Pd-based NOX adsorbent and preparation method and application thereof

An adsorbent and palladium ion technology, which is applied in the field of Pd-based NOX adsorbent and its preparation, can solve the problems of solid-state ion exchange operation difficulties, low Pd ion exchange rate, unfavorable large-scale production, etc., and solve the problem of excessive NOX emissions , Improve hydrothermal stability and reduce synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A Pd-based NO X The preparation method of adsorbent, comprises the steps:

[0057] S1. Take sodium-type zeolite molecular sieve and carry out ammonium ion exchange twice to obtain ammonium-type molecular sieve, wherein, the specific steps of ammonium ion exchange are: adding sodium-type zeolite molecular sieve into NH 4 + In an aqueous solution of ammonium chloride with a concentration of 0.5 mol / L, exchange ammonium ion at 65°C for 2 hours, then filter with suction, wash with water, and dry overnight in a blast drying oven at 80°C to obtain ammonium molecular sieves;

[0058] The framework structure of sodium zeolite molecular sieve is CHA, and its silicon-aluminum ratio is 20;

[0059] Sodium-type zeolite molecular sieves were dried in a constant temperature oven at 80°C for 12 hours, then placed in a muffle furnace, and roasted at 600°C for 12 hours in an air atmosphere;

[0060] S2. Add ammonium-type molecular sieves into the aqueous solution containing palladium...

Embodiment 2

[0065] A Pd-based NO X The preparation method of adsorbent, comprises the steps:

[0066] S1. Take sodium-type zeolite molecular sieve and carry out ammonium ion exchange twice to obtain ammonium-type molecular sieve, wherein, the specific steps of ammonium ion exchange are: adding sodium-type zeolite molecular sieve into NH 4 + In an aqueous solution of ammonium chloride with a concentration of 0.4mol / L, exchange ammonium ion at 70°C for 1.5h, then filter with suction, wash with water, and dry overnight in a blast drying oven at 80°C to obtain ammonium molecular sieves;

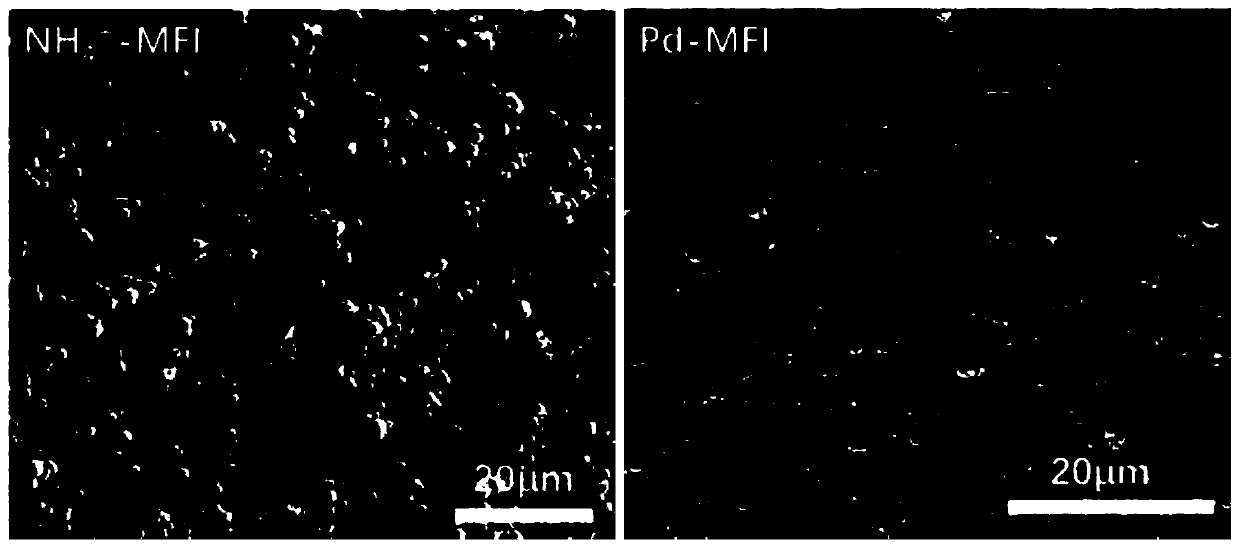

[0067] The framework structure of sodium zeolite molecular sieve is MFI, and its silicon-aluminum ratio is 50;

