Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Small transmission attenuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

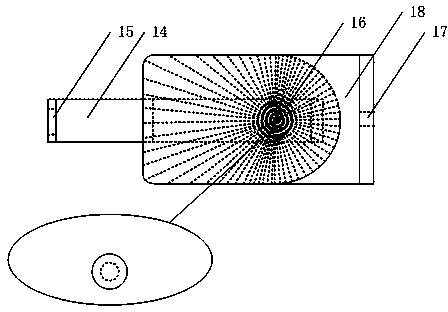

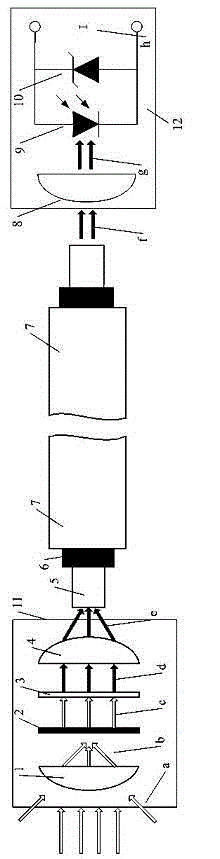

Underwater short-distance high-speed wireless optical information transparent transmission device

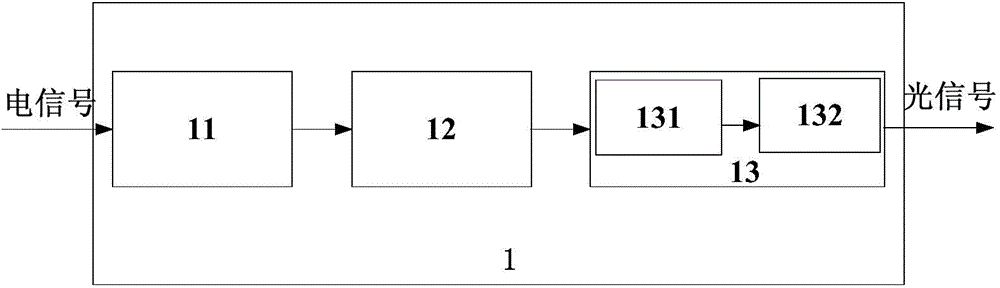

InactiveCN104038292ALow costSmall transmission attenuationElectromagnetic transmission optical aspectsPhysicsOptical path

An underwater short-distance high-speed wireless optical information transparent transmission device comprises a transmitting module and a receiving module, wherein the transmitting module sequentially comprises an LED modulation drive circuit, a blue-green mixed LED array, a transmitting light path, a beam expanding mirror and a homogenizing piece in the direction of an electrical signal to be transmitted, and the receiving module sequentially comprises a large-view-field receiving light path, a light filter, a Fresnel lens, a photoelectric detector and a photoelectric detection conditioning circuit. The underwater short-distance high-speed information transparent transmission problem can be solved, the lake, river and ocean environment application requirements are met, and the underwater short-distance high-speed wireless optical information transparent transmission device is especially suitable for connection of multiple sensors at deep position under the ocean, underwater data collection, ROV data interaction and continuous communication occasions for water surface platforms and underwater devices and has important significance in the ocean application field.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

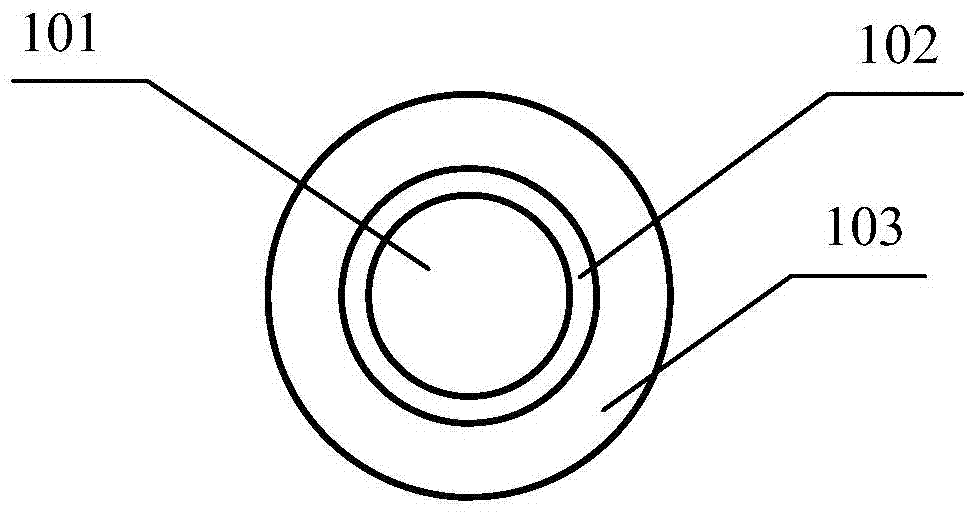

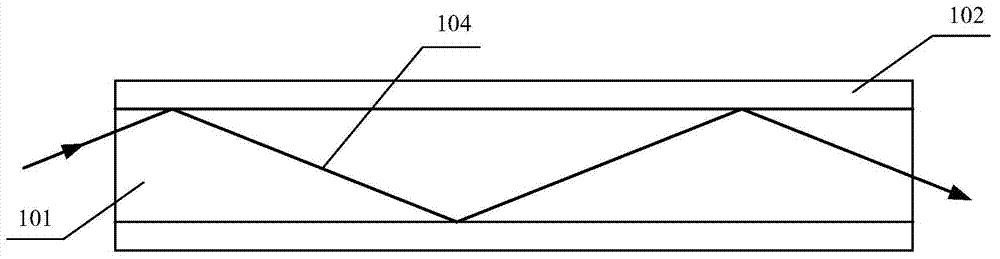

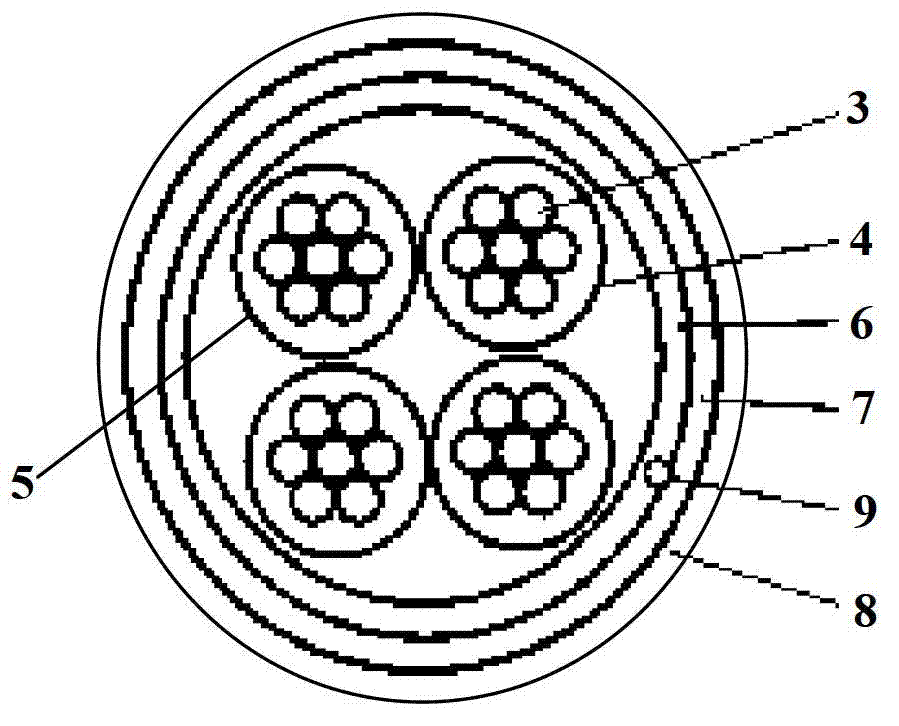

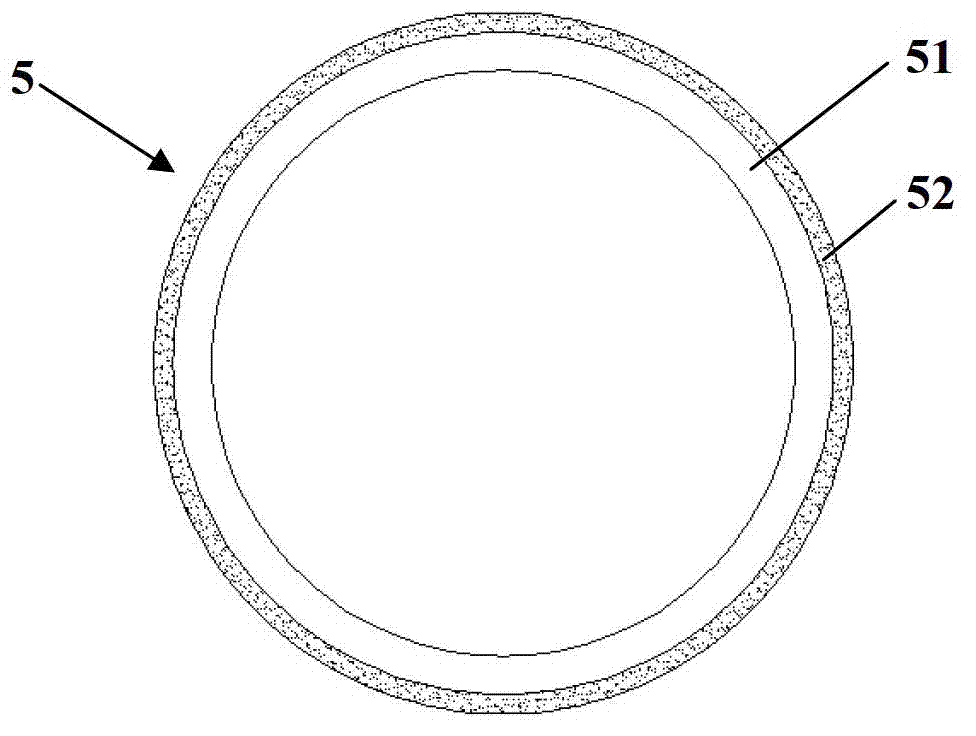

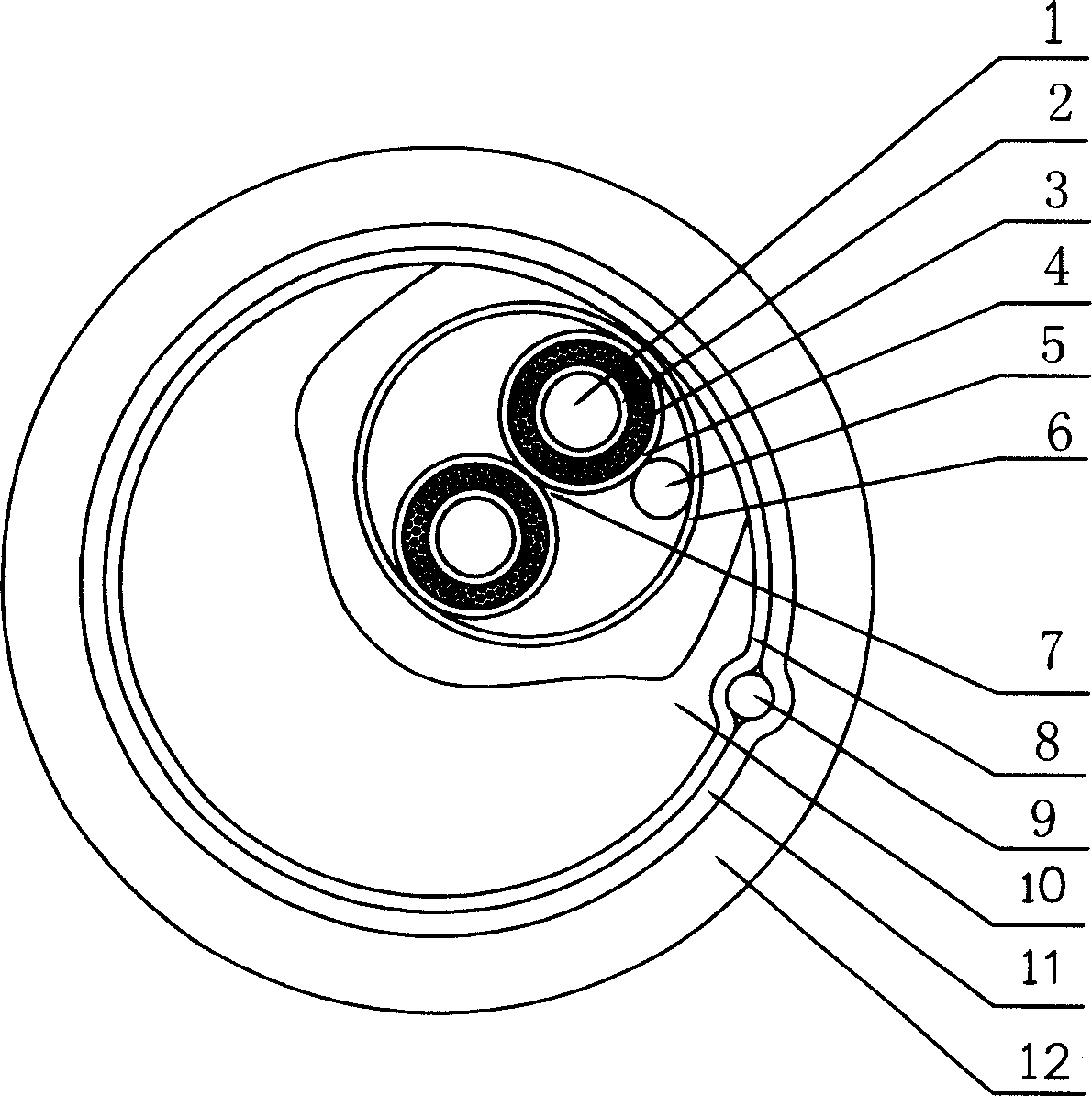

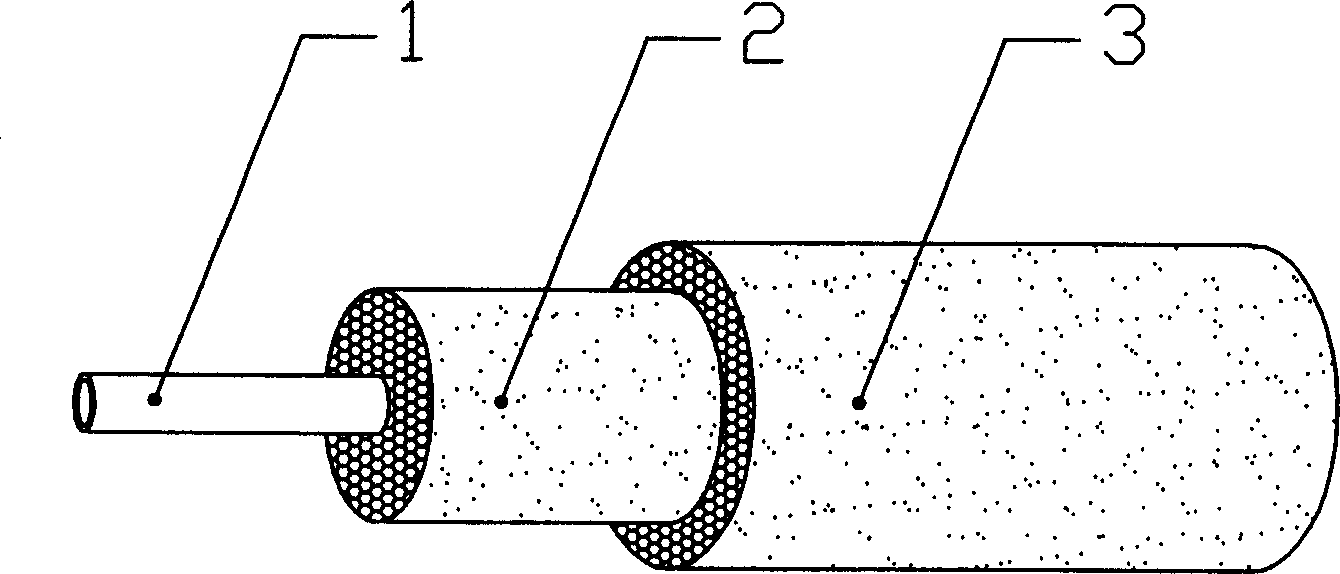

Hollow plastic optical fiber and optical cable

ActiveCN103941333ASmall transmission attenuationEnables full-spectrum light transmissionFibre mechanical structuresUltrasound attenuationFull-spectrum light

The invention discloses a hollow plastic optical fiber and an optical cable, wherein the hollow plastic optical fiber is provided with a coating layer, a transition layer and a hollow core layer; the hollow core layer is hollow; the refractive index of the transition layer is more than that of the coating layer. Through adopting the above scheme, the hollow plastic optical fiber adopts a hollow design, so that the transmission attenuation of optical signals is greatly reduced, the limitation that the plastic optical fiber only can transmit visible light is broken through, the plastic optical fiber can transmit full-spectrum light and is completely compatible with an existing optical fiber system for use; the production cost is reduced so as to be easy to industrialize; the transmission distance is much longer, the transmission rate is much higher, and the deficiencies of an existing step type plastic optical fiber are overcome; therefore, the hollow plastic optical fiber can completely substitute the existing communication-level step type plastic optical fiber but also can substitute a copper network cable, the effect and purpose of saving copper resources, saving energy and protecting environment are achieved, and very high market application value is provided.

Owner:SHEN ZHEN SINNO OPTOELECTRONICS TECH CO LTD

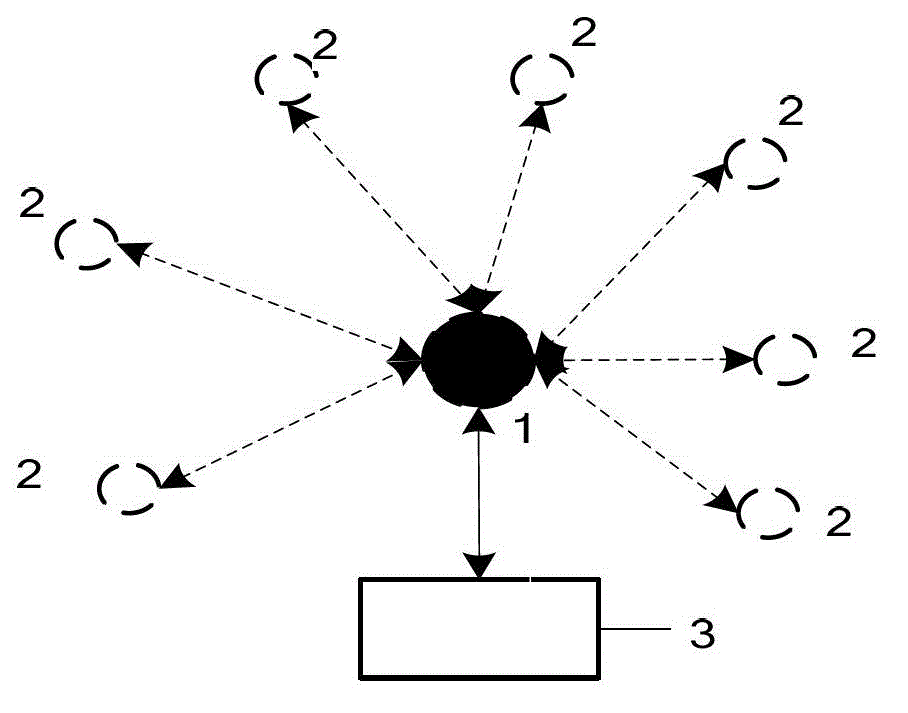

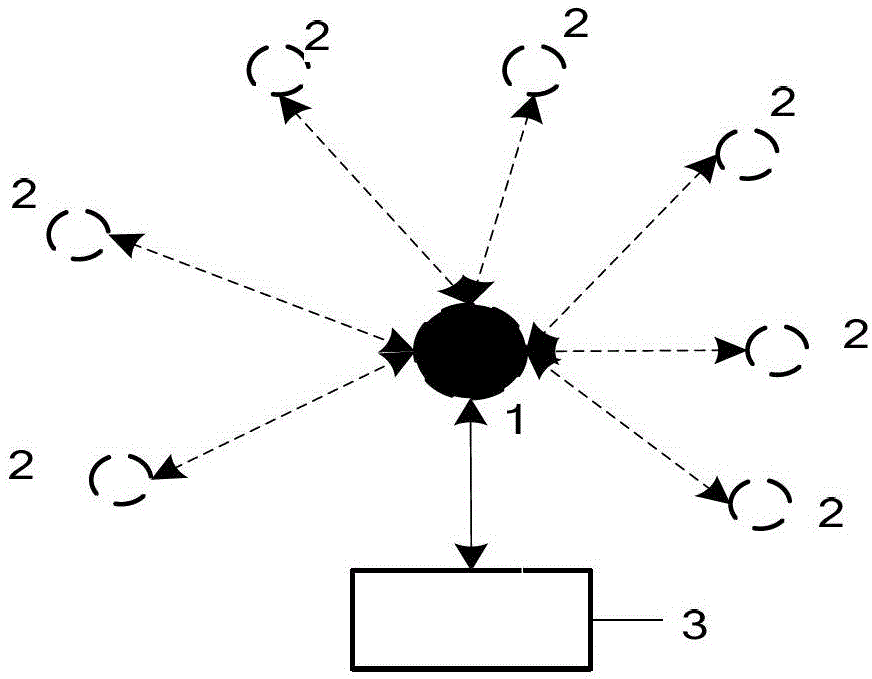

IEEE (Institute of Electrical and Electronic Engineers) 802.15.4g standard-based wireless monitoring communication protocol

InactiveCN103152752AReduce power consumptionLong transmission distancePower managementNetwork topologiesStructure of Management InformationSmart grid

The invention discloses an IEEE (Institute of Electrical and Electronic Engineers) 802.15.4g standard-based wireless monitoring communication protocol, and belongs to the technical field of embedded wireless monitoring. IEEE802.15.4g is a standard of a physical layer named SUN, which is established by Institute of Electrical and Electronic Engineers (IEEE) in recent two years, the physical layer is supplemented on the basis of an IEEE802.15.4 standard, and the IEEE802.15.4g standard is particularly suitable for battery powered infrastructure sensor networks which have ultralow power consumption, remote transmission and excellent anti-noise performance. Although IEEE802 is still standardized at present, a draft scale has been determined basically, so the set of standard is necessarily tracked and studied timely, and based on the underlying standard, a set of ultralow power consumption wireless upper-layer communication protocol applied to the field of smart grid monitoring is designed and developed. The protocol aims at a star network topological structure, working method steps for a network coordinator node and a sensor node are respectively designed, and the protocol has the characteristics of low velocity, ultralow power consumption, low complexity and the like.

