Chlorine-containing waste gas absorption system

An absorption system and exhaust gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of health, plant growth hazards, and greater impact on air quality, so as to solve the problem of excessive emission of exhaust gas and improve quality , to ensure the effect of emission standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

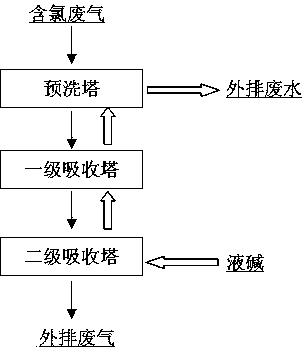

[0012] like figure 1 As shown, the chlorine-containing exhaust gas absorption system of the present invention includes a pre-washing tower, a primary tower and a secondary tower connected in series, and an alkali-adding pump connected with the secondary tower, and the pre-washing tower, the primary tower and the secondary tower Connected in sequence, the system also includes a control device, and the action of adding liquid caustic soda and draining liquid of the chlorine-containing waste gas absorption system is controlled by the control device.

[0013] Before use, pre-set the pH standard value of the absorption solution, generally 10-12. The alkali adding pump is controlled by the control device to add liquid alkali to the secondary tower. When the control device detects that the pH value of the first-stage tower absorption liquid is lower than the standard value, the first-stage tower absorption liquid is automatically discharged to the pre-washing tower, and the second-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com