Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Shorten the processing period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

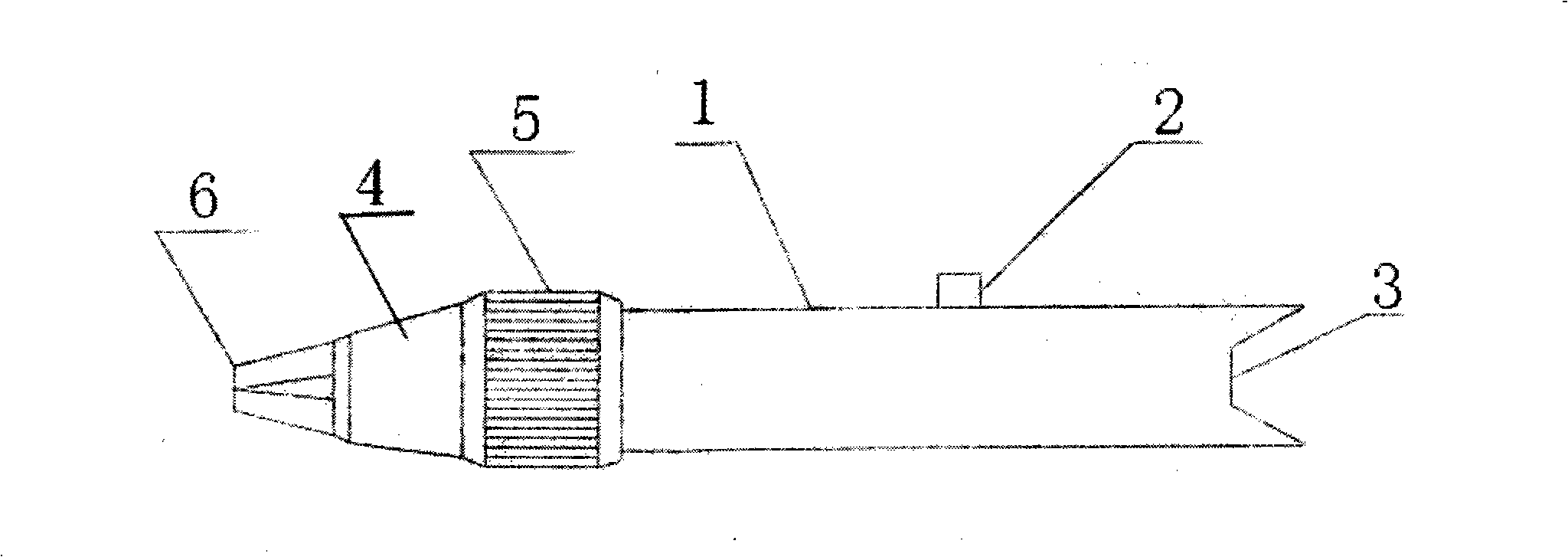

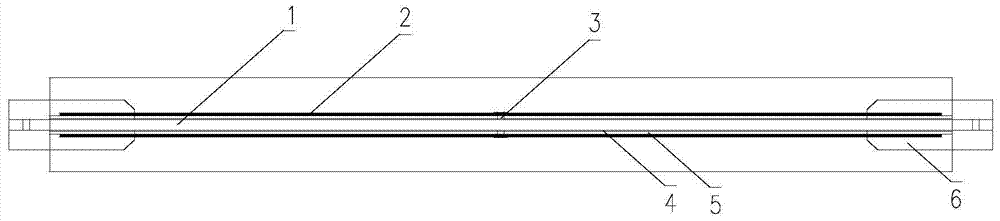

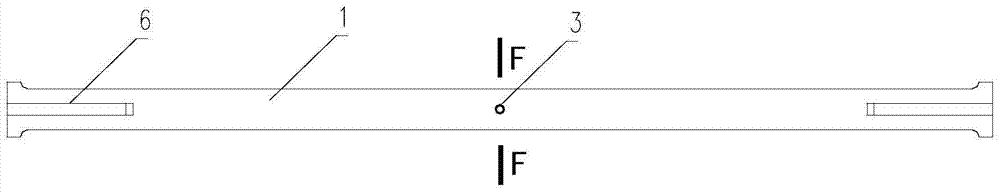

Adjustable clamping device for processing gem

The present invention discloses an adjustable clamp for processing jewels, which is a clamping tool consisting of a metal rod, a fixed pin, a tail slot, a cone collet, a fastening sleeve nut and a clamping jaw. The present invention replaces the traditional mucilage glue process that rubber is used for sticking jewel bosses for grinding so as to avoid 5 to 10 percent of the shedding stone rate when the rubber is used for sticking the jewel bosses for producing and grinding and increases the A-class goods rate of the product over 95 percent. The present invention not only saves a plurality of auxiliary materials such as rubber, shellac, alcohol, liquefied gas, and the like, but also prevents the materials from polluting the environment and harming the health of operating workers.

Owner:罗吉杰

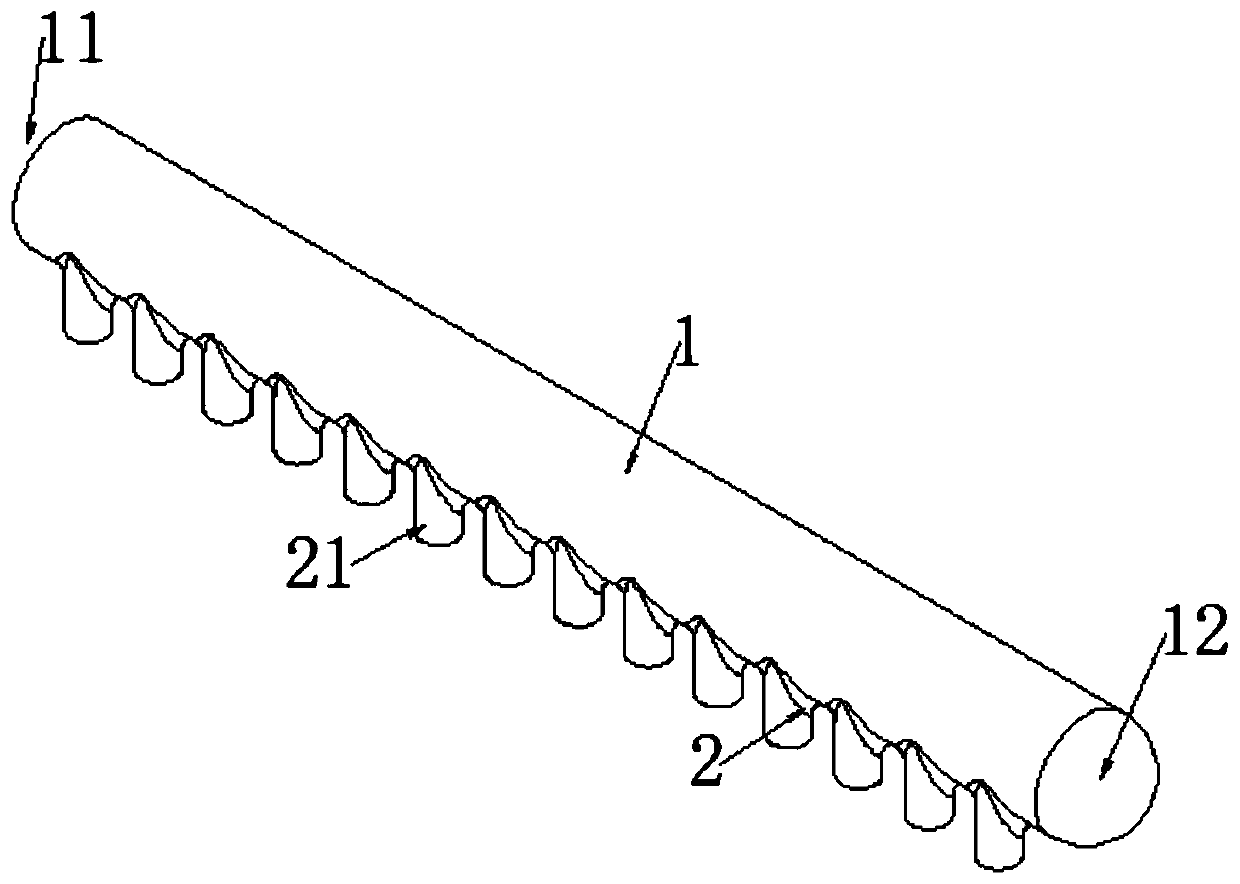

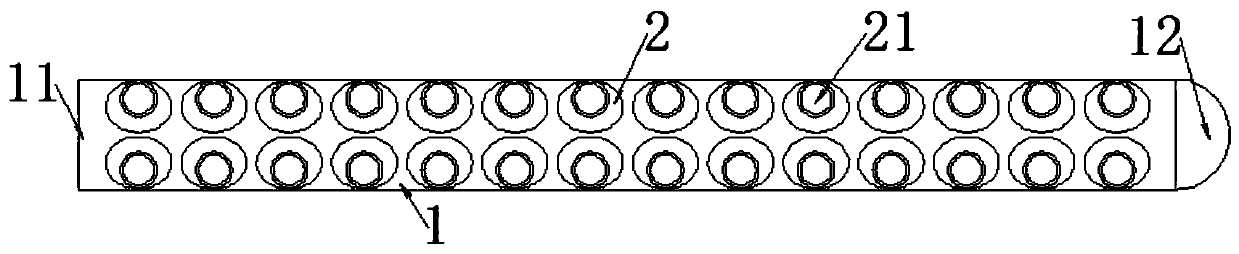

Method for fabricating a conductive yarn and conductive yarn fabricated by the method

InactiveUS20140318857A1Improve conductivityShorten the processing periodMaterial nanotechnologyLubricating devicesPolymer scienceElectrically conducting yarn

A method for fabricating a conductive yarn includes the steps of: moistening a preformed yarn with a conductive slurry to prepare the preformed yarn absorbed with the conductive slurry; and drying the preformed yarn absorbed with the conductive slurry. The conductive slurry includes a conductive nanometer structure, a solvent, and a resin component. The conductive nanometer structure has an aspect ratio sufficient to permit binding of the conductive nanometer structure to the preformed yarn.

Owner:ASIATIC FIBER CORP

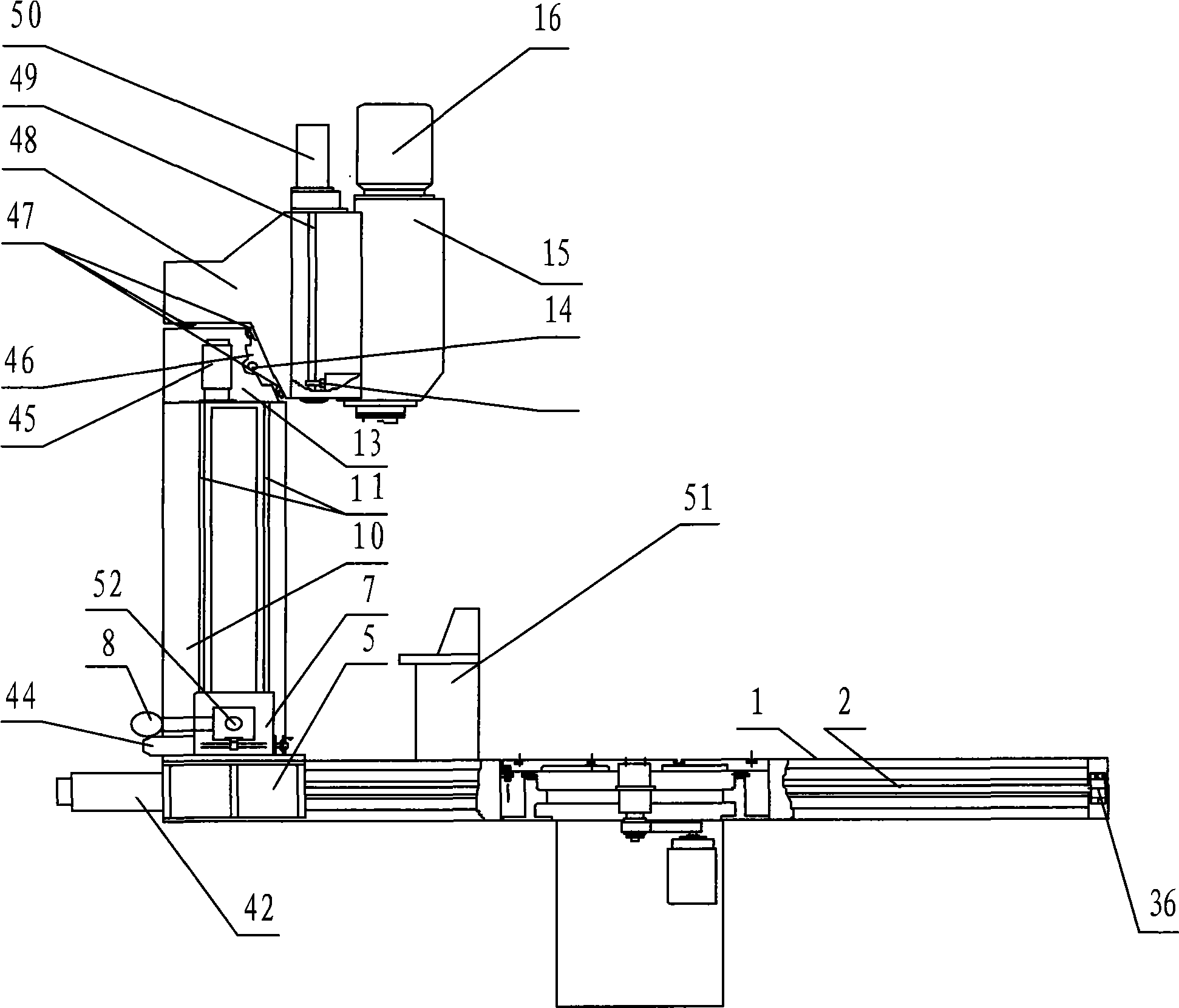

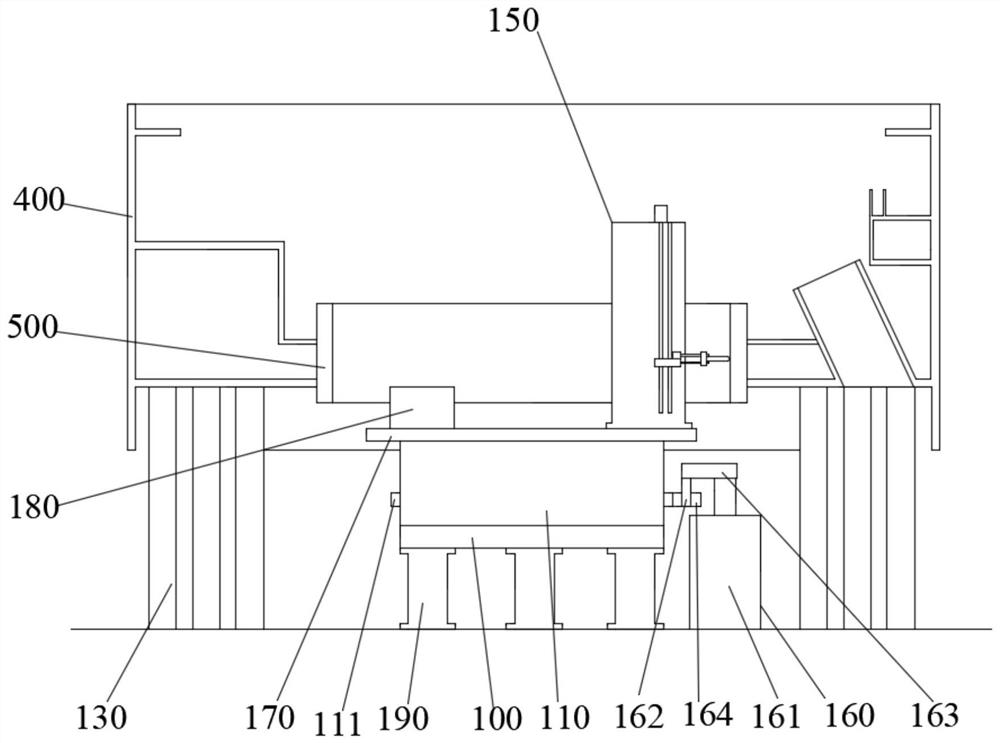

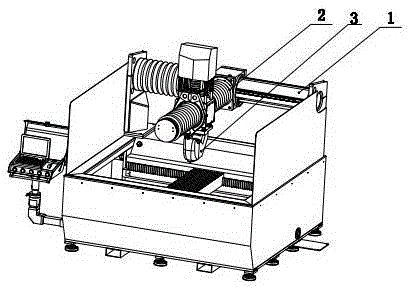

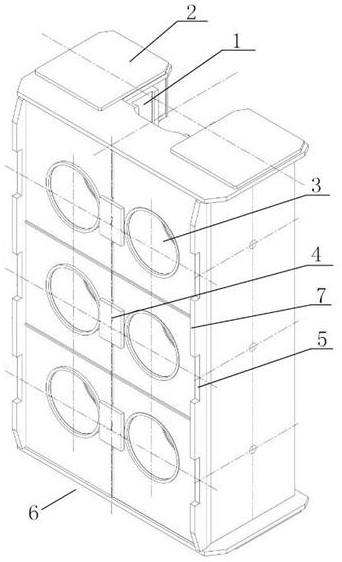

Aggregate machinery for machining large-sized mechanical components

InactiveCN101497162AImprove efficiencyImprove machining accuracyOther manufacturing equipments/toolsMechanical componentsAgricultural engineering

The invention discloses a combined machine tool for processing large mechanical parts, which comprises a numerical control system, a main worktable, a vertical lathe worktable, a portal frame, a vertical boring and milling head component, a left horizontal boring and milling head and a right horizontal boring and milling head, wherein the vertical lathe worktable is arranged in a center hole of the main worktable; in the portal frame, upper ends of a gantry right upright post and a gantry left upright post are fixedly or movably connected with a gantry beam, and lower ends of the two upright posts are in assembly connection with guide rail platforms at two sides of the main worktable through an upper right guide rail and an upper right guide rail groove, a lower right guide rail and a lower right guide rail groove, an upper left guide rail and an upper left guide rail groove, a lower left guide rail and a lower left guide rail groove; the vertical boring and milling head component comprises a vertical boring and milling head bracket and a vertical boring and milling head, and is in assembly connection with the gantry beam through a linear guide rail and a linear guide rail groove; right and left horizontal boring and milling head outer shells of the right and left horizontal boring and milling heads pass through rectangular through holes in the middle of the two upright posts from two sides of the portal frame respectively and pass through right and left horizontal boring and milling head brackets to form sliding connection; and the right and left horizontal boring and milling heads can be lifted vertically and moved transversely.

Owner:JILIN TIANLIN IND & TRADE

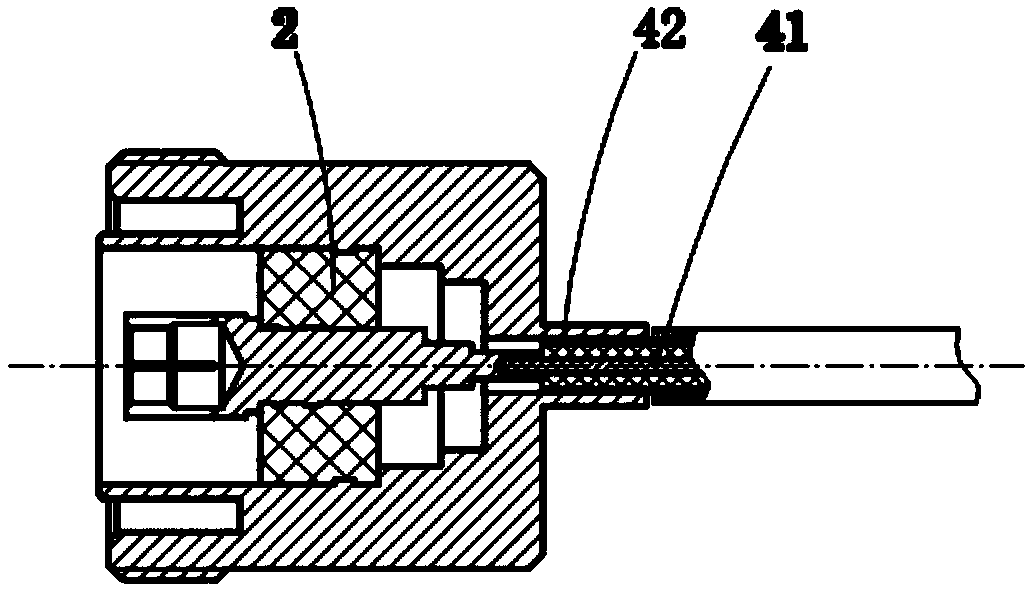

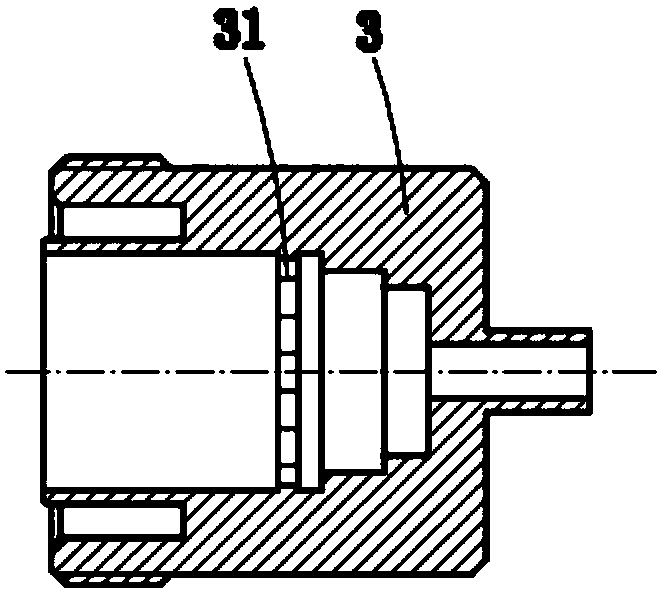

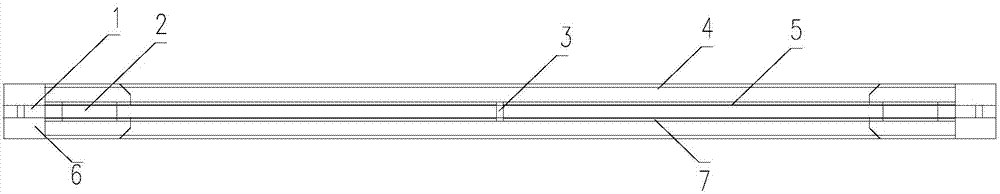

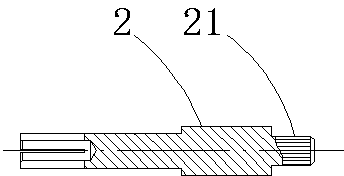

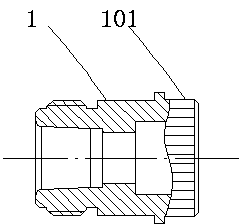

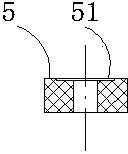

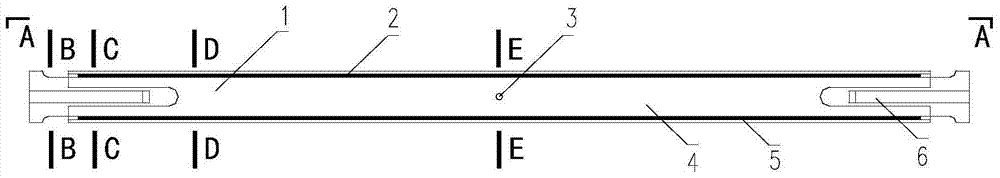

Connector of integral type adaptor cable

InactiveCN103474804AReduce disorderIncrease usageSecuring/insulating coupling contact membersCoupling contact membersElectrical conductorHigh volume manufacturing

The invention discloses a connector of an integral type adaptor cable. The connector comprises an inner conductor, insulating media and an outer conductor, wherein the inner conductor, the insulating media and the outer conductor are sequentially and coaxially distributed from the center; the tail of the inner conductor is coaxially provided with an inner core welding hole; the tail of the outer conductor is in a step shaft shape, the tail of the outer conductor is provided with a shielding layer welding pipe of a coaxial structure, and the inner diameter of the shielding layer welding pipe is matched with the outer diameter of a shielding layer of the cable. The connector is simple in structure, reliable in mechanical property, excellent in electrical performance, high in assembly efficiency, high in using rate of raw material, and high in one-time assembly percent of pass, has low intermodulation performance, and is suitable for mass production of cable assemblies.

