Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Solve the problem of excessive emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

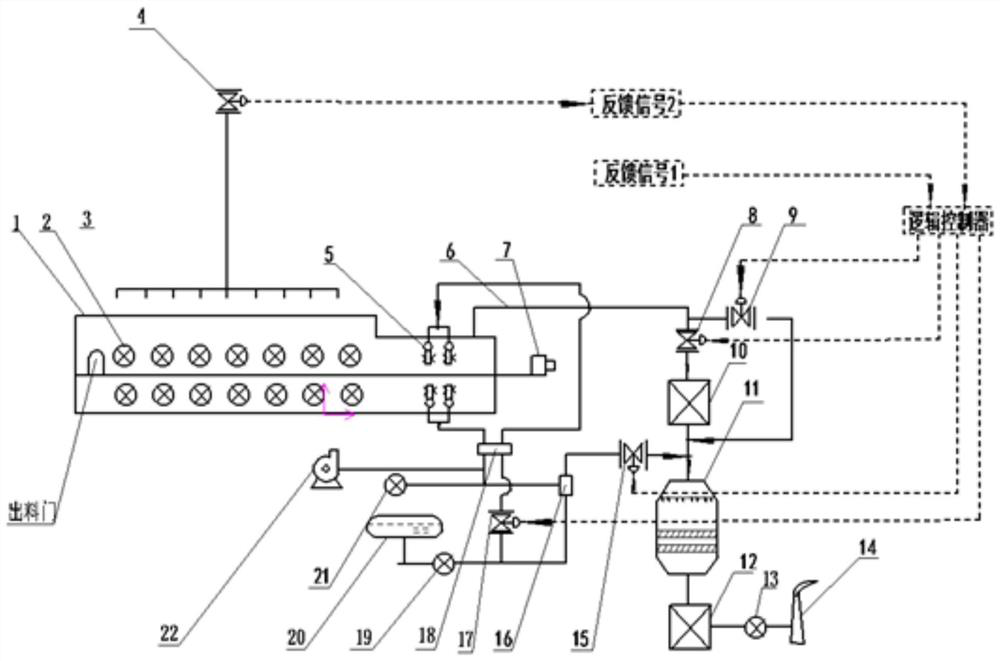

Optimal control method for flue gas circulating fluidized bed desulphurization

InactiveCN105116855AAvoid hysteresisSolve the problem of excessive emissionsTotal factory controlProgramme total factory controlFlue gasFluidized bed

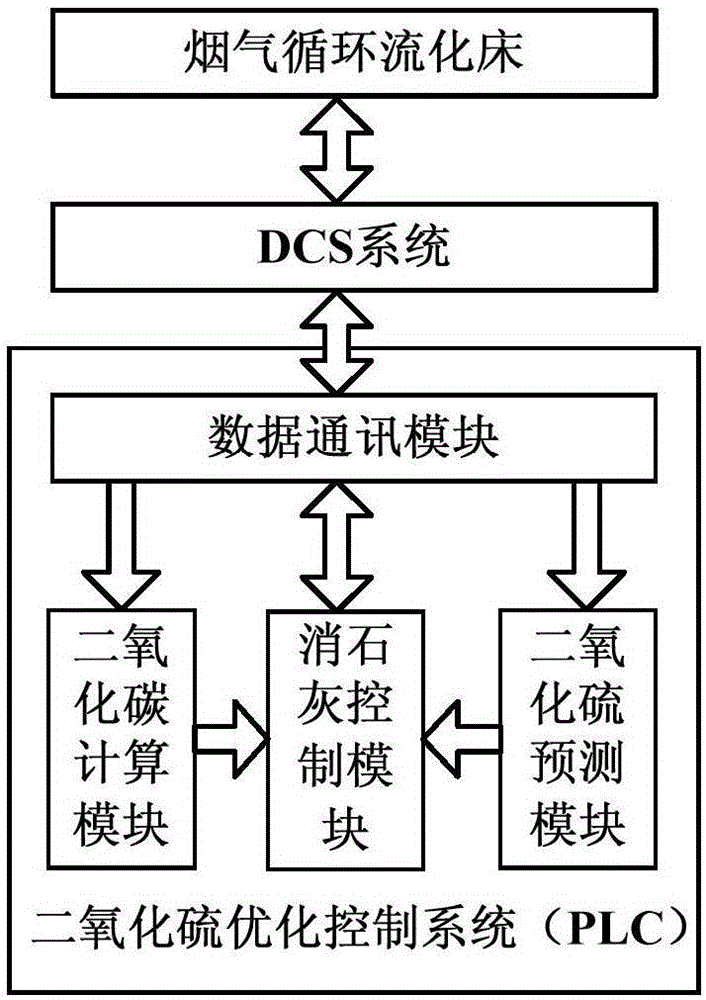

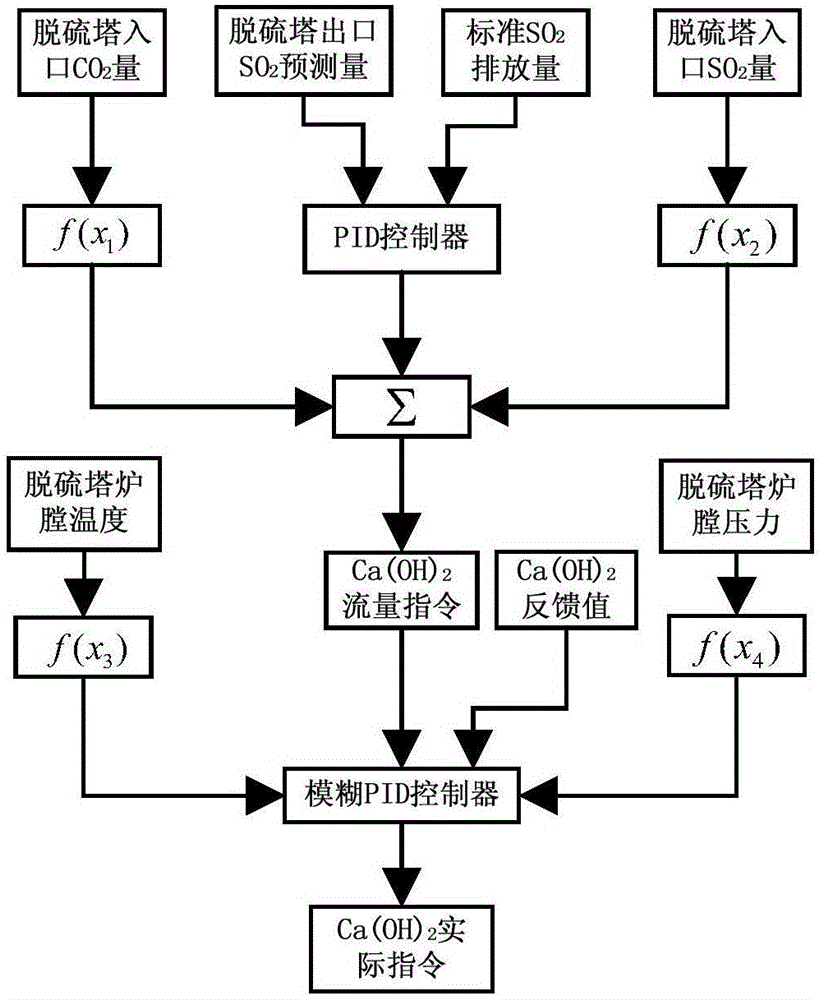

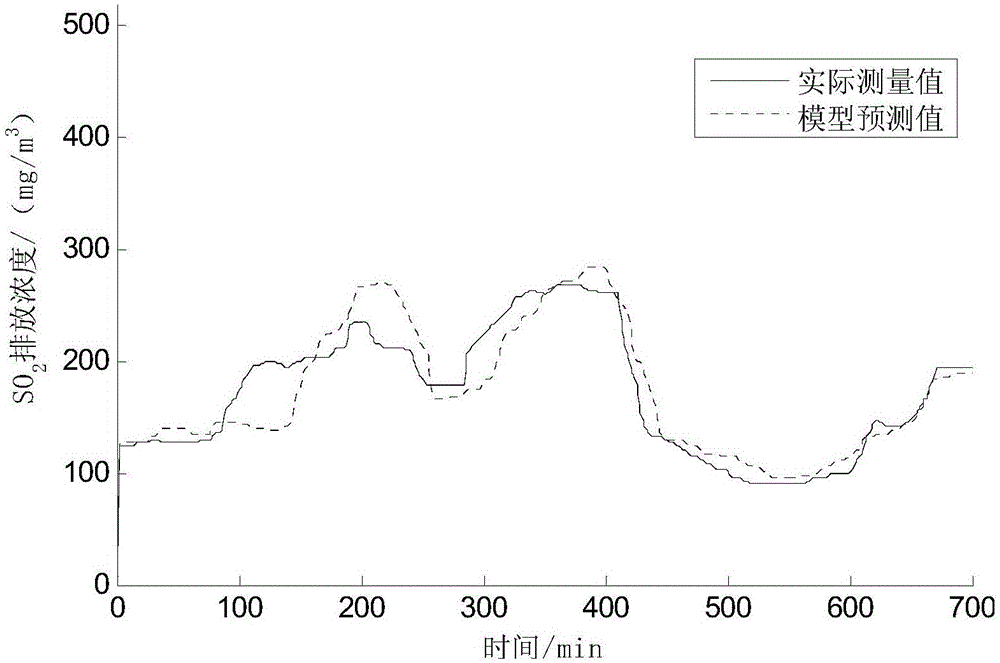

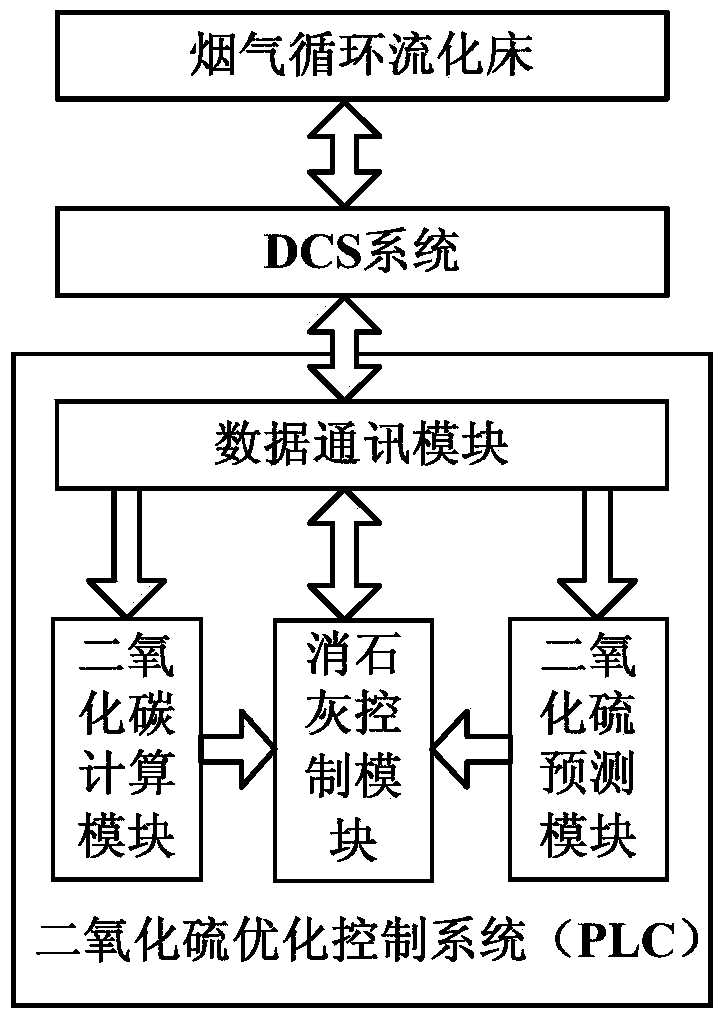

The invention discloses an optimal control method for flue gas circulating fluidized bed desulphurization in the technical field of thermal power plant desulphurization. A DCS system is connected with a flue gas circulating fluidized bed and a PLC-based sulfur dioxide optimal control system. The sulfur dioxide optimal control system is formed as follows: a sulfur dioxide prediction module and a carbon dioxide calculation module are respectively connected with a data communication module and a hydrated lime control module, and the hydrated lime control module is connected with the data communication module. The data communication module and the DCS system exchange data. According to the invention, the content of CO2 in the flue gas at the inlet of a desulfurization tower is calculated through an SO2 prediction model. The feeding amount of hydrated lime can be adjusted timely, dynamically and accurately. Excessive emission of SO2 and the waste of hydrated lime and resources are avoided fundamentally, and CO2 emission is reduced to a certain extent. The method is of high reference value in engineering.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

