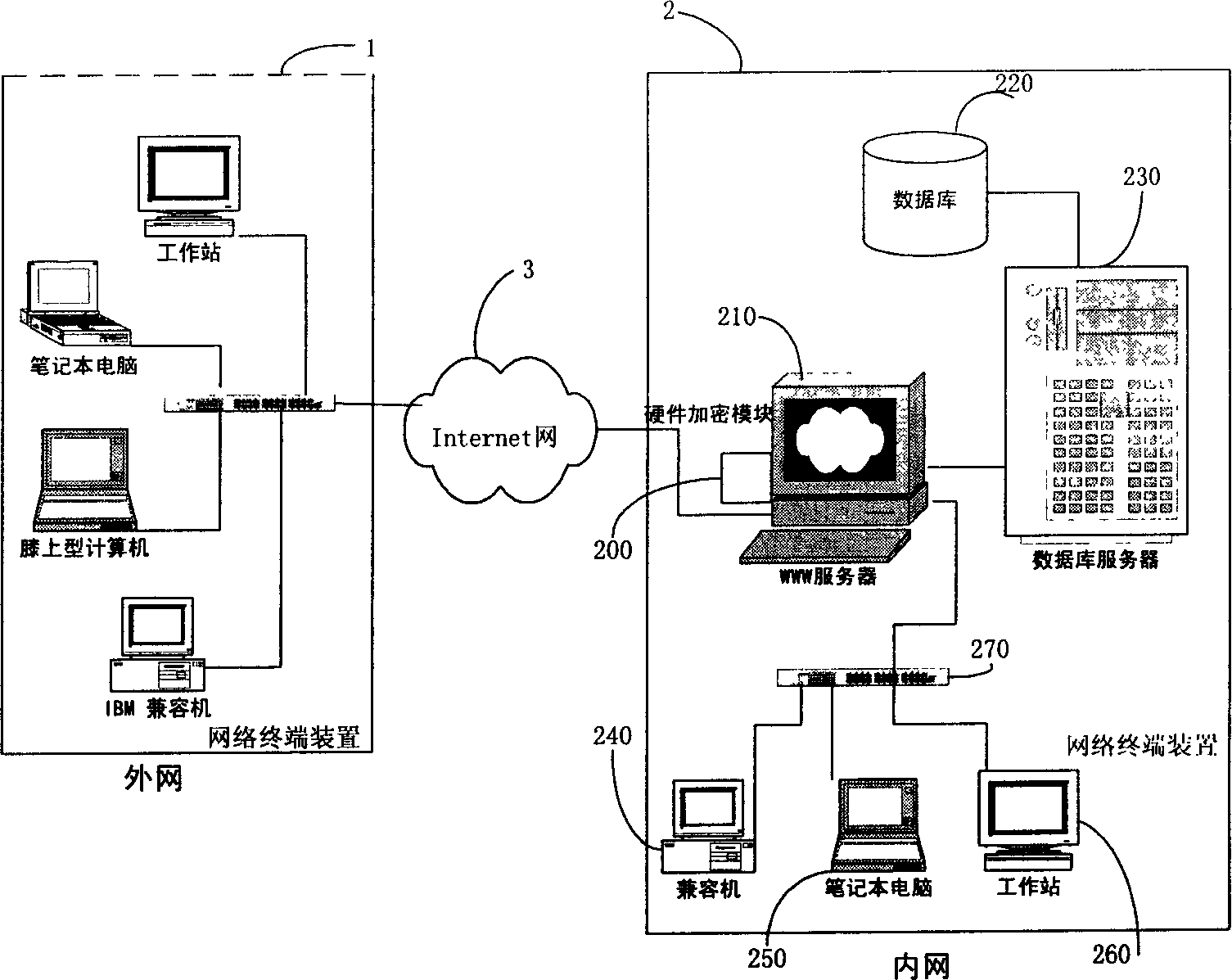

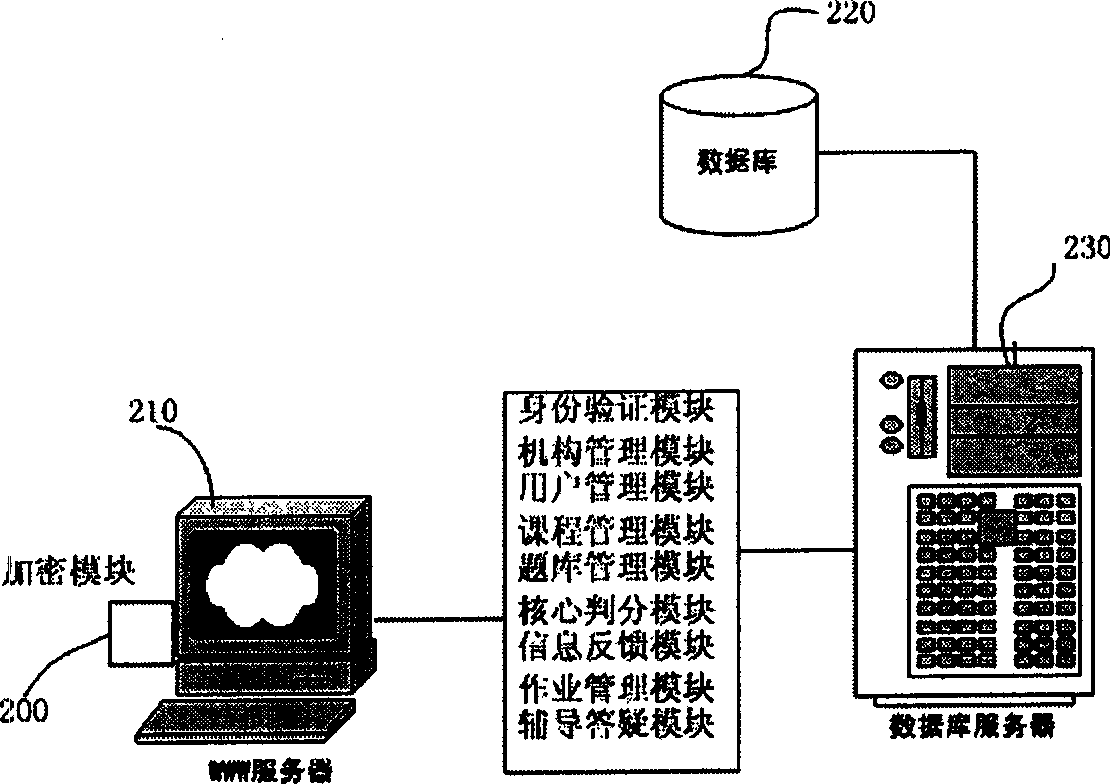

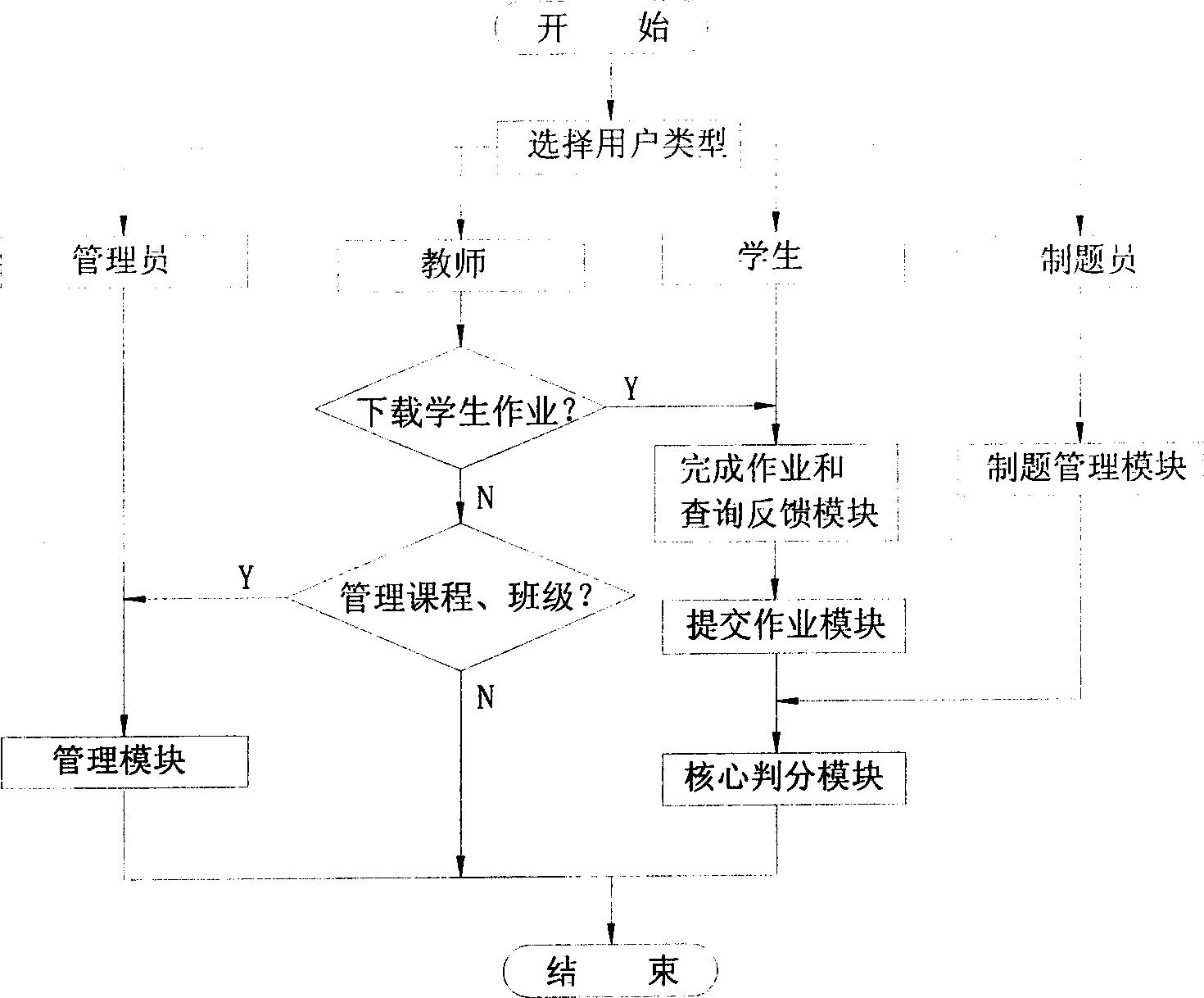

Network-based engineering drawing automatic judging method

InactiveCN1776724ADetailed Scoring DetailsSolve the problem of automatic scoringElectrical appliancesSpecial data processing applicationsGraphicsComputer aided instruction

The invention is applicable to computer aided instruction for engineering drawing. According to different users, the method decomposes relevant functions into different module units including management module based on network, kernel module for judging credit based on detailed analyzing knowledge points, module for students to submit homework, module for completing homework and querying feed back, and networked module for managing titles of engineering drawing. Under specific requirement, the system can implement specific rules for judging credits, possessing better flexibility. According to presetting rules, the method can mark highlighted tags on error positions in graph. Through colors, linewidth, line type, and text discrition, taking full advantage of graphical display, the invention realizes adding artificial comment automatically.