Owner:安徽蓝麦通信股份有限公司

Mobile lifting combined measuring point frame device

Owner:SHANGHAI BOILER WORKS

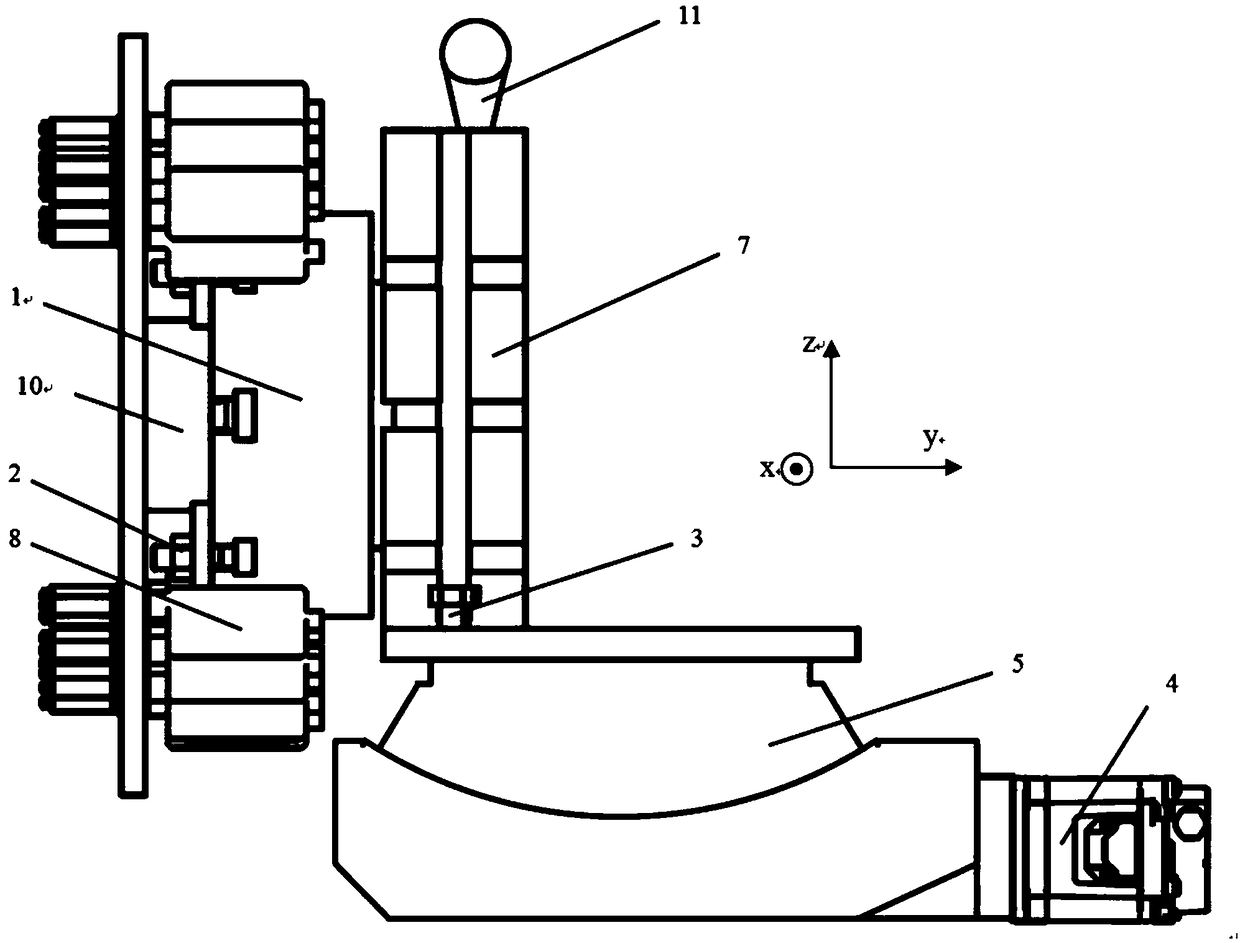

Vertical lathe special for machining large-diameter shield body

PendingCN112024909AAvoid safety hazardsImprove machining accuracyLarge fixed membersTurning machinesStructural engineeringMachine tool

The invention provides a vertical lathe special for machining a large-diameter shield body and relates to the field of shield machine devices. The vertical lathe special for machining the large-diameter shield body comprises a working table supporting plate, a working table installed on the working table supporting plate in a rotating manner, a supporting base in an inverted circular truncated cone shape, multiple shield body supporting stand columns arranged at intervals in the peripheral direction of the working table, a machining tool, and a feeding assembly used for driving the machining tool to be lifted and moving in the horizontal straight line, wherein the supporting base is detachably connected to the working table. The feeding assembly is arranged to be detachably connected to the top edge of the working table or the top edge of the supporting base. A revolution assembly used for driving the working table to rotate is further connected to the working table. According to the vertical lathe special for machining the large-diameter shield body, all the shield body is machined in place through one-time clamping, potential safety hazards caused to the large-diameter shield body due to multiple times of clamping are avoided, machining precision can be improved, and the earlier and middle shield machining period of the large-diameter shield body is shortened.

Owner:CHINA RAILWAY SCI & IND GRP RAIL TRANSPORTATION EQUIP LIMITED

Tube structure wood mold

PendingCN108466351AGuaranteed bearing capacityGuaranteed rigidityFoundry moulding apparatusWood working apparatusSolid woodMaterial consumption

The invention discloses a tube structure wood mold which comprises framework portions, an outer edge portion and end face portions. The whole outer edge portion is of a hollow tube structure, the twoends of the outer edge portion are provided with the end face portions, the end face portions are of disc-shaped structures matched with the tube inner diameter of the outer edge portion, cylindricalspaces formed between the outer edge portion and the inner walls of the end face portions are the framework portions, a plurality of solid wood frameworks are arranged in the framework portions, foamplastic filler is further arranged in the framework portions, and framework portions are filled with the solid wood frameworks and the foam plastic filler in a mutually matched mode. A multi-layer plate is used as a working face material, foam plastic is used as a filling material, the pressure bearing capacity and rigidity of the wood mold are ensured, smoothness of the working surface is ensured, convenience is brought to mold removal, the processing period is shortened, wood material consumption is reduced, moisture absorption is not likely to be caused, mold cracking is avoided, and mold precision is ensured.

Owner:HANGZHOU STEAM TURBINE CASTING & FORGING

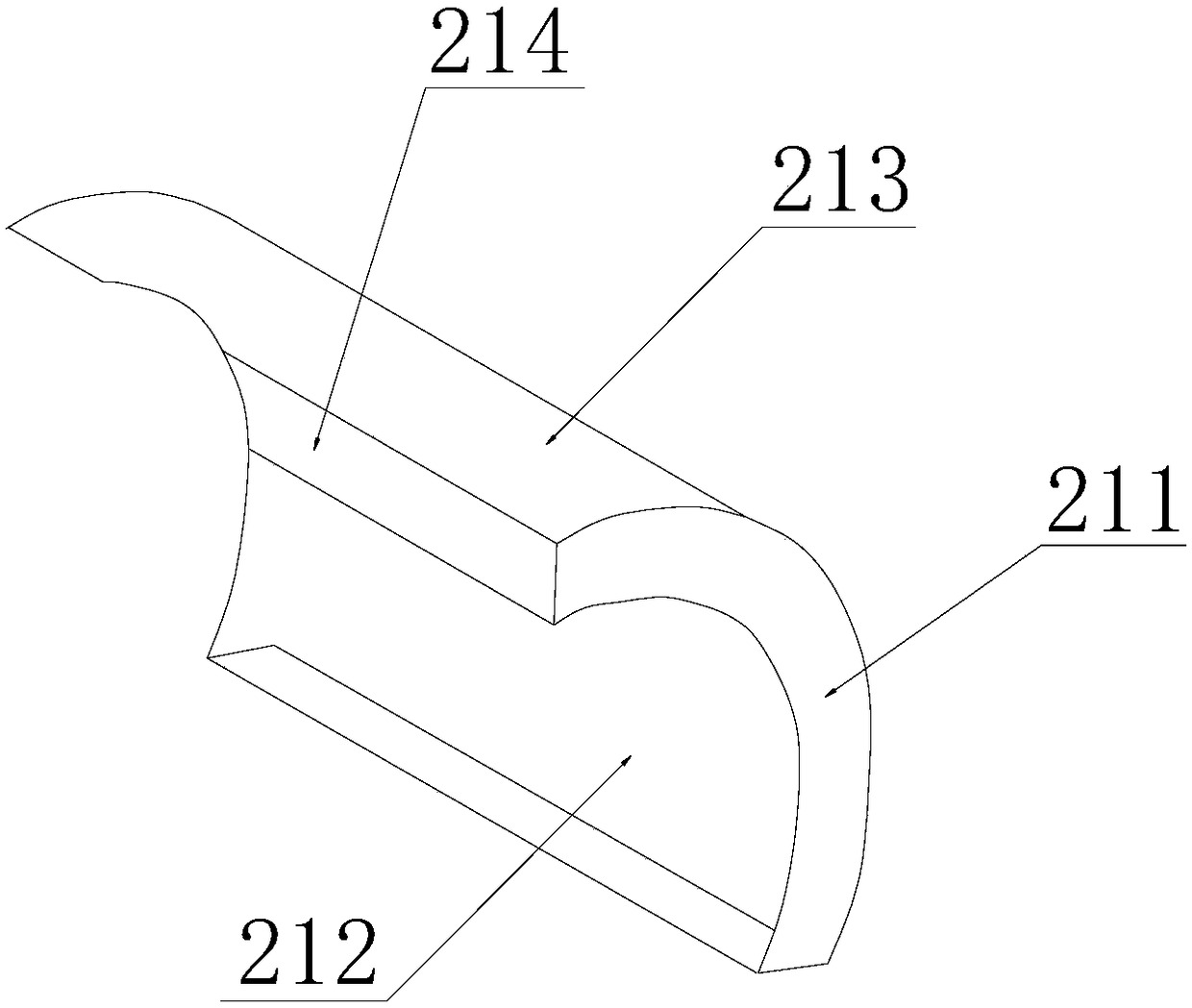

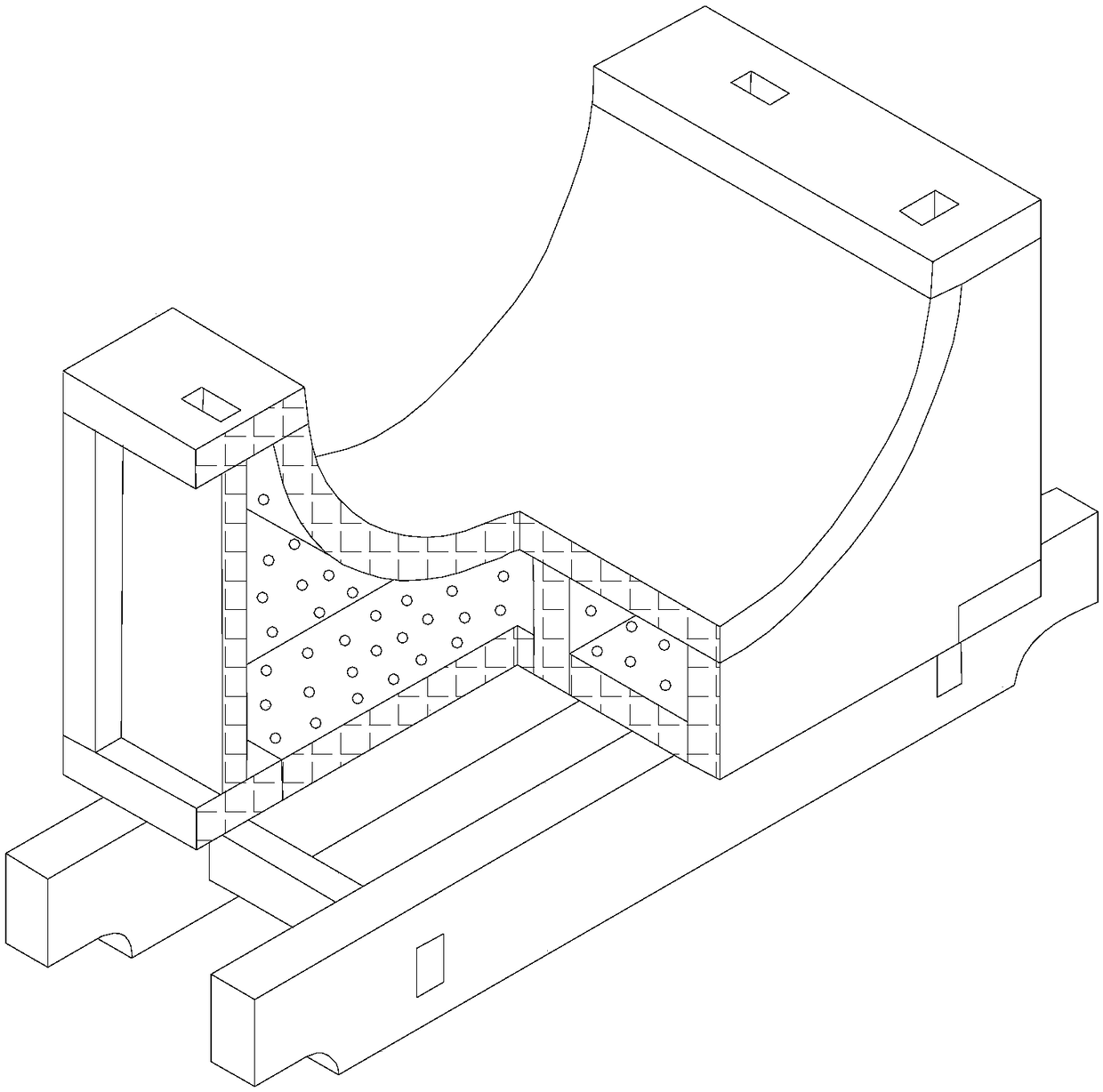

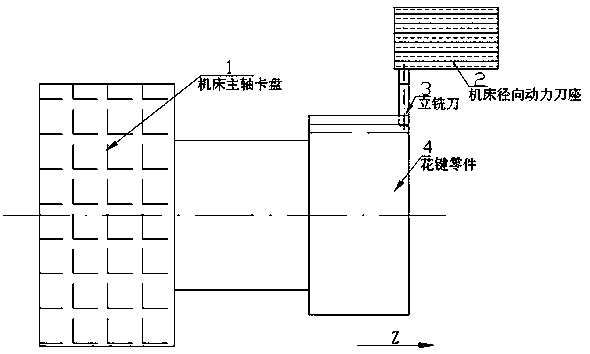

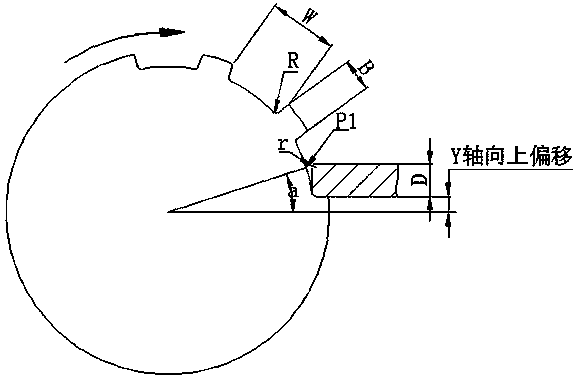

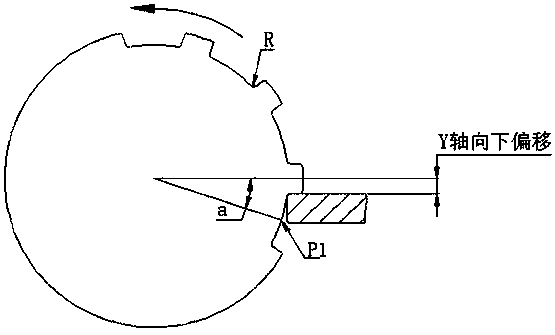

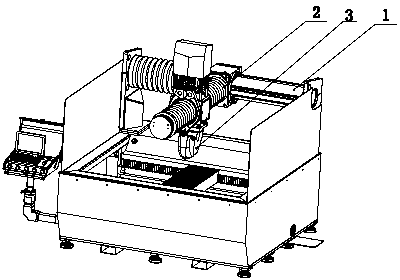

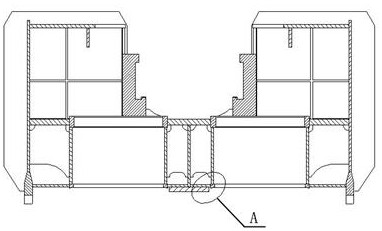

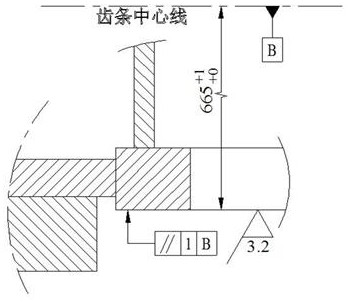

Rectangular external spline machining method suitable for numerical control turning center

ActiveCN107617768AFast one-shot machiningRealize one-time clamping processingMilling equipment detailsNumerical controlMilling cutter

The invention belongs to the field of numerical control turning part machining, and particularly relates to a rectangular external spline machining method suitable for a numerical control turning center. The rectangular external spline machining method is characterized by comprising the following steps that a, a milling cutter material is selected according to the material of a part to be machined; b, rough machining is carried out on an external spline groove, and allowances are reserved for all faces; c, finish milling is carried out on teeth on the upper side of the spline obtained in the step b; d, quilting cutting machining is carried out on the small-diameter upper half part of the spline obtained in the step c; e, teeth on the lower side of the spline obtained in the step d are machined; and f, the small-diameter lower half part of the spline is subjected to quilting cutting machining, and an end mill is arranged on a radial driven tool holder.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

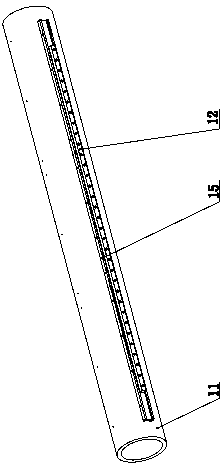

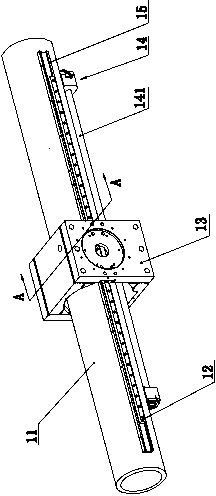

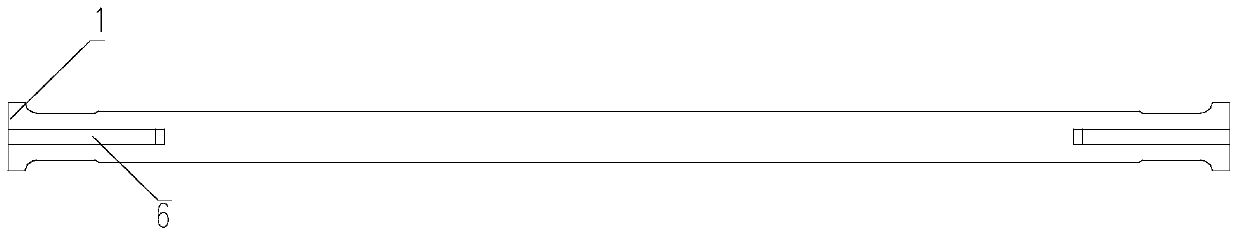

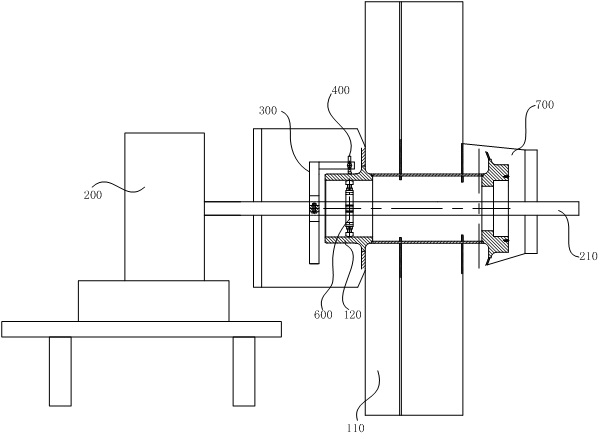

Processing method of machine tool mobile support cross beam shaft, the machine tool mobile support cross beam shaft and special clamp of the machine tool mobile support cross beam shaft

ActiveCN103009248AEnsure straightnessEnsure parallelismAbrasive machine appurtenancesAbrasive blasting machinesEngineeringProcessing cost

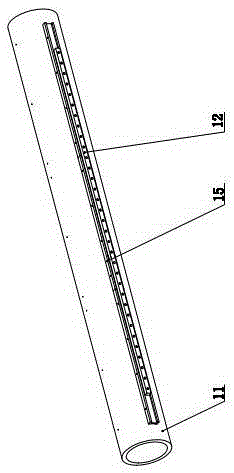

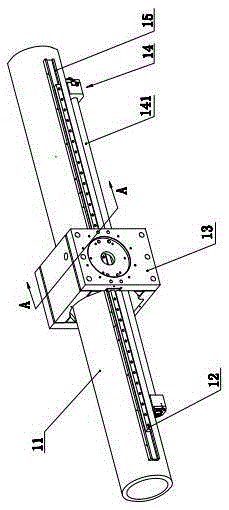

The invention discloses a processing method of a machine tool mobile support cross beam shaft, the machine tool mobile support cross beam shaft and a special clamp of the machine tool mobile support cross beam shaft. The processing method is characterized in that a side surface of a cross beam shaft is provided with a groove which is parallel to the axis and is used for supporting a guide rail; the cross beam shaft with the groove is arranged into the special clamp and the axis is allowed to be horizontal; a side clamp plate of the special clamp corresponding to the groove of the cross beam shaft is provided with a plurality of pairs of guide rail clamp blocks which are subject to standard horizontal correction; a guide rail is inserted into a travel cavity of the guide rail clamp block and a receiving cavity of the groove; the guide rail is fixed on the cross beam shaft through fasteners and the guide rail is allowed to be horizontal; and the special clamp is dismounted so that the cross beam shaft with the guide rail is obtained. According to the invention, the flatness and the parallelism of the guide rail of the processed mobile support cross beam shaft can be guaranteed, templated manufacture and repeated and convenient precision processing are realized, a corresponding processing cost is greatly reduced, a processing period is shortened, and stocks are reduced. The machine tool mobile support cross beam shaft disclosed herein is especially suitable for precision, light-load and long-axis occasions.

