Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Reduce auxiliary man-hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

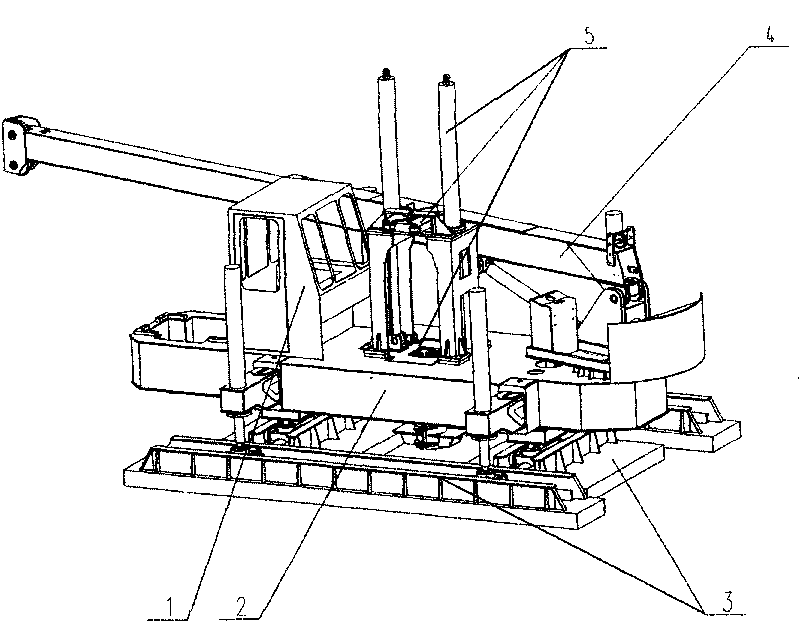

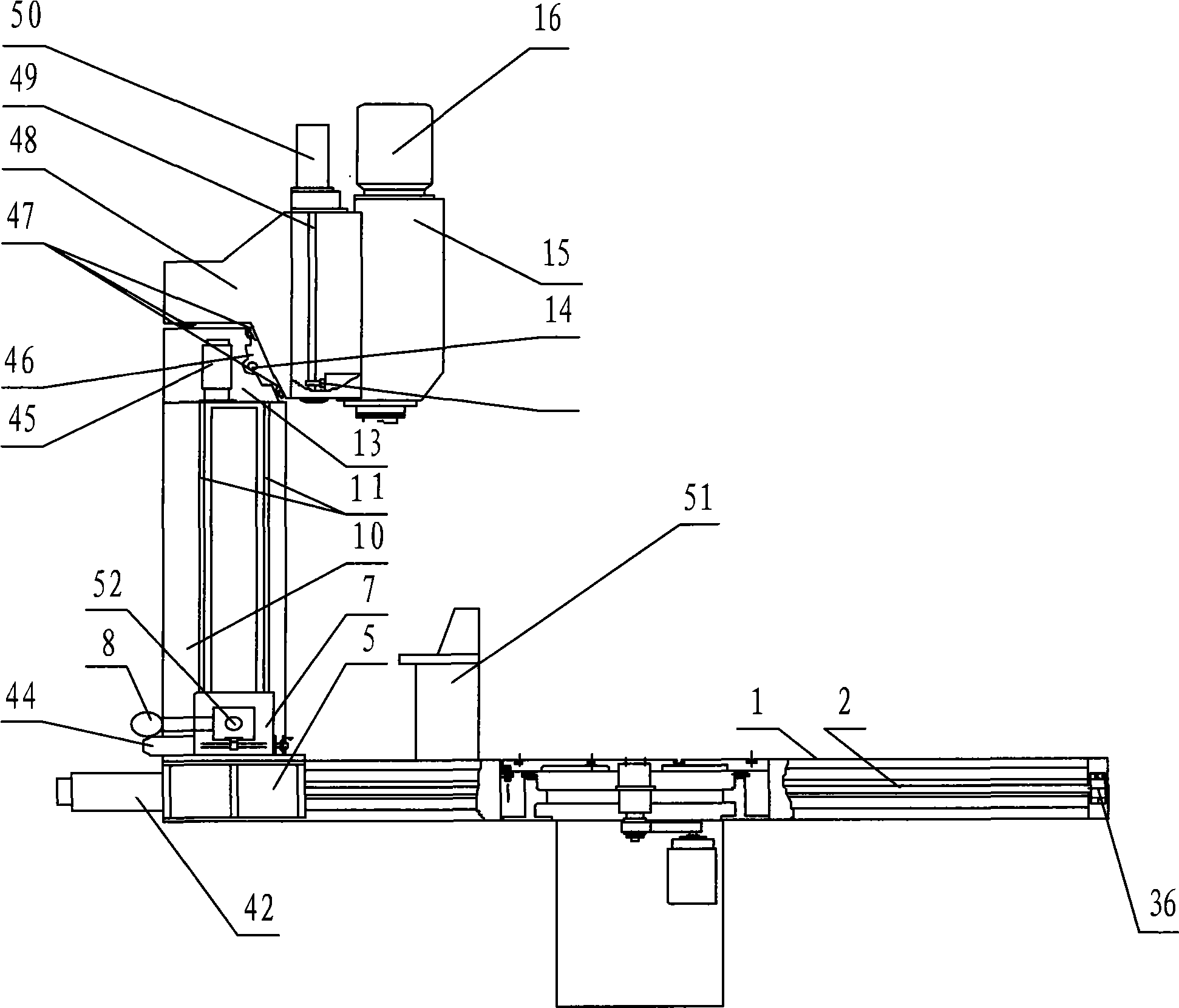

Cleaning equipment for outer wall of low-rise building

InactiveCN102334959AImprove applicabilityImprove effective working timeCarpet cleanersFloor cleanersElectrical controlElectric machinery