Owner:SHANDONG UNIV

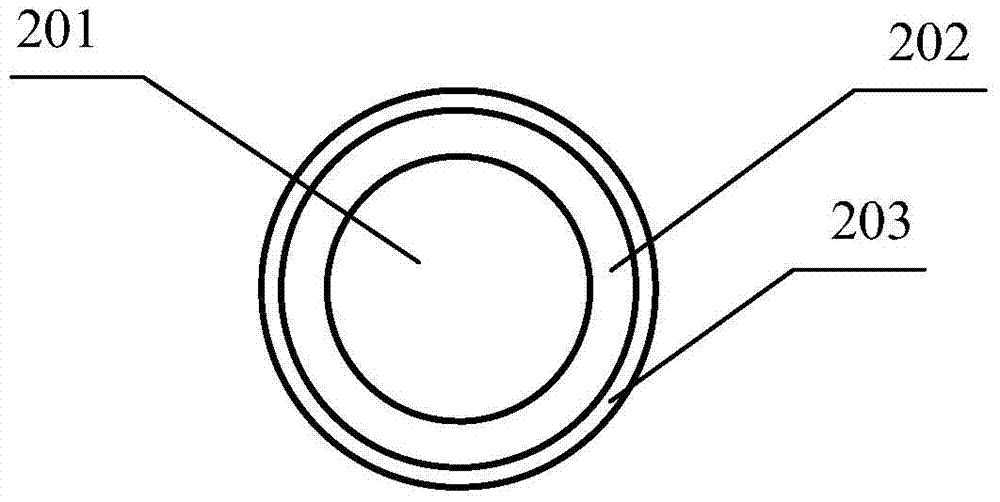

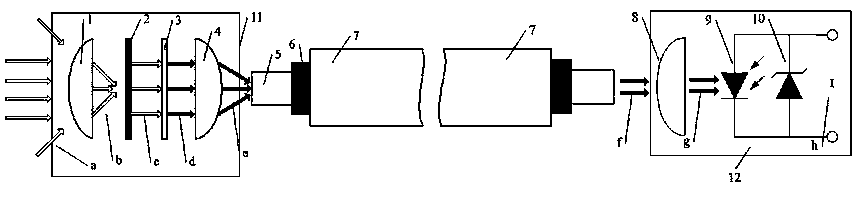

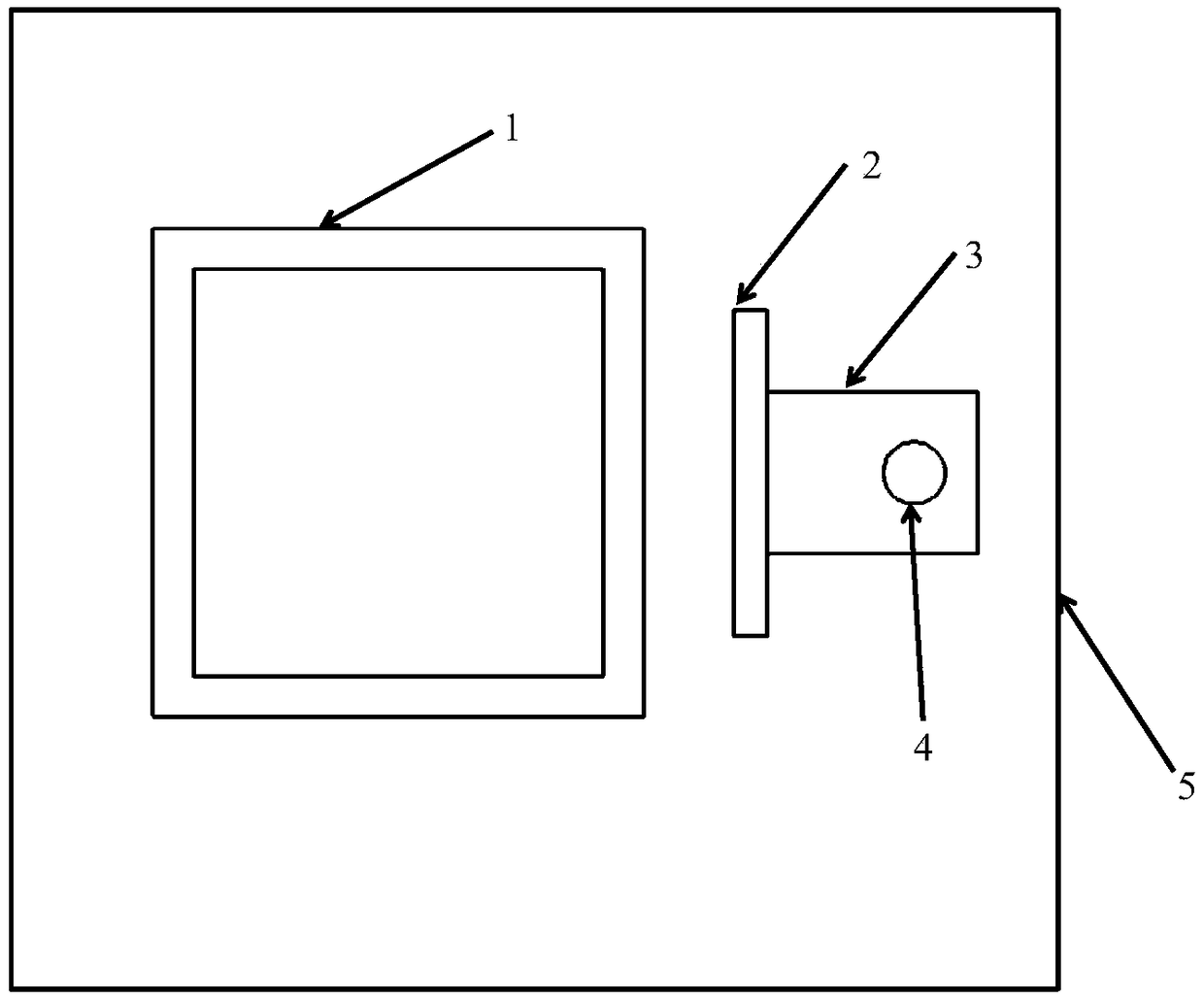

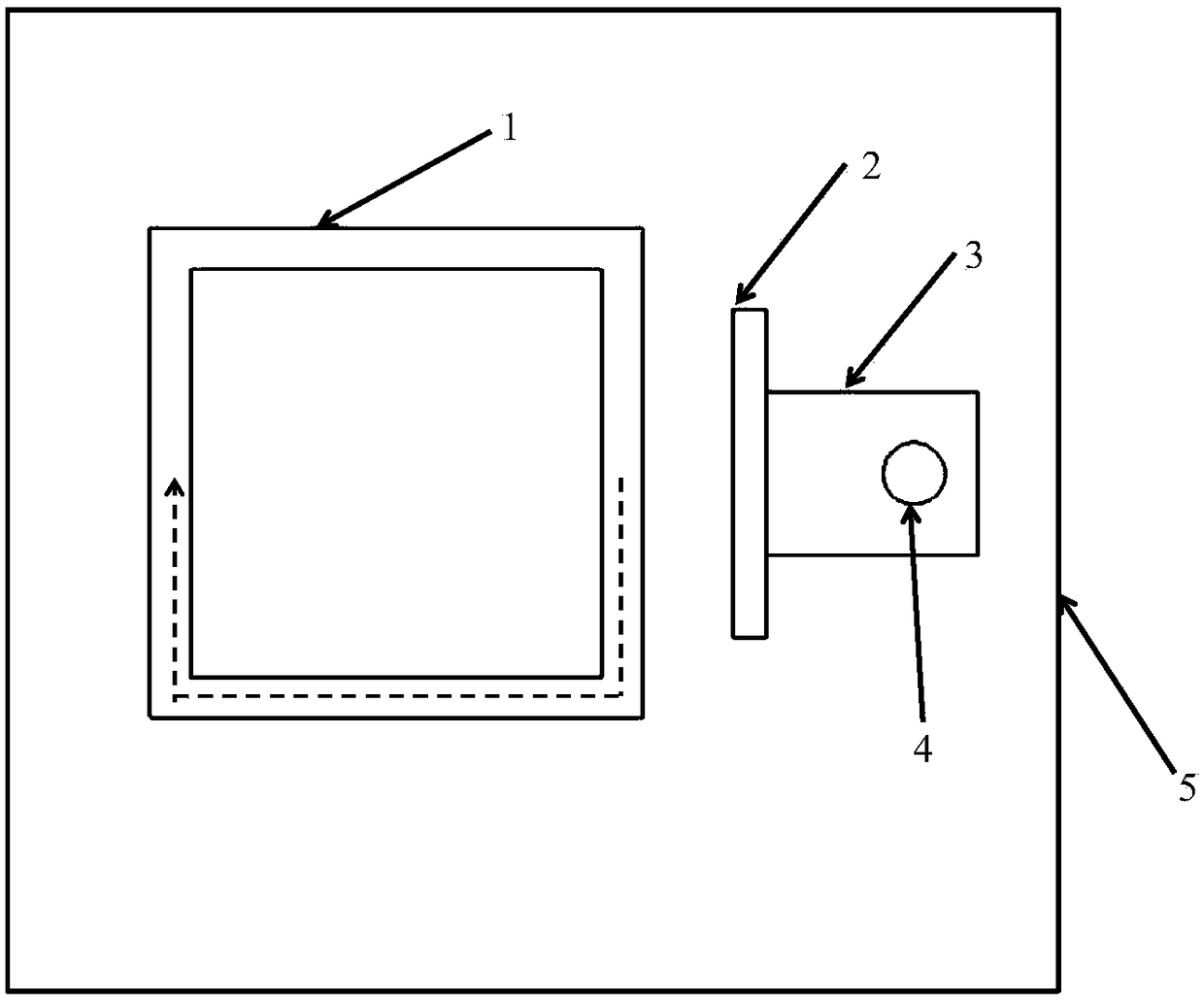

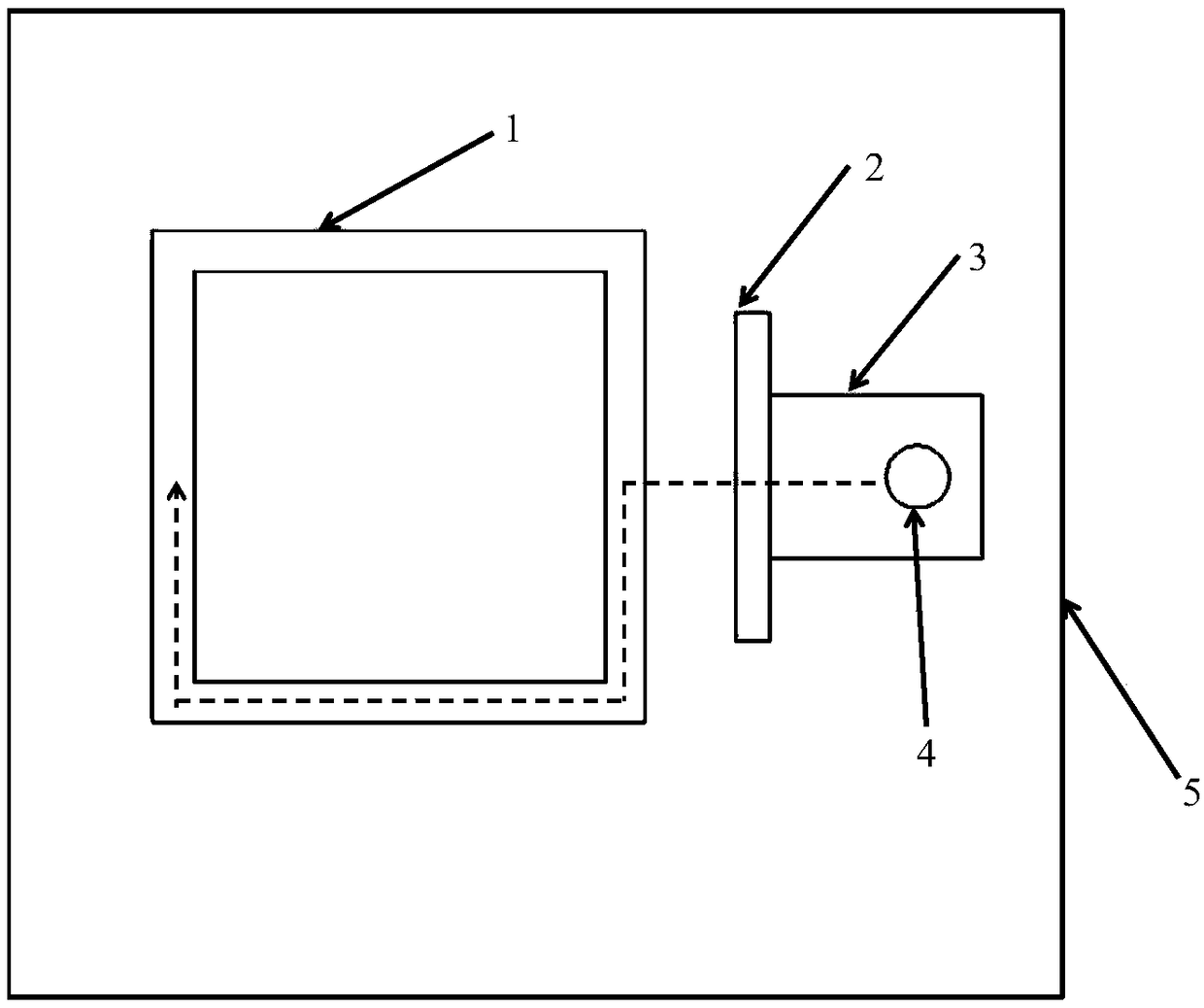

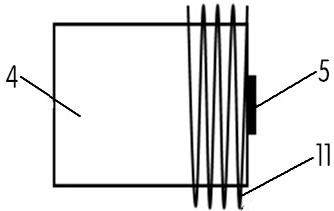

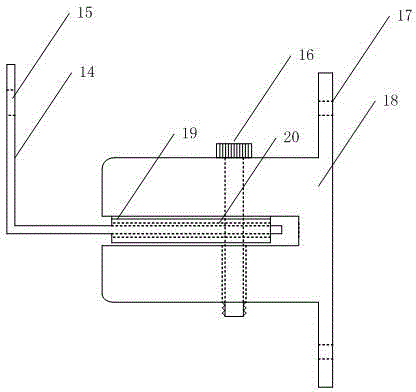

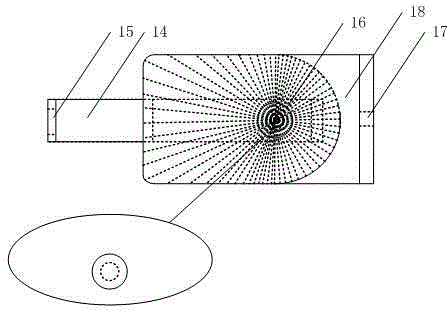

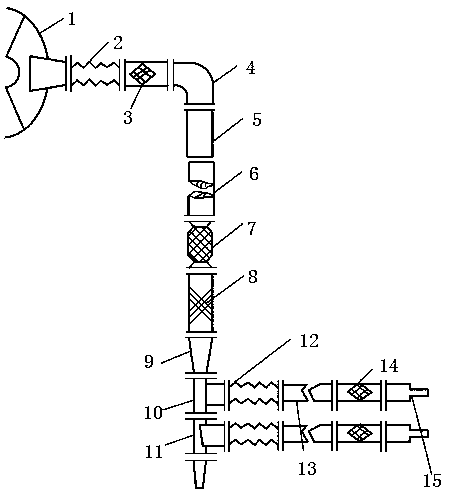

Optical sensor achieving switch cabinet flashover detection

ActiveCN103424664AA device impactEffective filteringPhotometryFault locationElectromagnetic interferenceEngineering

The invention discloses an optical sensor capable of effectively detecting produced electric arc light and converting the electric arc light into an electric signal to be output when an outgoing wire or a bus of a switch cabinet has a short-circuit fault. The optical sensor comprises a light acquisition lens, a photoelectric converter and a plastic optical fiber, wherein two ends of the plastic optical fiber are provided with ST connectors, and the plastic optical fiber is connected with the light acquisition lens and the photoelectric converter through the ST connectors. Due to the fact that the light acquisition lens is a passive device, the light acquisition lens is connected with the active photovoltaic conversion portion through the plastic optical fiber, and a primary device of the switch cabinet is not influenced. The light acquisition lens only acquires light information of specific wave bands in arc light and can effectively filter interference of other light sources. An electrical signal only existing at the photovoltaic conversion portion of the sensor, the rest is light signals, and electromagnetic interference produced during actions of the switch cabinet can be effectively avoided. By adopting anti-static design achieved by a transient diode, the device reliability is improved, and the optical sensor can adapt to various assembling and usage environments.