Owner:NANJING NORMAL UNIVERSITY

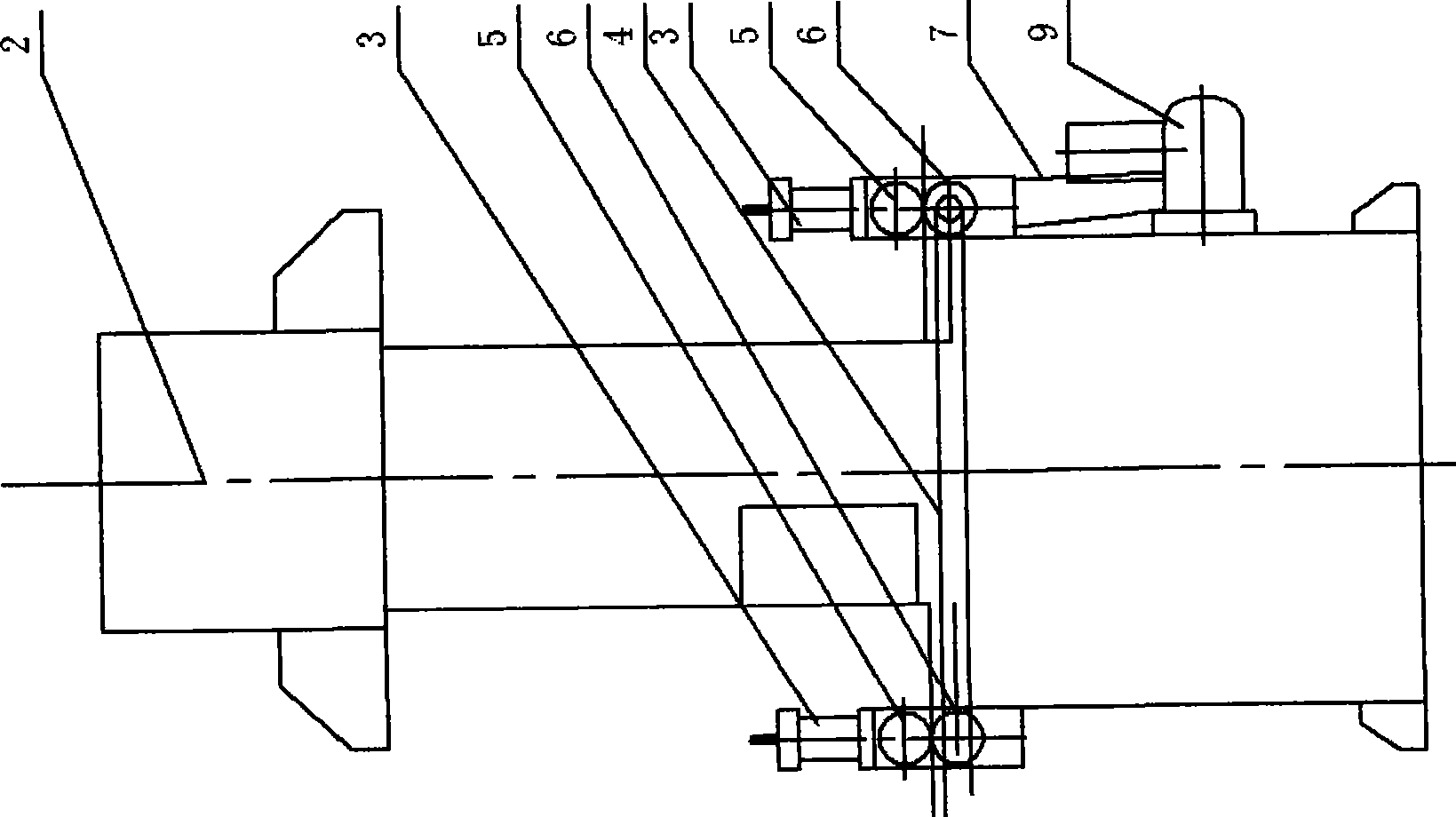

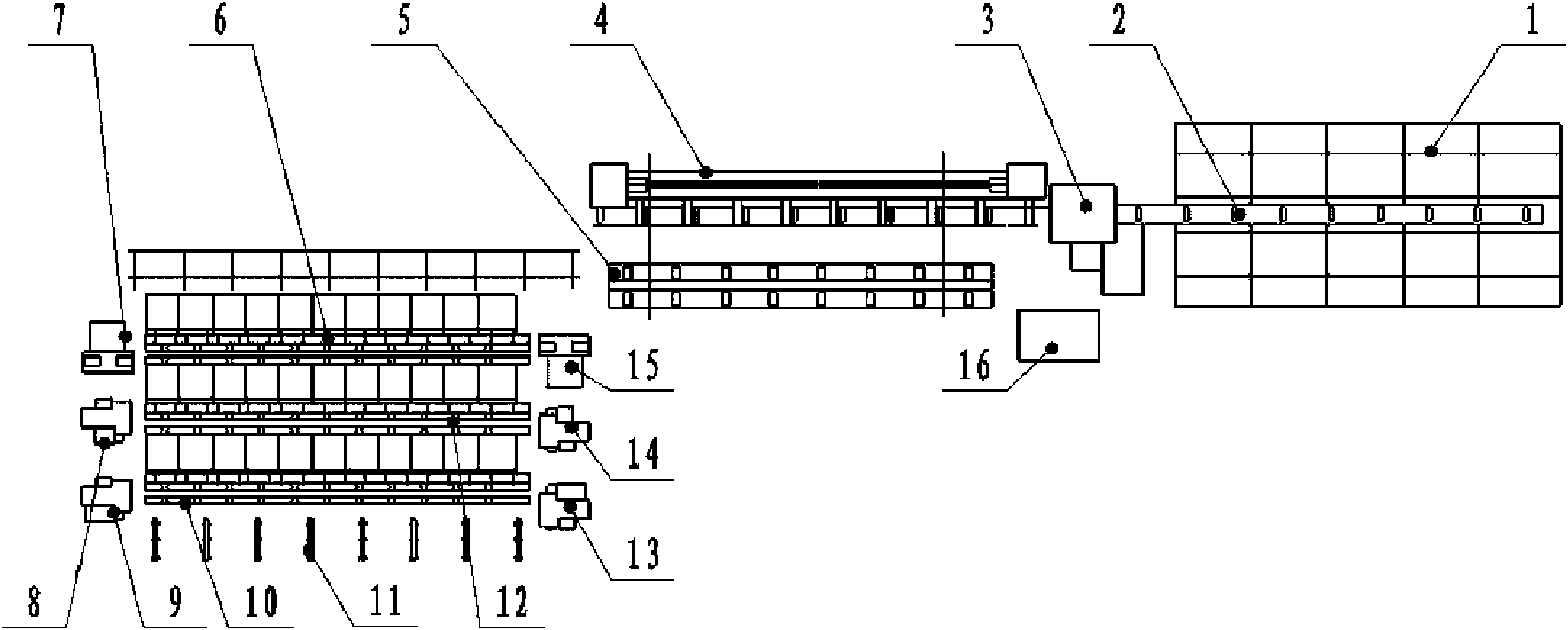

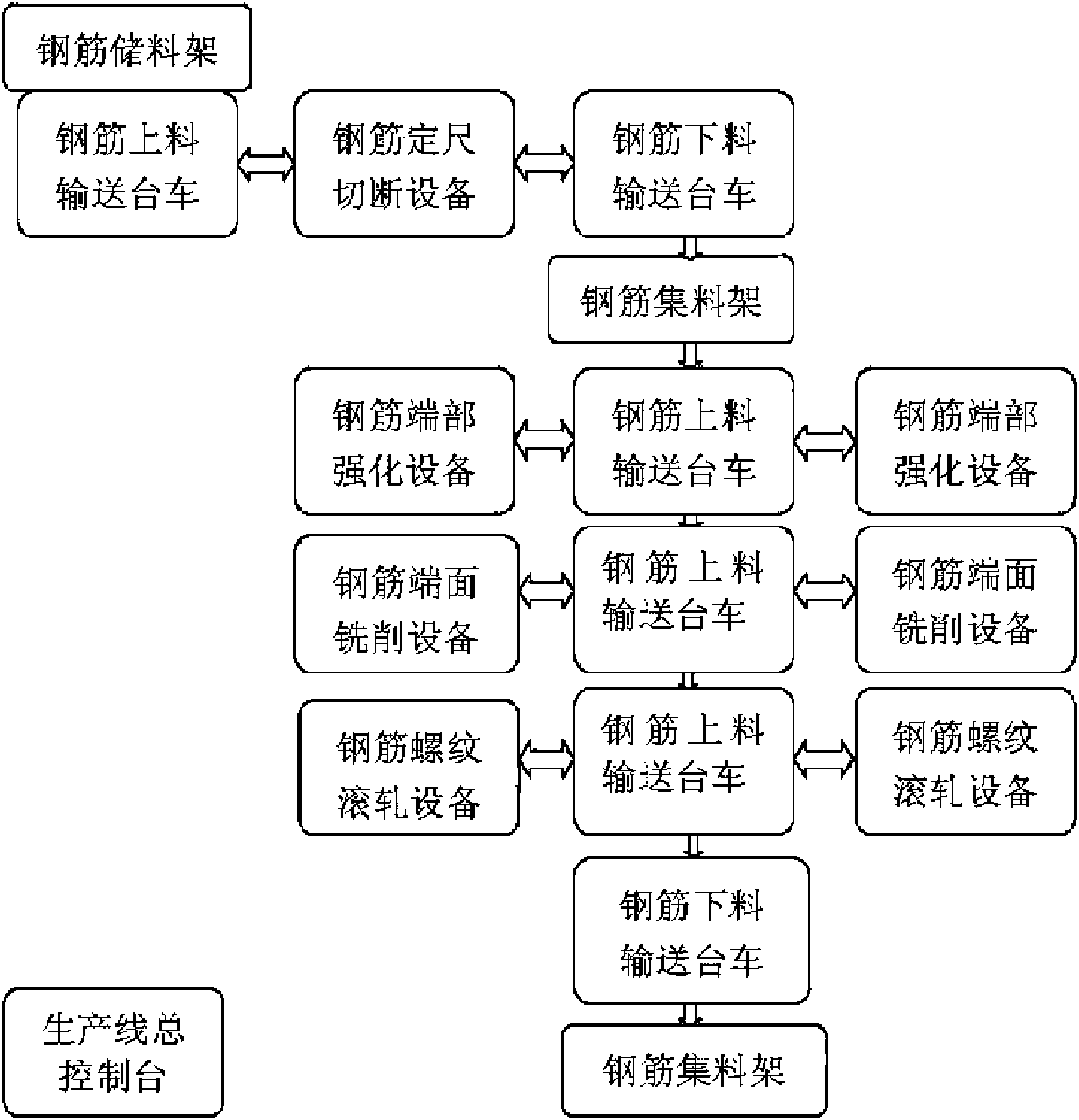

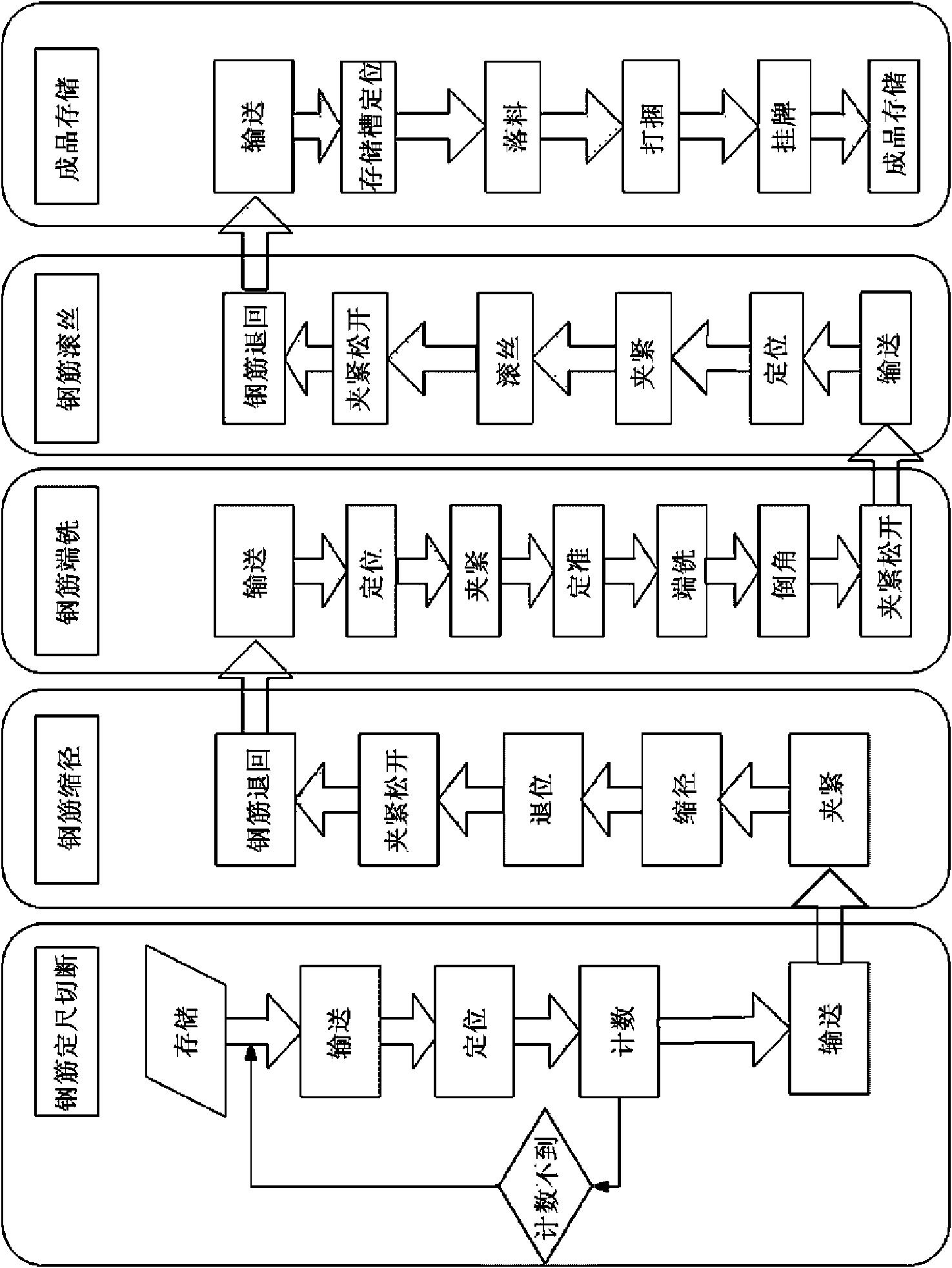

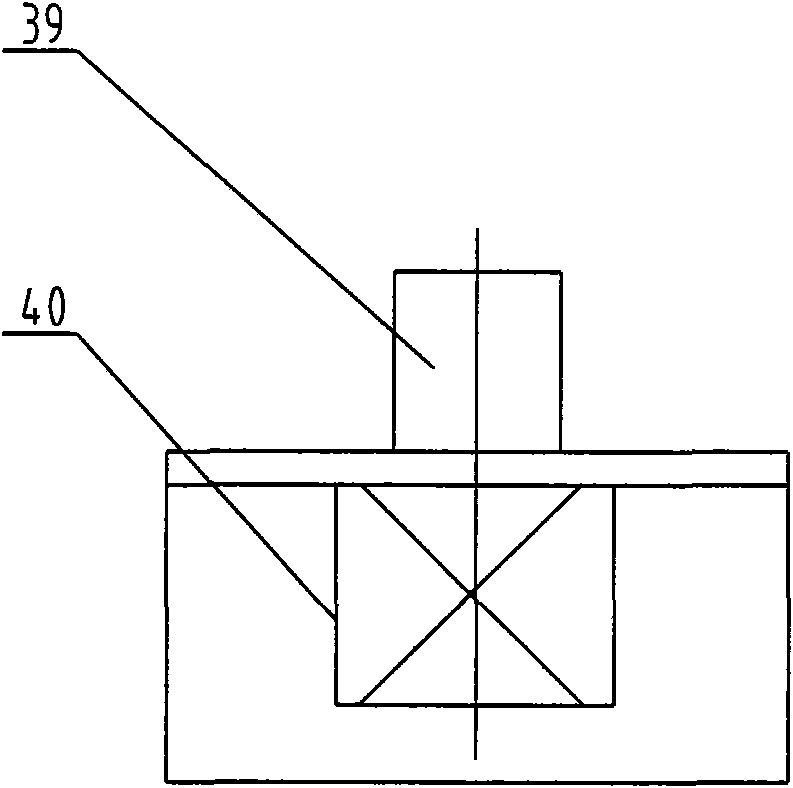

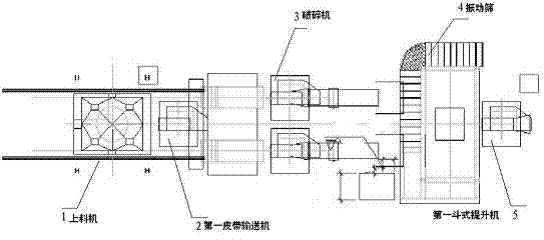

Processing production line and processing method of steel bar thread for connection of straight steel bar thread machine

InactiveCN101637870AImprove processing qualitySolve the problem of automation in the whole process of processingOther manufacturing equipments/toolsProduction lineControl system

The invention relates to a processing production line device of a steel bar thread for connection of a straight steel bar thread machine, which is formed by connecting a steel bar length-cutting device, an end reinforcement device, an end face milling device, a thread rolling device and a steel bar conveying trolley arranged among the devices into a processing line, wherein control systems of thesteel bar conveying trolley, the steel bar length-cutting device, the end reinforcement device, the end face milling device and the thread rolling device are all connected with a main control table. Aprocessing method of the invention comprises the following steps: firstly, flat cutting or length-cutting a steel bar end; secondly, reinforcing the steel bar end; thirdly, milling the obtained crosssection; and finally, thread-rolling the steel bar end. The whole processing process is controlled by the main control table by programming to realize the automation of the whole process of the steelbar thread processing line. The invention can realize the thread processing of various specifications of steel bars with diameters being between phi 12mm and phi 50mm.

Owner:CABR CONSTR MACHINERY TECH +1

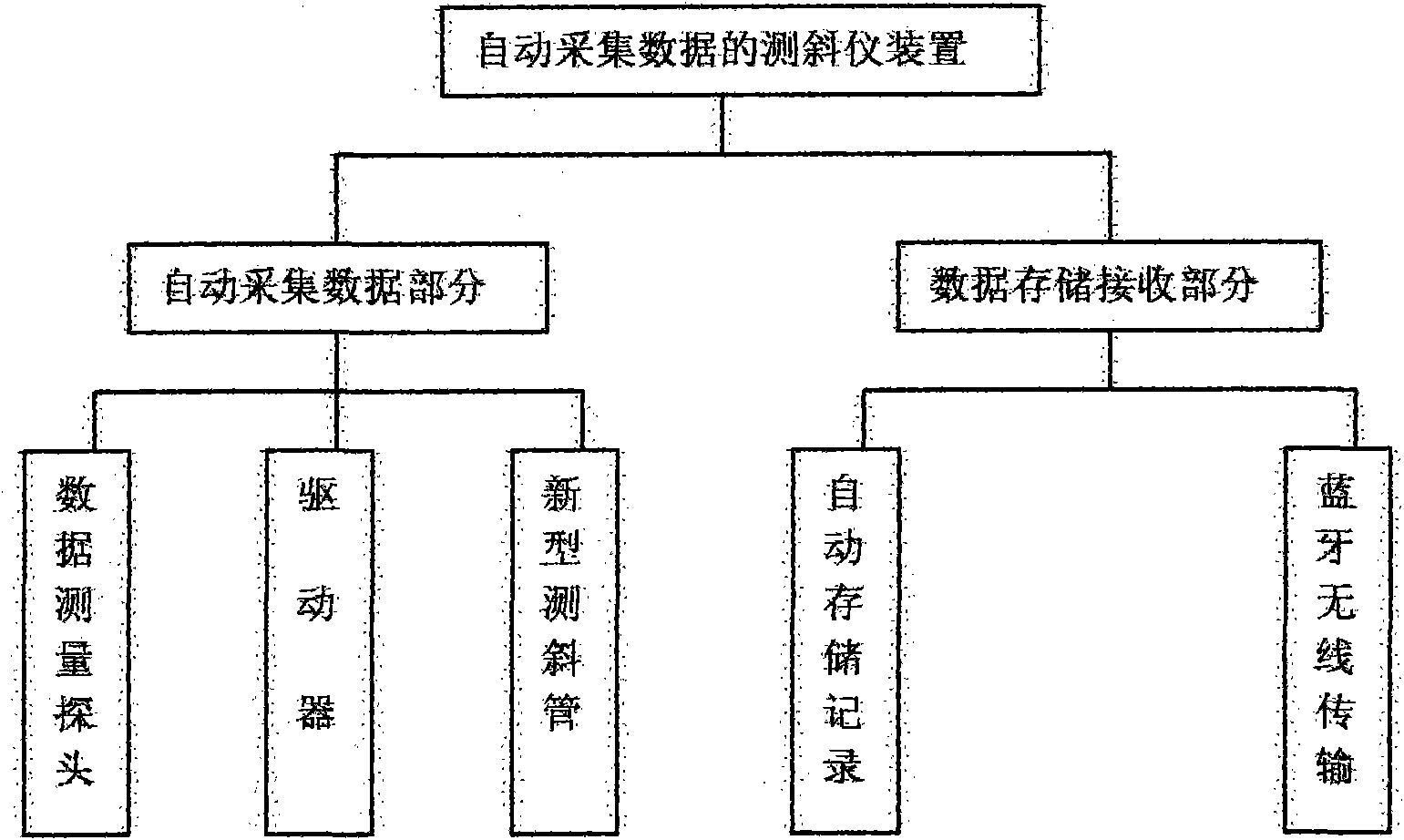

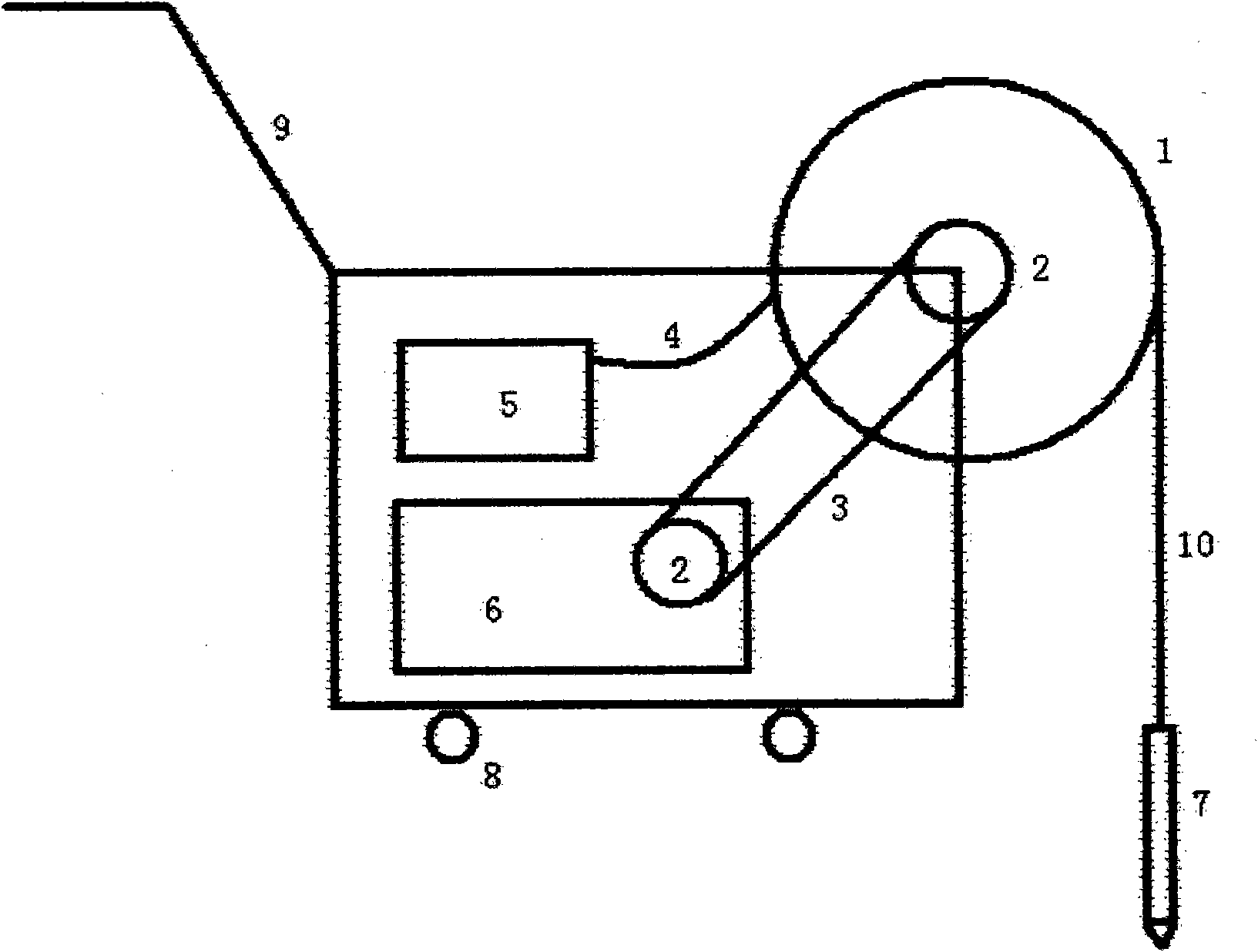

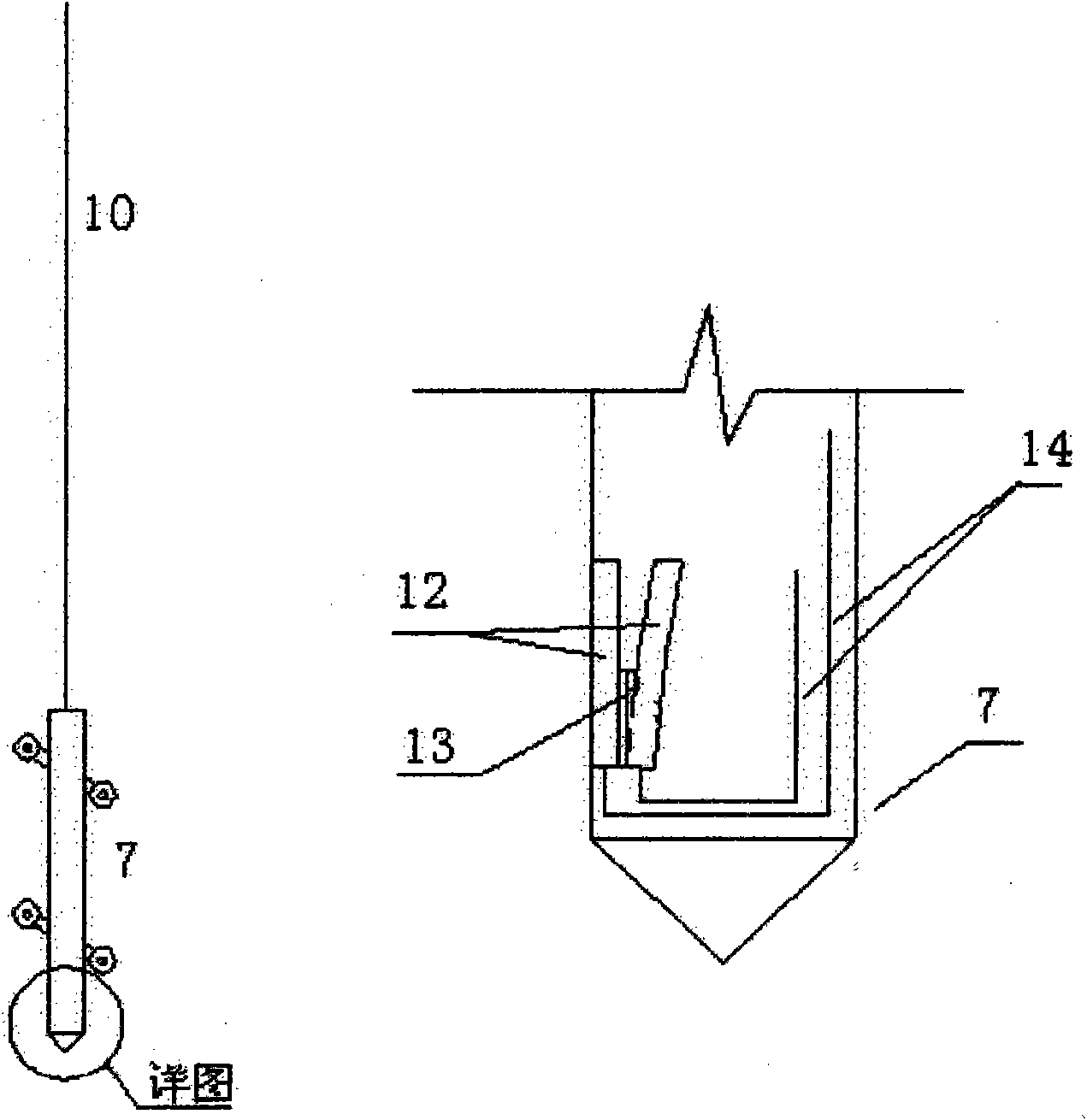

Method and device for automatically acquiring incline measuring data

ActiveCN102374857ASolving automation problemsRealize automatic collectionTransmission systemsIncline measurementData transmissionInclinometer

The invention which relates to a technology for measuring the horizontal displacement of a deep geotechnical body in the geotechnical engineering concretely relates to a method and a device for automatically acquiring incline measuring data. According to the invention, disadvantages comprising the need manual measurement and manual recording, the consumption of time and labor, and the low workingefficiency of traditional inclinometers are overcome. A technical scheme of the device, which comprises an automatic datum acquisition part and a datum reception and storage part, is characterized inthat: a microswitch is arranged in a measuring probe, magnetic rings or magnetic sheets are fixed on the outer wall of a novel incline measuring tube, and the microswitch can be automatically opened and closed under conditions of a magnetic field of the magnetic rings or the magnetic sheets on the outer wall of the novel incline measuring tube when the measuring probe of the inclinometer travels in the incline measuring tube, so functions of the automatic datum acquisition, the automatic datum recording and the automatic datum storage are realized; and a bluetooth module which is arranged in a datum acceptor can be connected with a palm computer to realize the wireless datum transmission. The device of the invention is suitable for the batch measurement of horizontal displacements of deepgeotechnical bodies in the geotechnical engineering.