The invention relates to cleaning equipment for the outer wall of a low-rise building, which is characterized by comprising a base part, a cleaning part and a folding type lifting part connected with the two parts, wherein an electric control system and a water supply system are also installed on the base part; the cleaning part comprises a box body, a first transverse plate installed in the box body in a vertical sliding way, a driving structure with vertical movement, a second transverse plate installed on the first transverse plate in a horizontal sliding way, a driving structure with horizontal reciprocating movement, a cleaning brush and a drive motor, wherein the cleaning brush and the drive motor are installed on the second transverse plate in parallel, and a brush head of the cleaning brush extends out of the box body; and the folding type lifting part comprises a plurality of sections of supporting arms which are sequentially connected, wherein driving oil cylinders are arranged between the adjacent supporting arms. The cleaning equipment is in an integral structure and is also supported on the bottom surface. Compared with traditional equipment, the cleaning equipment for the outer wall of the low-rise building is free from the restriction of the material of a wall body, and the applicability of the equipment is increased. In addition, the cleaning equipment for the outer wall of the low-rise building does not need to be installed before cleaning. On one hand, manpower is saved, and the safety of the operation is ensured. On the other hand, the auxiliary labor hour is reduced, and the effective working time of the equipment is increased.

Owner:天津悦辰清洗设备科技有限公司

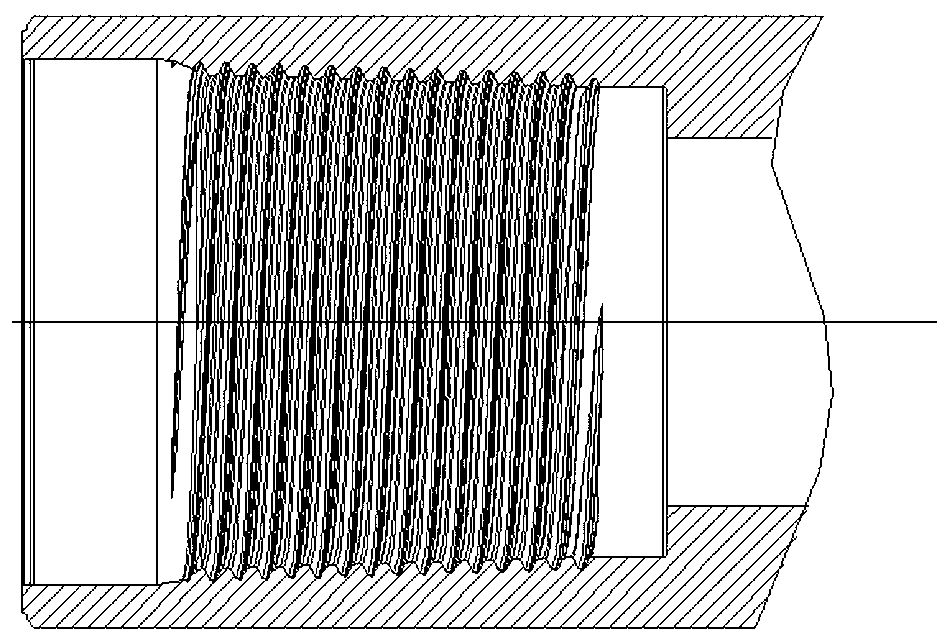

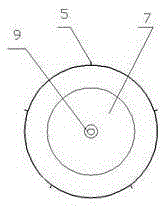

Wire winding machine for annular coil

ActiveCN102360943AImprove effective working timeIncrease productivityCoils manufactureWinding machineDrive shaft

The invention relates to a wire winding machine for an annular coil. The wire winding machine for the annular coil consists of a working platform, a motor, a wire winding actuating mechanism, a coil clamping mechanism and an electric appliance control part, wherein the wire winding actuating mechanism consists of a bracket, a wire storing ring, a supporting part, a slotting adjusting part and a pressing part; and the coil clamping mechanism consists of three clamping shafts which are uniformly distributed along a circumference, a clamping shaft opening and closing mechanism and a clamping sleeve. The wire winding machine for the annular coil is characterized in that the bracket consists of an upper bracket and a lower bracket which are rotationally connected; the slotting adjusting part consists of a first split and a second split which are respectively mounted on the upper bracket and the lower bracket; and the clamping shaft opening and closing mechanism comprises an opening actuating mechanism consisting of a driving shaft and a supporting arm, and a resetting mechanism consisting of a resetting shaft and a torsion spring. Compared with the prior art, the wire winding machine for the annular coil has the advantages that the opening and closing of the wire storing ring are realized by adjusting the second handle of the second split, two-step operation is simplified into one-step operation, the opening of the clamping shafts is realized by tightly holding a handle on the supporting arm, and bidirectional adjustment is simplified into unidirectional adjustment. Thus, the wire winding machine has the characteristics that operation is convenient, time is saved and production efficiency is improved.