Owner:柔锋机械科技(江苏)有限公司

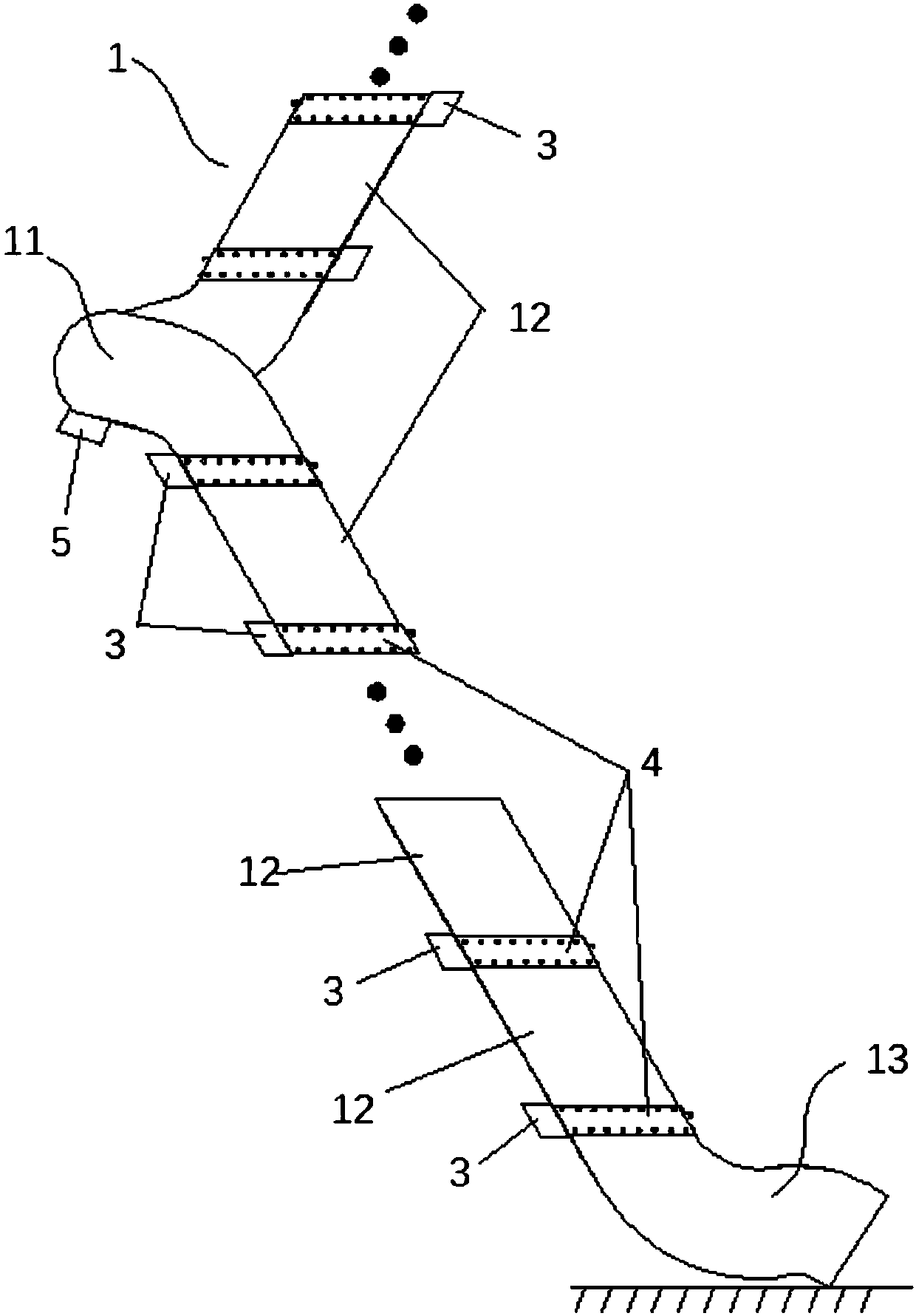

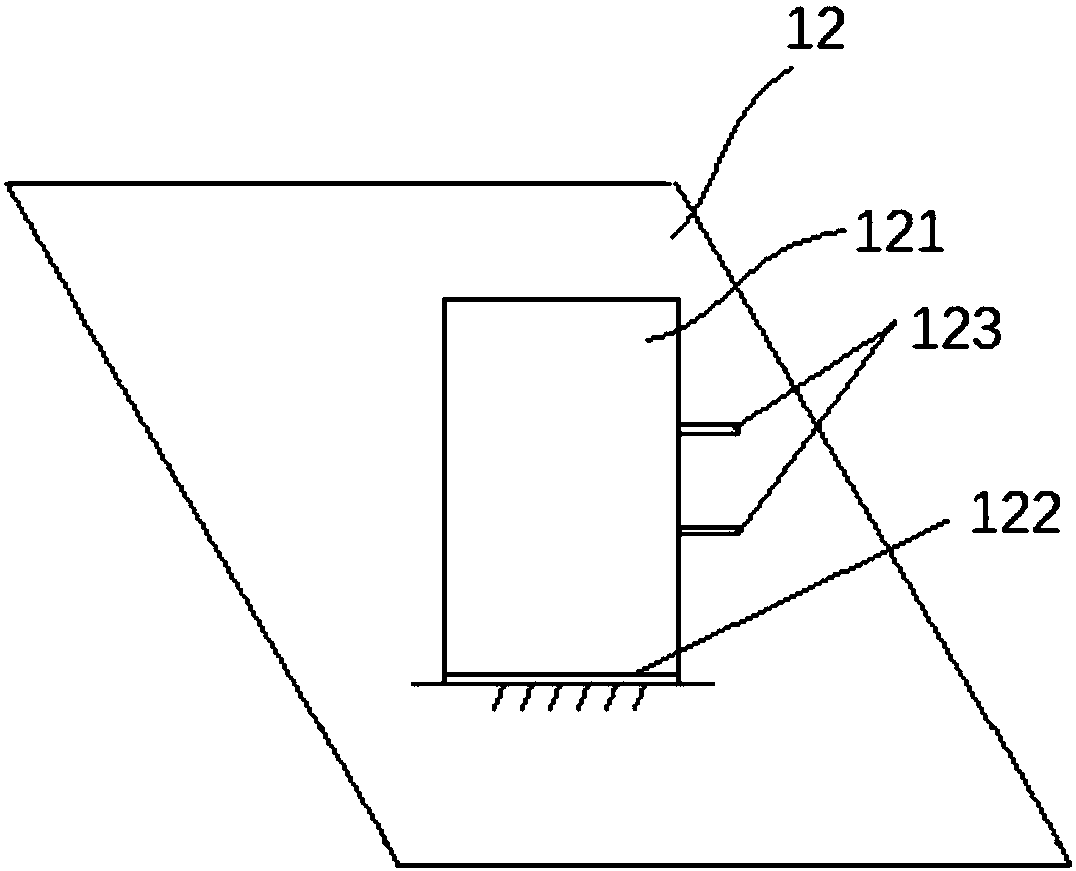

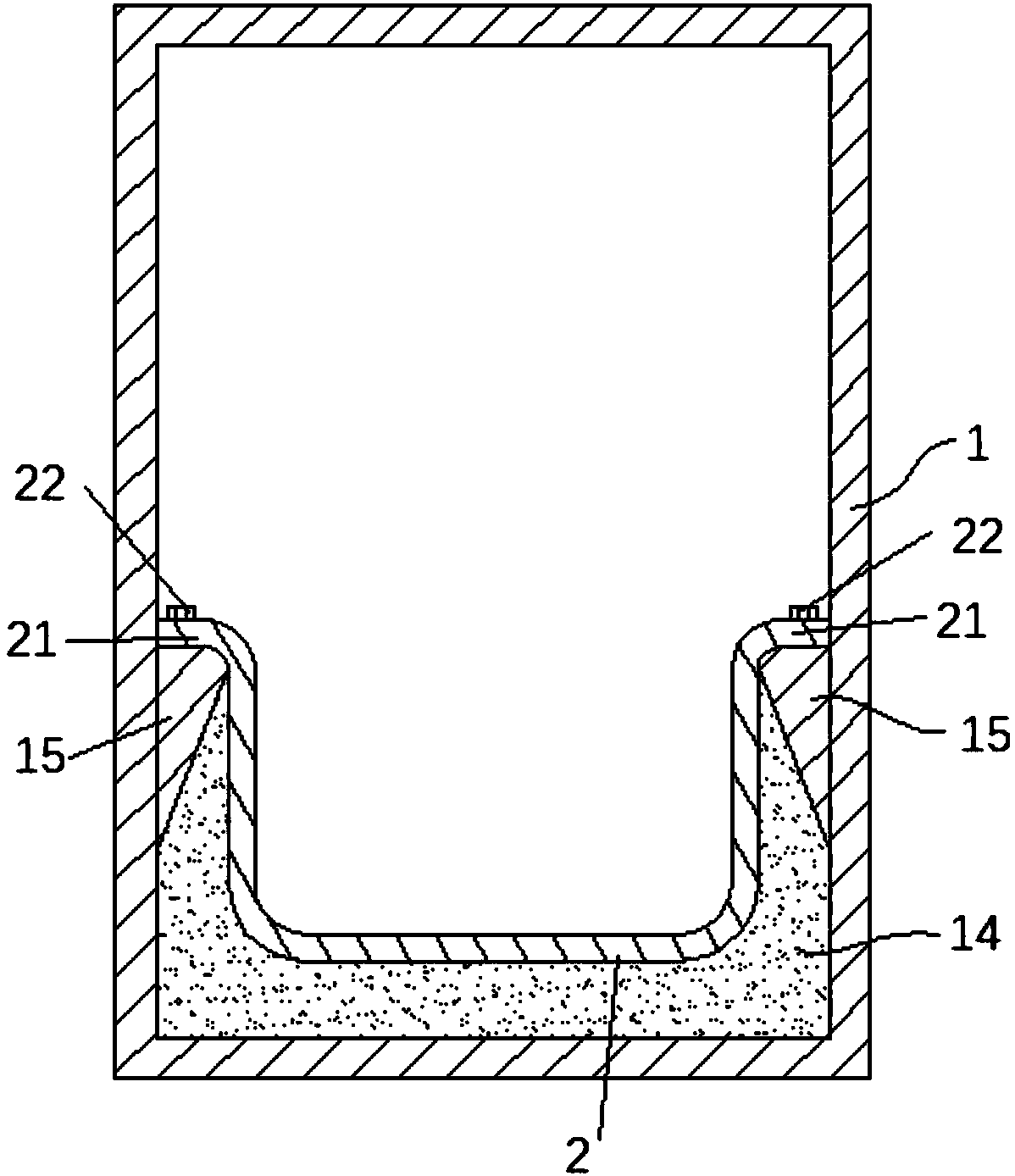

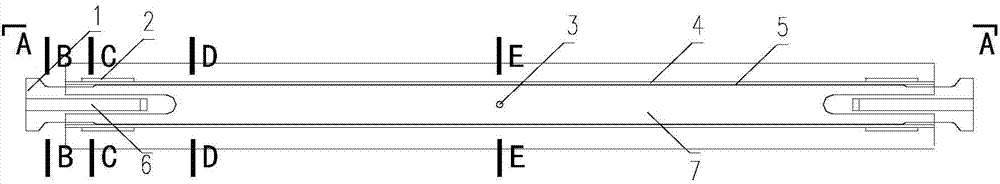

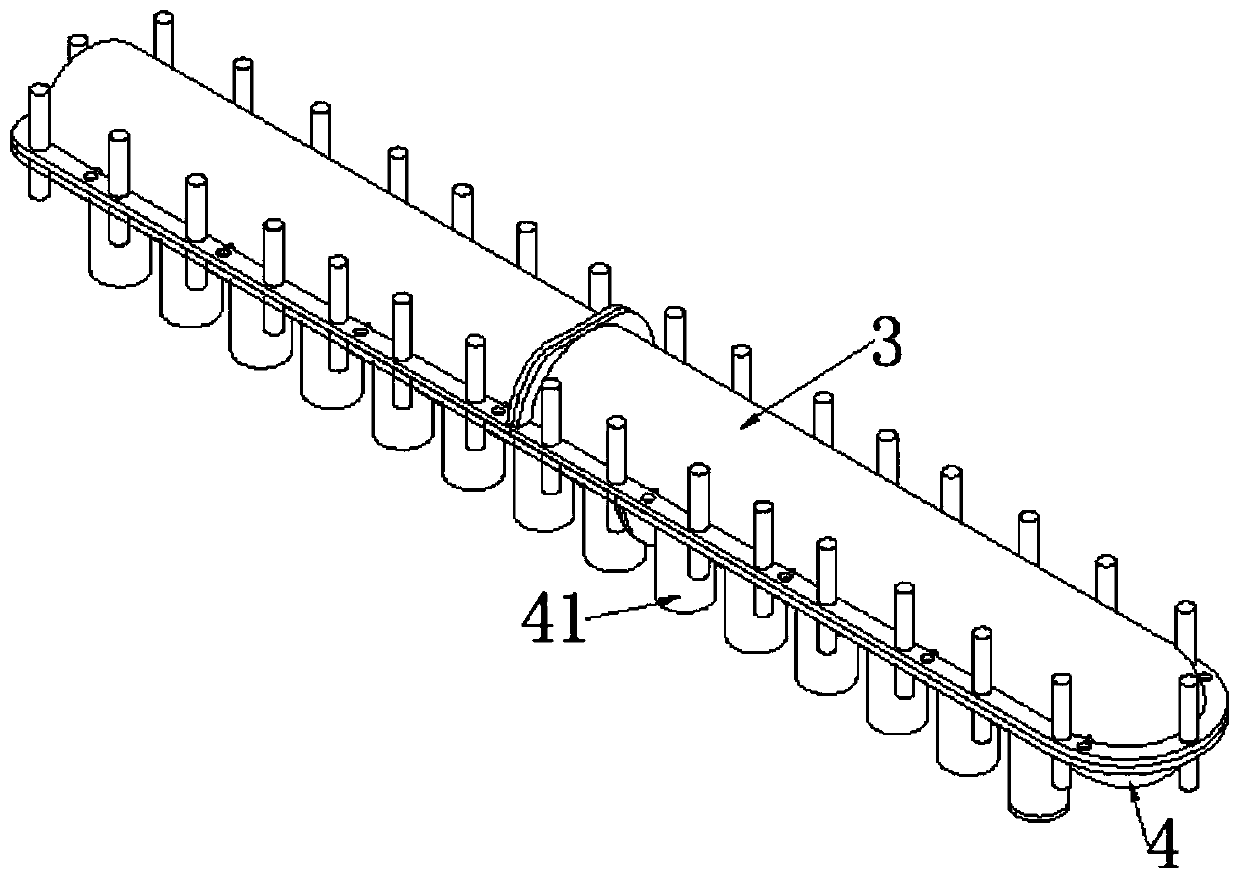

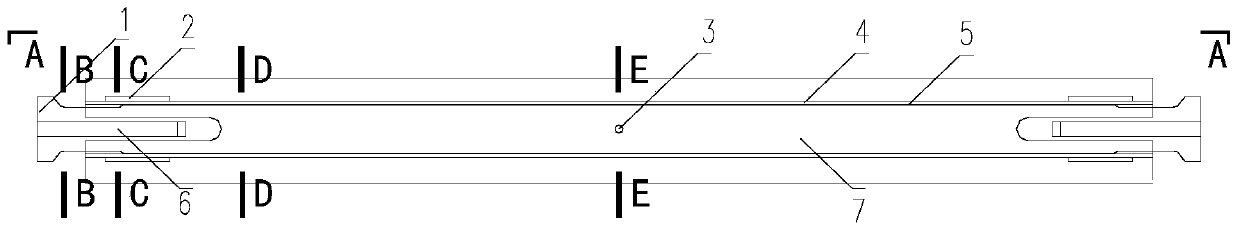

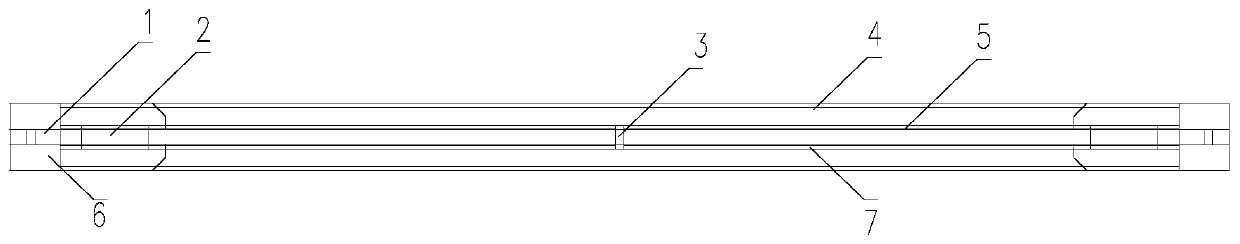

Pipeline sliding bed for emergency evacuation in high-rise fire and earthquakes

PendingCN107715329AReduce casualty rateQuick evacuationFire rescueBuilding rescueButt jointEngineering

