Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Solve the problem of sag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

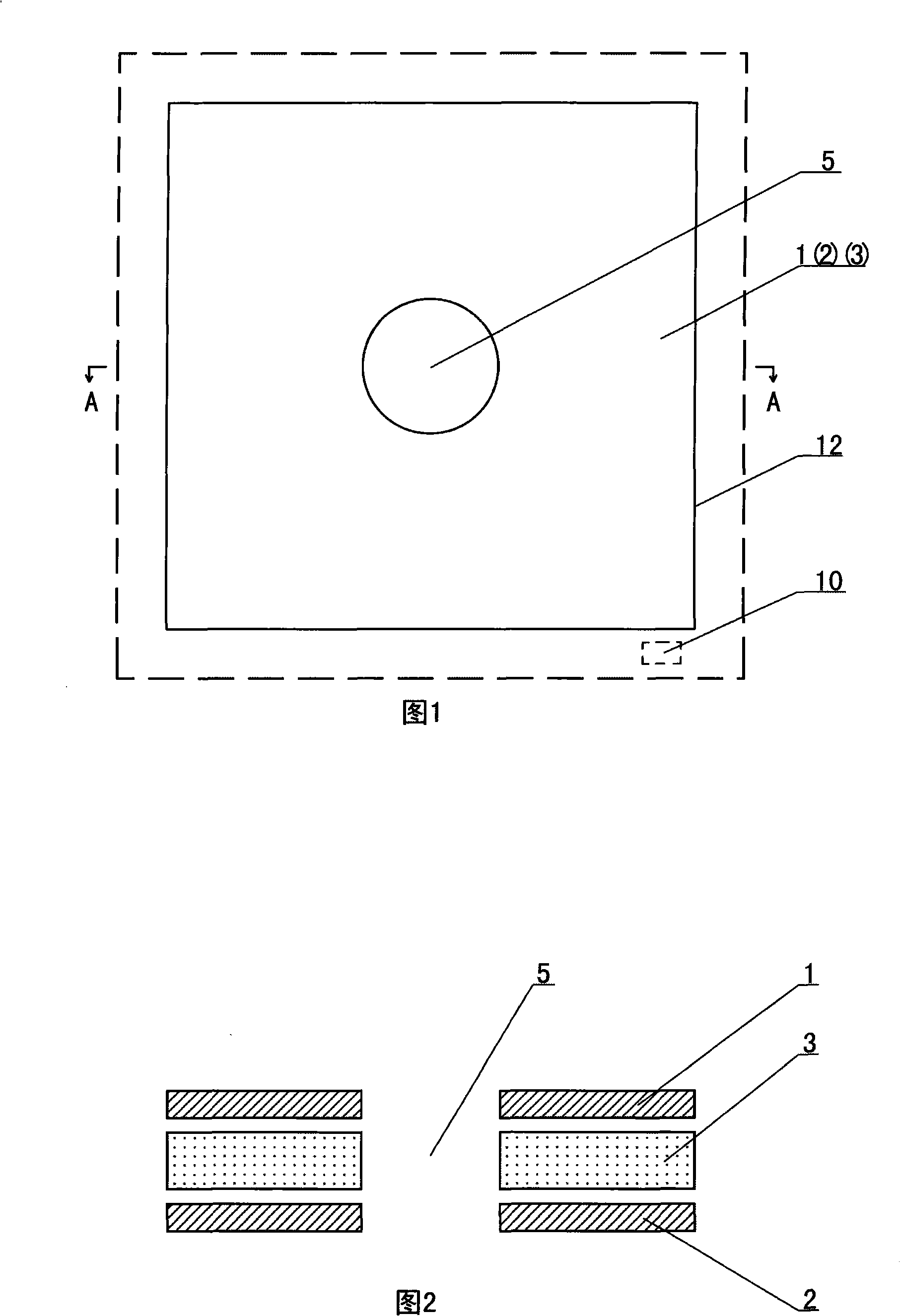

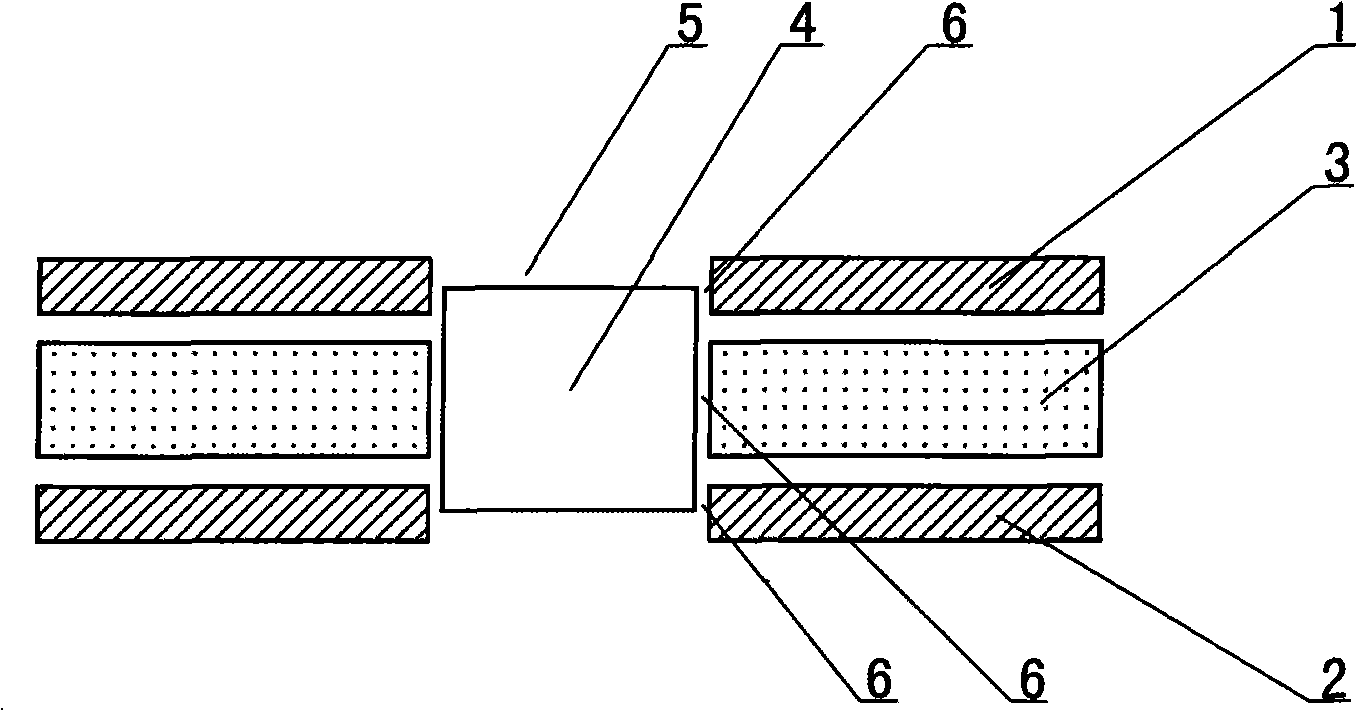

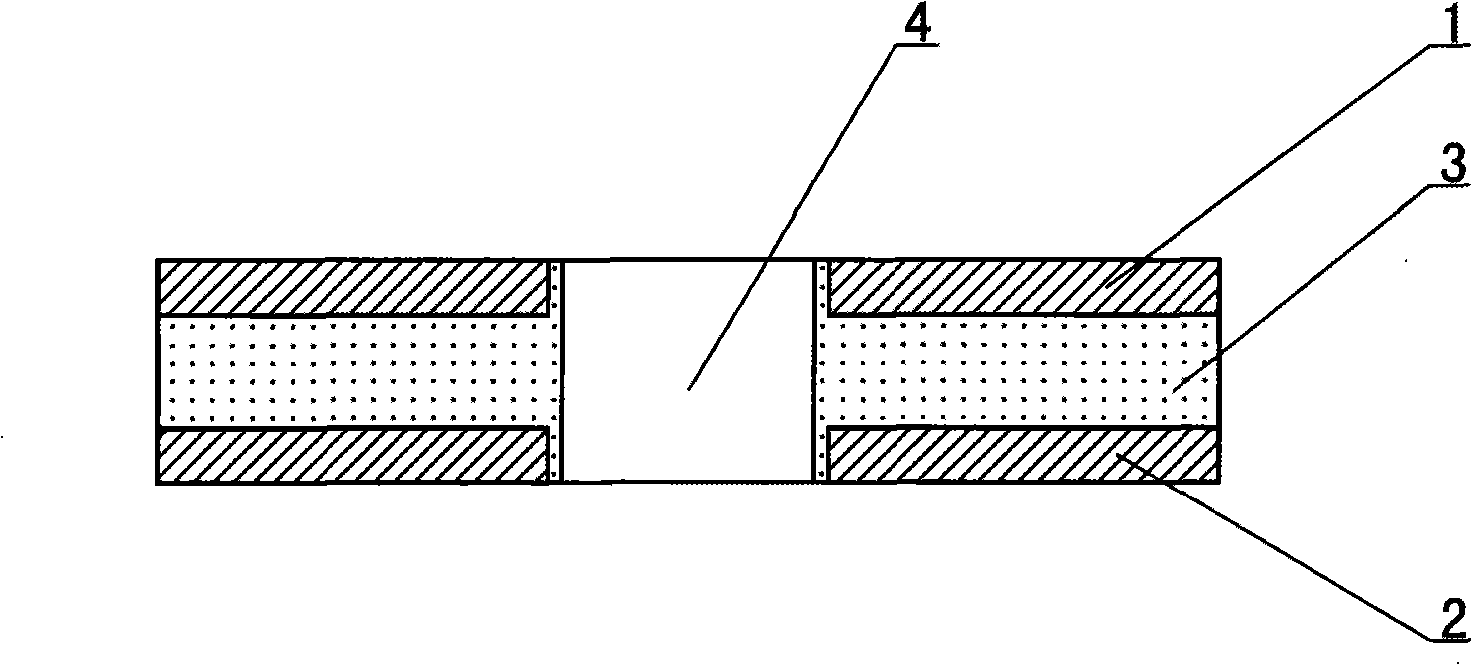

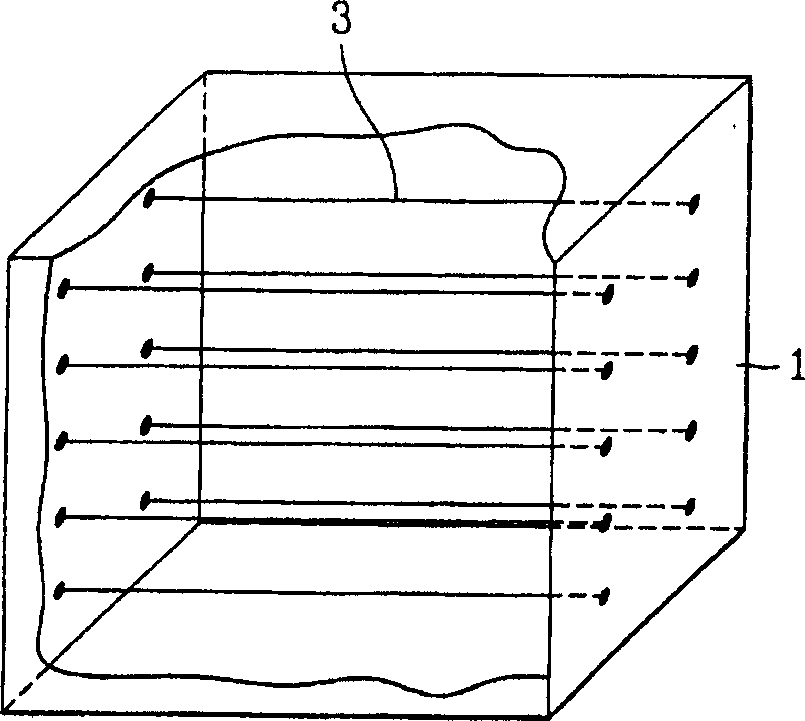

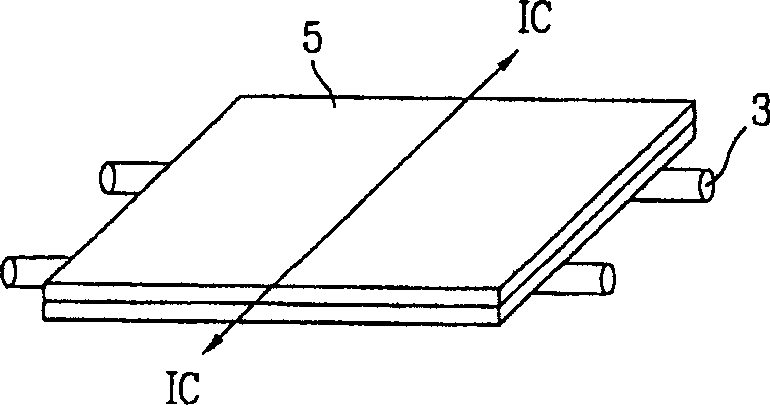

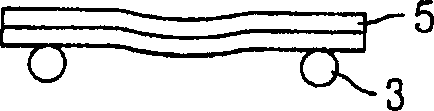

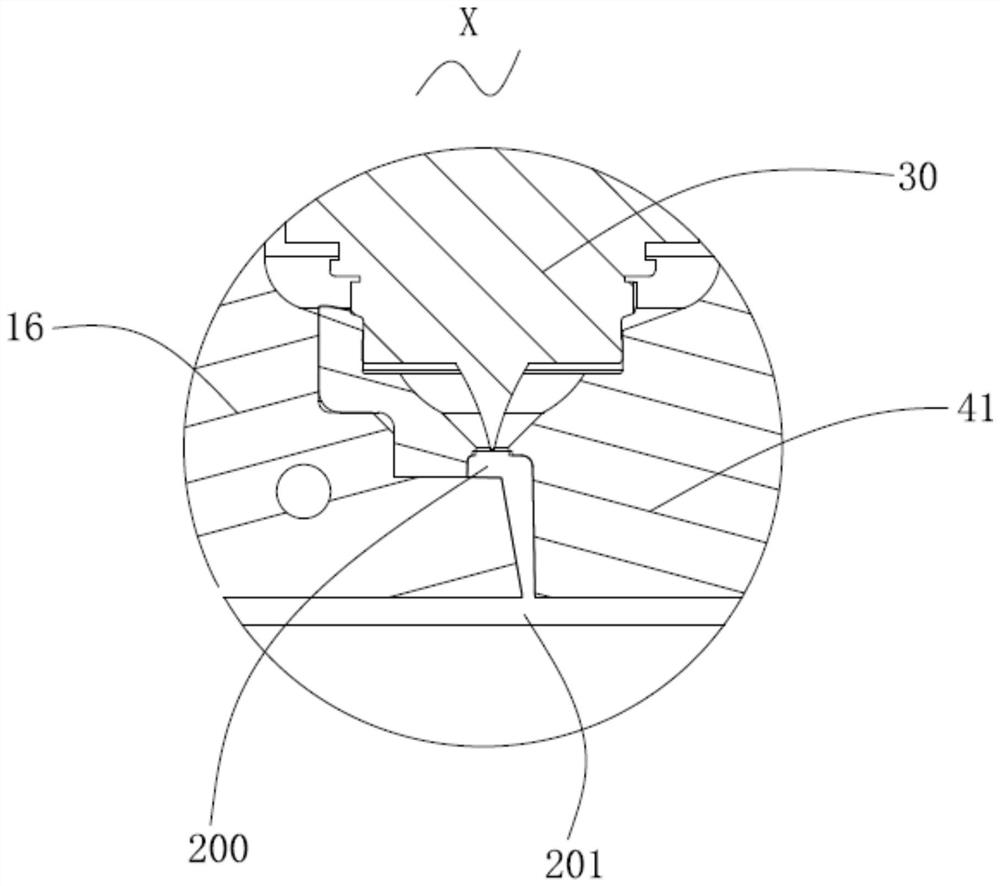

Manufacturing method for embedding heat radiating fin on printed circuit board

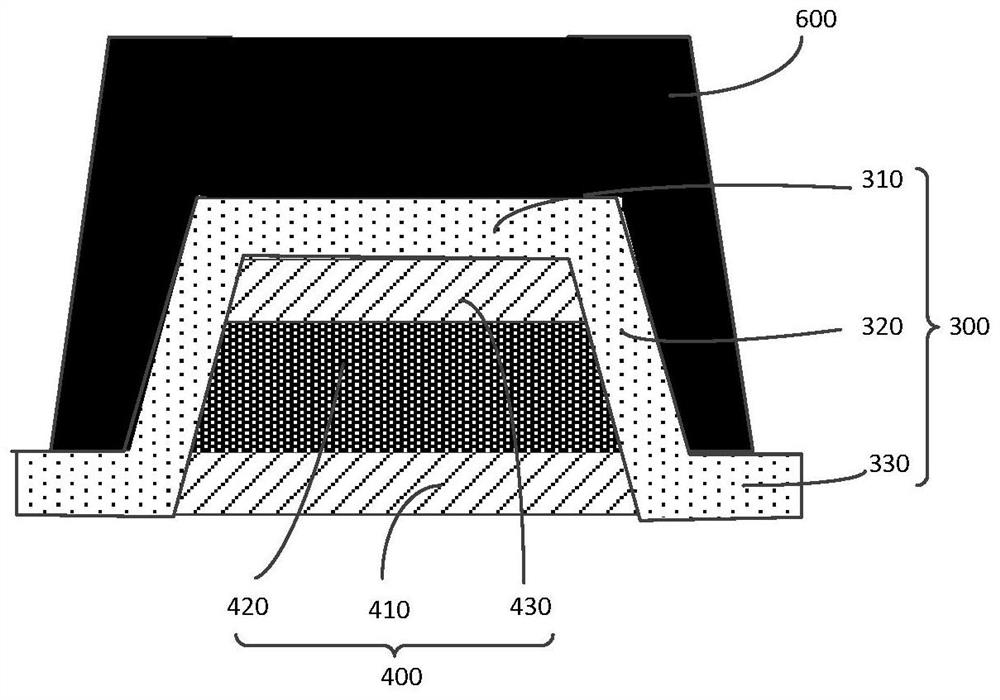

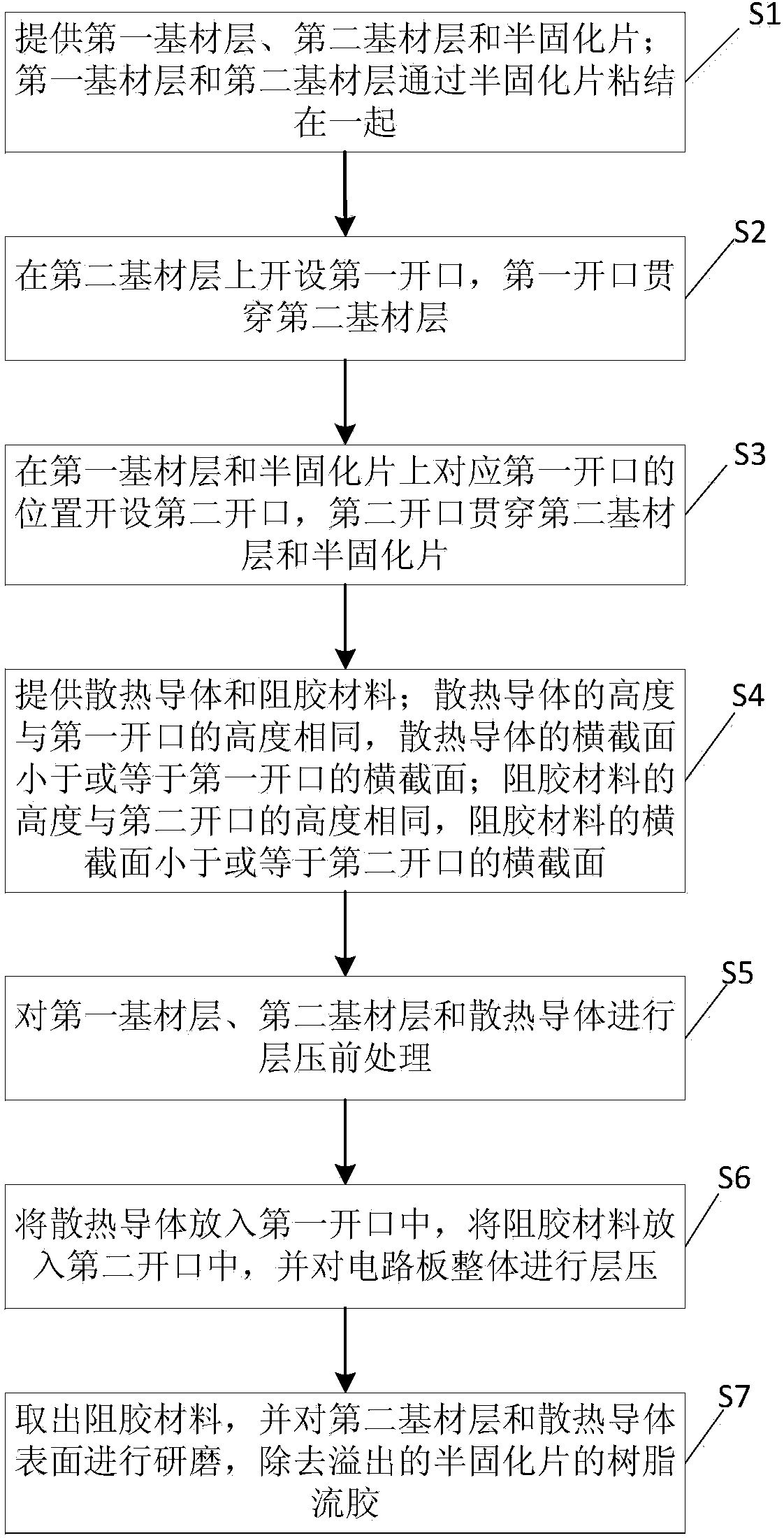

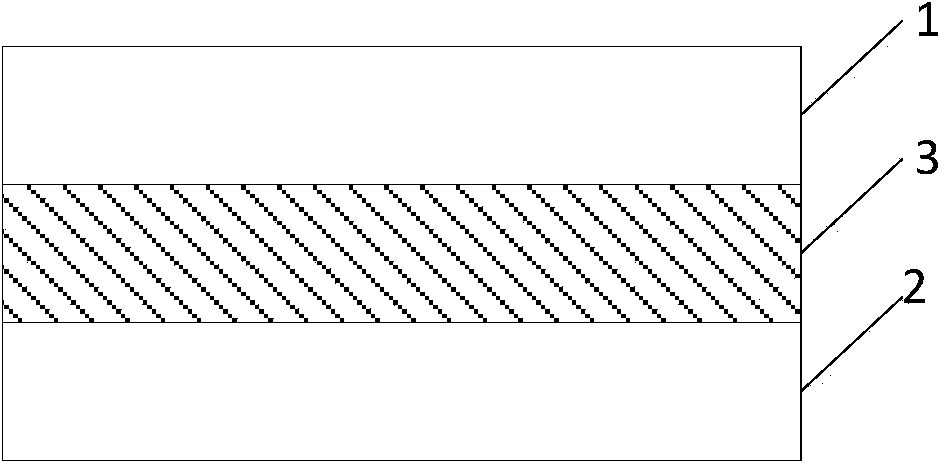

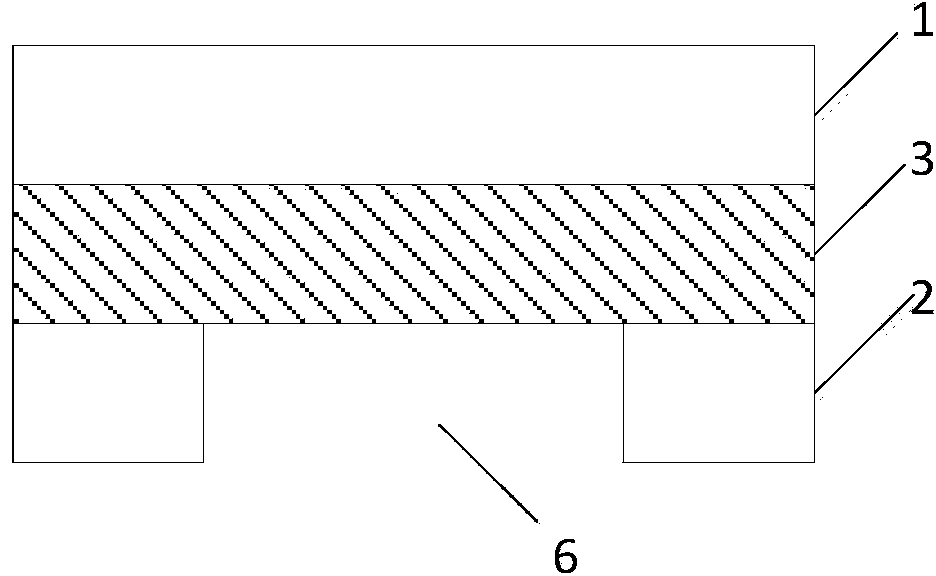

InactiveCN101257770AGood embedding effectSolve the problem of sagMultilayer circuit manufactureCooling/ventilation/heating modificationsHeat sinkPrinted circuit board