Owner:TIANJIN BINHAI ELECTRICAL EQUIP

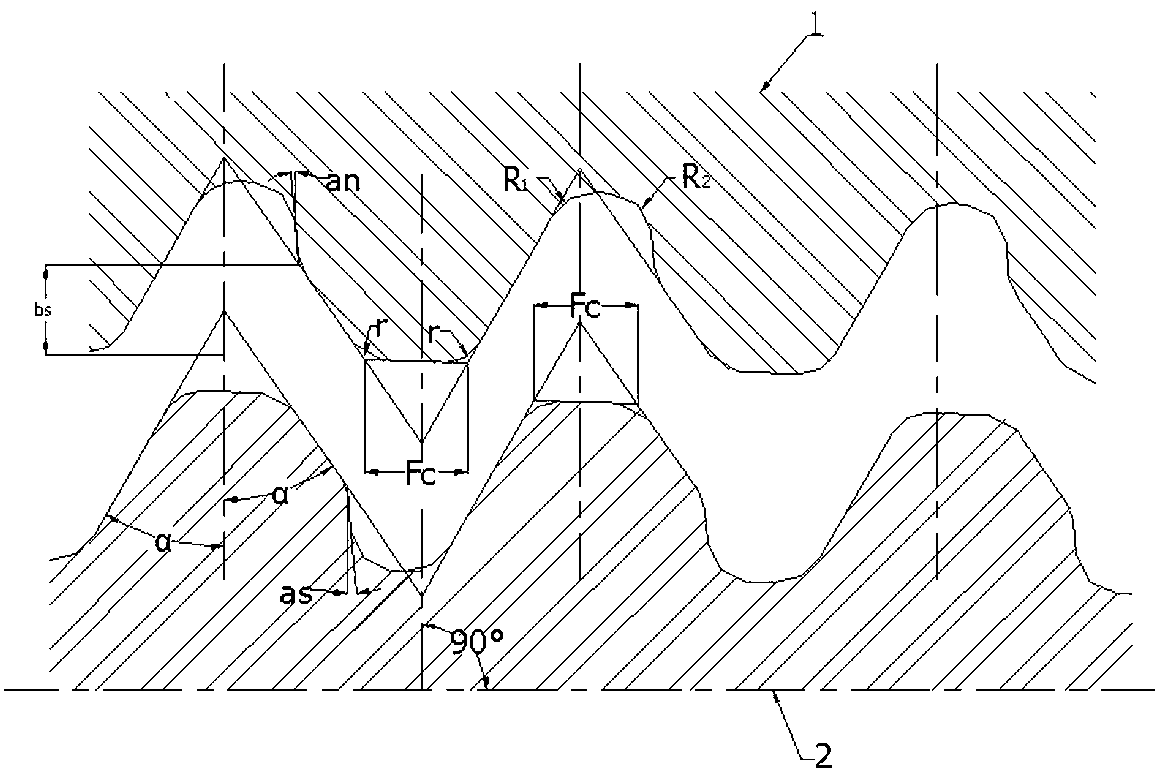

Fast-rotation type oil drill rod joint thread reinforcing structure

InactiveCN103216197AReduce auxiliary man-hoursImprove drilling efficiencyDrilling rodsDrilling casingsDrill pipeStress concentration

The invention discloses a fast-rotation type oil drill rod joint thread reinforcing structure which is arranged in taper internal threads and taper external threads, wherein the taper internal threads and the taper external threads are arranged at two ends of a drill rod joint. Fast-rotation connection of triple threads in the same rotation direction can be achieved, thread forms of threads with same standards are uniform, inclined surfaces on the left sides of the trapezoid-shaped thread forms are bearing sides, curved surfaces on the right sides of the trapezoid-shaped thread forms are lead-in sides, and arcs with big radius values are used on two sides for transition to form thread bottoms. The arc connecting structures reduce stress concentration, and have a significant reinforcing effect on the threads. The lead-in sides of the thread forms adopt curved surface structures which are important structural features, and the curved surfaces are circular bead type reinforcing structures and improve the anti-torsion capability of the threads. Geometrical shapes and sizes of the threads are optimized in view of a high anti-torsion demand of an oil drill rod joint, the threads are further reinforced, load bearing is evenly distributed onto each tooth, and the problems that the taper internal threads expansion and fatigue crack of the taper external threads occur are avoided, so that drilling efficiency and safety are directly improved.