Owner:张龙武

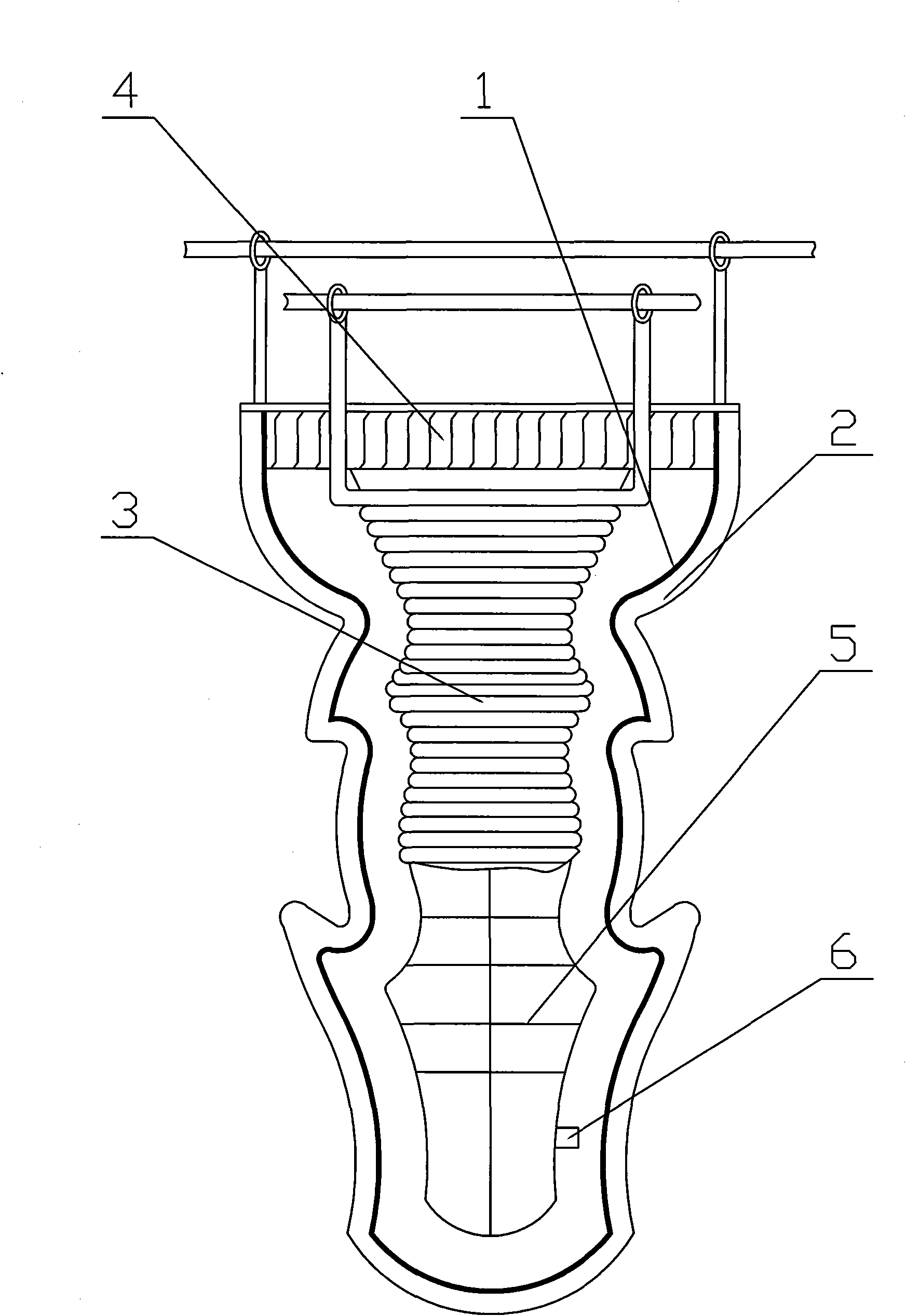

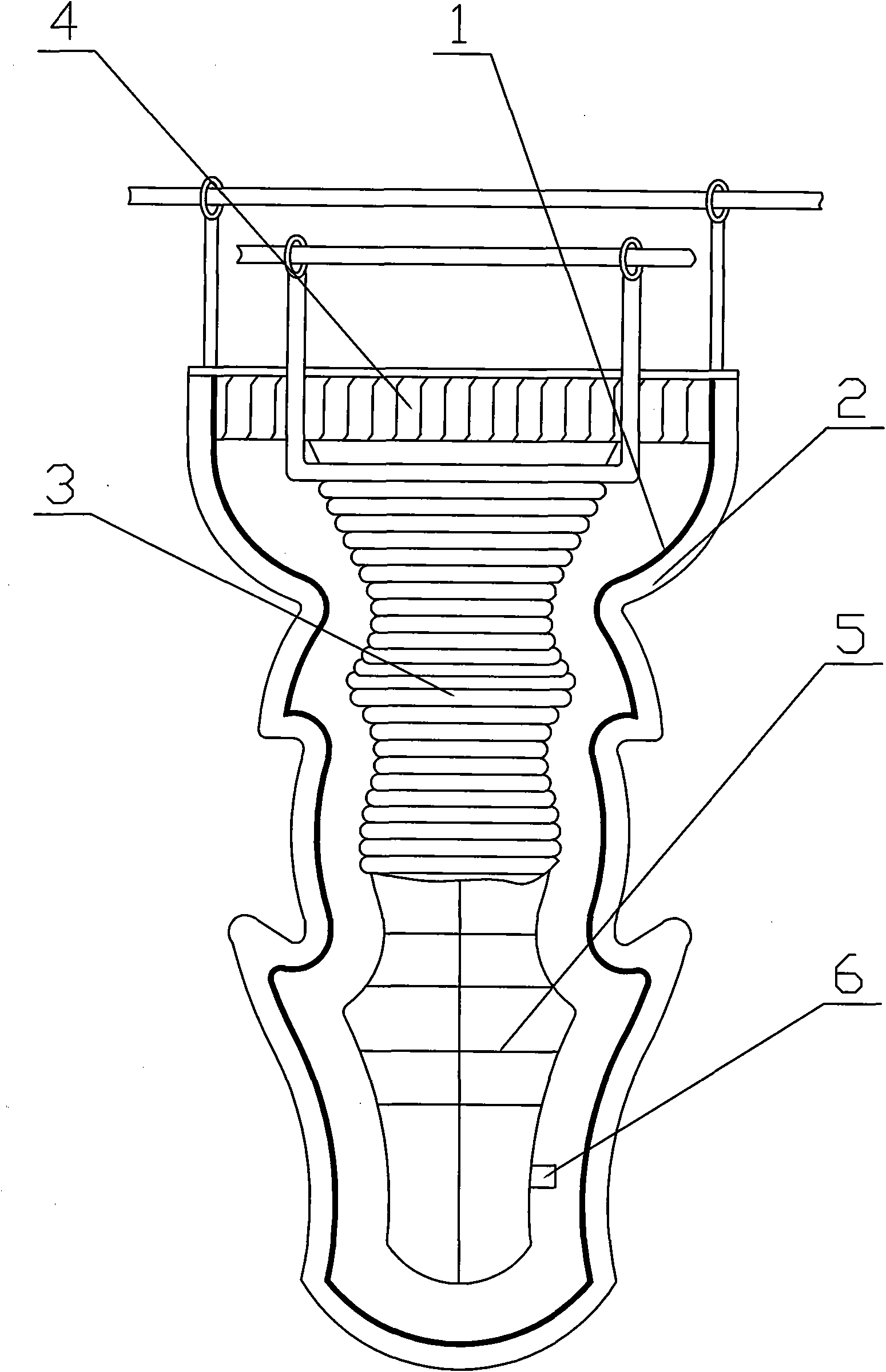

Steel channel sleeve restraining linear pure steel buckling restrained brace and manufacturing method thereof

InactiveCN104763072AImprove utilization efficiencyReduce dosageShock proofingBuckling-restrained braceAdhesive materials

The invention relates to a steel channel sleeve restraining linear pure steel buckling restrained brace and a manufacturing method thereof. The steel channel sleeve restraining linear pure steel buckling restrained brace comprises a core plate with a linear cross section, a non-adhesive material layer, a periphery restraining sleeve and a belly steel plate, wherein the section of the periphery restraining sleeve is a vertical section which is a steel channel, and the belly steel plate is a section with the interior being a rectangle, and the section is formed by a common steel plate; the core plate is retracted by 5 mm in the height direction from the variable cross section of the end to the internal length range of the periphery restraining sleeve, a 10-20 mm long steel plate is welded to the outer side of the end steel channel of the periphery restraining sleeve, the exterior of the core plate is wrapped in the non-adhesive material layer, and a plug welding hole is formed in the belly steel plate of the periphery restraining sleeve corresponding to the center position of the core plate so that the belly steel plate and the periphery restraining sleeve can be connected together in a welded mode. According to the steel channel sleeve restraining linear pure steel buckling restrained brace, due to the fact that the two sides of the core plate are clamped in steel channel sleeve belly plate restraining pieces respectively and face contact restraining is achieved, the anti-local-bending capacity of core materials is improved and utilized, filling of restraining materials is not needed, dead loads are greatly reduced, the steel material utilization rate is high, and therefore high economical efficiency is achieved.

Owner:SHANGHAI INST OF TECH

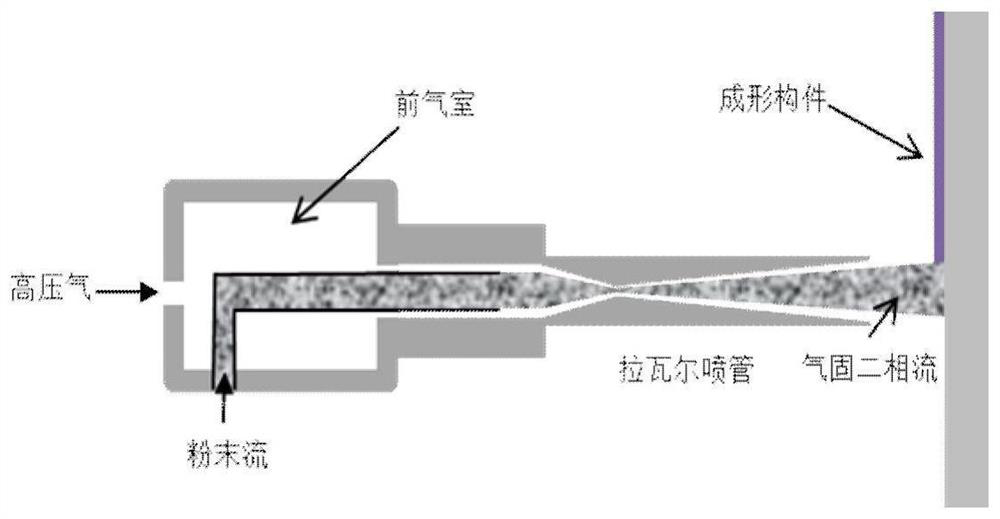

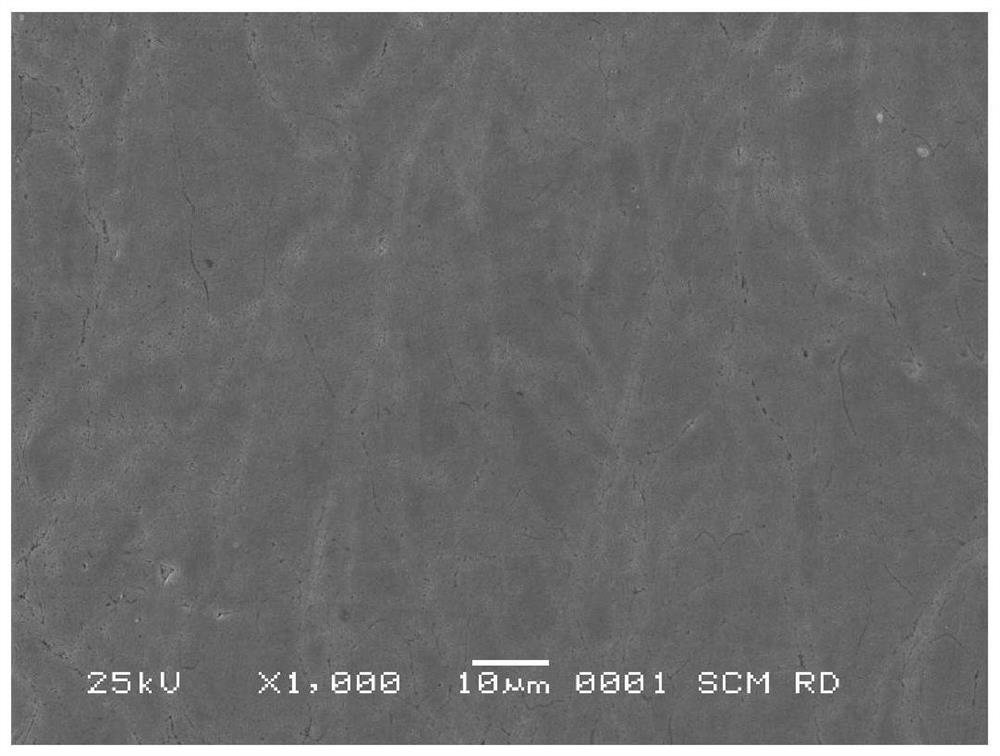

Additive manufacturing method for large dispersion strengthened copper component

ActiveCN113441730AUnlimited shapeUnlimited sizeAdditive manufacturing apparatusIncreasing energy efficiencyMachiningAdditive layer manufacturing

The invention discloses an additive manufacturing method for a large dispersion strengthened copper component. The additive manufacturing method comprises the following steps that (1) the surface of an aluminum alloy matrix is subjected to oil removal, drying and polishing treatment; (2) dispersion strengthened copper powder for cold spraying is subjected to heat treatment; 3) three-dimensional modeling is performed, and a three-dimensional model is converted into a two-dimensional plane model; (4) a moving track of a spray gun for cold spraying is optimized; (5) the powder is loaded into a cold spraying powder feeding tank, and a composite component is obtained through cold spraying equipment controlled by a mechanical arm; (6) the composite component is machined, and the aluminum alloy matrix is removed to obtain the dispersion strengthened copper component; and (7) the dispersion strengthened copper component is put into a hydrogen reduction furnace to be treated, and finally the needed dispersion strengthened copper component is obtained. The large complicated dispersion strengthened copper alloy component can be prepared, the size and the shape of the component are not limited, the preparation process is simple, the powder utilization rate is high, the machining period of a dispersion strengthened copper alloy is greatly shortened, and the preparation efficiency is improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

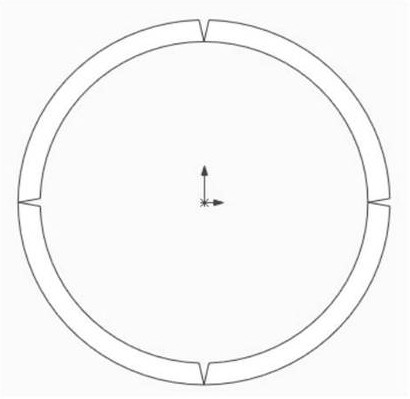

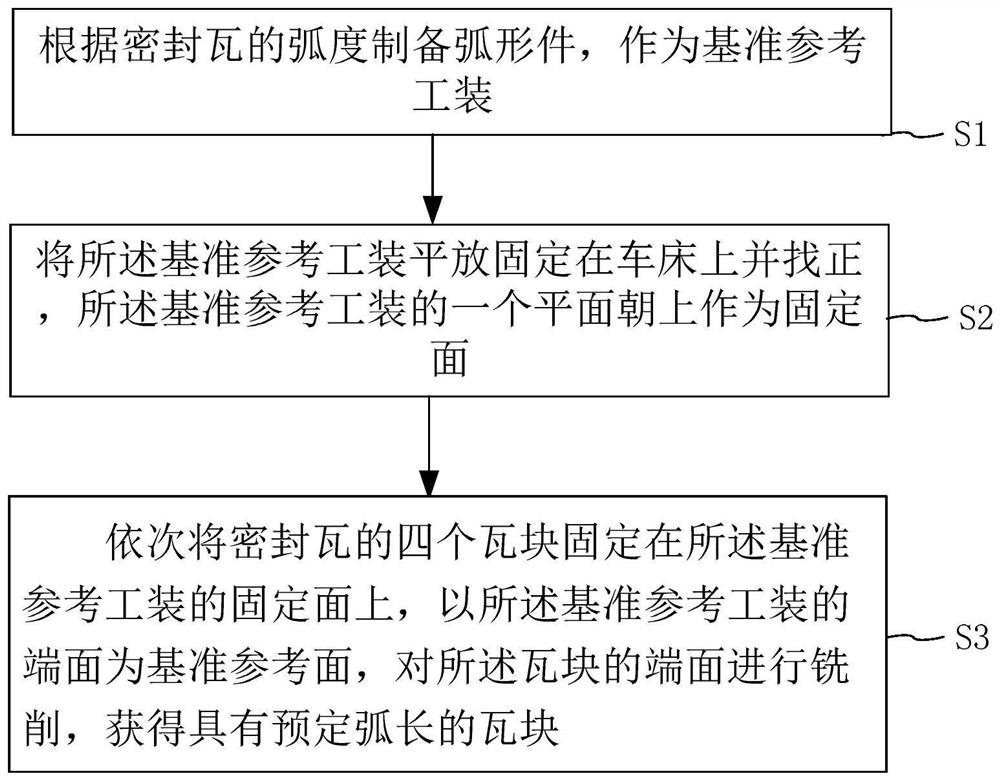

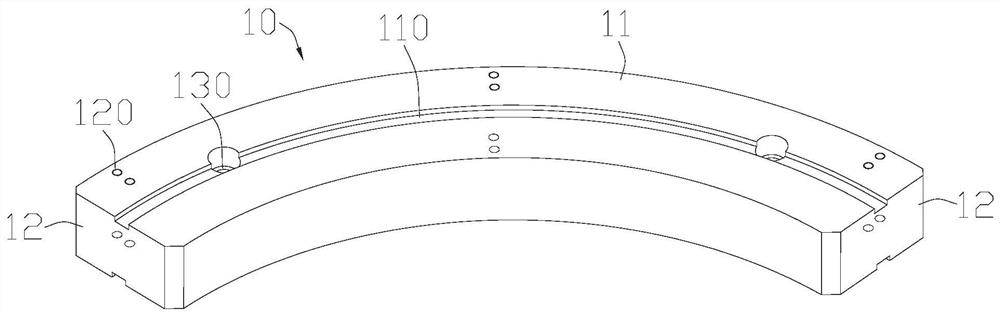

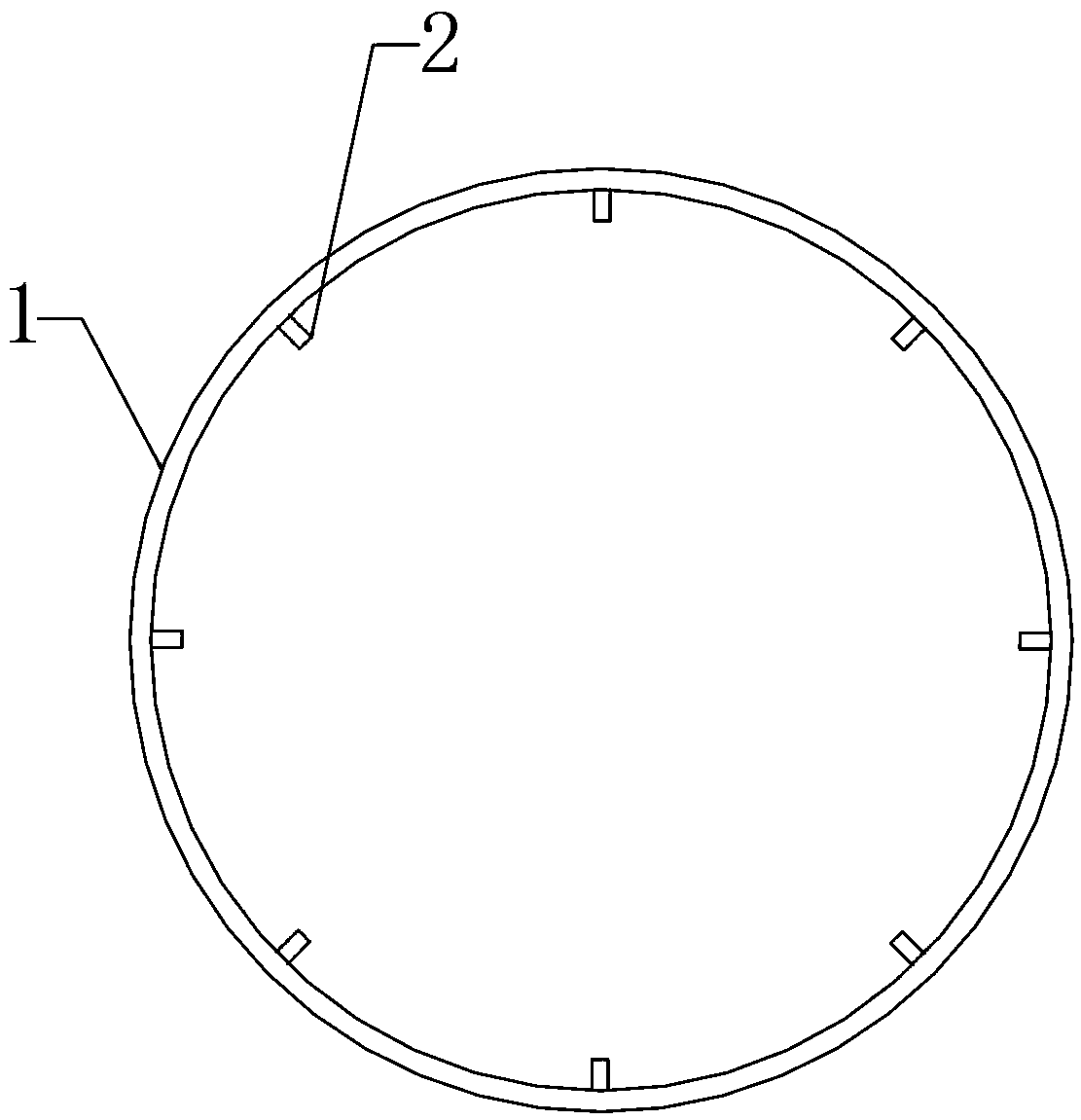

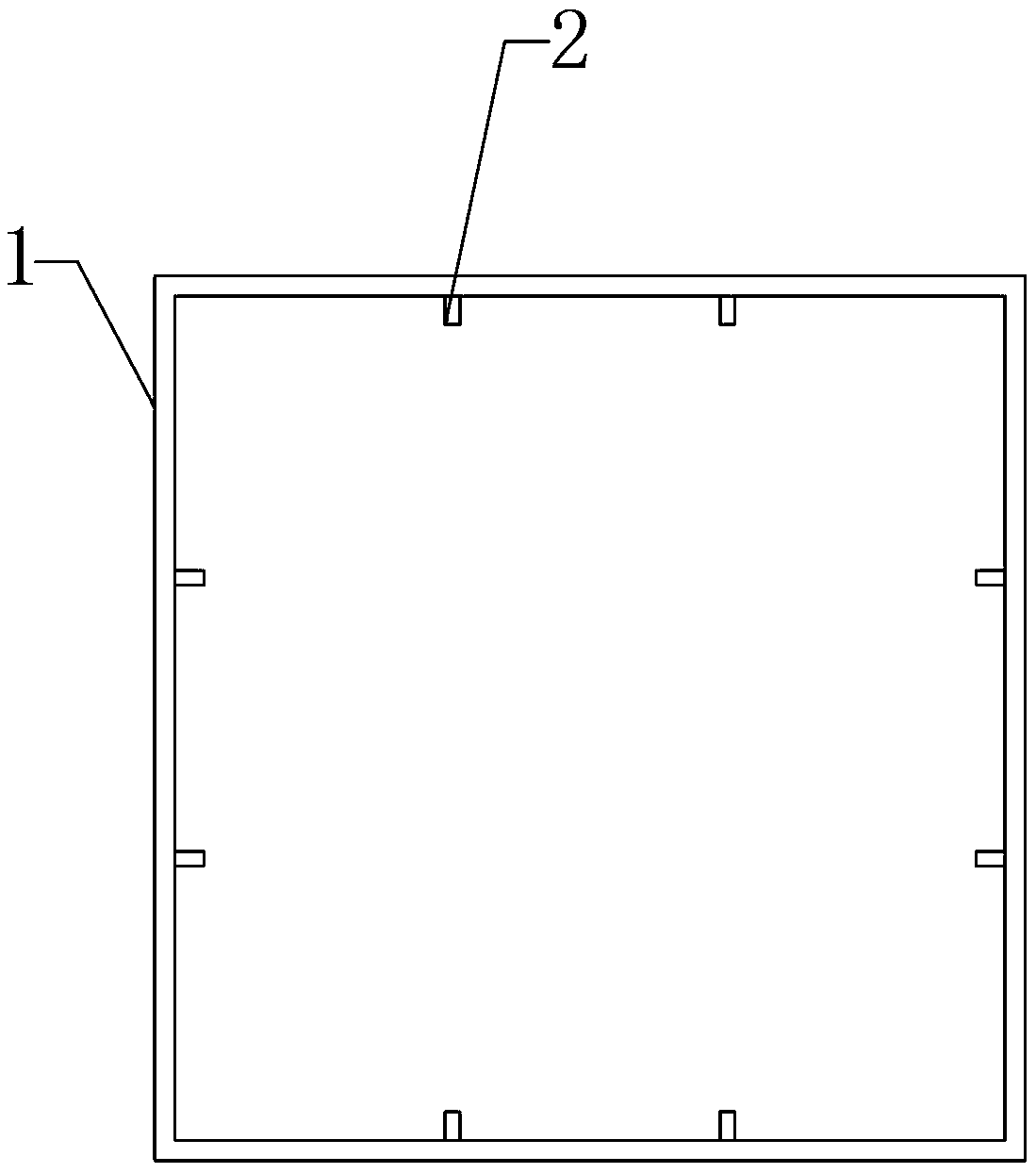

Nuclear power generator sealing pad machining method

The invention discloses a nuclear power generator sealing pad machining method. The nuclear power generator sealing pad machining method comprises the following steps: S1, preparing an arc-shaped piece according to the radian of a sealing pad to serve as a datum reference tool; S2, the datum reference tool is horizontally placed and fixed to a lathe and aligned, and one plane of the datum reference tool faces upwards to serve as a fixed surface; and S3, four pad blocks of the sealing pad are sequentially fixed to the datum reference tool, the end surface of the datum reference tool serves as a datum reference surface, the end surfaces of the pad blocks are milled, and the pad blocks with the preset arc length are obtained. According to the nuclear power generator sealing pad machining method, the datum reference tool is arranged as the machining datum of the pad, the machining accuracy of the end surfaces of the pad is improved, and the problems of incomplete contact and opening of the butt joint of the end surfaces of the pad are solved; and the deviation of the inner diameter of the circumference of the whole ring of the machined sealing pad is minimum, repeated machining is avoided, and manpower and lathe resource consumption are greatly reduced; and the machining period of the sealing pad is shortened.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