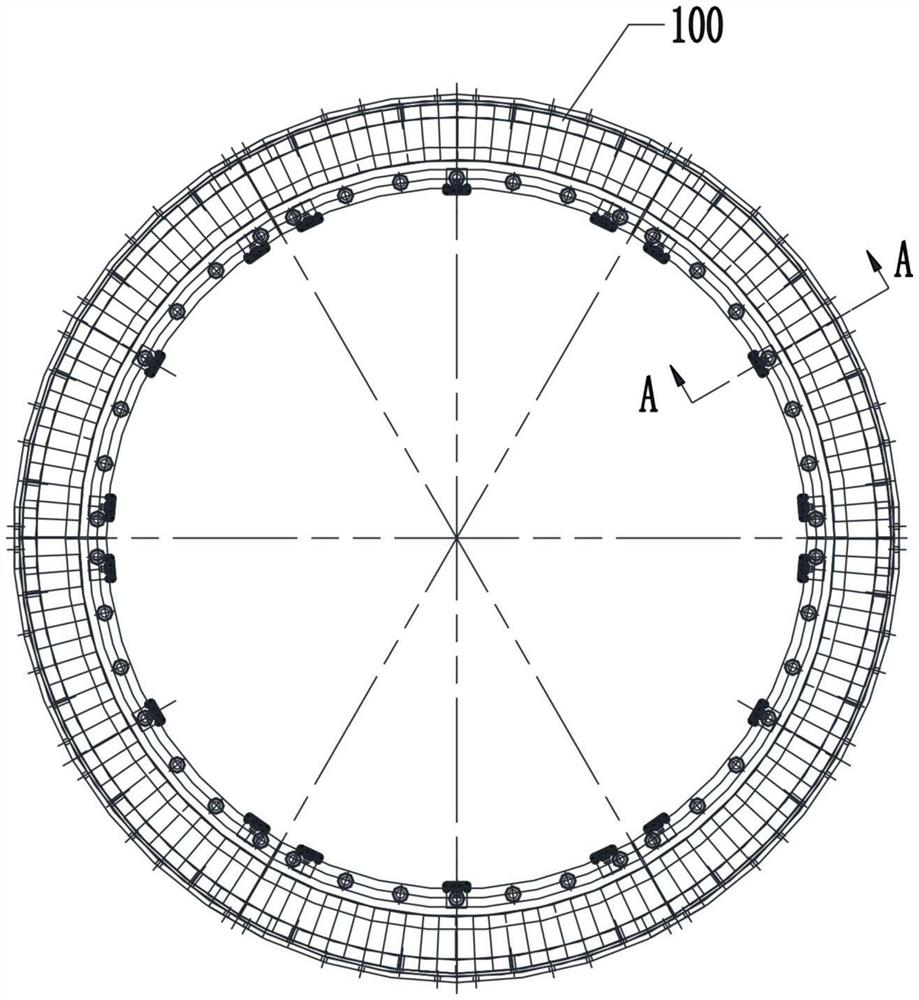

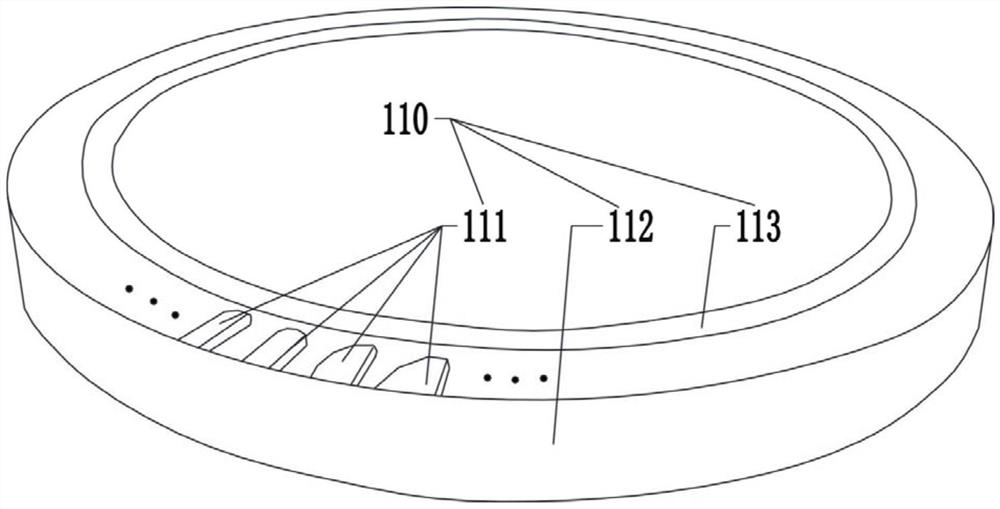

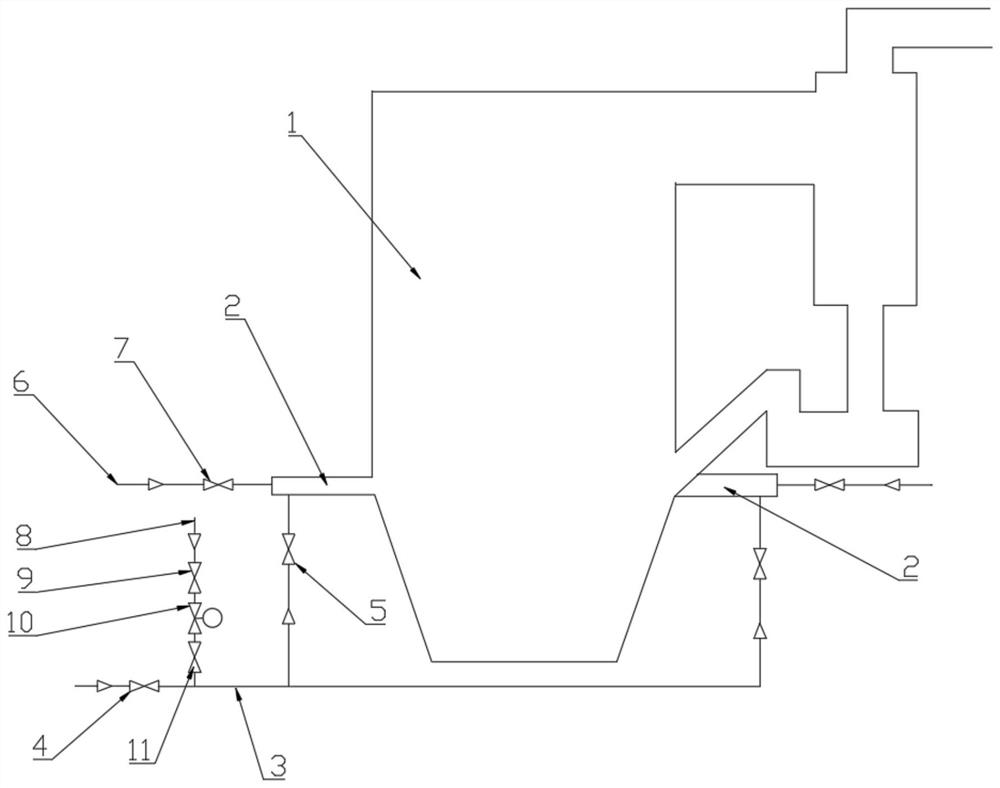

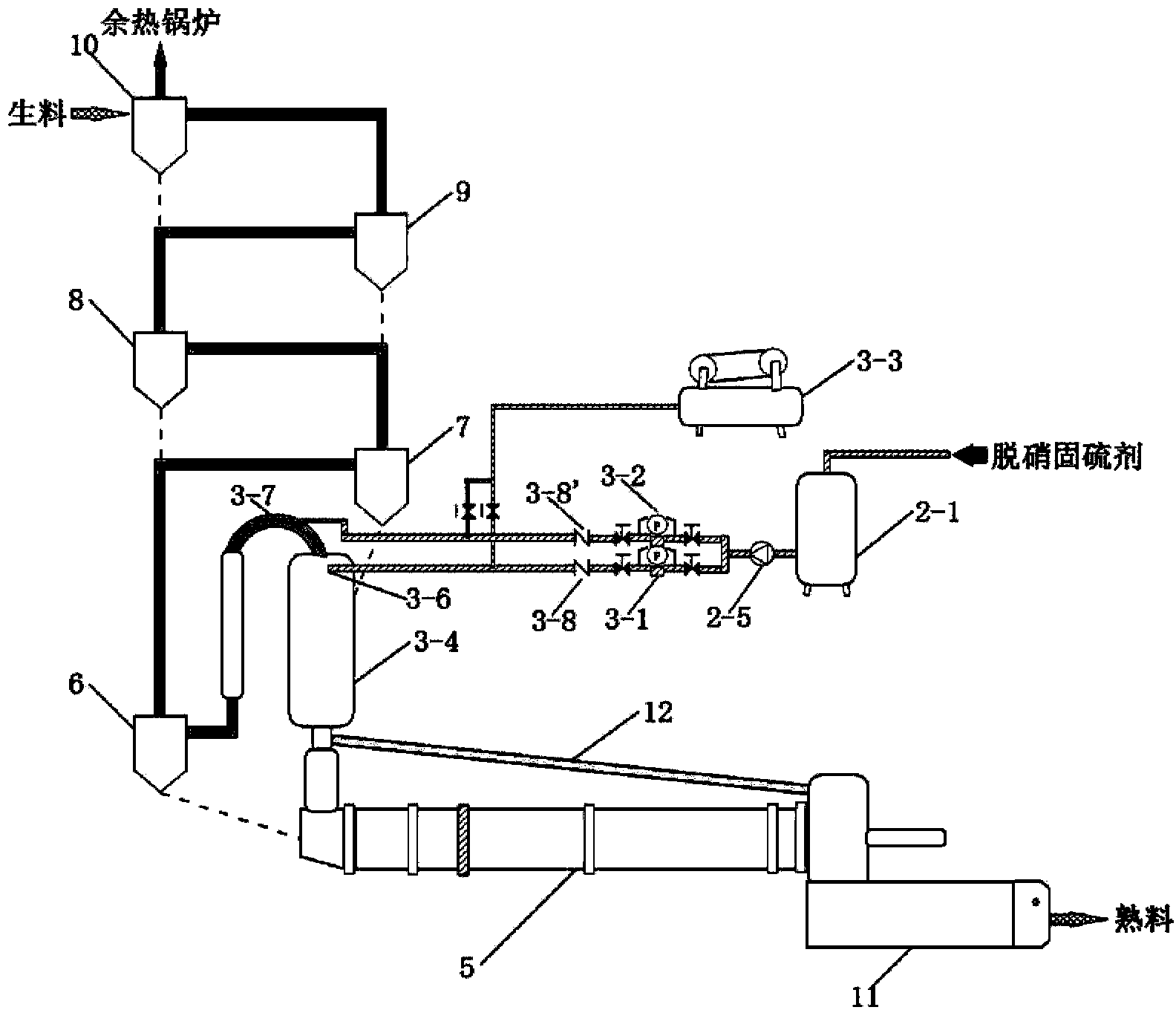

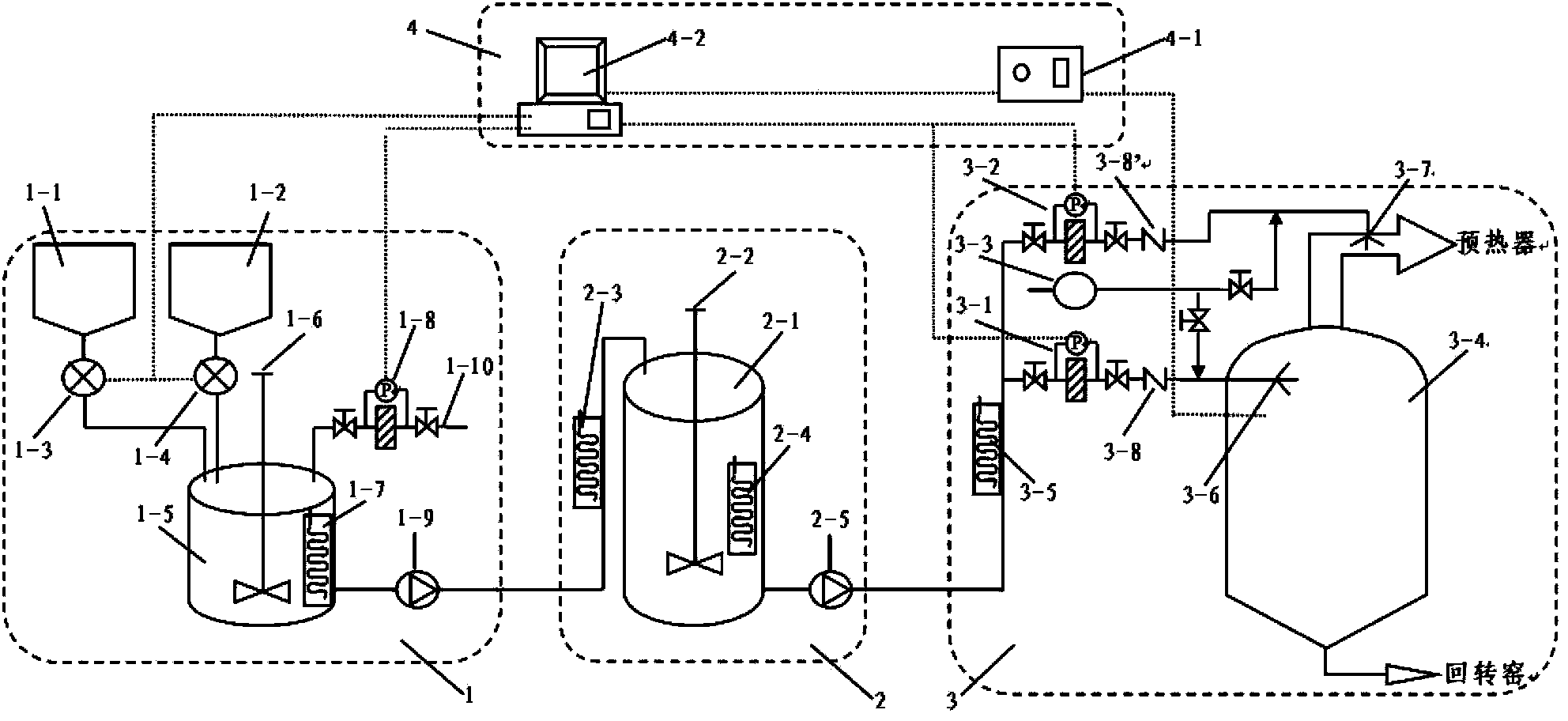

Method and apparatus for cement rotary kiln flue gas denitration and desulfurization

ActiveCN102974207ACost-effectiveSolve the problem of excessive emissionsDispersed particle separationAutomatic controlFlue gas

The present invention discloses a denitration sulphur-fixing agent used for cement rotary kiln flue gas denitration and desulfurization, and a method and an apparatus for cement rotary kiln flue gas denitration and desulfurization using the agent. The denitration sulphur-fixing agent includes a reducing agent with a mass percent concentration of15-25% and a sulphur-fixing agent with a mass percent concentration of 30-55%. The apparatus includes a denitration sulphur-fixing agent preparation system, a denitration sulphur-fixing agent storage system, a denitration sulphur-fixing agent injection system and an automatic control system, wherein the denitration sulphur-fixing agent preparation system, the denitration sulphur-fixing agent storage system and the denitration sulphur-fixing agent injection system are successively connected; and the automatic control system is respectively connected with the denitration sulphur-fixing agent preparation system and the injection system. The unique denitration sulphur-fixing agent provided by the present invention is injected into the nozzle of the cement rotary kiln in two routes. Compared with the conventional technologies of SCR denitration and wet desulfurization, the original production process is unchanged, the method and the apparatus have the characteristics of simple manipulation and economy and high-efficiency.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

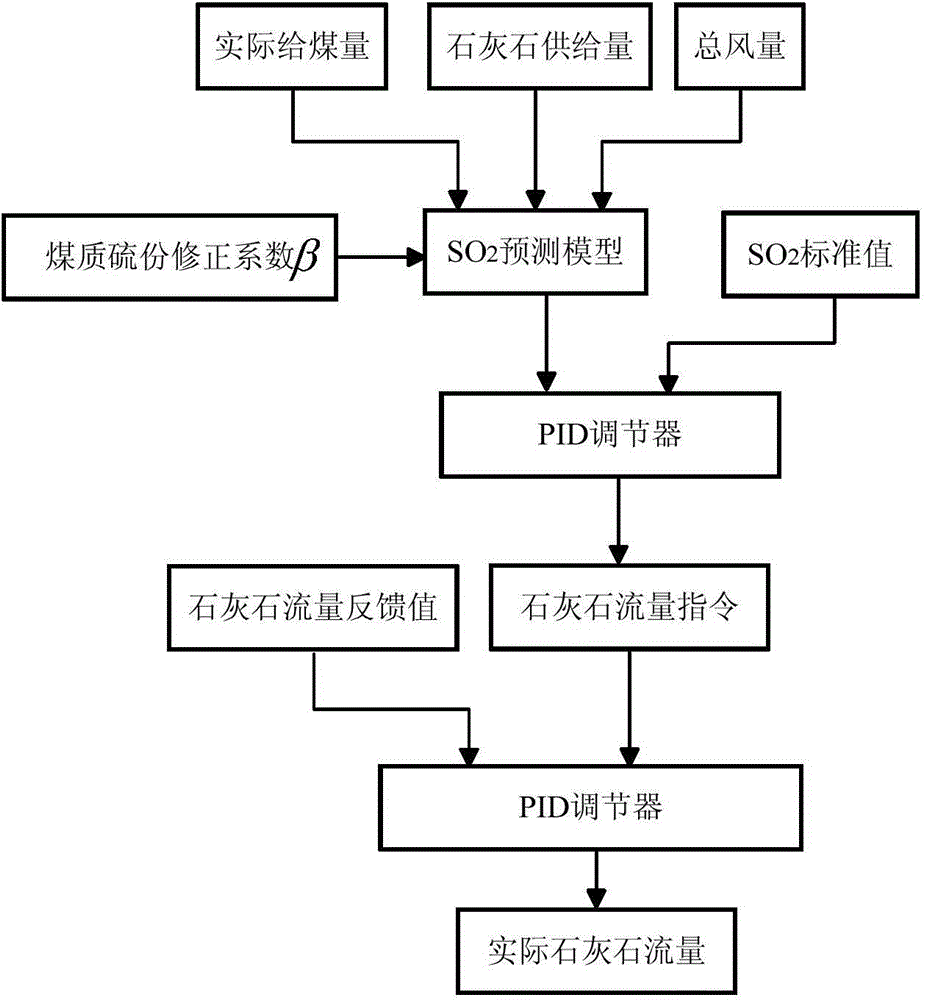

Furnace desulphurization optimization control method for circulating fluidized bed

InactiveCN104615114AAvoid hysteresisSolve the problem of excessive emissionsTotal factory controlProgramme total factory controlControl systemFluidized bed