[0068] The sodium-type zeolite molecular sieve was dried in a constant temperature oven at 75°C for 14h, then placed in a muffle furnace, and roasted at 550°C for 14h in an air atmosphere;

[0069] S2. Add ammonium-type molecular sieves into the aqueous solution containing palladium ions and mi...

Embodiment 3

[0074] A Pd-based NO X The preparation method of adsorbent, comprises the steps:

[0075]S1. Take sodium-type zeolite molecular sieve and carry out ammonium ion exchange twice to obtain ammonium-type molecular sieve, wherein, the specific steps of ammonium ion exchange are: adding sodium-type zeolite molecular sieve into NH 4 + In an aqueous ammonium nitrate solution with a concentration of 0.6mol / L, exchange ammonium ions at 60°C for 2.5h, then filter with suction, wash with water, and dry overnight in a blast drying oven at 80°C to obtain ammonium molecular sieves;

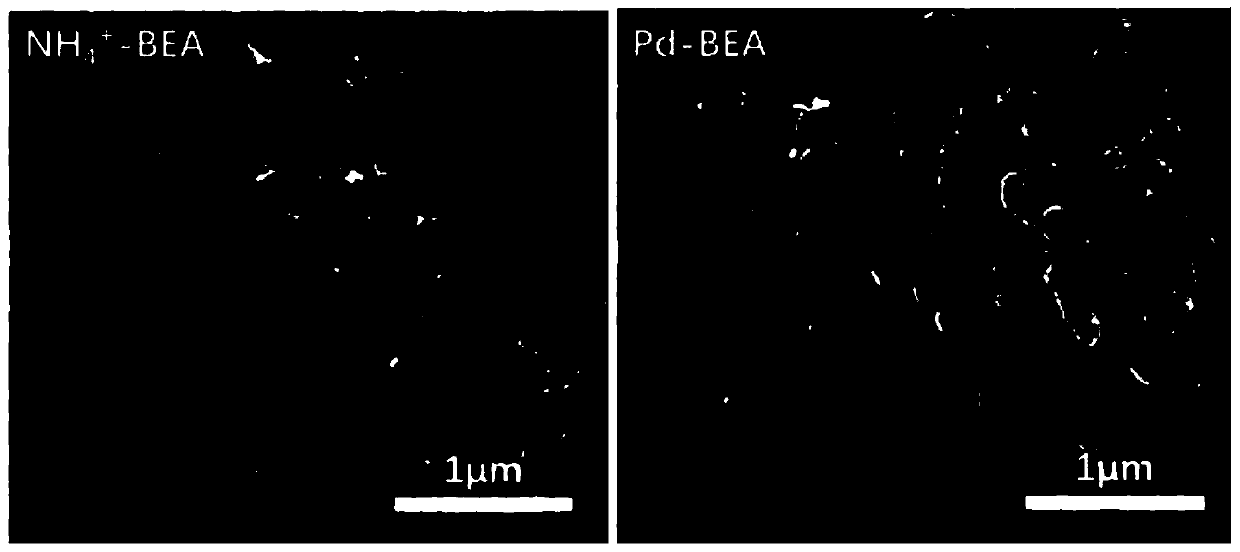

[0076] The framework structure of sodium zeolite molecular sieve is BEA, and its silicon-aluminum ratio is 10;

[0077] Sodium-type zeolite molecular sieves were dried in a constant temperature oven at 85°C for 10 hours, then placed in a muffle furnace, and calcined at 650°C for 10 hours in an air atmosphere;

[0078] S2. Add ammonium-type molecular sieves into the aqueous solution containing palladium ions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com