Owner:SHANGHAI WATERWAY ENG DESIGN & CONSULTING +1

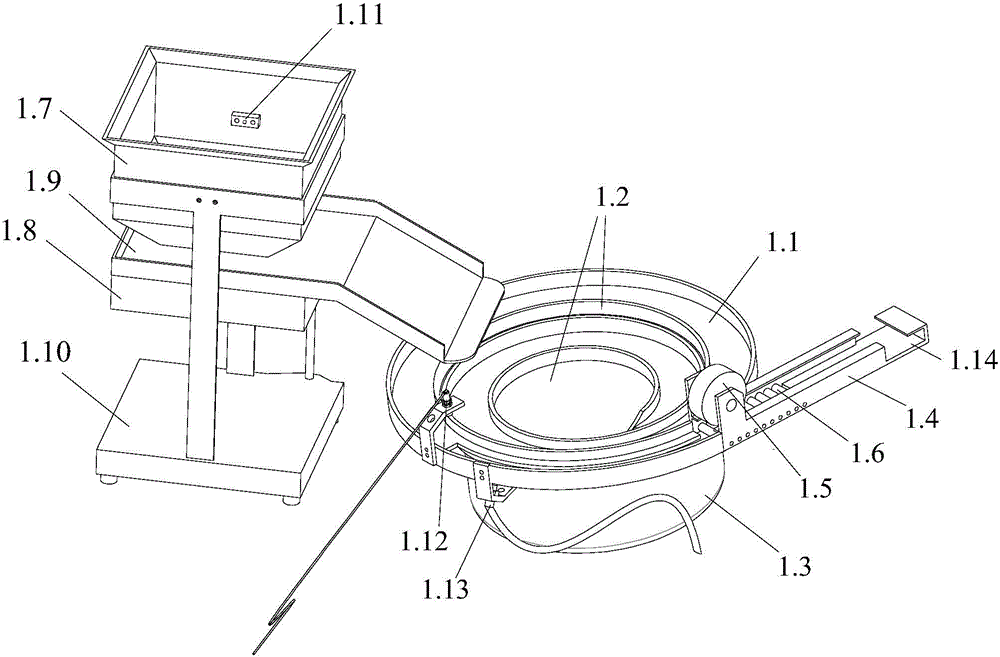

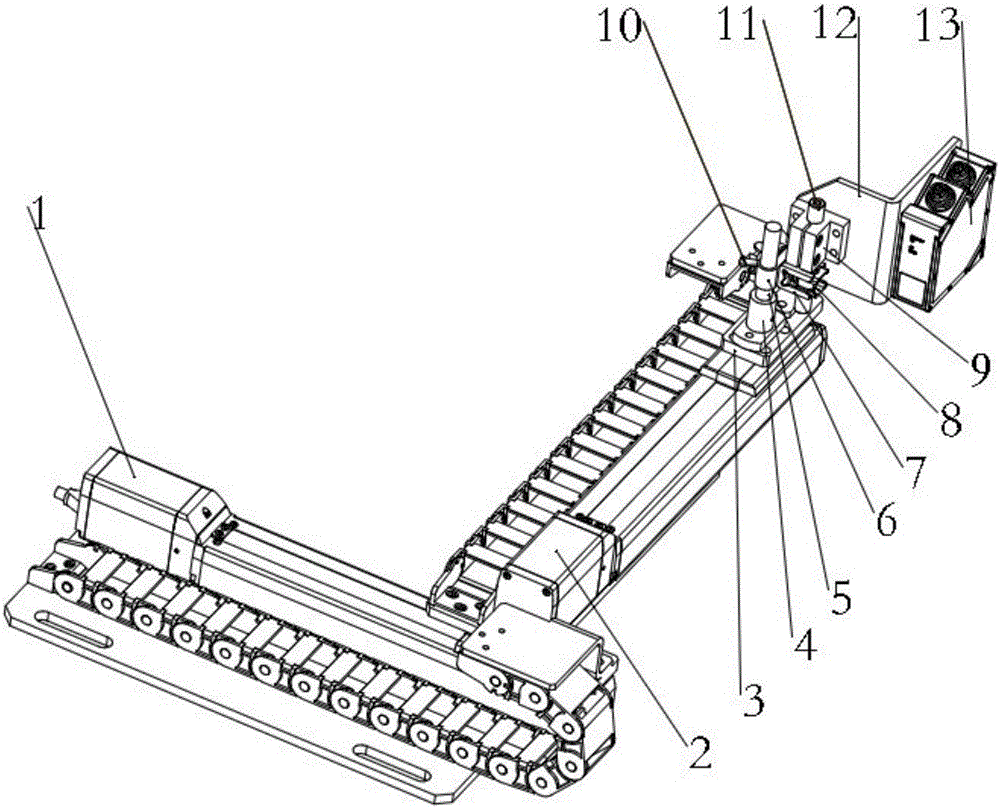

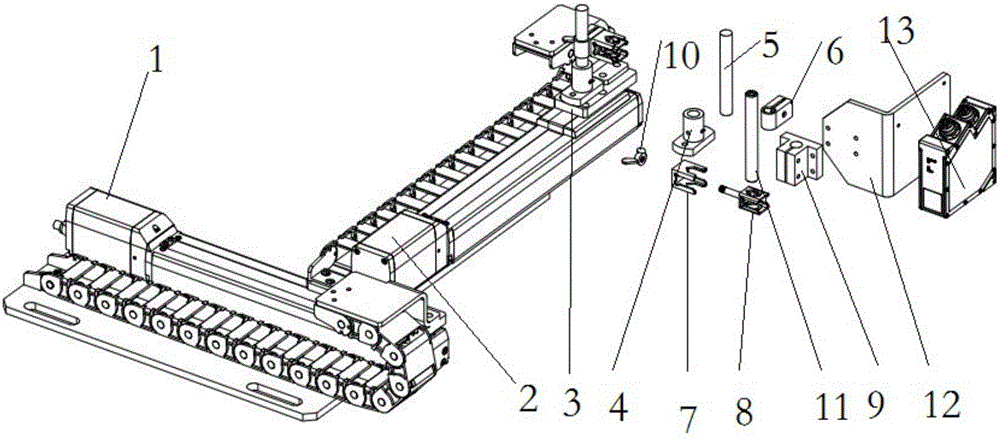

Automatic single-color mosaic-particle lay-up device and lay-up method thereof

ActiveCN104085241AImprove laying efficiencyHigh speedOrnamental structuresConveyor partsEngineeringAutomatic testing

The invention provides an automatic single-color mosaic-particle lay-up device and a lay-up method of the automatic single-color mosaic-particle lay-up device. The automatic single-color mosaic-particle lay-up device comprises a stander, a mosaic forming die which is arranged on the stander, at least one automatic mosaic-particle single-track lay-up unit, a loading device and a controller, wherein each automatic mosaic-particle single-track lay-up unit is used for gradually collecting mosaic particles one by one after transporting the mosaic particles one by one, arranging the mosaic particles into rows / columns according to a preset rule and then driving the entire row / column of mosaic particles to enter a loading procedure; the loading device is connected with the stander and used for sequentially transporting and loading the well-arranged entire row / column of mosaic particles in each automatic mosaic-particle single-track lay-up unit into the mosaic forming die; the controller is respectively connected with each automatic mosaic-particle single-track lay-up unit and the feeding device by signals. The automatic single-color mosaic-particle lay-up device is high in lay-up stability, high in lay-up speed and capable of effectively improving the lay-up efficiency and lay-up accuracy of the mosaic particles. The automatic lay-up method is used for substituting the traditional manual lay-up process, so that the problems that the current mosaic industry is low in automation degree and low in production efficiency can be solved.