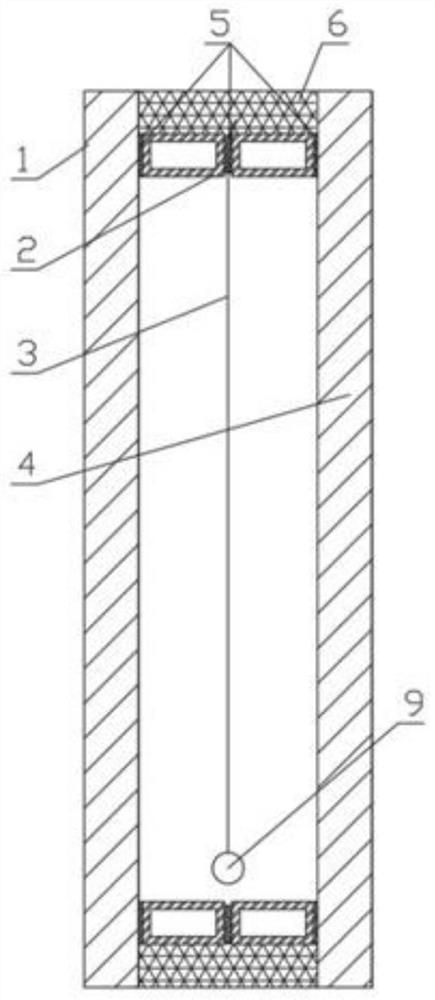

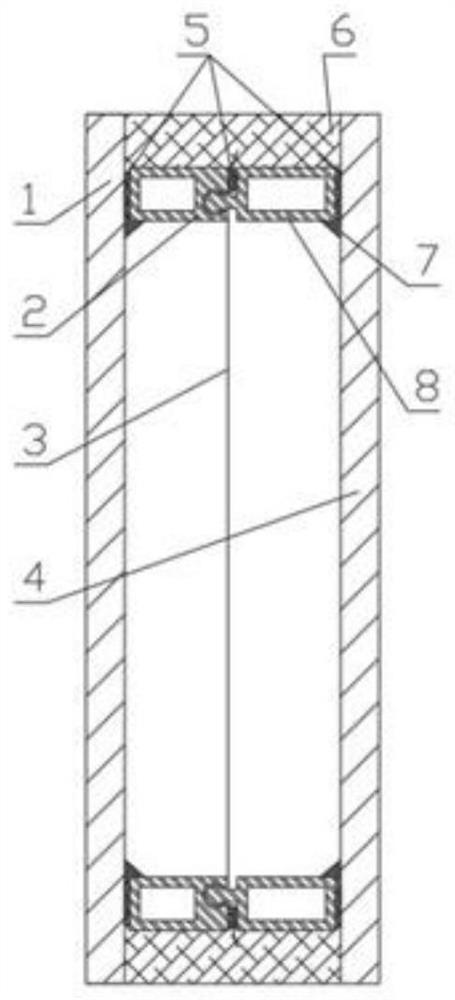

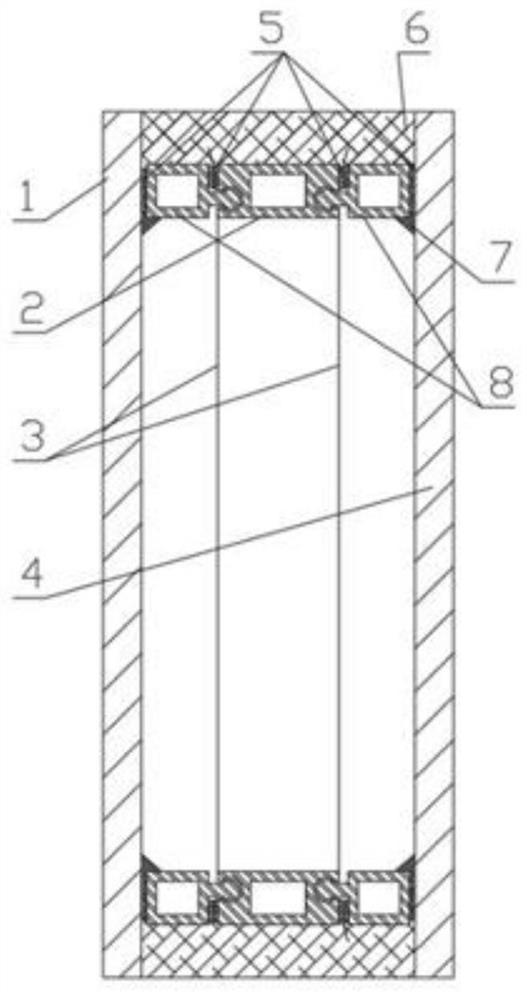

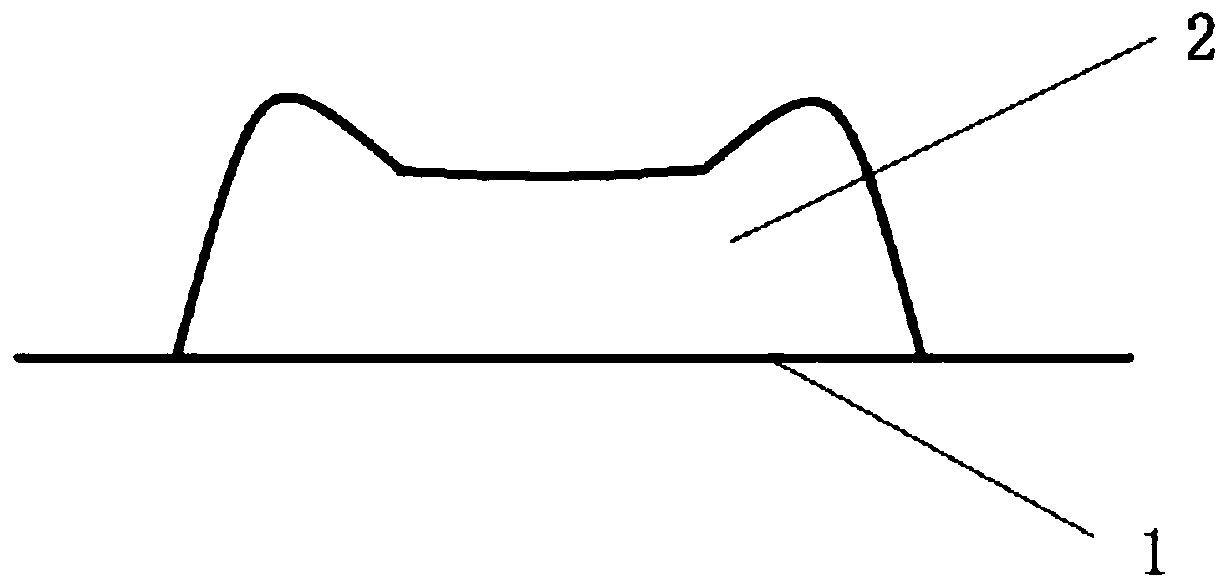

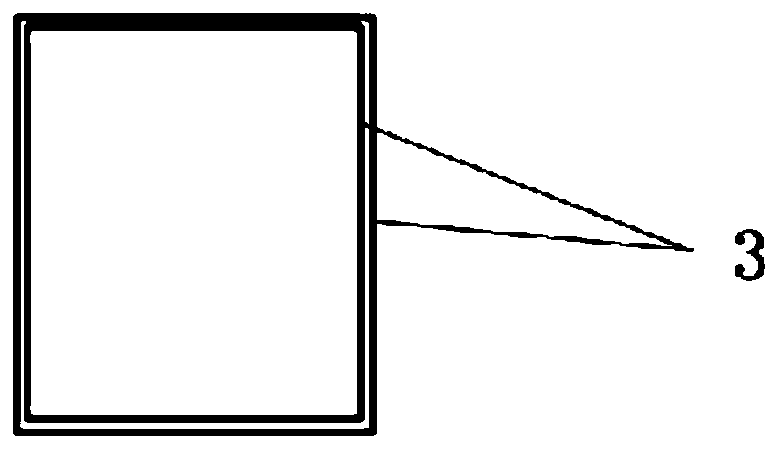

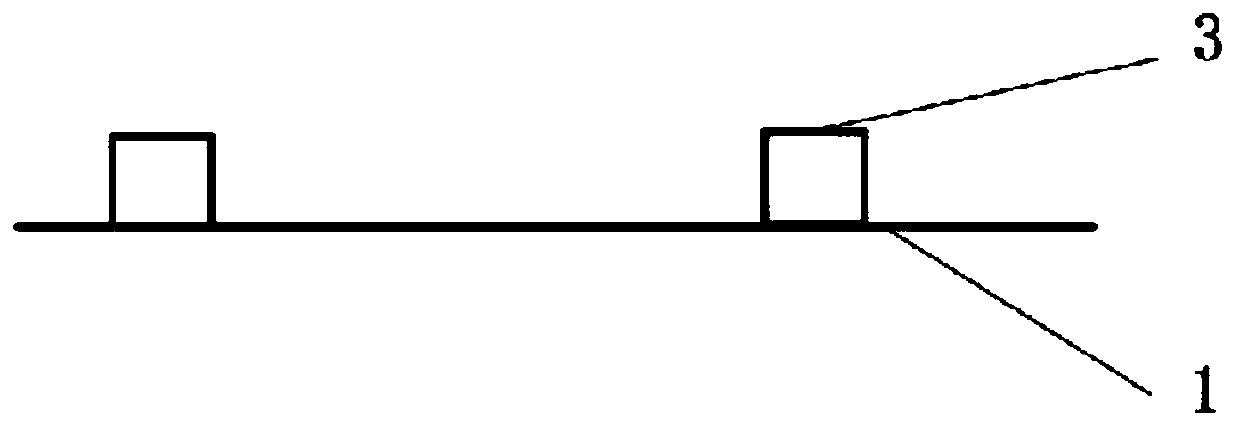

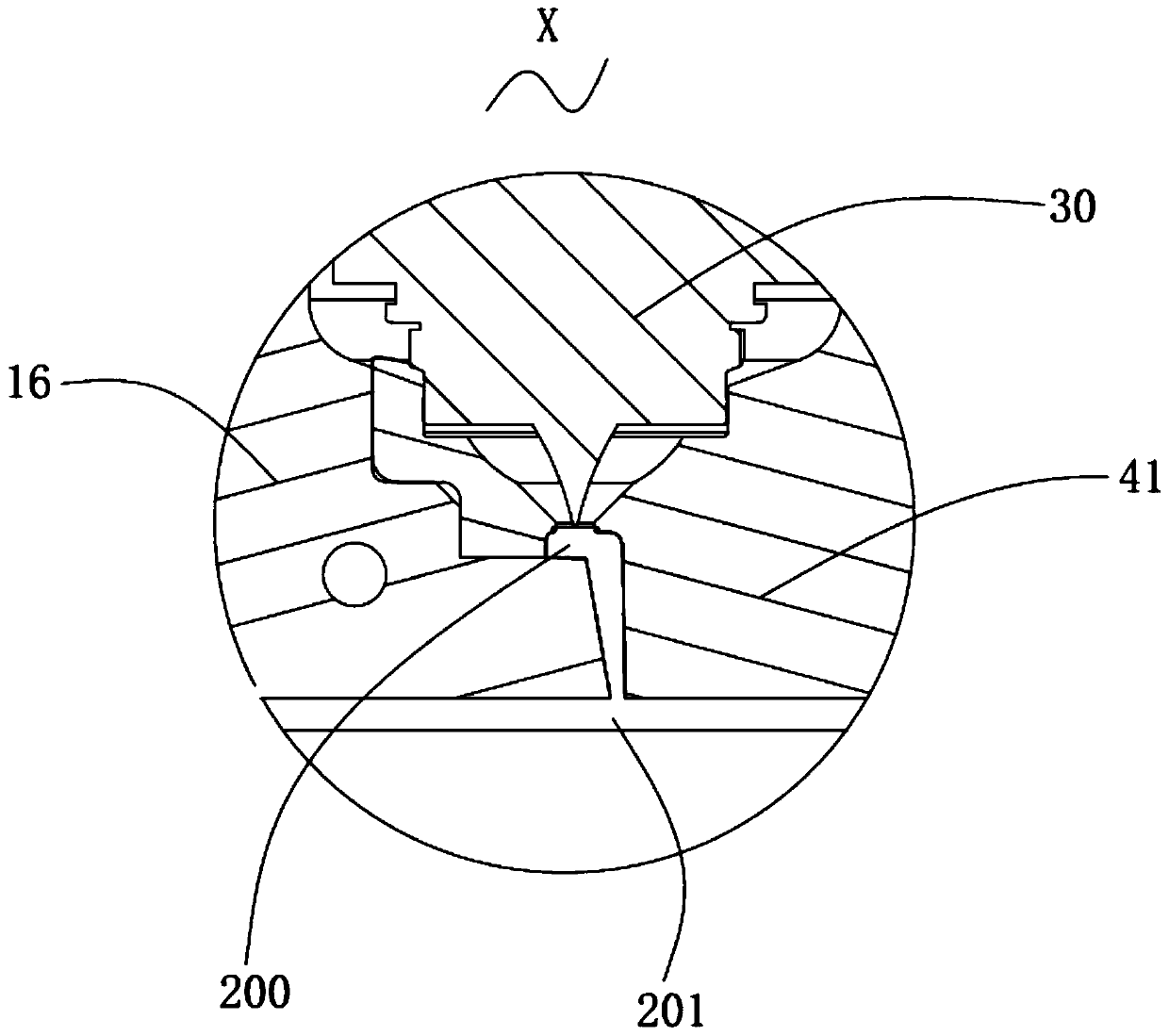

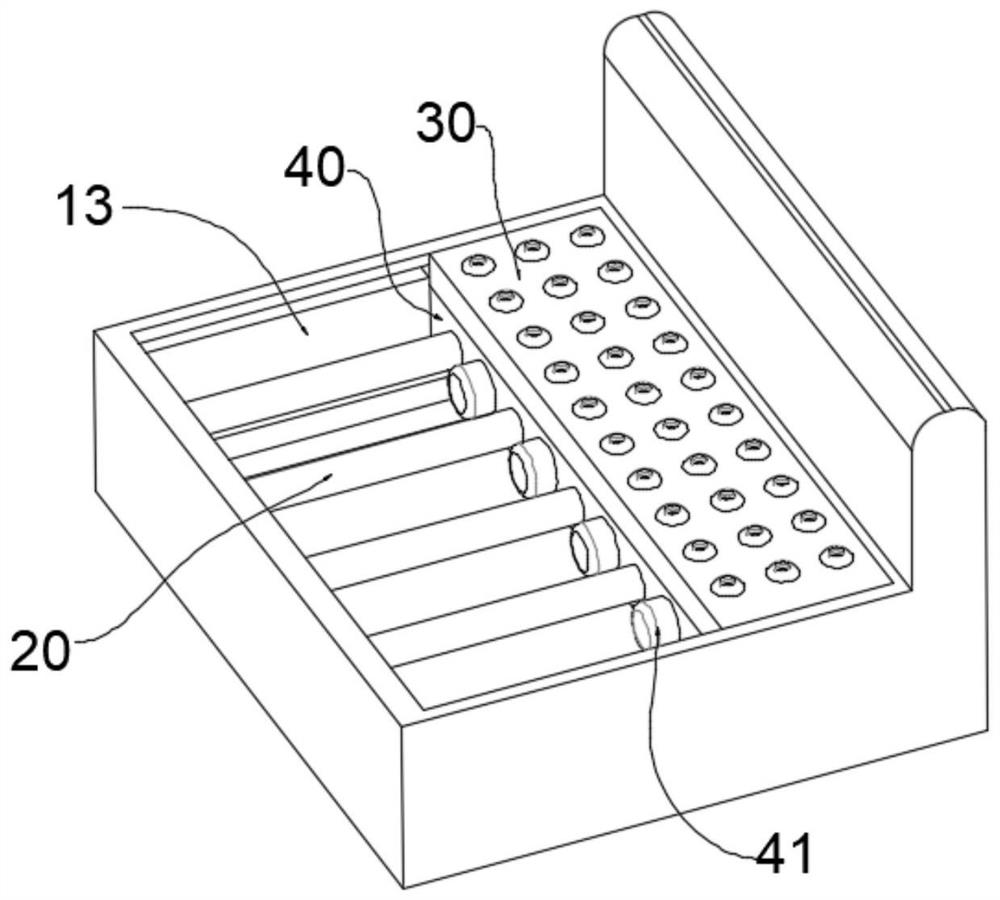

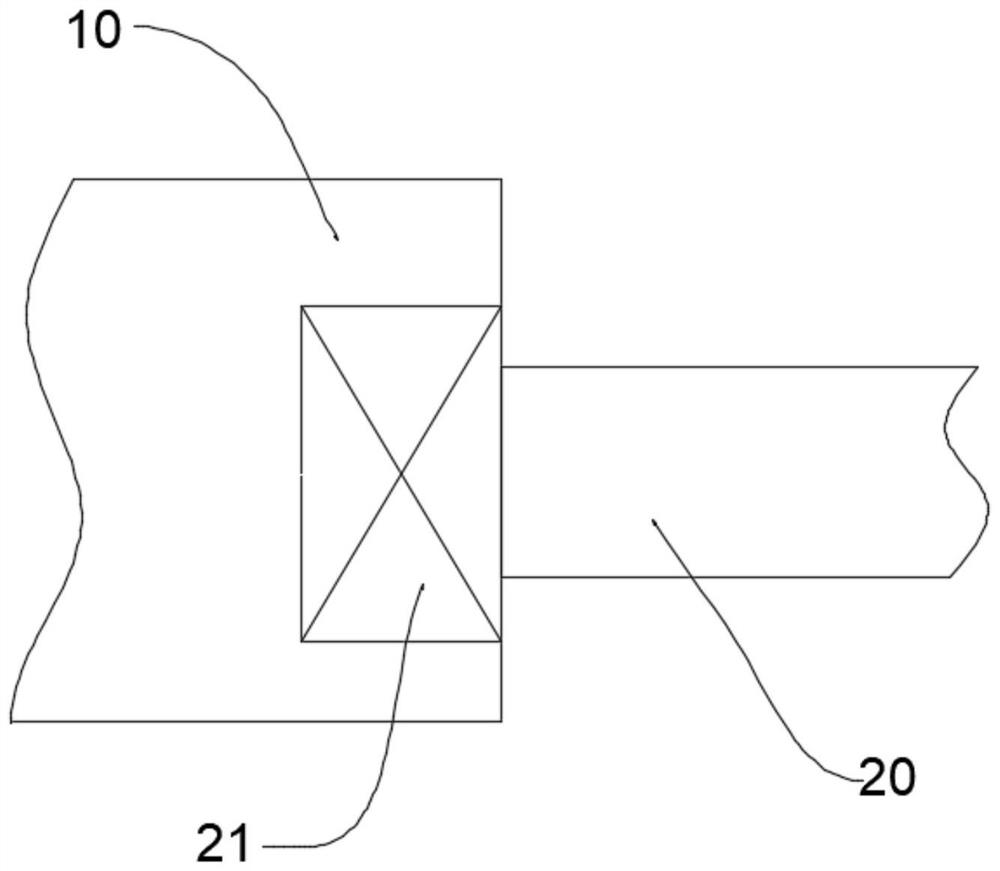

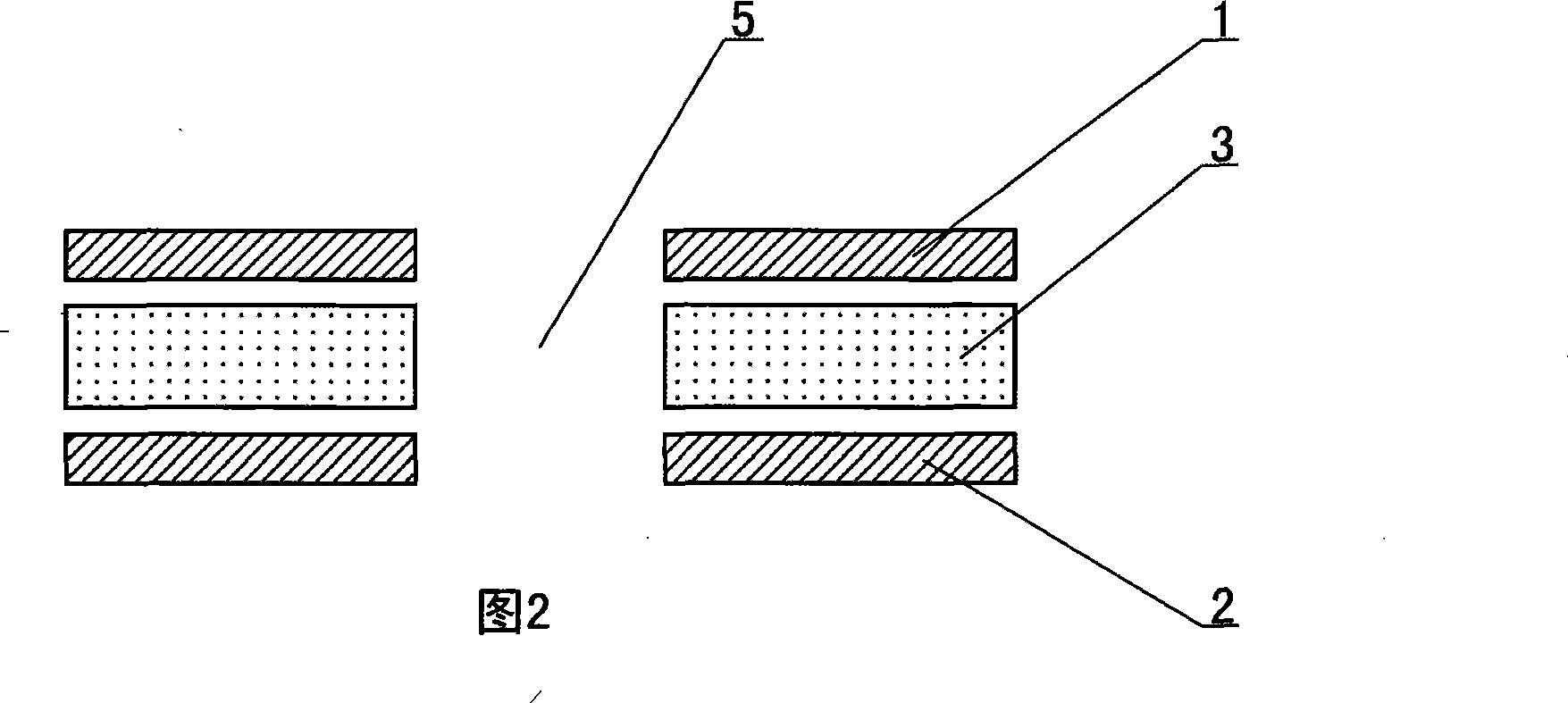

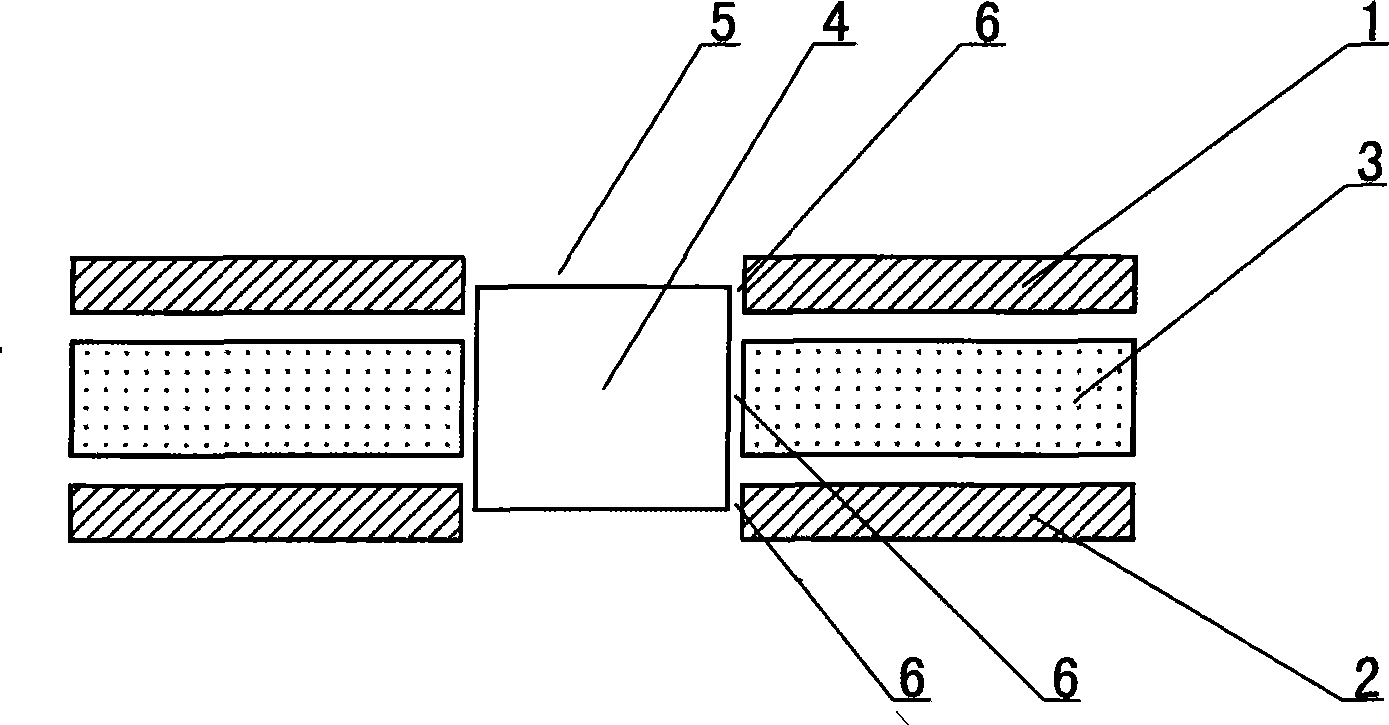

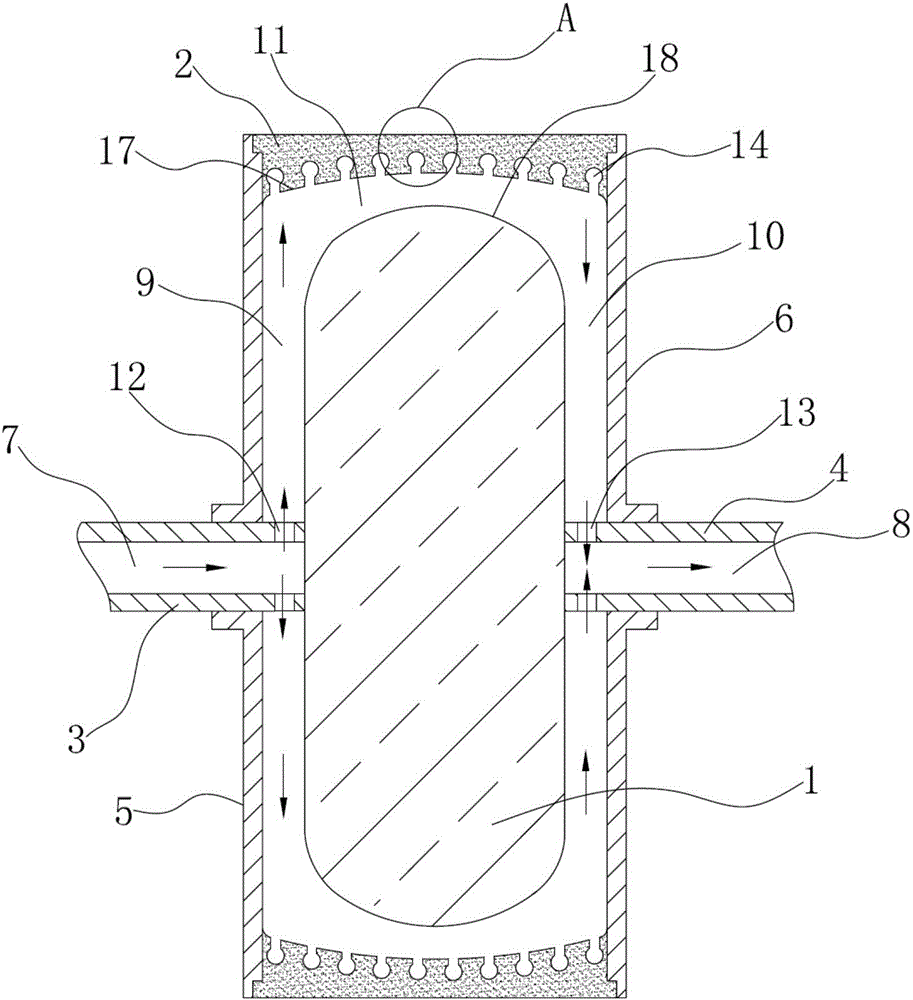

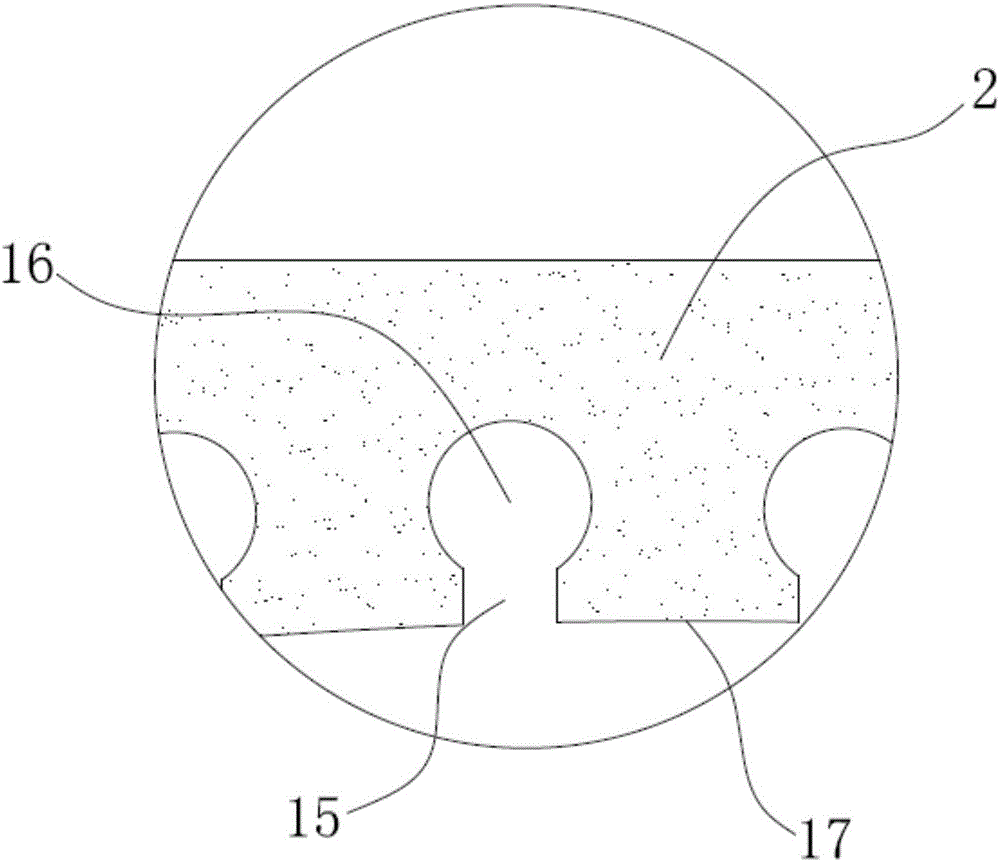

A making method for embedding fins on a printed circuit board includes following steps: 1) opening a tool hole on the position to be embedded with fins in a circuit board and a prepreg forming region, and drilling a pre-positioning hole outside of the forming region; 2) arranging the prepreg between two adjacent circuit board, pre-positioning the circuit boards and the prepreg through the pre-positioning hole; 3) arranging fins in the tool hole in a stitching pre-lamination process; 4) stitching the circuit boards and the prepreg to fill the gap between the tool hole and fins by flowing latex, the prepreg cures automatically during stitching, combining the fins and the circuit boards; 5) mechanical brushing and grinding board elements, cleaning residual prepreg material on surfaces of circuit boards. The invention avoids the inanition phenomenon, solves depression or protrusion of circuit board surfaces, reduces abnormal wear of grinding brush wheels in following process, thereby the embedding effect of fins is good.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

Technological process of making flat spring steel for automobile

The flat spring steel for automobile is produced via converter smelting process. Compared with available technology, the present invention has the following advantages and positive effects: utilizing molten iron with less harmful elements as material to result in high flat spring steel quality; higher finished product rate and lower power consumption to result in lower cost than production in electric furnace; casting molten steel into small square billet to omit the billet cutting step and lower cost; and high size precision of the continuously cast small square billet to ensure high size precision of flat spring steel.

Owner:青岛钢铁控股集团有限责任公司

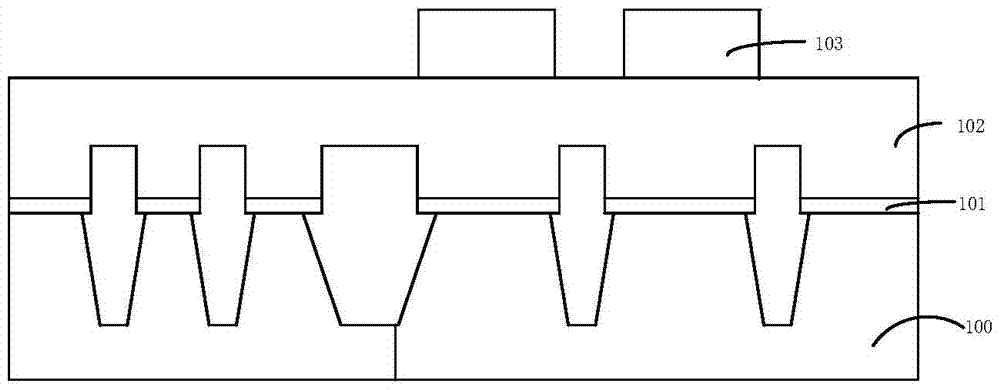

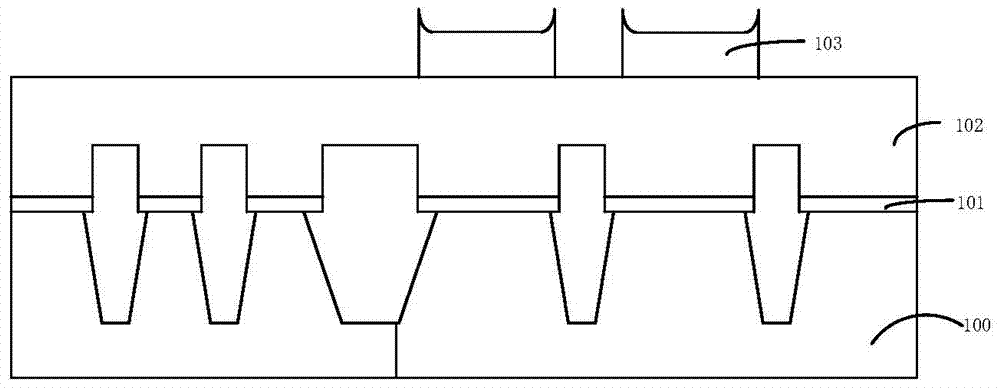

Manufacturing method for shallow trench isolation structure

InactiveCN103199052AReduce use costTo achieve a flattening effectSemiconductor/solid-state device manufacturingEtchingIsolation layer

The invention provides a manufacturing method for a shallow trench isolation structure. The method includes the following steps: covering a semiconductor substrate with an oxide layer and a nitride layer sequentially; carrying out exposure and etching process to form a shallow trench figure; depositing an isolation layer to fill the shallow trench figure; carrying out flattening processing on the isolation layer, and leaving part of the isolation layer; and removing the remaining isolation layer by adopting the method of wet etching, and then removing the nitride layer. According to the manufacturing method for the shallow trench isolation structure, in the process of flattening processing, the nitride layer is not contacted, flattening can be achieved by adopting common lapping fluid, cost of the lapping fluid is reduced, and meanwhile, the phenomena of indentation and corrosion caused by chemical and mechanical lapping are avoided due to the fact that the remaining isolation layer on the nitride layer is removed by using the method of wet etching.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for manufacturing shallow trench isolation structure

InactiveCN103236416AReduce use costAddressing Sag and ErosionSemiconductor/solid-state device manufacturingOxideSemiconductor

