Titanium and titanium alloy residual waste treatment device system and method for sorting titanium materials

A processing system and titanium alloy technology, applied in the field of scrap metal material processing device system, can solve the problems of low energy consumption, small floor space, and high qualification rate, and achieve low energy consumption, small floor space, and qualified rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Accompanying drawing is embodiment of the present invention.

[0047] Below in conjunction with accompanying drawing the content of invention is further described:

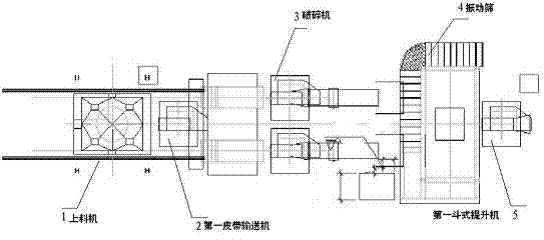

[0048] refer to figure 1 Shown is a schematic diagram of the structure of the crushing device.

[0049] a. The crushing device includes a feeder 1, a crusher 3, a vibrating screen 4, and a first bucket elevator 5;

[0050] The connection method is connected in the direction indicated by the arrow in turn: feeder 1→first belt conveyor 2→crusher 3→vibrating screen 4→first bucket elevator 5→first silo 6;

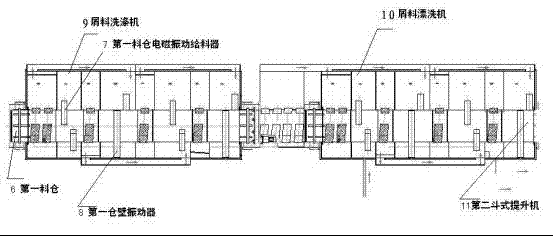

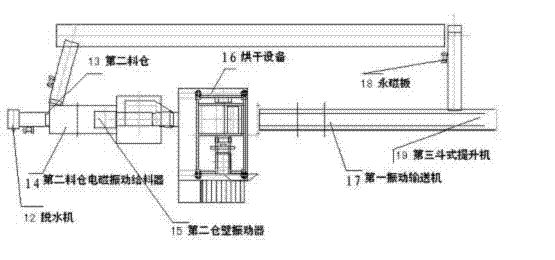

[0051]b. The cleaning device includes a first silo 6, a first silo electromagnetic vibrating feeder 7, a first silo wall vibrator 8, a scrap washing machine 9, a scrap rinsing machine 10, a dehydrator 11, a second bucket elevator 12;

[0052] The connection method is connected in the direction indicated by the arrow in sequence: the first silo 6 → the first silo electromagnetic vibration feeder 7 → the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com