Owner:FOSHAN UNIVERSITY

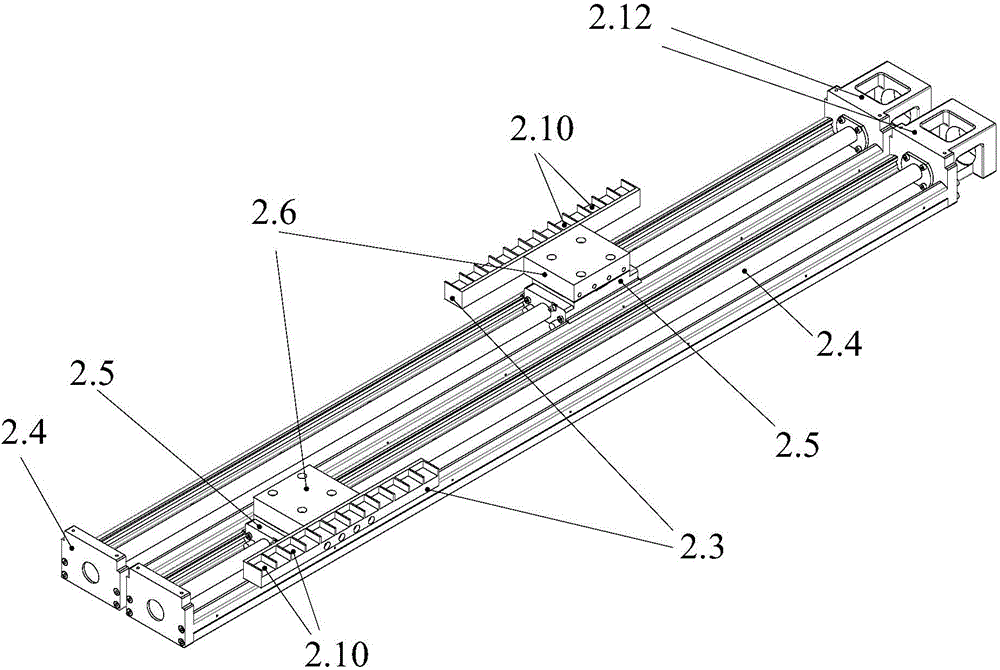

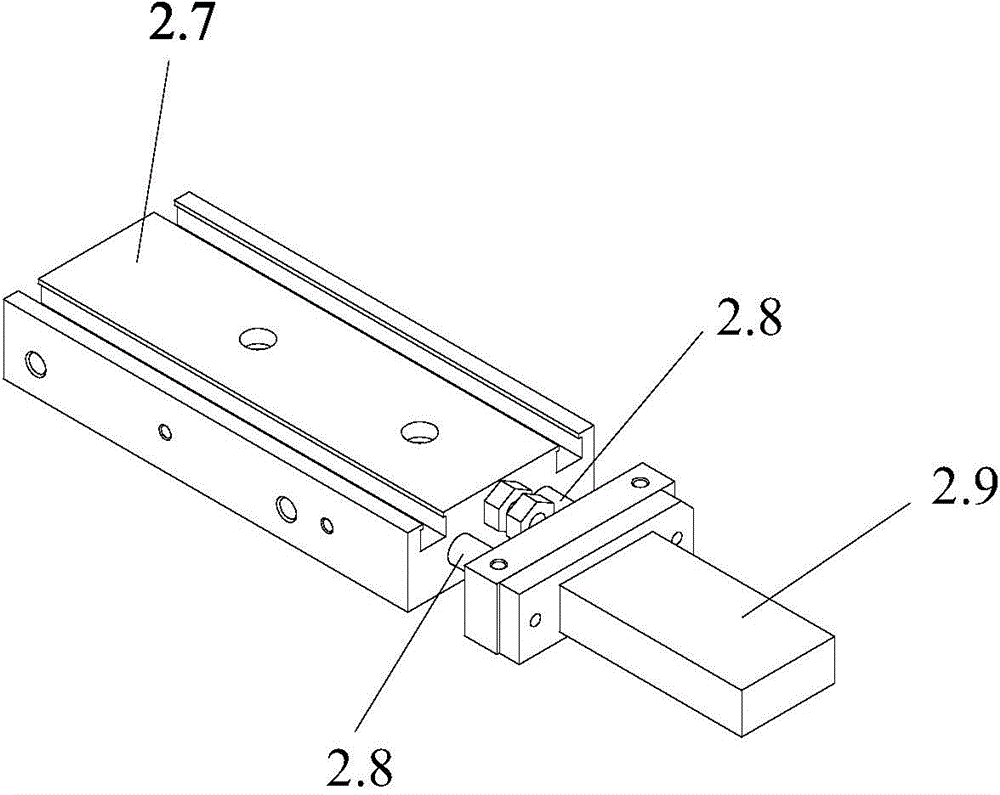

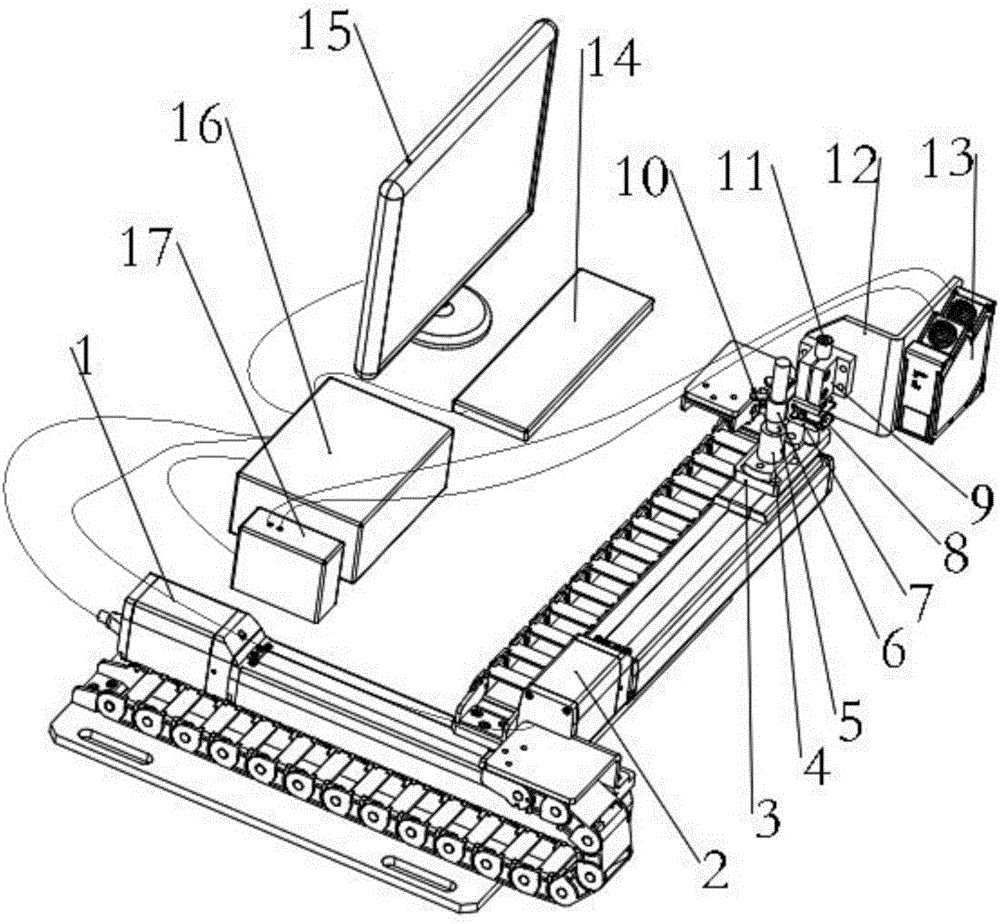

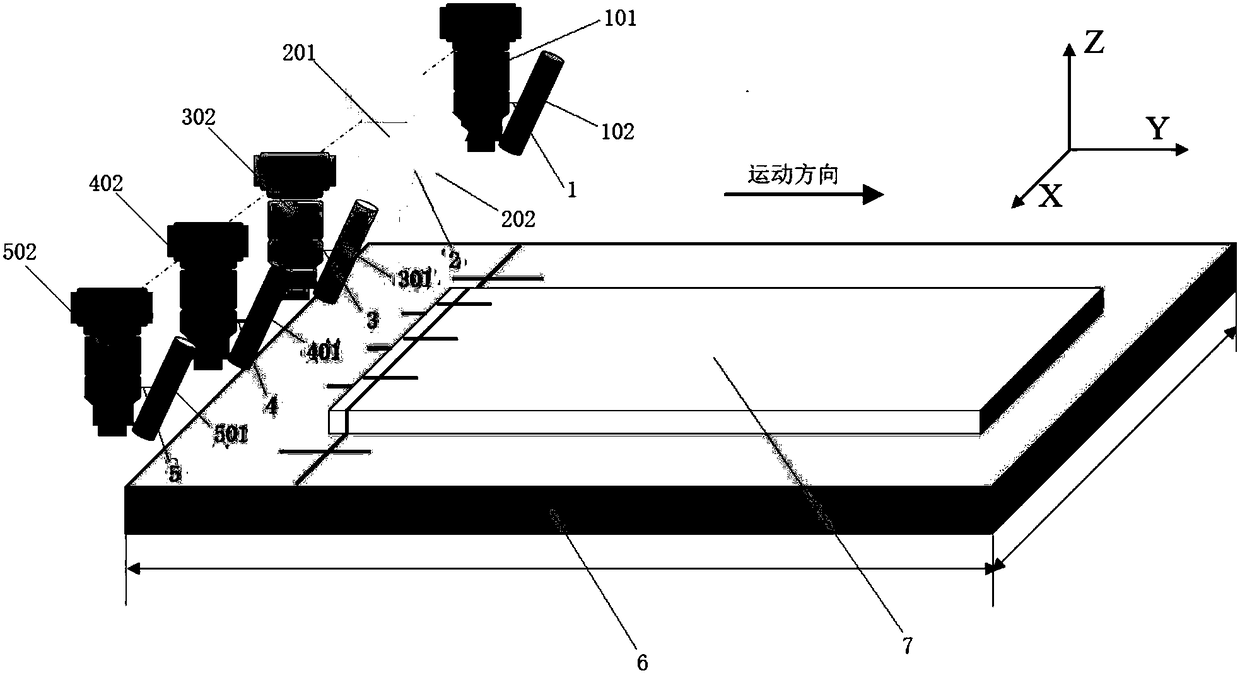

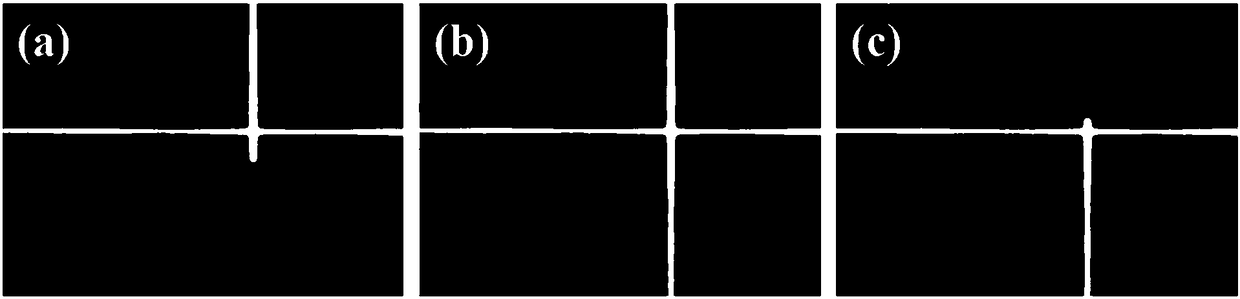

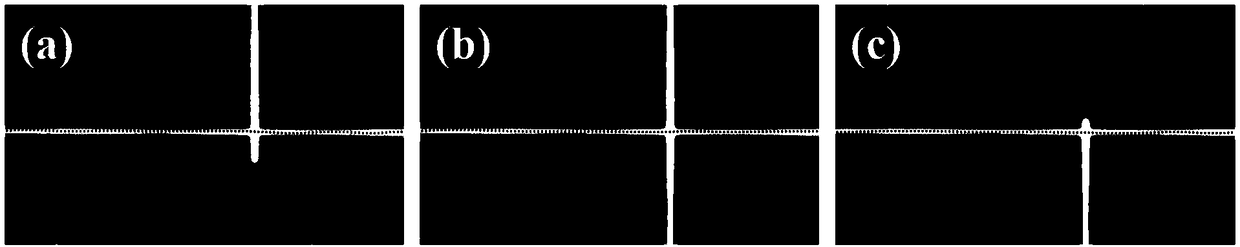

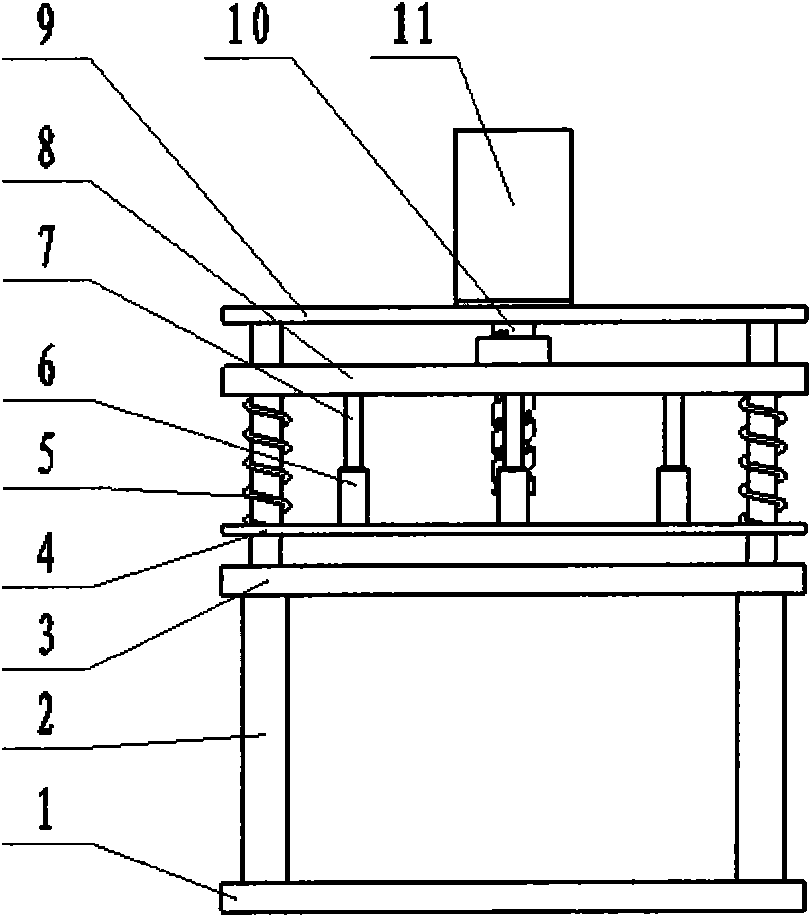

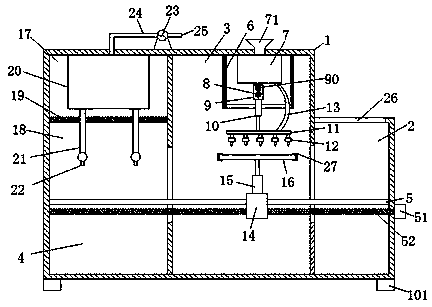

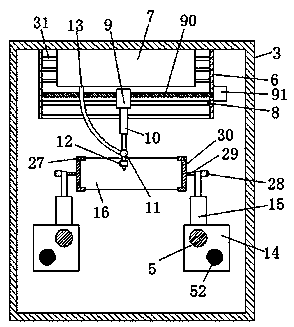

Online visual detecting system for robot polishing

ActiveCN106584273ARealize the automation of grinding inspectionSolve processabilityGrinding feed controlAutomatic grinding controlSimulationDisplay device

The invention relates to the technical field of detection in the robot polishing process, in particular to an online visual detecting system for robot polishing. The online visual detecting system for robot polishing is characterized by comprising a three-dimensional laser measuring mechanism and a two-dimensional moving mechanism; the two-dimensional moving mechanism is provided with a posture adjusting mechanism; the three-dimensional laser measuring mechanism includes an industrial personal computer; the industrial personal computer is connected with a signal processor; the signal processor is connected with a three-dimensional laser camera mounted on the posture adjusting mechanism; the industrial personal computer is connected with control variable frequency motors of an X-directional guide rail and a Y-directional guide rail of the two-dimensional moving mechanism; a keyboard and a display are connected with the industrial personal computer; and the X-directional guide rail of the two-dimensional moving mechanism is mounted on the Y-directional guide rail. The online visual detecting system for robot polishing solves re-positioning errors and waste of time caused by manual detection, preferably solves the machining and detecting problems in robot polishing, realizes the automation process of polishing and detection, and effectively improves the machining quality and efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

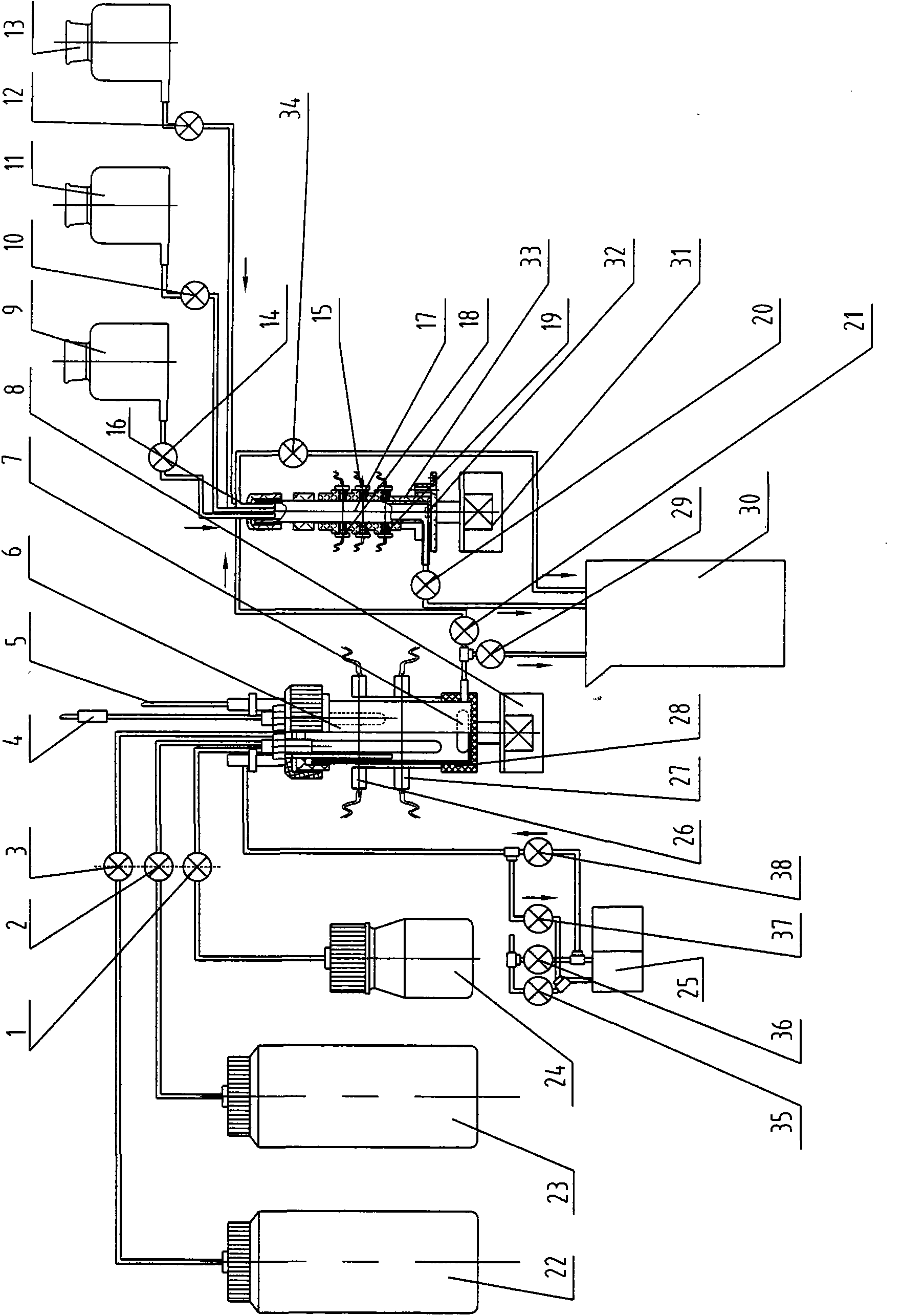

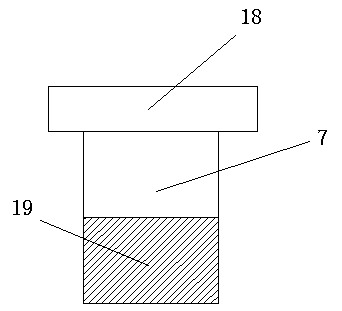

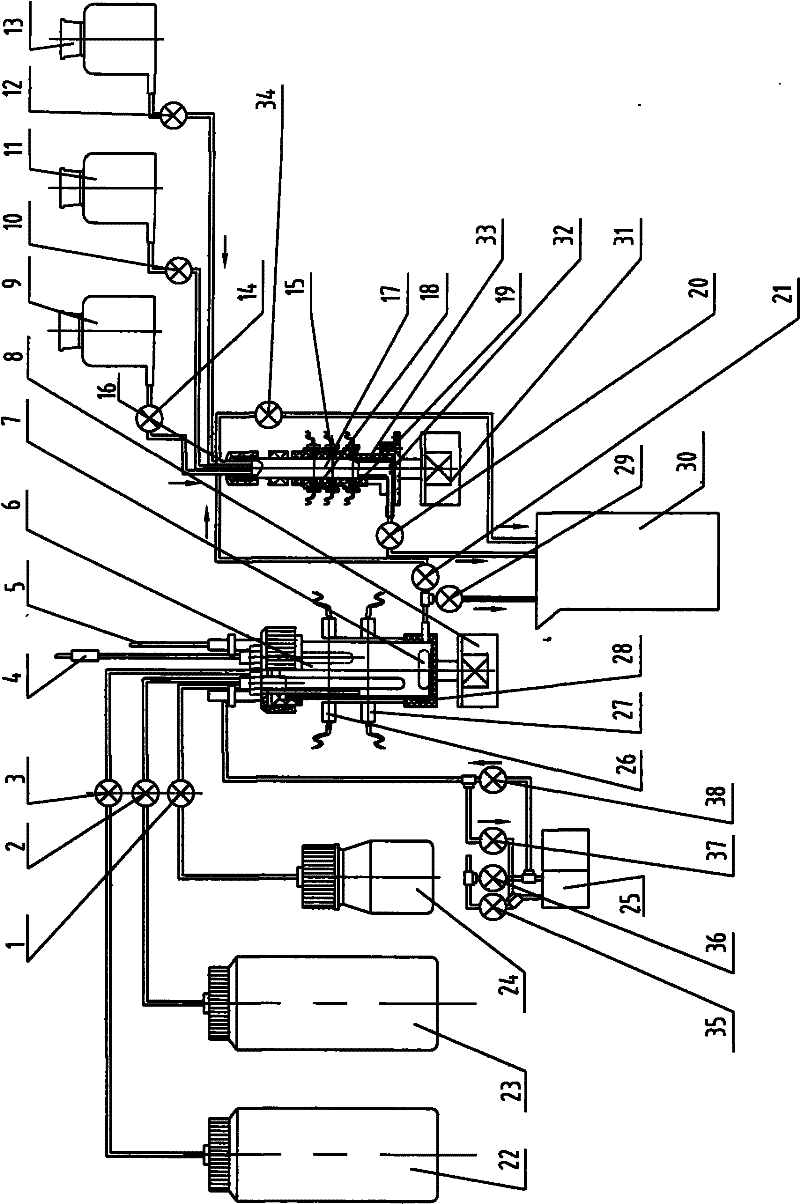

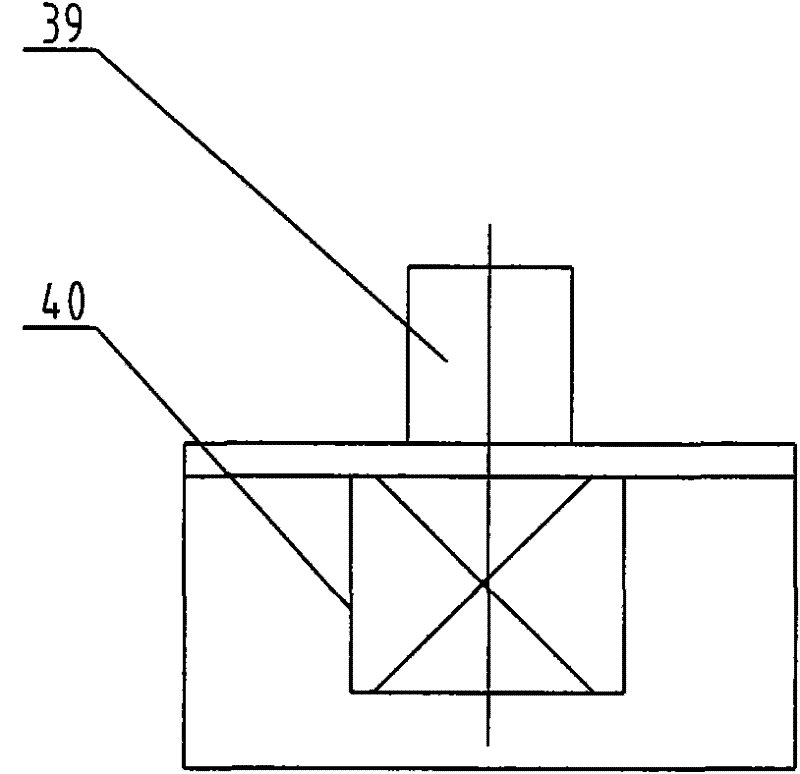

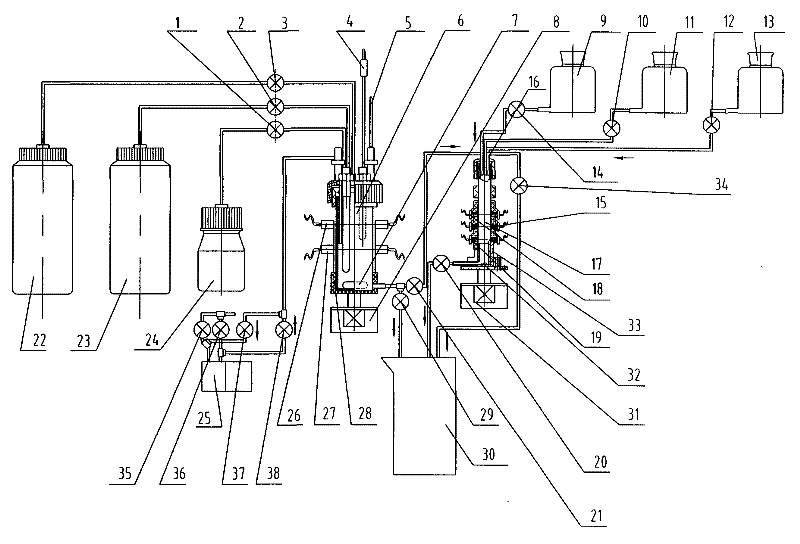

Fully automatic water-soluble acid tester

InactiveCN101614674AAvoid direct contactEasy to processMaterial analysis by observing effect on chemical indicatorDistilled waterEngineering

The invention belongs to the field of measurement apparatus, in particular to a fully automatic water-soluble acid tester which is characterized by comprising a test cup, a test tube, a cleaning agent bottle, a distilled water bottle, a sample bottle, a vacuum pump, a test tube, a waste liquid bottle and an indicator bottle, wherein the test cup is provided with a heater and a temperature sensor, the cup opening of the test cup is respectively communicated with the cleaning agent bottle, the distilled water bottle, the sample bottle and the vacuum pump through conveying pipes, the pipe opening of the test tube is provided with a closed needle head and is respectively communicated with the indicator bottle, the test tube and the waste liquid bottle through conveying pipes, and bottoms of the test cup and the test pipe are communicated with the waste liquid bottle through conveying pipes. The invention overcomes the defects of low efficiency and large test result error caused by adopting the manual visual colorimetry during the water soluble acid measurement of oil of a transformer and a steam turbine at present and has convenient processing and fabrication, low cost, convenient operation, stability and reliability, high working efficiency and accurate test result.