The invention provides a method for manufacturing a shallow trench isolation structure. The method includes sequentially covering an oxide layer and a nitride layer on a semiconductor substrate; carrying out exposure and etching processes to form shallow trench patterns; settling isolation layers and filling the isolation layers in the shallow trench patterns; flattening the isolation layers and reserving parts of the isolation layers; removing remaining parts of the isolation layers by means of dry etching; and removing the nitride layer by means of wet etching. The method for manufacturing the shallow trench isolation structure has the advantages that the nitride layer is unaffected when the isolation layers are flattened, the isolation layers can be flattened by common grinding fluid, the cost of the grinding fluid is reduced, the remaining parts, which are positioned on the nitride layer, of the isolation layers are removed by means of dry etching, and accordingly problems of depression and erosion due to chemical mechanical polishing are solved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Continuous casting crystallizer casting powder special for sorbite stainless steel and application thereof

The invention discloses continuous casting crystallizer casting powder special for sorbite stainless steel and application of the continuous casting crystallizer casting powder, and belongs to the technical field of steelmaking auxiliary materials. The casting powder comprises the following chemical components in percentage by mass: 23 to 30 percent of CaO, 27 to 34 percent of SiO2, 6.5 to 9.0 percent of Al2O3, 0.5 to 2 percent of Fe2O3, 1 to 3 percent of MgO, 4.5 to 8.0 percent of Na2O, 4.0 to 6 percent of F-, 0.18 to 1.6 percent of Li2O, 0.48 to 2 percent of B2O3, 0.35 to 1.6 percent of BaO, 2.8 to 5.5 percent of MnO, 3 to 6 percent of Ct and the balance of unavoidable impurities. The casting powder is suitable for continuous casting of S600E sorbite stainless steel, is reasonable in raw material selection and performance index design, has good lubrication and heat transfer control effects, can ensure smooth operation of a sorbite stainless steel continuous casting process, and obtains high casting blank quality.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Suspended film hollow glass, manufacturing method, continuous production device and application

PendingCN111827845ASimple processEasy to manufactureSolar heating energyDomestic cooling apparatusAdhesiveHigh productivity

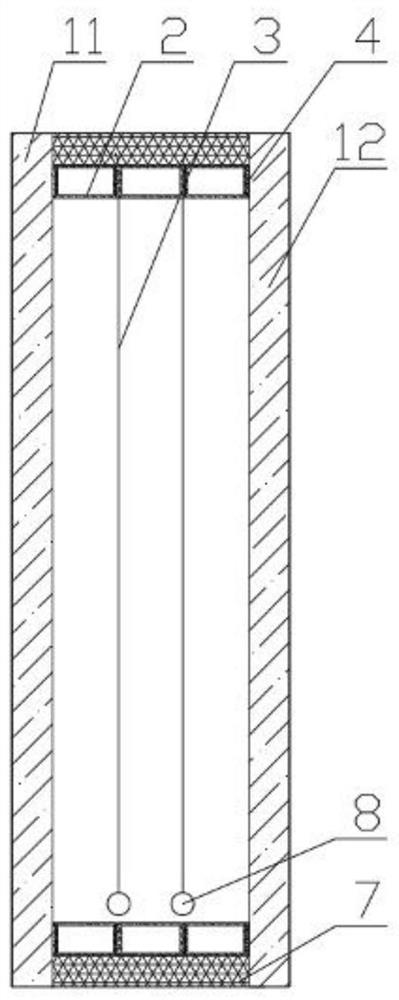

The invention belongs to the technical field of hollow glass, and discloses suspended film hollow glass, a manufacturing method, a continuous production device and application. Spacer frames are bonded to corresponding peripheral positions of front glass and rear glass, the edge of the upper end of a suspended film is fixed between every two adjacent spacer frames in a bonding or welding or clamping manner, the lower end of each suspended film is fixedly connected with a bottom rod with the length matched with the width of the suspended film, and the bottom rods are fixed to the lower ends ofthe spacer frames. Cavities are formed between the suspended films and the front and rear glass and between the suspended films respectively. Spaces formed by the front glass, the rear glass and the outer sides of the spacer frames are fully covered with a structural adhesive, and the double-cavity or multi-cavity suspended film hollow glass is formed after solidification of the structural adhesive. The suspended film hollow glass can be conveniently manufactured by a simple process at a low cost and high productivity and has good heat insulation and sound insulation effects, the packaging width of the glass edge is equivalent to that of existing hollow glass, and the inherent breathing phenomenon of the hollow glass can be effectively relieved.

Owner:WEIHAI RUNFENG GLASS

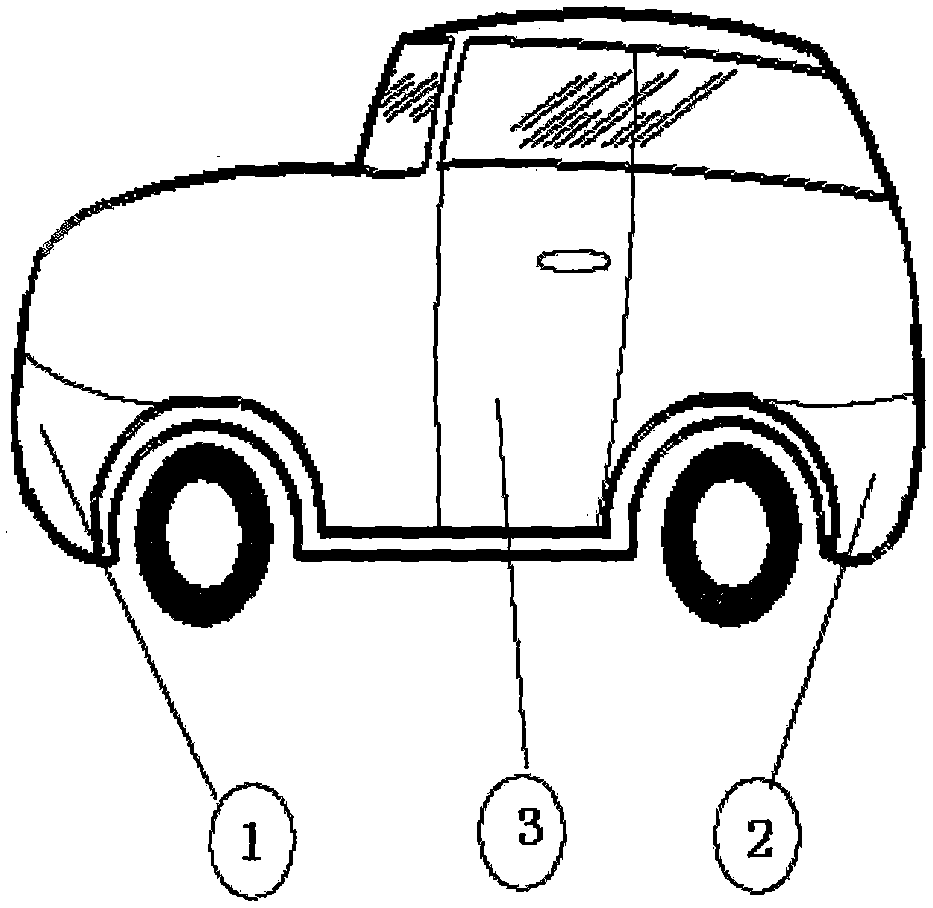

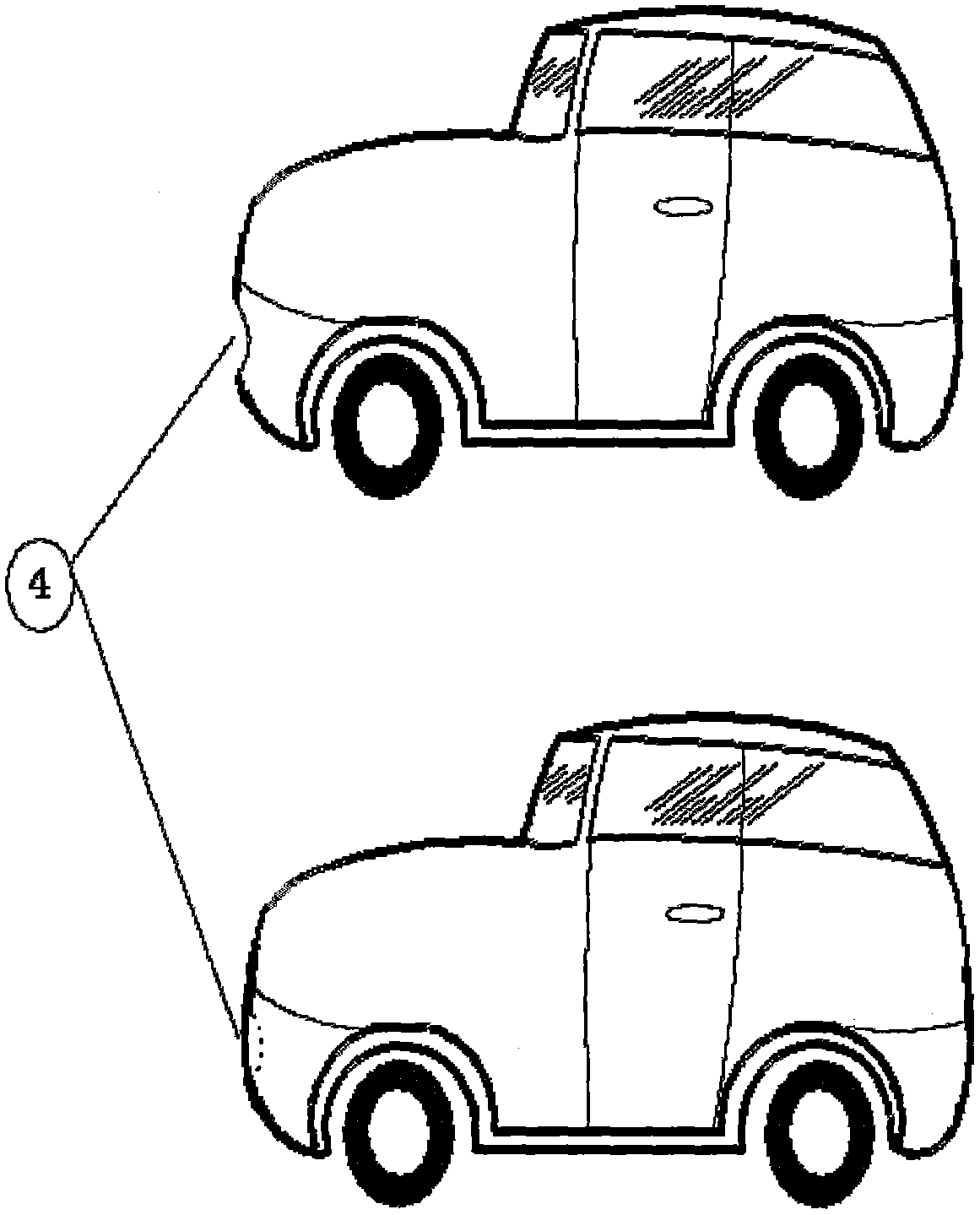

Automobile shell with self-healing function

An automobile shell with a self-healing function belongs to the technical field of application of new materials. The automobile shell is made of memory alloy sheets, and is composed of a front bumper (1), a rear bumper (2), and a door (3). A depressed part (4) caused by scraping can be restored to the original shape without using external mechanical means. When the memory alloy automobile shell with a self-healing function is depressed by scraping, there is no need to send the automobile shell to a repair shop for repair. As long as boiling water is spilt on the depressed part of the automobile shell, the depressed part of the automobile shell can be restored to the shape before scraping within a few minutes. The operation is simple and easy, neither professional technology nor special tool is needed, and the fee for automobile repair and the time wasted due to automobile repair can be saved. The automobile shell with a self-healing function is applicable to all kinds of cars.