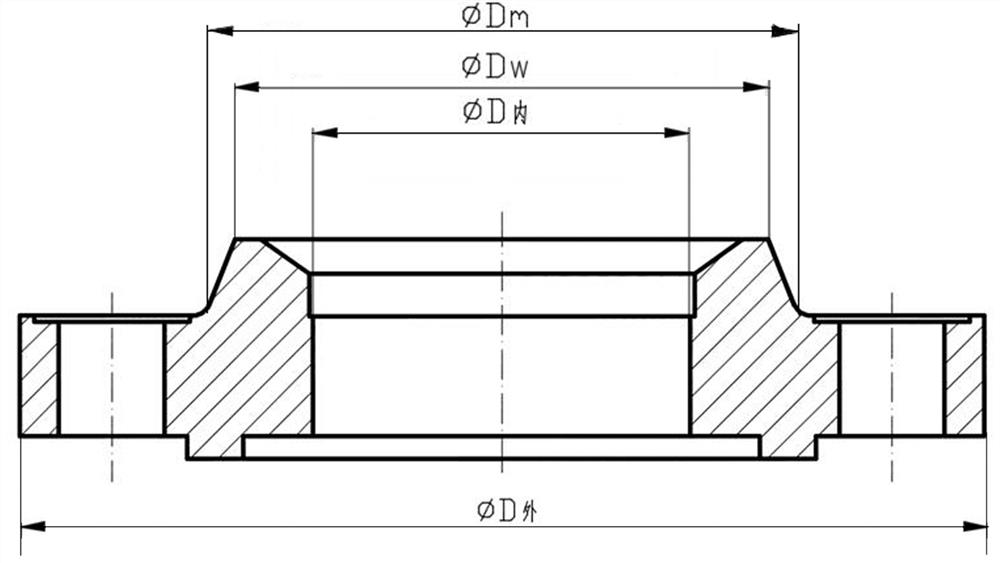

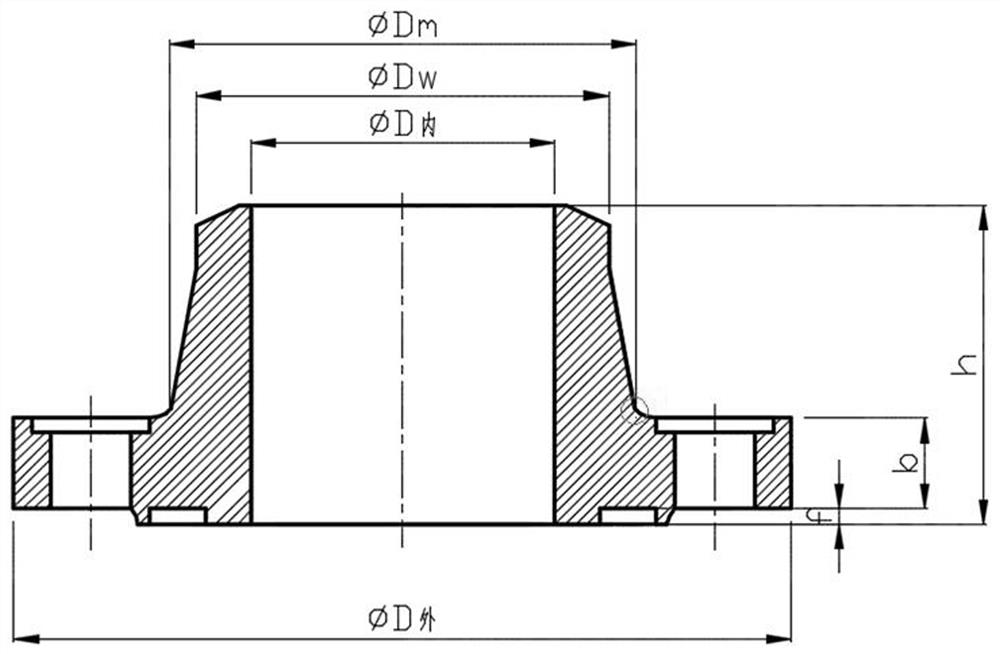

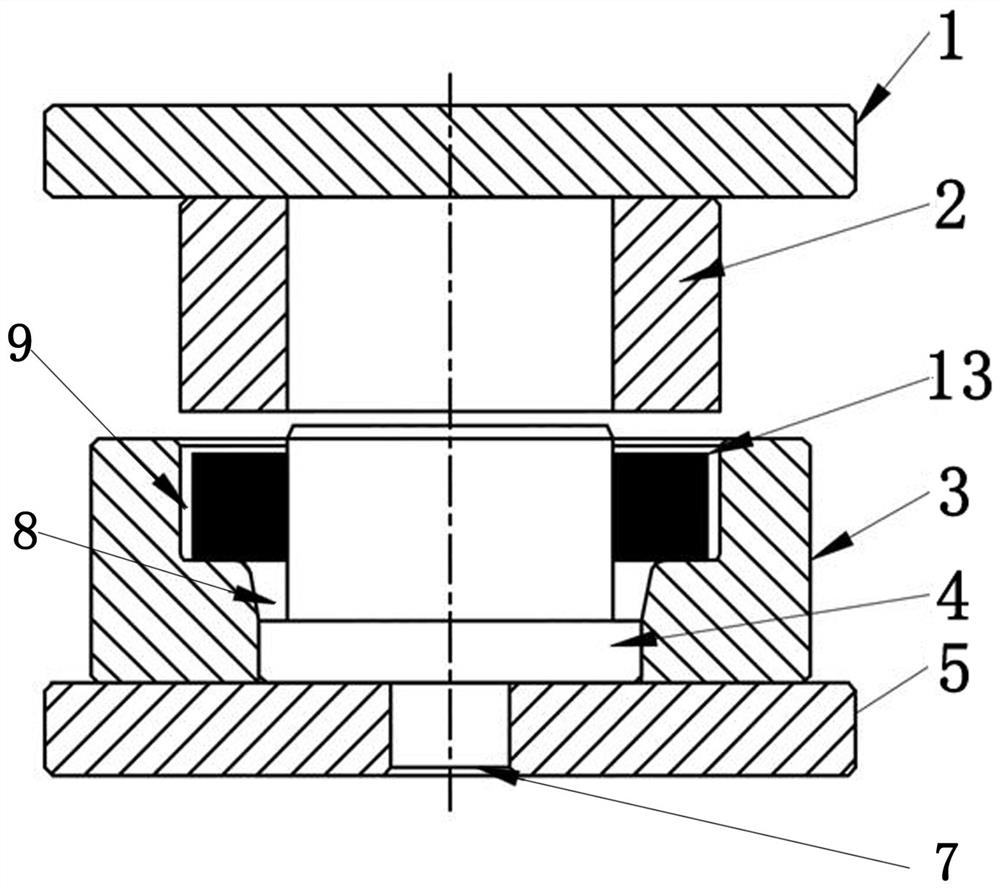

Closed large-sized copper-nickel alloy BFe30-1-1 flange forming die and machining method

PendingCN113020527AIncrease profitReduce extrusion processForging/hammering/pressing machinesMetallurgyEngineering

The invention provides a closed large-sized copper-nickel alloy BFe30-1-1 flange forming die and a machining method. According to the machining method, the original copper-nickel alloy flange machining mode is changed. The closed flange forming die is designed, and comprises an upper die assembly and a lower die assembly, wherein the upper die assembly comprises an upper die backing plate and a pressing head; the pressing head is fixedly arranged below the upper die backing plate; an inner cavity is formed in the center of the pressing head; the lower die assembly comprises a lower die, a core rod and a lower die backing plate; the lower die is arranged above the lower die backing plate; a die cavity is formed in the center of the lower die; in the die cavity, the diameter of an upper-section die cavity is greater than that of a lower-section die cavity; the upper-section die cavity is in clearance fit with the pressing head; the core rod is arranged in the die cavity; the small end of the core rod faces up; the large end of the core rod faces down; the bottom surface of the core rod is attached to the lower die backing plate; an through hole is formed in the lower die backing plate below the core rod; the large end of the core rod is in clearance fit with the lower-section die cavity; and consequently, the utilization rate of raw materials of a copper-nickel alloy BFe30-1-1 flange product is greatly improved and the material cost is reduced.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Ribbed steel tube concrete column and its design method

The invention discloses a ribbed steel tube, a concrete-filled ribbed steel tube column and a designing method of the ribbed steel tube. The concrete-filled ribbed steel tube column comprises a ribbed steel tube and a concrete column filled in the ribbed steel tube, wherein the ribbed steel tube is formed by turning, rolling or bending and welding a ribbed steel plate where ribs are rolled. A conventional stiffened concrete-filled steel tube column is replaced with the concrete-filled ribbed steel tube column, and compared with the conventional stiffened concrete-filled steel tube column, the welding work amount and the processing cost are reduced due to the fact that the ribs are rolled; and the processing period can be effectively shortened, and the quality stability is better.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

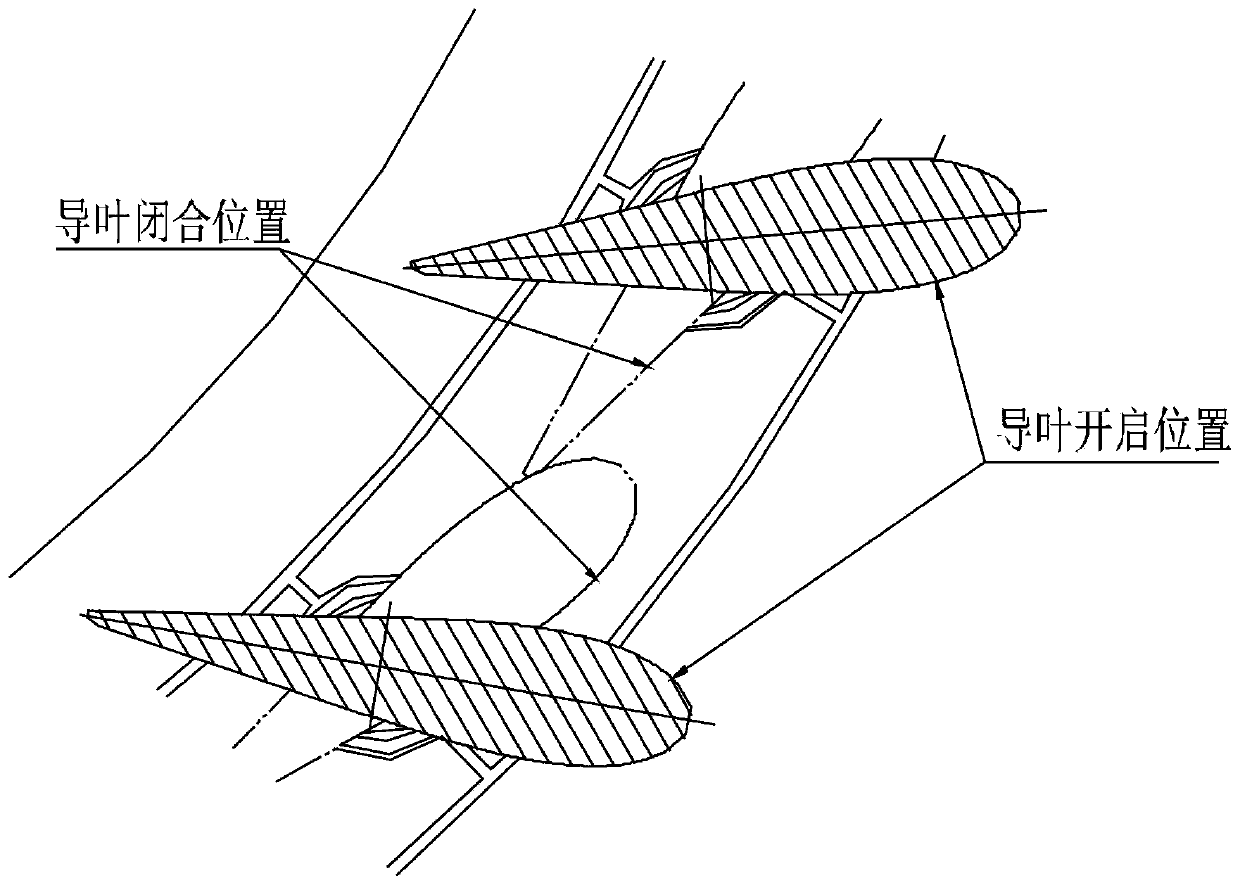

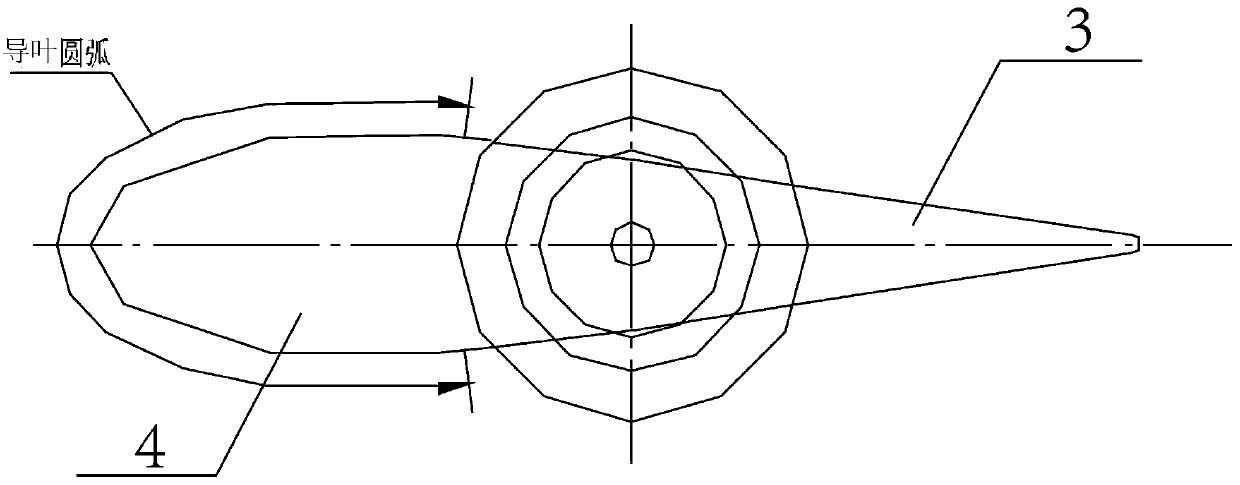

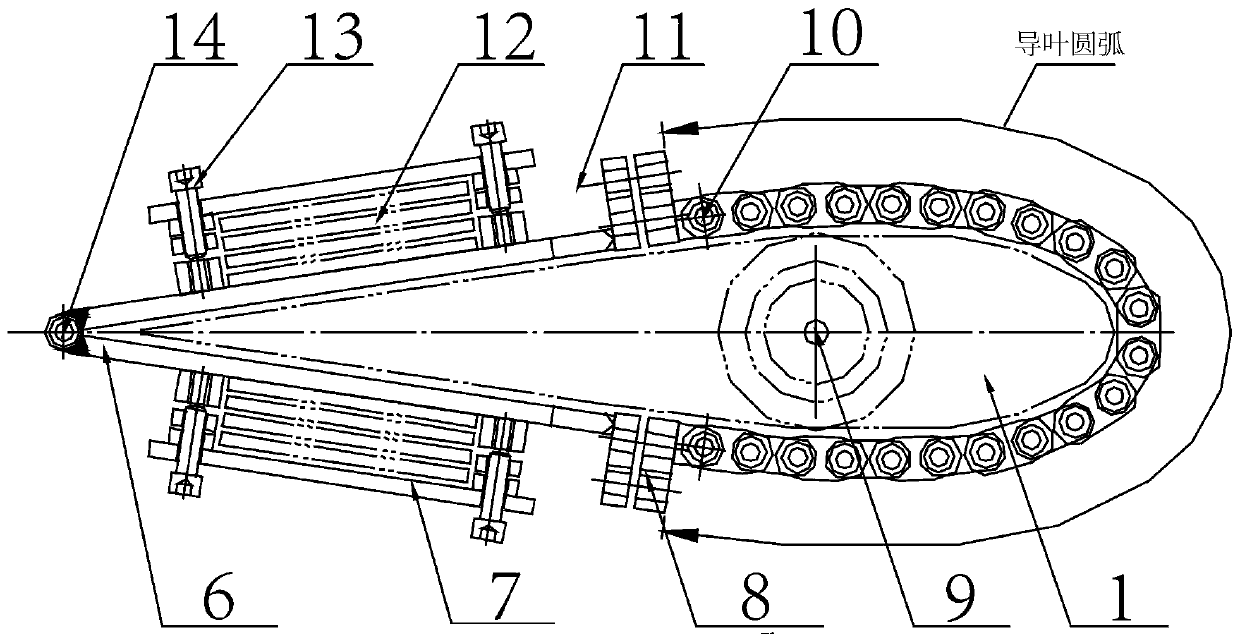

Balance weight assembly fixture for machining guide vanes with multiple specifications

PendingCN110000576AMeet the process requirementsShorten the processing periodWork clamping meansPositioning apparatusEngineeringMachining process

The invention aims to provide a balance weight assembly fixture for machining guide vanes with multiple specifications. The balance weight assembly fixture for machining guide vanes with the multiplespecifications is composed of balance weight brackets, a balance weight pressing block, a balance weight locking part and the like. The assembly angle and position of the fixture are adjusted with a hinge shaft and a chain to suit the guide vanes with different specifications. Counter weights with different specifications are fixed by the pressing block to realize rotating balance of the guide vanes. Fastening and connecting of assemblies of the fixture are realized by the connecting parts (high strength bolts, screws) and pin shafts. According to the balance weight assembly fixture for machining the guide vanes with the multiple specifications, corresponding parts of the guide vanes of the component parts of a water guide mechanism is machined on a horizontal lathe by using the balance weight assembly fixture in the machining process of a journal and a shaft shoulder, and the machining size meets the drawing requirements. The purpose of using the assembly fixture in the technical field of water turbines is realized. The balance weight assembly fixture for machining the guide vanes with the multiple specifications has the advantages of convenient assembly, simple use, convenient adjustment, wide application range, shortened guide vane machining time limit and the like, and can be widely applied to the machining process of the guide vanes with the multiple specifications in hydraulic turbine units.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