Owner:南京弘毅电气自动化有限公司

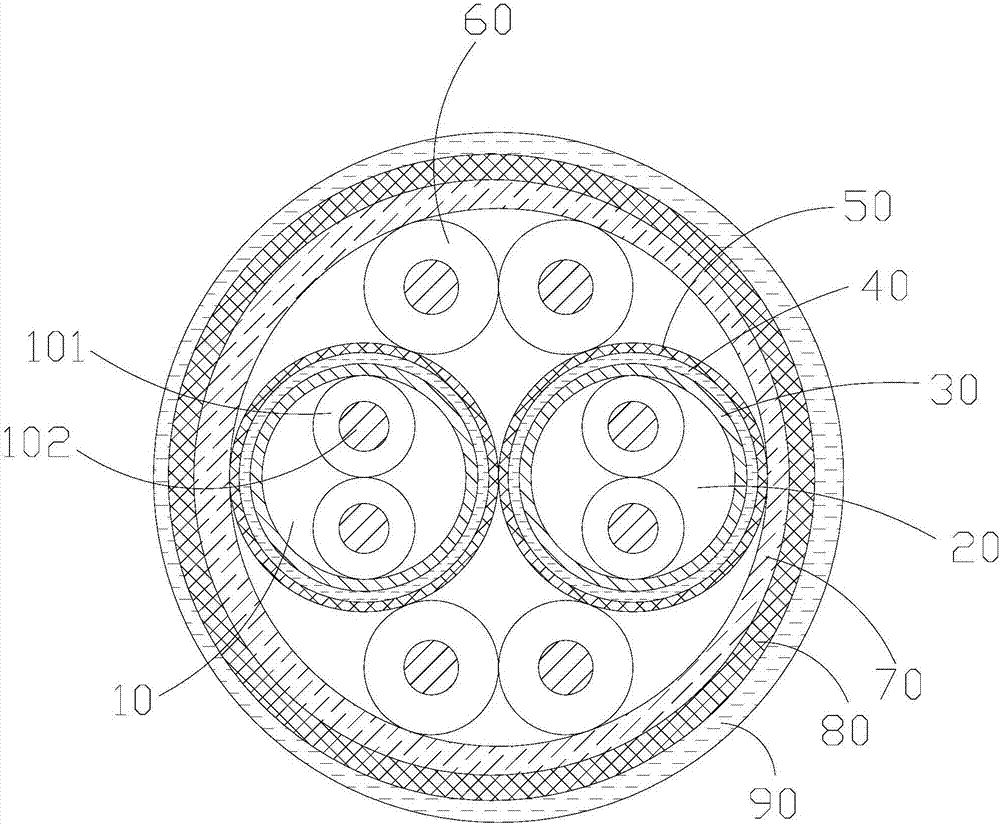

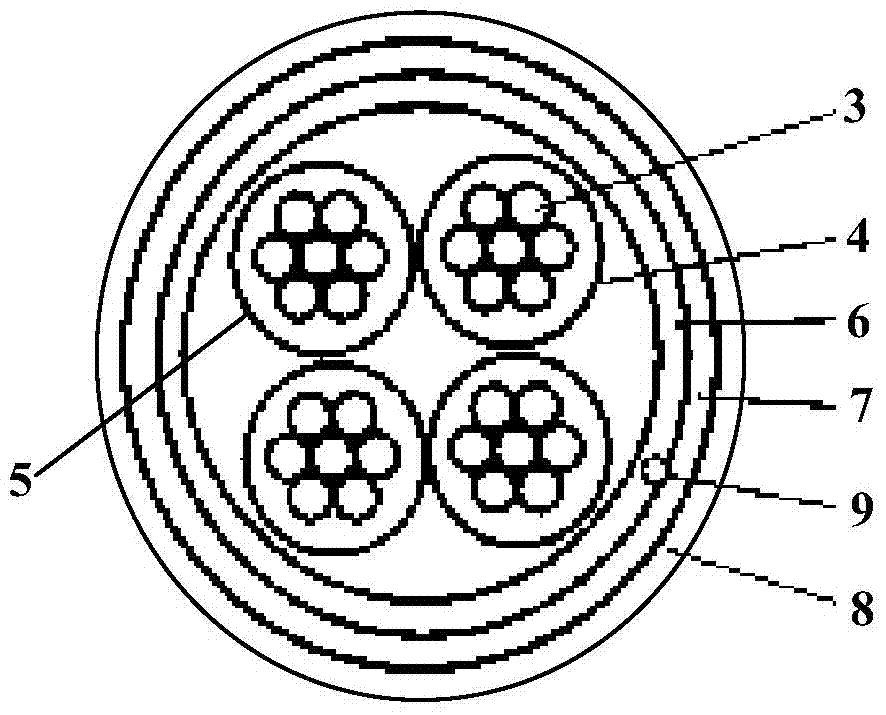

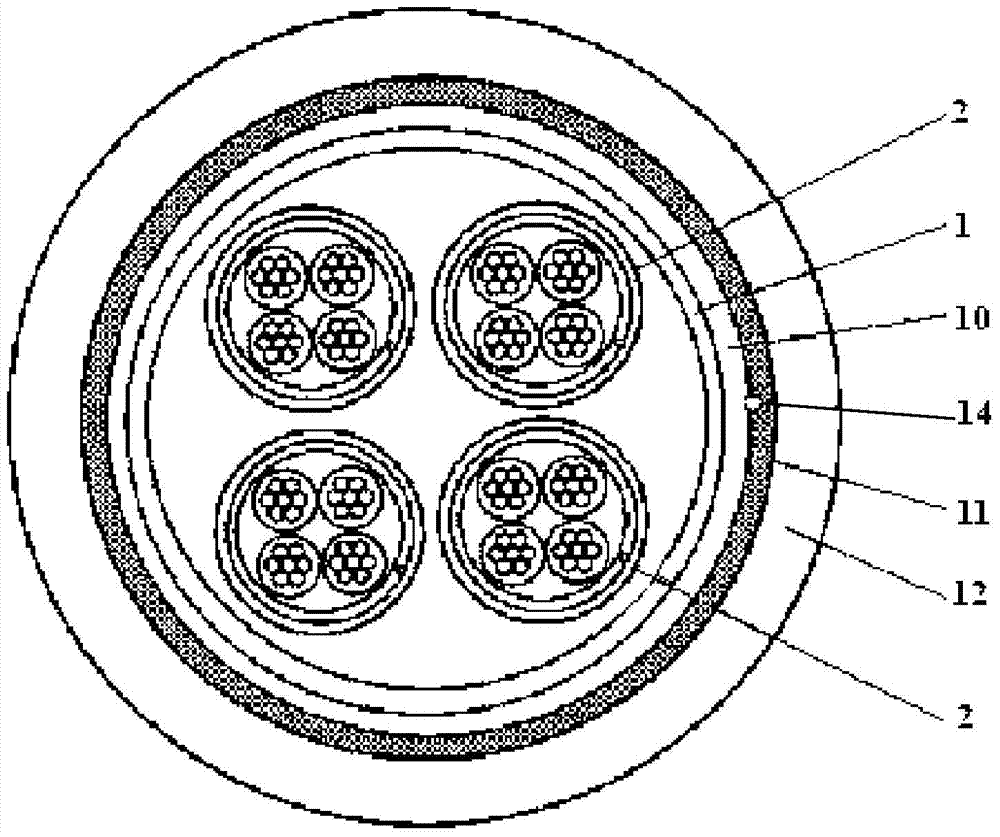

Flame retardant fire-resistant track traffic signal flexible cable

ActiveCN102768879AGuaranteed softnessImprove the ability to resist interference between groupsClimate change adaptationCommunication cablesPolyesterThermal ageing

The invention discloses a flame retardant fire-resistant track traffic signal flexible cable, which comprises at least three shielding line sets wrapped by a first polyester band, wherein each of the shielding line sets comprises at least two twisted single lines formed by twisting seven first tinned copper wires; each of the twisted single lines is provided with a single line insulation layer on the external surface; the at least two twisted single lines are wrapped by a second polyester band provided with a line resistance shielding layer; a line resistance insulation layer is wrapped on the external surface of each line resistance shielding layer; and each single line insulation layer is composed of an external single line insulation layer and an internal single line insulation layer; each external single line insulation layer comprises the following materials: 1%-3% of true crosslinked polyethylene and 97%-99% of plastic color masterbatch; and each external line resistance insulation layer comprises synthetic mica paper, of which both sides are covered by fiberglass cloth through silicon resin adhesive layers. The flexible cable provided by the invention can eliminate influences on the electric field by metal particles in the color masterbatch distributed around a conductor, lower transmission attenuation of the cable, and improve the mechanical performances as well as light and thermal ageing resistance of the insulation layers.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Environment protection digital type high-precise meter cable

InactiveCN1687997AGuaranteed performance and stabilityOil resistantInsulated cablesInsulated conductorsElectrical conductorInsulation layer

This invention relates to a data precision instrument cable. An insulation layer of expanded PE material in skin-foam-skin co-extrusion is set on the conductor to form a core of the cable, multiple pair-groups of pair wires with pair twist screen layers are set in the core, each set wire is set with a conduction wire, the cable core is set with a gird, a general screen layer and an outer sheathing are set on it orderly and a conduction lead is set between them.

Owner:BAOSHENG SCI & TECH INNOVATION

A wideband phased array antenna element and a radiation method thereof

ActiveCN109167162AHigh bandwidthSmall sizeRadiating elements structural formsLoop antennasImpedance matchingRadio frequency

The invention relates to a broadband phased array antenna unit and a radiation method thereof. The external radio frequency signal is fed into the broadband phased array antenna unit through a feedingcoaxial connector, and the fed external radio frequency signal forms two different current distributions on the cooperation of a ring radiator and a ring radiator, a matching branch and an additionalresonant branch respectively; the external radio frequency signal is fed into the broadband phased array antenna unit through a feeding coaxial connector. The current on the annular radiator resonates at high frequencies of the operating frequency, The loop radiator, the matching branch and the additional resonant branch form the resonant current at the low frequency, the two resonant points effectively increase the bandwidth of the antenna element, and the electromagnetic waves generated by the two resonant points are radiated into the free space by the wideband phased array antenna element;the loop radiator, the matching branch and the additional resonant branch form the resonant current at the low frequency. The impedance matching of wideband phased array antenna elements is realizedby changing the input impedance of wideband phased array antenna with matching branch and loop radiator. The invention can be widely applied to phased array antennas of mobile platforms such as satellite-borne, airborne, missile-borne and ground-based terminals.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

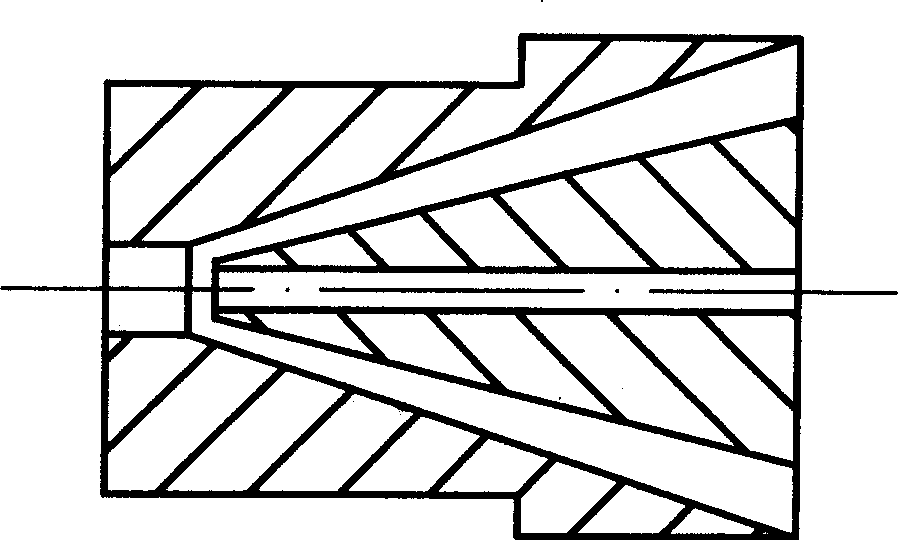

Preparation of signal transmission coaxial cable and physic foaming insulation layer and mould

InactiveCN1822245ARelieve pressureReduce high pressureCoaxial cables/analogue cablesInsulating conductors/cablesCable transmissionUltrasound attenuation

Said invention relates to improvement to signal transmission coaxial cable, featuring cable internal conductor outer physics sparkle insulating layer being secondary extruding composed double layer compound sparkle insulation. Due to adopting secondary physics sparkle extrusion laminating, said invention not only solves inside and outside cooling down misproportion problem and resulted fault of once extruded moulding of thick physics sparkle insulation, greatly raising radial and longitudinal sparkle hole uniformity without bunlla hole and cuniculus. For example the leakance RF coaxial cable sparkle degree can be raised to more than 78 per cent, reducing cable dielectric constant and dielectric loss tangent value, reducing cable transmission attenuation, voltage standing wave ratio less than 1.15 with fine product consistency. Said invented insulation physics sparkle forming method and mould is suitable for signal transmission coaxial cable sparkle insulation with greater than 10 mm sparkle insulation thickness.

Owner:JIANGSU HENGXIN TECH CO LTD

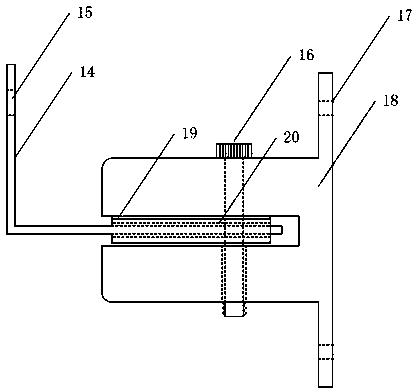

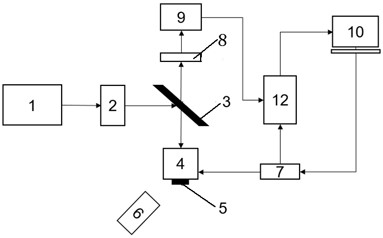

Diamond film fluorescence efficient collecting device

PendingCN113237859AFast scan magnetic imagingSmall transmission attenuationFluorescence/phosphorescenceGreen laserErbium lasers

The invention discloses a diamond film fluorescence efficient collecting device. The device comprises a laser and a computer, the laser emits green laser, and the green laser is coupled into an optical fiber through an optical fiber coupler and then transmitted to the tail end of an optical fiber probe through a double-color piece; a diamond film is fixedly arranged at the bottom of the tail end of the optical fiber probe; the microwave antenna is uniformly wound at the tail end of the optical fiber probe; a microwave signal of the microwave device acts on the NV color center of the diamond film through the microwave antenna; and a magnet is arranged below the diamond film and applies a magnetic field to the NV color center of the diamond film. The device has the beneficial effects that the diamond is adhered to the tail end of the optical fiber as a main sensing part, and laser is limited in the optical fiber by utilizing total reflection of electromagnetic waves in the optical fiber, so that the transmission attenuation of the optical fiber is reduced, and red fluorescence excited by a diamond film NV color center is efficiently collected.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

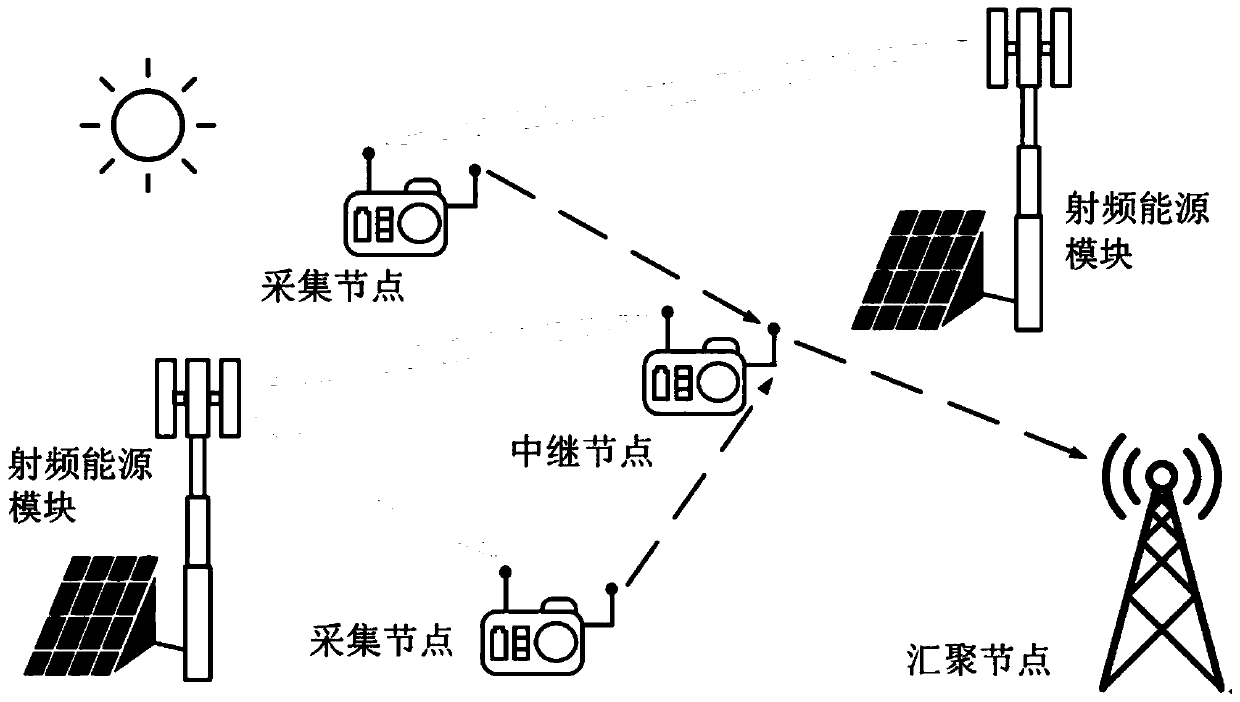

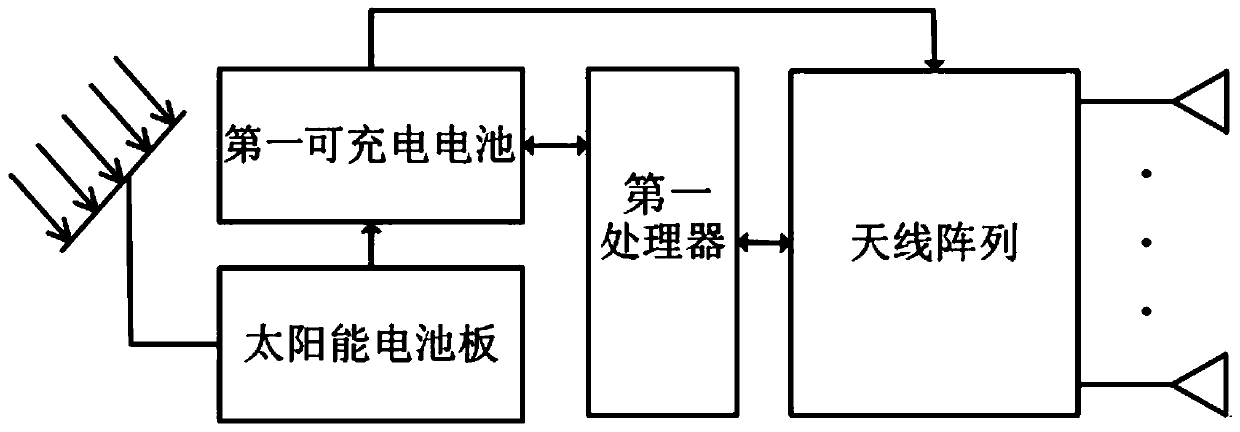

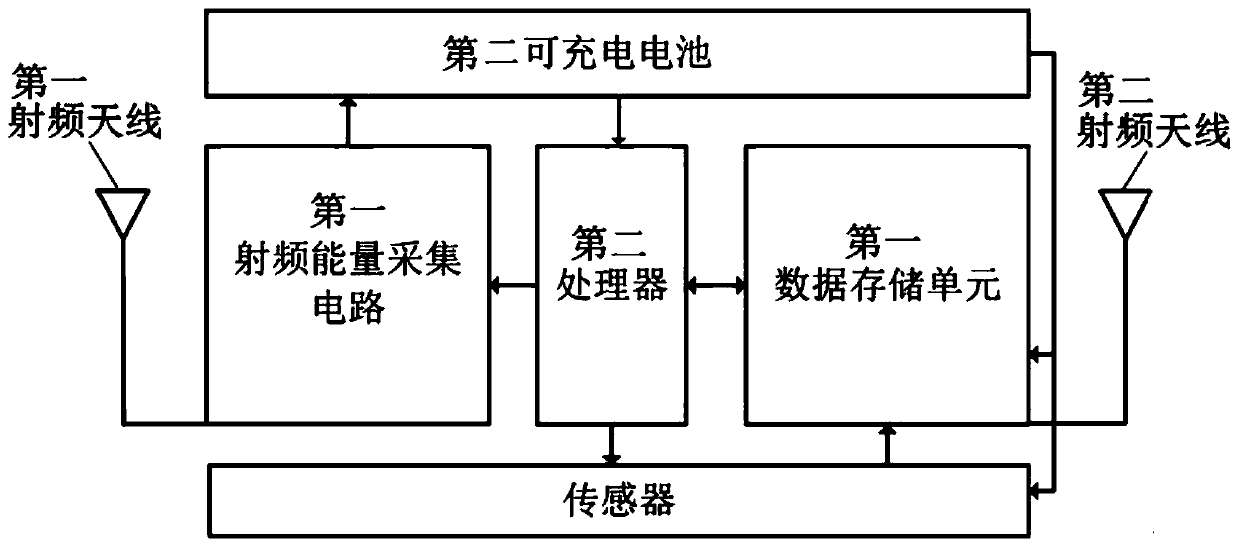

Monitoring system for large-scale rechargeable Internet of things, and distributed protocol

ActiveCN111245941AImprove utilization efficiencyWide coverageBatteries circuit arrangementsParticular environment based servicesRadio frequency energyThe Internet

The invention discloses a monitoring system for a large-scale rechargeable Internet of things, and a distributed protocol. The monitoring system comprises an Internet of Things node and a plurality ofradio frequency energy modules, wherein the Internet of Things node comprises an acquisition node used for acquiring environmental data, a relay node and an aggregation node; the acquisition node isconnected with the relay node and transmits node data to the relay node according to the data transmission probability of the acquisition node, and the relay node is connected with the aggregation node and transmits node data to the aggregation node according to the data transmission probability of the relay node; each radio frequency energy module is used for collecting energy and sending corresponding energy to surrounding collection nodes and relay nodes through radio frequency signals generated through radio frequency beam forming based on the sending power of the energy. According to theinvention, the node data can be fairly collected and the charging amount can be reasonably distributed based on the local information of the nodes, the node energy utilization efficiency can be improved, and the method can be applied to the rechargeable Internet of Things with a large network scale, a wide coverage range and a poor deployment environment.

