Multiple-cavity special-shaped double-layer thin-wall section pipe fitting correcting robot

A robot and special-shaped technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of long manual shaping time, increase labor costs, increase the burden on enterprises, etc., to reduce equipment weight, reduce equipment costs, The effect of easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

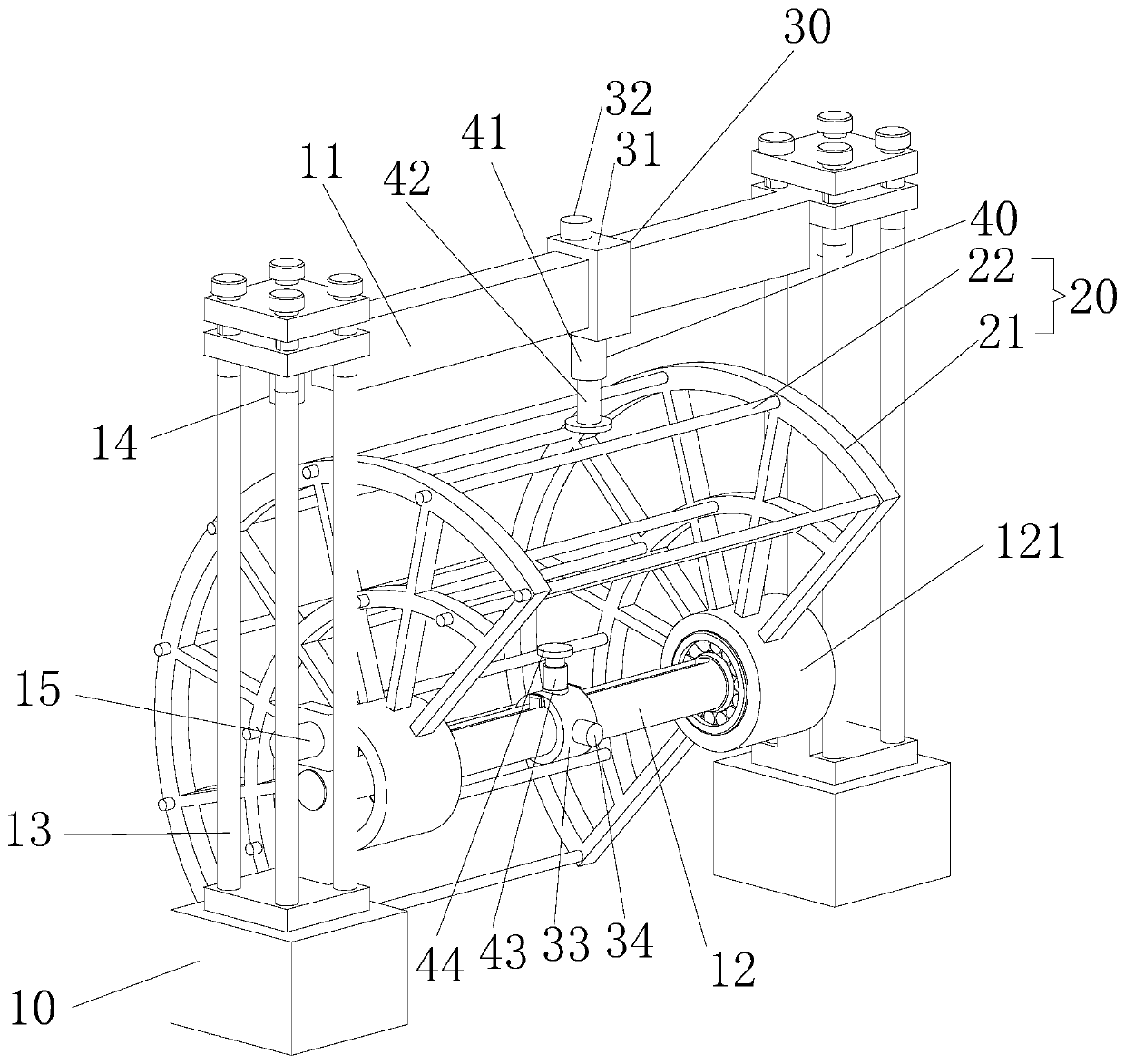

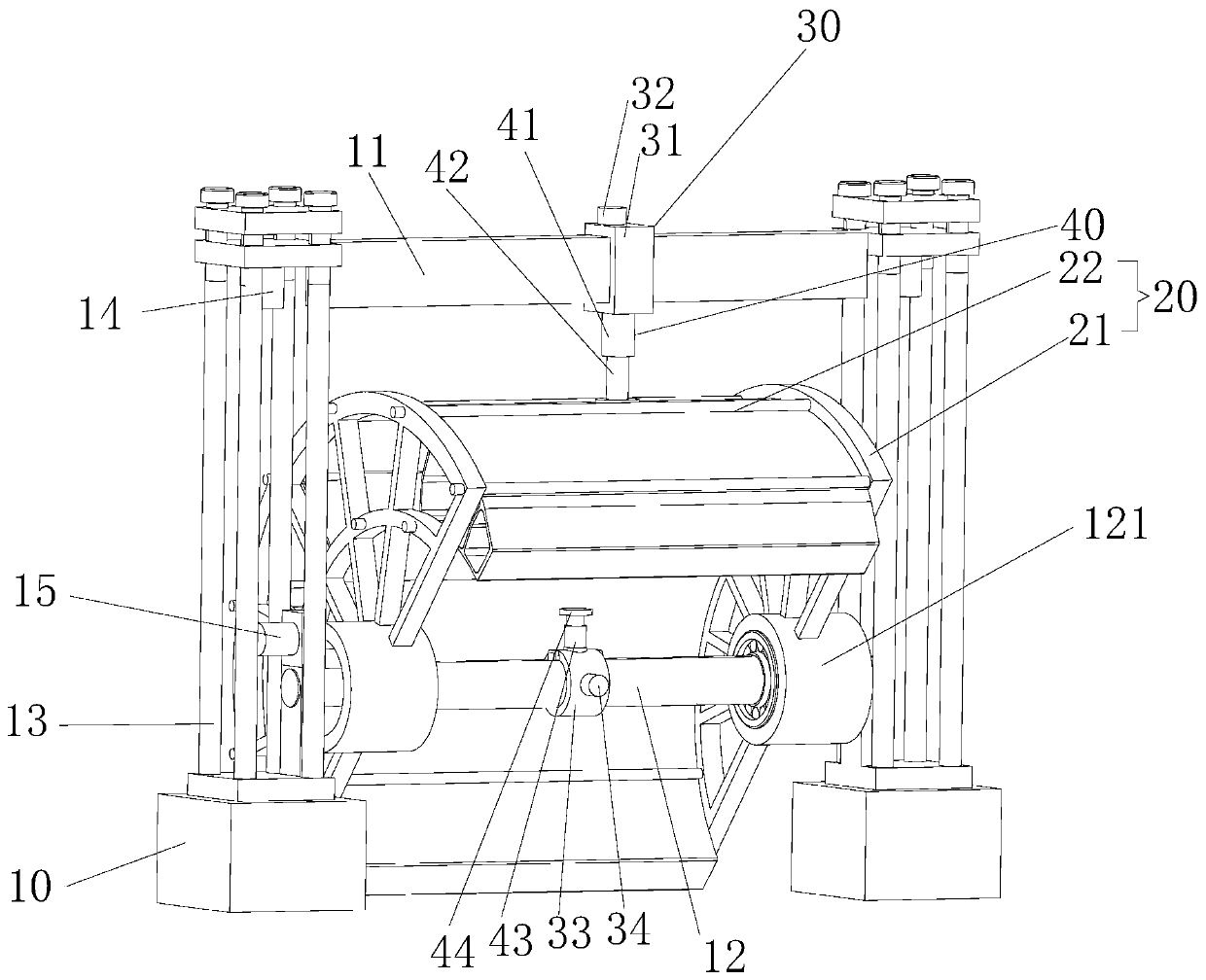

[0032] see figure 1 , figure 1 The three-dimensional structure diagram of the multi-cavity special-shaped double-layer thin-wall section pipe correction robot provided by the embodiment of the present invention. The pipe straightening robot includes a frame 10 , a fixed assembly 20 , a moving assembly 30 and a suction assembly 40 .

[0033] The frame 10 is a frame body erected. In this embodiment, the number of racks 10 is set to two, and the two racks 10 are horizontally symmetrical and parallel. The frame 10 includes a plurality of guide pillars 13, the guide pillars 13 are long cylinders wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com