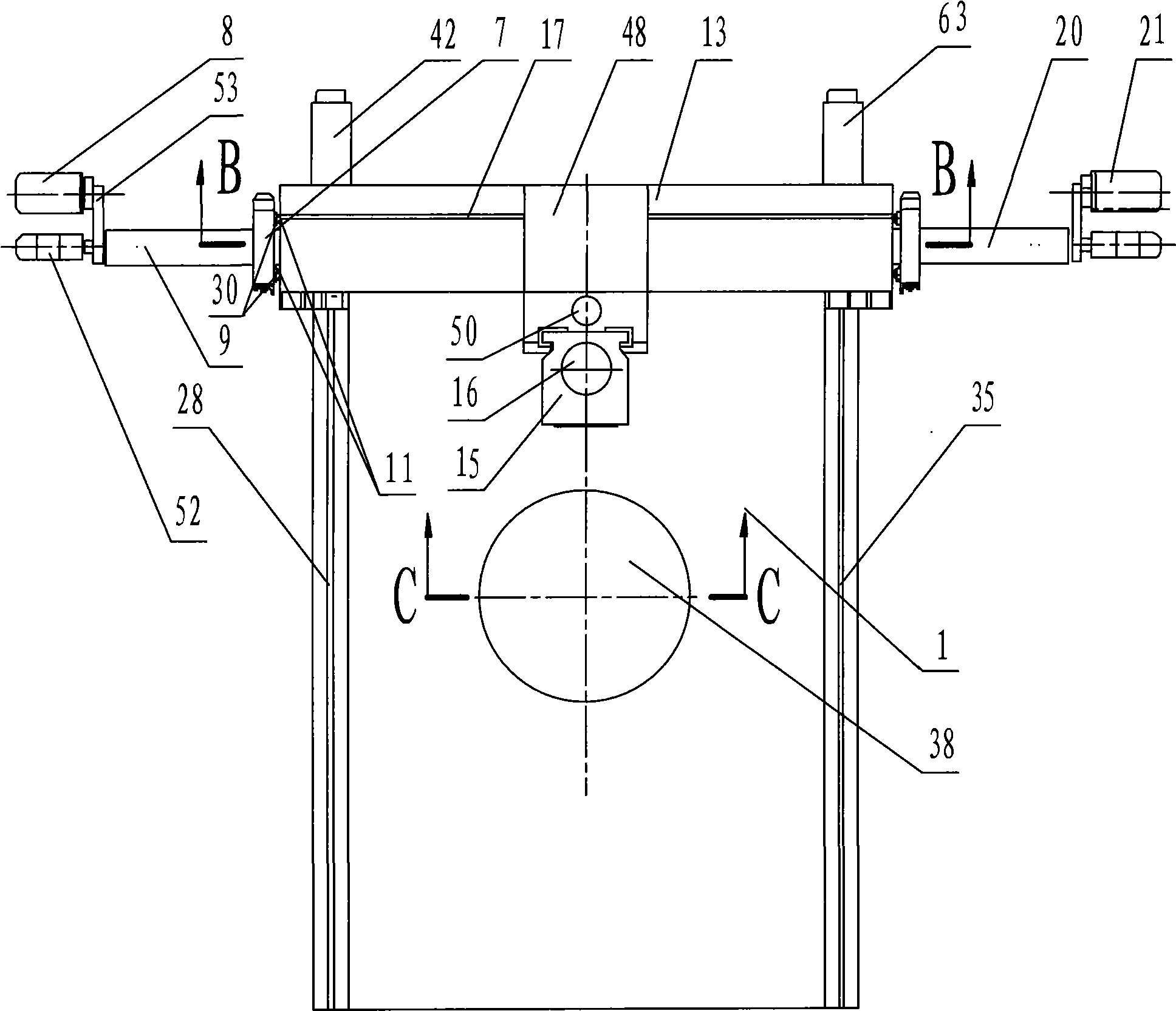

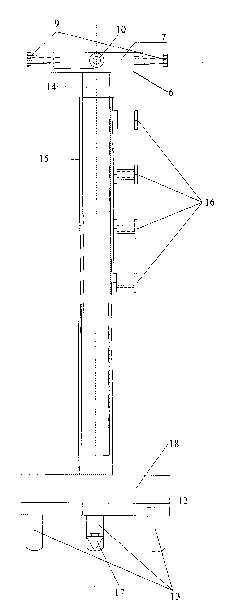

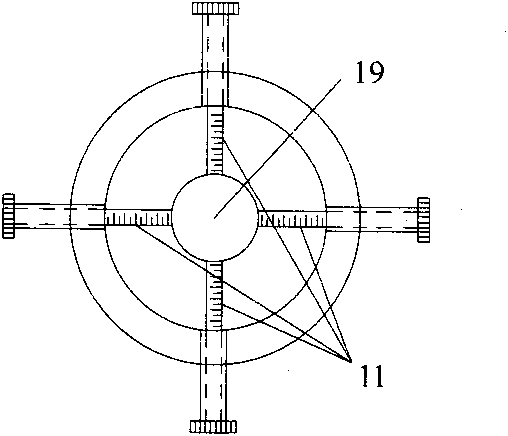

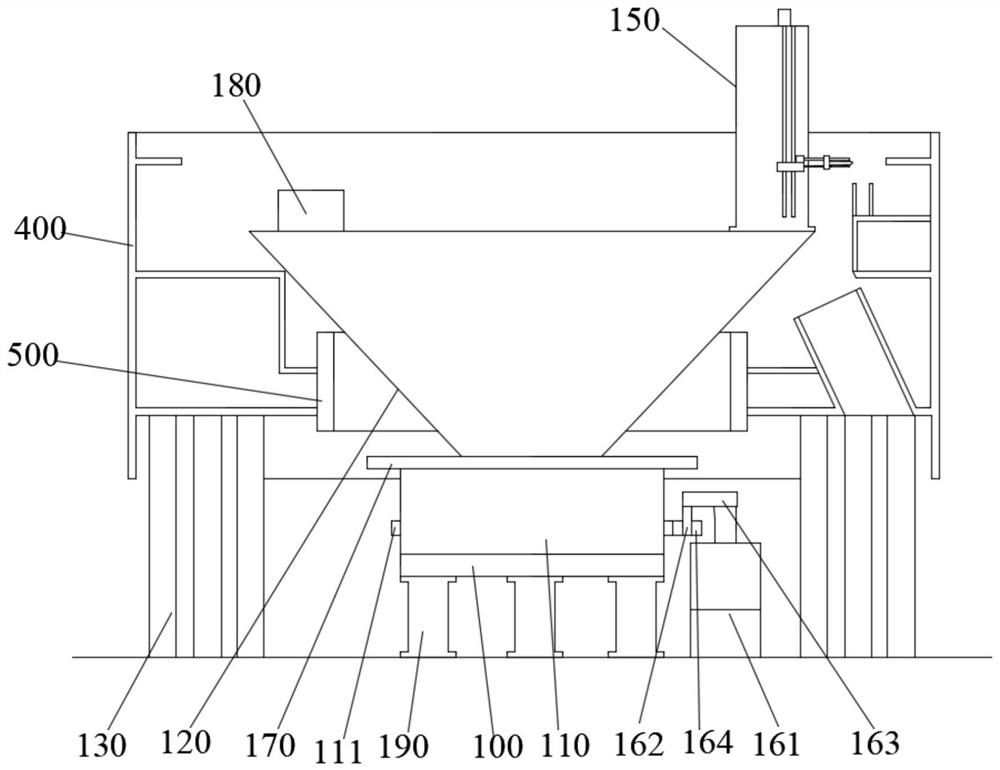

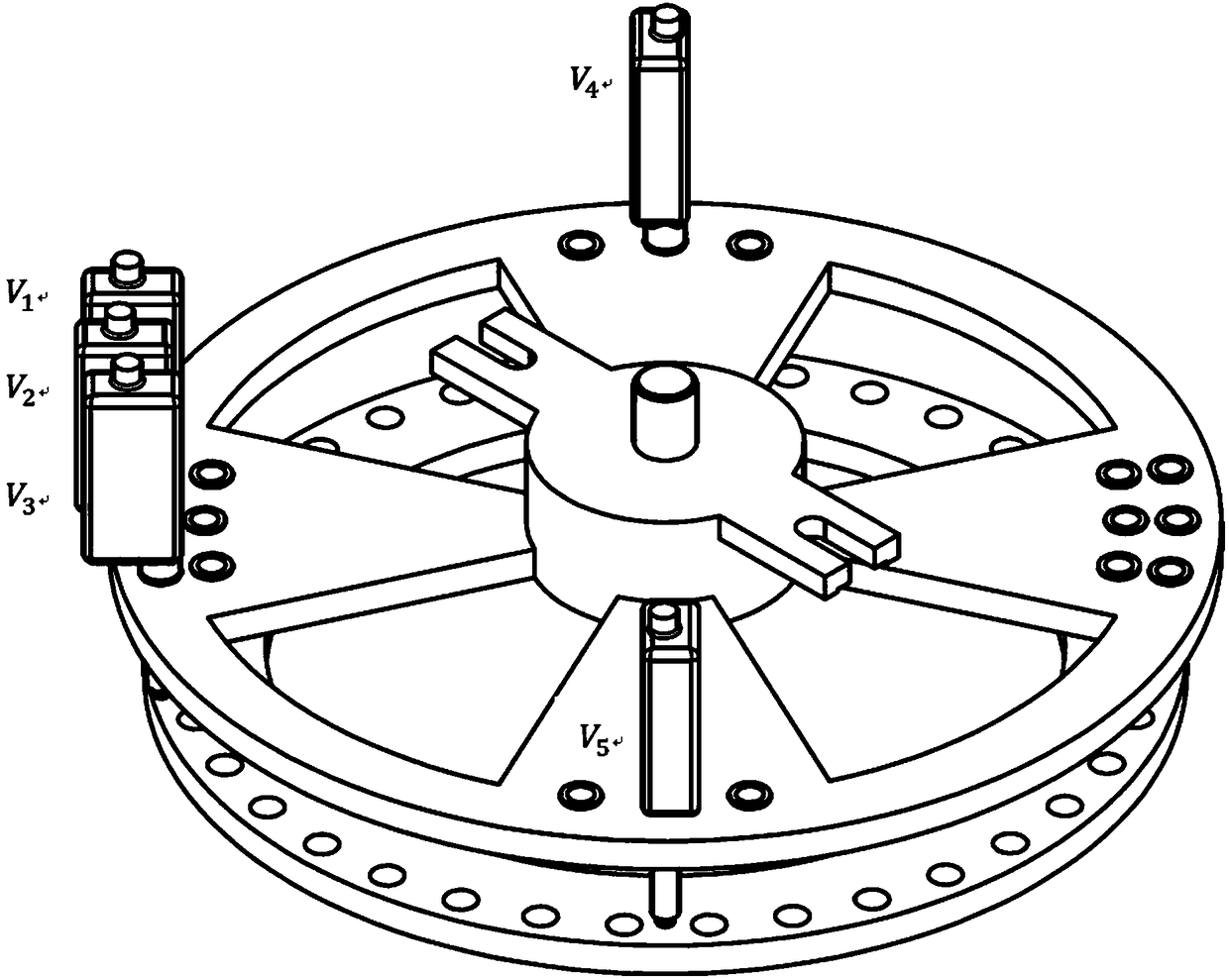

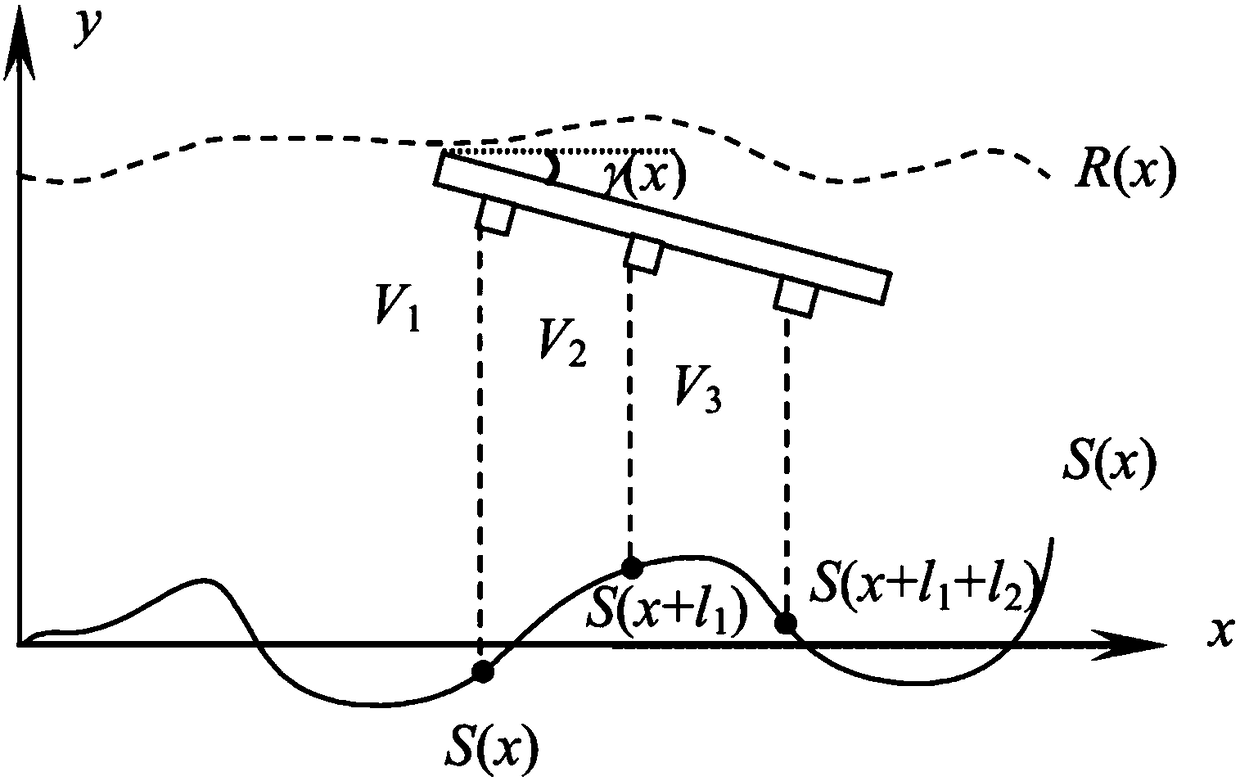

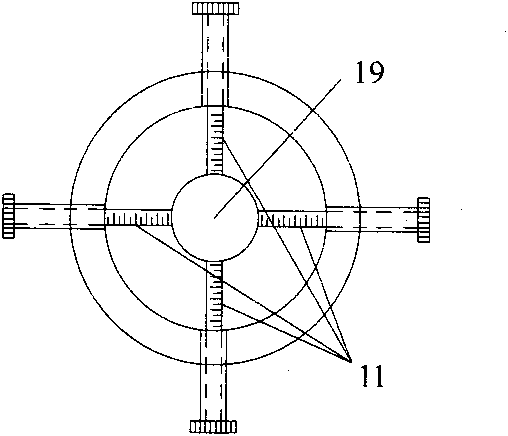

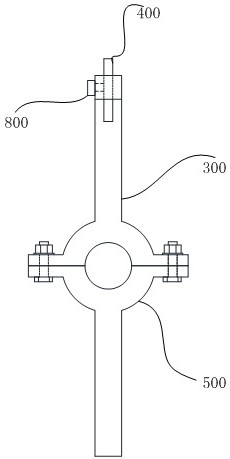

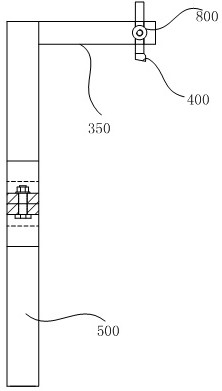

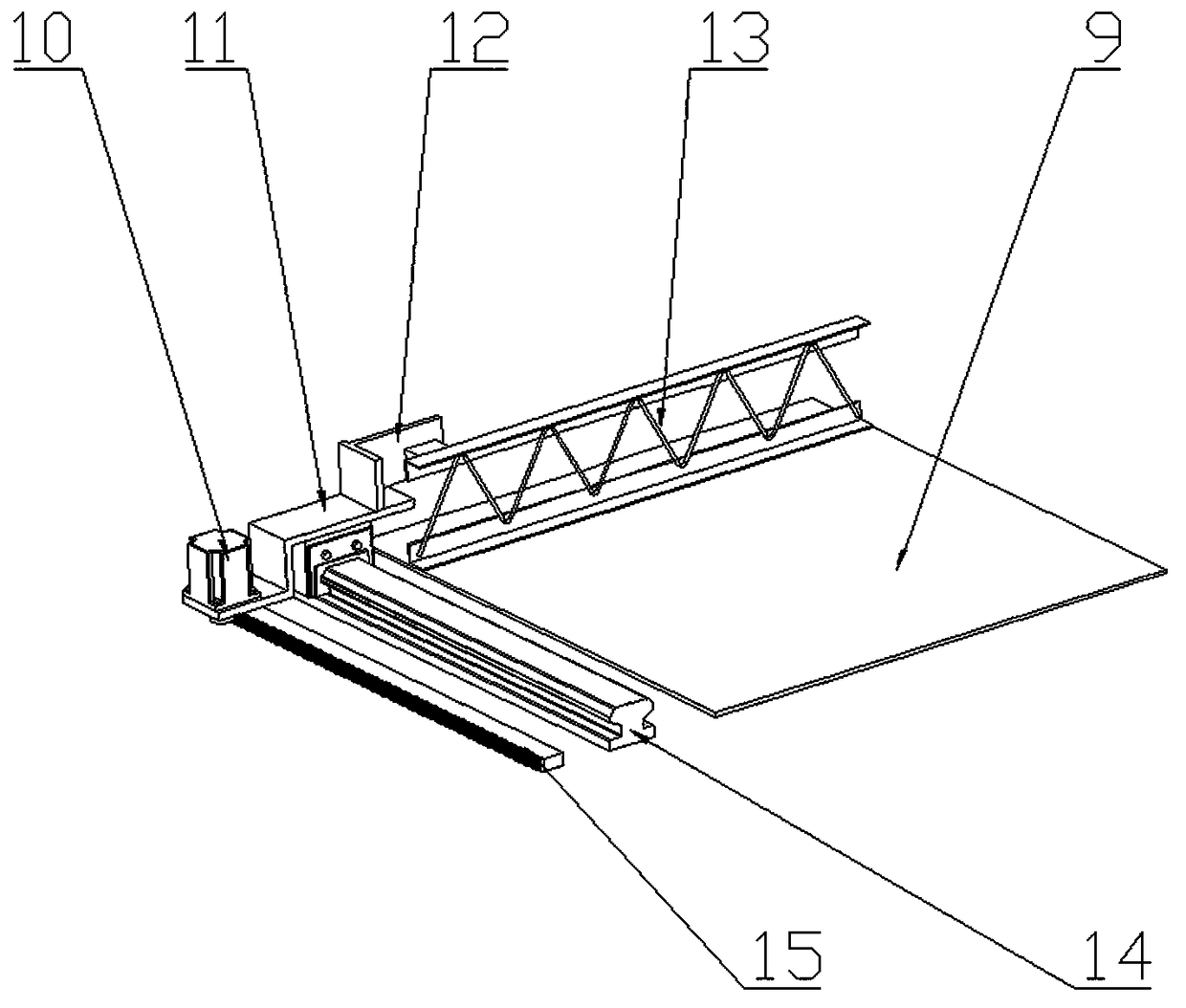

A Method of In-Situ Measuring Circular Plane Shape Error

ActiveCN107152922BRealize in-situ measurementShorten the processing periodMeasurement devicesIn planeClassical mechanics

The invention provides a method for measuring the shape error of a circular plane in situ, which is implemented based on a large circular plane shape error in-situ measurement system. The in-situ measurement system comprises a posture adjusting part, a rotating part, and a measuring part. The posture adjusting part comprises a posture adjusting table, a posture adjusting motor, and an adapter plate. The rotating part comprises a rotating index plate base and a high-precision rotating index plate. The measuring part comprises a sensor fixture, sensor holders, contact sensors and supporting equipment thereof. The application of a three-point method in measurement of the shape error of a circular plane is realized, and an algorithm for measuring the shape error of a circular plane in situ based on the three-point method is improved. Through the method, the shape error of a circular plane can be measured in situ, the processing time of parts is reduced greatly, and the influence of multiple times of clamping on the precision of parts is reduced.

Owner:DALIAN UNIV OF TECH

Processing method of machine tool movable support beam axis, its products and special fixture

ActiveCN103009248BAvoid the needReduced strength requirementsAbrasive machine appurtenancesAbrasive blasting machinesProcessing costMachine tool

The present invention relates to the mobile support beam shaft of machine tool and its manufacturing method and special fixture. The processing method is characterized in that a groove parallel to the axis is provided on the side of the beam shaft for supporting guide rails, and the beam shaft with the groove is placed in a special fixture. Centering and keeping the axis on the horizontal line, the special fixture is distributed with several pairs of guide rail clips that have been corrected by the reference level on the side splint corresponding to the groove of the beam axis, insert the guide rail into the row cavity of the guide rail clip and the placement cavity of the groove , and the guide rail is fixed on the beam shaft through fasteners and the guide rail is on the horizontal line, and the beam shaft with the guide rail is obtained by removing the special clamp. The present invention has the following outstanding effects: it can ensure the straightness and parallelism of the guide rails of the mobile support beam axis after processing, and can be manufactured by template to facilitate repeated precision processing, greatly reducing the corresponding processing cost and shortening the processing period And reduce inventory, especially suitable for applications in precision, light load and long axis occasions.