Owner:JINAN UNIVERSITY

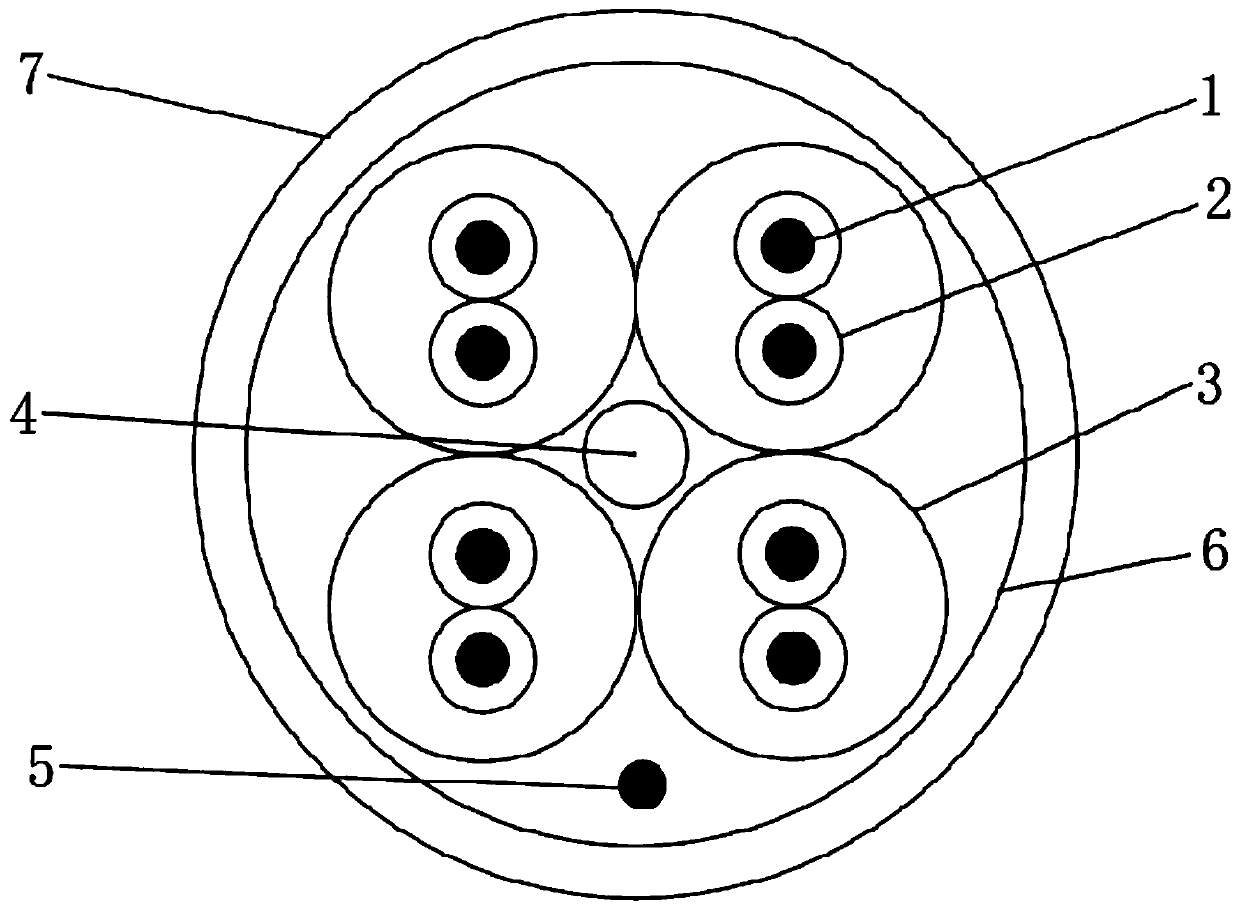

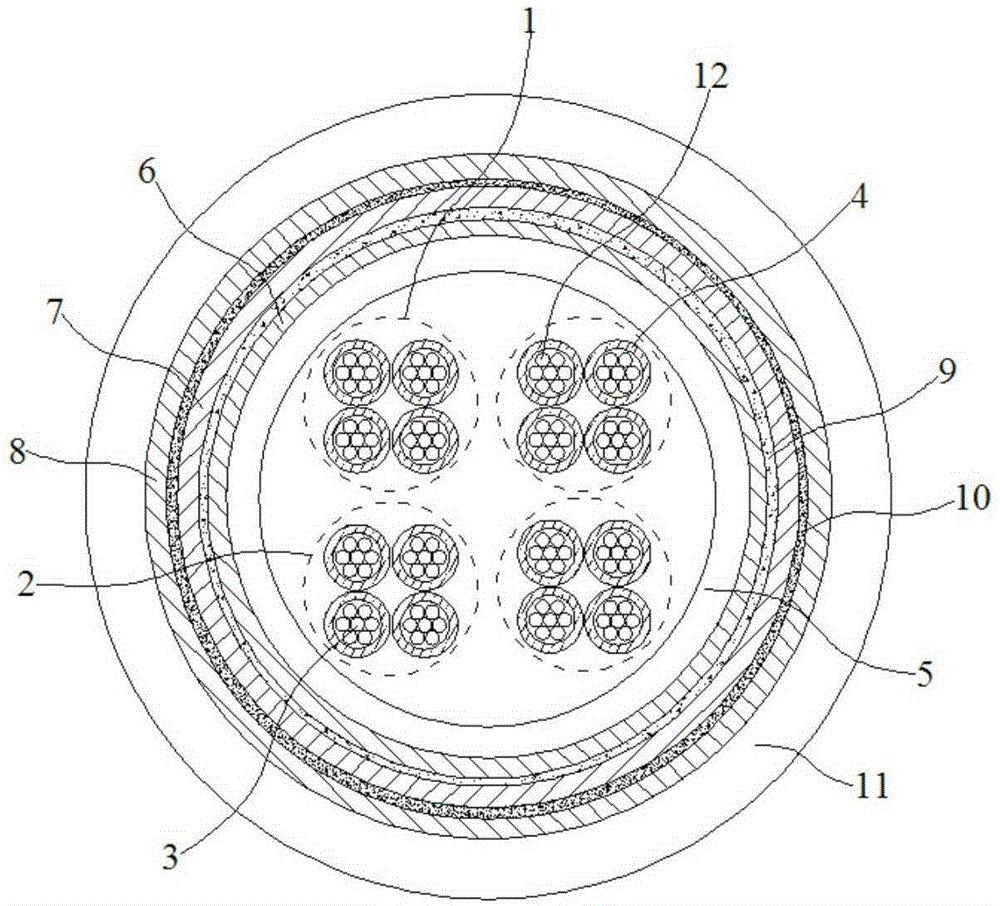

Special Cat-5e cable structure for aerospace and preparation method of cable structure

PendingCN106935327AImprove antioxidant capacityReduce lossInsulated cablesCable/conductor manufactureMetallic aluminumControl signal

The invention discloses a special Cat-5e cable structure for aerospace. The cable structure comprises a white-blue twisted wrapping core, a white-orange twisted wrapping core and control wires; the white-blue twisted wrapping core, white-orange twisted wrapping core and control wires are twisted to form a cable body structure; the innermost layers of the white-blue twisted wrapping core and the white-orange twisted wrapping core include a first cable core pair and a second cable core pair respectively, and the first cable core pair and the second cable core pair are wrapped in microporous polytetrafluoroethylene tapes respectively; each microporous polytetrafluoroethylene tape is wrapped in a polyimide tape; each polyimide tape is wrapped in a single-side plastic-aluminum composite tape; the cable body structure is wrapped in a double-side metal plastic-aluminum composite tape; a silvering copper wire braided shielding layer is arranged outside the double-side metal plastic-aluminum composite tape; and a fluorinated ethylene propylene sheath is extruded outside the silvering copper wire braided shielding layer. The cable structure of the invention is anti-oxidation, resistant to high and low temperature, low in weight, low in structural echo loss, resistant to radiation and capable of transmitting control signals.

Owner:湖南华菱线缆股份有限公司

Method for manufacturing instrument cable

InactiveCN102969079AReduce capacitanceAvoid interferenceInsulating conductors/cablesCopper conductorCapacitance

Disclosed is a method for manufacturing an instrument cable. The method includes that (1) a copper conductor which accords with the relevant standards and regulations of the instrument cable is utilized, and an expanded polyethylene insulating material is extruded and wrapped on the copper conductor to form insulated wire cores by a skin-foam-skin three-layer co-extrusion technology; (2) each two insulated wire cores prepared in the step (1) are subjected to pair twist to form pair twist wire groups, the pair twist wire groups are provided with various pitches, pitches of the same pair twist wire group are equal, pair twist wire groups with different pitches are selected to form the cable, and a tape is wrapped on the outer surface of a cable core. A copper wire is woven on the wrapped tape, or a copper tape shielding layer is wrapped on the wrapped tape, and a low smoke halogen-free flame retardant environment-friendly outer sheath is extruded and wrapped on the shielding layer. The method for manufacturing the instrument cable has the advantages that the method is advanced and scientific, low capacitance, low transmission attenuation and low insulation medium loss of the cable are achieved by means of designing of the conductor skin-foam-skin insulating wire core and the like, the signal transmission is stable, the shielding effect is good, and performance requirements of the cable used in modern instruments are met.