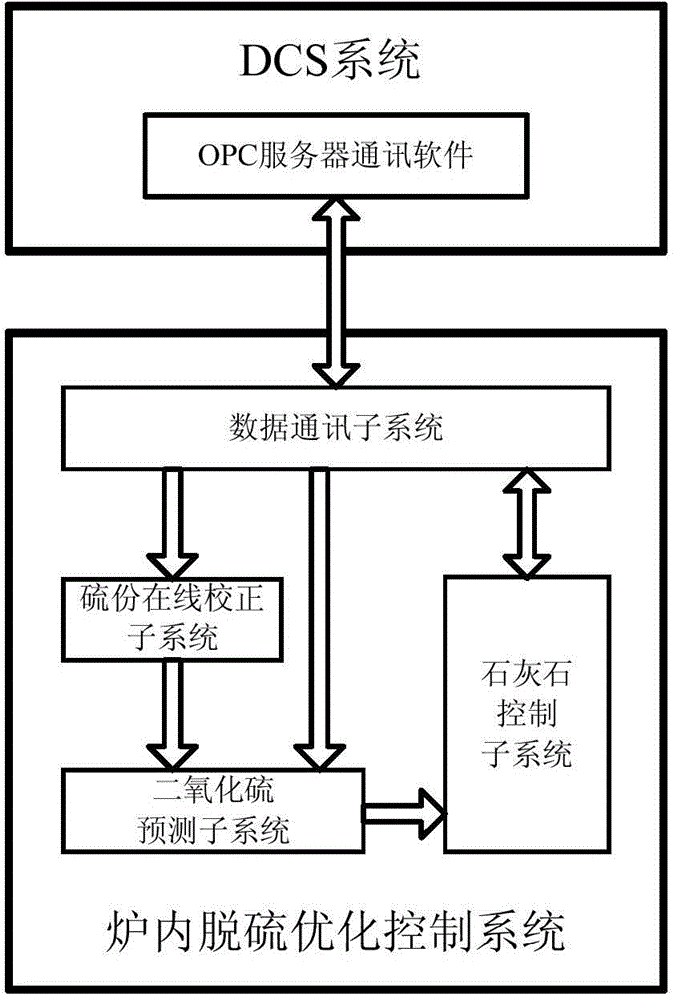

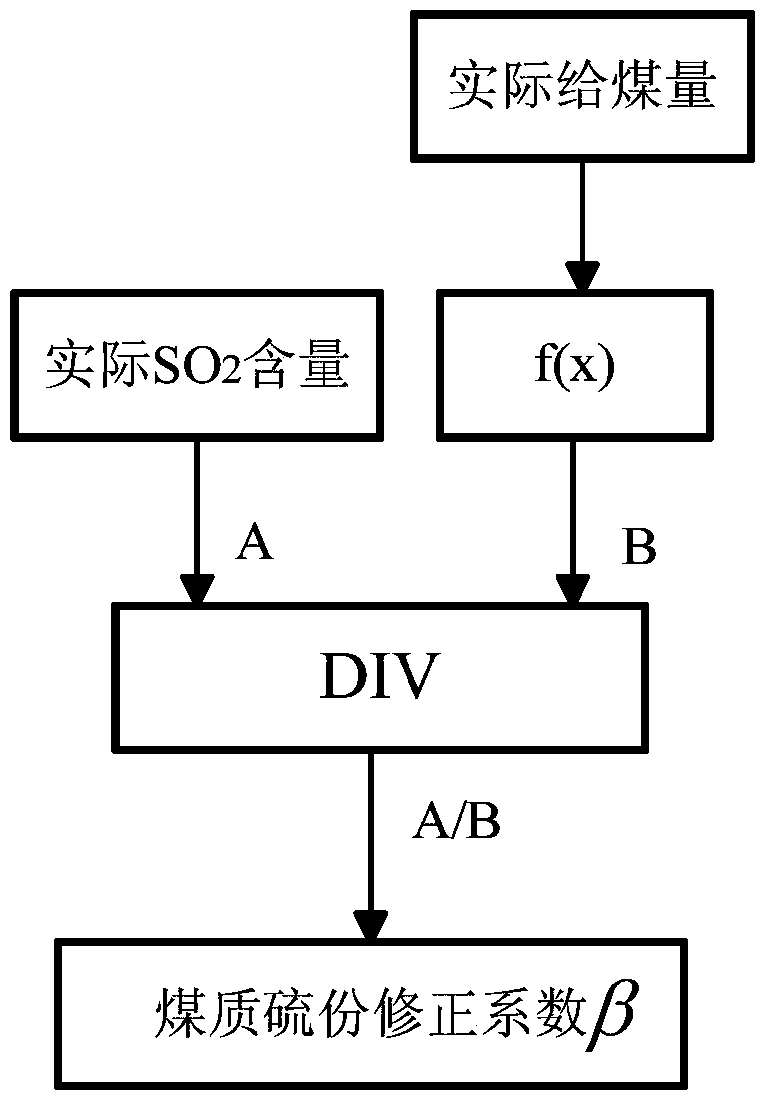

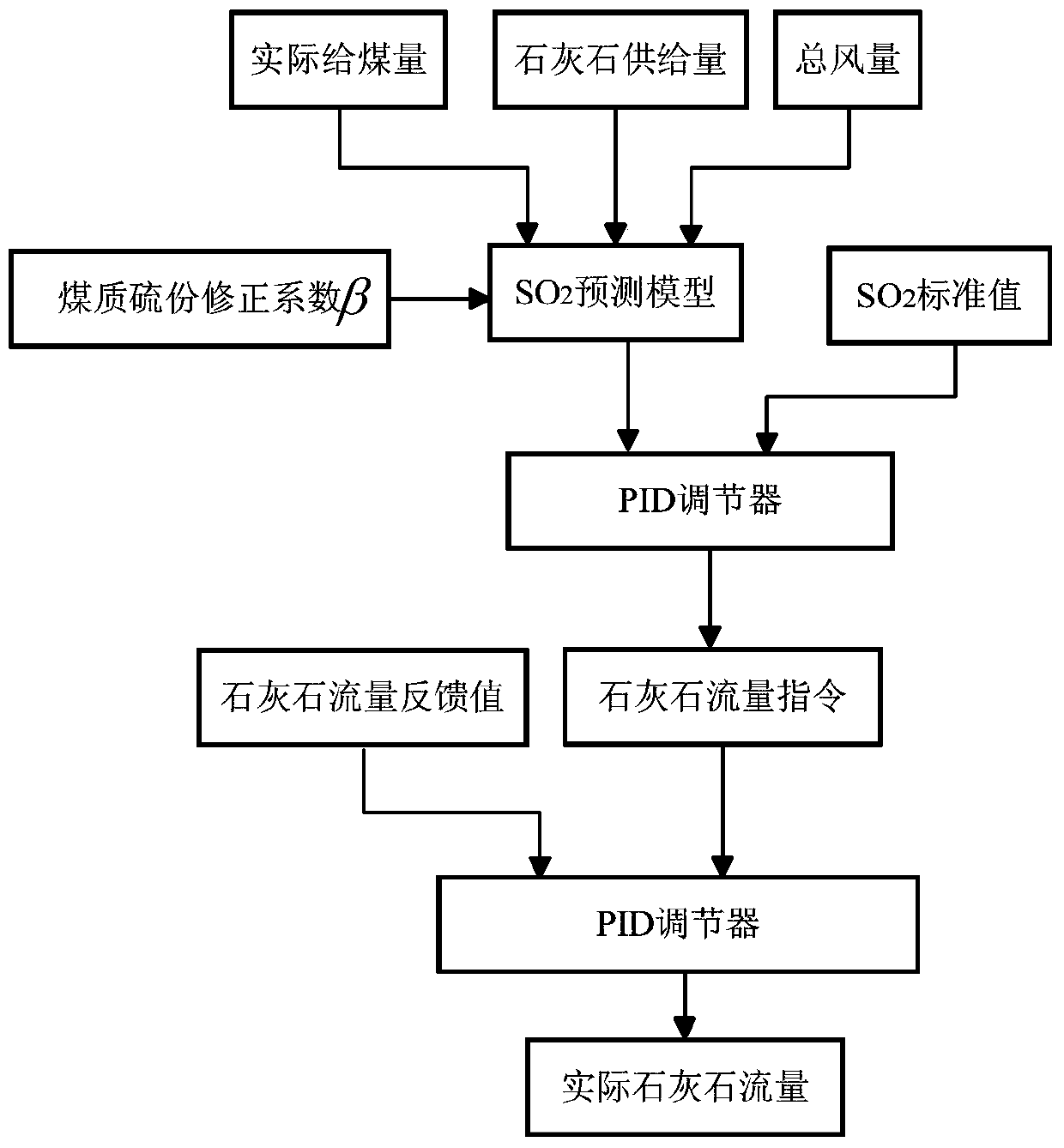

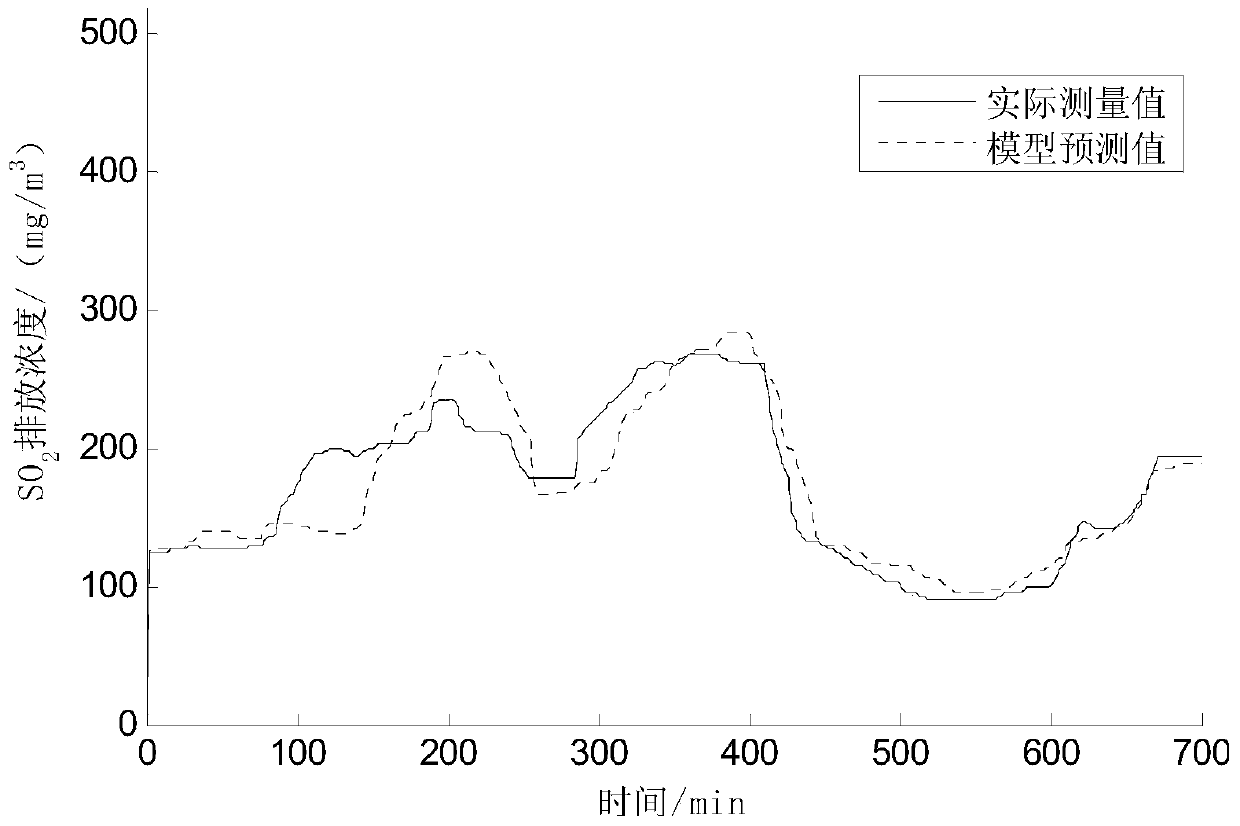

The invention belongs to the technical field of circulating fluidized bed boilers and discloses a furnace desulphurization optimization control method for a circulating fluidized bed. An optimization control system of the furnace desulphurization optimization control method comprises a data communication subsystem, a sulfur content online correction subsystem, a sulfur dioxide prediction subsystem and a limestone control subsystem; data interaction is performed on the data communication subsystem and OPC server communication software of a DCS system; the sulfur content online correction subsystem is connected with the data communication subsystem; the sulfur dioxide prediction subsystem is connected with the sulfur content online correction subsystem and the data communication subsystem; the limestone control subsystem is connected with the sulfur dioxide prediction subsystem and the data communication subsystem. According to the furnace desulphurization optimization control method for the circulating fluidized bed, a sulfur dioxide prediction model and a coal sulfur content self-adaptive correction method are established and accordingly the feeding amount of the limestone can be timely and dynamically adjusted, the excess emissions of the sulfur dioxide and the excessive use of the limestone and other resources are avoided, and the practical value in engineering is high.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

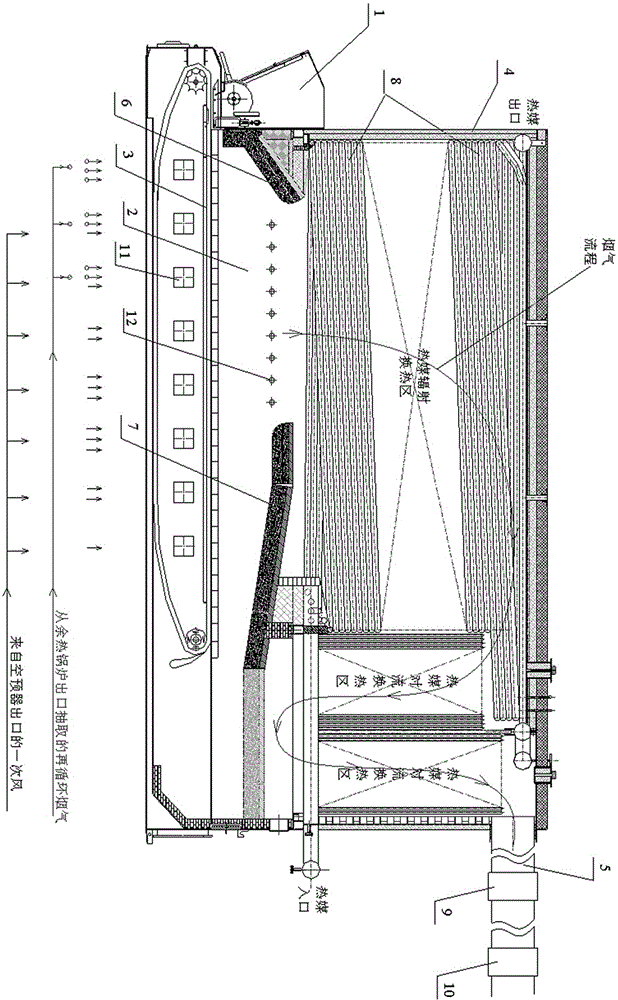

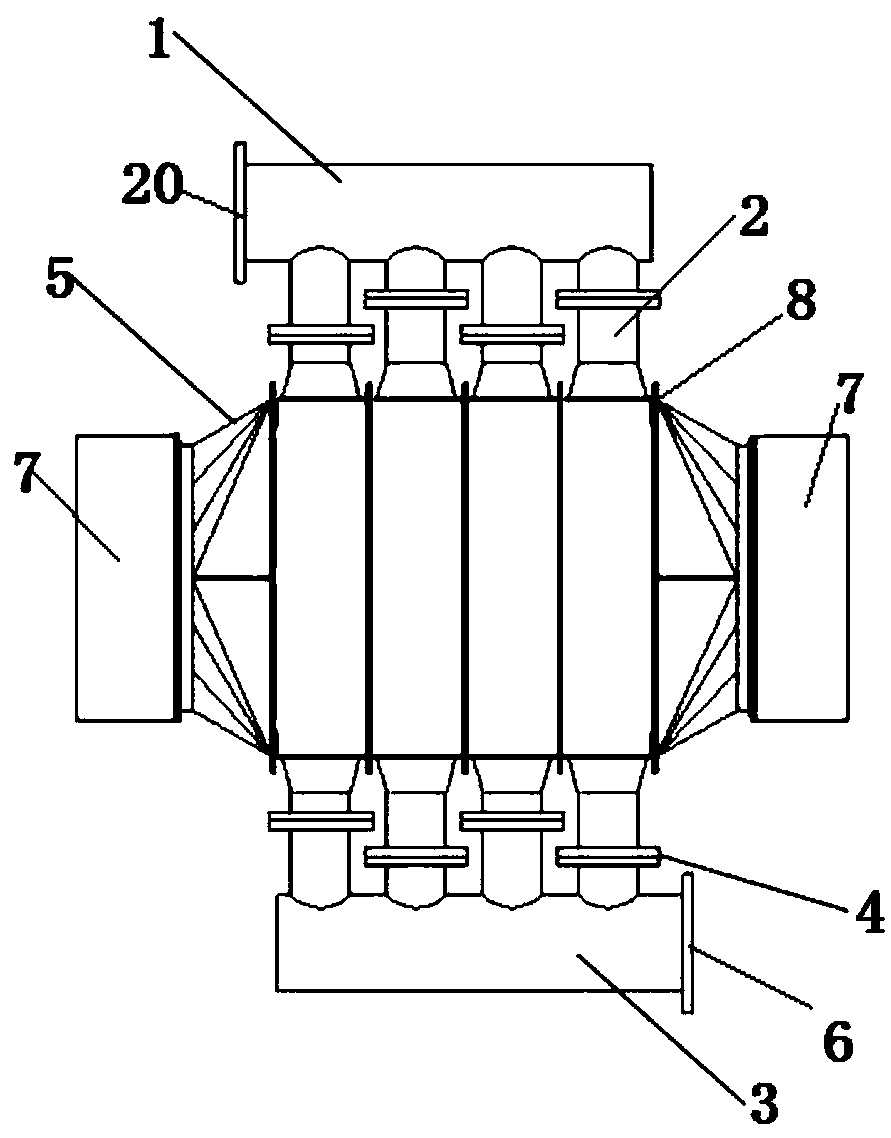

Hydrolysis reaction device for organic sulfur in blast furnace gas

PendingCN111500325ASolve the difficult problem of organic sulfurSolve the problem of excessive emissionsBlast furnace componentsGas purification by catalytic conversionPtru catalystEngineering

The invention provides a hydrolysis reaction device for organic sulfur in blast furnace gas, belonging to the technical field of fine desulfurization of blast furnace gas. The device comprises a middle flue, a flow baffle, an inlet elbow, an inlet reducing cone, an airflow uniform-distribution plate, a rectification grid, a reactor, a hydrolysis catalyst, an internal support beam, an outlet reducing cone, an outlet elbow and a sound wave soot blower, wherein the middle flue is connected with the inlet elbow of the device; the flow baffle is arranged in the inlet elbow; the inlet elbow is connected with the inlet reducing cone; the airflow uniform-distribution plate is positioned in the inlet reducing cone; the reactor is connected with the inlet reducing cone; the rectification grid is mounted at the uppermost part of the reactor; the internal support beam is arranged in the reactor; a catalyst is placed on the upper portion of the internal support beam and arranged in the reactor; theplacing intervals of all layers of the catalyst are equal; the sound wave soot blower is placed on the upper portion of the catalyst; and the reactor is connected with an external pipeline through the outlet reducing cone and the outlet elbow of the device. The device guarantees that a rear-end coal gas user finally discharges flue gas to achieve ultralow emission of sulfur dioxide.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