Owner:柔锋机械科技(江苏)有限公司

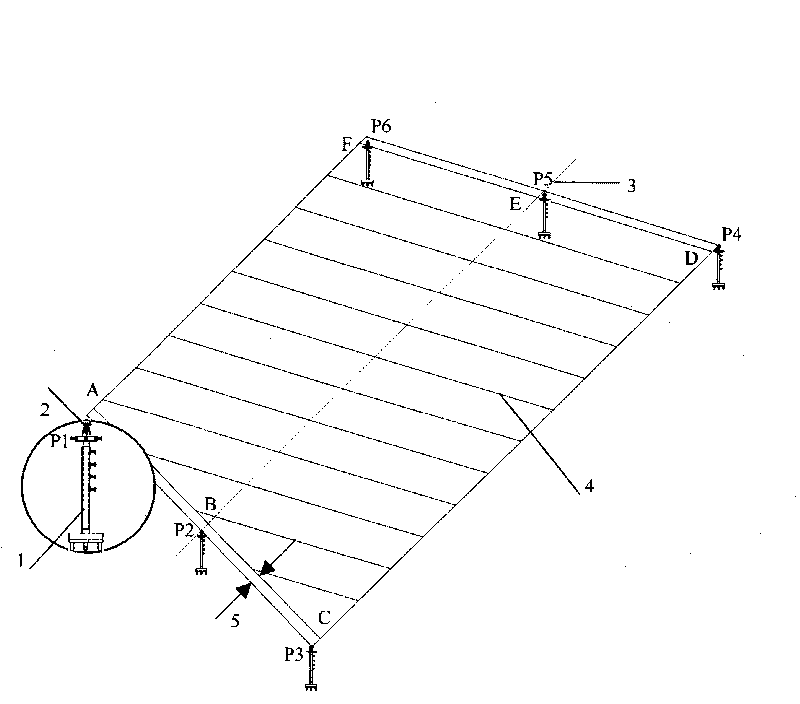

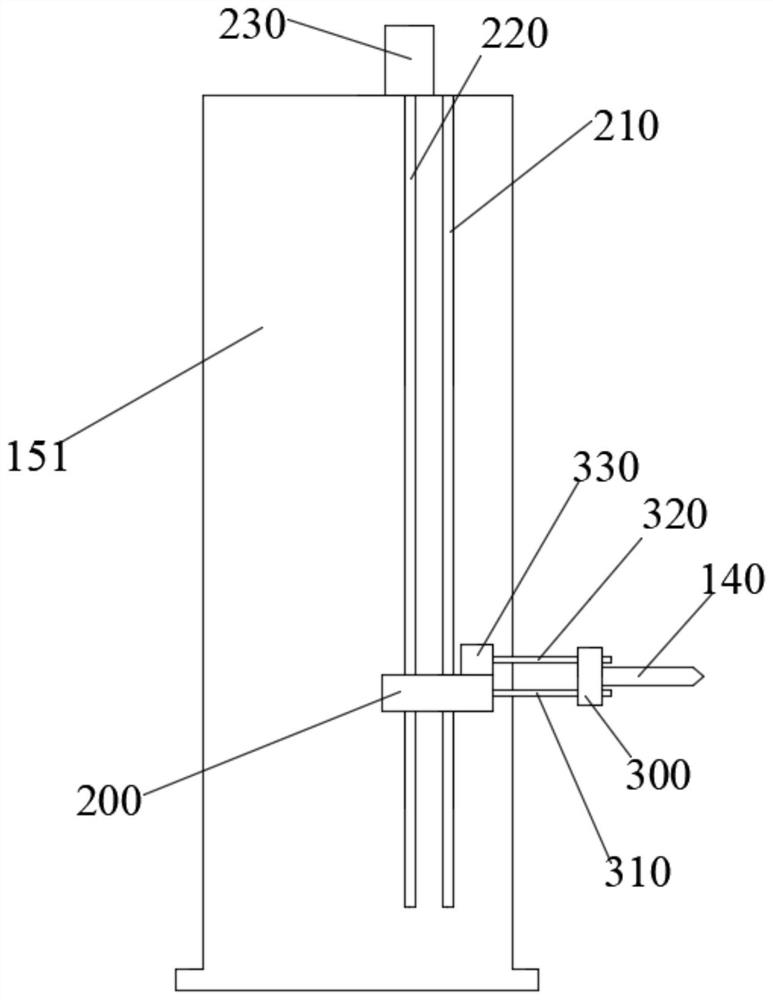

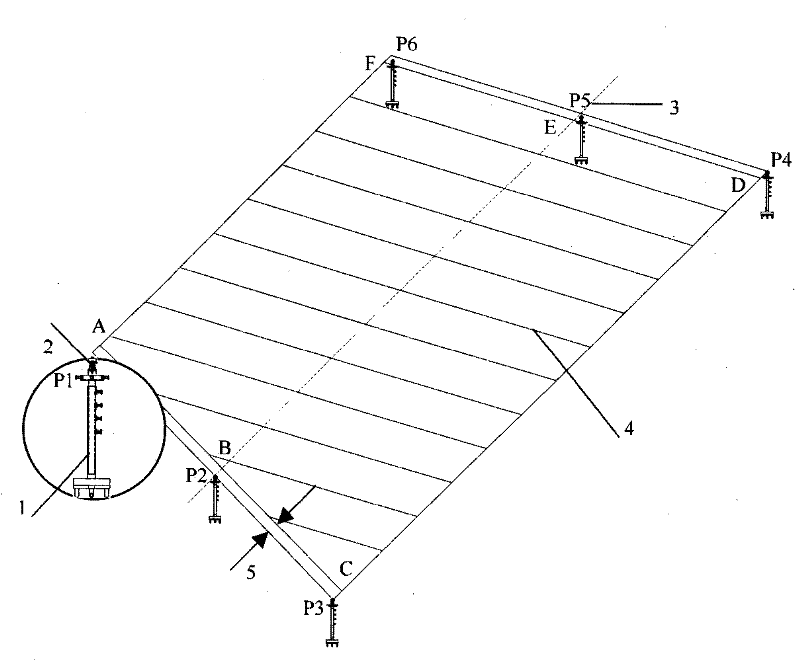

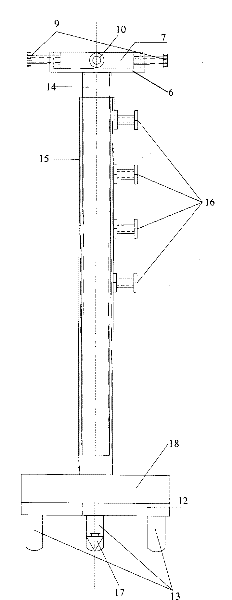

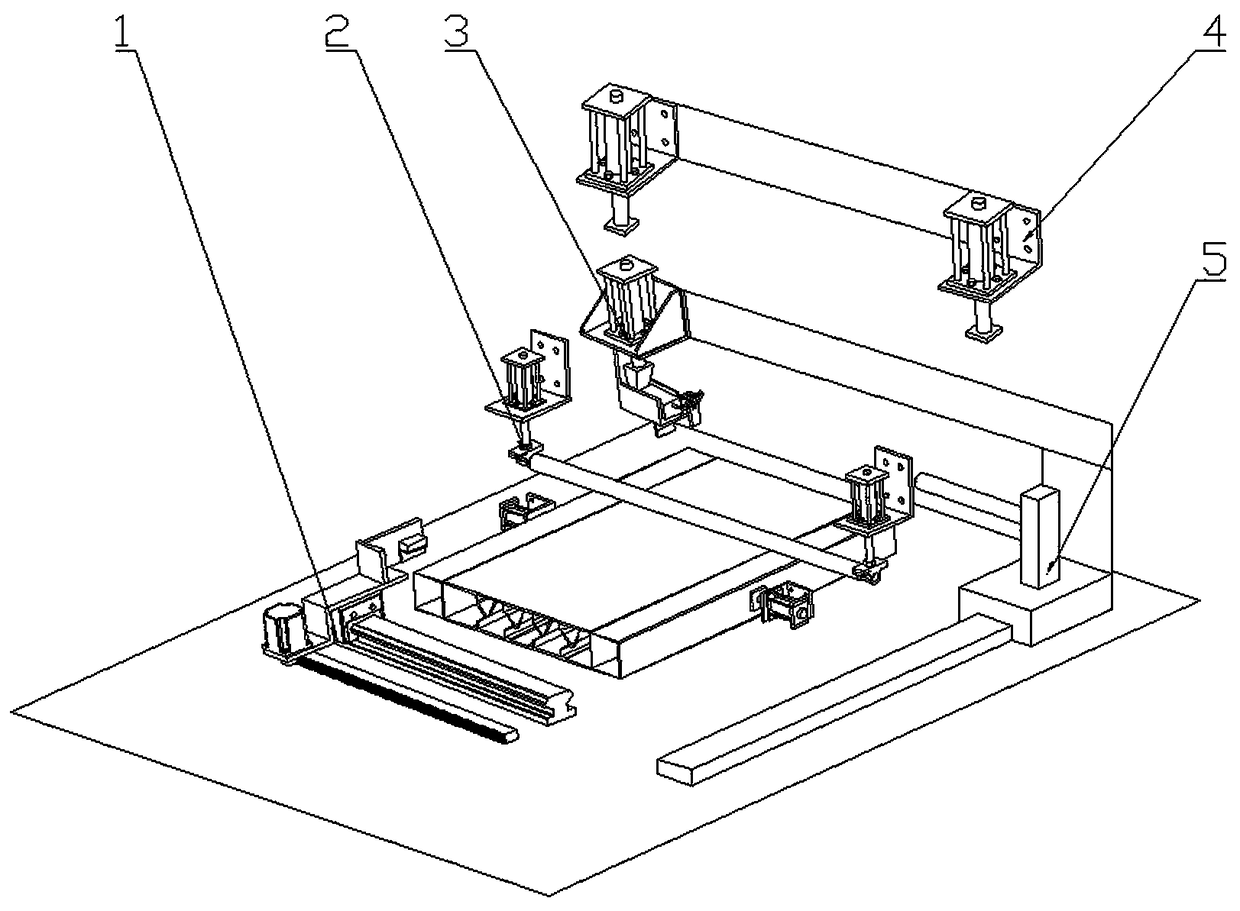

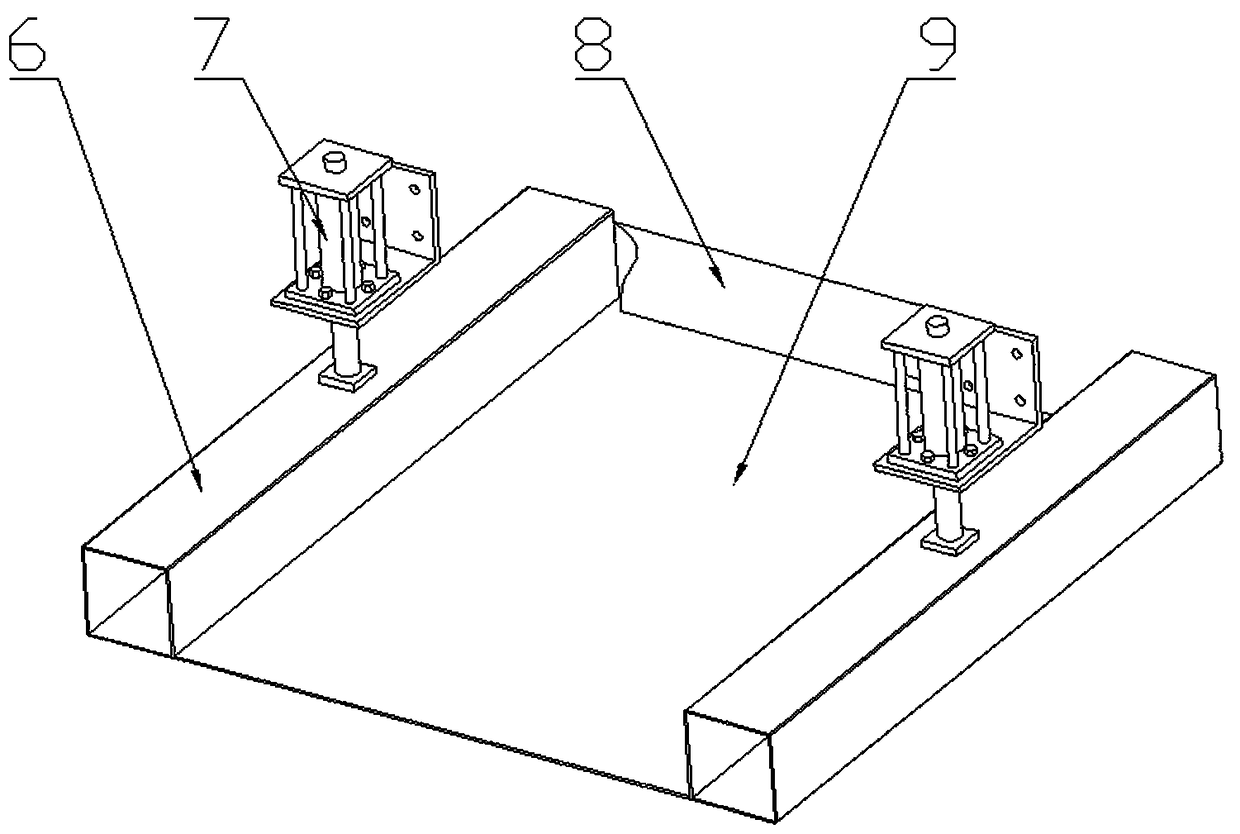

A mobile lifting combined measuring point frame device

ActiveCN101726275BGuaranteed successGuarantee shape qualityMeasurement devicesMeasurement pointEngineering

The invention relates to a mobile lifting combined measuring point frame device, which is characterized in that it consists of 6 moving lifting frames and 1 vertical measuring point frame, and the vertical measuring point frames are respectively placed on the 6 moving lifting frames. The advantages of the invention are: 1. A high-quality horizontal auxiliary benchmark measurement frame can be quickly established around the product; 2. According to the technical requirements of EU manufacturing measurement, the mobile lifting frame can be combined arbitrarily, reused, easy to operate and beautiful in appearance; 3. Reduce the waste of labor and materials; 4. It not only meets the measurement requirements of different companies in the European Union for the manufacture of spiral water walls in pre-assembly, but also overcomes the constraints of unfavorable factors such as the company's production site and manufacturing cycle.

Owner:SHANGHAI BOILER WORKS

Novel module device pipe fitting and manufacturing die thereof

PendingCN111059393AUniform wall thicknessGuaranteed outer diameterBranching pipesCoatingsPipe fittingMachining

The invention relates to a novel module device pipe fitting and a manufacturing die thereof, and belongs to the technical field of pipe fitting equipment. The pipe fitting comprises a main pipeline, aflow dividing pipe device and an end socket which are integrally formed, the flow dividing pipe device comprises multiple columns of flow dividing ports arranged along the length direction of the main pipeline, and the flow dividing ports are in arc transition connection with the inner wall and the outer wall of the main pipeline with the same radian, so that the pipe loss of the main pipeline iseffectively reduced, and the flow speed is increased. The die comprises an upper die body and a lower die body which are matched with each other, wherein the upper die body and the lower die body areeach provided with a main pipeline cavity and an end socket cavity, a feeding port is further formed in the end, away from the end socket cavities, of the upper die body, a flow dividing port pipeline at the bottom of the lower die body is in arc transition connection with the main pipeline cavities, and the upper die body and the lower die body are integrally formed or spliced by multiple parts.According to the novel module device pipe fitting and the manufacturing die thereof, machining is simple, welding of a large number of flow dividing pipe openings is avoided, the machining period iseffectively shortened, and the machining cost is greatly reduced.

Owner:SHANGHAI SUPRATEC MEMBRANE TECH CO LTD +1

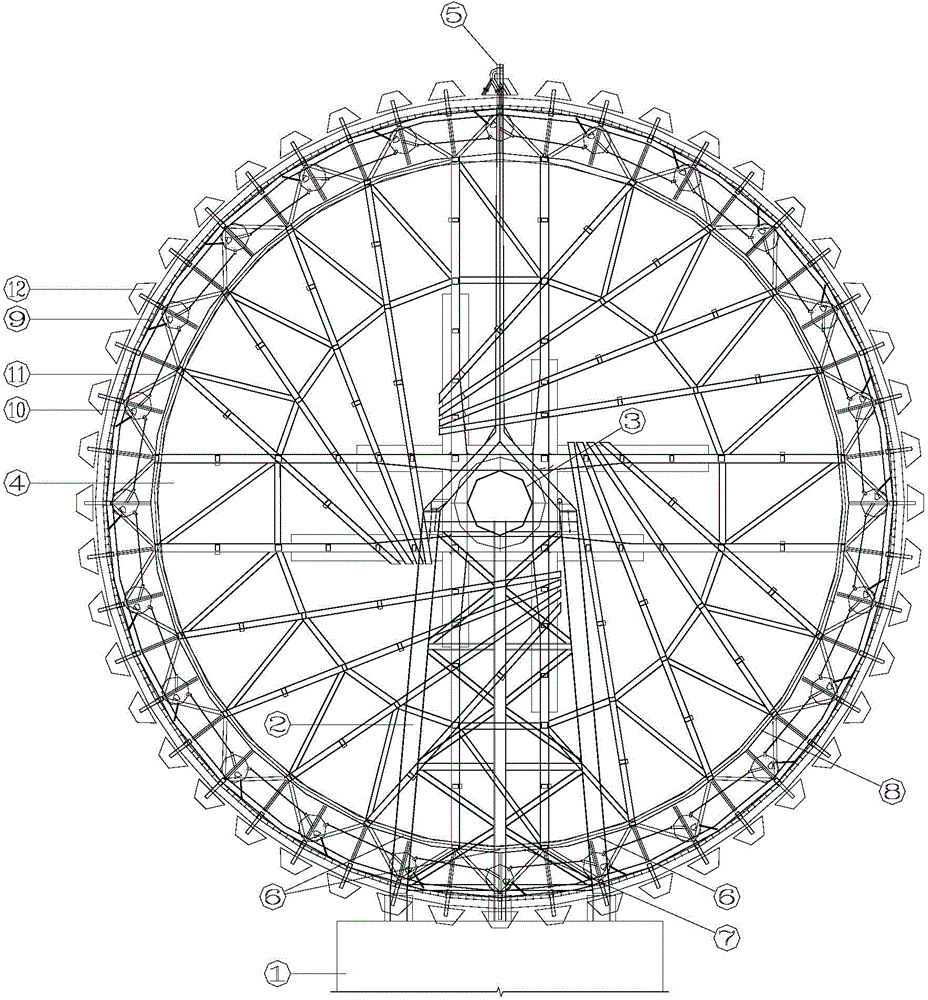

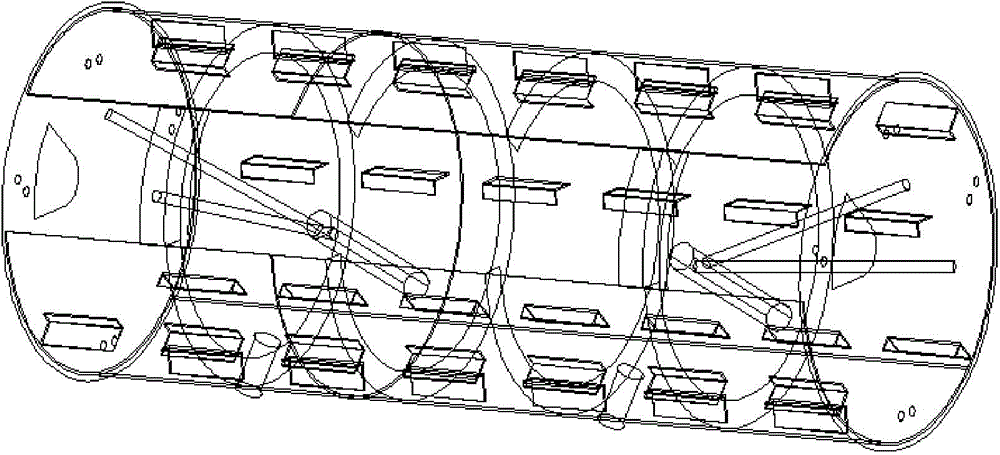

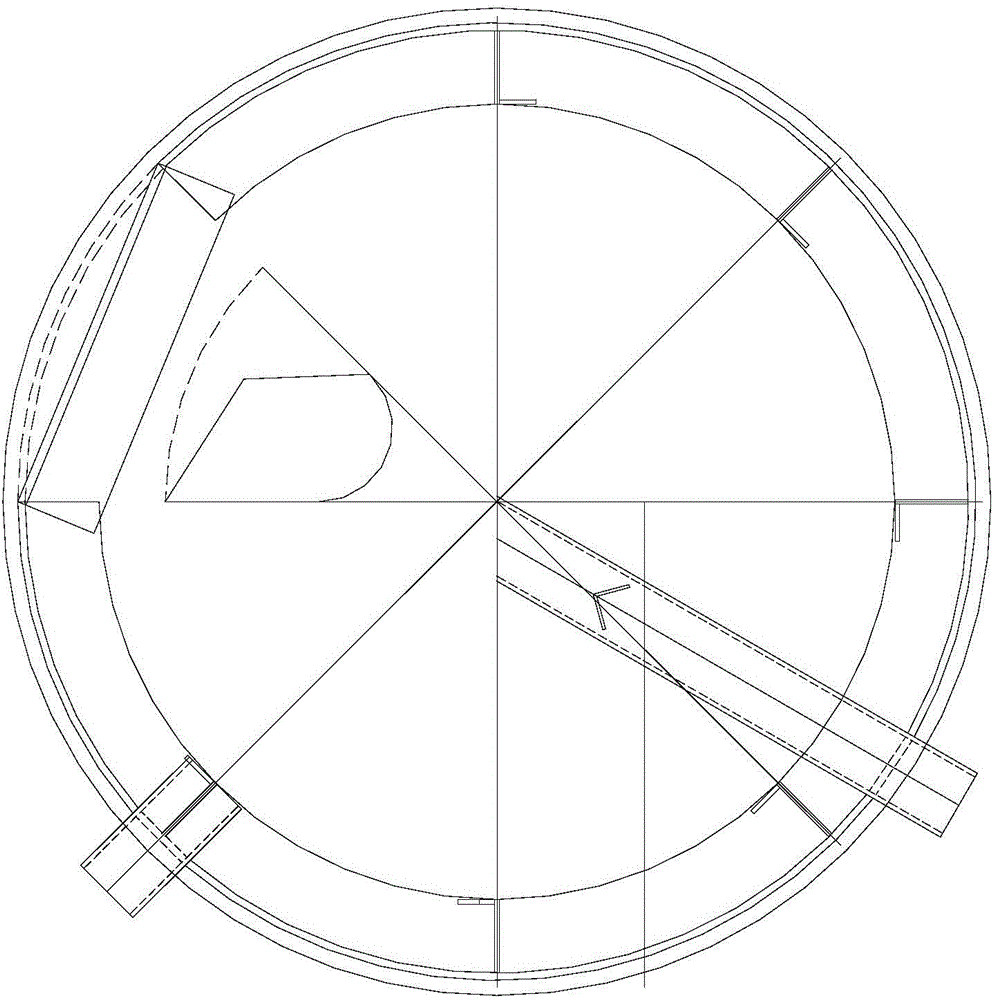

Giant waterwheel

ActiveCN104481775AGood lookingShorten the processing periodHydro energy generationSafety/regulatory devicesAutomatic brakingCommunicating vessels

The invention provides a giant waterwheel, comprising a waterwheel runner, a centre spindle, a steel support, a foundation platform, multiple special-shaped water buckets, communicating vessels, deceleration control devices, guide devices, a water supply system and a control system, wherein the steel support is fixedly arranged on the foundation platform; the waterwheel runner is installed on the top part of the steel support through the centre spindle; the centre spindle is a centre compound spindle; the waterwheel runner is fixedly arranged on the centre compound spindle; the multiple special-shaped water buckets are installed on the outer edge of the waterwheel runner; the water buckets are connected through the communicating vessels; the deceleration control devices are multi-point touch deceleration control devices; the guide devices are fixedly arranged on the steel support; the water system comprises a water pump, a connecting water pipe, a waterway and water channels; the deceleration control device and the water supply system are uniformly controlled by a speed control system. The giant waterwheel has the beneficial effects that as pipelines for water, electricity, control and the like are hidden in the steel support, the appearance effect is good; the centre compound spindle is short in processing time, and low in cost; the waterwheel runner is smooth to run; the automatic braking can be realized; the water channels are respectively provided with a side nozzle, a required water curtain effect is satisfied.