Owner:刘南林

Equipment for curing sealant

InactiveCN1445590AReduce defectsIncrease contact areaSemiconductor/solid-state device manufacturingDrying chambers/containersEngineeringSealant

The invention discloses an apparatus for curing a sealant on a substrate. The apparatus includes a chamber for accommodating at least one pair of bonded substrates, and at least one support unit for supporting the bonded substrates, the support unit being mounted on an inner side surface of the chamber and having a substantially flat surface in contact with the bonded substrates. contact surface.

Owner:LG DISPLAY CO LTD

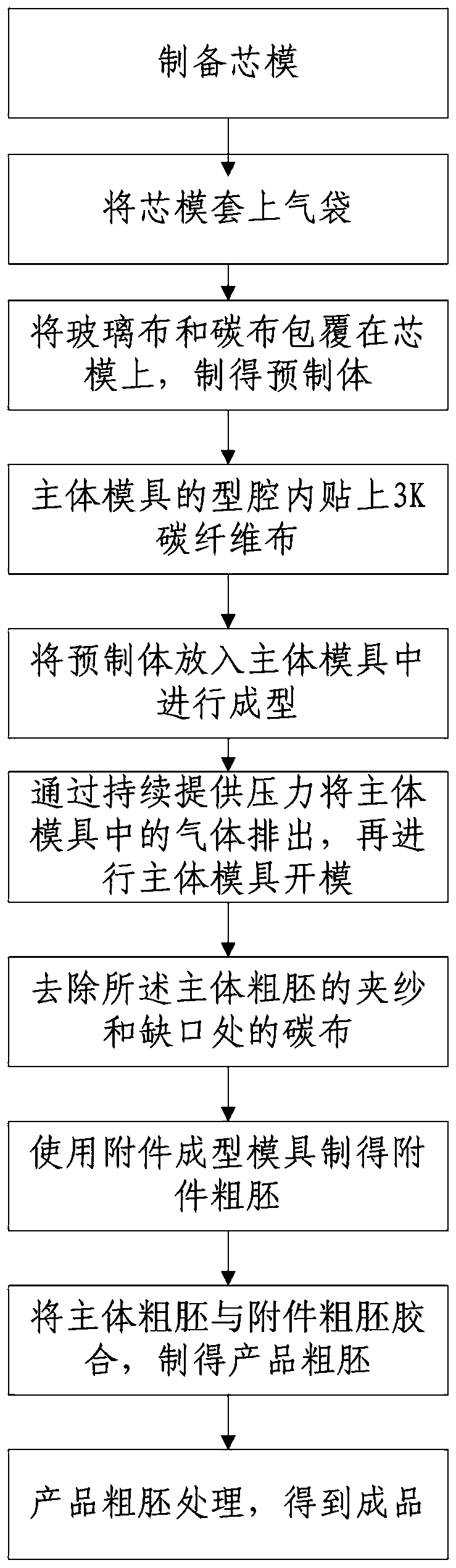

Forming process of hollow carbon fiber product

The invention provides a forming process of a hollow carbon fiber product, and relates to the technical field of carbon fiber preparation. The process comprises the following steps that a polystyrenefoam raw material is poured into a core mold, and the mold is put in a vacuum hot pressing furnace to be formed; the core mold is put into an air bag; glass cloth and carbon cloth are wrapped around the core mold according to the shape of the core mold, so that a product prefabricated body is obtained; 3K carbon cloth is affixed to a cavity of a main body mold; the prefabricated body is put into the main body mold, an air inlet pipe is connected, and forming control is conducted; the main body mold is opened so as to obtain a product main body rough blank; a yarn-contained flash of the main body rough blank is removed; an accessory is prepared by using an accessory forming mold, and an accessory rough blank is obtained; the main body rough blank and the accessory rough blank are glued together; and the product rough blank is treated, so that a finished product is obtained. The process solves the problems of material missing or depression in a hollow carbon fiber formed product.

Owner:ANHUI GUANTING TECH CO LTD

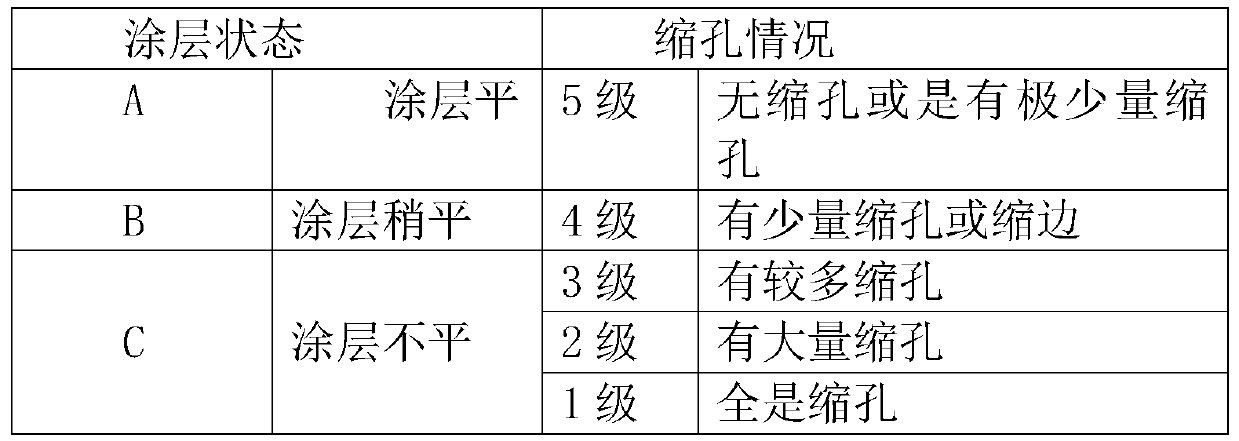

Mineral oil defoamer

InactiveCN110960893ASolve the shrinkage cavitySolve shrinkageFoam dispersion/preventionVegetable oilHydrophobic silica

The invention discloses a mineral oil defoamer. The defoamer comprises mineral oil, a carrier composed of vegetable oil and derivatives thereof, fatty acid metal soap, alkyl silicone oil, a defoamingaid, hydrophobic silica and an emulsifier. The vegetable oil and derivatives thereof and mineral oil are introduced into a system of alkyl silicone oil and silica, the average carbon atom number of the alkyl silicone oil is controlled to make the alkyl silicone oil well intermiscible with the mineral oil, and a ratio of the mineral oil to the vegetable oil and derivatives thereof is controlled between 1:6 and 4:7 to finally effectively solve the problems of cavity shrinkage, edge shrinkage and recession of a film and enhance the defoaming and foam-inhibiting properties and stability of the defoamer.

Owner:湖北新四海化工股份有限公司

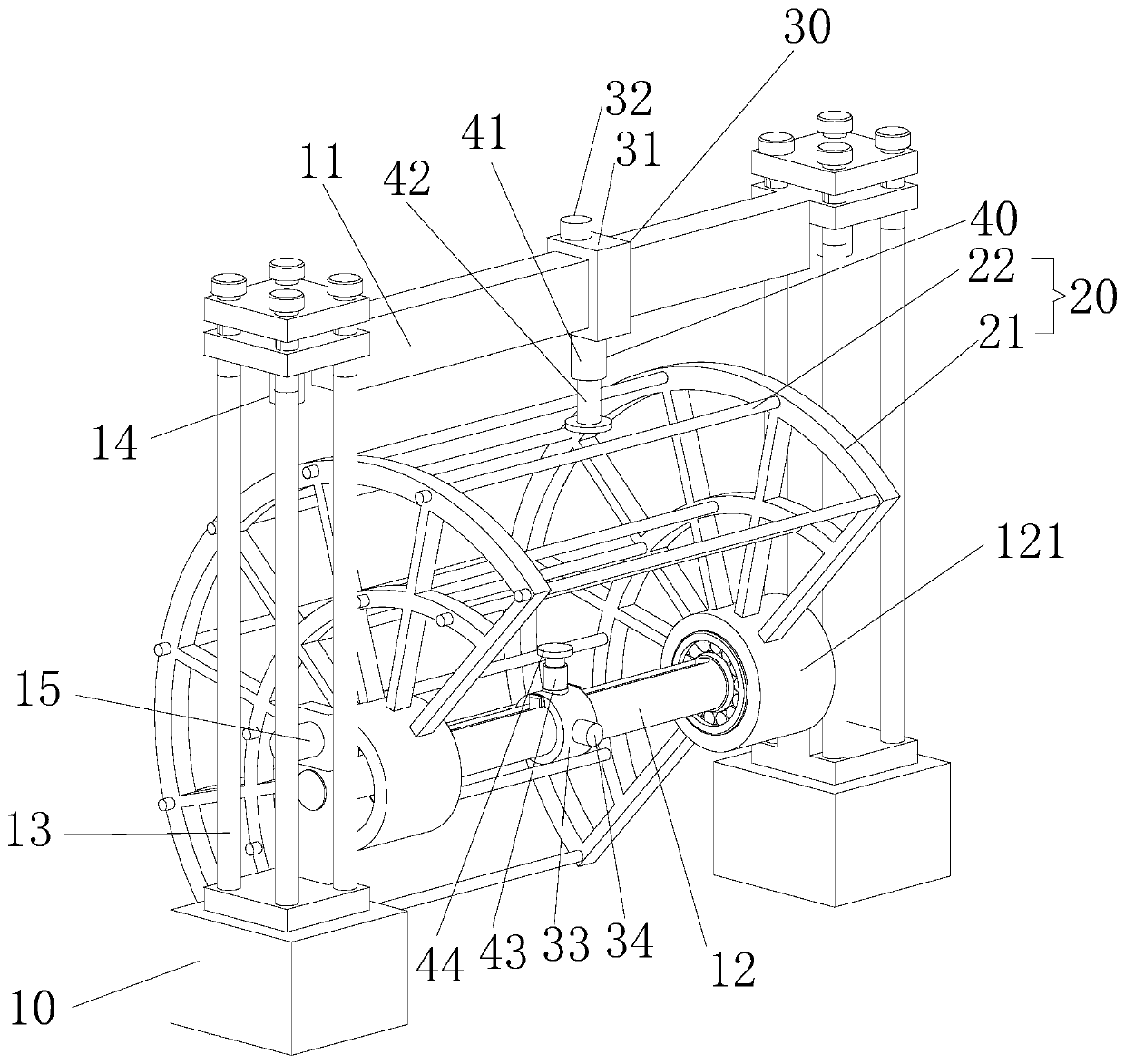

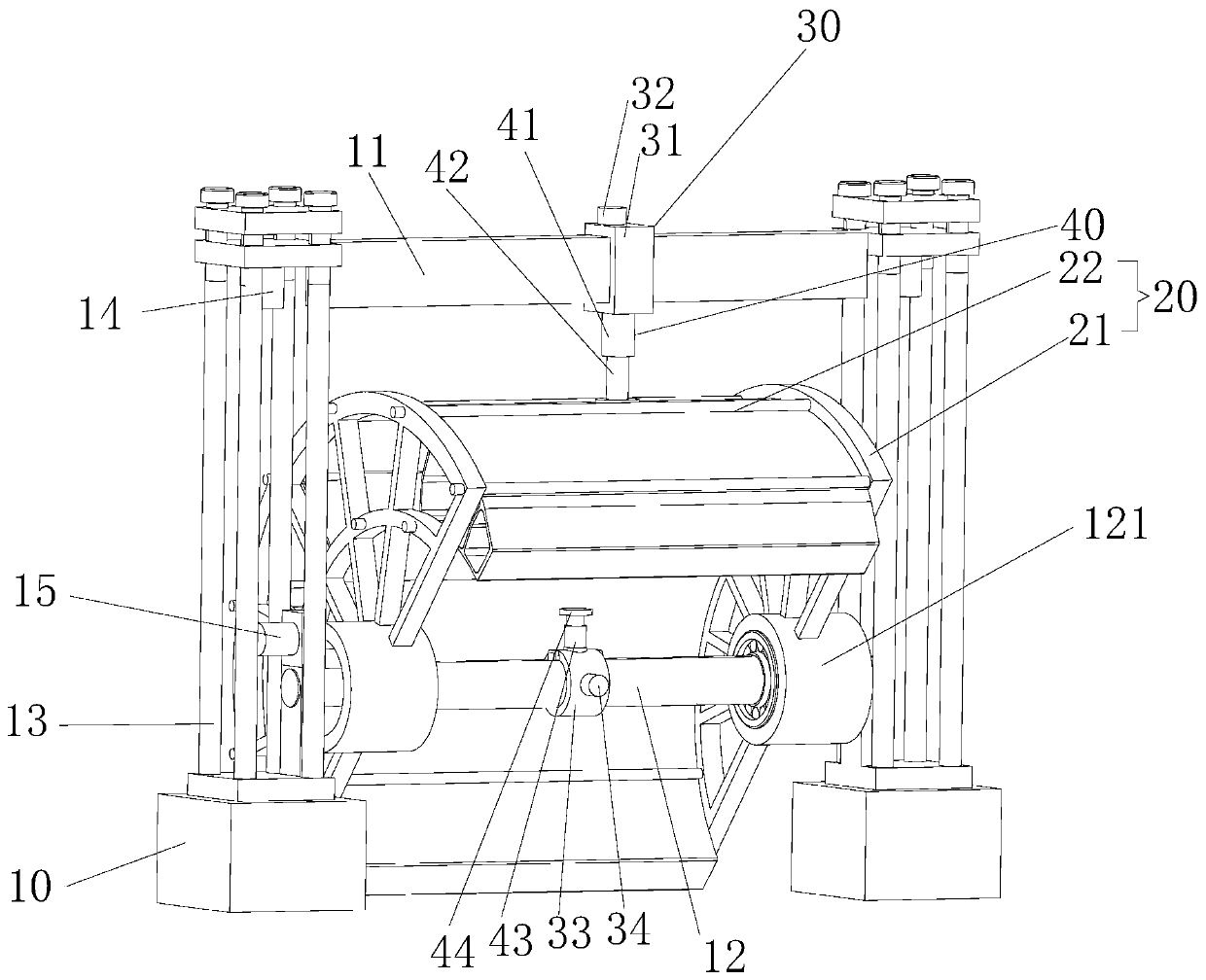

Multiple-cavity special-shaped double-layer thin-wall section pipe fitting correcting robot

The invention relates to the field of correcting and processing of multiple-cavity special-shaped double-layer thin-wall section pipe fittings for aviation, and discloses a multiple-cavity special-shaped double-layer thin-wall section pipe fitting correcting robot. The pipe fitting correcting robot comprises a machine frame, a fixing assembly, a moving assembly and a pressure suction assembly, wherein the pressure suction assembly comprises a first hydraulic cylinder, a first disc rack, a second hydraulic cylinder and a second disc rack, the fixed end of the first hydraulic cylinder is connected with the bottom of a first rack body, a piston rod of the first hydraulic cylinder is connected with the top of the first disc rack, the fixed end of the second hydraulic cylinder is connected with the top of the second rack body, and a piston rod of the second hydraulic cylinder is connected with the bottom of the second disc rack. According to a double-layer shell shaping device, the upper and lower pressure suction assemblies are used for shaping the upper-layer surface and lower-layer surface of a double-layer shell correspondingly, and a sucker or a pressure plate can be replaced so as to solve the problems that the surface of the material is recessed and raised.

Owner:HEFEI UNIV OF TECH

Display device packaging method

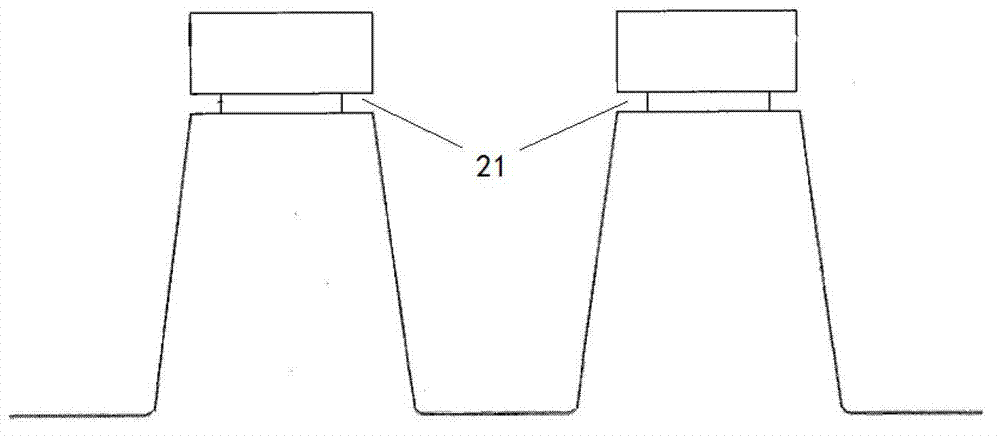

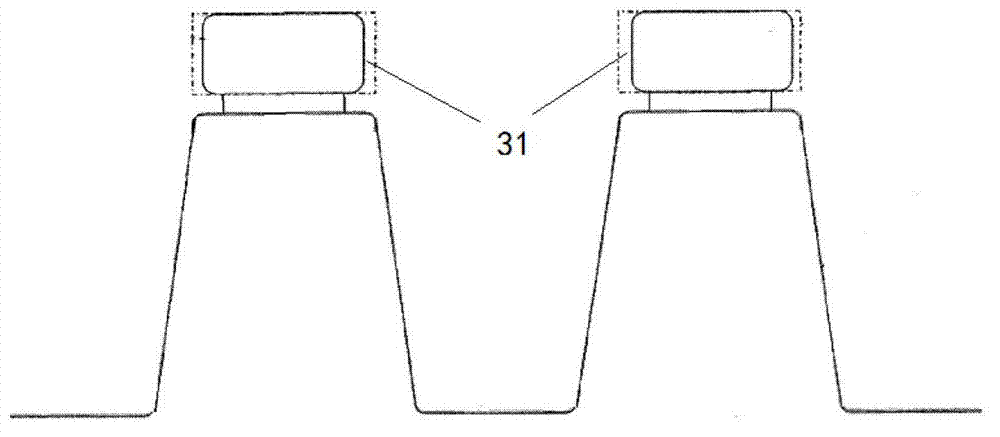

ActiveCN110993830ASolve the problem of sagIncrease temperatureSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingDisplay device

The invention discloses a display device packaging method. The method comprises the following steps of coating the cover plate glass with a heating decomposable glue; carrying out screen printing on the frit glue, wherein the frit glue is positioned on the heating decomposable glue; and baking the heating decomposable glue and the frit glue. The decomposition temperature of the heating decomposable glue is different from the curing crystallization temperature of the frit glue, and the frit glue is still in a molten state at the decomposition temperature required for the heating decomposable glue, so that the height generated by the decomposed frit glue is poor. The frit glue in the molten state automatically flows to fill the position occupied by the original heating decomposable glue, sothat recesses generated during the screen printing of the frit glue are eliminated, and the frit glue is cured and crystallized along with the temperature rise, and accordingly the recesses generatedby the screen printing of the frit glue are eliminated, and the quality of a packaging process is improved.