Owner:山东三泵科森仪器有限公司

Three-dimensional measuring device and method used for large dimension surface

ActiveCN108592816ARealize 3D measurementHigh precisionUsing optical meansThree dimensional measurementContact type

The invention discloses a three-dimensional measuring device and method used for a large dimension surface, and relates to the field of dimension measuring. The device comprises a measuring module, anadjustable fixture, a moving framework, a servo motor, a main control computer and a detection platform, the measuring module is fixed with the adjustable fixture, the adjustable fixture is fixed onthe moving frame, the moving frame is driven by the servo motor to move in the length direction of the detection platform, all detection movements are controlled by the main control computer, and a to-be-detected workpiece is placed on the detection platform. The method is simple, effective, easy for an operator to handle and high in measuring precision, the adaptability and accuracy of a measuring system of a large dimension surface can be effectively achieved, and the device and the method have better application prospect in the field of non-contact type three-dimensional high precision measuring.

Owner:SHANGHAI JIAO TONG UNIV +1

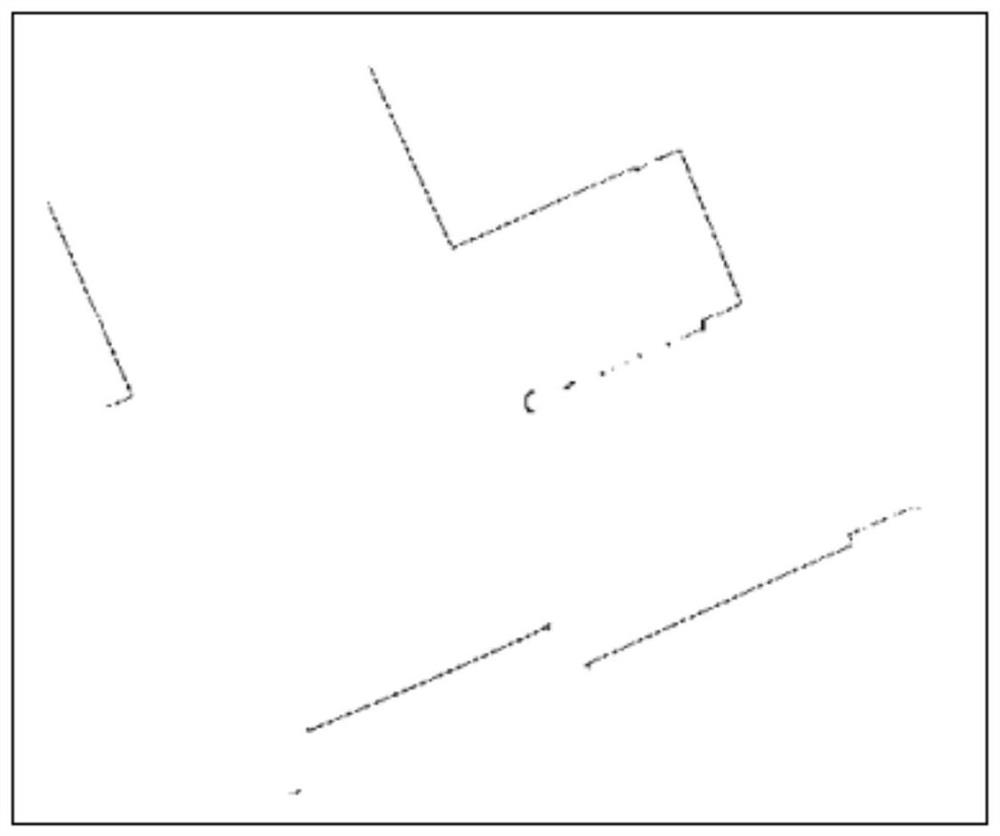

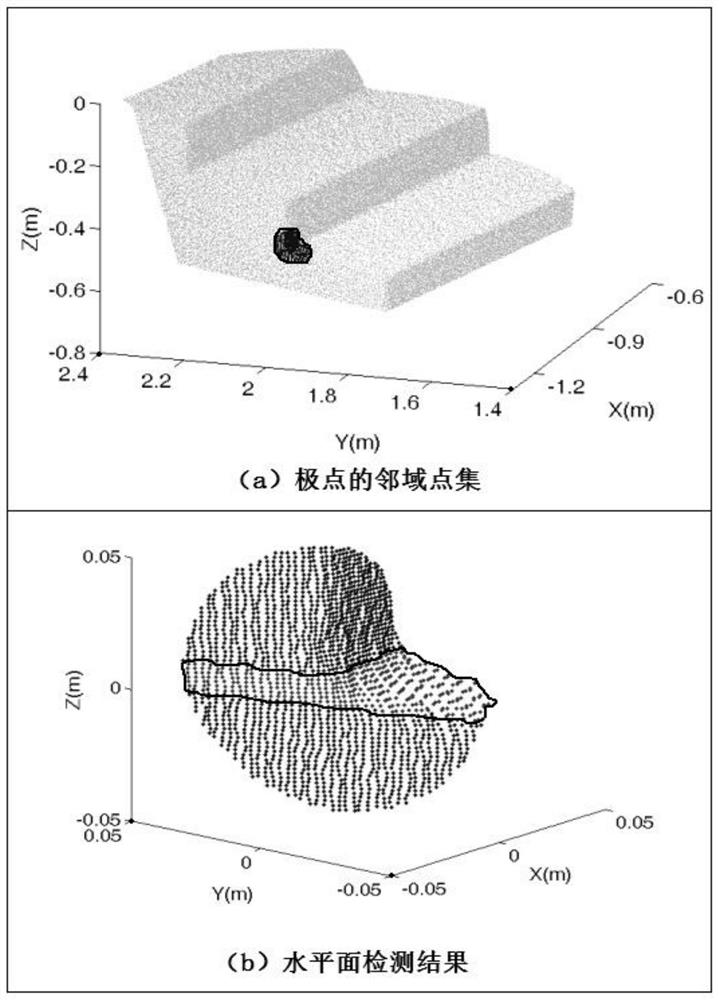

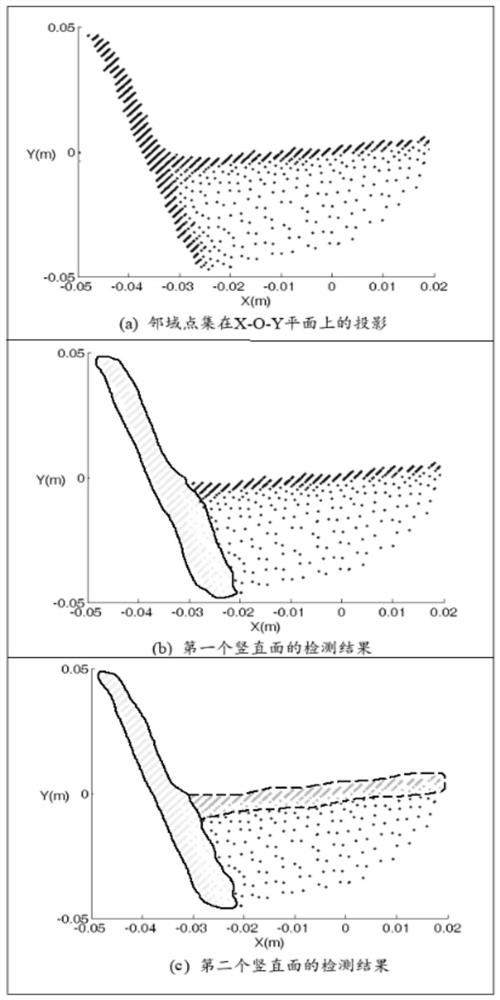

Indoor three-dimensional point cloud automatic registration method for pole extraction

PendingCN113052881AEasy to set upSolve the accuracy problemImage enhancementImage analysisPoint cloudComputer graphics (images)

According to an indoor three-dimensional point cloud automatic registration method for pole extraction, on the premise of avoiding network construction and normal direction estimation of point cloud data, automatic registration of multi-station ground laser scanning point cloud data in an indoor scene of a building is achieved, and the method mainly comprises two parts of pole extraction and point cloud registration. The method is analyzed and verified by using real indoor point cloud data of a building, registration parameter calculation is performed on multiple groups of point cloud data, a registration result is compared with a result calculated through a manual target selection mode, and the precision and reliability of the method are further verified. According to the point cloud automatic registration method based on pole extraction provided by the invention, the reliability and the precision meet the working requirements, the target does not need to be manually arranged, the parameter setting is simple, and the automation degree is high.

Owner:王程

Cloth blanking equipment

InactiveCN101555662AProtect your healthReduced physical fitnessPreparing sample for investigationSevering textilesWorking environmentEngineering

The invention relates to cloth blanking equipment which comprises a machine frame and a clamping mechanism that is used for clamping cloth and includes a lower clamping plate, an upper clamping plate and a puller spring, wherein the lower clamping plate is fixedly arranged on the machine frame, the upper clamping plate is arranged over the lower clamping plate, and the upper clamping plate is arranged on the machine frame and can slide up and down; a cutting board is arranged over the upper clamping plate, the cutting board is arranged on the machine frame and can slide up and down, both ends of the puller spring are respectively fixed on the cutting board and the upper clamping plate; a knife group is arranged below the cutting board, the upper clamping plate is provided with a cutting hole, a charging hole is arranged on the lower clamping plate, the cutting hole and the charging hole are respectively arranged under each knife of the knife group, the cutting board is connected with a drive mechanism used for controlling the cutting board to lift up and down, and the drive mechanism is arranged on the machine frame. The cloth blanking equipment effectively prevents polluting the work environment and improves the reliability of the test results.

Owner:ZHEJIANG UNIV OF TECH

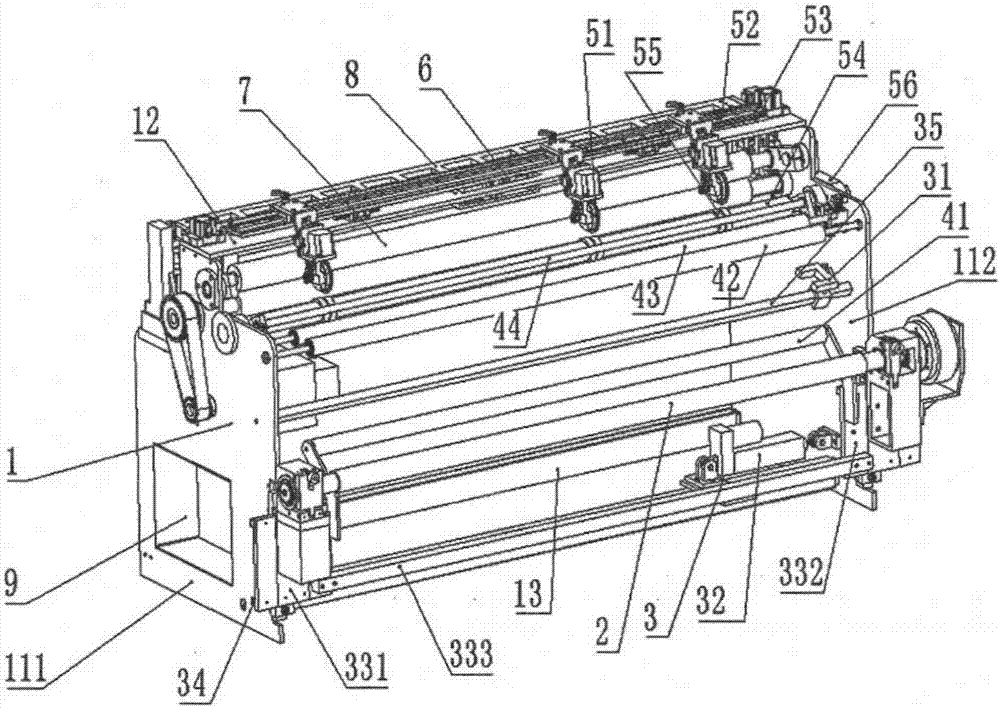

Slicing machine

InactiveCN107128732AChange manual cutting modeSolving automation problemsArticle deliveryWebs handlingEngineeringTension control

The invention relates to a slicing machine. The slicing machine is characterized in that the slicing machine comprises a rack, a depolarized part, a feeding part, a tension roller part, a traction roller part, a longitudinal knife part, a longitudinal knife transverse moving part, a transverse knife part and a control cabinet. A picture medium is spread out of a material roll, makes feeding conveying movement under the effect of a traction roller assembly, is longitudinally sliced when passing through the longitudinal knife part, continues moving and is transversely sliced when passing through the transverse knife part, and therefore picture partition slicing is completed. The depolarized part achieves the condition that the picture medium cannot skew during slicing operation. The slicing machine has the advantages that automatic slicing operation for the picture medium is achieved, and the slicing machine can also be applicable to slicing for picture media of large thicknesses. The problems of picture medium conveying skewing and tension control are solved, so that picture slicing is more orderly, and slicing quality is improved.

Owner:DONGHUA UNIV +1

Spraying method for wood preservation

The invention discloses a spraying method for wood preservation. A spraying device is used and comprises a device body; support legs are arranged on four corners of the bottom part of the device body;the device body comprises a placement chamber, a spraying chamber and a drying chamber; the placement chamber, the spraying chamber and the drying chamber are sequentially arranged horizontally and linearly; the placement chamber and the spraying chamber communicate with each other; the spraying chamber and the drying chamber communicate with each other; first slide rails extending left and rightare arranged in the placement chamber; a first threaded rod extending left and right is further arranged in the placement chamber; the two first slide rails are arranged in a front-and-back symmetrical way; and the left ends of the two first slide rails penetrate through the spraying chamber and are fixedly connected with the inner wall of the left side in the drying chamber. The spraying deviceis compact in structure and convenient to use; and a third motor drives a rotary shaft to rotate, and wood raw materials can be further rotated, so that automation is realized, and the problem that the wood raw materials need to be turned over manually according to traditional spraying is solved.

Owner:NINGBO HANGZHOU BAY NEW DISTRICT NO 9 TECH SERVICE

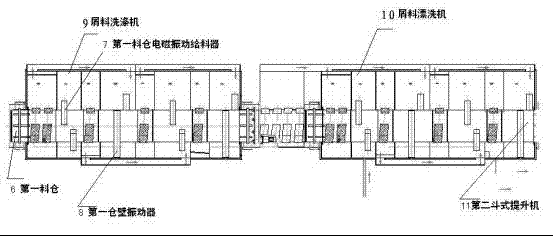

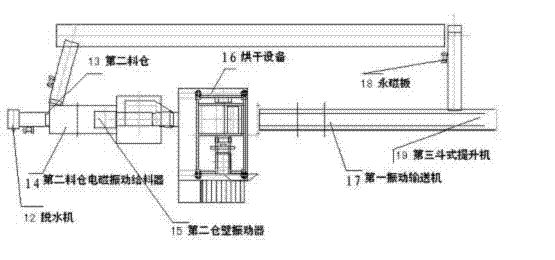

Titanium and titanium alloy residual waste treatment device system and method for sorting titanium materials

InactiveCN102259109AImprove pass rateReduce energy consumptionSolid waste disposalSolid separationSmall footprintMaterials processing

The invention discloses a titanium and titanium alloy remnant waste material processing apparatus system and a titanium material sorting method. The apparatus system comprises a crushing apparatus, a washing apparatus, a drying apparatus, a sieving apparatus, an apparatus for removing high specific weight substances and magnetic substances, and a material distributing apparatus. The titanium material sorting method comprises the steps of: feeding, crushing, sieving, washing and deoiling, rinsing, drying, sieving, high specific gravity substance removing, magnetic substance removing, material distributing, and stuffing. The system and the method provided by the invention have high recovery efficiency and high automation. With the system and the method, titanium product chain can be prolonged, and characteristics of titanium and titanium alloy remnant waste materials in recovery of high qualified rate, low energy consumption, low land occupation, low water resource consumption, and no environmental pollution are achieved. With a manual sorting method, the sorting efficiency is low; acid and alkali washing are adopted; surface impurity processing is not thorough; subsequent titanium product processing is greatly influenced; and unqualified product is likely to be produced. With the system and the method provided by the present invention, the defects are overcome, a cost of 100 million to 160 million kilowatts of power can be saved per year, and a direct economic benefit exceeds 200 millions RMB.