Owner:大连市建筑设计研究院有限公司

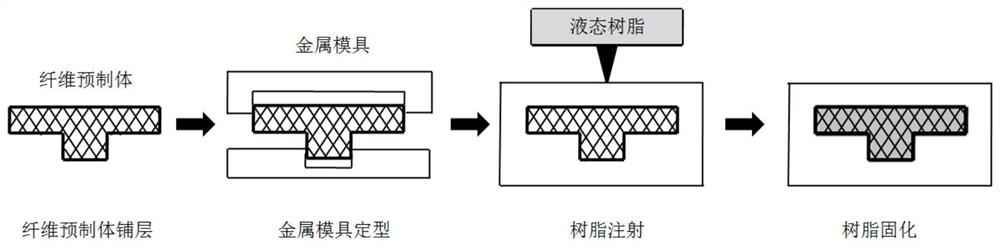

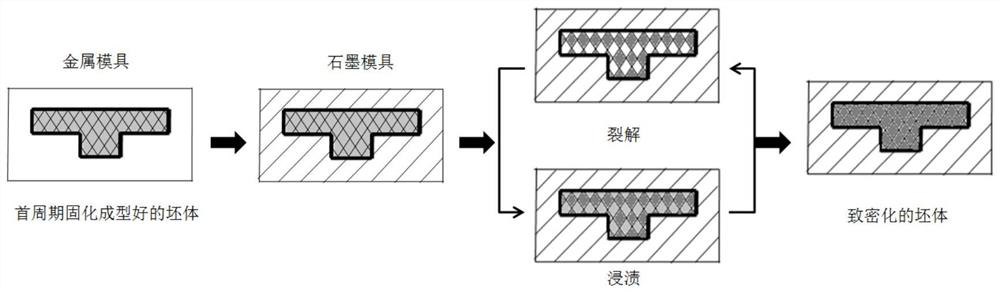

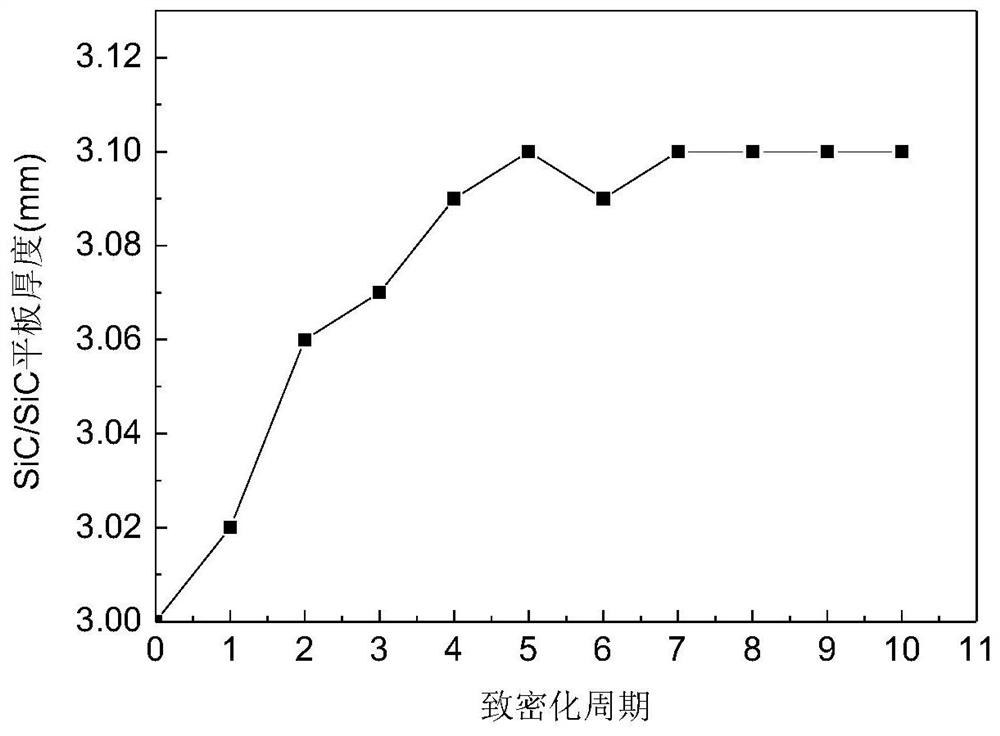

A kind of molding method of fiber-reinforced SIC-based composite material

The invention belongs to the technical field of preparation of ceramic-based composite materials, and relates to a molding method of fiber-reinforced SiC-based composite materials. The invention adopts the method of combining the metal injection mold molding in the first cycle and the graphite cracking mold molding in the densification cycle, so that the fiber-reinforced SiC-based composite material can be shaped in a near-net size during the entire PIP process. Firstly, fiber preforms are prepared with fibers as raw materials. After preforming the fiber preforms in graphite molds, the fiber preforms are transferred to metal injection molds in a solvent-free liquid state for the first cycle of molding. Finally, the precursor is impregnated and cracked. (PIP), fiber-reinforced SiC-based composites were subjected to densification cycle molding in a perforated graphite pyrolysis mold. The method can realize near-net size molding of the fiber-reinforced SiC-based composite material, and the prepared material has high dimensional accuracy, saves processing costs, shortens the processing period, and promotes the engineering process of the ceramic-based composite material.

Owner:AVIC BASIC TECH RES INST

Channel Steel Sleeve Restraint Straight Steel Buckling Restraint Brace

InactiveCN104763072BImprove utilization efficiencyReduce dosageShock proofingBuckling-restrained braceAdhesive materials

The invention relates to a steel channel sleeve restraining linear pure steel buckling restrained brace and a manufacturing method thereof. The steel channel sleeve restraining linear pure steel buckling restrained brace comprises a core plate with a linear cross section, a non-adhesive material layer, a periphery restraining sleeve and a belly steel plate, wherein the section of the periphery restraining sleeve is a vertical section which is a steel channel, and the belly steel plate is a section with the interior being a rectangle, and the section is formed by a common steel plate; the core plate is retracted by 5 mm in the height direction from the variable cross section of the end to the internal length range of the periphery restraining sleeve, a 10-20 mm long steel plate is welded to the outer side of the end steel channel of the periphery restraining sleeve, the exterior of the core plate is wrapped in the non-adhesive material layer, and a plug welding hole is formed in the belly steel plate of the periphery restraining sleeve corresponding to the center position of the core plate so that the belly steel plate and the periphery restraining sleeve can be connected together in a welded mode. According to the steel channel sleeve restraining linear pure steel buckling restrained brace, due to the fact that the two sides of the core plate are clamped in steel channel sleeve belly plate restraining pieces respectively and face contact restraining is achieved, the anti-local-bending capacity of core materials is improved and utilized, filling of restraining materials is not needed, dead loads are greatly reduced, the steel material utilization rate is high, and therefore high economical efficiency is achieved.

Owner:SHANGHAI INST OF TECH

Machining tool for bucket wheel body of stacker-reclaimer

PendingCN114192831AAvoid back and forthAvoid Shipping RisksMeasurement/indication equipmentsPositioning apparatusButt jointReclaimer

The invention discloses a stacker-reclaimer bucket wheel body machining tool, a bucket wheel body comprises a shaft sleeve, the machining tool comprises a boring machine body, and the boring machine body comprises a boring rod; the outer circle machining device comprises a first outer supporting body and a second outer supporting body, and a boring cutter is arranged on the first outer supporting body; the second outer supporting body and the first outer supporting body are locked and fixed on the boring rod on the outer side of the shaft sleeve after being in butt joint; the inner supporting device is arranged in the inner hole of the shaft sleeve, is used for supporting the shaft sleeve, and comprises two inner supporting bodies which are locked and fixed on the boring rod after being butted and matched; and the supporting part is arranged in the inner supporting body, part of the supporting part extends out of the inner supporting body, and the position of the supporting part relative to the inner supporting body is adjustable. According to the machining device for the bucket wheel body of the stacker-reclaimer, the bucket wheel body is prevented from being transferred back and forth, the bucket wheel body is directly machined on site, the production cost is reduced, and the transportation risk is avoided.

Owner:青岛港口装备制造有限公司

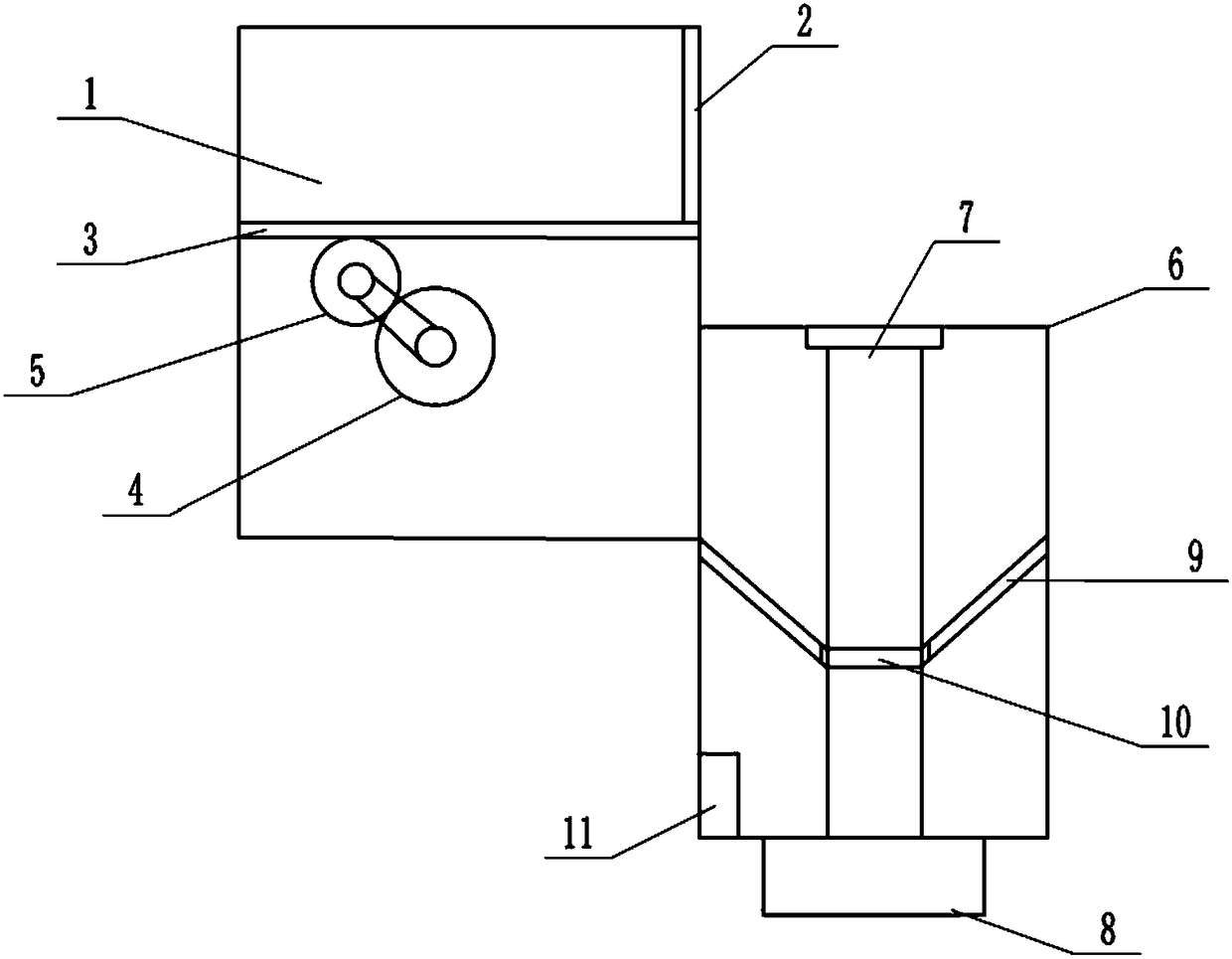

Automobile part cleaning device

InactiveCN108325929ATo achieve the purpose of cleaningAchieve separationDrying machines with local agitationDrying machines with materials at restGear driveEngineering

The invention particularly discloses an automobile part cleaning device. The device comprises a cleaning tank and a dewatering tank, wherein a driving gear driven by external driving equipment is arranged at the bottom of the cleaning tank, a driven gear is meshed with the edge of the driving gear, rotating shafts of the driving gear and the driven gear are fixedly connected through a conveying belt, and a layer of plastic diaphragm located on the driving gear is arranged on the inner wall of the cleaning tank; a discharging port is formed in the right side wall of the cleaning tank, the dewatering tank is located outside the discharging port of the cleaning tank, a motor is arranged at the bottom center of the dewatering tank, a screw extending into the dewatering tank is arranged at an output end of the motor, and the surface of the screw is plated with an antirust oxidation film; a threaded ring is connected to the screw, an elastic filter net capable of covering the dewatering tankis arranged on the inner wall of the dewatering tank, and one side, away from the inner wall of the dewatering tank, of the filter net is gathered with the outer edge of the threaded ring. The devicerequires no manual cleaning and can shorten automobile part air-drying time and shorten the machining cycle.

Owner:重庆市长寿区惠峰汽车修理有限公司

Control method of multi-cavity steel component assembling and positioning mechanism

ActiveCN109048166AIncrease productionImprove qualityWelding/cutting auxillary devicesAuxillary welding devicesDrive motorEngineering

The invention relates to a control method of a multi-cavity steel component assembling and positioning mechanism, and belongs to the technical field of multi-cavity steel component assembling equipment. The mechanism comprises a square tube positioning and pressing frame. Two ends of the square tube positioning and pressing frame are provided with square tube positioning and pressing pieces connected with the square tube positioning and pressing frame in a displacement mode. An electromagnet is arranged at a front end of an end primary positioning piece. A lower end of the end primary positioning piece is provided with an end primary positioning piece guide rail which is in sliding connection with the end primary positioning piece. A driving motor is arranged at the rear end of the end primary positioning piece. A rack guide rail parallel to the end primary positioning piece guide rail is arranged below the driving motor. The rack guide rail is movably engaged with the drive motor. Thelower end of a displacement cylinder is provided with a lock pressing piece which is movably contacted. Two ends of a pressing roller are provided with bearing seats which are movably sleeved with the pressing roller. Pressing cylinders are arranged on the bearing seats. According to the control method of the multi-cavity steel component assembling and positioning mechanism, the method has the advantages of being compact in structure, accurate in positioning and integrated in assembling and welding; and the machining precision of the multi-cavity steel components is improved, and the machining period is shortened.

Owner:浙江东南网架股份有限公司

Press-fit cavity power divider

The invention discloses a press-fit cavity power divider which comprises a microwave conducting rod and a signal transmission cavity which are successively coaxially arranged, internal conductors directly connected with the microwave conducting rod, external conductors directly connected with the signal transmission cavity and insulating mediums which are coaxially arranged between the internal conductors and the external conductors. The microwave conducting rod is successively in a trapezoid step shape from an input press-fit hole to an output press-fit hole. The signal transmission cavity and the microwave conducting rod are coaxially arranged. The insulating mediums are positioned between the internal conductors and the external conductors. Thus, relative fixation between the internal conductors and the external conductors is realized, and central axis of the insulating mediums overlap central axis of the internal conductors and the external conductors. The invention relates to a press-fit cavity power divider which has advantages of simple structure, reliable mechanical property, excellent electrical property, high transmission power, high production efficiency and low cost and is suitable for mass production.

Owner:镇江市明基电子有限公司

Z-shaped sleeve constrained in-line pure steel buckling constrained support and manufacturing method thereof

InactiveCN104805927BImprove utilization efficiencyReduce dosageShock proofingBuckling-restrained braceFilling materials

Owner:上海源同建筑科技有限公司

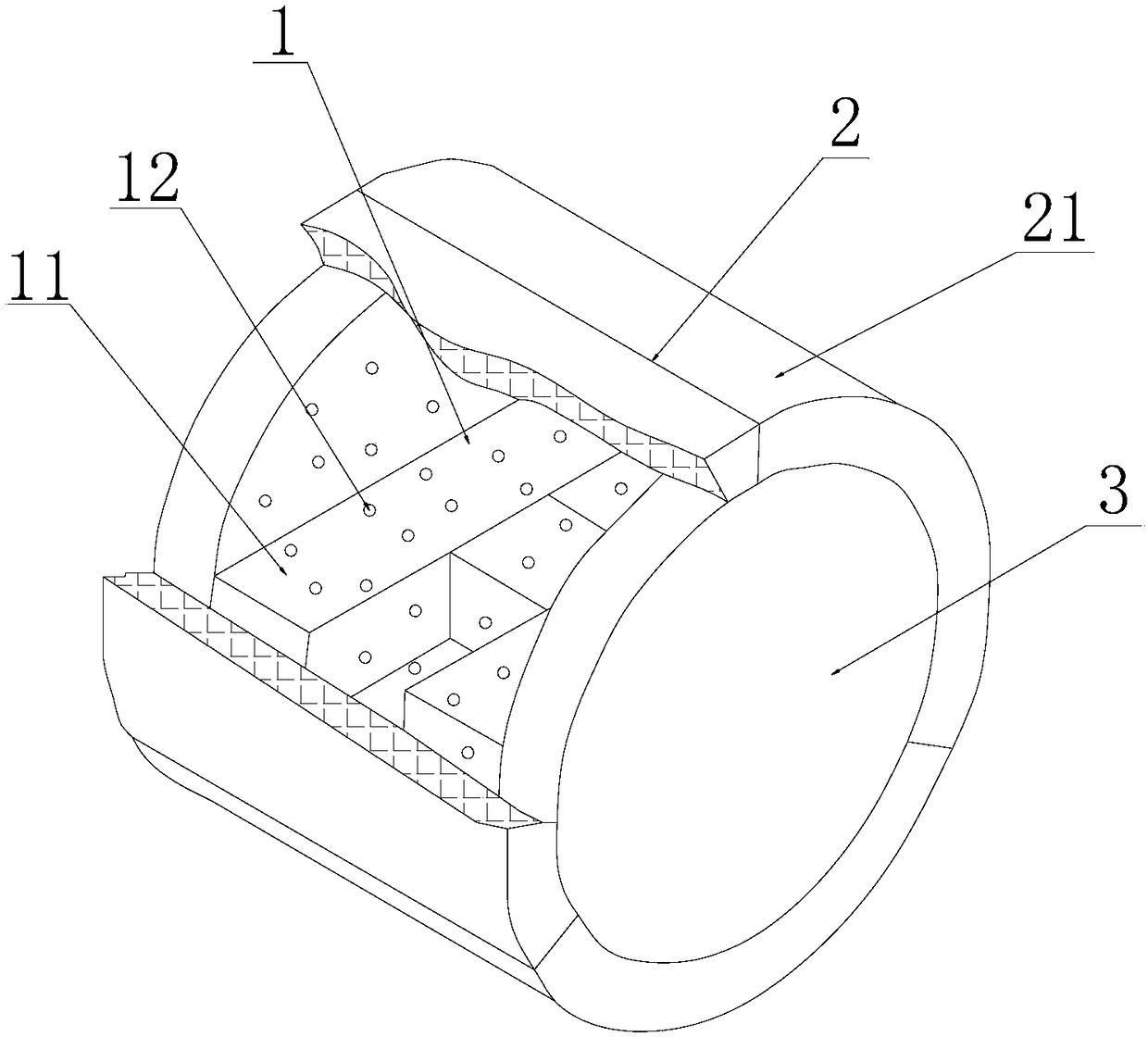

Integral electroforming method and dedicated die of three-dimensional sculpture

The invention discloses an integral electroforming method of three-dimensional sculpture, which can reserve the advantages of separated electroforming and time and labour saving for processing and has the 100% similarity with a master mould. The integral electroforming method comprises: a three-dimensional hollow female die (2) of which the upper part is provided with an opening and the inner wall is coated with a conducting layer (1) is installed in a electrolytic cell; the inner cavity of the female die (2) is provided with a three-dimensional natural shape anode (3) of which the external surface is corrugated; the space between the external surface of the natural shape anode (3) and the conducting layer (1) is 1-7 cm, and the area ratio of the external surface of the natural shape anode (3) and the conducting layer (1) is 1.5-2:1; electrolyte is filled into the electrolytic cell; a female die conducting electrode (4) and the three-dimensional natural shape anode (3) are connected with a power supply; a metal casting layer with set thickness is accumulated on the conducting layer (1) by electroforming; and the female die (2) coated with the metal casting layer is taken out and is removed.

Owner:DALIAN JIAHUA ART DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com