Owner:JIANGSU SHUGUANG OIL DRILLING EQUIP CO LTD

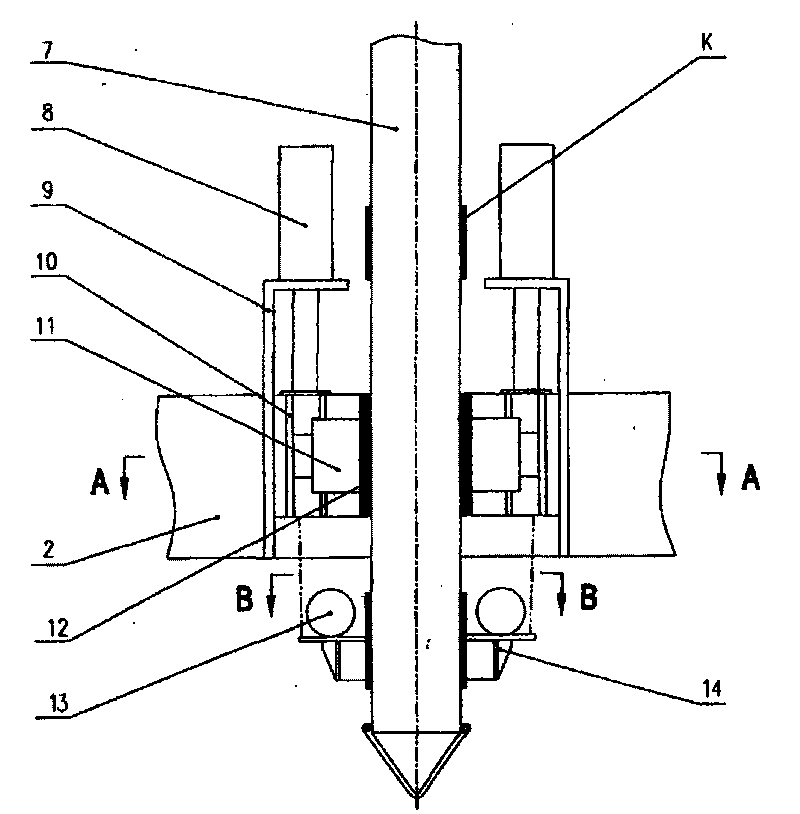

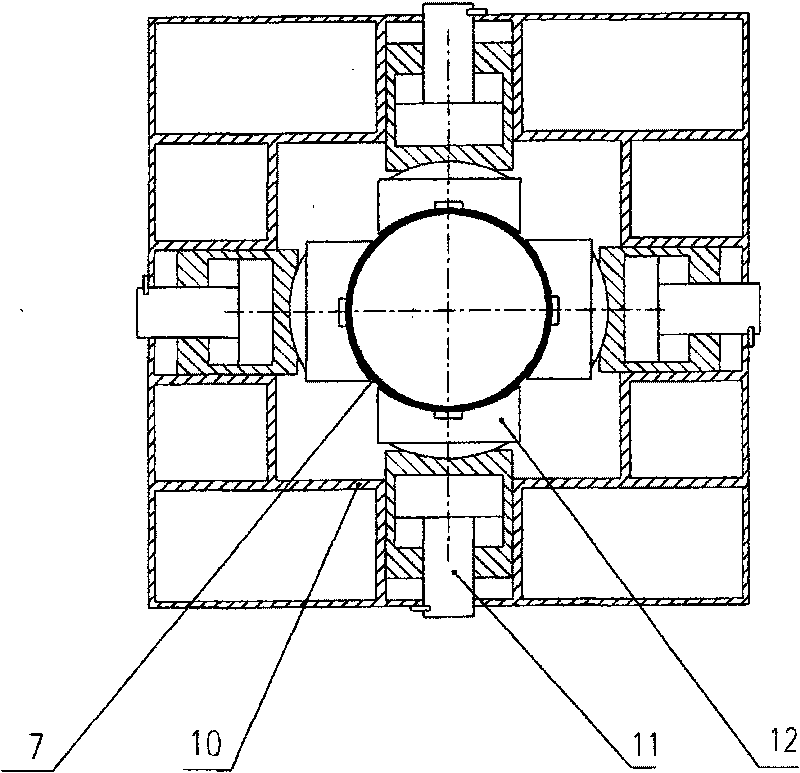

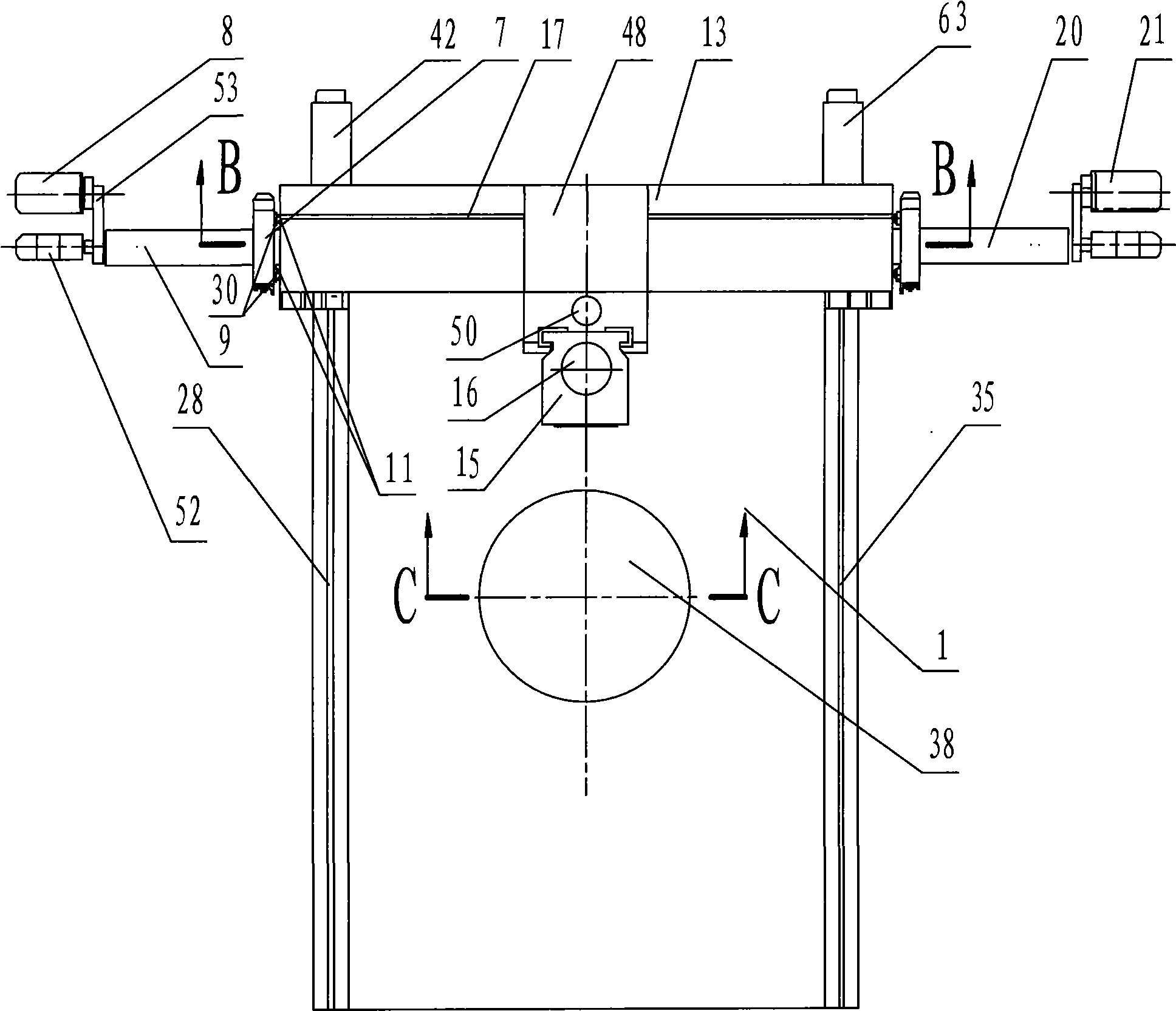

Construction method and equipment of holding and pressing type static-pressure driven cast-in-place pile

InactiveCN101761081ANo fume pollutionReduce labor intensityBuilding material handlingBulkheads/pilesPressure.driveImmersed tube

The invention relates to a construction method of a holding and pressing type static-pressure driven cast-in-place pile by adopting a holding and pressing type static-pressure immersed tube pile machine. The machine comprises a machine body, a pile hanging mechanism, a walking mechanism, a control device and a side holding type pile clamping and pressing mechanism, wherein the side holding type pile clamping and pressing mechanism is connected with a pile clamping box sliding up and down along a slide rail through a pile pressing oil cylinder by a pile pressing frame, a pile clamping oil cylinder is arranged in the pile clamping box and connected with a clamping block for clamping a pile tube, and the pile clamping box is elastically connected with a concrete jolt ramming mechanism. The construction method comprises the following steps of: immersing the pile tube to an underground designed elevation part in a holding and pressing mode from the side face of the pile tube; primarily pouring concrete to an elevation part at the bottom of a reinforcing steel bar cage; then putting the reinforcing steel bars into a pile tube hole; and pouring concrete to the top of the reinforcing steel bar cage, wherein during pulling the pile tube, the concrete in the pile hole is jolt rammed while the pile tube is pulled. The invention has the advantages of no vibration, no noise and no oily fume environmental pollution, and the length of the pile tube is not limited by the height of the pile pressing frame.