Owner:XIAN WORLDLINK AUTOMATION TECH

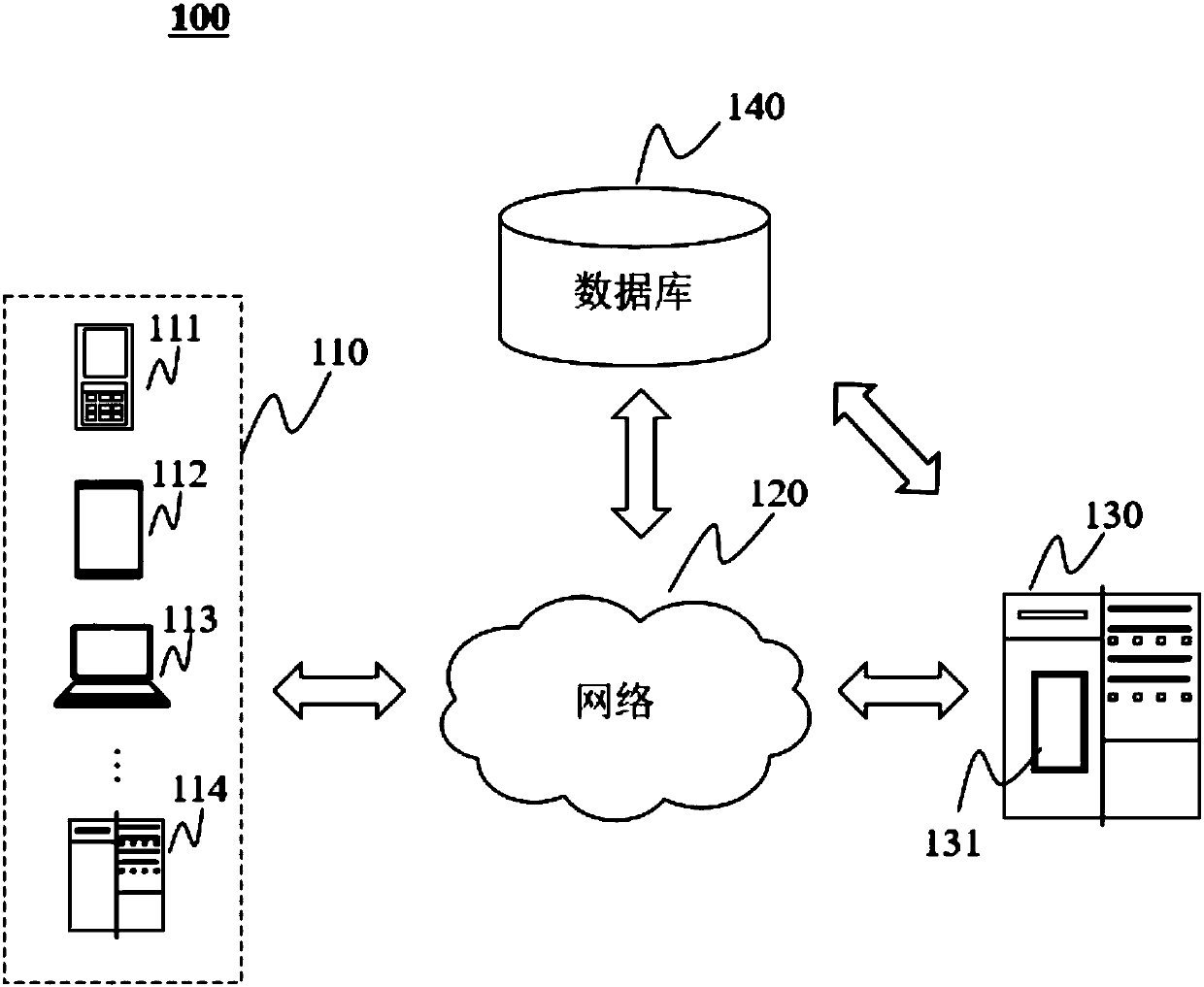

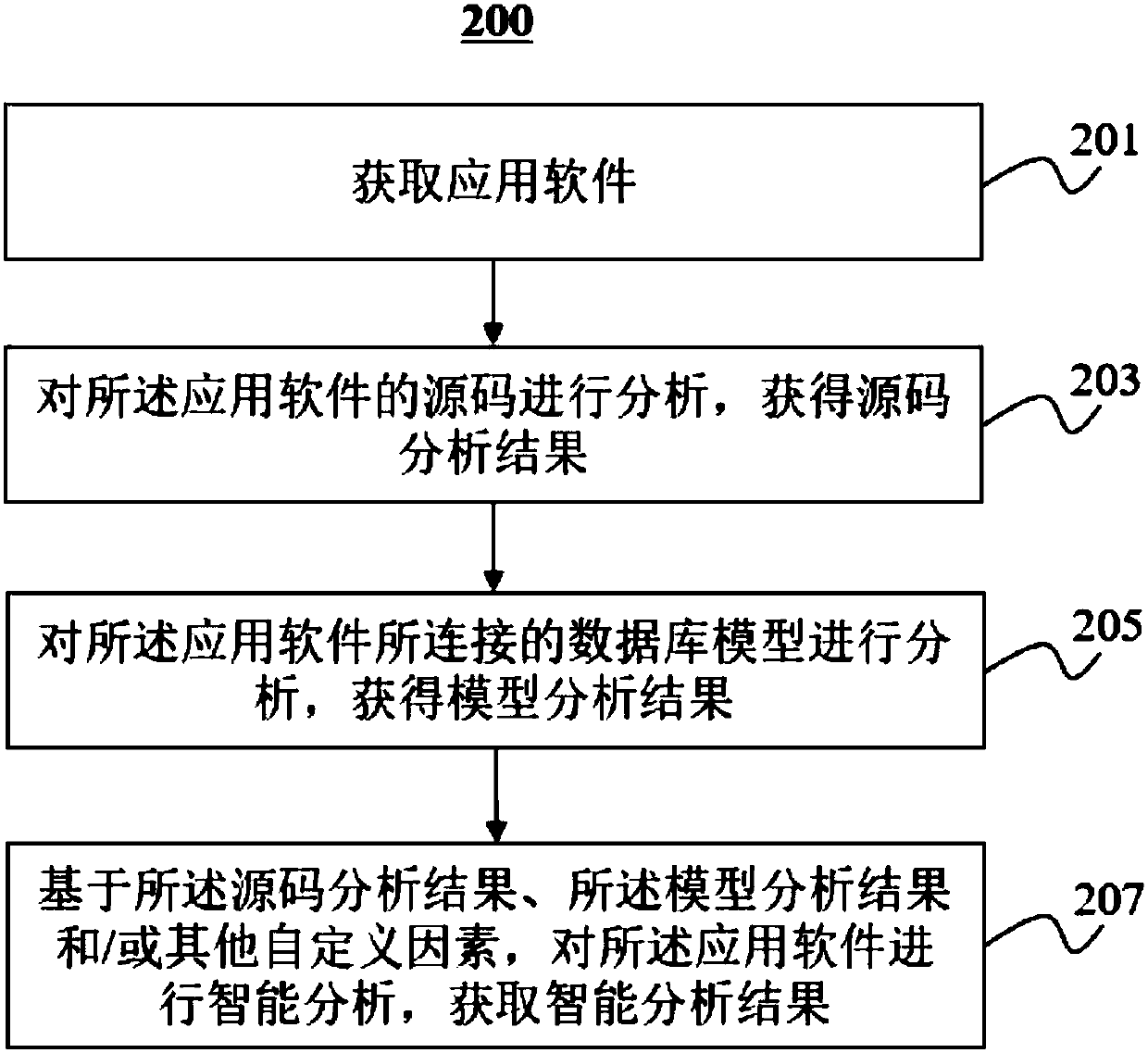

Method, device and equipment for automatically detecting and analyzing application software performance and medium

PendingCN109992502AImprove automation management levelReduce the probability of failureSoftware testing/debuggingSoftware developmentApplication software

The invention provides a method, device and equipment for automatically detecting and analyzing the performance of application software and a medium. The method comprises the steps of obtaining application software; analyzing the source code of the application software to obtain a source code analysis result; analyzing a database model connected with the application software to obtain a model analysis result; and carrying out intelligent analysis on the application software based on the source code analysis result, the model analysis result and / or other custom factors to obtain an intelligentanalysis result. According to the technical scheme, source code compliance and data processing performance conditions can be found in advance, some hidden dangers generated after application softwareis online are solved in advance, and a large amount of workload of application software development and later operation and maintenance can be saved.

Owner:CHINA MOBILE GROUP SICHUAN +1

Preparation method of catalyst for directly synthesizing dimethyl ether from synthesis gas

InactiveCN104646049AReduce manufacturing costHigh activityMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsEvaporationSolvent

The present invention relates to a preparation method of a catalyst for directly synthesizing dimethyl ether from synthesis gas, wherein the problems of high catalyst synthesis cost and low dimethyl ether selectivity in the prior art are mainly solved through the preparation method of the present invention. According to the preparation method of the present invention, inorganic salts of Cu, Zn and Al are adopted as a methanol synthesis active component raw material, an HY molecular sieve, alpha-Al2O3, or an H-ZSM-5 molecular sieve is adopted as a methanol dehydration active component, a low carbon alcohol is adopted as a solvent, a silica sol, an alumina sol or white carbon black is adopted as a binder, a method selected from rotary evaporation, spray drying method and flash evaporation is adopted to dry, the obtained powder is calcined, then is added with graphite or cellulose ether and other processing aids, and is subjected to extrusion forming to prepare catalyst particles, and calcination is performed again so as to prepare the catalyst. According to the present invention, the catalyst production process is simple, the catalyst has characteristics of high activity, good selectivity, excellent activity at high space velocity, and high dimethyl ether time space yield, and the preparation method can be used for the industrial production of direct preparation of the dimethyl ether from the synthesis gas.

Owner:CHIA TAI ENERGY MATERIALS DALIAN

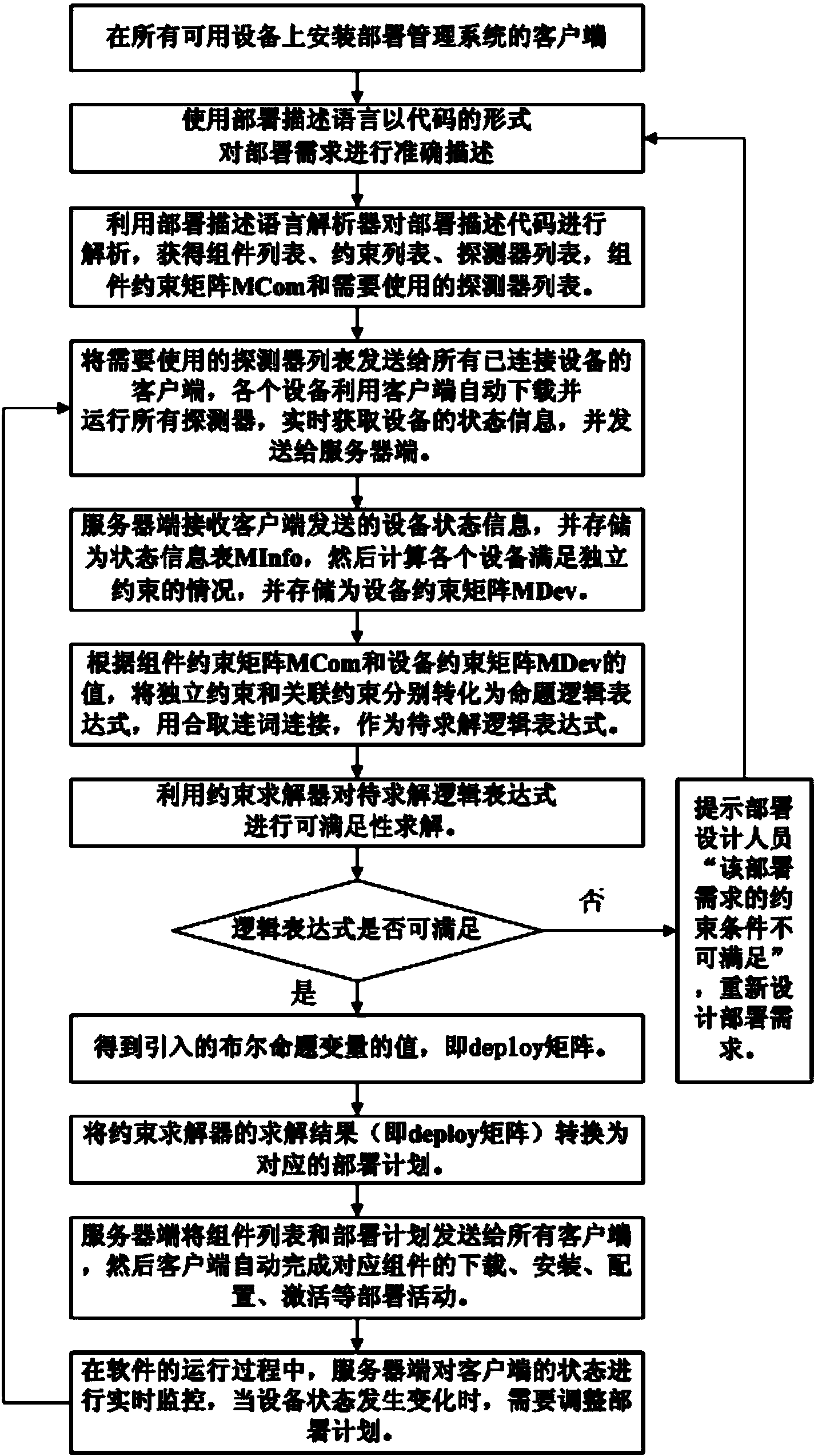

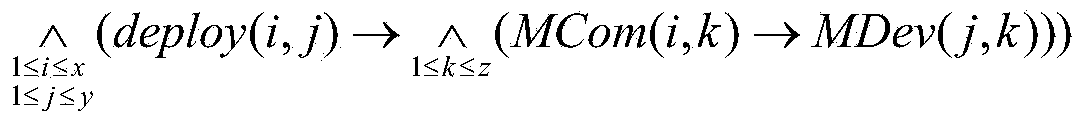

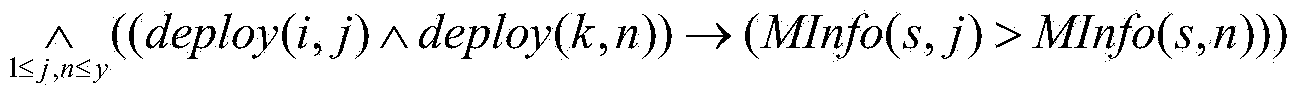

Automation and self-adaptation method for deploying multi-component software under complex constraint conditions and deployment management system thereof

InactiveCN104298525AFully automatedStrong deployment automationProgram loading/initiatingSoftware deploymentComputer software

The invention discloses an automation and self-adaptation method for deploying multi-component software under complex constraint conditions and a deployment management system thereof, and belongs to the technical field of deployment and maintenance of computer software. Firstly, the deployment demand and deployment constraint conditions of the multi-component software are described in a deployment description language; then, according to the deployment demand and equipment status information detected in real time, the deployment management system can automatically and dynamically generate a deployment plan meeting the constraint conditions and automatically perform the deployment activity by using an equipment status information detector, a constraint solver and an automatic deployment device and calling the constraint solver. Thus, the automation and self-adaptation of deploying the multi-component software under the complex constraint conditions are achieved. Meanwhile, the software deployment efficiency is high, the software deployment cost is low, and the software deployment quality is good.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

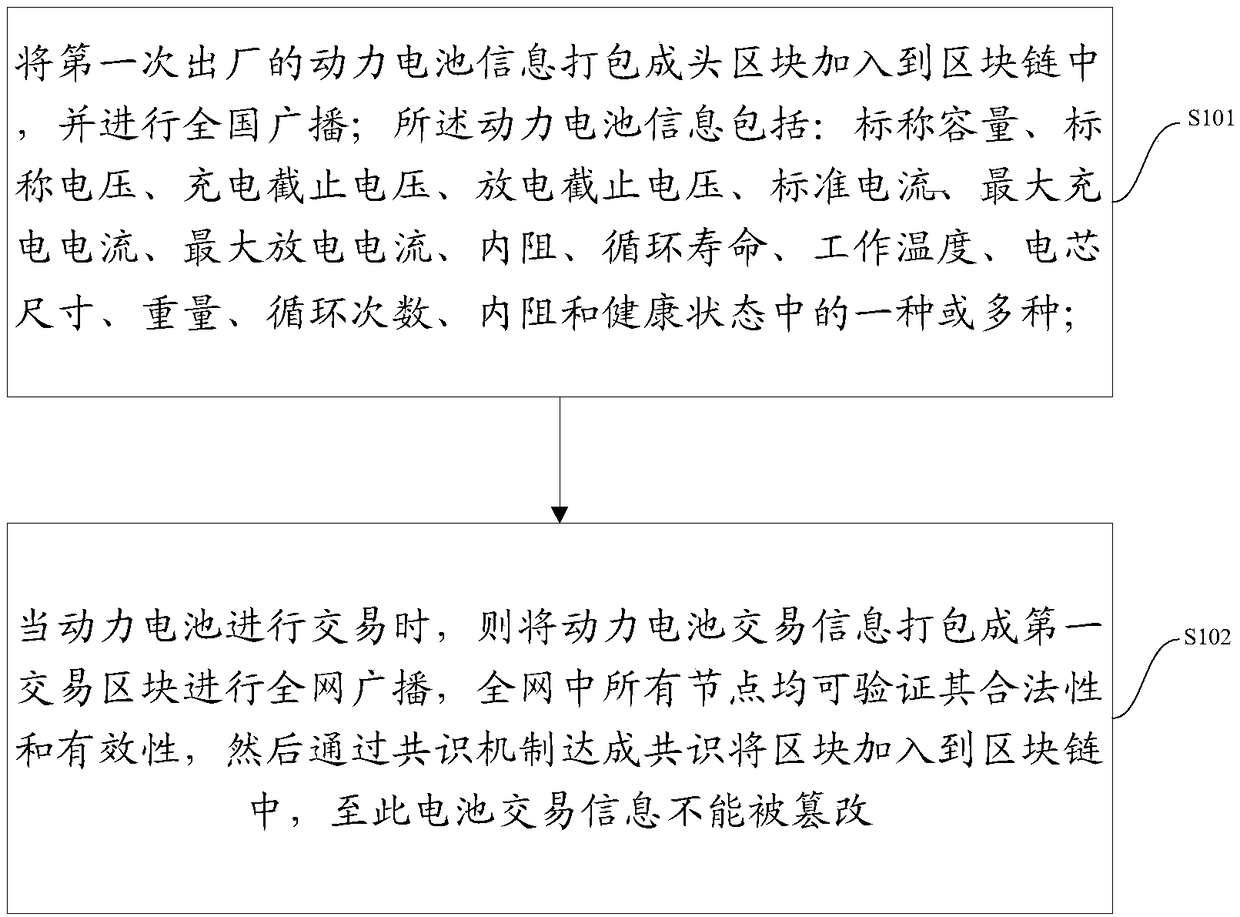

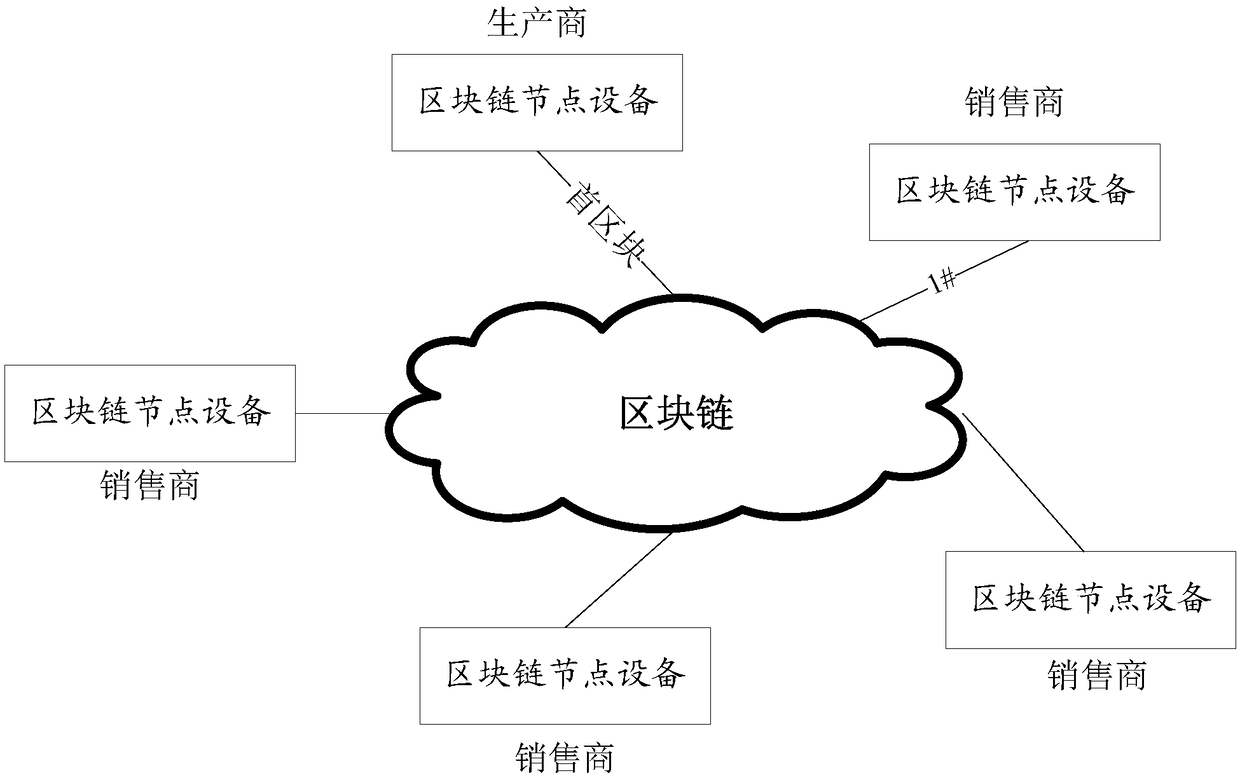

A traceability method of power battery cascade utilization based on block chain technology and a system thereof

InactiveCN109165530AResolve trust issuesRealize uploadDigital data protectionPayment protocolsOperating temperatureBlockchain

The invention relates to a traceability method of power battery cascade utilization based on block chain technology and a system thereof. The method comprises the following steps: packaging the powerbattery information of the first shipment into a head block and adding the head block into the block chain, and broadcasting nationwide, wherein the power battery information comprises one or more ofa factory number, an information ID, a cell material, a nominal capacity, a nominal voltage, a charging cut-off voltage, a discharging cut-off voltage, a standard current, a maximum charging current,a maximum discharging current, a DC internal resistance, an operating temperature, a cell size, a weight, a number of cycles and a healthy state of the battery; when the power battery is traded, packaging the trading information of the power battery into a first trading block for broadcasting throughout the network, wherein all nodes in the network can verify its legitimacy and effectiveness, andthen adding the block into the block chain by a consensus mechanism. The invention realizes the functions of uploading, storing, inquiring, encrypting and decrypting the data of the whole battery supply chain, and the data is open, transparent, traceable and non-alterable.