Owner:李青余

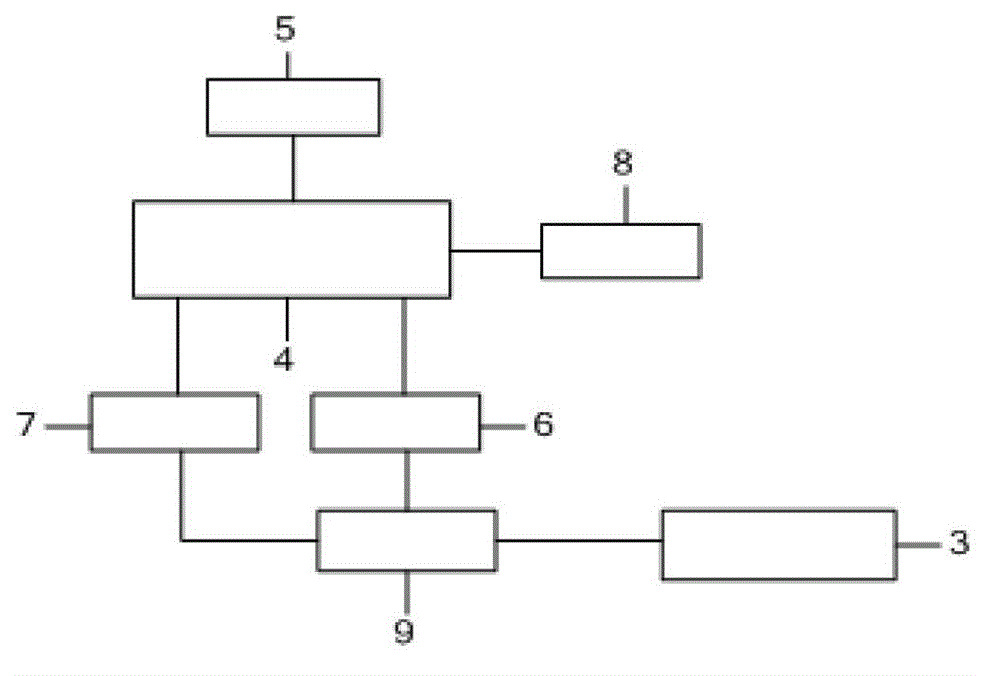

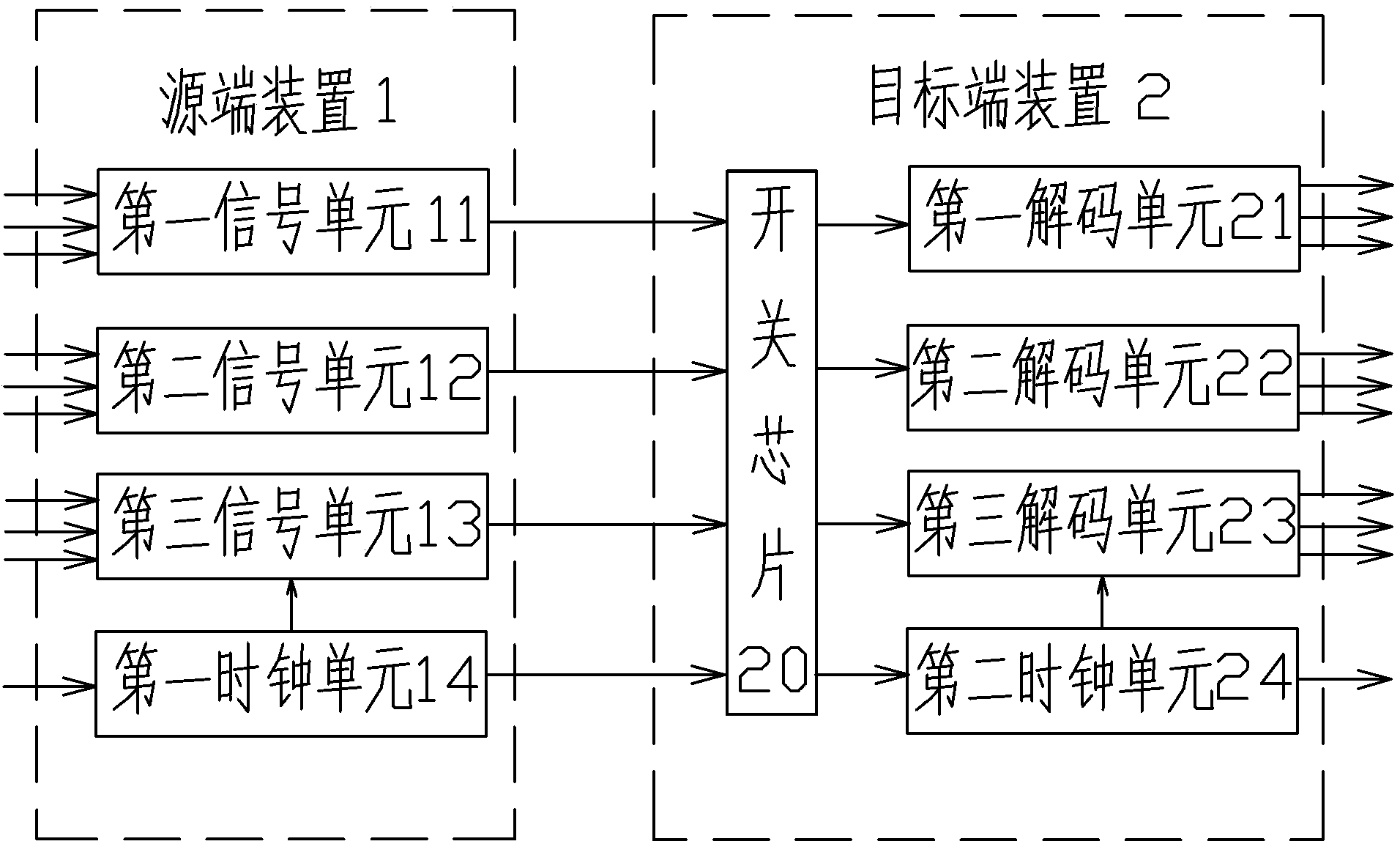

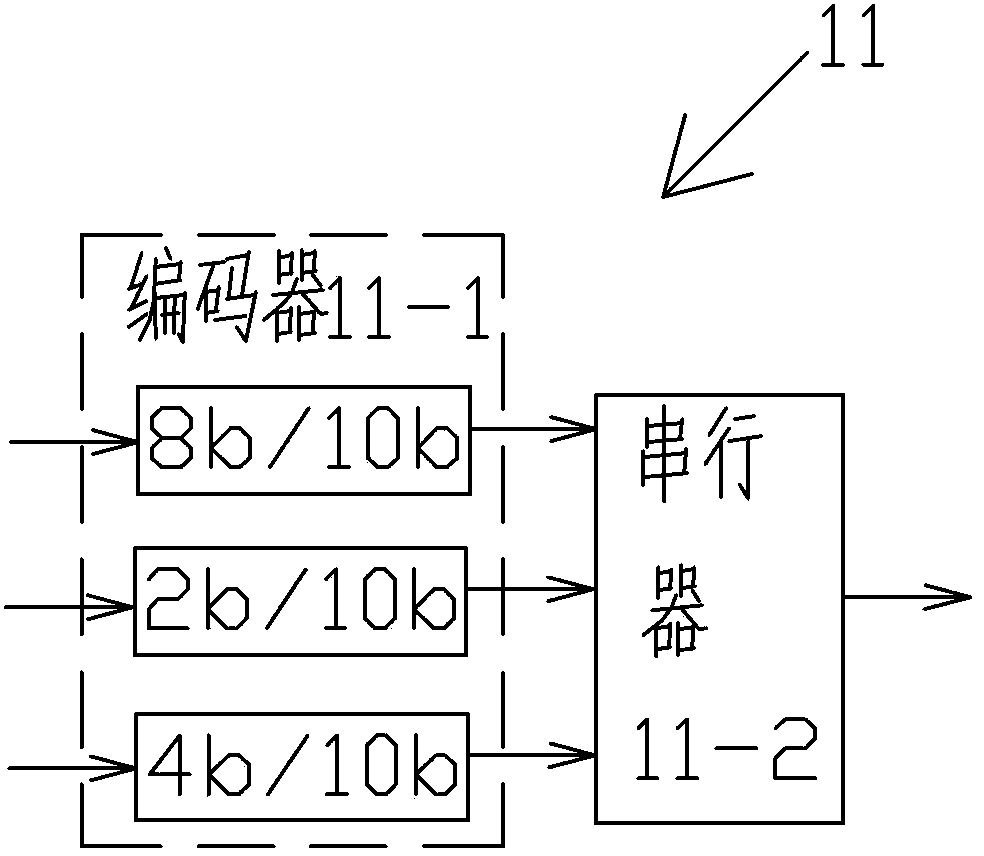

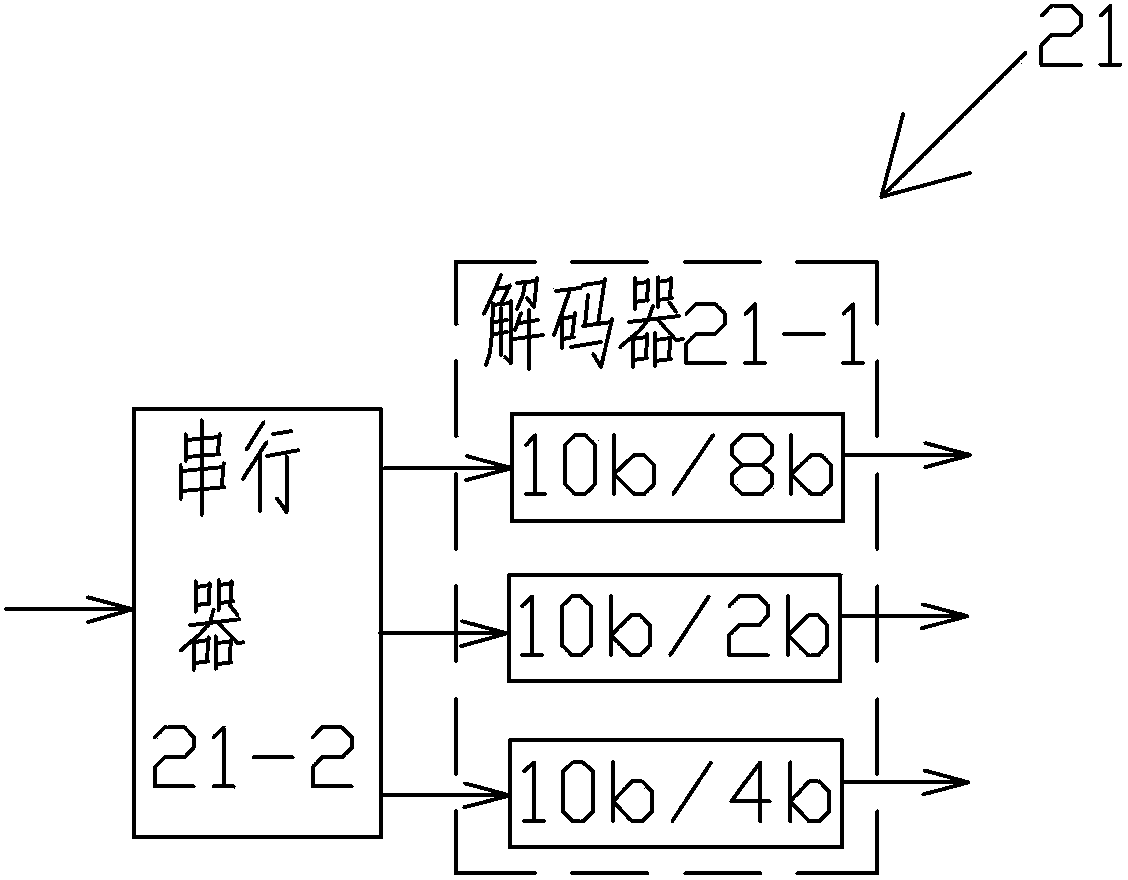

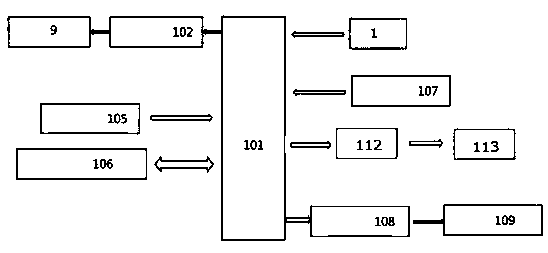

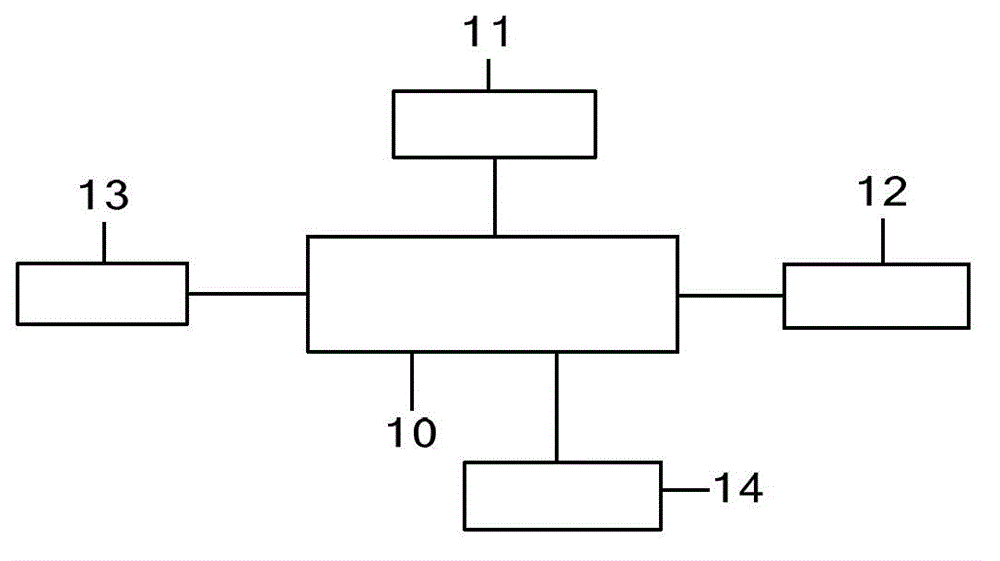

HDMI multi-service optical transceiver

ActiveCN103856763ASmall transmission attenuationBandwidthTelevision system detailsOptical transmission adaptationsUltrasound attenuationElectricity

The invention provides an HDMI multi-service optical transceiver comprising a source-side device and a target-side device. The source-side device comprises a first signal unit, a second signal unit, a third signal unit and a first clock unit. The target-side device comprises a switch chip, a first decoding unit, a second decoding unit, a third decoding unit and a second clock unit. The signal units and the first clock unit of the source-side device are electrically connected with a signal source when used, and are electrically connected with the decoding units and the second clock unit by signals through the switch chip of the target-side device. The output ends of the decoding units and the output end of the second clock unit are electrically connected with target equipment when used. Each of the signal units comprises an encoder and a serializer. Each of the decoding units comprises a decoder and a serializer. The HDMI multi-service optical transceiver has the characteristics of low transmission attenuation, wide bandwidth, strong anti-interference capability, high safety performance and long transmission distance. When used, the HDMI multi-service optical transceiver is convenient in wiring, saves construction cost and satisfies a plurality of using requirements.

Owner:常州华龙通信科技股份有限公司

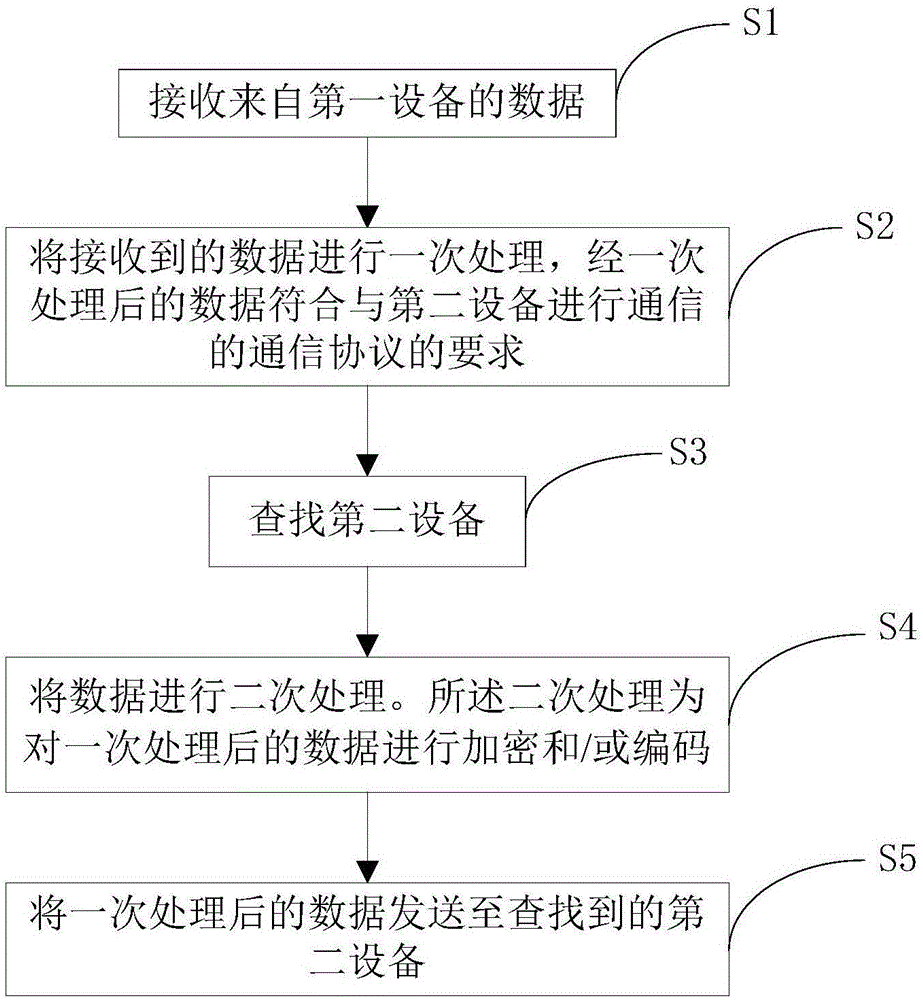

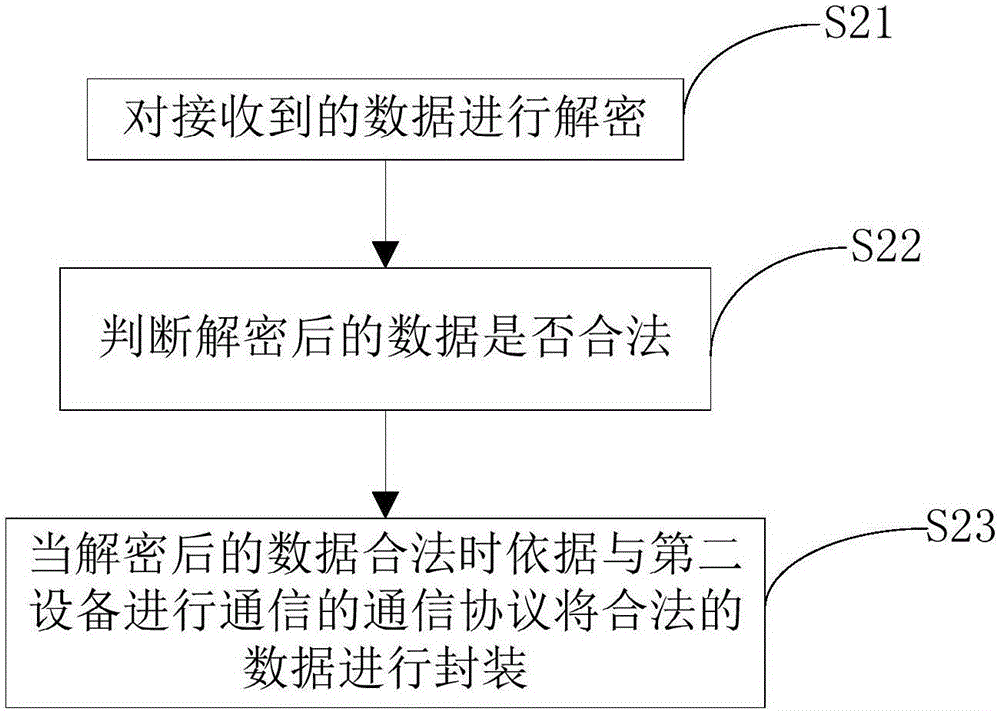

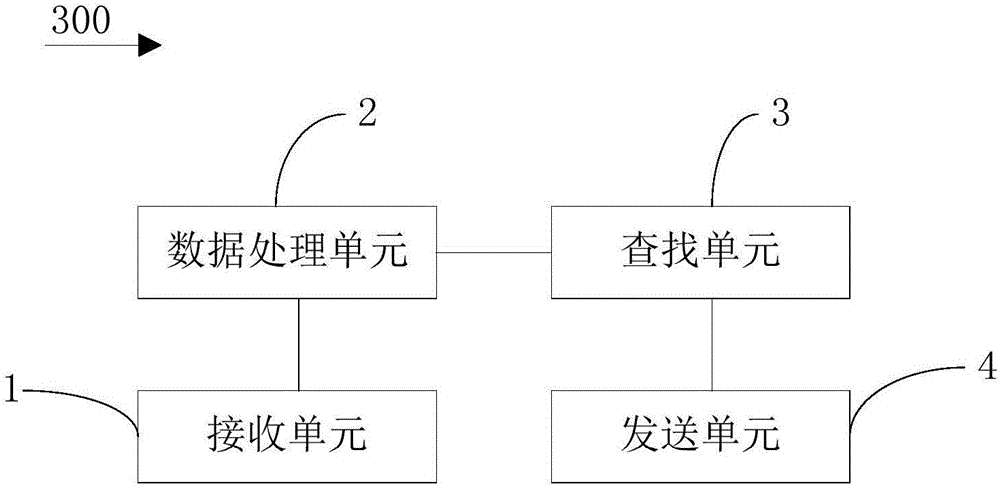

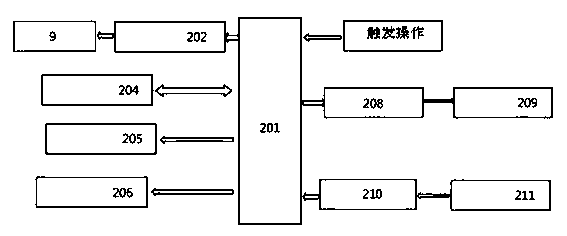

Communication conversion method, conversion apparatus and conversion system

InactiveCN106657118AReduce power consumptionStrong signalWireless commuication servicesTransmissionComputer hardwareConversion method

The invention relates to a communication conversion method, conversion apparatus and conversion system. The communication conversion method comprises the following steps: receiving data from a first device; performing primary processing on the received data, wherein the data satisfy the requirements of a communication protocol for communication with a second device after the primary processing; searching a second device; and sending the data after the primary processing to the found second device.

Owner:HANGZHOU BROADLINK ELECTRONICS TECH

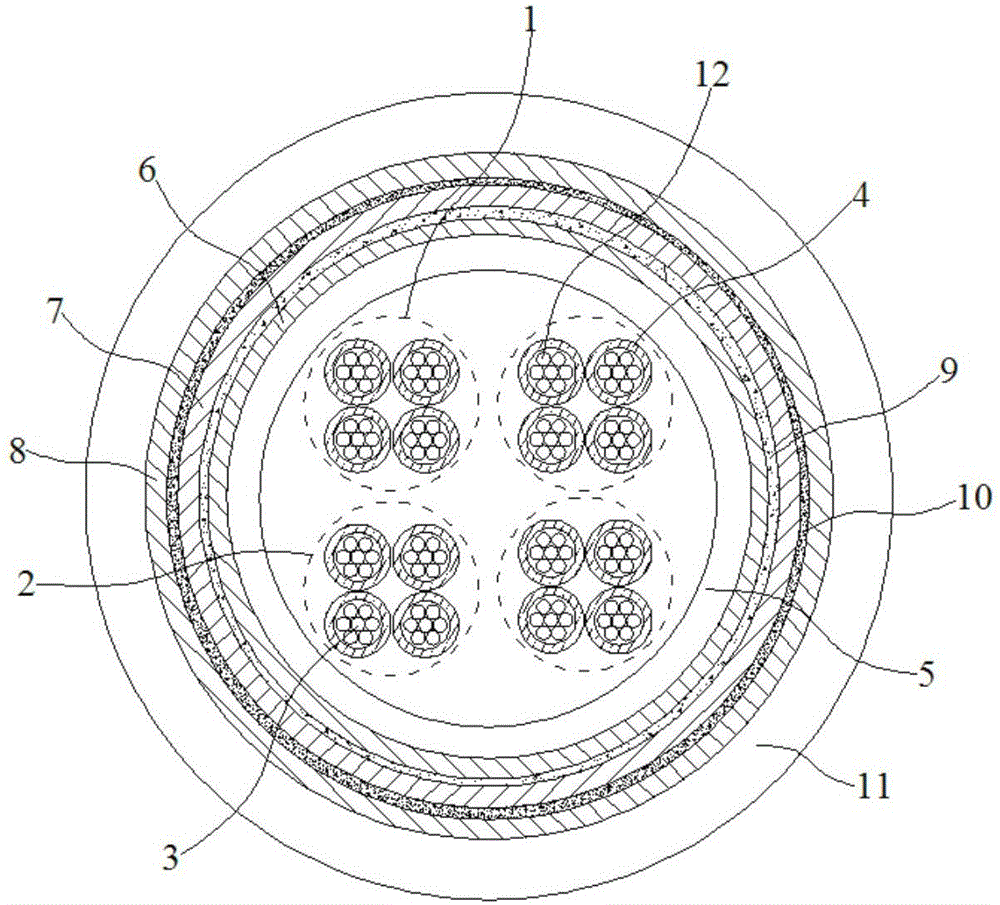

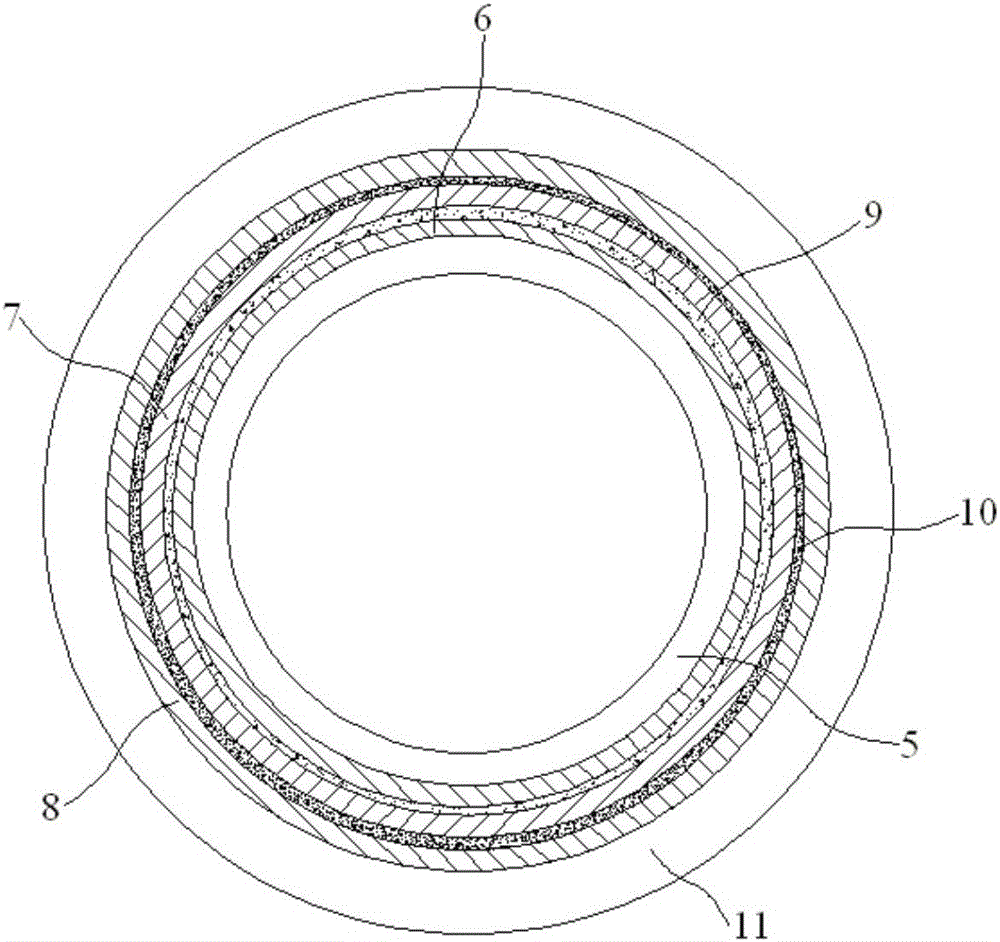

Corrosion-resistant type flame-retardant orbital digital signal cable

InactiveCN105741927ASmall transmission attenuationImprove shielding effectExtensible conductorsExtensible conductor cablesUltrasound attenuationPolyester

The invention discloses a corrosion-resistant type flame-retardant orbital digital signal cable. An inner insulating layer is arranged on the outer surfaces of twisted single wires; a coating layer coats the outer surfaces of 2-20 wire groups; a first copper layer coats the outer surface of the inner insulating layer; a steel layer coats the outer surface of the first copper layer; a second copper layer coats the outer surface of the steel layer; the first copper layer is tightly connected with the inner surface of the steel layer through a first alloy layer; the second copper layer is tightly connected with the outer surface of the steel layer through a second alloy layer; an outer protective layer coats the outer surface of the second copper layer; the first alloy layer comprises copper, iron, molybdenum, chromium and carbon; the second alloy layer comprises copper, iron, molybdenum, chromium and carbon; and the thickness of a polyester tape is 0.03-0.06mm. According to the corrosion-resistant type flame-retardant orbital digital signal cable, the transmission attenuation of the cable is reduced; the formability, extensibility and good electrical conductivity of a product are improved; and the tensile strength is improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

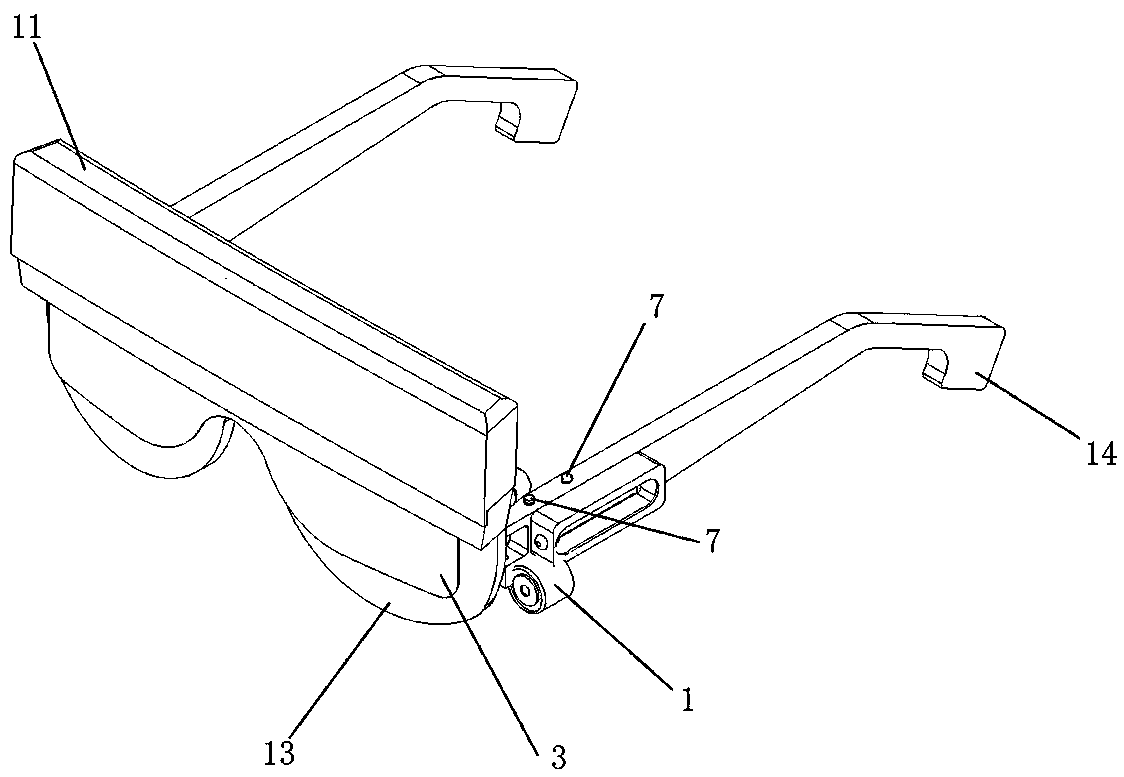

Intelligent glasses with sheltering function as well as control system

PendingCN109164599AMaster eye habits in real timeFlexible useNon-optical adjunctsOptical partsControl systemPersonal computer

The invention discloses intelligent glasses with a sheltering function as well as a control system. A sensor judges whether people are out of the limited distance when washing televisions, computers,mobile phones and tablet personal computers; when the sensor senses that people are in the limited distance, a sheltering sheet shelters glass lenses on a glasses frame, voice and vibration prompt isconducted on the glass fame, and the effect of protecting eyesight is achieved. In addition, a glasses box which is in wireless communication with the glasses frame is designed, so that the glasses box and the glasses frame can perform voice prompt synchronously in the same space, the intelligent glasses are particularly suitable for young users, and parents can master the eye using habit of teenagers in real time through the prompt of the glasses box and can perform human reminding or intervention.