Owner:FUJIAN HUAJIACAI CO LTD

Hollow channel isolation region preparation method

InactiveCN103247567AImprove performanceGood lookingSemiconductor/solid-state device manufacturingEtchingEngineering

The invention discloses a hollow channel isolation region preparation method which comprises the following steps: providing a supporting base; sequentially depositing buffering oxide layers and nitride layers on the supporting base; etching a hollow channel by utilizing the shallow trench isolation (STI) manufacturing technique; etching buffering oxide layer cuts on two sides of the shallow channel to form a groove; performing the first etching on the nitride layers on two sides of the shallow channel; growing a layer of oxidation film on the surface of the supporting base; and performing the second etching on the nitride layers on two sides of the shallow channel. The method starts from morphology of nitrides and realizes performance improvement of devices through modification of fewer craft processes, and utilizes twice etching to improve morphology of silicon nitride, so that the problem that the shallow channel isolation top edge lacks corners or hollows after the silicon nitride is removed is solved; and at the same time, the outline of corners of the shallow channel isolation region can be improved, so that the subsequent handling is facilitated.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

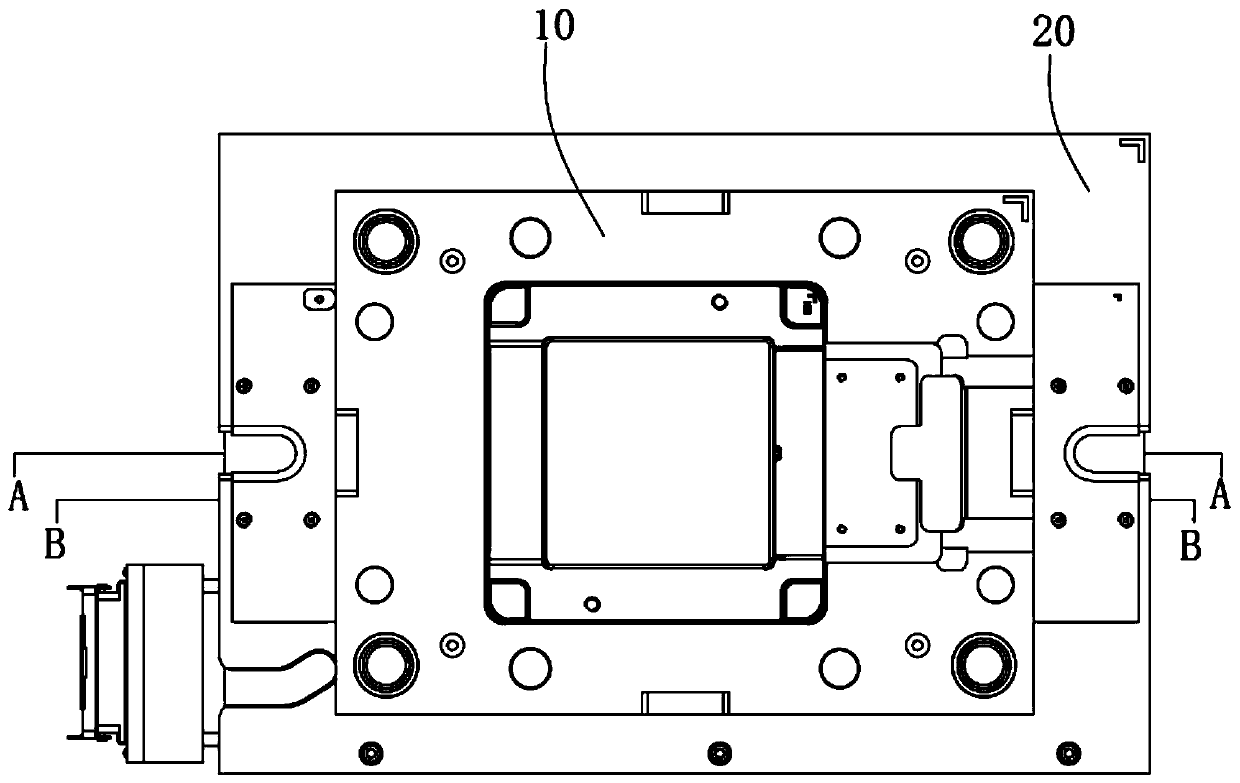

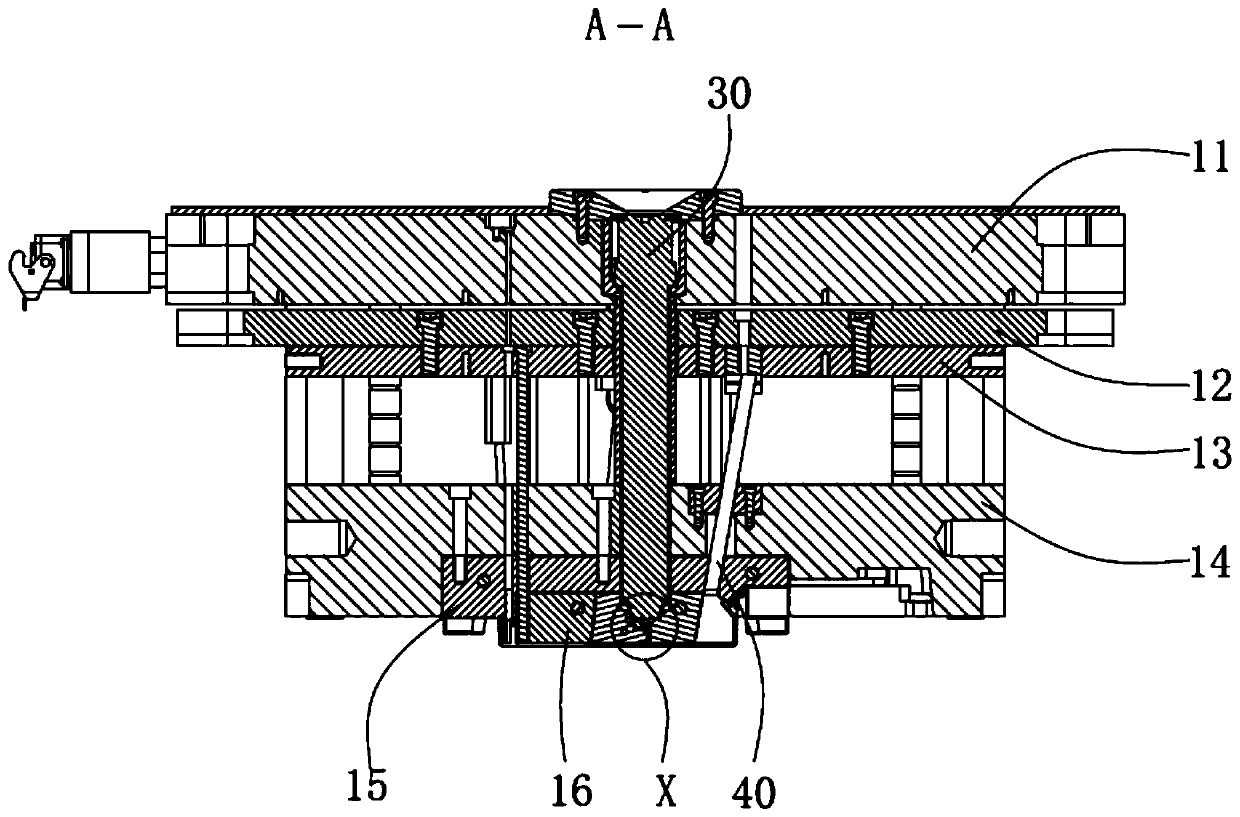

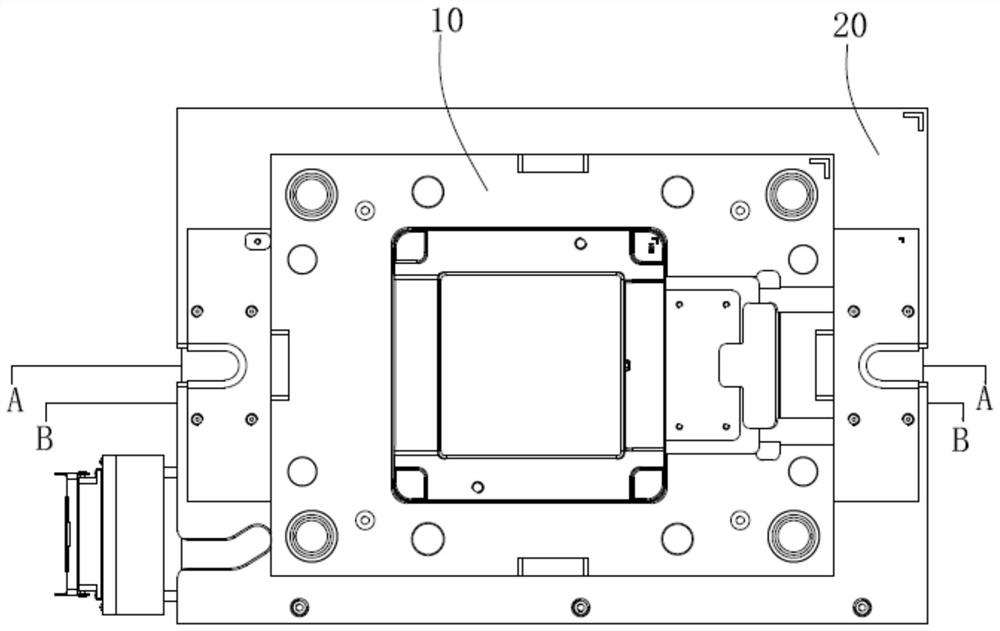

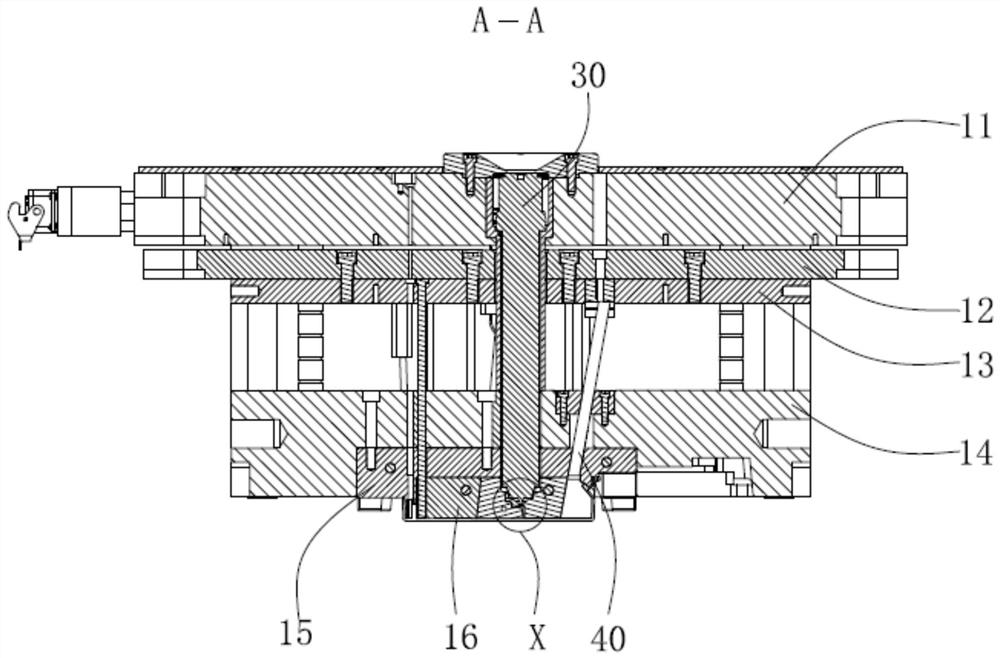

Injection mold for buffering L-shaped sheets

The invention belongs to the technical field of injection molding, and provides an injection mold for buffering L-shaped sheets. The injection mold comprises a front mold structure and a rear mold structure, wherein the front mold structure comprises an upper mold plate, a feeding assembly, an ejector pin bottom plate, an ejector pin panel, an upper mold block, an upper mold core, an insert and aninclined top assembly; and the inclined top assembly comprises an inclined top head, an inclined top rod, an inclined top pin, an inclined top base, a pin and a fixing assembly, wherein the upper endof the inclined top base is connected to the ejector pin panel, the insert and the inclined top head form an L-shaped cavity, and the L-shaped cavity is in communication with a product cavity. Duringmachining, the feeding assembly is used for feeding glue, the L-shaped cavity is impacted firstly, so that the glue flow does not directly impact the product cavity, and the buffering effect can be realized; when the glue material flows into the product cavity, the sectional area of the L-shaped cavity is larger than that of a glue inlet of the feeding assembly, the flow rate is reduced, and theproblems that the appearance of the front surface of the product is free of bubbles, trapped gas, jet lines and shrinkage cavities are solved; and the L-shaped cavity is arranged in the middle of theproduct cavity, the distance from the glue inlet to the periphery of the product is shorter, and the product size precision is ensured.

Owner:友信精密实业(深圳)有限公司

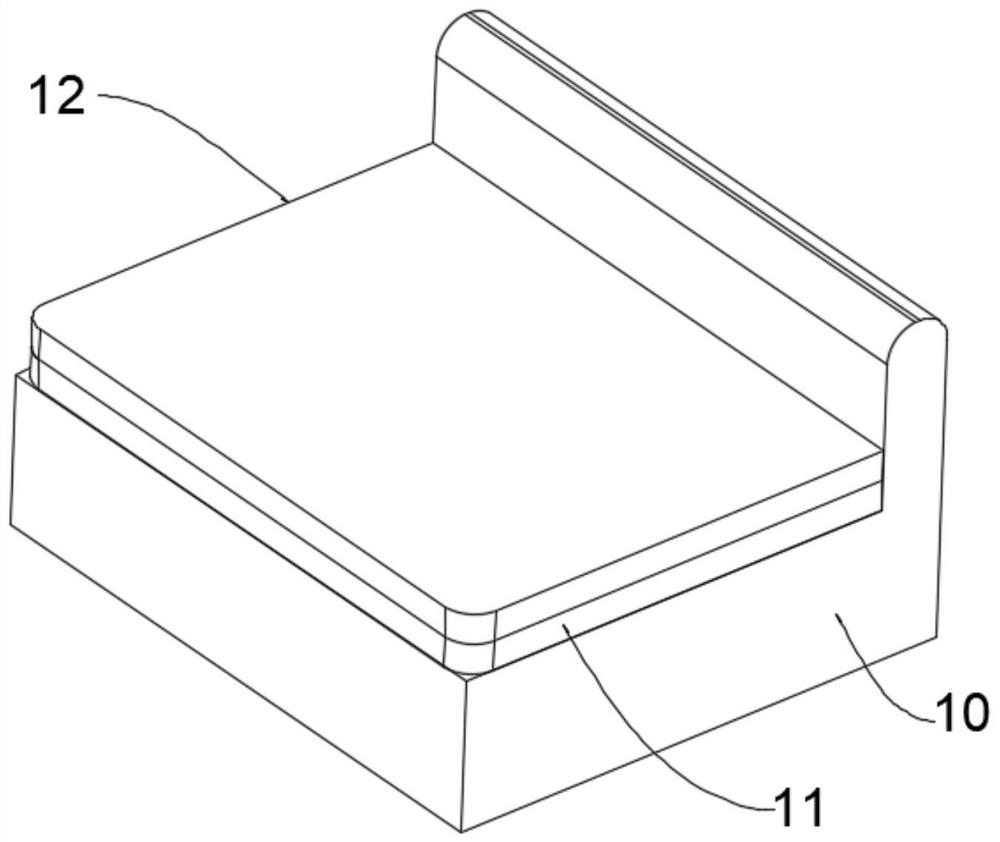

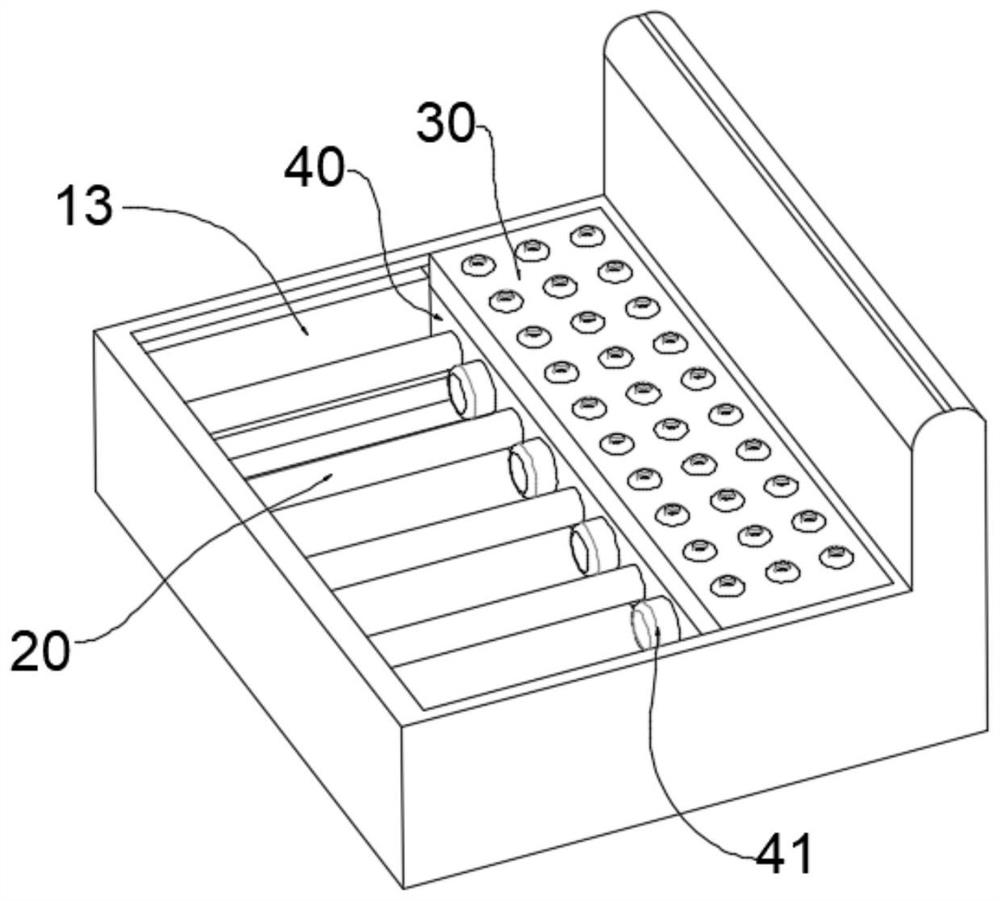

Intelligent sofa convenient to clean

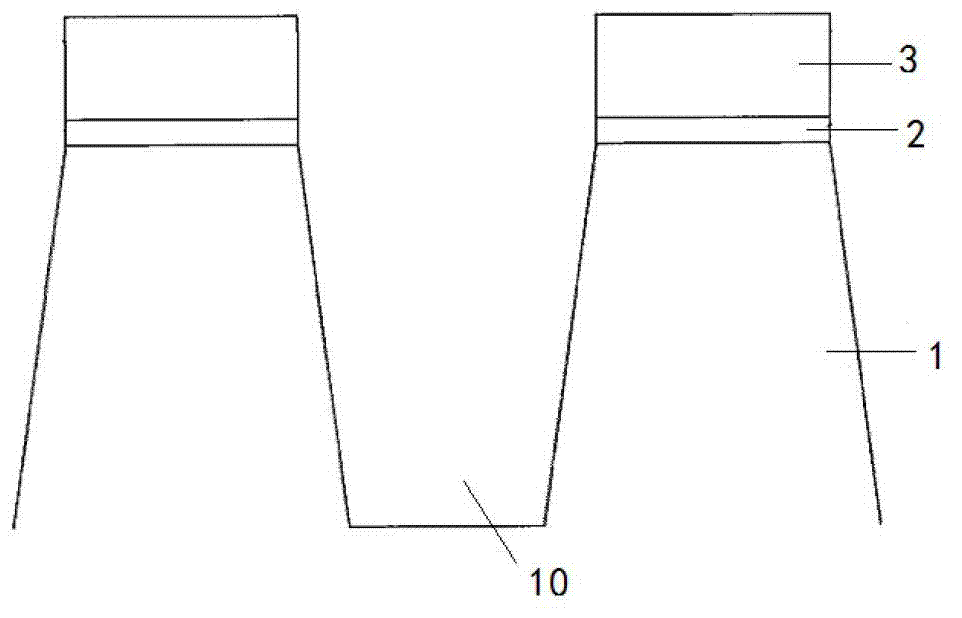

PendingCN114468659ASolve the problem of sagReduce labor intensitySofasFluid mattressesStructural engineeringMechanical engineering

The invention discloses an intelligent sofa convenient to clean. The intelligent sofa comprises a sofa bracket, a first supporting sponge, a moving block, a supporting block, a driving mechanism and a maintenance mechanism, the first supporting sponge is horizontally stacked on the sofa support, a hollowed-out cavity is formed in the sofa support, the moving block is arranged in the hollowed-out cavity in a sliding mode, and the supporting blocks are vertically stacked on the moving block; the driving mechanism is arranged in the hollowed-out cavity and is in power connection with the moving block, the driving mechanism drives the moving block to horizontally move in the hollowed-out cavity, the cleaning mechanism is arranged in the moving block, the cleaning mechanism conducts dust collection operation on the ground in an air draft mode, the cleaning mechanism synchronously moves along with the moving block, and the maintenance mechanism is installed in the supporting block. The maintenance mechanism provides supporting force in the vertical direction for the concave position of the first supporting sponge through gas pressure. According to the invention, the labor intensity of a user is reduced, and meanwhile, the tidiness of a sofa mounting position is improved.

Owner:陈诚

Manufacturing method for embedding heat radiating fin on printed circuit board

InactiveCN101257770BGood embedding effectSolve the problem of sagMultilayer circuit manufactureCooling/ventilation/heating modificationsHeat sinkPrinted circuit board

A making method for embedding fins on a printed circuit board includes following steps: 1) opening a tool hole on the position to be embedded with fins in a circuit board and a prepreg forming region, and drilling a pre-positioning hole outside of the forming region; 2) arranging the prepreg between two adjacent circuit board, pre-positioning the circuit boards and the prepreg through the pre-positioning hole; 3) arranging fins in the tool hole in a stitching pre-lamination process; 4) stitching the circuit boards and the prepreg to fill the gap between the tool hole and fins by flowing latex, the prepreg cures automatically during stitching, combining the fins and the circuit boards; 5) mechanical brushing and grinding board elements, cleaning residual prepreg material on surfaces of circuit boards. The invention avoids the inanition phenomenon, solves depression or protrusion of circuit board surfaces, reduces abnormal wear of grinding brush wheels in following process, thereby theembedding effect of fins is good.