Owner:深圳汽航院科技有限公司

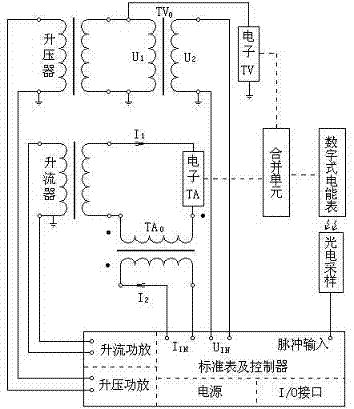

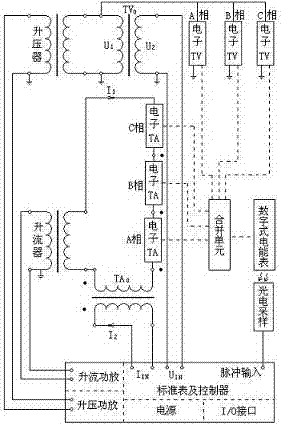

Integral detection method of intelligent substation electric energy metering device

InactiveCN102854488ASolving automation problemsFully automatedElectrical measurementsPhase currentsSingle-phase electric power

The invention provides an integral detection method of an intelligent substation electric energy metering device. The method comprises the following steps of: forming a single-phase integral detection connection mode and a three-phase integral detection connection mode of the intelligent substation electric energy metering device by using a standard potential transformer, a standard current transformer, a voltage booster, a current booster, a standard meter and a controller with a single-phase current and voltage programmed switch power amplifier, and a photoelectric sampler through different connection modes; and integrally detecting single-phase components and three-phase components according to the connection methods. By the method, the automation of state detection process of the intelligent substation electric energy metering device is realized. The method has the advantages of being concise, exact, scientific, practical, and strong in operability and the like. The method is suitable for the technical field of measuring accuracy of the intelligent substation electric energy metering device.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

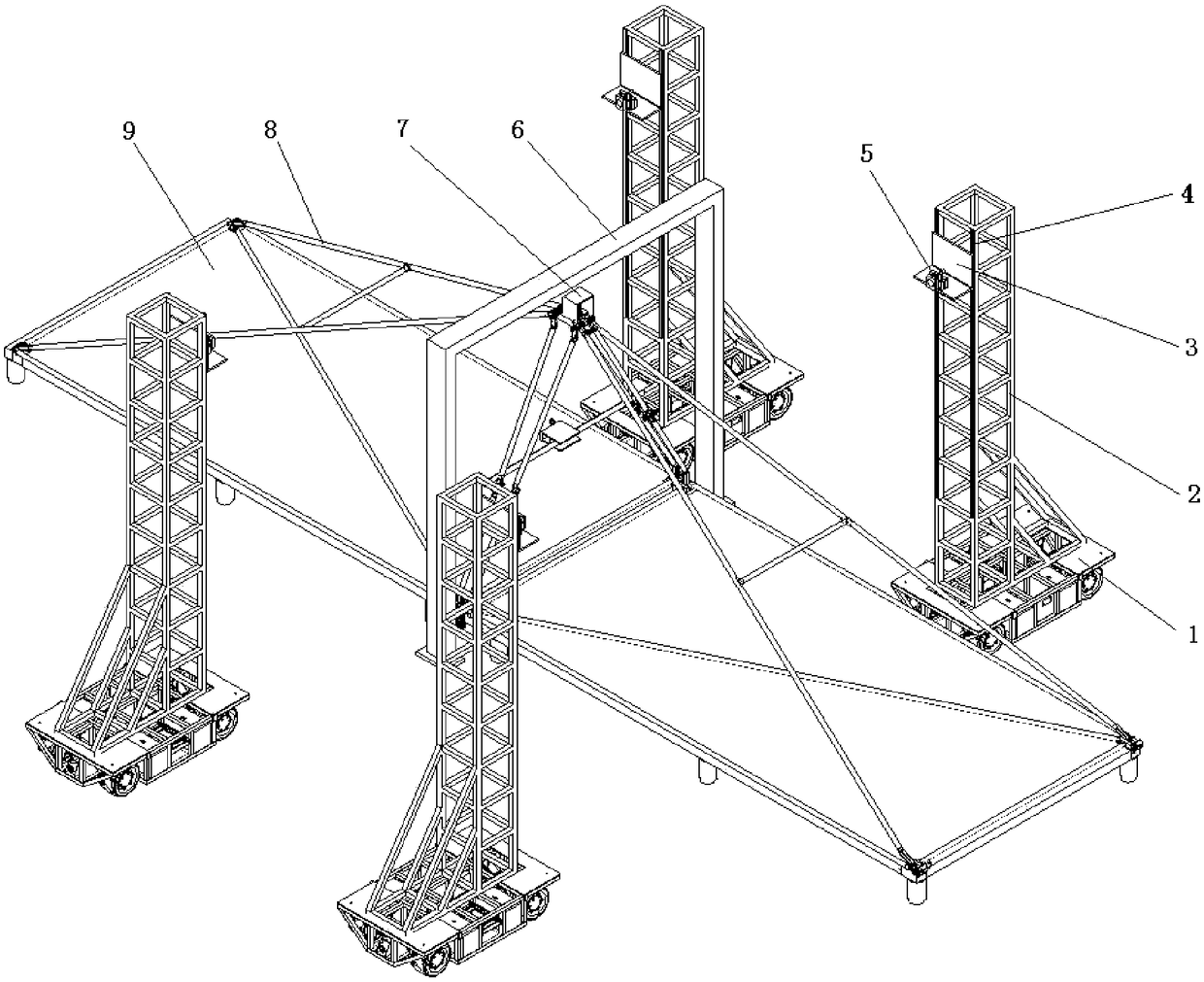

Assembling precision measurement method and device of satellite antenna unfolding system

ActiveCN108132029ASolve the accuracy problemSolving automation problemsUsing optical meansFast measurementComputer image

The invention relates to an assembling precision measurement method and device of a satellite antenna unfolding system. A four-camera photogrammetric system measures point-like coding signs in a panel, a hinge and a rod system of the satellite antenna unfolding system, digital images with the point-like coding signs of the panel, hinge and rod system in different positions are obtained, the flatness of the panel and the axis positions of the hinge and the rod system are calculated via computer image processing and least square fitting, and the assembling precision of the satellite antenna unfolding system is determined. Thus, the positions of the linkage and the rod system of the satellite antenna unfolding system can be measured automatically and rapidly in high precision, the flatness ofthe panel within the range of 10m*2.5m is <=0.1mm, the axis measuring precision of the hinge within the range of 2.5m*0.5m is <=0.1mm, the measuring precision of the rod system whose length is lowerthan 1m is <=0.1mm, and the measuring precision of the rod system whose length is greater than 4m is <=0.3mm.

Owner:BEIJING SATELLITE MFG FACTORY

Electromagnetic water heater

The electromagnetic water heater consists of electromagnetic heating converter, sensors, casing, metal water pipe, magnetic ferrite strip, water pipe skeleton, heat conducting medium passage, electromagnetic coil, coil skeleton, reflux pipe, afterheat absorber, pump, screw propeller, heat sink, motor, great power transistor IGBT, circuit board, isolating board, LED panel, functional switch, etc. The present invention has optimal work performance of the electromagnetic elements, raised heat efficiency, no electromagnetic interference and other advantages.

