Preparation method of NOx adsorbing material with HC catalytic oxidation function

An adsorption material and catalytic oxidation technology, which is applied to chemical instruments and methods, separation methods, molecular sieve catalysts, etc., can solve the problems of high temperature requirements, failure to meet temperature requirements, and inability to meet nitrogen oxide emission reduction requirements. Cost, improvement of adsorption capacity, effect of low temperature, efficient and fast adsorption storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

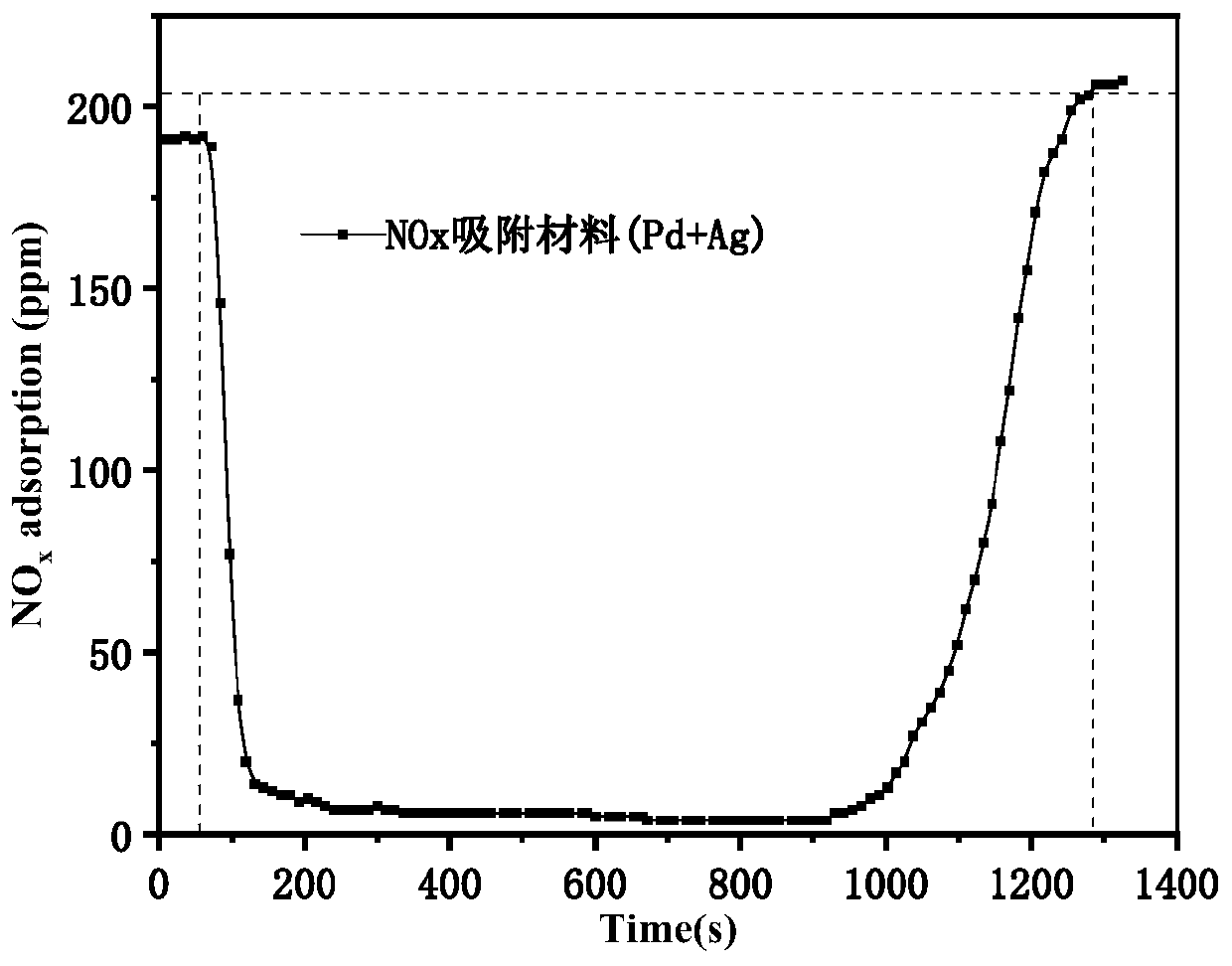

[0033] A kind of preparation method that the present invention proposes has the NOx adsorption material of HC catalytic oxidation function, comprises the following steps:

[0034] S1. Molecular sieve pretreatment: roasting the zeolite molecular sieve at constant temperature, cooling, adding ammonium salt solution, stirring, washing, and drying to obtain ammonium-type zeolite molecular sieve;