Owner:CHINA CIRCUIT TECH SHANTOU CORP

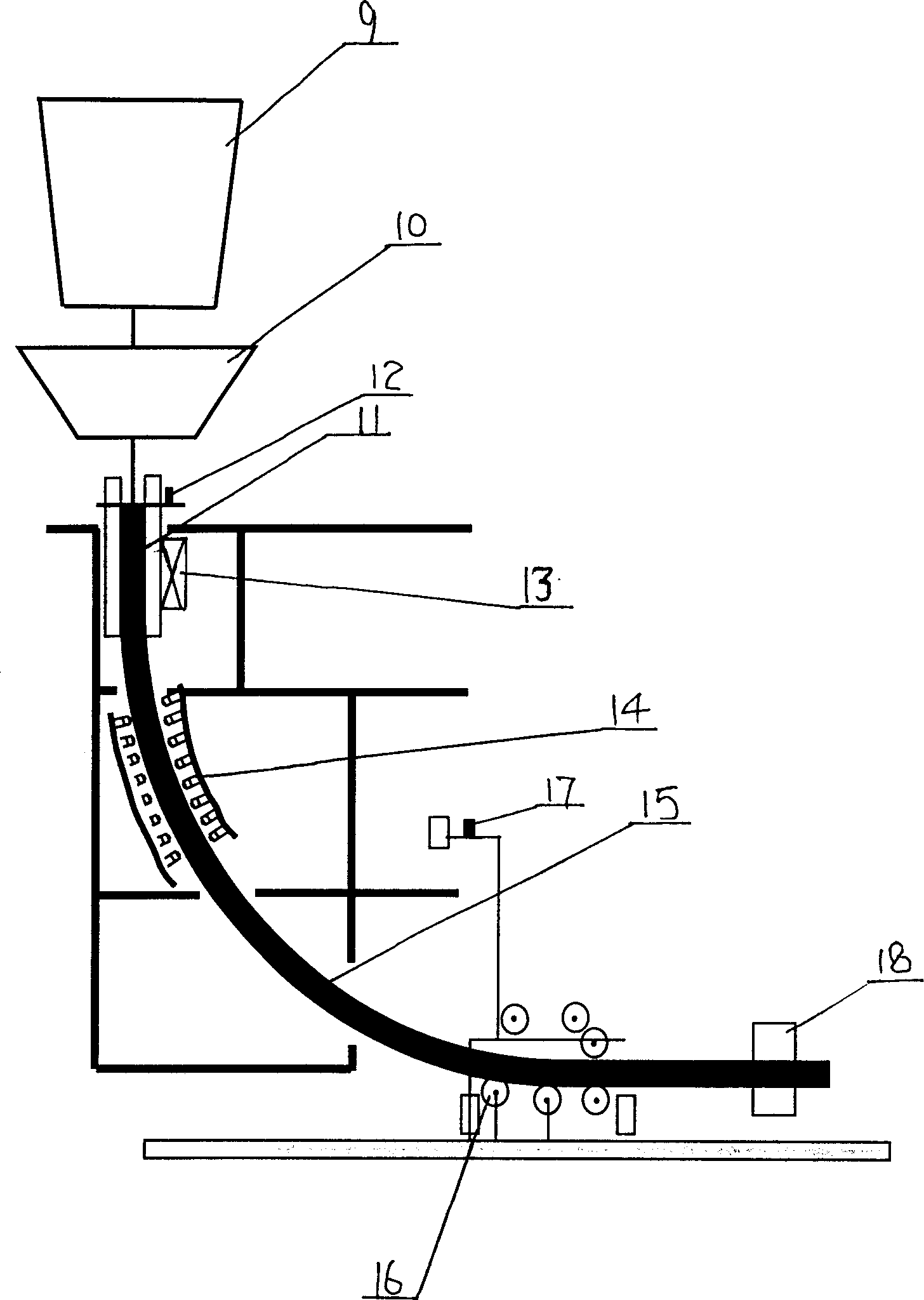

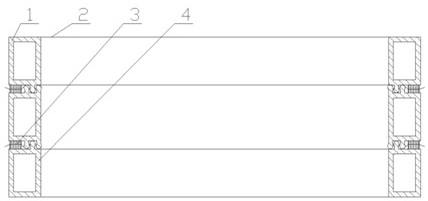

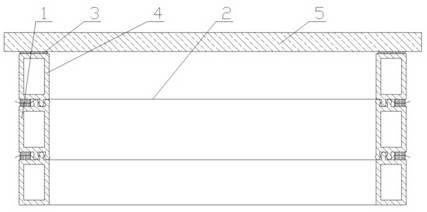

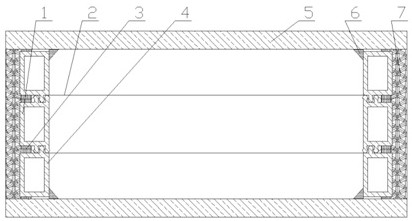

Film suspended hollow glass and manufacturing method and continuous production line thereof

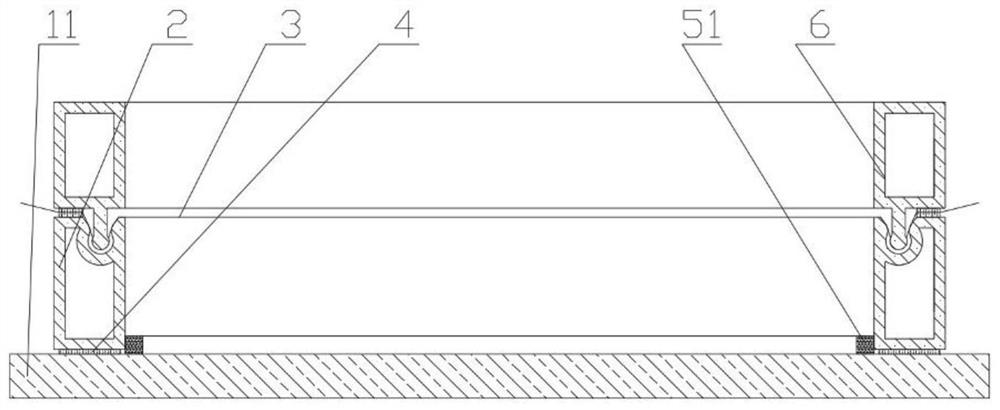

PendingCN111894409APrecise positioningIncrease productivitySolar heating energyDomestic cooling apparatusGlass manufacturingManufacturing line

The invention discloses film suspended hollow glass. The film suspended hollow glass comprises front glass, spacing frames and suspended films, wherein the front glass is bonded with the spacing frames, the suspended films are connected with the spacing frames, the area of the front glass is larger than that of the spacing frames, and a matched positioning structure can be additionally arranged between the front glass and the spacing frames according to needs. Film stretching frames and rear glass are additionally added, the film stretching frames are connected with the spacing frames throughthe suspended films to obtain single-glass film suspended hollow glass, and matched concave-convex structures are arranged on the connecting surfaces between the film stretching frames and the spacingframes; and a piece of rear glass is adhered to the other side of each film stretching frame to obtain double-glass double-cavity film suspended hollow glass, and two pieces of single-glass film suspended hollow glass are connected to obtain double-glass three-cavity film suspended hollow glass. The invention further discloses a manufacturing method of the pieces of glass and a glass manufacturing production line.

Owner:WEIHAI RUNFENG GLASS

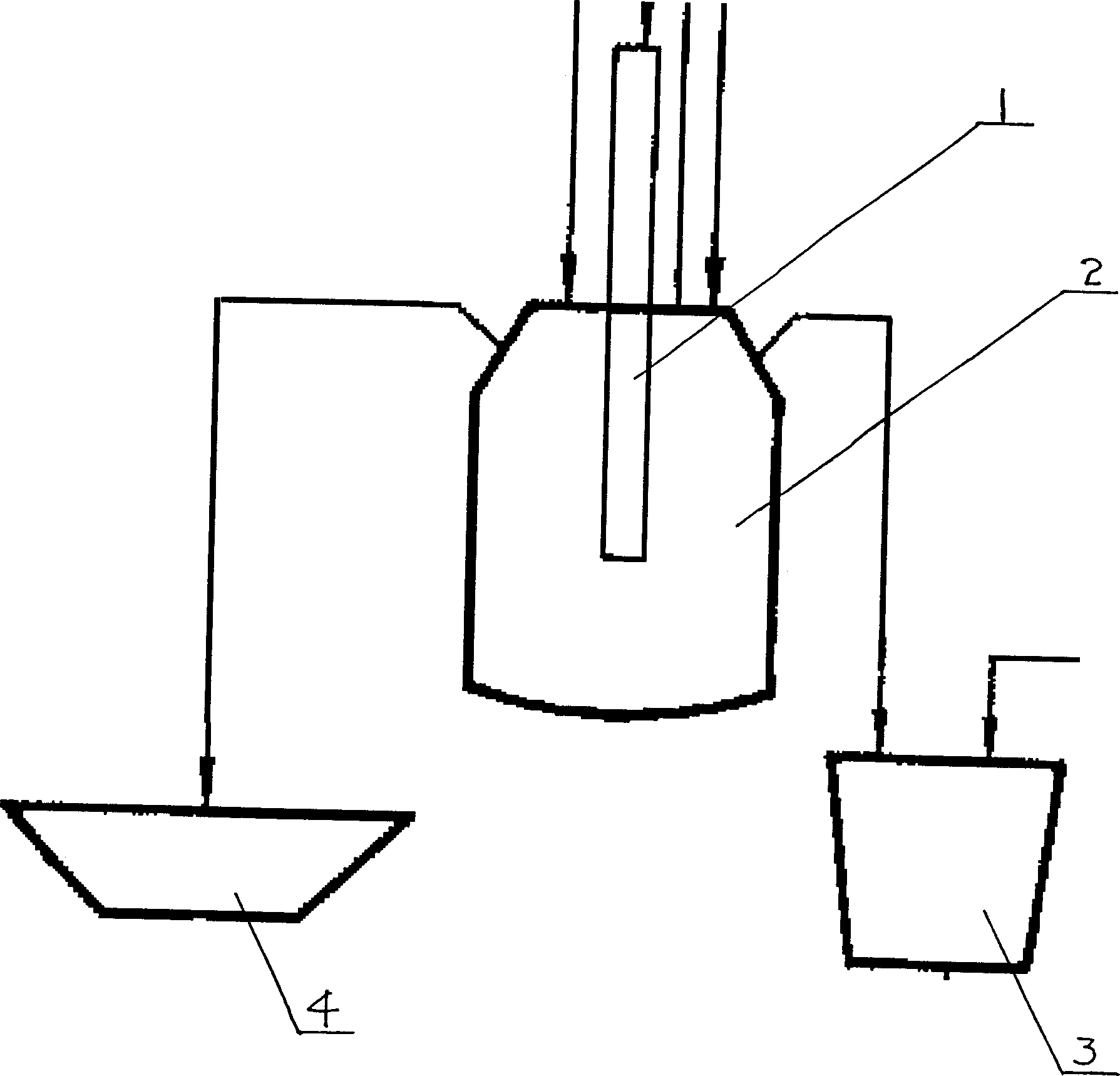

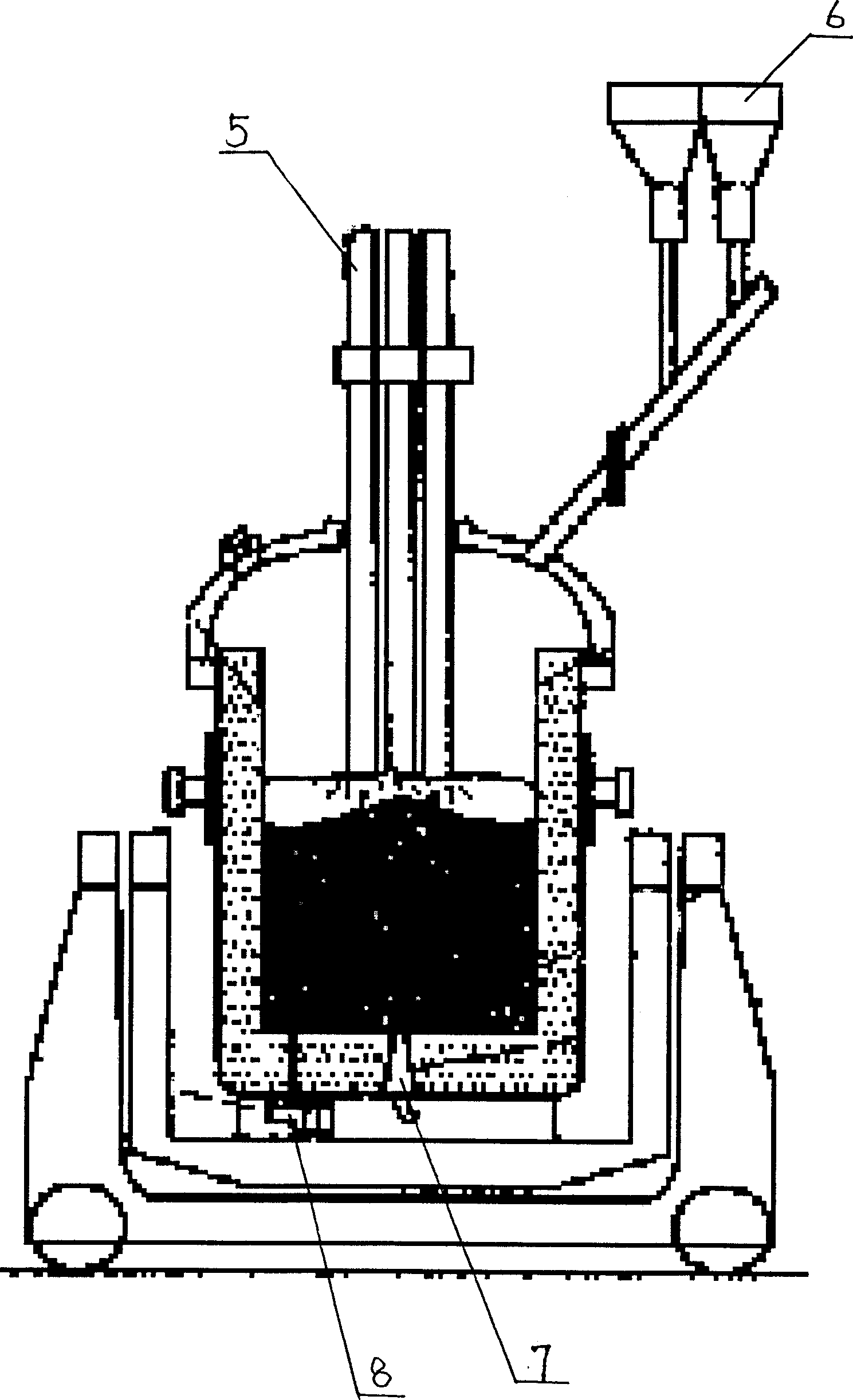

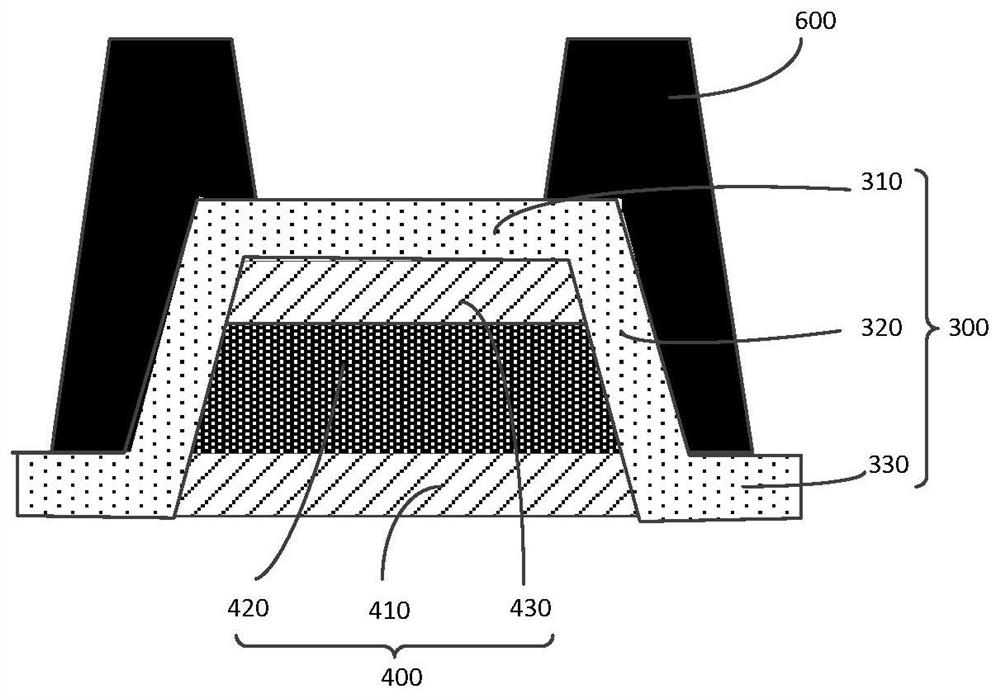

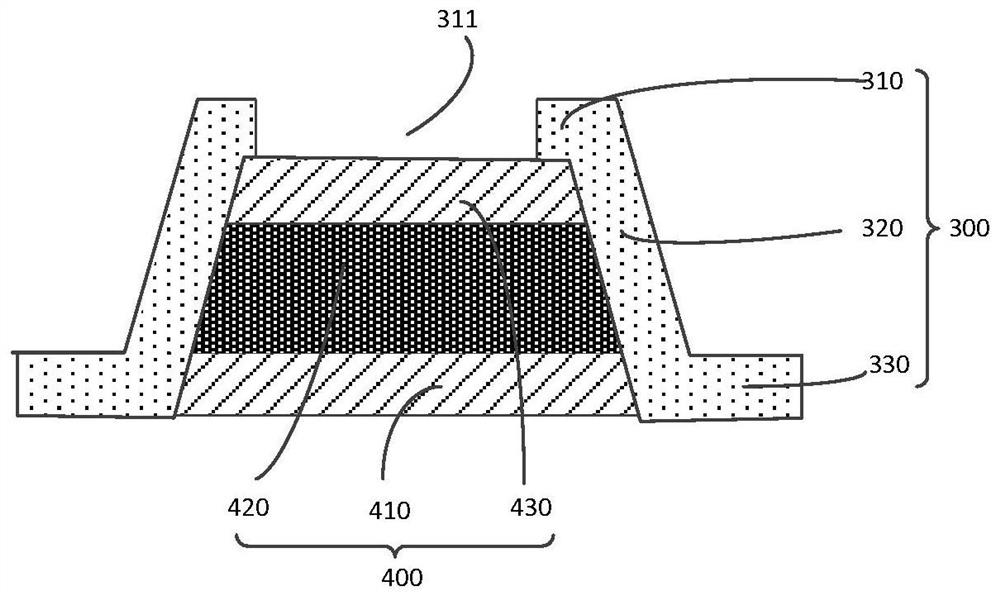

Cooling roller for turbulence high heat exchange amorphous strip production

InactiveCN107520415AImprove heat transfer efficiencySolve the problem of sagEngineeringCooling medium

The invention discloses a cooling roll for the production of turbulent flow and strong heat exchange amorphous strip, which comprises a roll core, a roll sleeve, a left main shaft, a right main shaft, a left cover plate and a right cover plate, and a cooling medium enters a channel inside the left main shaft. There is a cooling medium outflow channel in the right spindle, the space between the left cover plate, the right cover plate and the roller core respectively forms the left circulation channel of the cooling medium, the right circulation channel of the cooling medium, and the space between the roller sleeve and the roller core forms a turbulent flow and strong heat exchange There is a cooling medium radial outlet in the left main shaft, and a cooling medium radial inlet in the right main shaft. The thickness of the roller sleeve and the depth of the turbulent heat exchange channel increase from the longitudinal centerline of the roller sleeve to both sides. A plurality of annular grooves for turbulent heat exchange are arranged at intervals in the width direction of the cover, and the annular grooves for turbulent heat exchange include a notch section with a rectangular cross-section and a groove bottom section with a spherical cross-section. The heat exchanging effect of the invention is good, and the problem of large difference in axial temperature distribution of the roller sleeve in the contact area with the strip, which leads to the depression in the middle of the strip and the poor degree of amorphousness in the middle of the strip is solved.

Owner:浙江艾默可科技有限公司

High gain holographic impedance modulation surface antenna design method and antenna

InactiveCN109546314AHigh gainImprove performanceRadiating elements structural formsDesign optimisation/simulationAntenna designImpedance modulation

The invention discloses a high gain holographic impedance modulation surface antenna design method and an antenna. The method comprises steps of S1, establishing a model of a lattice unit based on a circular metal patch; S2, fitting the mathematical relationship between a geometric parameter and a surface impedance value between a distance g of a circular metal patch from an edge of the lattice unit and the surface impedance Z; S3, obtaining surface impedance distribution of the holographic impedance modulation surface; and S4, calculating a parameter value of the circular metal patch of the holographic impedance modulation surface and establishing a model of the entire holographic impedance modulation surface. The method is advantaged in that through the holographic impedance modulation surface antenna form of the step structure, the gain of the antenna can be effectively improved, radiation deviating from the normal direction is realized, overall performance of the antenna is improved, moreover, the holographic impedance modulation surface antenna has a planar structure, no additional introduction of a feed source and the feed network is required, the structure is simple, bandwidth is wide, and radiation deviating from the normal direction can be further realized.

Owner:CHENGDU UNIV

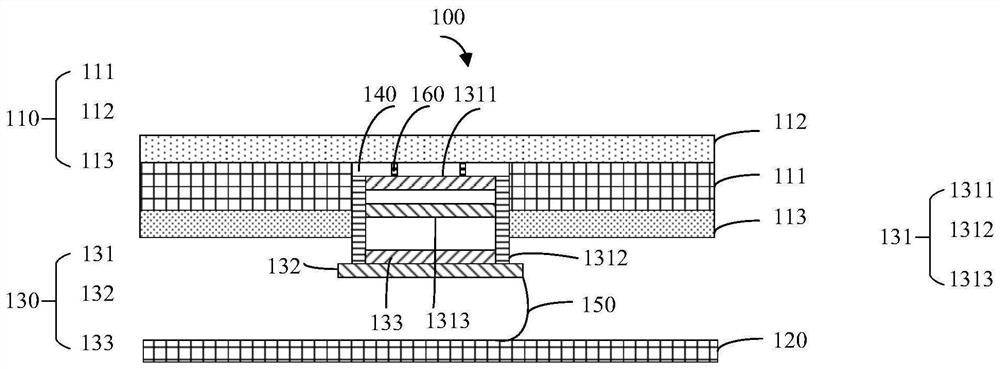

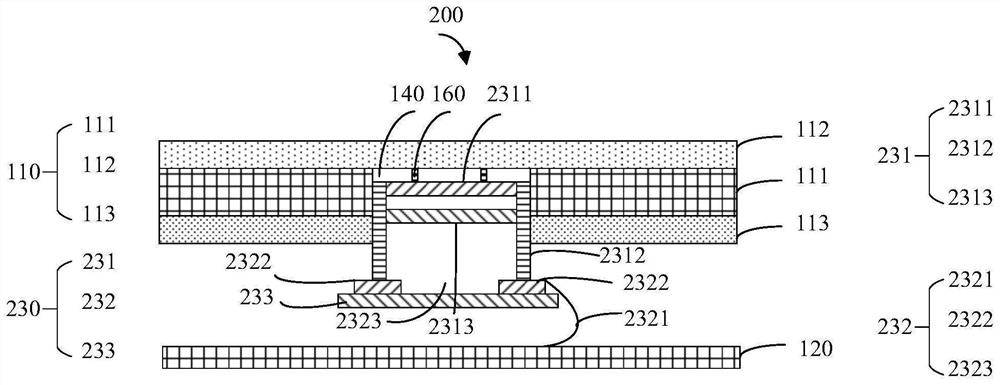

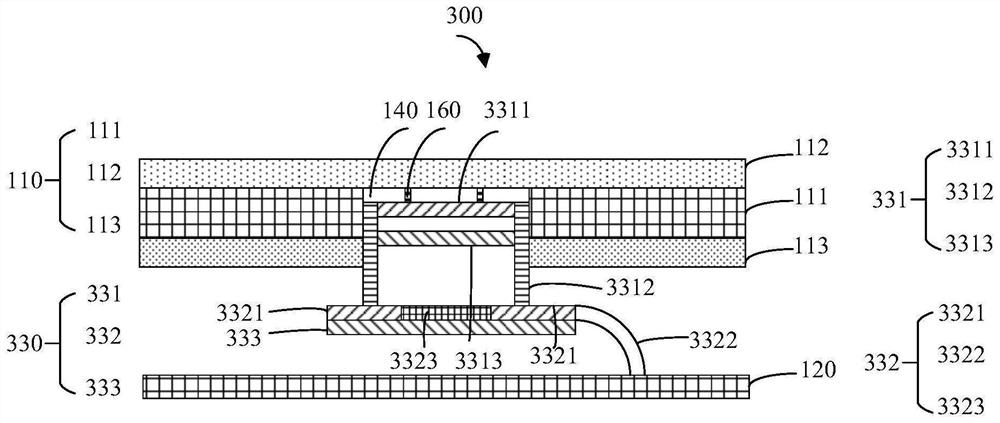

Display substrate, manufacturing method thereof and display device

PendingCN113629079ASolve the problem of sagSolve the problem that caused the badSolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhysics

The invention provides a display substrate, a manufacturing method thereof and a display device. The display substrate comprises an underlayment substrate, and a source-drain metal layer, a flat layer and an electrode layer which are sequentially arranged from the side close to the underlayment substrate to the side far away from the underlayment substrate. The source-drain metal layer at least comprises a first source-drain metal pattern covered by the flat layer and a second source-drain metal pattern not covered by the flat layer. The electrode layer comprises an electrode pattern and a shielding pattern, and the electrode pattern is located on the flat layer. The shielding pattern directly covers at least part of the second source-drain metal pattern and is arranged along the pattern edge of the second source-drain metal pattern. According to the display substrate, the manufacturing method thereof and the display device provided by the embodiment of the invention, the technical problem of badness caused by side surface defects of the source-drain metal pattern when the electrode layer is etched can be solved.