Owner:赵黎明

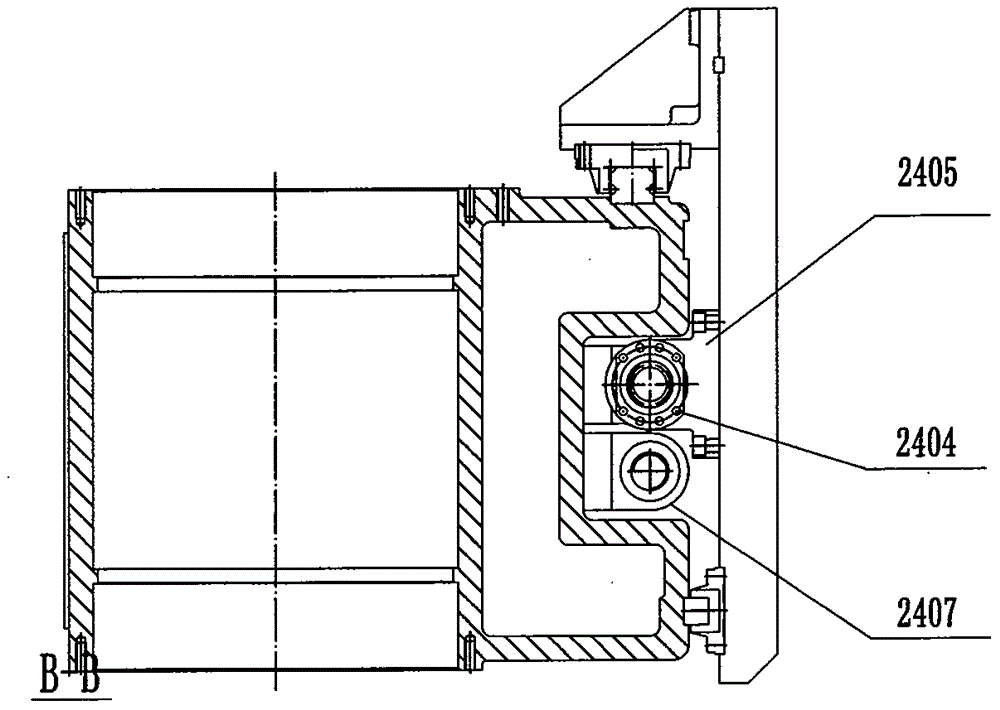

Gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine

ActiveCN104924466ASimple structureQuality improvementWorking accessoriesStone-like material working toolsNumerical controlSlide plate

Provided is a gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine, comprising a gantry structure of a main machine base, a stand columns and a top beam, and a cross beam, a translation workbench, and power head assemblies. The machine is characterized in that the number of the power head assemblies is two. A first power head assembly and a second power head assembly do rotary motion respectively through two same worm gear rotation executive devices, and are respectively connected with a left cross-shaped sliding plate and a right cross-shaped sliding plate through a linear guide rail pair, and are respectively driven by a hydraulic mechanism and are slidably cooperated up and down along the linear guide rail pair. The left cross-shaped sliding plate and the right cross-shaped sliding plate are arranged on two sides of the cross beam, and are slidably cooperated with the cross beam through a cross-shaped sliding plate drive device. The cross beam is slidably cooperated along the stand columns in an up-down manner through a cross beam elevating device which is arranged on the top beam. The translation workbench is hinged with an auxiliary rotary workbench. The auxiliary rotary workbench is cooperated with the translation workbench through an auxiliary rotary workbench shaft, and is locked by a locking device. Single machine can complete all processes, and can complete a plurality of processes by one-time assembling. The machine is high in processing precision and high in work efficiency.

Owner:蔡崇友

Drilling and slotting integrated machine for coal mines

InactiveCN103670402AImprove work efficiencyImprove anti-shock effectCutting machinesControl systemEngineering

The invention discloses a drilling and slotting integrated machine for coal mines. The machine comprises a machine body, a power mechanism and a hydraulic control system, wherein the power mechanism is arranged at the upper end of the machine body; the hydraulic control system is arranged near the front end of the machine body; traveling gears are arranged on two sides of the machine body; support devices are arranged at front and rear ends of the machine body; a telescopic boom is arranged at the front end of the machine body; the movement direction of the telescopic boom is controlled through hydraulic parts; a drilling and water jet slotting device is fixed at the front end of the telescopic boom. According to the invention, different from a conventional device of performing slotting operation after the drilling is completed, the machine disclosed by the invention can switch the movement of the inserted drilling and water jet slotting device into high-pressure abrasive jet slotting movement in the drilling process of the drilling and water jet slotting device on request, so that the purpose of drilling while slotting is achieved, the problem that water jet slotting knife of the drilling and water jet slotting device cannot extend to a hole and perform slotting, caused by phenomena, such as hole collapse, can be effectively solved and the working efficiency is remarkably increased in the meantime.