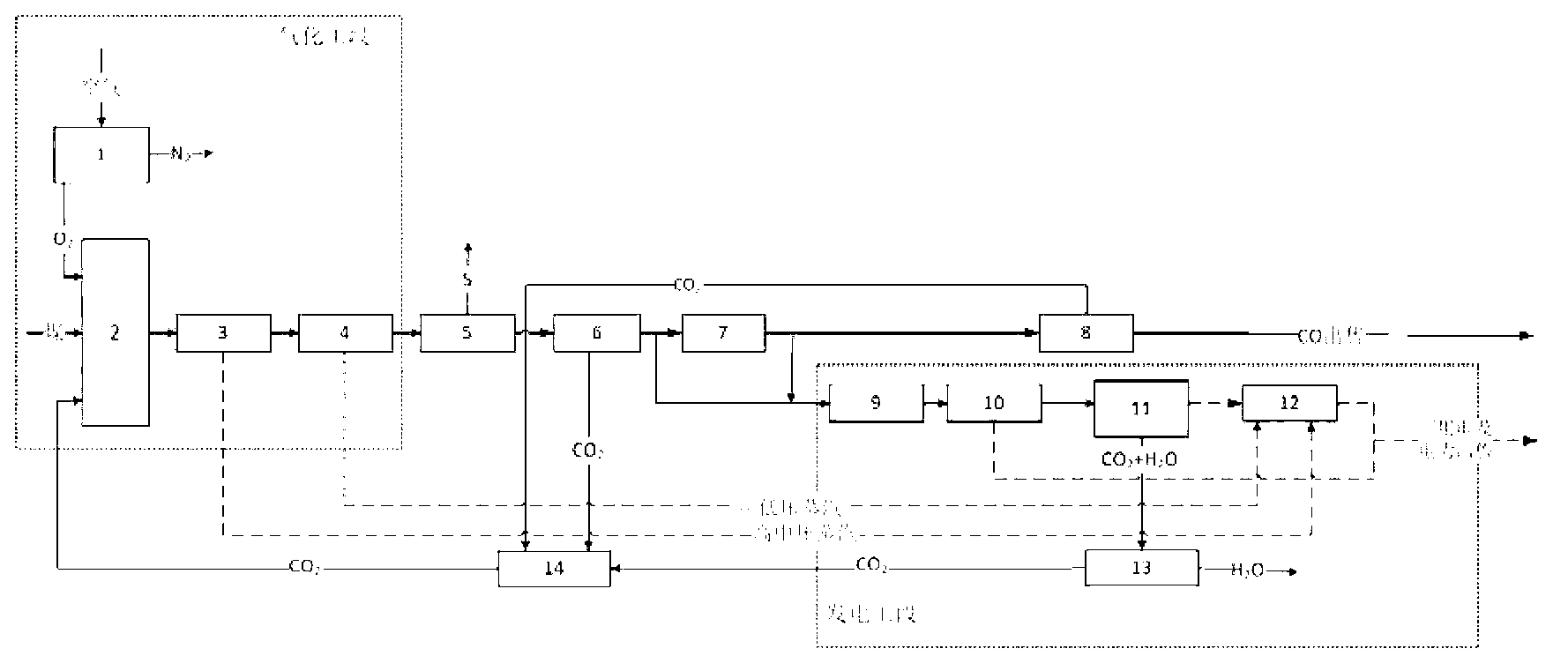

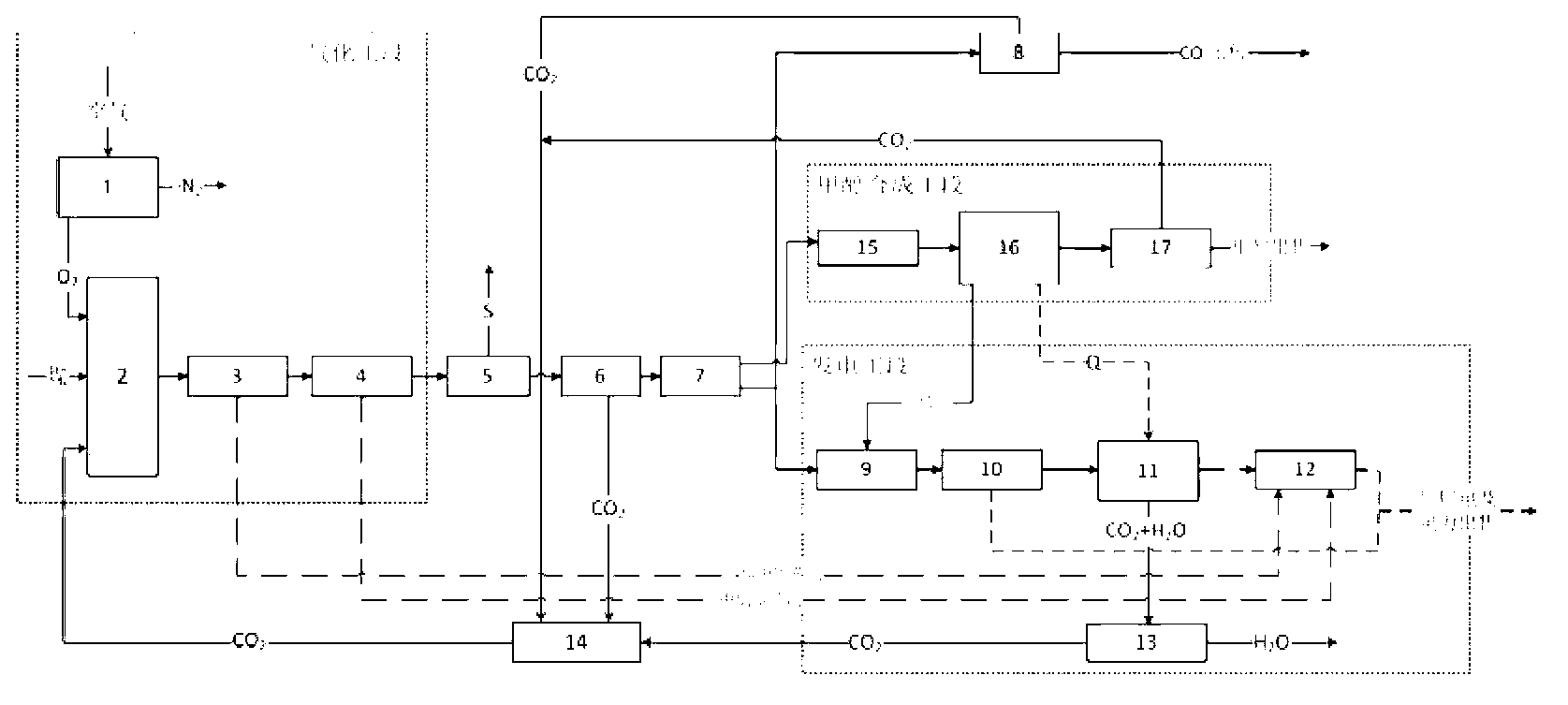

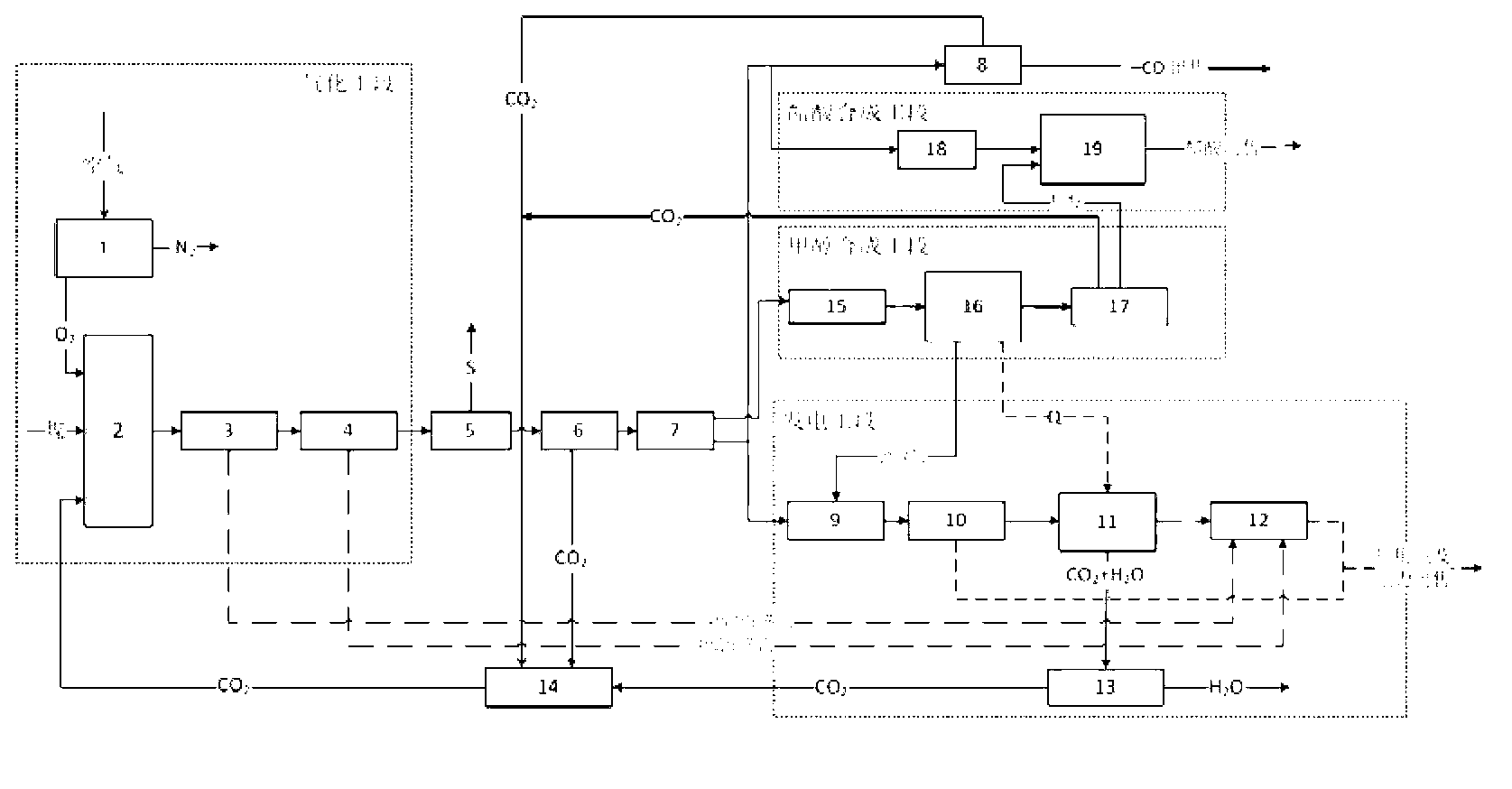

Coal-based electric power and chemical product coproduction process capable of realizing zero discharge of CO2

InactiveCN103232857ASolve recyclingAchieving zero emissionsOrganic compound preparationBiofuelsChemical industryElectric power system

The invention provides a coal-based electric power and chemical product coproduction process capable of realizing zero discharge of CO2. A new coal gasification process which uses CO2 instead of steam as a coal gasification agent is taken as the core; chemical production of chemical products such as methanol, acetic acid and the like, cogeneration by a gas turbine and a steam turbine, and output of CO used as a product are organically combined; and CO2 generated in combustion power generation, steam conversion and other procedures in the coproduction process is separated and enriched, and then is wholly conveyed to a gasifier and used as the coal gasification agent for cyclic utilization, thereby realizing zero discharge of CO2 in the whole process. The process integrally couples different sciences and different industries, solves the key technology that a large amount of greenhouse gas CO2 is discharged in the existing poly-generation process, and achieves the purposes of CO2 recycling and green energy source and chemical industry.

Owner:EAST CHINA UNIV OF SCI & TECH

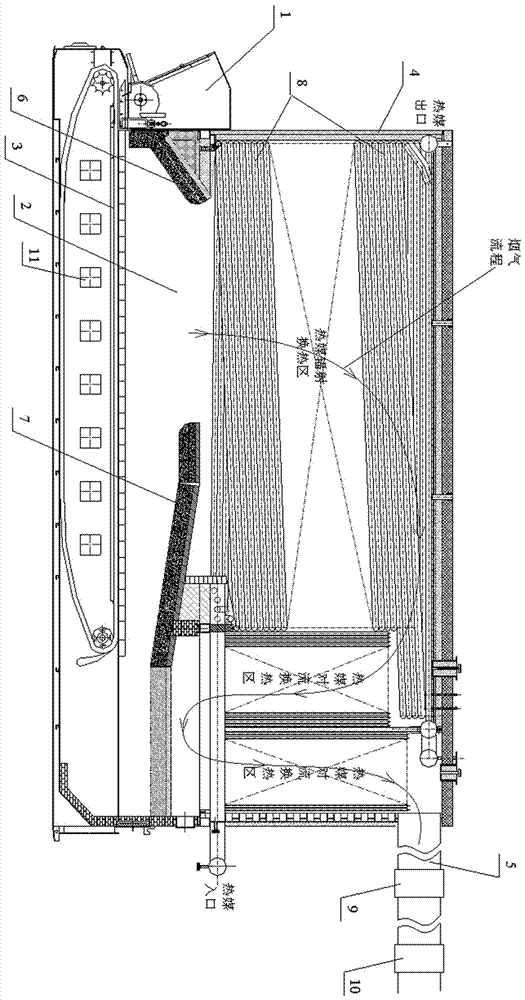

Desulfurization system and desulfurization method for cement kiln

PendingCN107362668AEfficient use ofSolve the problem of excessive emissionsDispersed particle filtrationDecompositionCement kiln

The invention relates to a desulfurization system and a desulfurization method, and specially relates to a cement kiln desulfurization system and cement kiln desulfurization method used for a cement kiln. Ammonia water is sprayed into a preheater, and the sprayed ammonia water reacts with SO2 produced in the preheater to form (NH4)2SO4; the formed (NH4)2SO4 passes through a waste heat power generation boiler along with flue gas and enters a bag-type dust collector; in the bag-type dust collector, dust is collected to a dust bin, and flue gas subjected to desulfurization enters a chimney; dust which is rich in (NH4)2SO4 in the dust bin is conveyed to the middle-upper part of a decomposition furnace; and a stable sulfate is formed in the decomposition furnace by the (NH4)2SO4 formed in a desulfurization process, the formed sulfate enters a rotary kiln, and finally the sulfate is discharged from the rotary furnace along with clinkers. The desulfurization method is less in investment, and high in efficiency, does not produce secondary pollution, and can effectively solve a problem that discharge exceeds the standard that the content of SO2 of flue gas in a chimney of a cement plant is less than or equal to 1000mg / Nm<3>.

Owner:NANJING KISEN INT ENG

Water-based underwater reflecting roads sign coating

The invention discloses a water-based underwater light-reflection road marking coating material, which comprises the following compositions in percentage by mass: 8.00 to 12.00 percent of rutile type titanium pigment, 0.30 to 0.50 percent of poly acrylate pigment dispersing agent, 0.10 to 0.14 percent of sodium tripolyphosphate, 2.00 to 2.60 percent of alcohol, 0.20 to 0.40 percent of fatty acid lower alcohol acid ester, 15.00 to 25.00 percent of glass bead, 20.00 to 40.00 percent of quartz sand, 8.00 to 12.00 percent of calcite in powder, 0.08 to 0.12 percent of Kathon, 0.10 to 0.30 percent of ethyl cellulose ether, 18.00 to 28.00 percent of acrylic acid latex base material, 0.20 to 0.40 percent of ammonia water and 2.68 to 3.88 percent of water. The marking coating material has convenient construction, high construction safety, excellent underwater light reflection, environment protection, and is nontoxic and noninflammable; moreover, the marking coating material can be directly coated again on a solvent type or hot melt type marking, thereby reducing cost and increasing construction efficiency.