Owner:BOE TECH GRP CO LTD +1

Method for manufacturing circuit board

ActiveCN103716997ASolve sunken or raised problemsSolve the bonding problemPrinted circuit manufactureElectrical conductor

Owner:GCI SCI & TECH

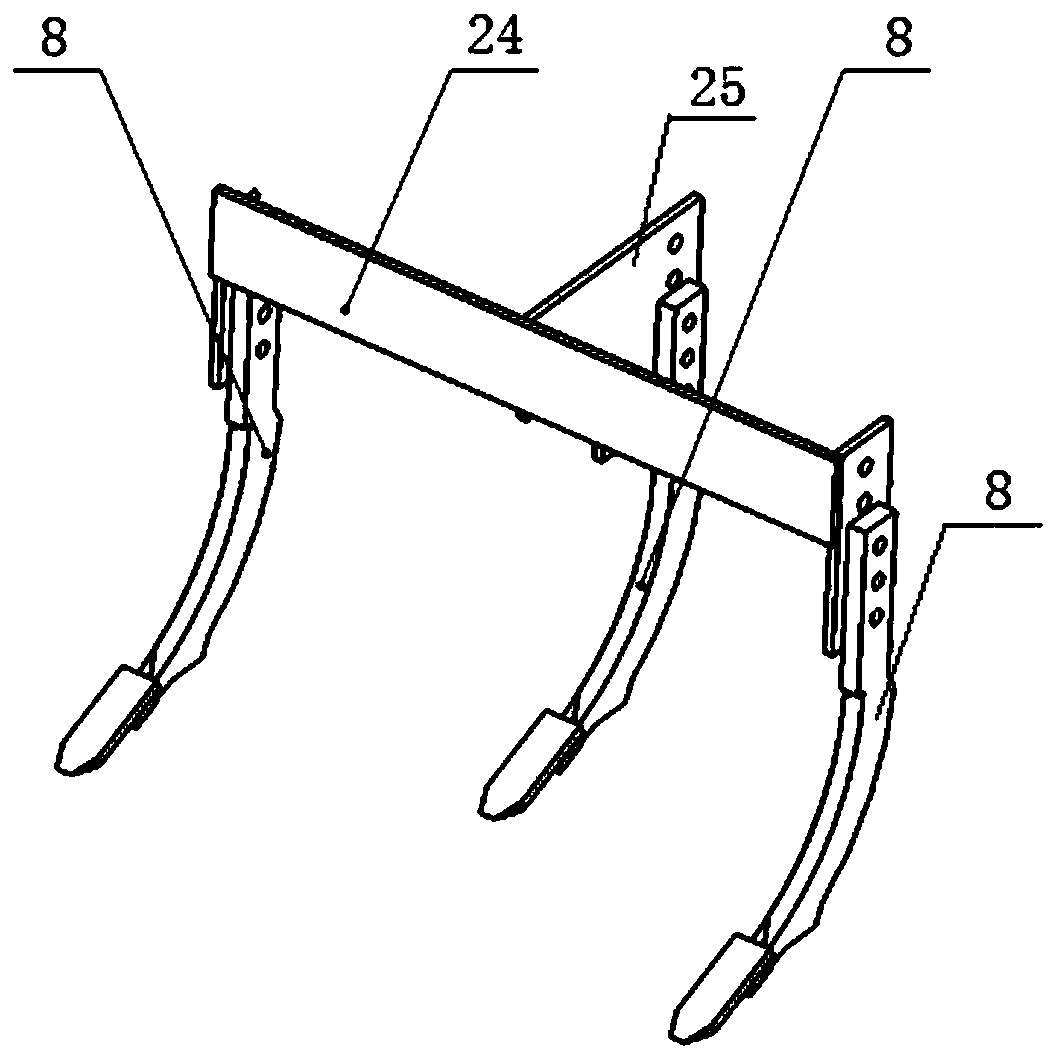

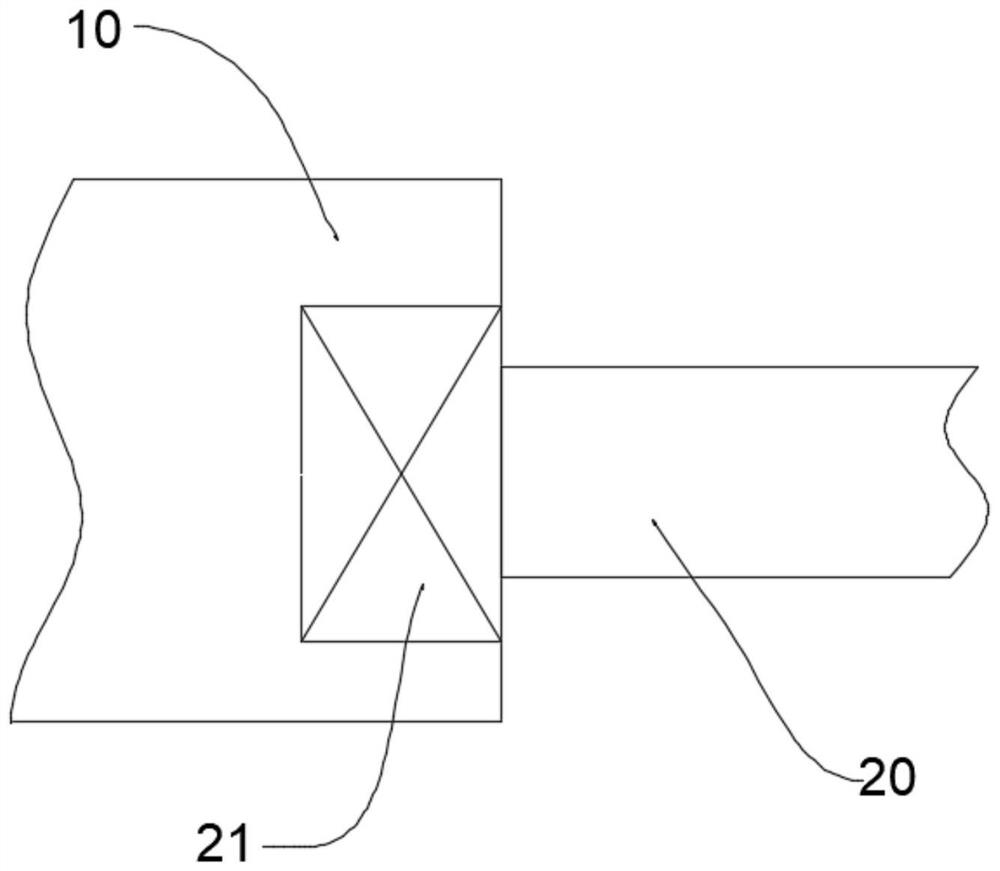

Combined passive soil stirring device of no-tillage planter

The invention discloses a combined passive soil stirring device of a no-tillage planter. The combined passive soil stirring device comprises a primary structural rack, a subsoiler assembly, a profiling body and a rake flatting shovel; the profiling body comprises a mount with a square through hole, a square supporting vertical-bar, four elastic triangular rods and a connecting rod, wherein the cross section of each elastic triangular do is in the shape of an isosceles right triangle, the four elastic triangular rods surround to form a box with a square hole, and then penetrate the square through hole in the mount, bevels of the elastic triangular rods closely fit corresponding surfaces of the square supporting vertical-bar, and two right-angle surfaces of each elastic triangular rods closely fit the wall faces of the square through hole. The profiling of the rake flatting shovel is realized through the elastic triangular rods, and accordingly surface soil depth difference of concave areas can be reduced, adaptability of the combined passive soil stirring device of the no-tillage planter to uneven earth surface in tillage can be improved, and secondary damage to the even surface from the rake flatting shovel after stirring can be reduced.

Owner:HUAZHONG AGRI UNIV

Cavity film with film stretching frames and cavity film hollow glass

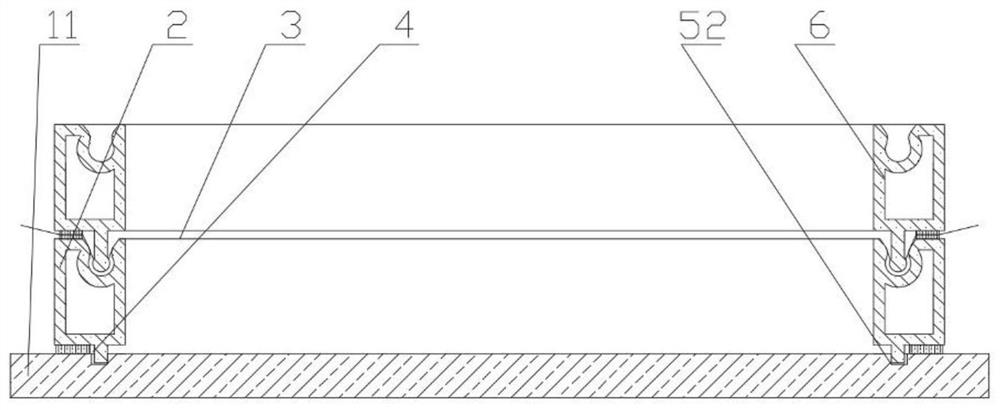

PendingCN113969732APrecise positioningStrong combinationSolar heating energyDomestic cooling apparatusAdhesiveCeramic materials

The invention discloses a cavity film with film stretching frames. The cavity film comprises a spacing frame, two diaphragms and two film stretching frames, the two diaphragms are respectively fixed on two sides of the spacing frame, and a cavity is formed among the diaphragms, the spacing frame and the diaphragms to form the cavity film; and the outer sides of the two diaphragms are respectively provided with one film stretching frame, the spacing frame and the film stretching frames are provided with convex-concave structures which are matched with each other, and when the film stretching frames and the spacing frame are pressed, the convex-concave structures are embedded with each other, so that the diaphragms can be stretched. The invention further discloses cavity film hollow glass. The cavity film hollow glass comprises the cavity film with the film stretching frames and two pieces of glass, the two pieces of glass are pasted on the two sides of the cavity film, and the space formed by the two pieces of glass and the outer side of the cavity film is fully coated with the structural adhesive. The invention further provides a manufacturing method of the cavity film and the cavity film hollow glass. The manufacturing method has the characteristics of being simple in process, convenient to manufacture, low in cost and large in productivity.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

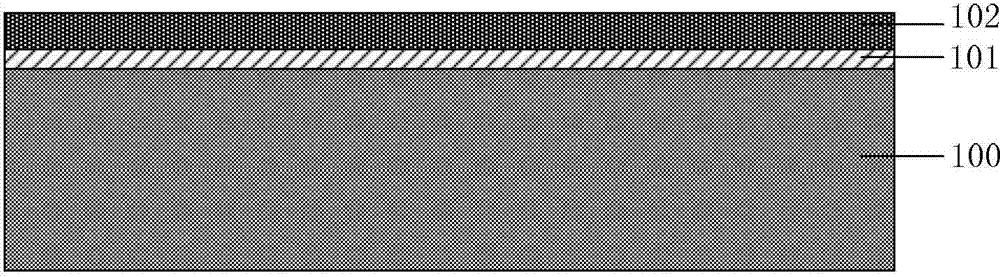

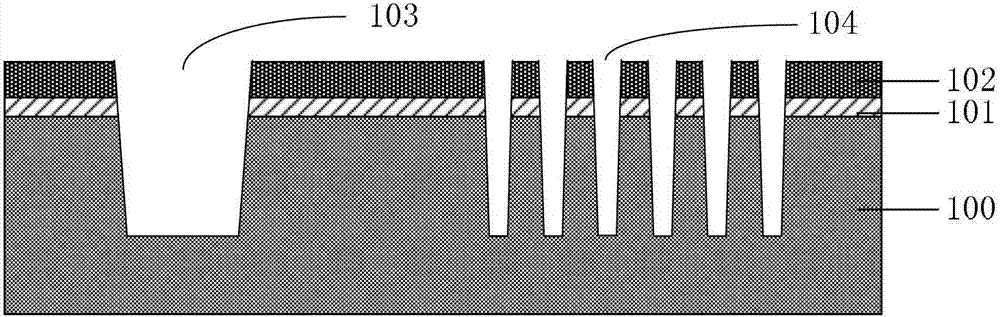

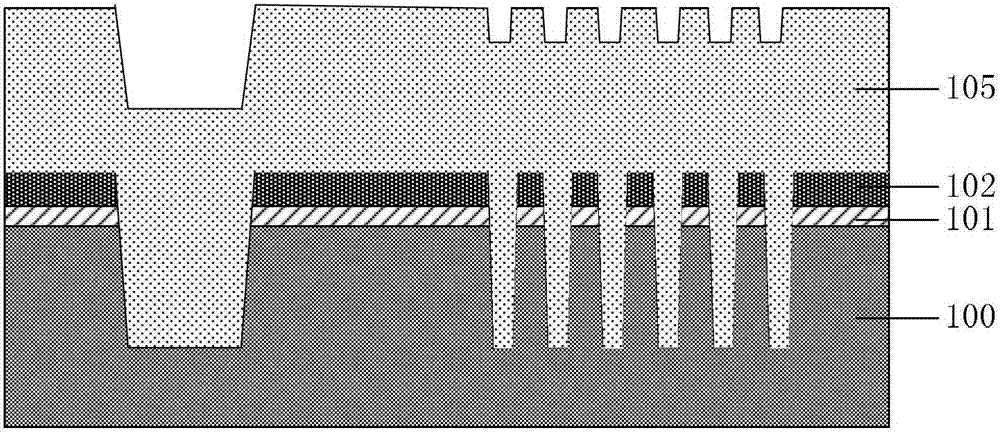

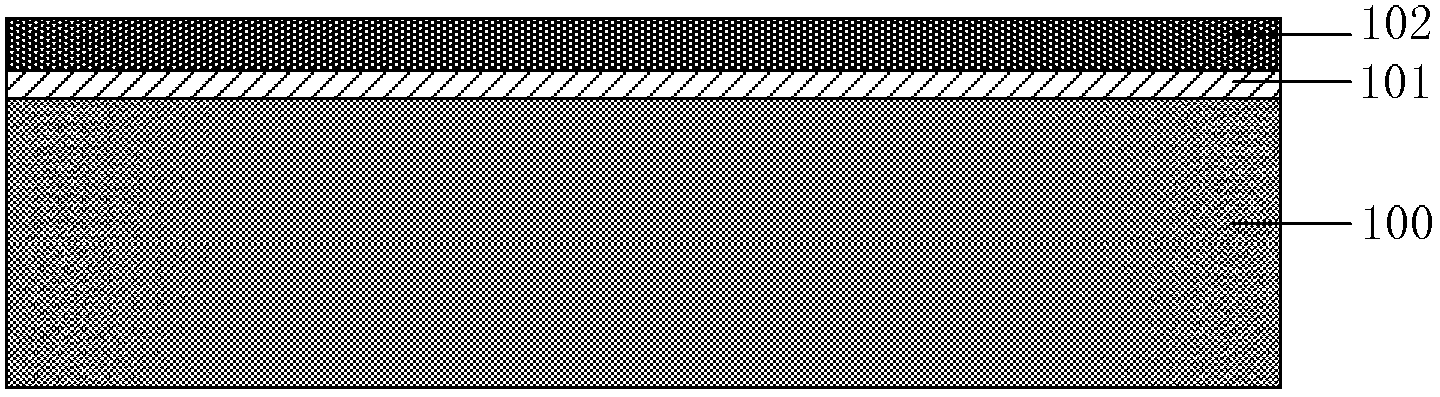

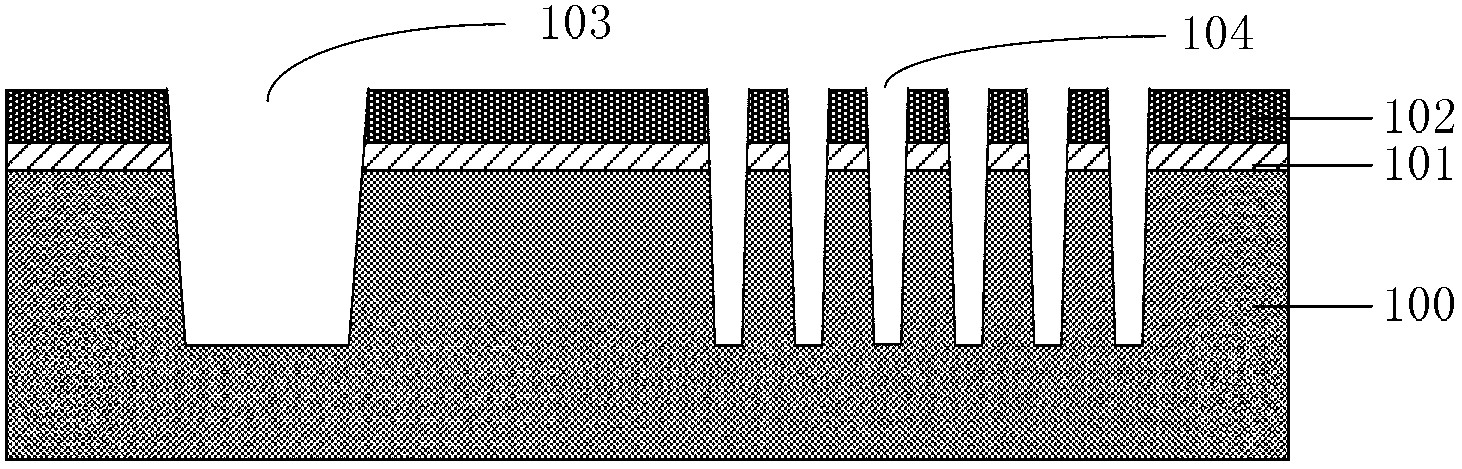

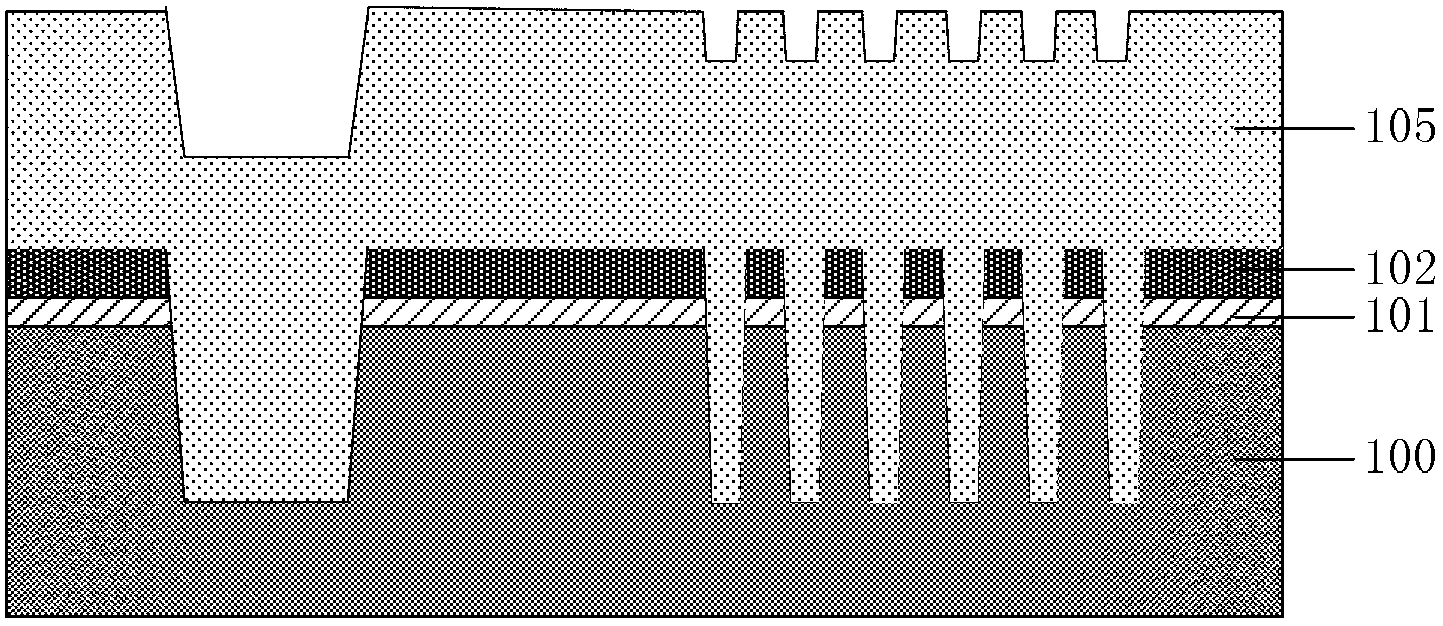

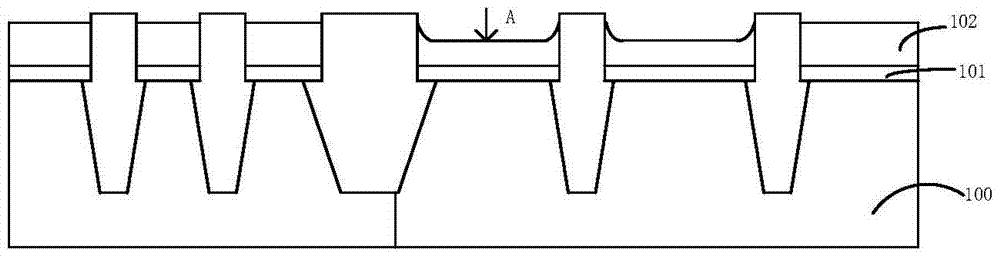

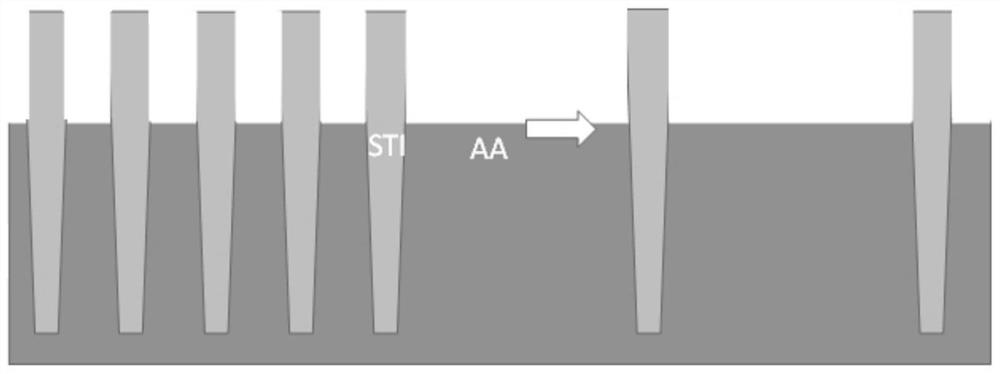

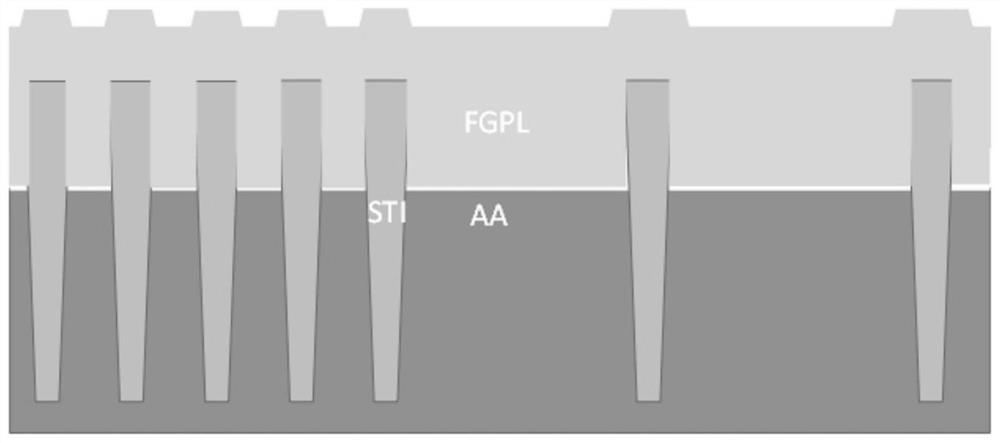

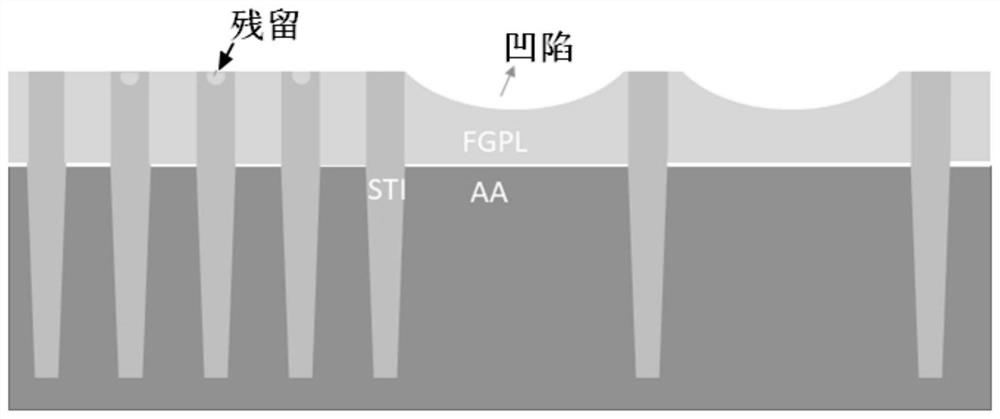

A method of manufacturing a semiconductor device

ActiveCN104576341BSolve the problem of sagImprove performanceSemiconductor devicesLithography processDevice material

