Film suspended hollow glass and manufacturing method and continuous production line thereof

A production method and technology of suspended film, which are applied in parallel glass structure, installation of window glass, household refrigeration device, etc., can solve the problems of cold edge, influence of thermal insulation effect, complex structure of suspended film insulating glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

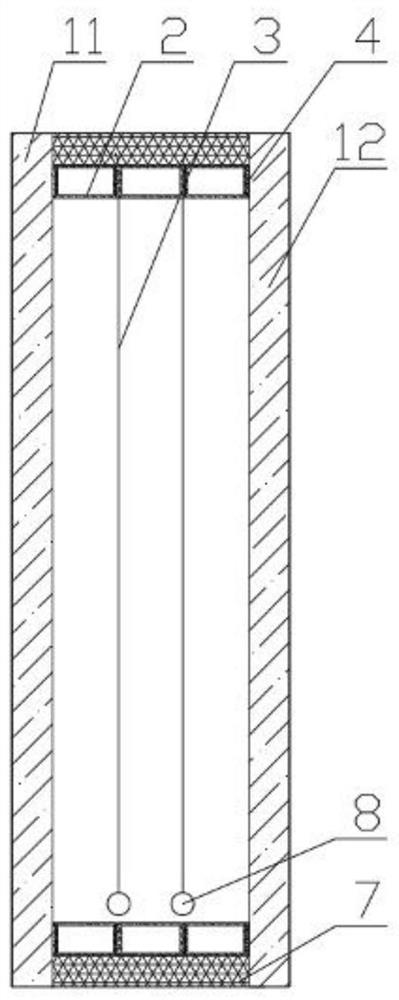

[0092] refer to figure 1, a kind of two-glass three-cavity suspended-film hollow glass fixed on one side, comprising a front glass 11, a rear glass 12, a spacer frame 2, a film 3, a sealant 4, a structural glue 7 and a bottom bar 8, and the spacer frame 2 is provided with 3, the suspension film 2 is provided with two sheets, the front glass 11 and the rear front glass 12 are placed in parallel, and a spacer frame 2 is bonded and fixed by a sealant 4 at corresponding positions around the two sides of the front glass 11 and the rear front glass 12, A spacer frame 2 is also bonded between the two spacer frames 2, the sealant 4 adopts butyl glue, and a suspension film 3 is bonded and fixed between two adjacent spacer frames 2 by the sealant 4, so that the two The suspension film 3 is suspended in the cavity between the two front glasses 11 at the same time, and three hollow cavities are formed between the suspension film 3 and the front glass 11, between the suspension film 3 and ...

Embodiment 2

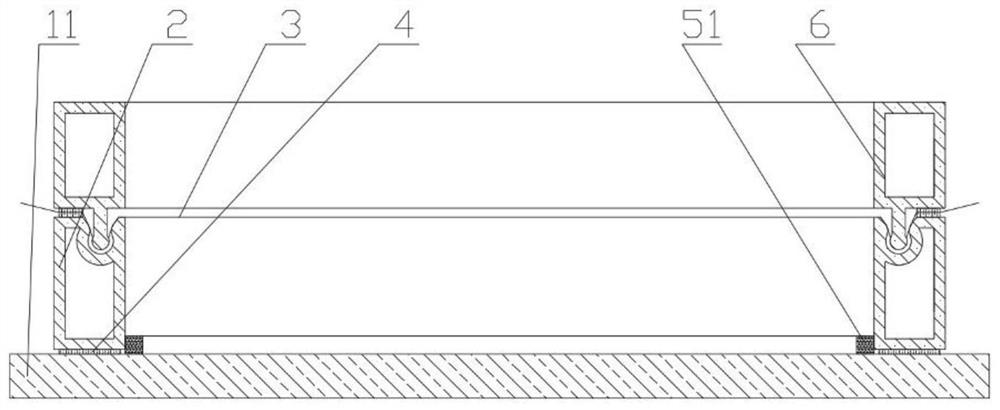

[0095] refer to figure 2 , a kind of single-glass suspension film hollow glass, comprising front glass 11, spacer frame 2, suspension film 3, sealant 4, positioning bar 51 and stretch film frame 6, cut front glass 11 according to required size, and carry out edging and Cleaning; after the front glass 11 dries, utilize screen printing to make a positioning strip 51 in the inner circle of the peripheral bonding place of the glass, the positioning strip 51 is a continuous wire frame, and the positioning strip 51 is made of a composite material containing an adhesive, according to The size of the positioning bar 51 is respectively made into a spacer frame 2 with a groove and a stretch film frame 6 with a protrusion of a corresponding size. The spacer frame 2 and the stretch film frame 6 can be fitted together by the convex-concave structure. The circle is adapted to the size of the positioning bar 51, and molecular sieves are packed into the warm edge strips of the spacer frame 2...

Embodiment 3

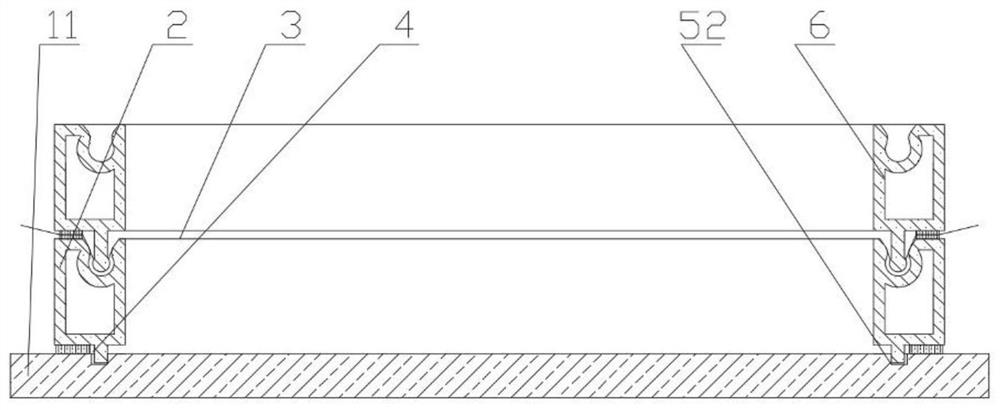

[0101] refer to image 3 , a kind of single-glass suspension film hollow glass, comprising front glass 11, spacer frame 2, suspension film 3, sealant 4, positioning groove 52 and stretch film frame 6, basically the same as embodiment 2, its difference is to locate Groove replaces positioning bar, spacer frame 2 has protrusion, and the protrusion on spacer frame 2 is embedded in the positioning groove 5 on the front glass 11, reaches the purpose that prevents spacer frame 2 from moving in the film stretching process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com