Owner:HENAN POLYTECHNIC UNIV

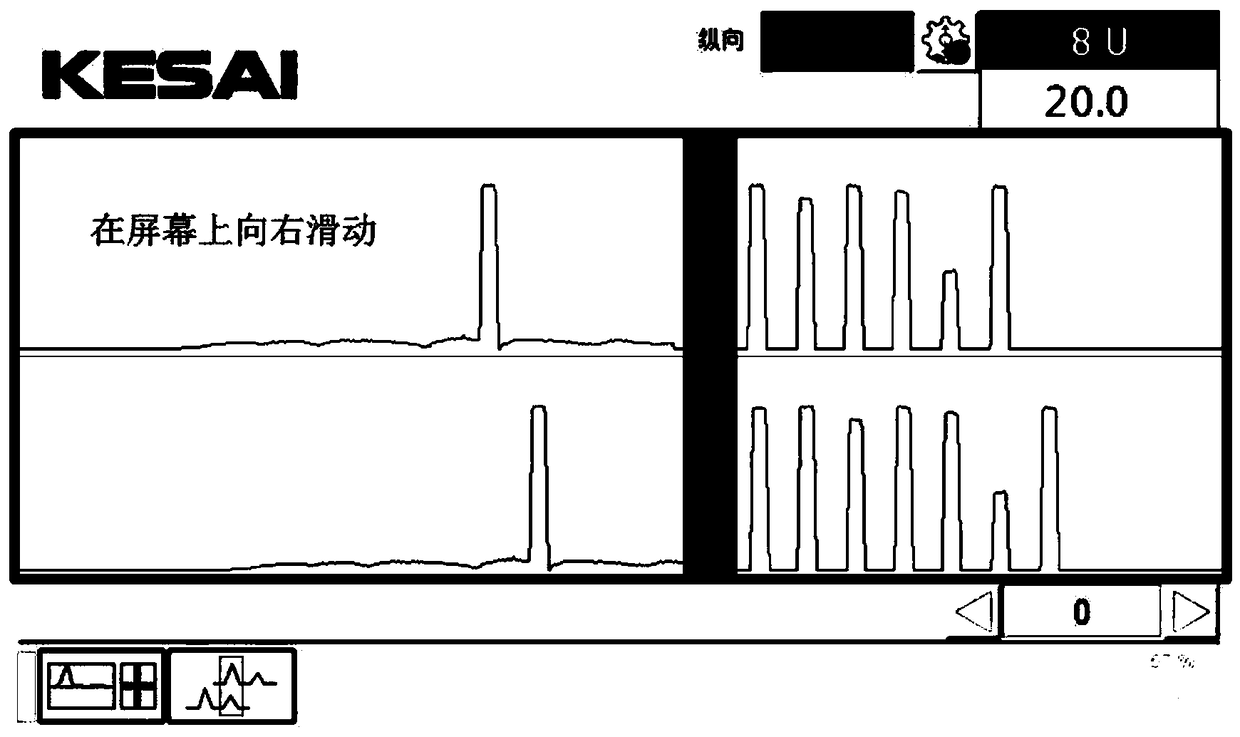

Quick register method for electronic-shaft gravure press

InactiveCN108973308AReduce wasteSave registration preparation timeRotary pressesPrinting press partsPhase differencePrinting press

The invention relates to the field of electronic-shaft gravure pressing, in particular to a quick register method for an electronic-shaft gravure press, mainly overcoming the defects of low precision,low efficiency and the like of existing alignment technology utilized by the conventional presses. According to the method, a post-print color patch test process is carried out, particularly, position of the current color patch and the previous patch is detected by setup of printing (printing in sequence or inverted sequence), and phase difference of the current color patch and the previous colorpatch is calculated, further, a servo motor of a current color cell is controlled directly, a press roll is lifted under control while a printing plate phase position is adjusted in place rapidly bya set adjusting speed, and then the press roll is recovered into a pressing state automatically. By the quick register method, any new plates can be put into printing production process after being set up while phase position of the plates is stored, thus, application efficiency is high; besides, short alignment time is needed, fewer wastes are formed, pre-alignment precision is improved, auxiliary work time is shortened, and work efficiency is improved.

Owner:KESAI ELECTROMECHNICAL EQUIP

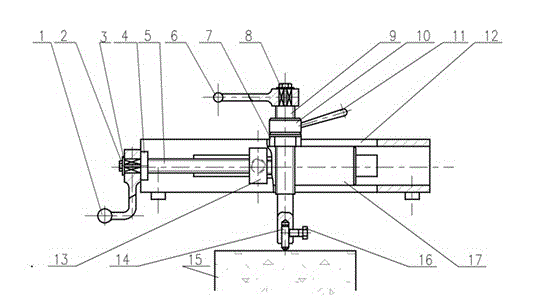

Guide wheel modifier for centerless grinding machine

InactiveCN103056774ASimple structureLow input processing costAbrasive surface conditioning devicesEngineeringProcessing cost

The invention relates to a guide wheel modifier, specifically relates to a guide wheel modifier for a centerless grinding machine and belongs to the technical field of bearing processing and centerless grinding. The guide wheel modifier comprises a modifier body, a horizontal moving mechanism and a vertical moving mechanism, and the horizontal moving mechanism and the vertical moving mechanism are arranged on the modifier body. The manufacture structure of the guide wheel modifier for the centerless grinding machine is simple, investing processing costs are much lower than those of an old guide wheel modifier, height adjustment and horizontal moving of a diamond pen are flexible by means of a bidirectional adjustable mechanism, and more importantly, the problem of frequent maintaining in the past is solved; and the operation is convenient, an operator can master work methods after the operator is slightly trained and guided, work efficiencies are greatly improved, and subsidiary work time is reduced.