Owner:廊坊小猴哈尼智能科技有限公司

Physically foamed insulation data signal line structure

InactiveCN108242280AReasonable structural designImprove tensile propertiesInsulated cablesInsulated conductorsCopper conductorPolyolefin

The invention provides a physically foamed insulation data signal line structure, which comprises a cable core and an insulated wrapping tape layer, a conductive shielding thermal insulation layer, aninner sheath, a double-steel-belt armor layer and an outer sheath, which are arranged outside the cable core. The cable core is formed by stranding a plurality of insulated single wires, wherein eachinsulated single wire is formed by a copper conductor and a skin-foam-skin physically foamed polyolefin insulation structure outside the copper conductor. The conductive shielding thermal insulationlayer is internally embedded with discharge copper wires. Cotton and hemp ropes are filled between the insulated single wires and the insulated wrapping tape layer and between the insulated single wires. The signal line structure is reasonable in design; the filled cotton and hemp ropes can improve tensile and anti-pressure performance of the signal line, so that the signal line is not vulnerableto external shock damage; the skin-foam-skin physically foamed polyolefin insulation structure has a good moisture-proof function and excellent insulation performance, thereby reducing transmission attenuation of the cable and effectively improving transmission performance of the cable; and besides, the conductive shielding thermal insulation layer improves shielding and thermal insulation performance of the signal line, and thus anti-signal interference ability is high.

Owner:天津菲林建筑工程有限公司

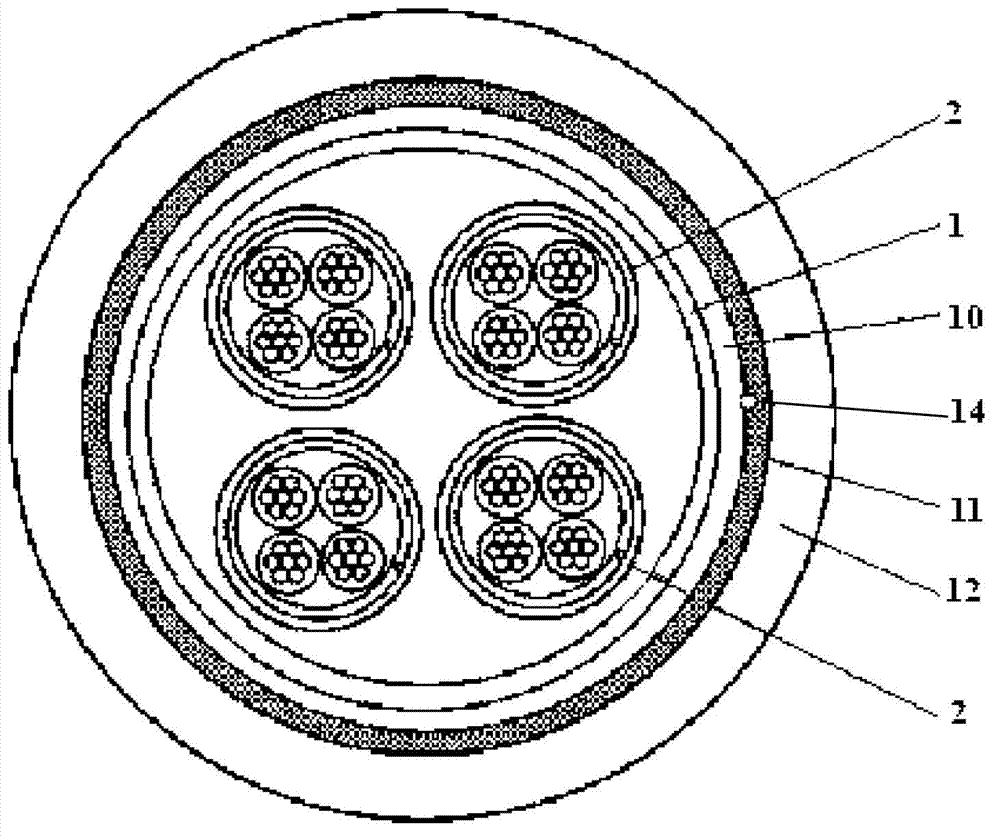

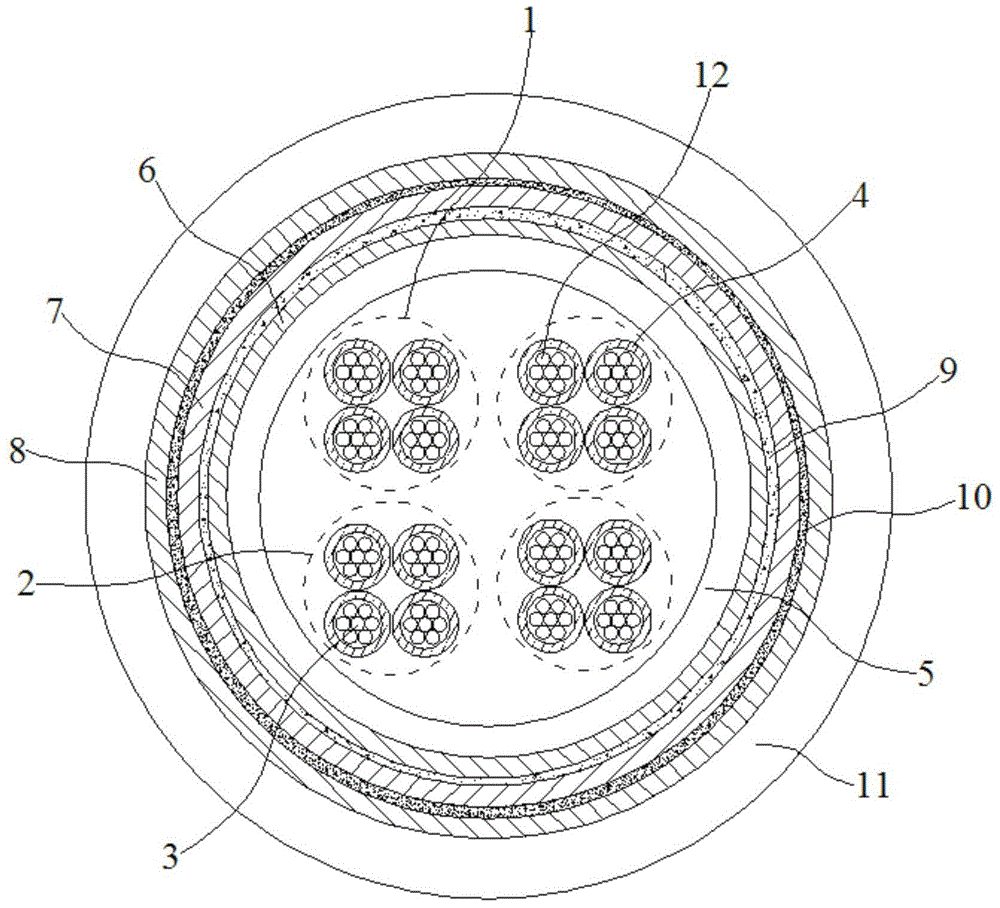

Super-flexible communication cable in 5G industrial internet digital system and manufacturing method

PendingCN111312445ALow dielectric constantIncrease transfer rateConductive materialInsulated cablesCopper conductorThe Internet

The invention discloses a super-flexible communication cable in a 5G industrial internet digital system and a manufacturing method. An upper side of a conductor structure is formed by twisting a tin-plated oxygen-free copper conductor with the purity of 99.99% and 250D nylon wires. The maximum value of the direct-current resistance is 14 ohm / 100 m, and a physical foaming fluorinated ethylene propylene insulating layer is used on an upper side of an insulating structure such that the dielectric constant of a cable core is reduced, the requirement of low attenuation of signal transmission is met, and the transmission rate of the cable core is improved. The invention relates to the technical field of communication cables. The invention discloses the super-flexible communication cable in the 5G industrial internet digital system and the manufacturing method. In order to improve the electromagnetic compatibility, a cable product adopts a form of extruding a semi-conductive surface insulating layer on the shielding structure; the manufacturing method is completed by using a one-step method, that is, four signal line pairs extrude a semi-conductive shielding material and a sheath materialsynchronously by using a special die such that a pair-twisting and longitudinal-wrapping aluminum foil process and a cabling process are reduced, two production processes are reduced, and the processcost is reduced.

Owner:湖北宇洪光电实业有限公司

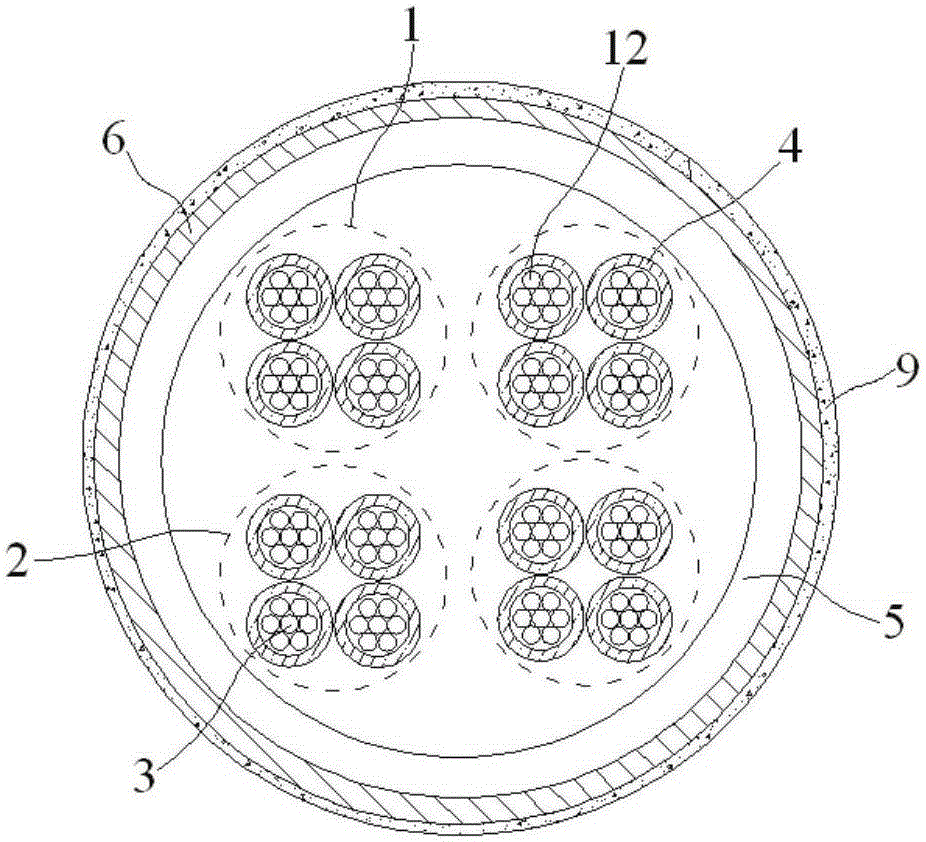

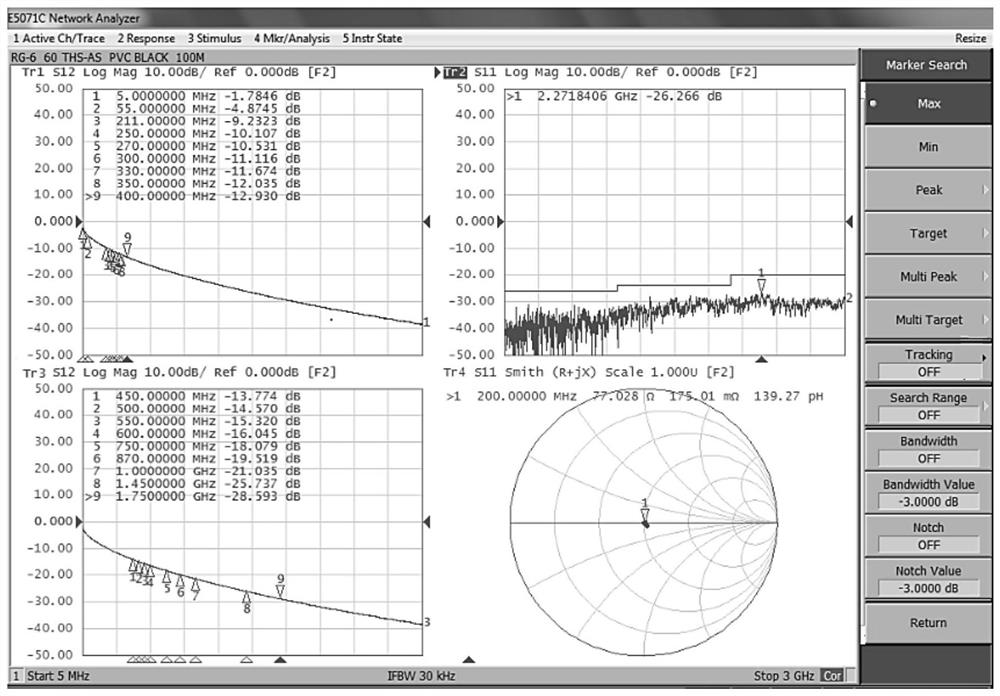

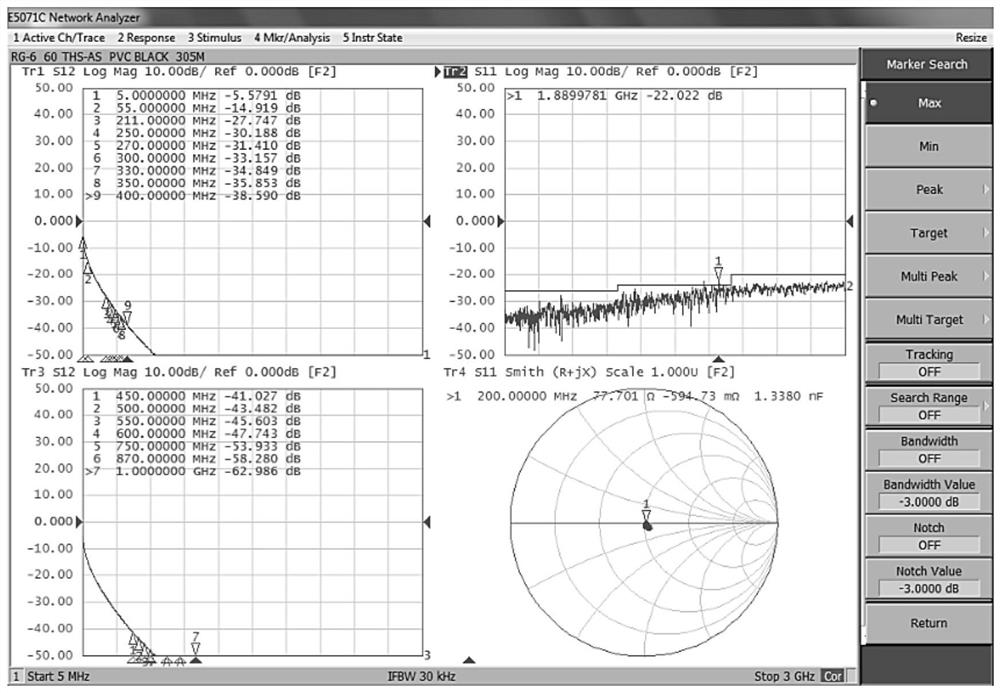

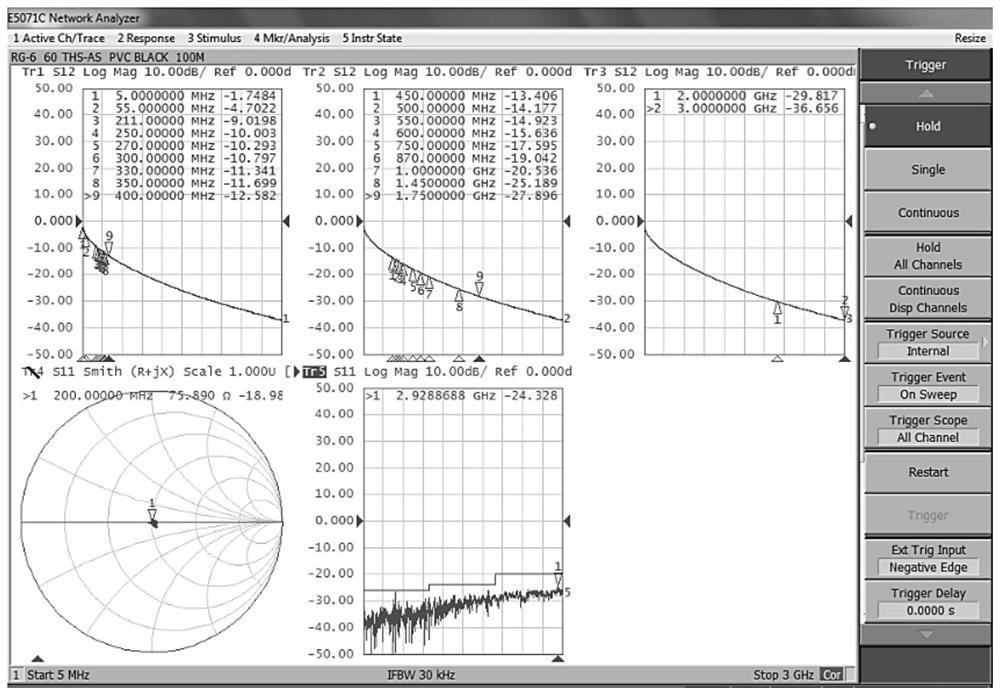

RG-6 copper-coated steel coaxial cable and fabrication method thereof

ActiveCN110233001AReduce lossLow dielectric constantPlastic/resin/waxes insulatorsApparatus for feeding conductors/cablesUltrasound attenuationLow-density polyethylene

The invention relates to the technical field of a RG-6 copper-coated steel coaxial cable fabrication process, in particular to a RG-6 copper-coated steel coaxial cable. The RG-6 copper-coated steel coaxial cable comprises a copper-coated steel conductor, an inner skin layer, a foam layer and an outer skin layer, wherein the raw material for fabricating the inner skin layer comprises the followingconstituents based on parts by weight: 0.3-0.7 part of ethylene-ethylhexyl copolymer and 23-27 parts of low-density polyethylene, the raw material for fabricating the foam layer comprises the following constituents based on parts by weight: 23-27 parts of HDPE 2911, 23-27 parts of HMA, 23-27 parts of low-density polyethylene and 0.3-0.7 of nucleating agent, and the raw material for fabricating theouter skin layer comprises the following constituents based on parts by weight: 0.3-0.7 part of ethylene-ethylhexyl copolymer and 23-27 parts of low-density polyethylene. The fabricated RG-6 copper-coated steel coaxial cable has the advantage of small transmission attenuation, and the signal transmission quality of the coaxial cable is favorably improved.