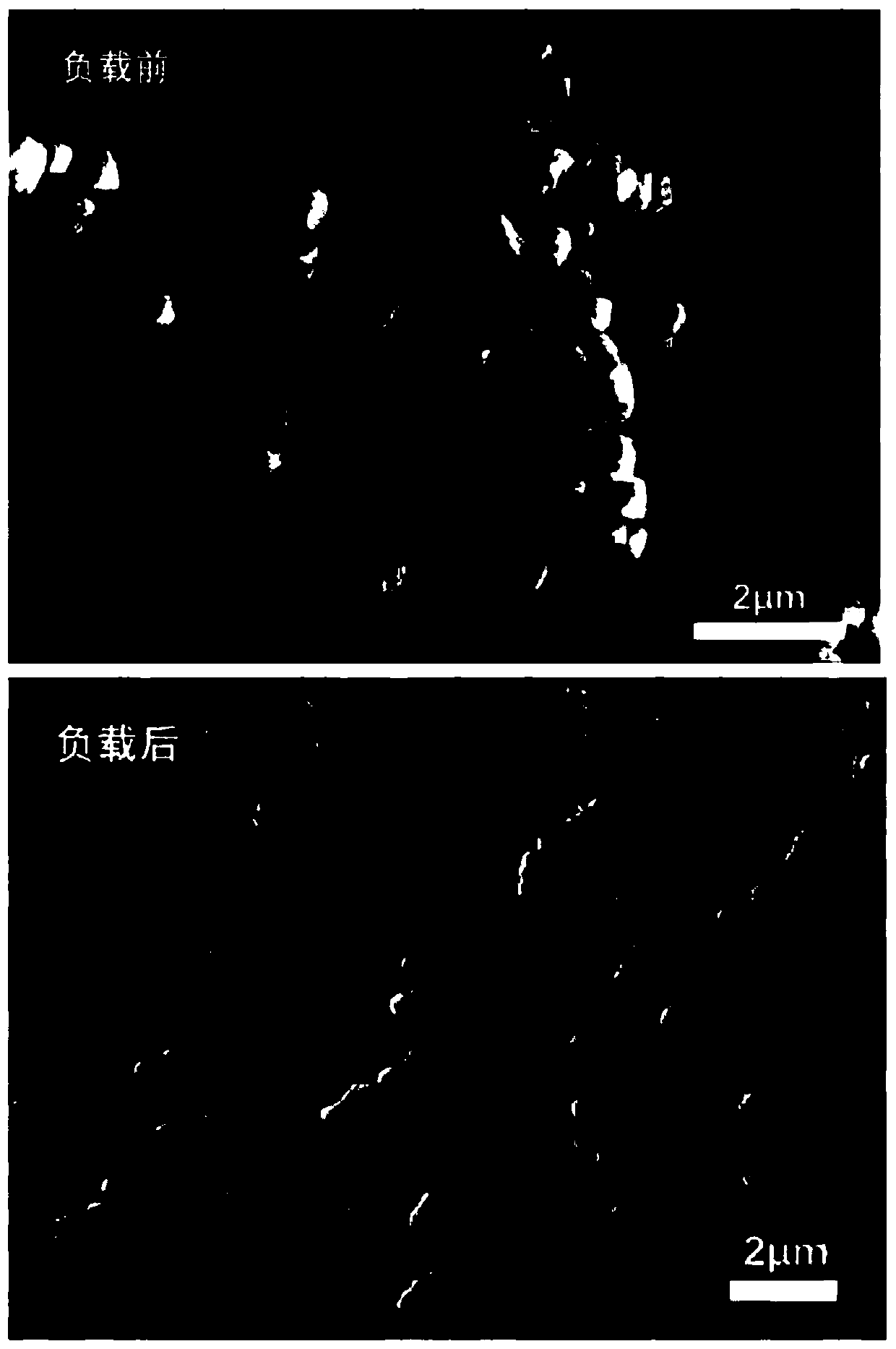

[0035] S2, load precious metal: silver nitrate solution, palladium nitrate solution and distilled water are mixed, stir, then join in the ammonium type zeolite molecular sieve, stir, leave standstill, dry, obtain NOx adsorbent precursor;

[0036] S3. Roasting: roasting the NOx adsorbent precursor at a constant temperature to obtain a fresh NOx adsorbent;

[0037] S4. Hydrothermal aging: the fresh state NOx adsorbent undergoes hydrothermal aging treatment to obtain NOx adsorbent material with HC catalytic oxidation function.

Embodiment 2

[0039] A kind of preparation method that the present invention proposes has the NOx adsorption material of HC catalytic oxidation function, comprises the following steps:

[0040] S1. Molecular sieve pretreatment: Introduce air at a flow rate of 60ml / min, roast the Na-type zeolite molecular sieve at 530°C for 13h at a constant temperature, cool, add ammonium nitrate solution with a concentration of 0.5mol / L, stir in a water bath at 75°C for 21h, pump filter, then wash with distilled water, and then dry at 85°C to obtain an ammonium-type zeolite molecular sieve; wherein, the zeolite molecular sieve has a CHA-type framework structure, and the Si / Al molar ratio in the zeolite molecular sieve is 14;

[0041] S2. Mix silver nitrate solution, palladium nitrate solution and distilled water, stir, then dropwise add to ammonium-type zeolite molecular sieve, stir while adding dropwise, let stand at room temperature for 18h, and then dry at 115°C for 22h to obtain NOx adsorbent precursor ...

Embodiment 3

[0045] A kind of preparation method that the present invention proposes has the NOx adsorption material of HC catalytic oxidation function, comprises the following steps:

[0046]S1. Molecular sieve pretreatment: Introduce air at a flow rate of 70ml / min, roast the Na-type zeolite molecular sieve at a constant temperature of 550°C for 12h, cool, add ammonium nitrate solution with a concentration of 2.0mol / L, stir in a water bath at 80°C for 20h, pump filter, then wash with distilled water, and then dry at 80°C to obtain an ammonium-type zeolite molecular sieve; wherein, the zeolite molecular sieve has a CHA-type framework structure, and the Si / Al molar ratio in the zeolite molecular sieve is 14.5;

[0047] S2. Mix silver nitrate solution, palladium nitrate solution and distilled water, stir, then dropwise add to ammonium-type zeolite molecular sieve, stir while adding dropwise, let stand at room temperature for 20h, and then dry at 105°C for 24h to obtain NOx adsorbent precursor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com