Owner:张永光

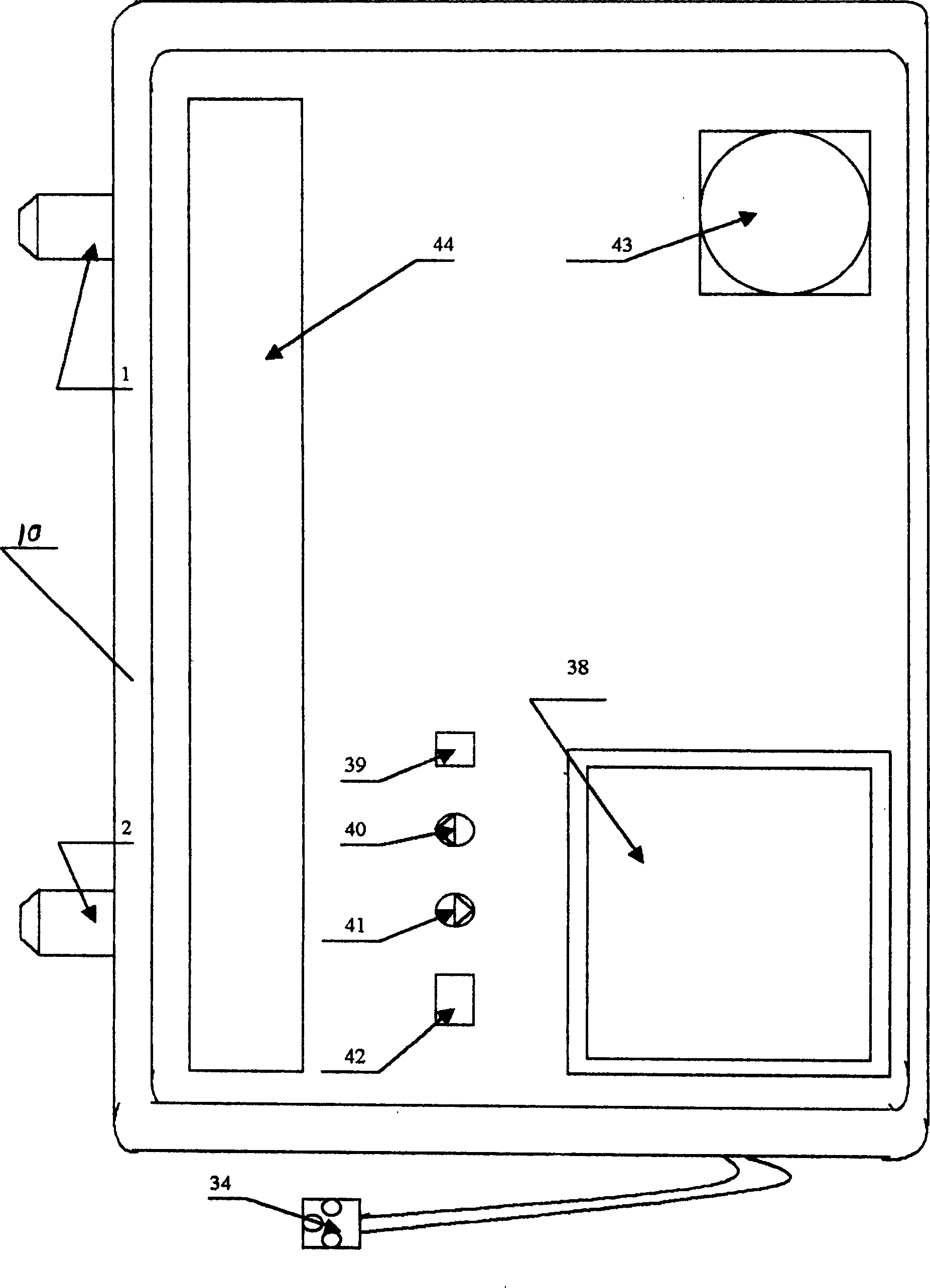

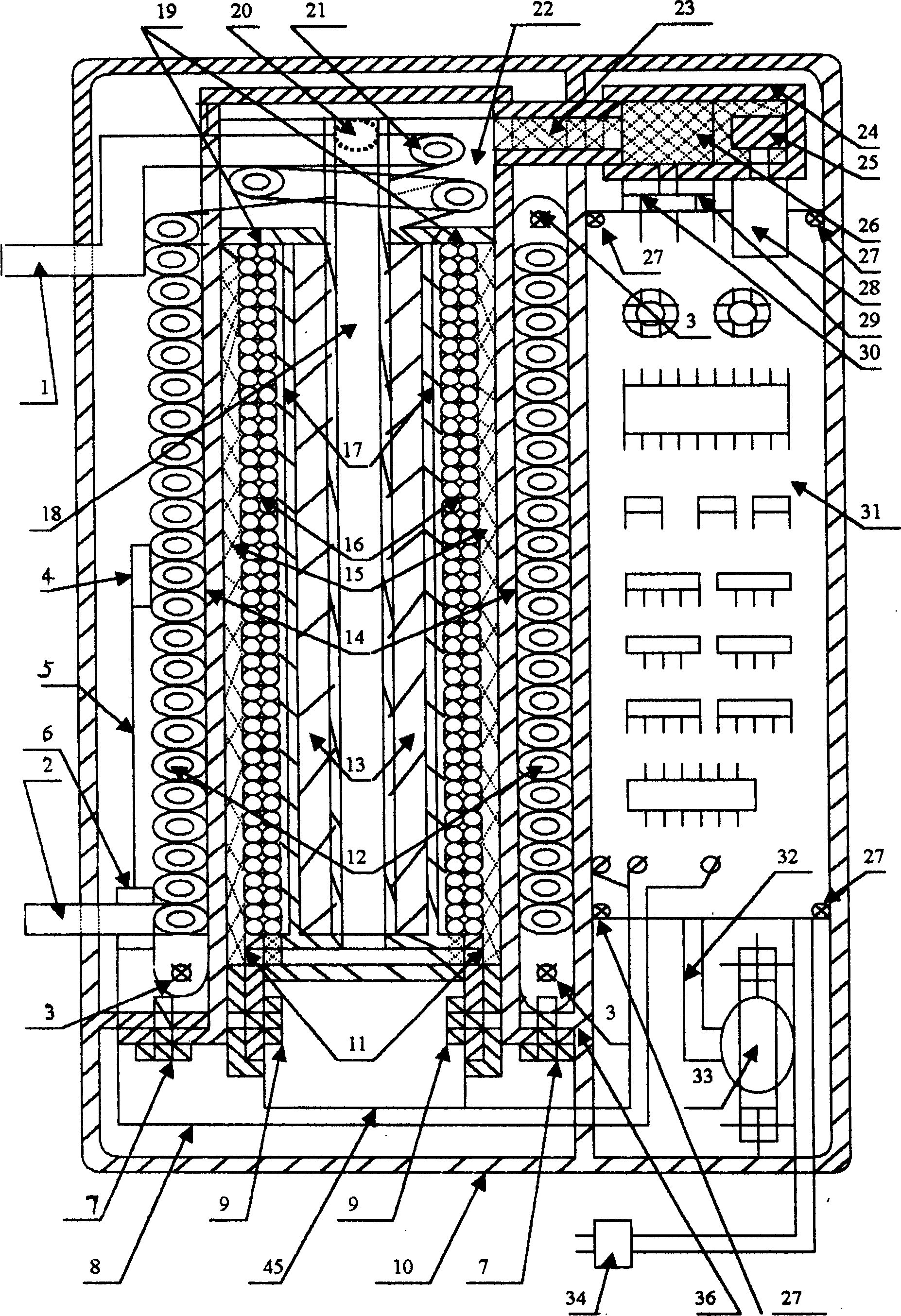

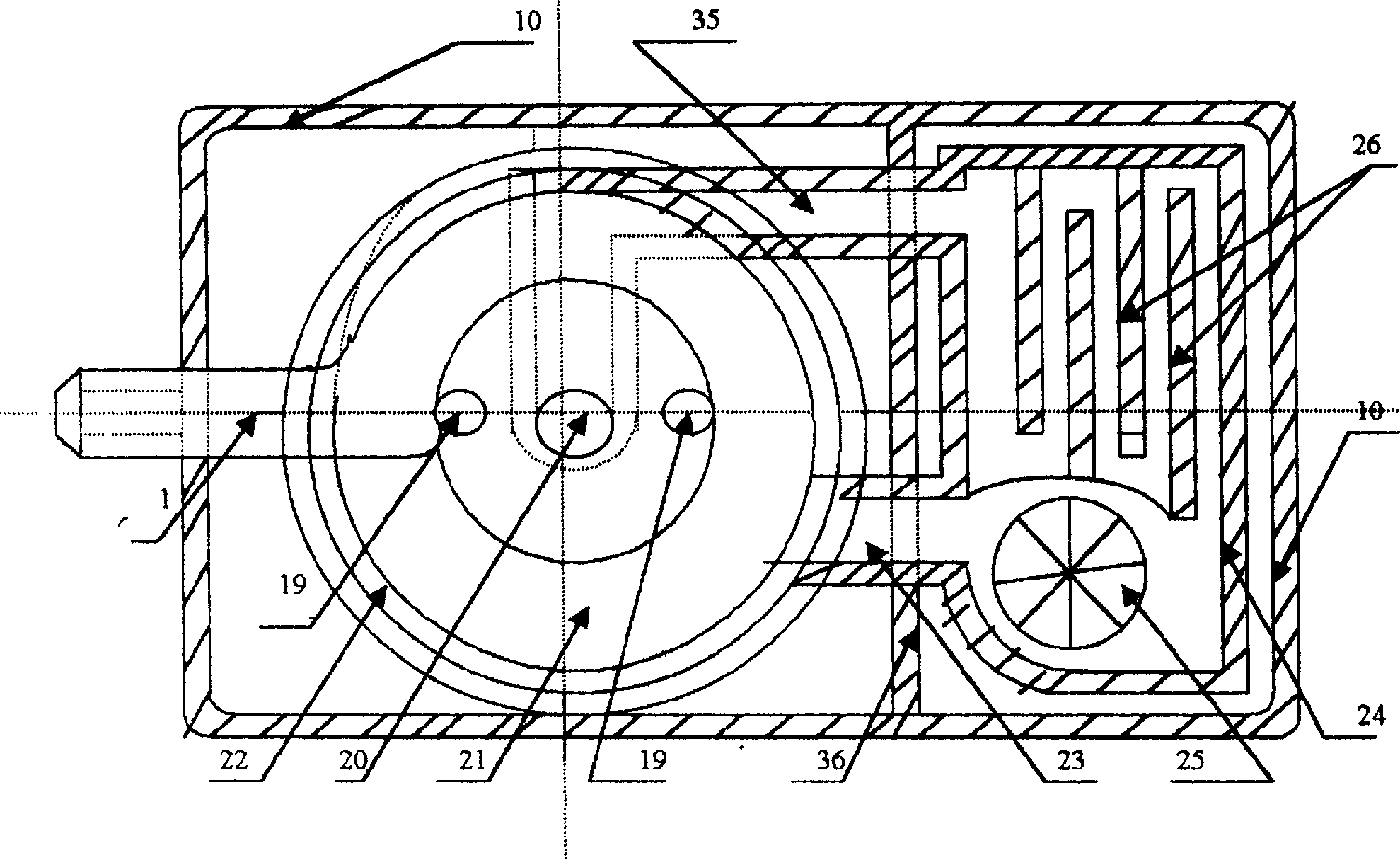

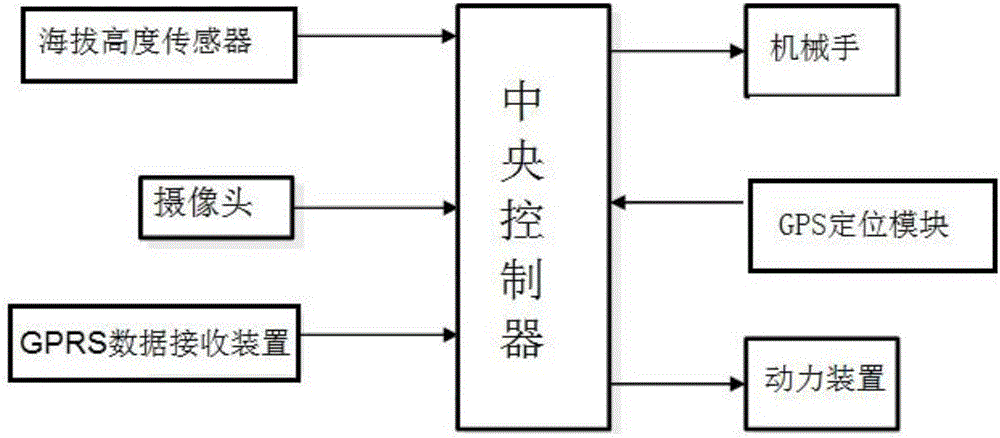

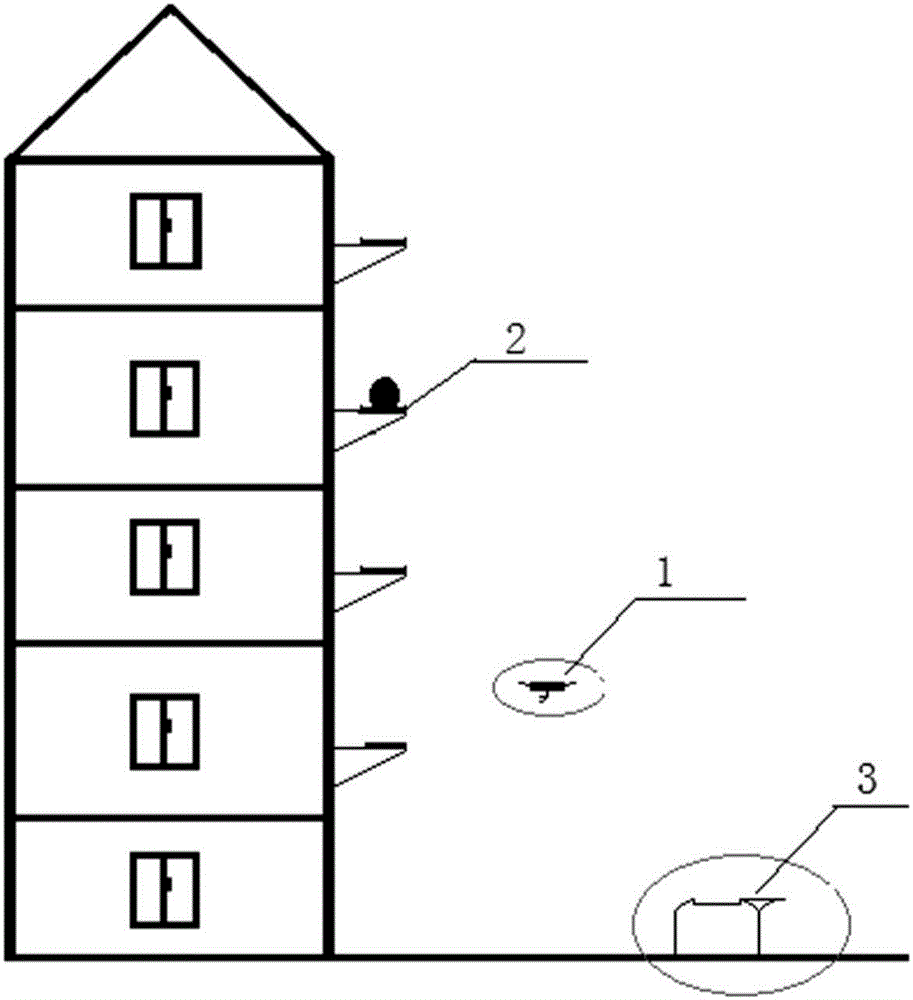

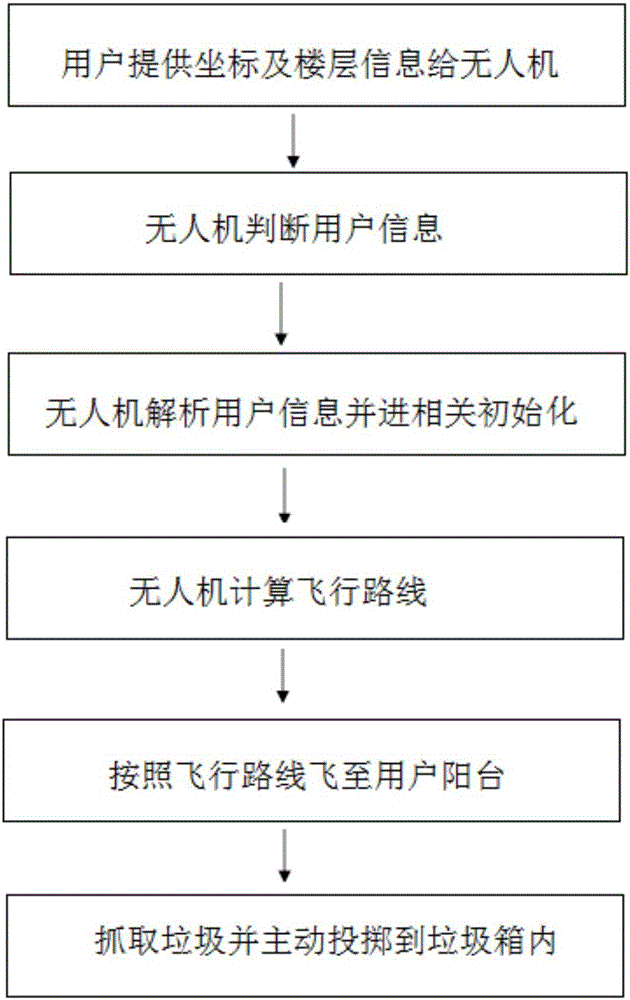

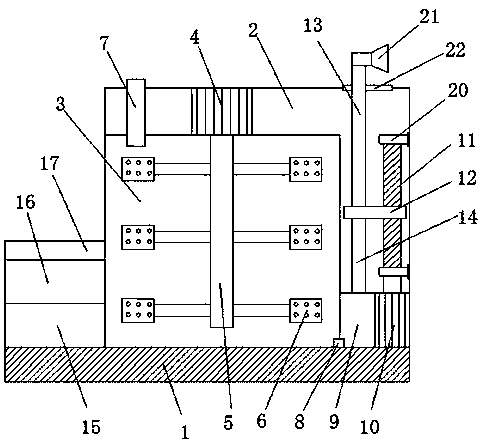

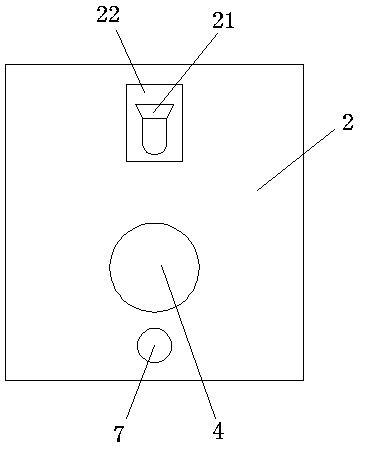

Automatic unmanned plane system for garbage transportation and working method thereof

ActiveCN106094869AImprove protectionAvoid collisionPosition/course control in three dimensionsComputer terminalWorking set

The invention discloses an automatic unmanned plane system for garbage transportation. The system includes an unmanned plane system, a control device and a user terminal. The control device is arranged inside the unmanned plane system, and a mechanical hand is arranged on the unmanned plane system. The user terminal is equipped with a garbage placement region and an RFID electronic tag. The garbage placement region is arranged on a balcony, and the RFID electronic tag is arranged on the garbage placement region. Through arranging a GPS positioning module, an altitude height sensor, a GPRS data reception device, a camera and an RFID ultra-high frequency card reader in the unmanned plane, functions of the unmanned plane are improved, and the whole working process and operation are very simple. Automated and intelligent garbage processing is realized, so that the problem of garbage processing is solved, environment protection is largely improved, great contribution is made to the society, safety problems caused by thrown garbage are avoided, and thus user requirements are better satisfied.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

Automatic garden irrigation device controlled by computer

InactiveCN108738618AAvoid automatic start and stopRealize automatic start and stopTransportation and packagingRotary stirring mixersWater storage tankAgricultural engineering

The invention relates to an automatic garden irrigation device controlled by a computer. The device comprises a bottom plate, wherein the top of the bottom plate is fixedly connected with a shell, aninner cavity of the shell is provided with a water storage tank, the bottom of the water storage tank is fixedly connected with the bottom plate, the top of the water storage tank is fixedly providedwith a first motor, an output end of the bottom of the first motor is fixedly connected with a rotating shaft, the rotating shaft is fixedly connected with stirring blades, the left side of the firstmotor is provided with a water inlet pipe, the water inlet pipe is fixedly connected with the water storage tank, the right side of the water storage tank is connected with a water pump through a water outlet, the right side of the water pump is provided with a second motor, the bottoms of the water pump and second motor are both fixedly arranged on the bottom plate, an output end of the top of the second motor is fixedly connected with a screw rod, and the screw rod is movably connected with a lifting plate through a nut. The automatic garden irrigation device controlled by the computer can perform stirring automatically, facilitate the worker's operation, achieve the automatic start and stop of the irrigation device, avoid the waste of resources, and improve the irrigation efficiency.

Owner:黄小翠

Fully automatic water-soluble acid tester

InactiveCN101614674BAvoid direct contactEasy to processMaterial analysis by observing effect on chemical indicatorDistilled waterEngineering

Owner:山东三泵科森仪器有限公司

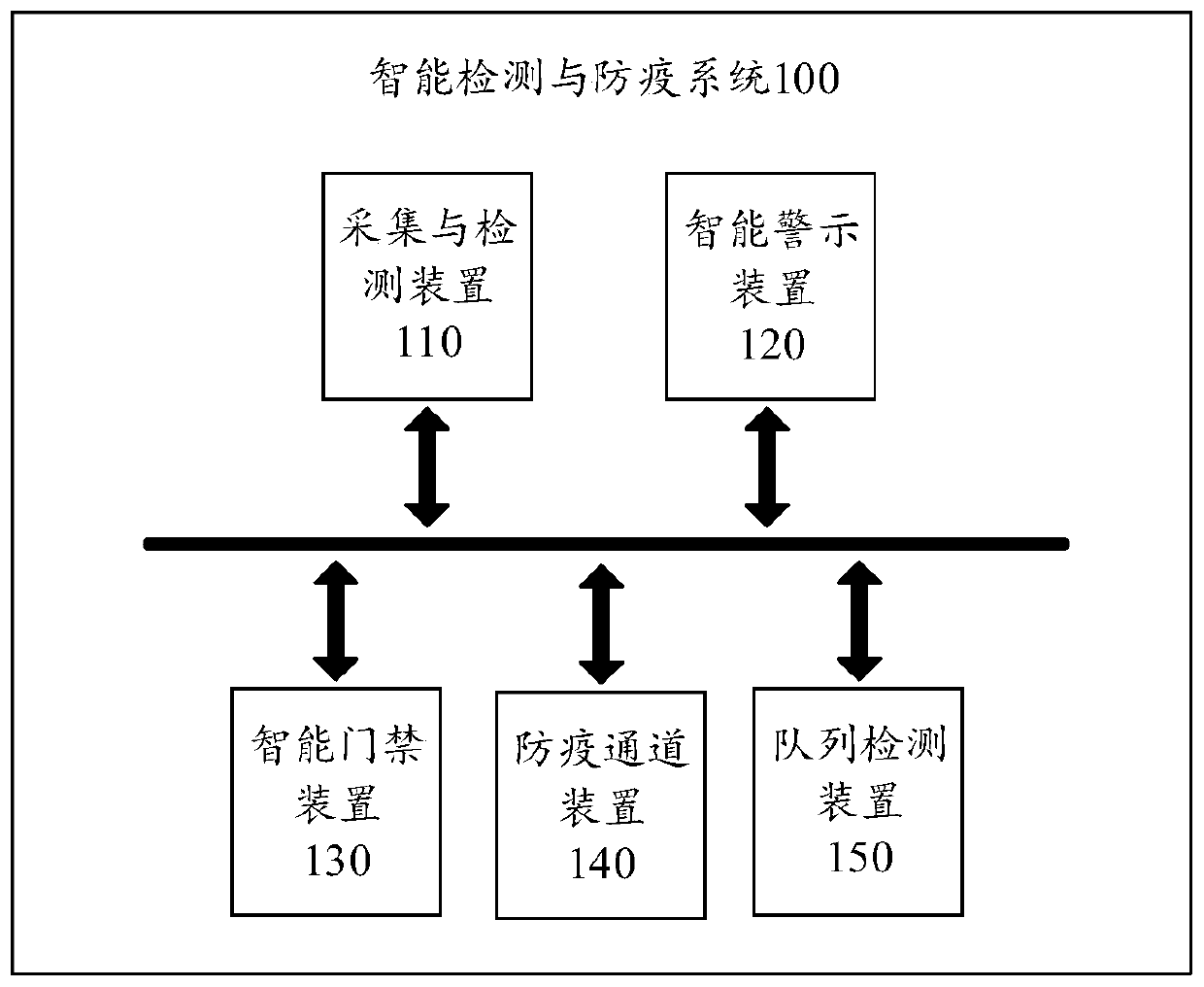

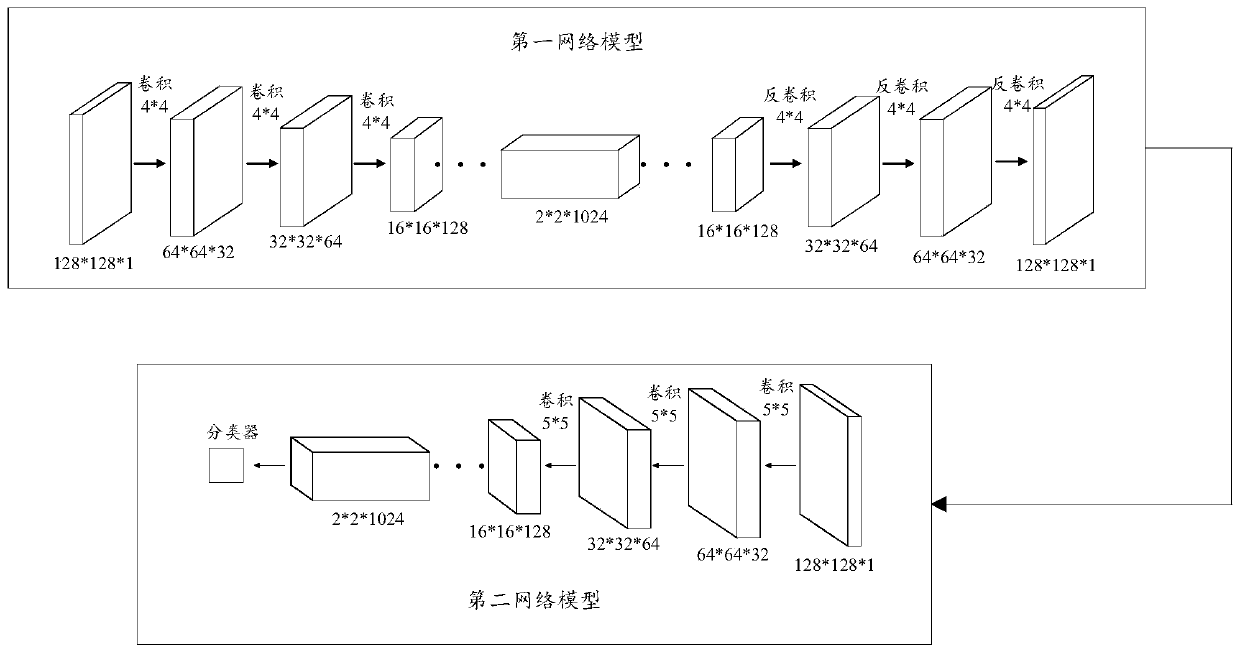

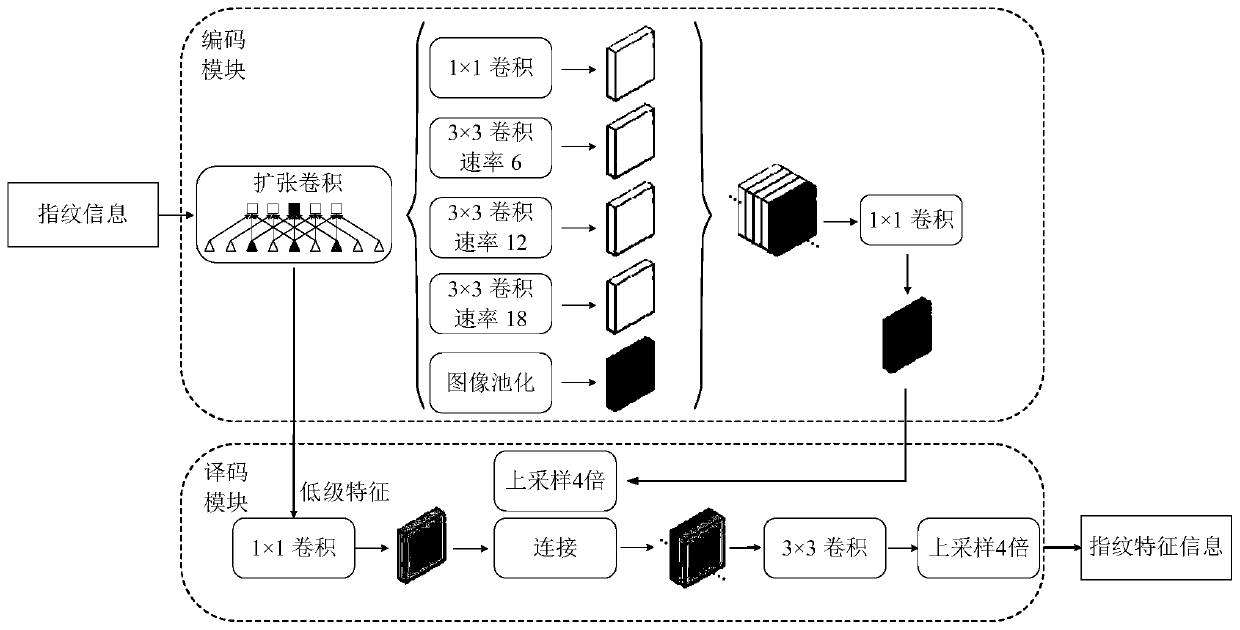

Intelligent detection and epidemic prevention system and method

ActiveCN111524608AAvoid accessImprove securityEpidemiological alert systemsIndividual entry/exit registersAbnormal vital signsComputer science

An embodiment of the invention discloses an intelligent detection and epidemic prevention system and method. The system comprises an acquisition and detection device, an intelligent warning device, anintelligent access control device, an epidemic prevention channel device and a queue detection device, wherein the acquisition and detection device is used for acquiring identity information and signinformation of first personnel and detecting the identity information and the sign information; the intelligent warning device is used for determining a warning operation for the first personnel; theintelligent access control device is used for determining access control operation for the first personnel; the epidemic prevention channel device is used for determining epidemic prevention operation for the first personnel; and the queue detection device is used for determining detection and epidemic prevention operation for persons included in the first personnel. Therefore, the embodiment ofthe invention is beneficial for realizing the automation of the whole detection and epidemic prevention work, discovering and preventing people with unknown identities and abnormal vital signs in time, and improving the safety and efficiency of the whole detection and epidemic prevention work.

Owner:深圳市奥雅装饰工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com