Owner:杭州三元电缆有限公司

An Optical Sensor Realizing Arc Flash Detection in Switchgear

The invention discloses an optical sensor capable of effectively detecting produced electric arc light and converting the electric arc light into an electric signal to be output when an outgoing wire or a bus of a switch cabinet has a short-circuit fault. The optical sensor comprises a light acquisition lens, a photoelectric converter and a plastic optical fiber, wherein two ends of the plastic optical fiber are provided with ST connectors, and the plastic optical fiber is connected with the light acquisition lens and the photoelectric converter through the ST connectors. Due to the fact that the light acquisition lens is a passive device, the light acquisition lens is connected with the active photovoltaic conversion portion through the plastic optical fiber, and a primary device of the switch cabinet is not influenced. The light acquisition lens only acquires light information of specific wave bands in arc light and can effectively filter interference of other light sources. An electrical signal only existing at the photovoltaic conversion portion of the sensor, the rest is light signals, and electromagnetic interference produced during actions of the switch cabinet can be effectively avoided. By adopting anti-static design achieved by a transient diode, the device reliability is improved, and the optical sensor can adapt to various assembling and usage environments.

Owner:南京弘毅电气自动化有限公司

Wireless measurement and control communication protocol based on ieee802.15.4g standard

InactiveCN103152752BReduce power consumptionLong transmission distancePower managementEnergy efficient ICTElectrical batteryEngineering

The invention discloses an IEEE (Institute of Electrical and Electronic Engineers) 802.15.4g standard-based wireless monitoring communication protocol, and belongs to the technical field of embedded wireless monitoring. IEEE802.15.4g is a standard of a physical layer named SUN, which is established by Institute of Electrical and Electronic Engineers (IEEE) in recent two years, the physical layer is supplemented on the basis of an IEEE802.15.4 standard, and the IEEE802.15.4g standard is particularly suitable for battery powered infrastructure sensor networks which have ultralow power consumption, remote transmission and excellent anti-noise performance. Although IEEE802 is still standardized at present, a draft scale has been determined basically, so the set of standard is necessarily tracked and studied timely, and based on the underlying standard, a set of ultralow power consumption wireless upper-layer communication protocol applied to the field of smart grid monitoring is designed and developed. The protocol aims at a star network topological structure, working method steps for a network coordinator node and a sensor node are respectively designed, and the protocol has the characteristics of low velocity, ultralow power consumption, low complexity and the like.

Owner:SHANDONG UNIV

Flame-retardant railway signal cable

InactiveCN105741948ASmall transmission attenuationImprove shielding effectInsulated cablesInsulated conductorsCopper wireChromium

The invention discloses a flame-retardant railway signal cable. Six tinned copper wires are twisted on the outer surface of the tinned copper wire at the center; an inner insulating layer is arranged on the outer surfaces of the twisted single wires; a coating layer coats the outer surfaces of 2-20 wire groups; a first copper layer coats the outer surface of the inner insulating layer; a steel layer coats the outer surface of the first copper layer; a second copper layer coats the outer surface of the steel layer; the second copper layer is tightly connected with the outer surface of the steel layer through a second alloy layer; an outer protective layer coats the outer surface of the second copper layer; and the first alloy layer comprises copper, iron, molybdenum, chromium and carbon. The flame-retardant railway signal cable is beneficial to absorption of a magnetic field in an electromagnetic field; and the extensibility and the electrical conductivity are also improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

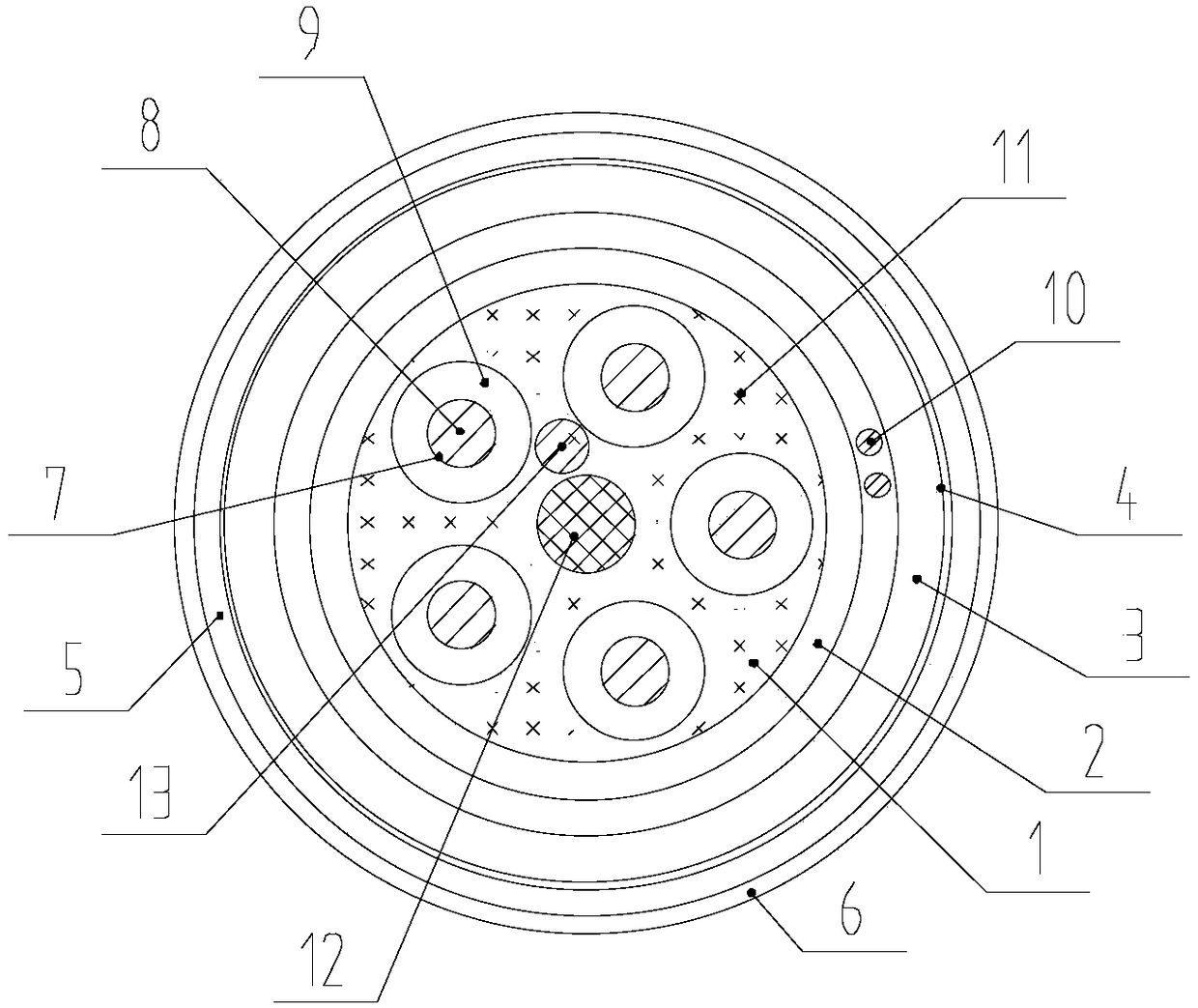

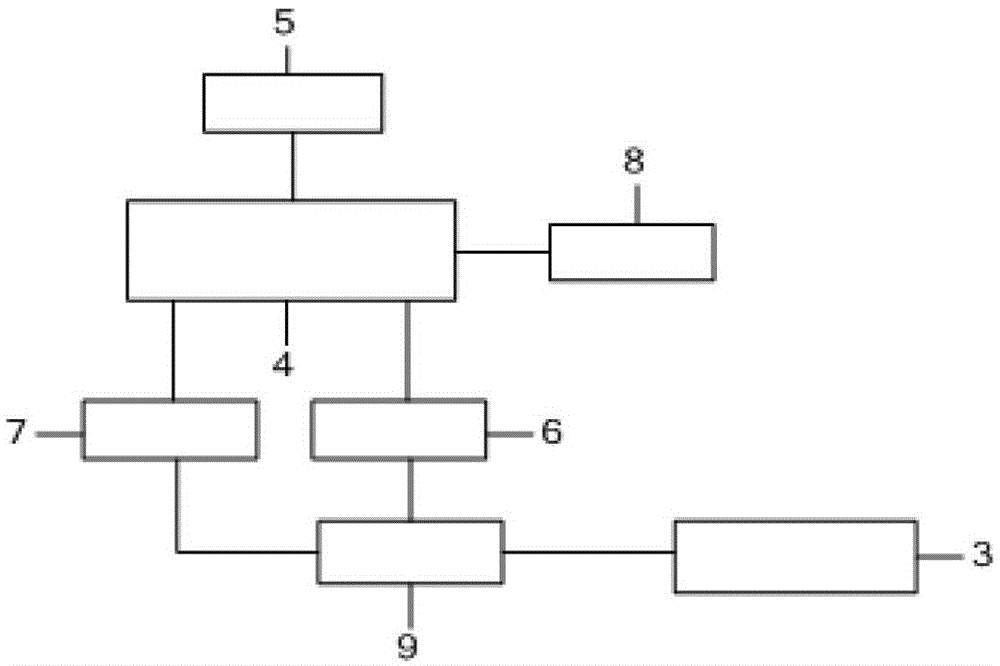

A Circular Waveguide Antenna-fed Antenna System

ActiveCN103474768BEasy to receiveLarge power capacityAntennas earthing switches associationUltrasound attenuationExpansion joint

The invention discloses a circular waveguide antenna feeder antenna system which comprises an antenna, a circular and flexible waveguide, an upper sealing section, a circular waveguide bend, a parasitic mode filter, a circular waveguide tube, a polarization expansion joint, a polarization rotating joint, a convertor, a polarization separator and a waveguide bend. The antenna, the circular and flexible waveguide, the upper sealing section, the circular waveguide bend, the parasitic mode filter, the circular waveguide tube, the polarization expansion joint, the polarization rotating joint, the convertor, the polarization separator and the waveguide bend are connected in sequence. The polarization separator and the waveguide bend are respectively connected with a rectangular flexible waveguide, a rectangular waveguide, a rectangular waveguide sealing section and a step convertor. As the circular waveguide is adopted in the circular waveguide antenna feeder antenna system to transmit information, the circular waveguide antenna feeder antenna system has the advantages that steering is convenient, information receiving is facilitated, power capacity for microwave transmission is larger and transmission attenuation is less.

Owner:STATE GRID CORP OF CHINA +1

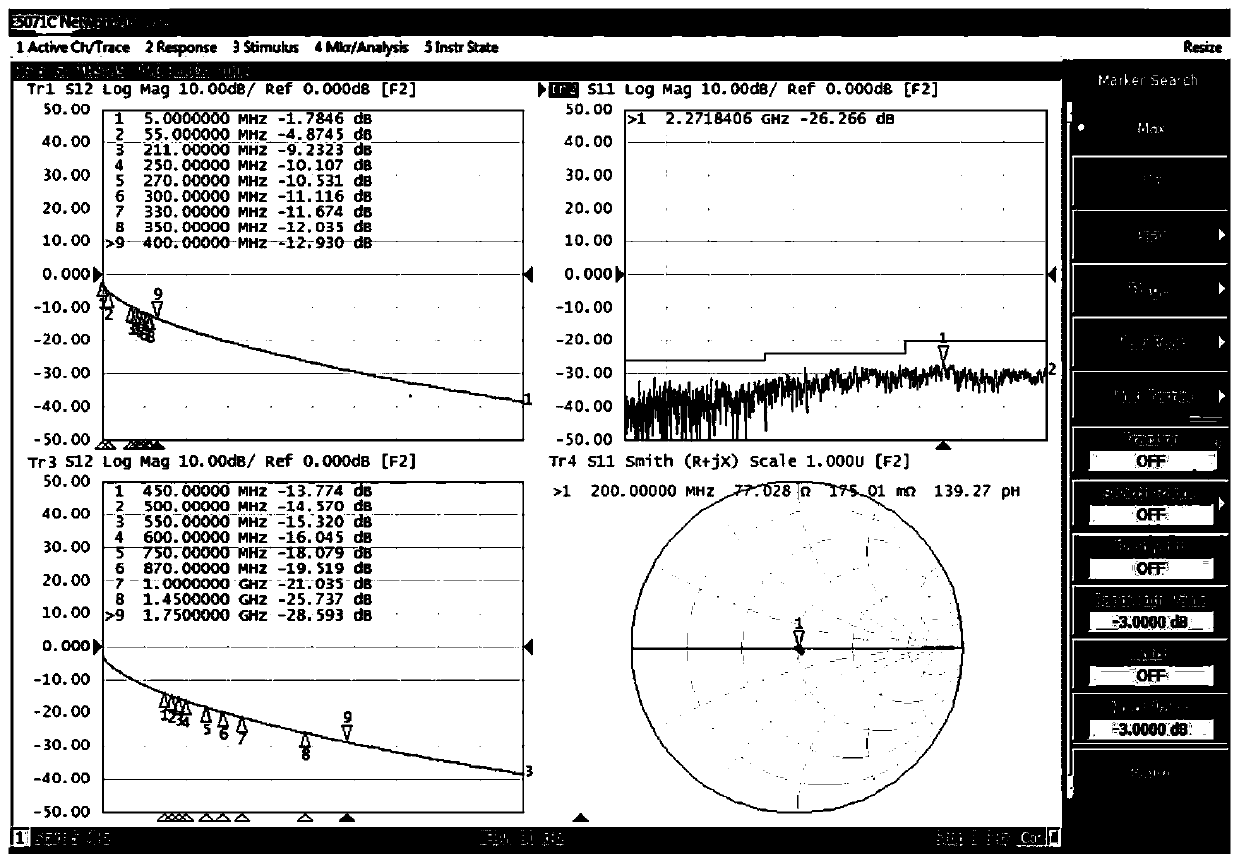

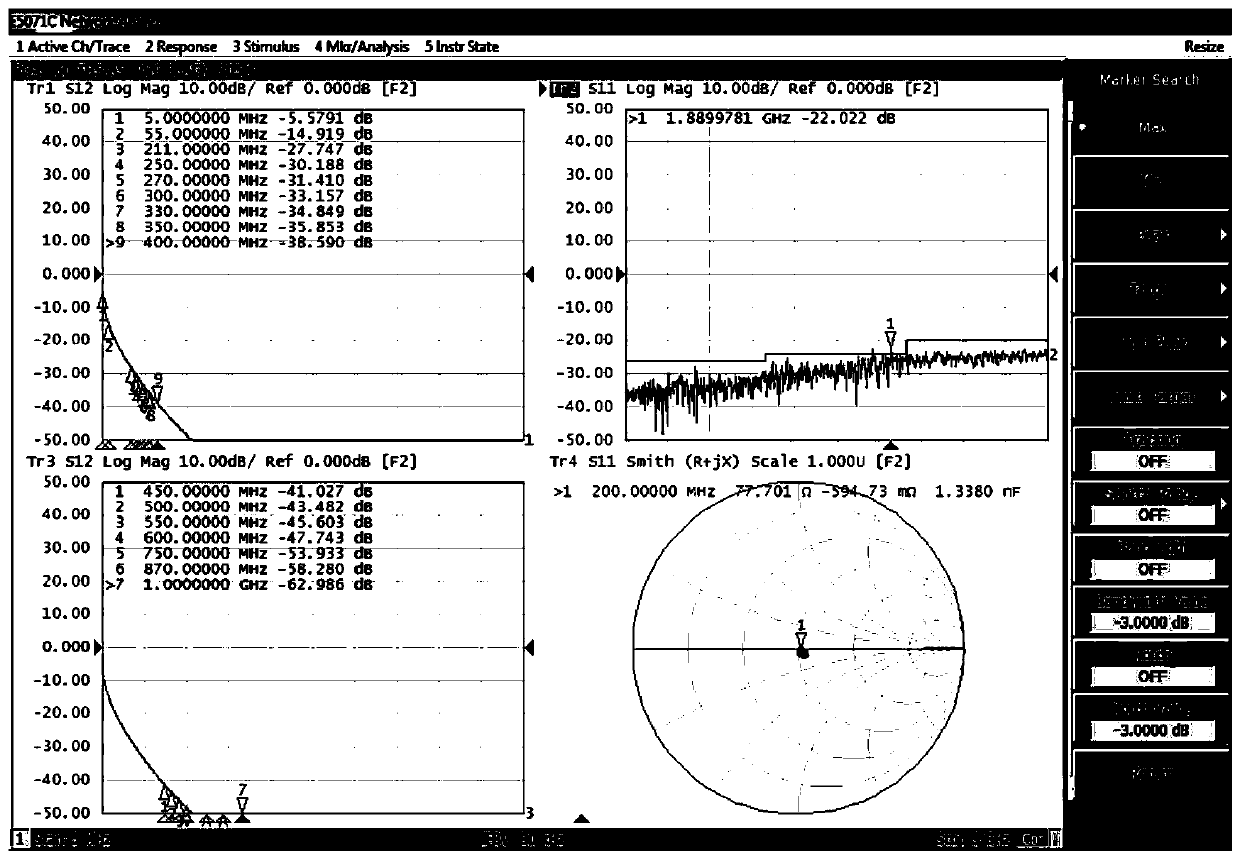

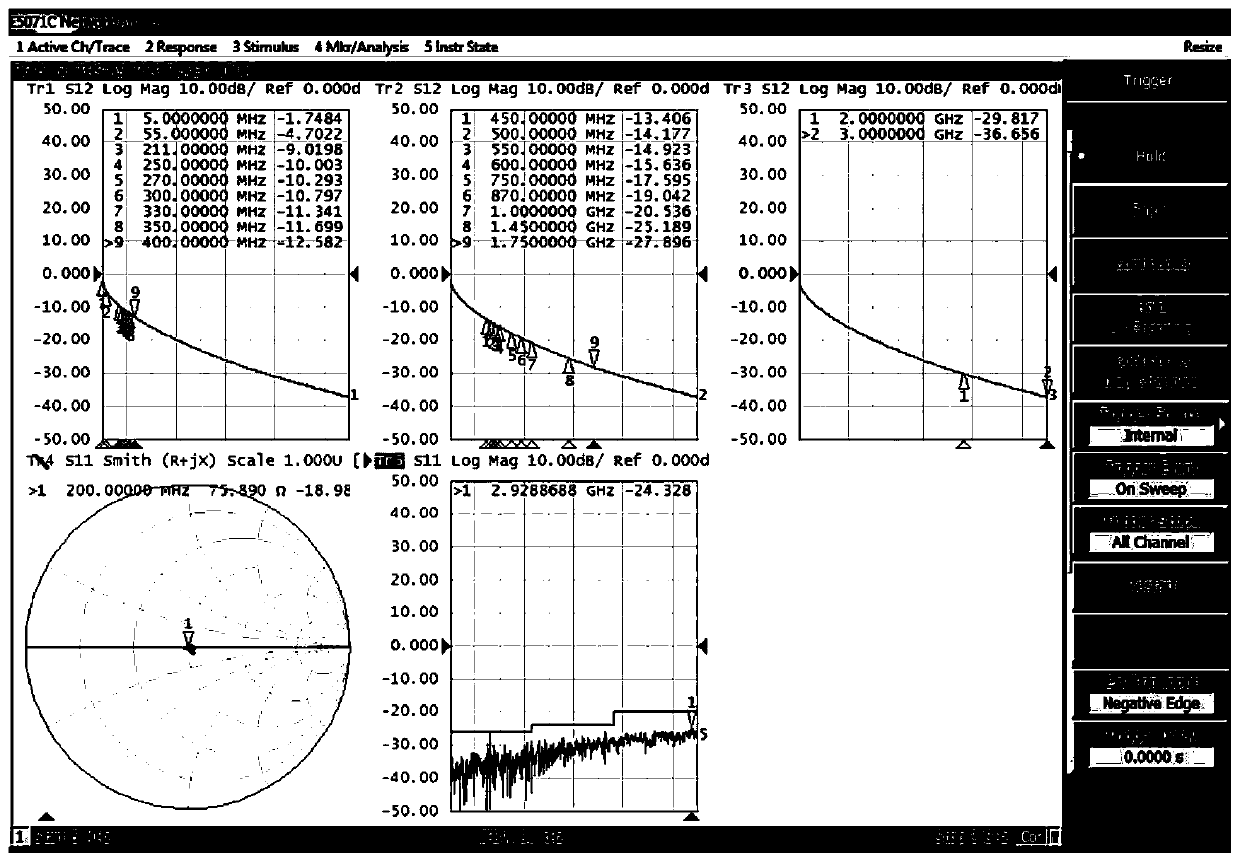

Low-attenuation signal transmission cable

InactiveCN105225761ASmall transmission attenuationImprove shielding effectQuad constructionsConductive materialUltrasound attenuationCopper wire