Owner:潘东海

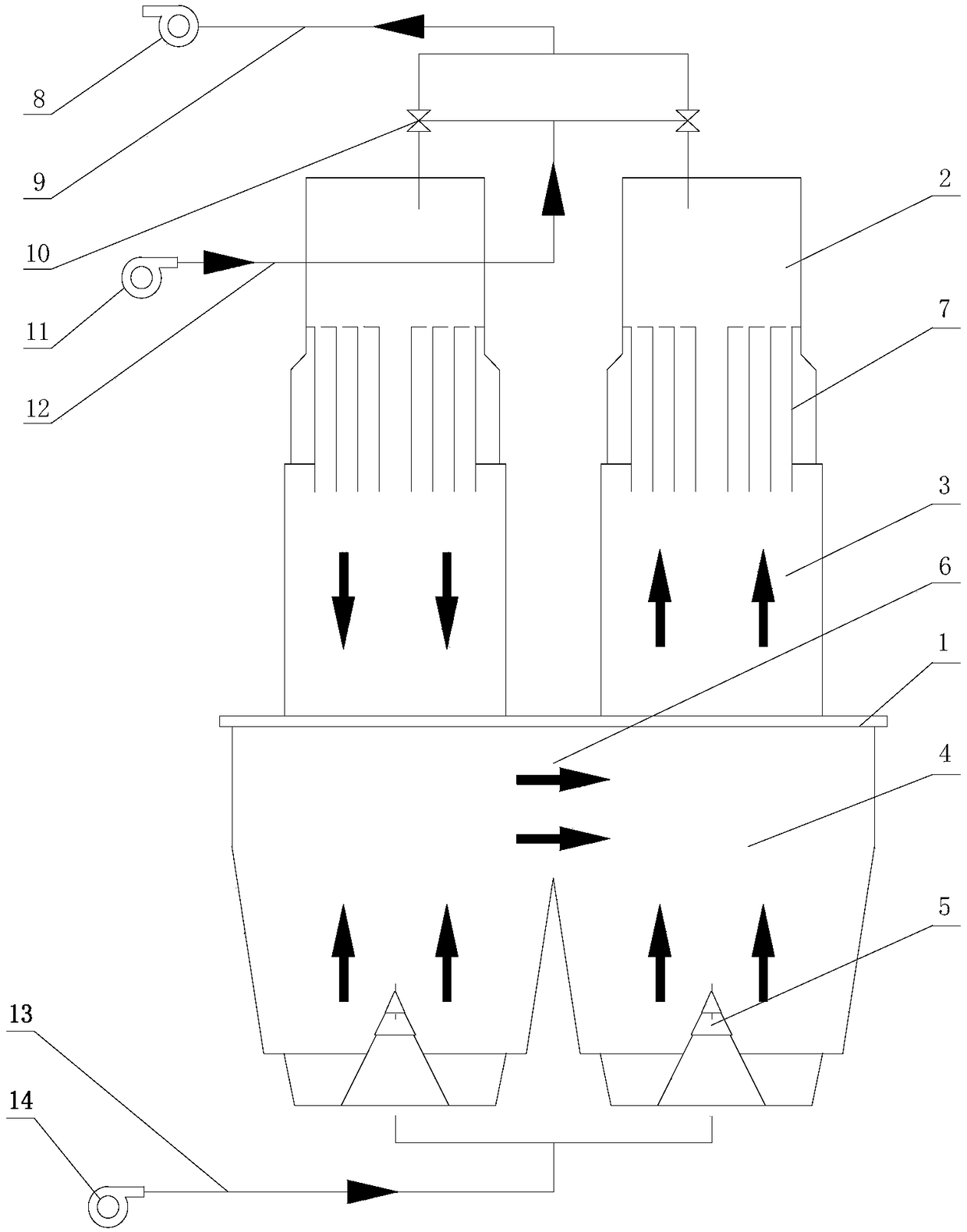

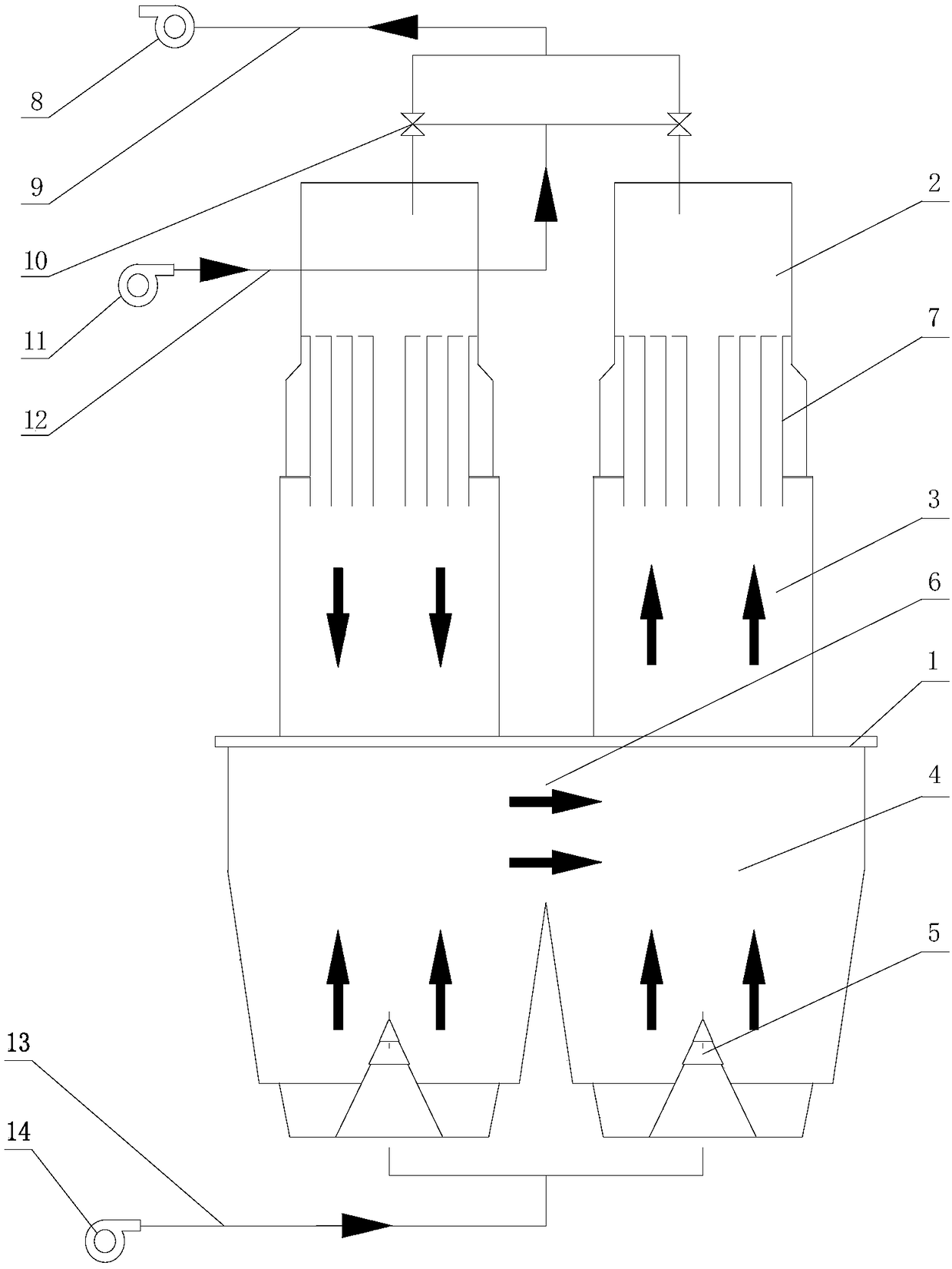

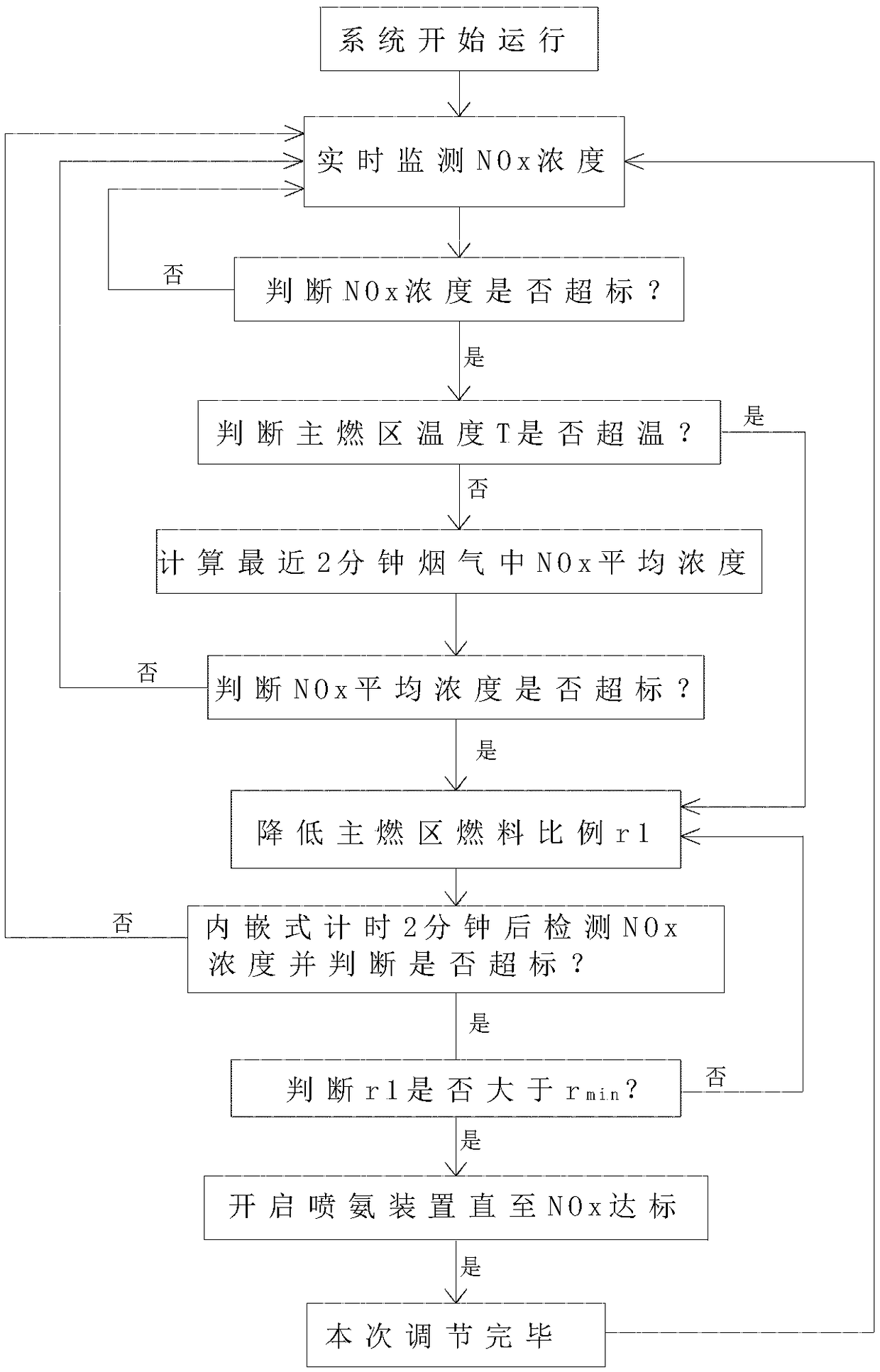

Low NOx clean combustion type lime production method and device as well as control method of low NOx clean combustion type lime production device

InactiveCN109111132ASolve the problem of excessive emissionsReduce contentMaintainance of heating chambersCharge treatment typeEngineeringAir–fuel ratio

The invention discloses a low NOx clean combustion type lime production method and a device as well as a control method of the low NOx clean combustion type lime production device. The production method comprises the following steps that combustion-supporting wind required for calcining quicklime is divided into primary air and over fire air, and the primary air is input from the upstream of a fuel input portion to enable a region, corresponding to the fuel input portion, to form a main combustion region for calcining the quicklime; and the over fire air is input from the downstream of the fuel input portion to form a secondary combustion region for calcining the quicklime at the downstream of the main combustion region. For the lime production method and device as well as the control method, through deviation of air-fuel ratio equivalence, combination process control from NOx production sources can be performed to lower the content of NOx, and the problem of too high NOx emission in the lime production process and various disadvantages caused by adopting a subsequent denitration technology are solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

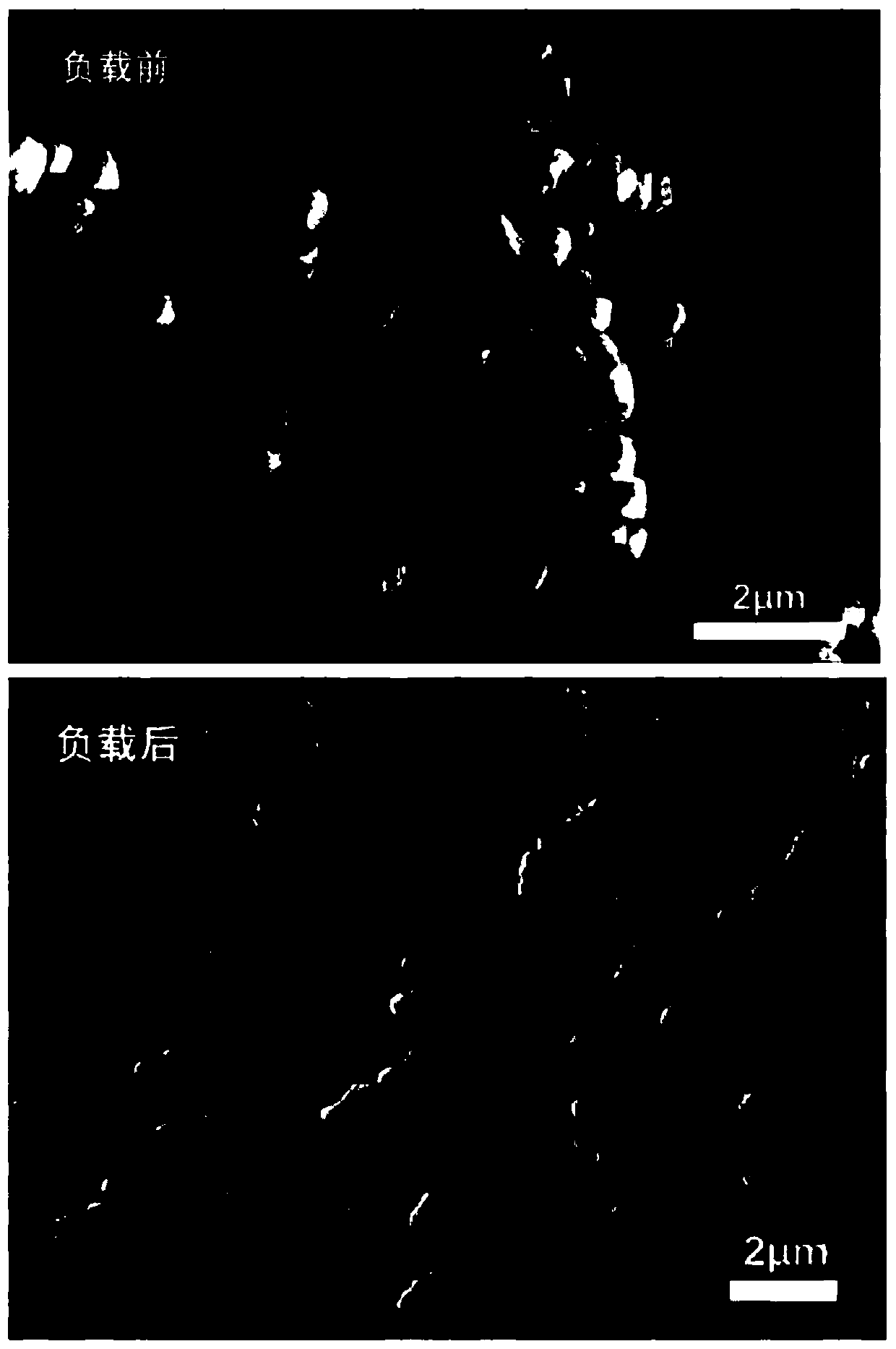

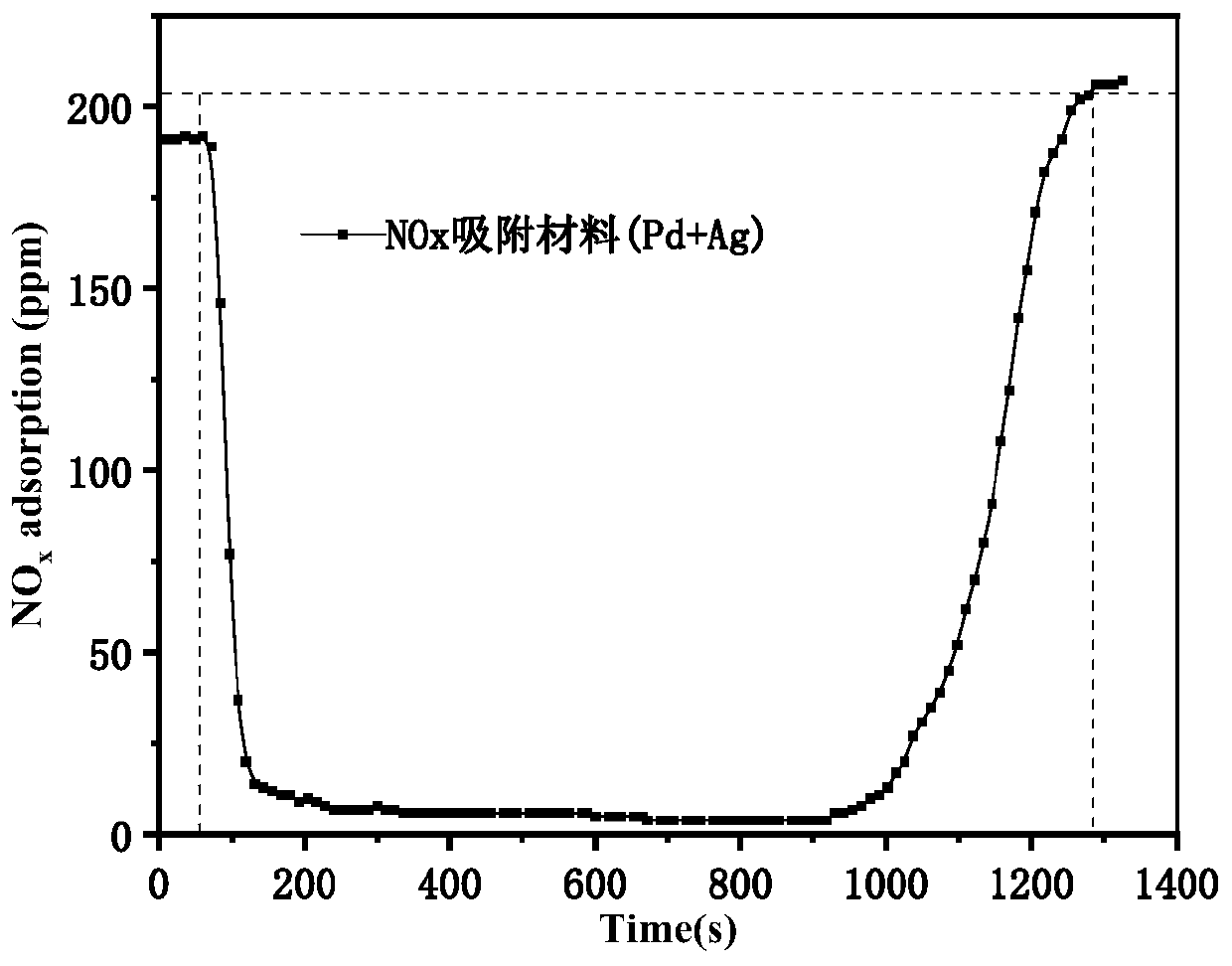

Preparation method of NOx adsorbing material with HC catalytic oxidation function

InactiveCN110201633AImprove adsorption capacityIncrease the rate of NOx adsorptionGas treatmentMolecular sieve catalystsMolecular sieveCatalytic oxidation

The invention discloses a preparation method of a NOx adsorbing material with an HC catalytic oxidation function. The method comprises the following steps of S1, molecular sieve pretreatment; S2, loading with precious metal; S3, roasting; S4, hydrothermal aging. The provided preparation method of the NOx adsorbing material with the HC catalytic oxidation function has the advantages that the obtained NOx adsorbing material has the functions of efficiently adsorbing and storing NOx at a low temperature and thermally desorbing the NOx at a high temperature, and also has a certain function catalytic oxidation function on the hydrocarbons.

Owner:安徽纳蓝环保科技有限公司

Horizontal type chain grate heat medium heater capable of coupling side wall staging air and flue gas recirculation

ActiveCN104792007AReduce generationLower combustion temperatureStorage heatersAir preheaterCombustion chamber

The invention discloses a horizontal type chain grate heat medium heater capable of coupling side wall staging air and smoke recirculation. The horizontal type chain grate heat medium heater is composed of a scraper coal feeder, a combustion chamber, a chain grate, a horizontal type heater body and a rear smoke channel. According to the horizontal type chain grate heat medium heater, staging air is distributed on the two side walls of the horizontal type chain grate heat medium heater, and meanwhile primary air is supplied in sections under the grate to build the staging combustion conditions in the heater; smoke is extracted from the position, between a waste heat boiler and an air preheater, of the rear smoke channel and fed into multiple primary chambers located on the front portion of the chain grate to organize smoke recycling. Accordingly, on one hand, the retention time of coal particles in the heater in a combustion state of being far away from the stoichiometric ratio is prolonged; on the other hand, in a coal seam combustion area, the oxygen concentration is diluted, the combustion temperature is lowered, the combustion intensity is weakened, therefore, the combustion process is delayed, and finally the low NOx combustion in the coal-fired horizontal type chain grate heat medium heater is achieved.

Owner:江苏宇澄环境工程设备有限公司

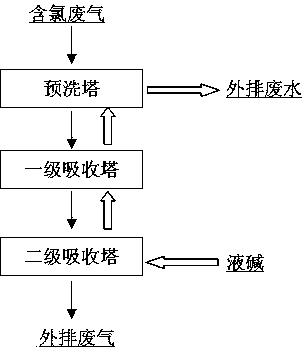

Chlorine-containing waste gas absorption system

ActiveCN103736378AGuaranteed emission standardsSolve the problem of excessive emissionsDispersed particle separationProcess engineeringTower

The invention discloses a chlorine-containing waste gas absorption system which comprises a prewashing tower, a first level tower and a second level tower which are sequentially connected with one another in series, an alkali pump connected with the second level tower, and a control device for controlling liquid alkali adding and draining movements of the chlorine-containing waste gas absorption system. The invention also discloses a chlorine-containing waste gas absorption method. Liquid alkali is added into the second level tower through the alkali pump. When the control device detects that the pH value of an absorption liquid of the first level tower is lower than a standard value, the absorption liquid of the first level tower is automatically discharged to the prewashing tower, and an absorption liquid of the second adsorption tower is automatically discharged to the first level tower. When the control device detects that the pH value of a washing liquid in the prewashing tower is lower than a standard value, the washing liquid is automatically discharged, and the absorption liquid of the first level tower is automatically discharged to the prewashing tower. According to the system provided by the invention, the pH value of the liquid in each level tower is maintained in a high state all the time, so that chlorine-containing waste gas is discharged by reaching the standard.

