Optimal control method for flue gas circulating fluidized bed desulphurization

A technology of optimized control and flue gas circulation, applied in electrical program control, program control, comprehensive factory control, etc., can solve the problems of large delay of output signal of gas analyzer, increase of Ca/S molar ratio, large consumption of slaked lime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention proposes an optimal control method for flue gas circulating fluidized bed desulfurization. The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

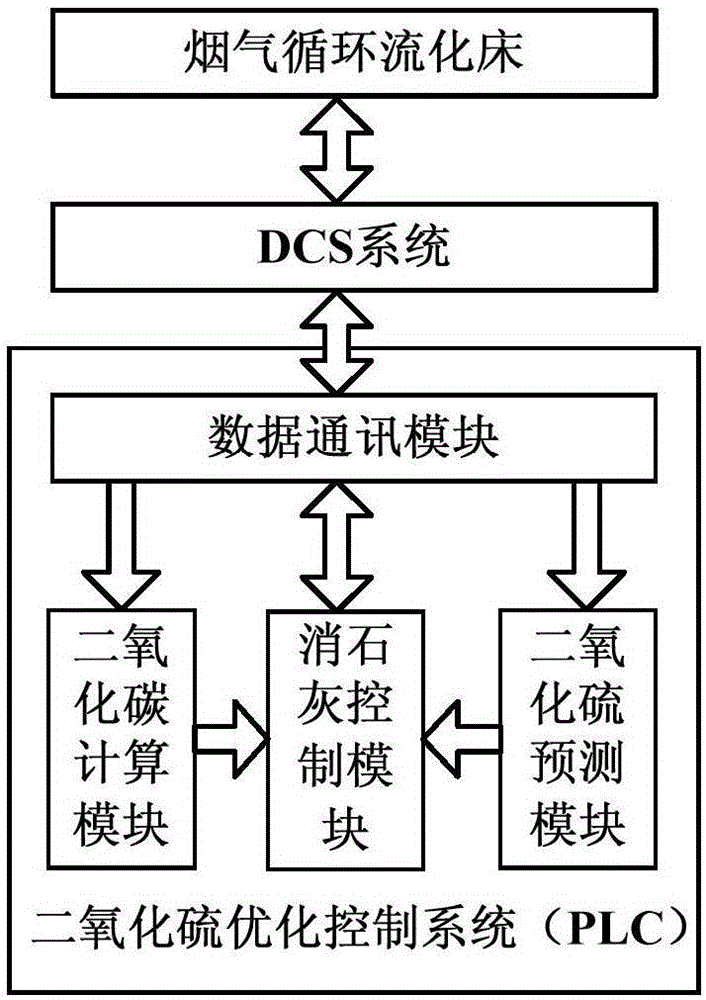

[0042] figure 1 It is a schematic diagram of an optimal control method for flue gas circulating fluidized bed desulfurization. The DCS system is respectively connected to the flue gas circulating fluidized bed and the sulfur dioxide optimization control system based on PLC. The optimization system includes: data communication module, sulfur dioxide prediction module, carbon dioxide calculation module and slaked lime control module. Among them, the data communication module exchanges data with the DCS system, the sulfur dioxide prediction module and the carbon dioxide calculation module are respectively connected to the data communication module and the slaked lime control module, and the slaked lime control module is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com