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

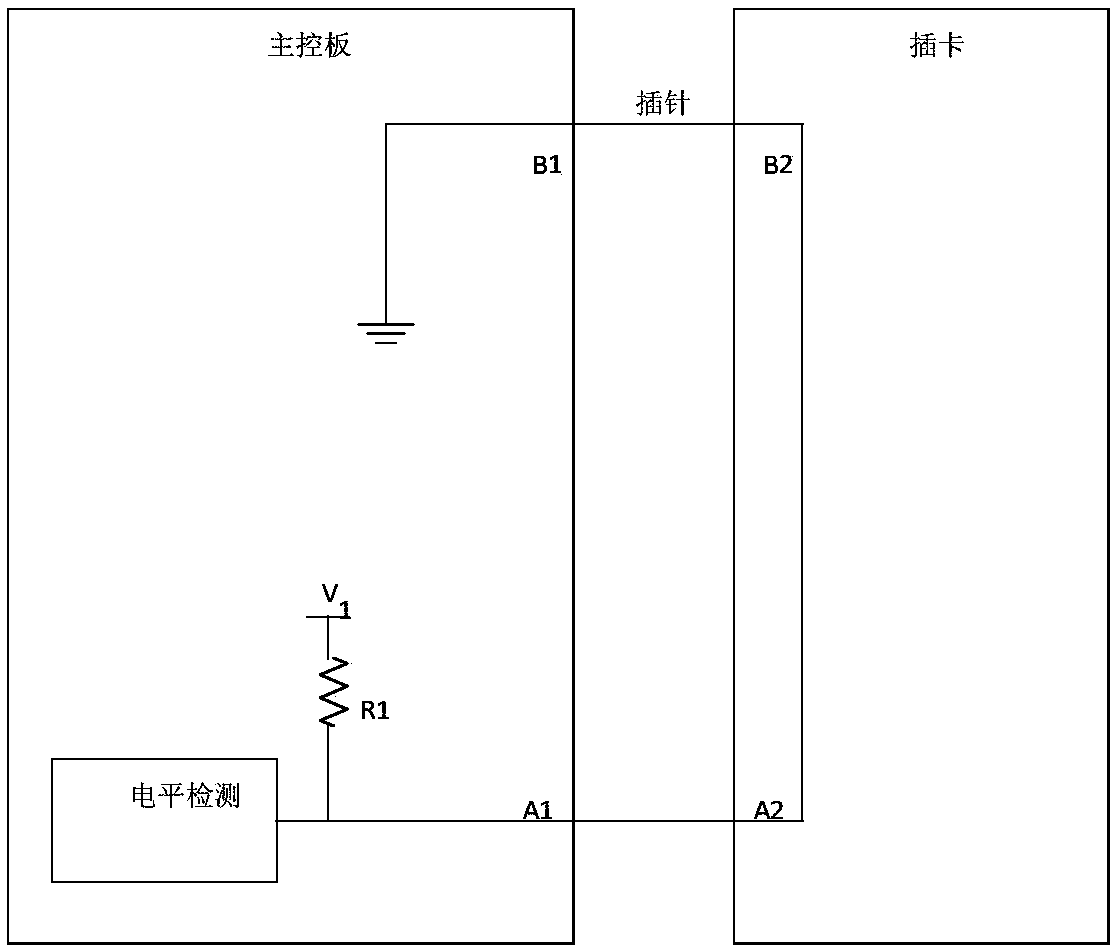

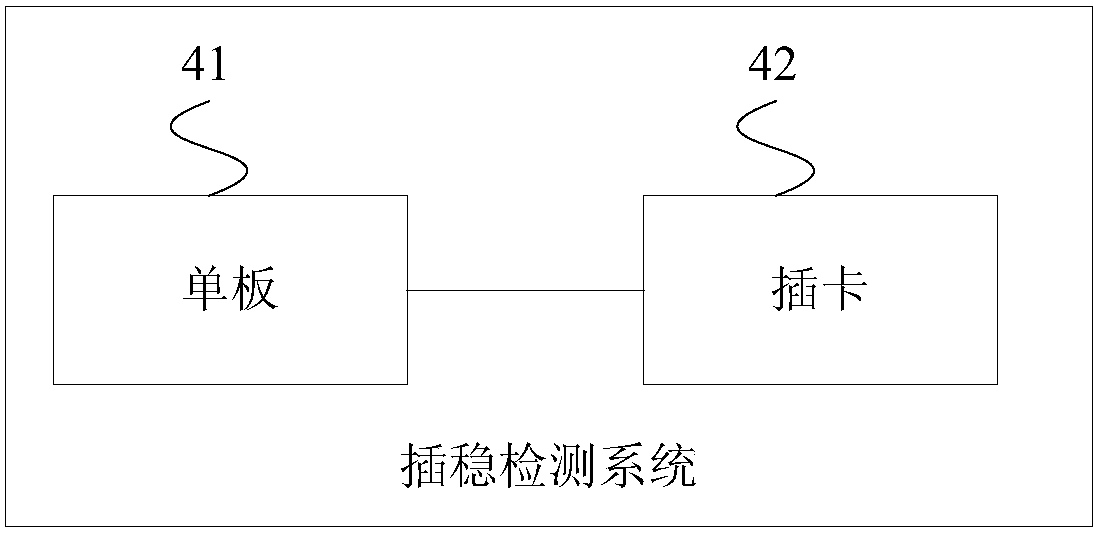

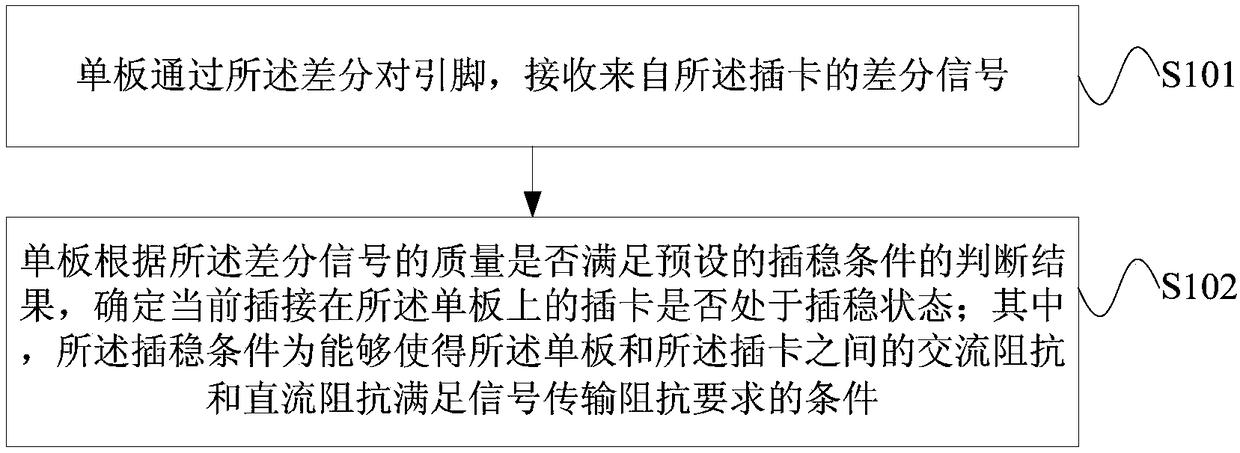

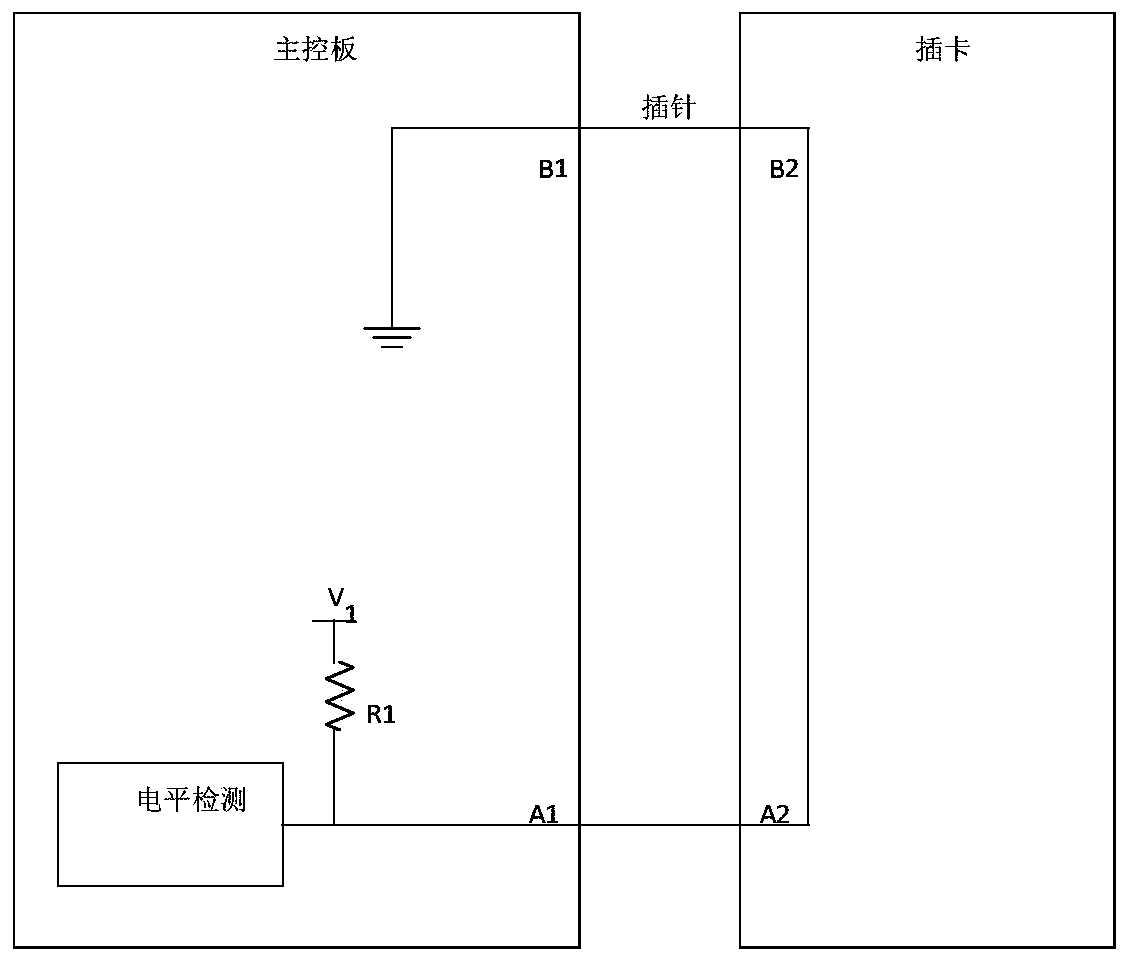

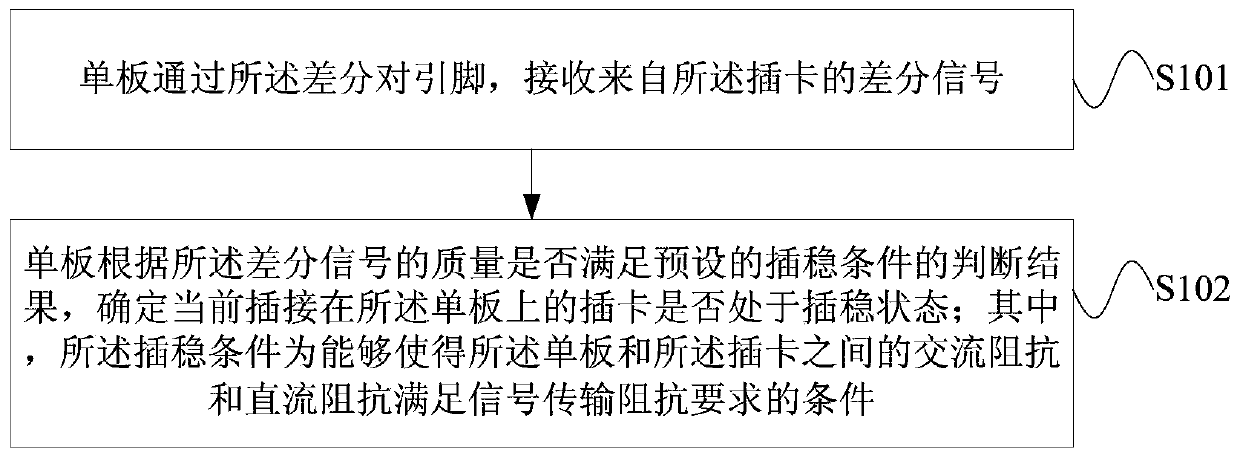

Detection method and device for stable plug-in state of plug-in card, and equipment

ActiveCN109270398AImprove accuracyGuaranteed transmission qualityElectric connection testingUltrasound attenuationDifferential signaling

The invention provides a detection method and device for the stable plug-in state of a plug-in card, and equipment. The method comprises the following steps that: a single board receives a differential signal from the plug-in card through a differential pair pin between the plug-in card and the single board; the single board determines whether the plug-in card which is plugged into the single board at present is under the stable plug-in state or not according to a judgment result which shows whether the quality of the differential signal meets a preset plug-in state or not, wherein the plug-instate condition is that alternating current impedance and direct current impedance between the single board and the plug-in card meet signal transmission impedance requirements. By use of the methodprovided by the invention, the accuracy of the stable plug-in detection of the stable plug-in card is greatly improved, in addition, when a serdes signal is transmitted between the single board and the stable plug-in card, serdes signal transmission quality can be guaranteed, serdes signal transmission attenuation is lowered, and meanwhile, the transmission quality of a direct current signal whendirect current transmission is carried out between boards can be guaranteed.

Owner:HUAWEI TECH CO LTD

Method, device and equipment for detecting stable state of plug-in card

ActiveCN109270398BImprove accuracyGuaranteed transmission qualityElectric connection testingMonoboardAc impedance

The invention provides a detection method and device for the stable plug-in state of a plug-in card, and equipment. The method comprises the following steps that: a single board receives a differential signal from the plug-in card through a differential pair pin between the plug-in card and the single board; the single board determines whether the plug-in card which is plugged into the single board at present is under the stable plug-in state or not according to a judgment result which shows whether the quality of the differential signal meets a preset plug-in state or not, wherein the plug-instate condition is that alternating current impedance and direct current impedance between the single board and the plug-in card meet signal transmission impedance requirements. By use of the methodprovided by the invention, the accuracy of the stable plug-in detection of the stable plug-in card is greatly improved, in addition, when a serdes signal is transmitted between the single board and the stable plug-in card, serdes signal transmission quality can be guaranteed, serdes signal transmission attenuation is lowered, and meanwhile, the transmission quality of a direct current signal whendirect current transmission is carried out between boards can be guaranteed.

Owner:HUAWEI TECH CO LTD

Anti-electromagnetic interference railway digital signal cable

InactiveCN105225762ASmall transmission attenuationImprove shielding effectQuad constructionsConductive materialPolyesterUltrasound attenuation

The invention discloses an anti-electromagnetic interference railway digital signal cable. The cable comprises 2-20 conductive wire groups wrapped by polyester bands. Each conductive wire group comprises four stranded single wire formed by stranding of seven tin-coated copper wires. The outer surface of the stranded single wire is provided with an inner insulating layer. A covering layer covers the outer surfaces of the 2-20 conductive wire groups. A first copper layer covers the outer surface of the inner insulating layer. A steel layer covers the outer surface of the first copper layer. A second copper layer covers the outer surface of the steel layer. The first copper layer and the inner surface of the steel layer are connected in a sealed manner through a first alloy layer, and a second copper layer and the outer surface of the steel layer are connected in a sealed manner through a second alloy layer. An outer protection layer covers the outer surface of the second copper layer. The first alloy layer is composed of 78% copper, 15% iron, 3% molybdenum, 3% chromium and 1% carbon. The anti-electromagnetic interference railway digital signal cable has the advantages that the transmission attenuation of the cable is reduced, and the adaptation and the mechanical force resistance are improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Digital transmission flexible cable for security signal system

ActiveCN103700434AGuaranteed softnessStrong interference abilityPlastic/resin/waxes insulatorsClimate change adaptationPolyesterTinning

The invention discloses a digital transmission flexible cable for a security signal system, which comprises three shielding line groups, wherein each shielding line group comprises two stranded single lines stranded by seven first tinned copper wires; a single line insulation layer is arranged on the external surface of each stranded single line; the two stranded single lines are wrapped and coated with a second polyester tape; the external surface of the second polyester tape is covered with a line resistance shielding layer; the external surface of the line resistance shielding layer is coated with a line resistance isolation layer; each single line insulation layer consists of an outer single line insulation layer and an inner single line insulation layer; each outer single line insulation layer comprises the following materials: 1-3% of natural color cross-linked polyethylene material and 97-99% of plastic color masterbatch; the line resistance isolation layer comprises synthetic mica paper; and the two sides of the synthetic mica paper are adhered and covered with glass fabric through silicon resin adhesive phases. The flexible cable can eliminate the influence of metal particles in the color masterbatch distributed around a conductor on an electric field, so that the transmission attenuation of the cable is reduced; mechanical and physical properties and light and heat ageing resistance of the insulation layers are improved; and performance indices of a product are increased.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Multifunctional track traffic digital signal cable

InactiveCN105225740ASmall transmission attenuationImprove shielding effectQuad constructionsConductive materialExtensibilityCopper wire

The invention discloses a multifunctional track traffic digital signal cable. The multifunctional track traffic digital signal cable is characterized in that a conductive wire group comprises four stranded signal wire formed by stranding of seven tin-coated copper wires, one of the seven tin-coated copper wires is arranged at the center position, and other six tin-coated copper wires are stranded and arranged at the outer surface of the central tin-coated copper wire; a first steel layer and the inner surface of a steel layer are connected in a sealed manner through a first alloy layer, and a second steel layer and the outer surface of the steel layer are connected in a sealed manner through a second alloy layer; an outer protection layer covers the outer surface of the second steel layer; and the second alloy layer is composed of 33% copper, 60% iron, 4% molybdenum, 2.2% chromium and 0.8% carbon. The multifunctional track traffic digital signal cable has the advantages that the transmission attenuation of the cable is reduced, the formability, the extensibility and the electrical conductivity are improved, and the tensile strength and the impact resistance are improved.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

A kind of rg-6 copper clad steel coaxial cable and preparation method thereof

ActiveCN110233001BReduce lossLow dielectric constantPlastic/resin/waxes insulatorsApparatus for feeding conductors/cablesLow-density polyethyleneCoaxial cable

The invention relates to the technical field of a RG-6 copper-coated steel coaxial cable fabrication process, in particular to a RG-6 copper-coated steel coaxial cable. The RG-6 copper-coated steel coaxial cable comprises a copper-coated steel conductor, an inner skin layer, a foam layer and an outer skin layer, wherein the raw material for fabricating the inner skin layer comprises the followingconstituents based on parts by weight: 0.3-0.7 part of ethylene-ethylhexyl copolymer and 23-27 parts of low-density polyethylene, the raw material for fabricating the foam layer comprises the following constituents based on parts by weight: 23-27 parts of HDPE 2911, 23-27 parts of HMA, 23-27 parts of low-density polyethylene and 0.3-0.7 of nucleating agent, and the raw material for fabricating theouter skin layer comprises the following constituents based on parts by weight: 0.3-0.7 part of ethylene-ethylhexyl copolymer and 23-27 parts of low-density polyethylene. The fabricated RG-6 copper-coated steel coaxial cable has the advantage of small transmission attenuation, and the signal transmission quality of the coaxial cable is favorably improved.

Owner:杭州三元电缆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com