Owner:JINCHUAN GROUP LIMITED

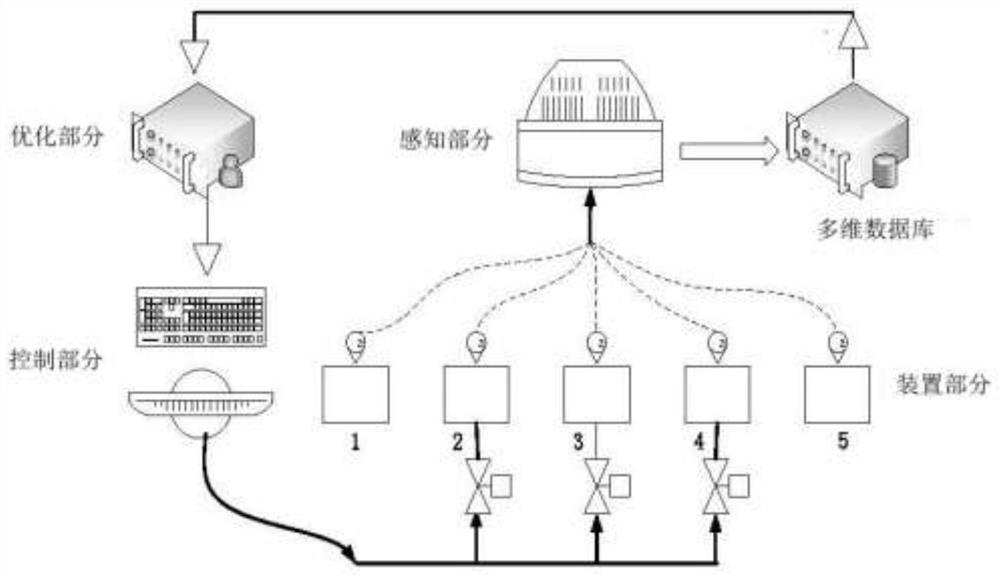

Green and efficient ship exhaust gas multi-pollutant purification system and intelligent regulation and control method

PendingCN112933965ASolve the problem of excessive emissionsImprove adaptabilityUsing liquid separation agentResource consumptionDieseling

The invention relates to a green and efficient ship exhaust gas multi-pollutant removal and purification system and an intelligent regulation and control method, and the system comprises a device part, a sensing part, a control part and an optimization part. The device part comprises a marine diesel engine, a multi-pollutant detergent preparation device, a multi-pollutant enhanced removal device, a multi-pollutant washing residual liquid integrated purification device and a waste gas exhaust barrel. The sensing part is used for acquiring, preprocessing, integrating, storing and issuing information; the control part is used for adjusting the key manipulated variable by setting real-time operation conditions and optimization parameters, and ensuring that the system stably reaches the standard and is subjected to optimization adjustment; the optimization part comprises a calculation platform constructed by a pollutant generation concentration and outlet pollutant concentration prediction model, and realizes intelligent switching of desulfurization operation modes under frequent change of a navigation environment and frequent fluctuation of a load, and accurate adjustment and optimization regulation and control of system operation key parameters. Energy is saved, consumption is reduced, emission stability is improved, and environmental pollutants and resource consumption are reduced.

Owner:浙江程润云环境科技有限公司

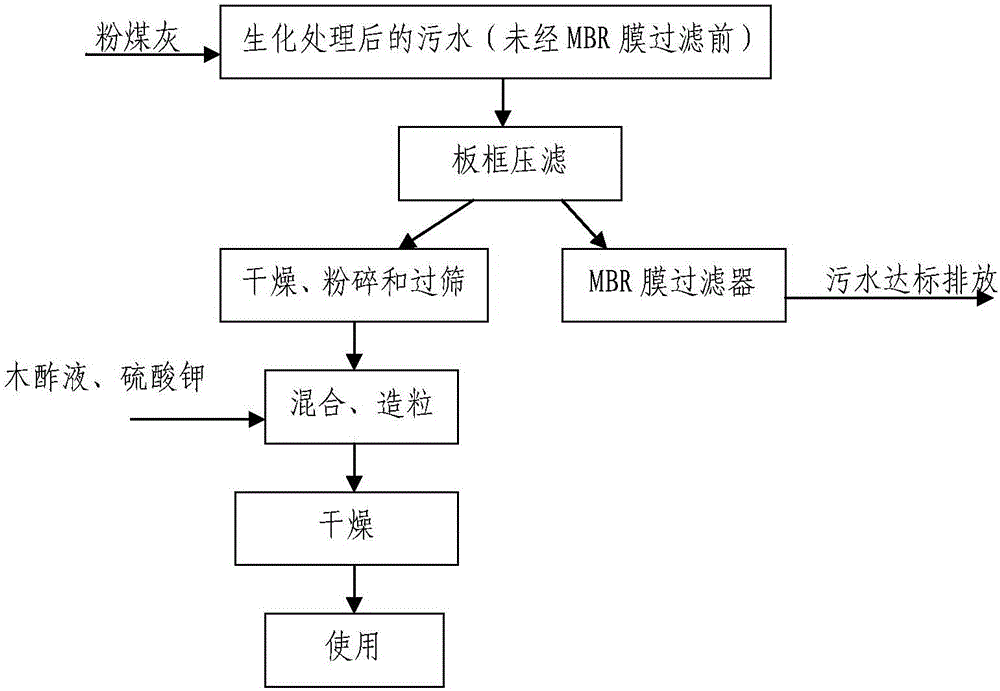

Comprehensive utilization method of fly ash in wastewater treatment and soil conditioner preparation

InactiveCN106748269AReduce CODImprove drainage qualityWater contaminantsMultistage water/sewage treatmentWastewaterSewage

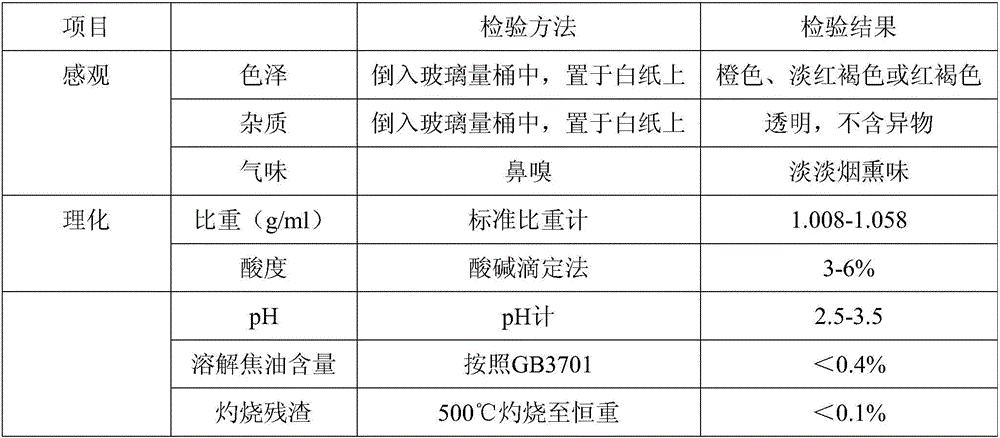

The invention discloses a comprehensive utilization method of fly ash in wastewater treatment and soil conditioner preparation. The method comprises the following sequential steps: adding fly ash into sewage after biochemical treatment and stirring; performing filter pressing of the obtained suspension by a plate-and-frame filter press to obtain a fly ash filter cake I and sewage I after adsorption treatment; drying the fly ash filter cake I, grinding and sieving to obtain the treated fly ash II; and adding wood vinegar and potassium sulfate into the treated fly ash II, stirring and mixing uniformly, granulating and drying to obtain a soil conditioner. The sewage I after adsorption treatment is filtered by an MBR membrane; the sewage after the membrane filtration can reach the discharge standard.

Owner:章誉之

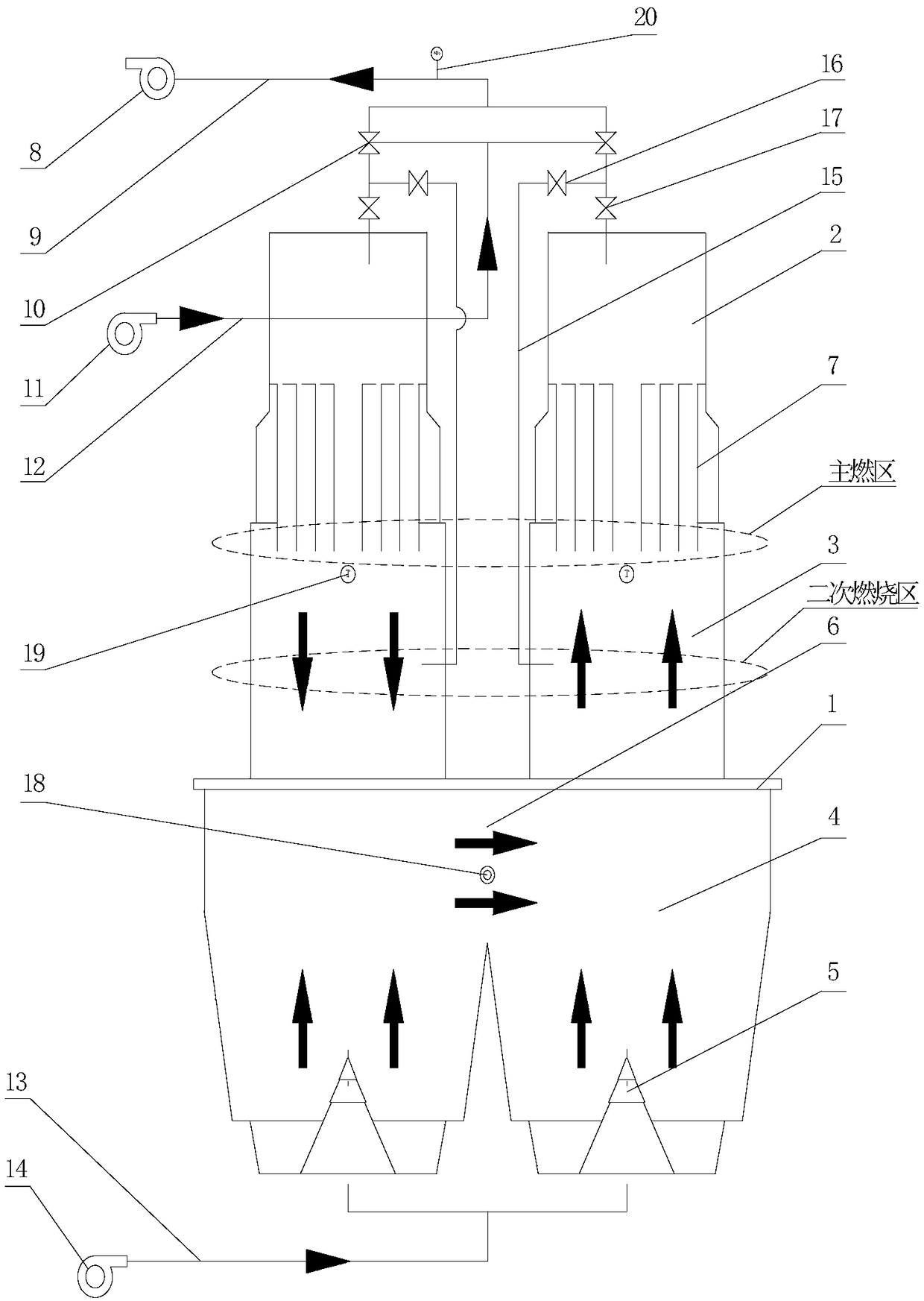

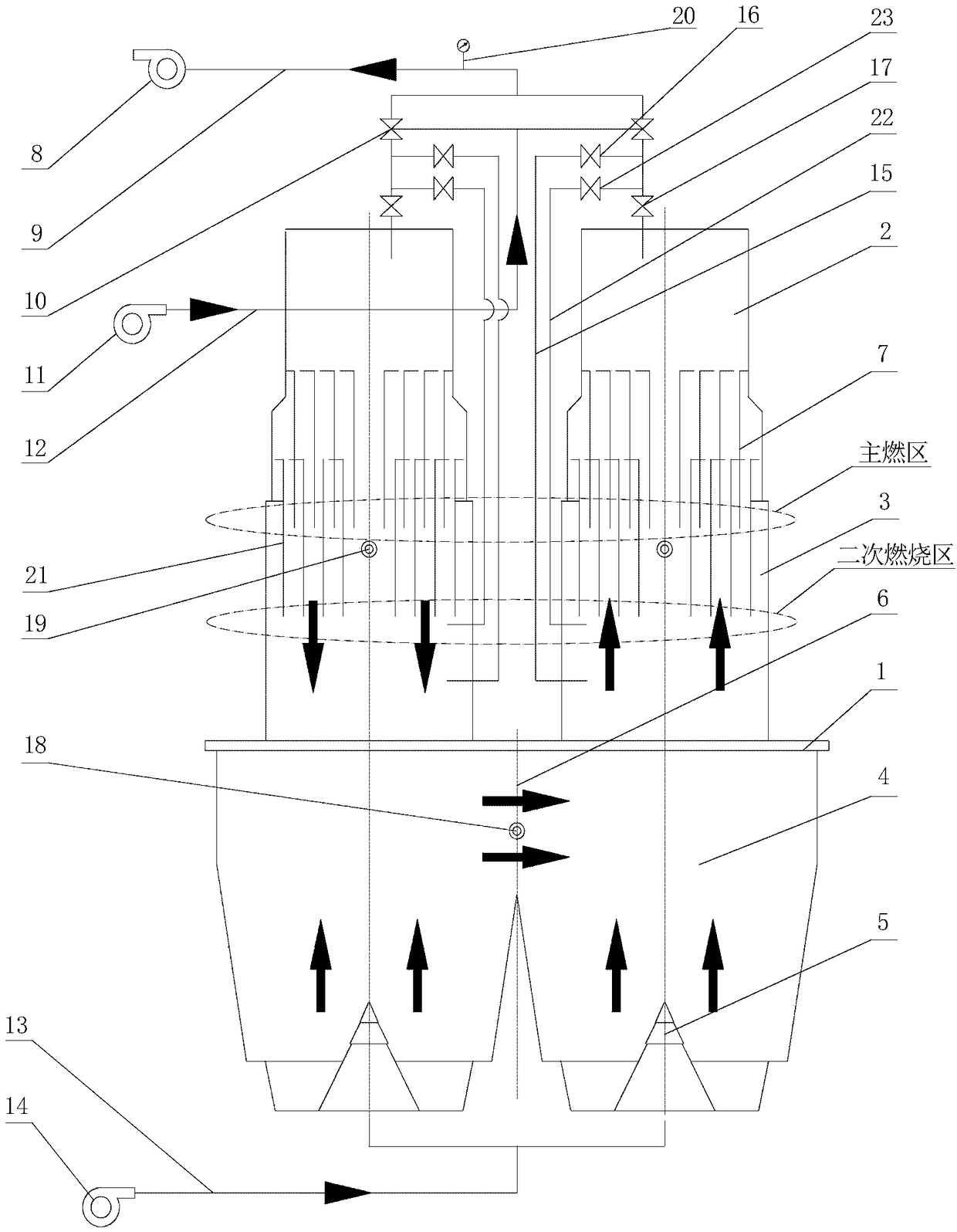

Low-NOx cleaning combustion type lime production method and device and control method thereof

PendingCN109354420ASuppress generationReduce contentFuel supply regulationStaged combustionEquivalent weightMethods of production

The invention discloses a low-NOx cleaning combustion type lime production method and device and a control method thereof. The production method comprises the following steps: dividing combustion airrequired for calcining quicklime into primary air, secondary combustion air and over firing air; feeding the primary air from the upstream portion of a main fuel feeding portion, enabling a region which corresponds to the main fuel feeding portion to become a main combustion region for calcining the quicklime; feeding the secondary combustion air into a region which corresponds to a secondary combustion fuel feeding portion to form a secondary combustion region which is positioned at the downstream of the main combustion region; feeding the over firing air from the downstream of the secondarycombustion fuel feeding portion, forming an over firing region at the downstream of the secondary combustion region, and meanwhile changing single-position one-time spraying of fuel into up-down double-position multiple-time spraying of the fuel so as to further strengthen fuel grades. Through the lime production method, the production device and the control method, by deviation of an air-fuel ratio equivalent weight, a combustion process can be controlled on a NOx generation source to reduce NOx content, and the problem of over-high NOx emission amount in a lime production process is solved.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