The present invention proposes a method for manufacturing a semiconductor device, comprising: providing a semiconductor substrate; sequentially forming a gate oxide layer and a floating gate polysilicon layer on the semiconductor substrate; forming a large-sized floating gate buffer oxide layer; dividing the large-sized floating gate buffer oxide layer into a plurality of small-sized floating gate buffer oxide layers of the same size; performing chemical mechanical polishing. The method of the present invention provides a relaxed window for subsequent processes by optimizing the pattern of the floating gate buffer oxide layer formed on the floating gate polysilicon layer located in the large-area active region after the FGBF photolithography process, to solve the problem of the floating gate polysilicon layer After CMP, recesses are formed in the floating gate polysilicon layer located in the large-area active region, so as to improve the overall performance of the embedded flash memory and the yield rate of the embedded flash memory.

Owner:SEMICON MFG INT (SHANGHAI) CORP

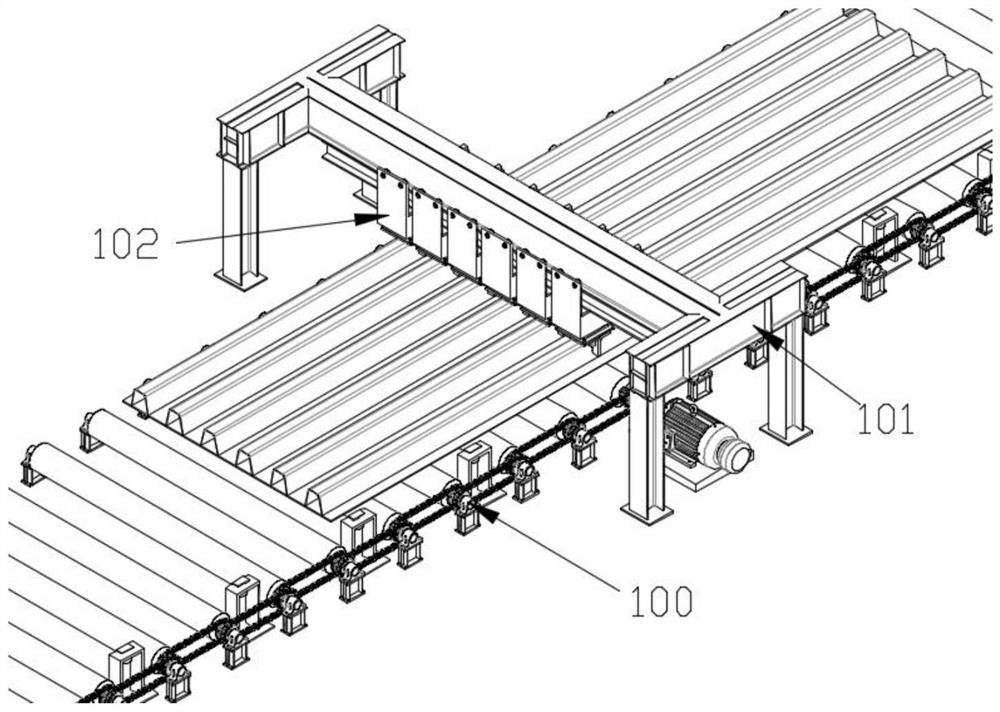

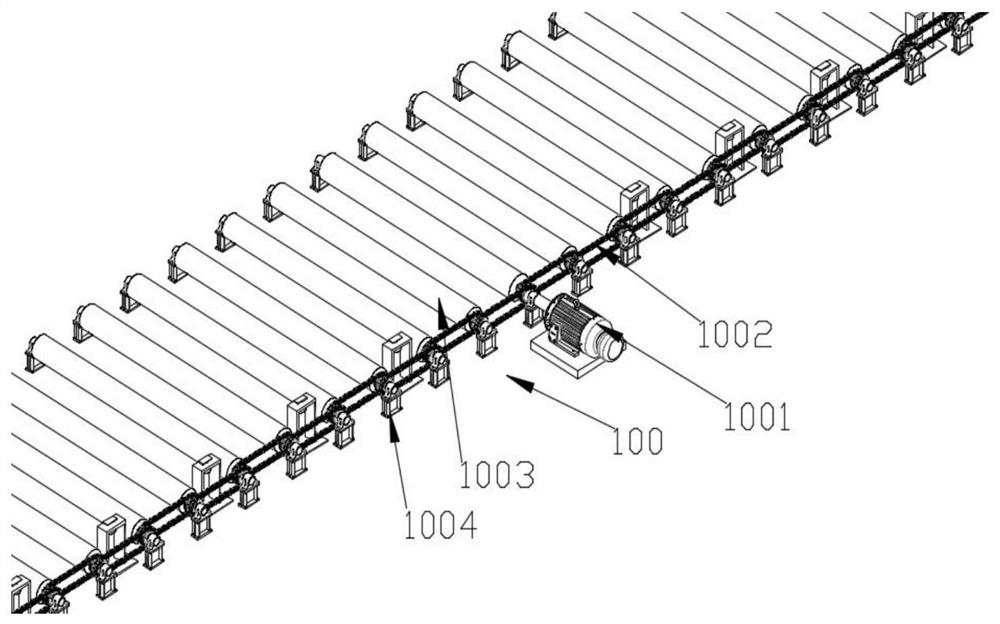

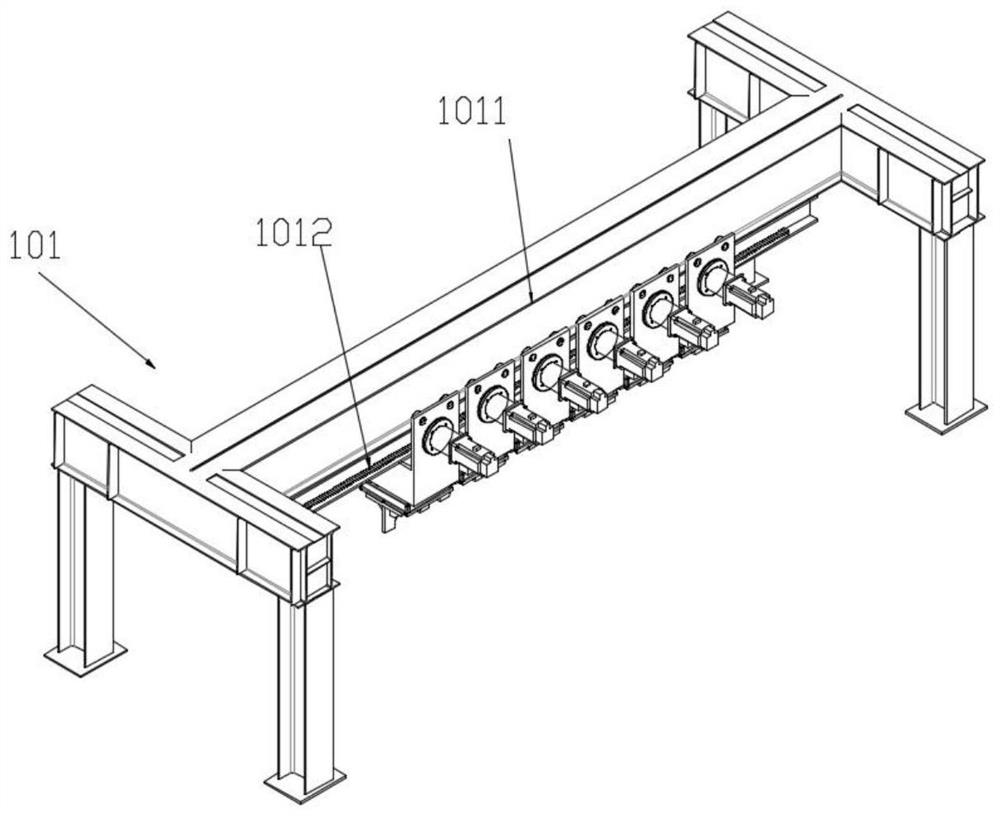

Fixed gantry type plate unit longitudinal rib assembling equipment system

PendingCN113753479AGuaranteed flatnessSolve the problem of sagConveyor partsRoller-waysClassical mechanicsStructural engineering

The invention discloses a fixed gantry type plate unit longitudinal rib assembling equipment system. The equipment system at least comprises a gantry frame, a longitudinal rib positioning device and a conveying roller shaft. A fixed gantry type plate unit longitudinal rib assembling device is convenient to operate and high in assembling precision, and the process defects of existing movable gantry plate unit longitudinal rib assembling equipment are overcome.

Owner:HUBEI TIANGAO BRIDGE ENG CO LTD

Self-maintenance type intelligent sofa

PendingCN114468658ASolve the depressionReduce extrusion pressureSofasFluid mattressesStructural engineeringMechanical engineering

The invention discloses a self-maintenance type intelligent sofa which comprises a sofa bracket, a first supporting sponge, a supporting block and a maintenance mechanism, the first supporting sponge is horizontally stacked on the sofa support, a hollow cavity is formed in the sofa support, the supporting block is arranged in the hollow cavity in a sliding mode, the maintenance mechanism is installed in the supporting block, and the maintenance mechanism provides supporting force in the vertical direction for the concave position of the first supporting sponge through gas pressure. The maintenance mechanism comprises a sensing head, an air inlet cavity, an air pressure cavity, an inflation assembly and an elastic assembly. The maintenance mechanism is added, so that the problem that the sofa sinks after being used for a long time can be solved.

Owner:陈诚

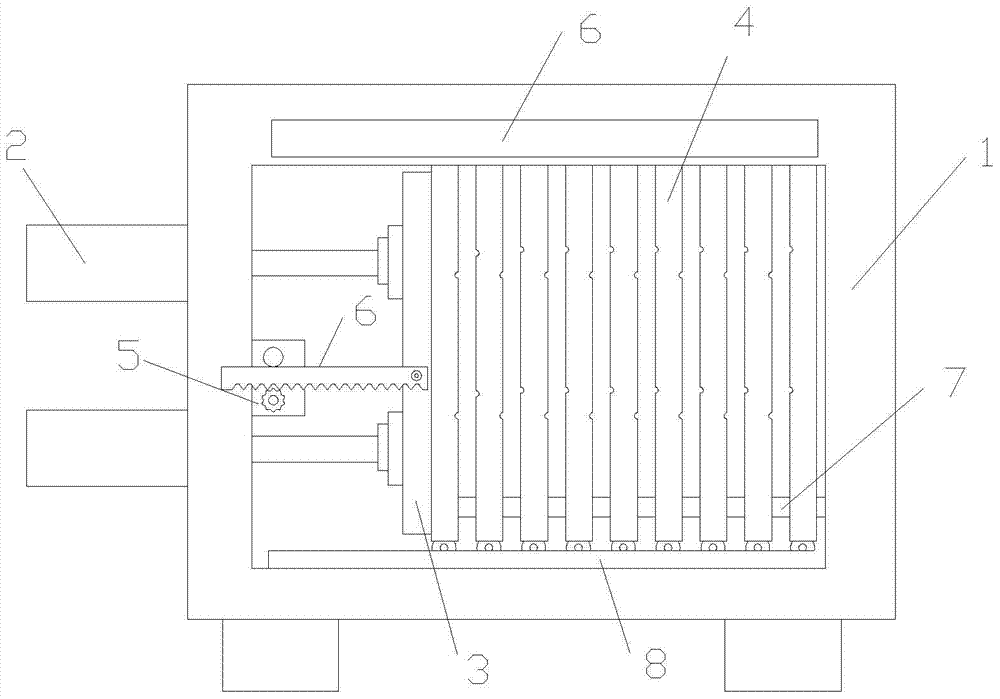

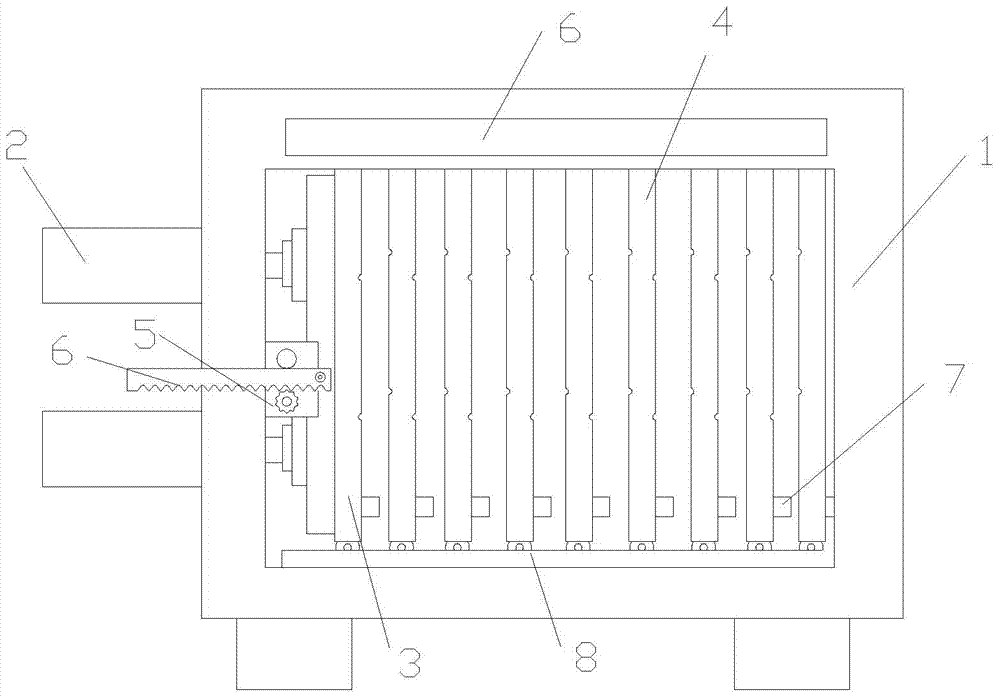

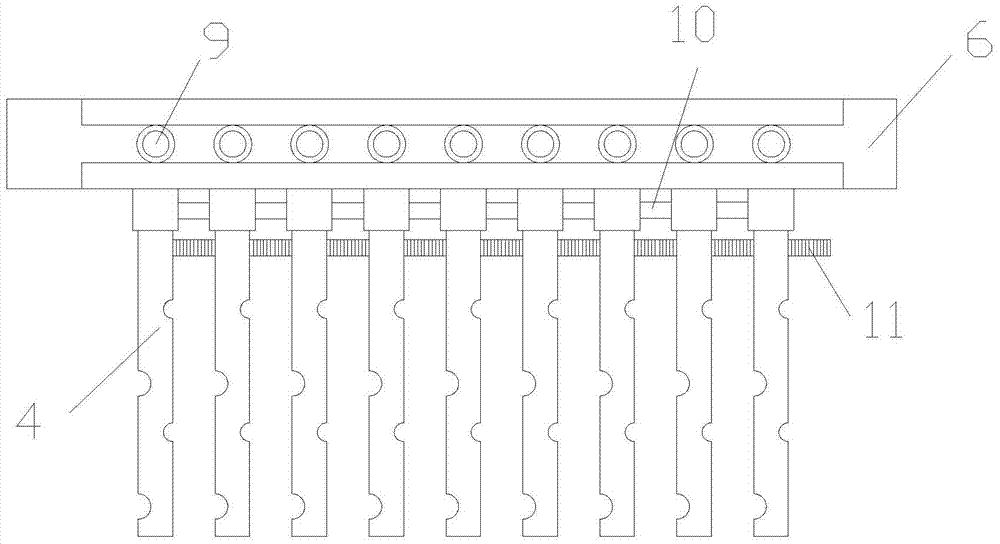

FRP door panel foam pressing machine

The invention relates to a glass fiber reinforced plastic door board foaming pressing machine and relates to the technical field of glass fiber reinforced plastic door board production equipment. The glass fiber reinforced plastic door board foaming pressing machine is composed of a machine frame, a power system, a pressing system and a rail system. The machine frame is of an integrated structure and of a regular rectangular structure. The power system is installed on one side of the machine frame. The rail system is installed at the upper end and the lower end of the machine frame. The pressing system is arranged in the center position of the machine frame. The power system is composed of hydraulic boosters, a coordinated gear and a rack. The pressing system is composed of a side board, heating boards and a locating strip. The rail system is composed of a rail groove in the upper portion and a sliding groove in the lower portion. The glass fiber reinforced plastic door board foaming pressing machine is novel in structural design, convenient to use and high in pressing efficiency, the problem that the surface of a door board is recessed due to the fact that air in a contact face is not exhausted and delivered smoothly when the door board is pressed can be solved, multiple door boards can be pressed and foamed at the same time, and work efficiency and door board quality are improved.

Owner:ANHUI XINYU FIBER GLASS DOOR

Foldable display screen and terminal equipment with foldable display screen

InactiveCN112187976AImprove stabilityAvoid pullingTelevision system detailsColor television detailsComputer graphics (images)Terminal equipment

The invention discloses a foldable display screen and terminal equipment with the foldable display screen, and the foldable display screen comprises a display panel, a mainboard and a camera module, and the mainboard is located at one side, deviating from a light outgoing surface, of the display panel; the camera module comprises a camera, a circuit board and a photosensitive chip, and the camerais located on the side, close to the light emitting surface, of the circuit board or the photosensitive chip and is arranged corresponding to the photosensitive chip; an accommodating part is arrangedon the display panel, and the camera is accommodated in the accommodating part; and the circuit board is movably connected with the main board. According to the foldable display screen provided by the invention, the display panel can be prevented from being pulled by the camera module after the functional layers of the display screen move in a staggered manner when the display screen is folded, the problem that the surface of the screen is sunken is solved, and the imaging effect of the camera module and the stability of the display screen are improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

CMP (chemical mechanical polishing) method

InactiveCN113223956ASolve residual problemsSolve the problem of sagSemiconductor/solid-state device manufacturingSemiconductor devicesThin membraneSilicon oxide

The invention discloses a CMP (chemical mechanical polishing) method, which comprises the following steps of: firstly, after a polycrystalline silicon thin film is deposited in a furnace tube, performing an oxidation process, and generating a layer of silicon oxide thin film on the surface of a polycrystalline silicon layer; secondly, adopting a DSTI CMP process for grinding, and removing the silicon oxide thin film on the surface of the polycrystalline silicon thin film at the protruding patterns, wherein the silicon oxide thin film comprises an STI region, an active region and an isolation region; and finally, performing a polycrystalline silicon CMP process for the polycrystalline silicon thin film. According to the CMP method, the silicon oxide thin film at the protruding position is firstly taken out through utilizing a high selection ratio of the oxide film CMP technology, grinding is terminated on the polycrystalline silicon thin film, then the high selection ratio of the polycrystalline silicon CMP technology is used for increasing the technology windows and removing the residual polycrystalline silicon, the polycrystalline silicon residue problem is more effectively solved, and meanwhile the sunken problem caused by excessive grinding is solved.

Owner:HUA HONG SEMICON WUXI LTD

A kind of injection mold for cushioning l-shaped piece

The invention belongs to the technical field of injection molding processing. The invention provides an injection mold for cushioning L-shaped pieces, which includes a front mold structure and a rear mold structure. The front mold structure includes an upper mold plate, a feeding assembly, a thimble bottom plate, a thimble panel, an upper mold core, an upper mold core, and an insert And the inclined top assembly, the inclined top assembly includes the inclined top head, the inclined top rod, the inclined top foot, the inclined top base, the pin and the fixing assembly, the upper end of the inclined top base is connected with the thimble panel, and the insert and the inclined top form an L-shaped cavity , the L-shaped cavity communicates with the product cavity. During processing, the glue is fed by the feeding component, and it impacts the L-shaped cavity first, so that the glue flow does not rush against the product cavity, which plays a buffer role. When the rubber flows into the product cavity, the cross-sectional area of the L-shaped cavity is larger than that of the input The glue inlet of the material component slows down the flow rate to ensure that there are no air marks, trapped air, jet lines and shrinkage depressions on the front appearance of the product; the L-shaped cavity is set in the middle of the product cavity, from the glue inlet to the periphery of the product The distance is relatively short to ensure the dimensional accuracy of the product.

Owner:友信精密实业(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com