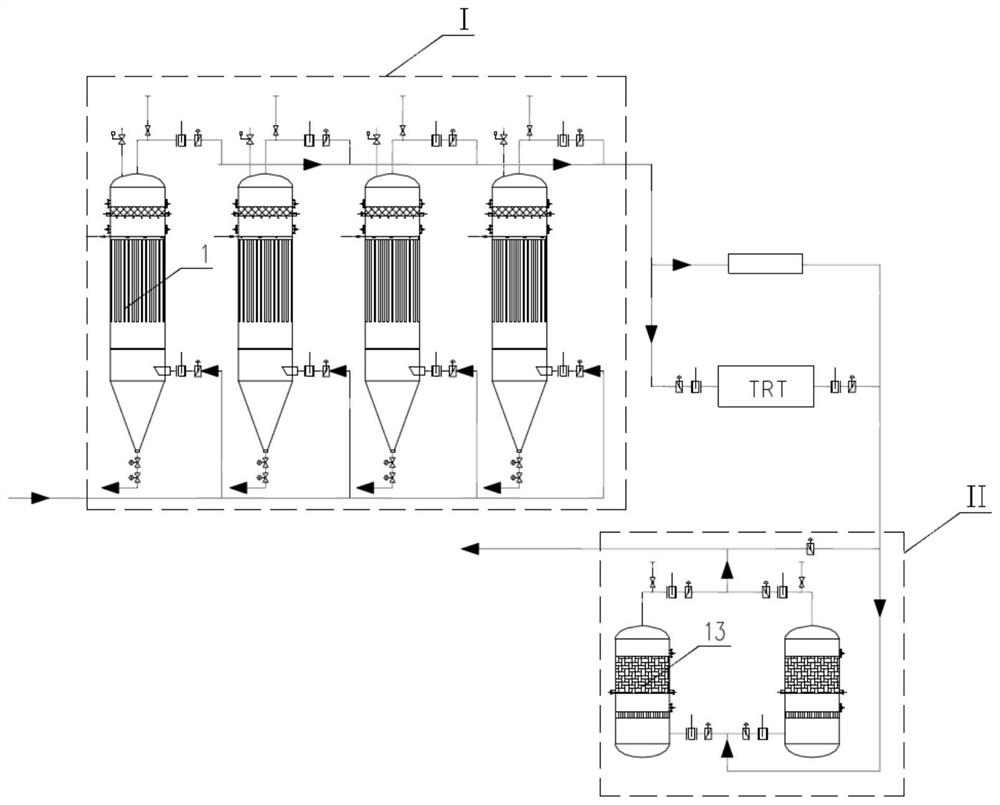

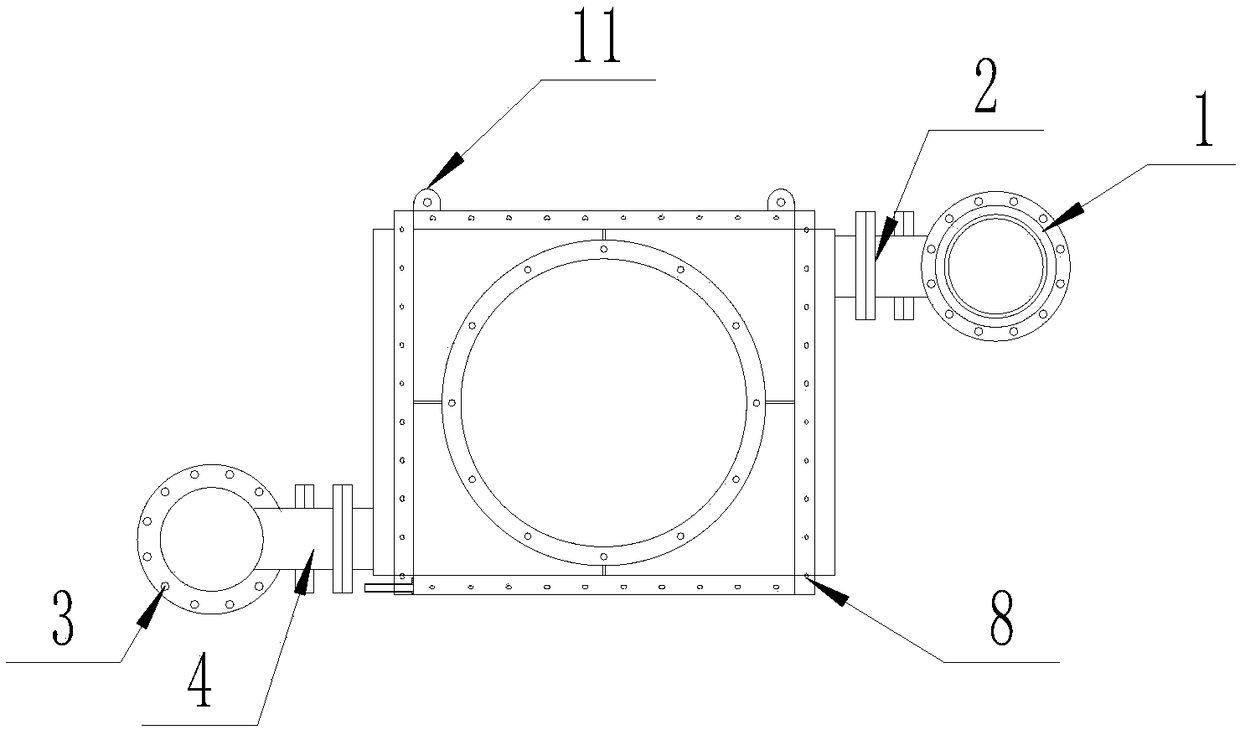

Dust removal/hydrolysis integrated desulfurization system for blast furnace gas

InactiveCN111944564ASolve the problem of excessive smoke emissionAvoid space occupationGas purification by catalytic conversionBlast furnace detailsGas pipelineProcess engineering

The invention provides a dust removal / hydrolysis integrated desulfurization system for blast furnace gas, belonging to the technical field of fine desulfurization of blast furnace gas. The system comprises a dust removal / hydrolysis integrated system and a desulfurization system, wherein the dust removal / hydrolysis integrated system is formed by connecting a plurality of dust removal / hydrolysis integrated devices in parallel, and cut-off valves are arranged between the devices and a main gas pipeline. According to the invention, blast furnace gas firstly enters the dust removal / hydrolysis integrated devices through a raw gas pipe network, and raw gas enters from the lower parts of the devices; firstly, dust in the gas is captured through cloth bags, the captured dust is conveyed to ash bins, and the gas having been subjected to dust removal is converted into hydrogen sulfide through hydrolysis catalyst bed layers; the blast furnace gas having undergone dust removal and hydrolysis entersa desulfurization tower of the desulfurization system; and purified clean gas is converged into a clean gas main pipe network. According to the invention, dust removal of the gas and catalytic hydrolysis of carboxyl sulfur in the gas are combined into the same device, and a gas hydrolysis reactor does not need to be independently arranged, so the occupied area of the gas desulfurization system isreduced, system investment is reduced, and cost is saved.

Owner:北京北科环境工程有限公司

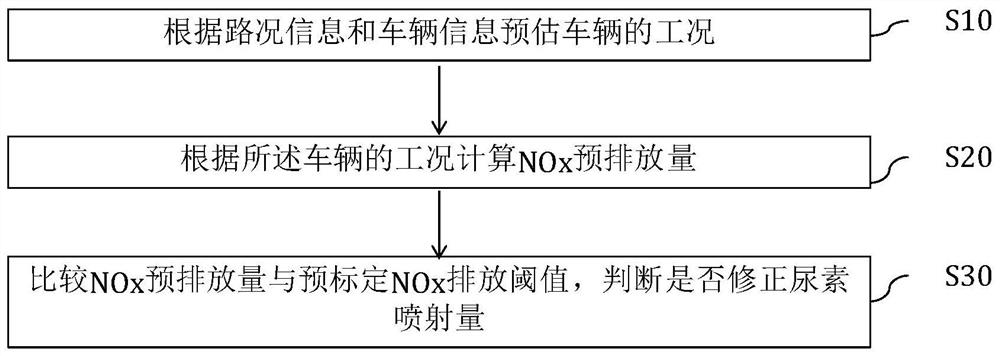

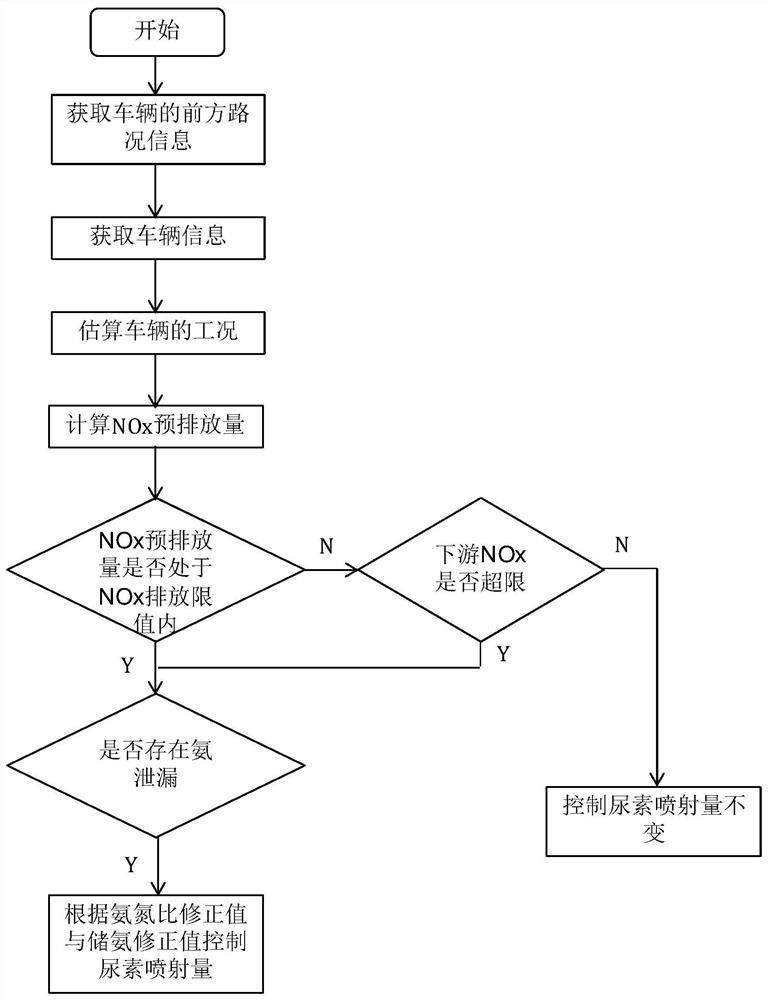

Urea injection amount control method and system and vehicle

ActiveCN113266448ASolve the problem of excessive emissionsInternal combustion piston enginesExhaust apparatusEnvironmental engineeringRoad condition

The invention belongs to the technical field of vehicles, and particularly relates to a urea injection amount control method and system and a vehicle. The urea injection amount control method comprises the following steps that the working condition of the vehicle is estimated according to road condition information and vehicle information; the NOx pre-emission amount is calculated according to the working condition of the vehicle; and the NOx pre-emission amount is compared with a pre-calibrated NOx emission threshold value, and whether the urea injection amount is corrected or not is judged. According to the urea injection amount control method, firstly, the working condition of the vehicle is estimated according to the road condition information in front of the vehicle, then the NOx pre-emission amount is calculated in advance according to the working condition, the NOx pre-emission amount is compared with the pre-calibrated NOx emission threshold value, whether the urea injection amount is corrected or not is further judged, therefore, the urea injection amount corresponding to the road condition is calculated before the vehicle reaches the changed road condition, the urea injection amount is controlled in time, vehicle emission is reduced, and it is guaranteed that the vehicle emission does not exceed the standard.

Owner:WEICHAI POWER CO LTD

Aqueous finishing-free high-gloss solid color paint for vehicles

InactiveCN111234630ASolve the problem of excessive emissionsHigh glossCoatingsPtru catalystAcid catalyzed

The invention discloses an aqueous finishing-free high-gloss solid color paint for vehicles. The paint comprises a main film-forming substance, an assistant, deionized water and color paste, and the main film-forming substance comprises an aqueous acrylic acid dispersion, an aqueous polyester resin, a fully methylated amino resin and an aqueous blocked isocyanate; wherein the assistant comprises graphene dispersion liquid, an acid catalyst, a defoaming agent, an aqueous base material wetting agent, a first thickening agent, a second thickening agent, a third thickening agent, a neutralizing agent, an aqueous wetting dispersing agent and a coalescing agent; and the color paste comprises aqueous polyester resin, an aqueous wetting dispersant, a defoaming agent, a neutralizer and a pigment. Graphene is added into a coating; a resin system capable of generating a synergistic effect with graphene is screened out; on the premise of satisfying various physicochemical properties of the traditional aqueous solid color paint for vehicles matched with an oil-based finishing varnish film, the production process of coating the oil varnish on the traditional solid color paint is reduced, the VOCs emission is reduced by more than 95%, the energy consumption is reduced by more than 30%, the working hours are reduced by more than 20%, and the national requirements on energy conservation, emission reduction and consumption reduction are met.

Owner:重庆亿隆涂料股份有限公司

Nano combustion catalyst and preparation method thereof

InactiveCN108311157ASolve the problem of excessive emissionsHigh activityHeterogenous catalyst chemical elementsCatalyst activation/preparationCerium(IV) oxideManganese oxide

The invention provides a nano combustion catalyst. The nano combustion catalyst is prepared from the following raw materials: aluminium oxide, silicon dioxide, cerium oxide, ferric oxide and manganeseoxide with the weight ratio being (40-60):(20-30):(1-5):(10-30):(5-10), wherein cerium oxide is nano cerium oxide, ferric oxide is nano ferric oxide, and manganese oxide is nano manganese oxide. Theinvention also provides a preparation method of the nano combustion catalyst. The preparation method comprises the following steps of: weighing aluminium oxide, silicon dioxide, cerium oxide, ferric oxide and manganese oxide according the weight percent, and mixing with water to obtain preparation raw materials; placing the preparation raw materials into a ball mill for ball milling; adopting a forming process to prepare the ball-milled preparation raw materials into spheres or cylinders; placing in a roasting furnace for roasting, then taking out, and cooling to room temperature. The nano combustion catalyst provided by the invention has the beneficial effects that the problem of exceeding-standard tail-gas emission caused by failure of the three-way catalyst due to poisoning and ageing can be solved, and the activity and the efficiency are high.

Owner:天津爱蓝天环保科技有限公司

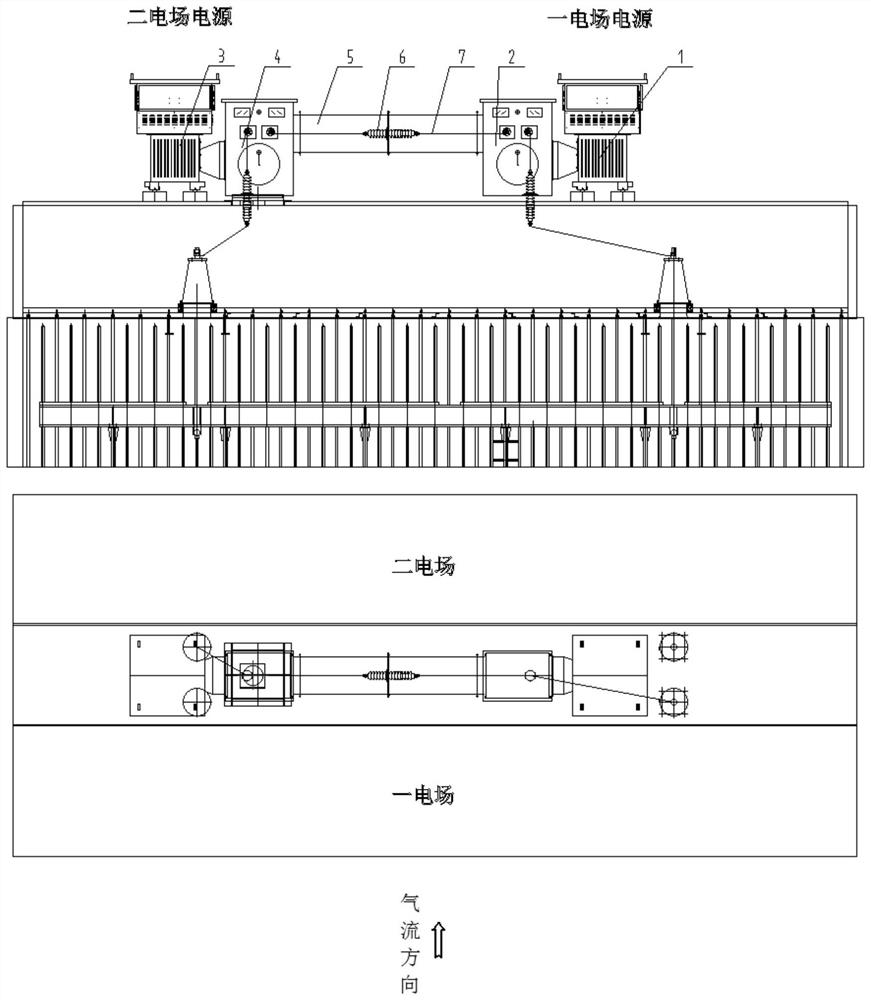

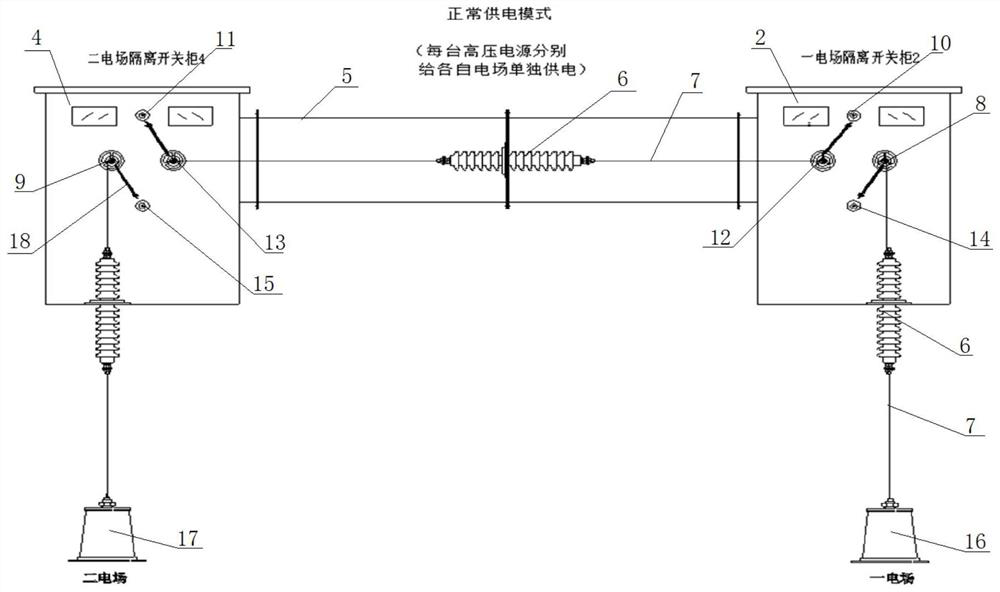

Mutual redundancy power supply system and method for adjacent electric fields of electric precipitator

InactiveCN112007758ASolve the problem of excessive emissionsElectric supply techniquesTransformerEngineering

The invention relates to a mutual redundancy power supply system for adjacent electric fields of an electric precipitator. The system comprises a first high-voltage silicon rectifier transformer, a second high-voltage silicon rectifier transformer, a connecting wire, a first high-voltage input end, a second high-voltage input end, an electric field connection end, a second electric field connection end, an electric field standby connection end and a second electric field standby connection end. The first high-voltage silicon rectifier transformer is connected with an electric field connectionend, the second high-voltage silicon rectifier transformer is connected with a second electric field connection end, and an electric field standby connection end is connected with the second electricfield standby connection end through a connection wire. According to the mutual redundancy power supply system, the two high-voltage power supplies are standby for each other, and when any one electric field power supply fails and stops, the two electric fields can be simultaneously switched on by the power supplies of the adjacent electric fields to supply power to the two electric fields throughswitching of the adjacent electric field mutual redundancy power supply system, so that the two electric fields of the electric precipitator are in an electrified normal working state.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

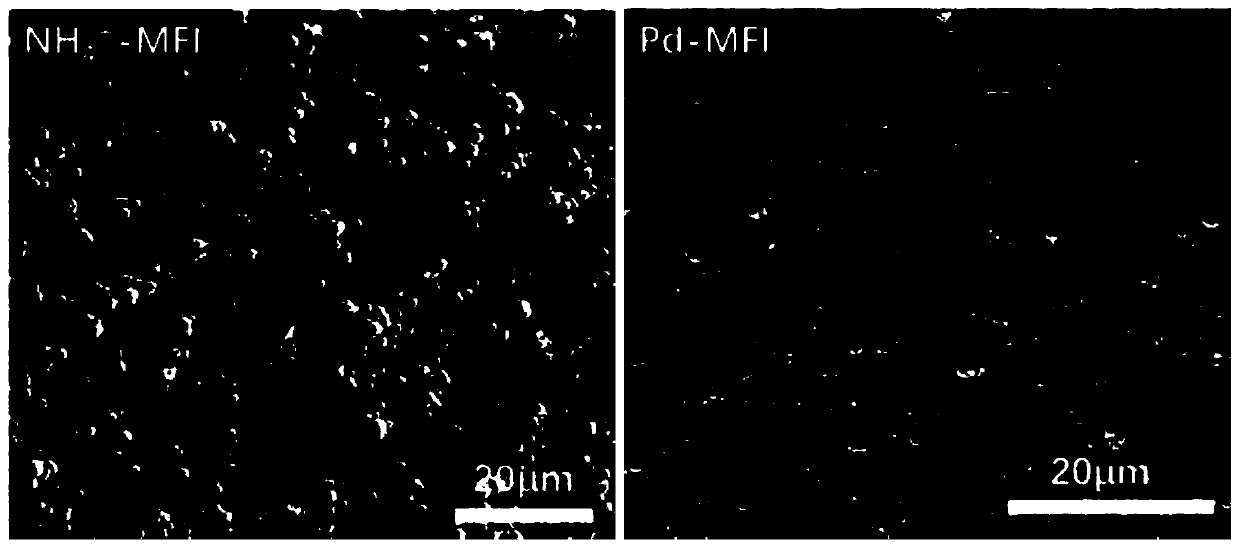

Pd-based NOX adsorbent and preparation method and application thereof

PendingCN110975800AHigh hydrothermal stabilityAdd exchange sitesGas treatmentOther chemical processesIon exchangeMolecular sieve

The invention discloses a preparation method of a Pd-based NOX adsorbent. The preparation method comprises the following steps: S1, performing ammonium ion exchange on a zeolite molecular sieve to obtain an ammonium type molecular sieve; S2, performing palladium ion exchange on the ammonium type molecular sieve to obtain a first precursor; S3, dropwise adding an aqueous solution containing palladium ions into the first precursor, uniformly mixing, standing for dipping and drying to obtain a second precursor; and S4, roasting the second precursor and performing hydrothermal activation to obtainthe Pd-based NOX adsorbent. The invention also discloses the Pd-based NOX adsorbent which is prepared according to the preparation method of the Pd-based NOX adsorbent. The invention also discloses an application of the Pd-based NOX adsorbent in adsorption of automobile exhaust. The Pd-based NOX adsorbent prepared has the functions of efficiently and quickly adsorbing and storing NOX at low temperature and thermally desorbing NOX at high temperature and can realize harmless treatment of NOX in a cold start stage of a diesel engine.

Owner:安徽纳蓝环保科技有限公司

Combined denitration system and method for preheating section and tail flue of steel rolling heating furnace

PendingCN112546861AReduce dosageSolve the problem of excessive emissionsGas treatmentDispersed particle separationAir preheaterTemperature control

The invention discloses a combined denitration system for a preheating section and a tail flue of a steel rolling heating furnace. The combined denitration system comprises a heating furnace, a steelpusher, a spraying device, a high-temperature air preheater, an SCR reactor, a low-temperature air preheater, an SCR mixer, an SNCR mixer, an exhaust hood, an air compressor, a dilution fan and a reducing agent storage device. The reducing agent storage device is connected with the SCR reactor through a second reducing agent pipeline via the SCR mixer; the air compressor is connected with the spraying device through an air pipeline via the SNCR mixer; the dilution fan is connected with the SCR mixer and the SCR reactor through a dilution pipeline; and a temperature control bypass flue is arranged between the inlet and the outlet of the high-temperature air preheater. According to the combined denitration process combining SNCR primary denitration arranged at the preheating section of the heating furnace and SCR secondary denitration arranged at the tail flue, the use amount of a reducing agent is controlled through an SCR regulating valve and an SNCR regulating valve, the use amount ofa catalyst is greatly reduced, the problem that NOx emission exceeds the standard in the roller changing period of the heating furnace can be effectively solved, and the investment and operation costof the system are reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

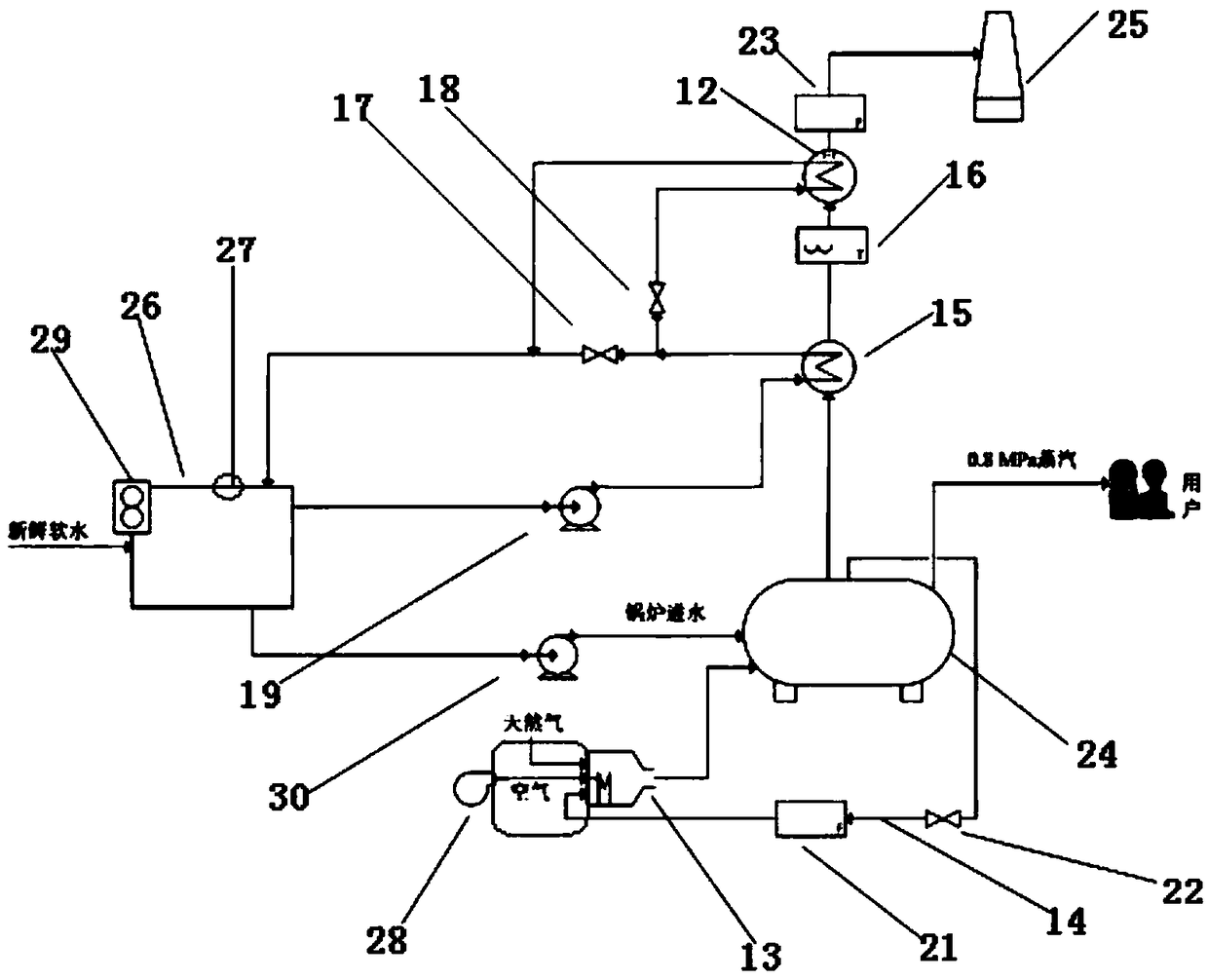

Nitrogen oxide ultralow emission system, emission energy saving device and flue gas waste heat recoverer

PendingCN108758678AEasy to installEasy to operate and maintainCombustion technology mitigationFeed-water heatersAutomatic controlCombustor

The invention relates to the field of energy protection, in particular to a nitrogen oxide ultralow emission system. an emission energy saving device and a flue gas waste heat recoverer. According tothe system, the device and the recoverer, the flue gas is treated by combining the flue gas waste heat recoverer and a low-nitrogen combustor, so that the mode is a reasonable and effective mode, thesmoke is promoted to be discharged cleanly, moreover, most of waste heat is recycled, and the energy-saving effect is achieved while the environment is protected. Besides, an automatic control systemis equipped, so that the monitoring can be realized at any time, the parameters which can be flexibly adjusted is facilitated, and the efficiency can be improved.

Owner:陕西大秦环境科技有限公司

A horizontal chain grate heat medium furnace coupled with side wall grading air and flue gas recirculation

ActiveCN104792007BSolve the problem of excessive emissionsStorage heatersAir preheaterCombustion chamber

The invention discloses a horizontal chain grate heat medium furnace coupled with side wall grading air and flue gas recirculation. The horizontal chain grate heat medium furnace is composed of a scraper coal feeder, a combustion chamber, a chain grate, a horizontal furnace body and a tail flue. The invention relies on: while arranging the graded air on the two side walls of the horizontal chain grate heat medium furnace, the primary air is fed in sections under the grate to construct the graded combustion conditions in the furnace; from the tail flue between the waste heat boiler The flue gas is extracted from the position between the air preheater and sent to several primary air chambers at the front of the chain grate, which is used to organize the recirculation of the flue gas. As a result, on the one hand, the residence time of coal particles in the furnace away from the stoichiometric combustion state is prolonged; on the other hand, the oxygen concentration in the coal seam combustion zone is diluted, the combustion temperature is reduced, and the combustion intensity is weakened, thereby delaying the combustion process. Finally, low NOx combustion is realized in the coal-fired horizontal chain grate heat medium furnace.

Owner:江苏宇澄环境工程设备有限公司

A kind of optimal control method for furnace desulfurization of circulating fluidized bed

InactiveCN104615114BAvoid hysteresisSolve the problem of excessive emissionsTotal factory controlProgramme total factory controlFluidized bedControl system

The invention belongs to the technical field of circulating fluidized bed boilers and discloses a furnace desulphurization optimization control method for a circulating fluidized bed. An optimization control system of the furnace desulphurization optimization control method comprises a data communication subsystem, a sulfur content online correction subsystem, a sulfur dioxide prediction subsystem and a limestone control subsystem; data interaction is performed on the data communication subsystem and OPC server communication software of a DCS system; the sulfur content online correction subsystem is connected with the data communication subsystem; the sulfur dioxide prediction subsystem is connected with the sulfur content online correction subsystem and the data communication subsystem; the limestone control subsystem is connected with the sulfur dioxide prediction subsystem and the data communication subsystem. According to the furnace desulphurization optimization control method for the circulating fluidized bed, a sulfur dioxide prediction model and a coal sulfur content self-adaptive correction method are established and accordingly the feeding amount of the limestone can be timely and dynamically adjusted, the excess emissions of the sulfur dioxide and the excessive use of the limestone and other resources are avoided, and the practical value in engineering is high.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Tail gas processing method in biodiesel processing process

ActiveCN102553397ASimple processing methodSolve the problem of excessive emissionsDispersed particle separationIncinerator apparatusAlcohol contentBiodiesel

The invention provides a tail gas processing method in a biodiesel processing process. The tail gas contains C1-C8 low-carbon alcohol and C1-C8 dialkyl ether. According to the invention, the tails gas contacts water, such that a liquid-phase product containing the C1-C8 low-carbon alcohol and at least partially the C1-C8 dialkyl ether is obtained; tail gas discharged after contacting the water is collected; liquid in the tail gas discharged after contacting the water is removed, and the liquid-removed gas is burned; with a condition for the tail gas to contact the water, the C1-C8 low-carbon alcohol content in the obtained liquid-phase product is at least 1% by weight. When the tails gas produced during a biodiesel processing process is processed by using the processing method provided by the invention, low-carbon alcohol in the tail gas can be effectively recovered, the influence of the burning product to the environment is small, a problem of excessive tail gas discharging in the biodiesel processing process can be effectively solved, and the processing cost is low.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Tail gas processing method in biodiesel processing process

ActiveCN102553397BSimple processing methodSolve the problem of excessive emissionsDispersed particle separationIncinerator apparatusAlcohol contentBiodiesel

The invention provides a tail gas processing method in a biodiesel processing process. The tail gas contains C1-C8 low-carbon alcohol and C1-C8 dialkyl ether. According to the invention, the tails gas contacts water, such that a liquid-phase product containing the C1-C8 low-carbon alcohol and at least partially the C1-C8 dialkyl ether is obtained; tail gas discharged after contacting the water is collected; liquid in the tail gas discharged after contacting the water is removed, and the liquid-removed gas is burned; with a condition for the tail gas to contact the water, the C1-C8 low-carbon alcohol content in the obtained liquid-phase product is at least 1% by weight. When the tails gas produced during a biodiesel processing process is processed by using the processing method provided by the invention, low-carbon alcohol in the tail gas can be effectively recovered, the influence of the burning product to the environment is small, a problem of excessive tail gas discharging in the biodiesel processing process can be effectively solved, and the processing cost is low.

Owner:CHINA NAT OFFSHORE OIL CORP +2

An Optimal Control Method for Flue Gas Circulating Fluidized Bed Desulfurization

InactiveCN105116855BAvoid hysteresisSolve the problem of excessive emissionsTotal factory controlProgramme total factory controlData controlFlue gas

The invention discloses an optimization control method for flue gas circulating fluidized bed desulfurization, which belongs to the technical field of desulfurization of thermal power units. The DCS system is respectively connected to the flue gas circulating fluidized bed and a PLC-based sulfur dioxide optimization control system. The system consists of a sulfur dioxide prediction module and a carbon dioxide calculation module respectively connected to the data communication module and the slaked lime control module, and the slaked lime control module is connected to the data communication module; the data communication module and the DCS system exchange data with each other. The present invention can adjust the feeding amount of slaked lime in a timely, dynamic and accurate manner through the SO2 prediction model and the calculation of the CO2 amount of the flue gas at the inlet of the desulfurization tower, and fundamentally avoids the excessive discharge of SO2 and the waste of resources such as slaked lime, etc. It reduces CO2 emissions to a certain extent, and has high reference significance in engineering.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Impeller device and coal mill

PendingCN112317115AThrough smooth and evenReduce leakageGrain treatmentsImpellerStructural engineering

The invention provides an impeller device and a coal mill, and relates to the technical field of coal milling equipment. The impeller device is arranged in a side machine body device of the coal mill,and the coal mill comprises a milling bowl device with a milling bowl. The impeller device comprises an impeller mechanism, the impeller mechanism comprises an inner ring, an outer ring arranged around the inner ring, and a plurality of flow guide plates arranged in a flow guide gap between the inner ring and the outer ring and used for connecting the inner ring and the outer ring, the flow guidegap is divided into a plurality of flow guide cavities by the flow guide plates, flow guide openings for air outlet are formed in the upper portions of the flow guide cavities, and the flow guide openings are as high as the milling bowl. The impeller device further comprises a guide mechanism arranged above the impeller mechanism and an adjusting cover arranged on the guide mechanism, and the adjusting cover can move up and down relative to the impeller mechanism so as to adjust a gap between the adjusting cover and the impeller mechanism. The coal mill comprises the side machine body device,a separator device, a milling bowl device, a milling roller device and the impeller device.

Owner:XIAMEN JINBANGDA IND

Low-load denitration system of circulating fluidized bed boiler

PendingCN112403251ASolve the problem of excessive emissionsNo environmental accidentsGas treatmentEmission preventionNitrogen oxidesBoiler furnace

The invention discloses a low-load denitration system of a circulating fluidized bed boiler, and the system comprises a urea spray gun, a urea solution component, a compressed air component and a flushing water component which are additionally arranged at each secondary air port of a boiler hearth, wherein the urea solution component comprises a urea solution main pipe connected with the urea spray gun; the urea solution main pipe is provided with a stokehole denitration system main pipe manual door and a urea solution to spray gun manual door, the compressed air assembly comprises a compressed air main pipe connected with a urea spray gun, the compressed air main pipe is provided with a compressed air to spray gun manual door, and the flushing water assembly comprises a flushing water pipeline. By arranging the urea spray gun, the urea solution assembly, the compressed air assembly and the flushing water assembly, the problem that nitrogen oxide emission of the low-load circulating fluidized bed boiler exceeds the standard can be solved, the denitration efficiency is improved, the nitrogen oxide emission of the circulating fluidized bed boiler is reduced, and it is guaranteed thatenvironmental protection accidents do not happen to a power plant.

Owner:江苏徐矿综合利用发电有限公司

Method and apparatus for cement rotary kiln flue gas denitration and desulfurization

ActiveCN102974207BCost-effectiveSolve the problem of excessive emissionsDispersed particle separationAutomatic controlThermodynamics

The present invention discloses a denitration sulphur-fixing agent used for cement rotary kiln flue gas denitration and desulfurization, and a method and an apparatus for cement rotary kiln flue gas denitration and desulfurization using the agent. The denitration sulphur-fixing agent includes a reducing agent with a mass percent concentration of15-25% and a sulphur-fixing agent with a mass percent concentration of 30-55%. The apparatus includes a denitration sulphur-fixing agent preparation system, a denitration sulphur-fixing agent storage system, a denitration sulphur-fixing agent injection system and an automatic control system, wherein the denitration sulphur-fixing agent preparation system, the denitration sulphur-fixing agent storage system and the denitration sulphur-fixing agent injection system are successively connected; and the automatic control system is respectively connected with the denitration sulphur-fixing agent preparation system and the injection system. The unique denitration sulphur-fixing agent provided by the present invention is injected into the nozzle of the cement rotary kiln in two routes. Compared with the conventional technologies of SCR denitration and wet desulfurization, the original production process is unchanged, the method and the apparatus have the characteristics of simple manipulation and economy and high-efficiency.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com