Owner:WAFANGDIAN BEARING GRP CO LTD

Surface grinder spindle grinding disc device

InactiveCN101947754AIncrease speedReduce centrifugal forceGrinding drivesToothed gearingsEngineeringCentrifugal force

The invention relates to a surface grinder spindle device and a planetary grinding disc device. The spindle device comprises an inner spindle and an outer spindle. The grinding disc device comprises a revolving disc, a solar grinding disc and a planetary grinding disc. The revolving disc moves at low speed while the solar grinding disc and the planetary grinding disc move at high speed, the inner and outer spindles and the planetary grinding disc are associated with an upper gear case and a lower gear case, and the inner and outer spindles can be driven by one or two variable frequency speed-adjusting motors. The device has the advantage that: by means of the modification of traditional technology, namely one large grinding disc is changed into a plurality of small grinding discs, centrifugal forces of the grinding discs is reduced, overall linear speed of grinding heads is enhanced, surface shape of grinding tools can be repaired effectively by utilizing workpieces to realize constant removal, and repair times of grinding tools is reduced. Therefore, the effect of increasing yield and efficiency and saving energy is obtained, and simultaneously, an outer planetary grinding disc can be further arranged on the grinder according to the requirement of processed products.

Owner:周伟宏

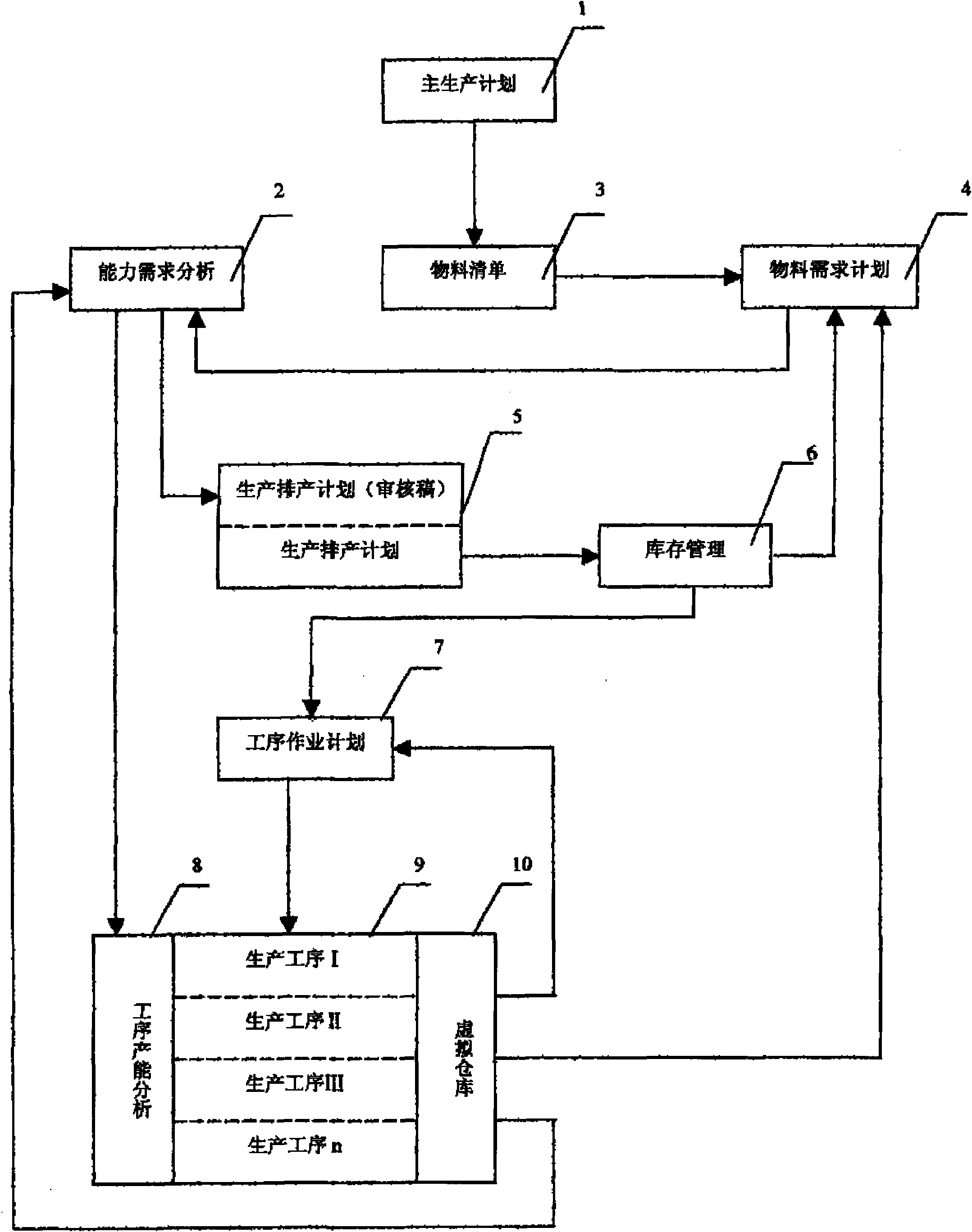

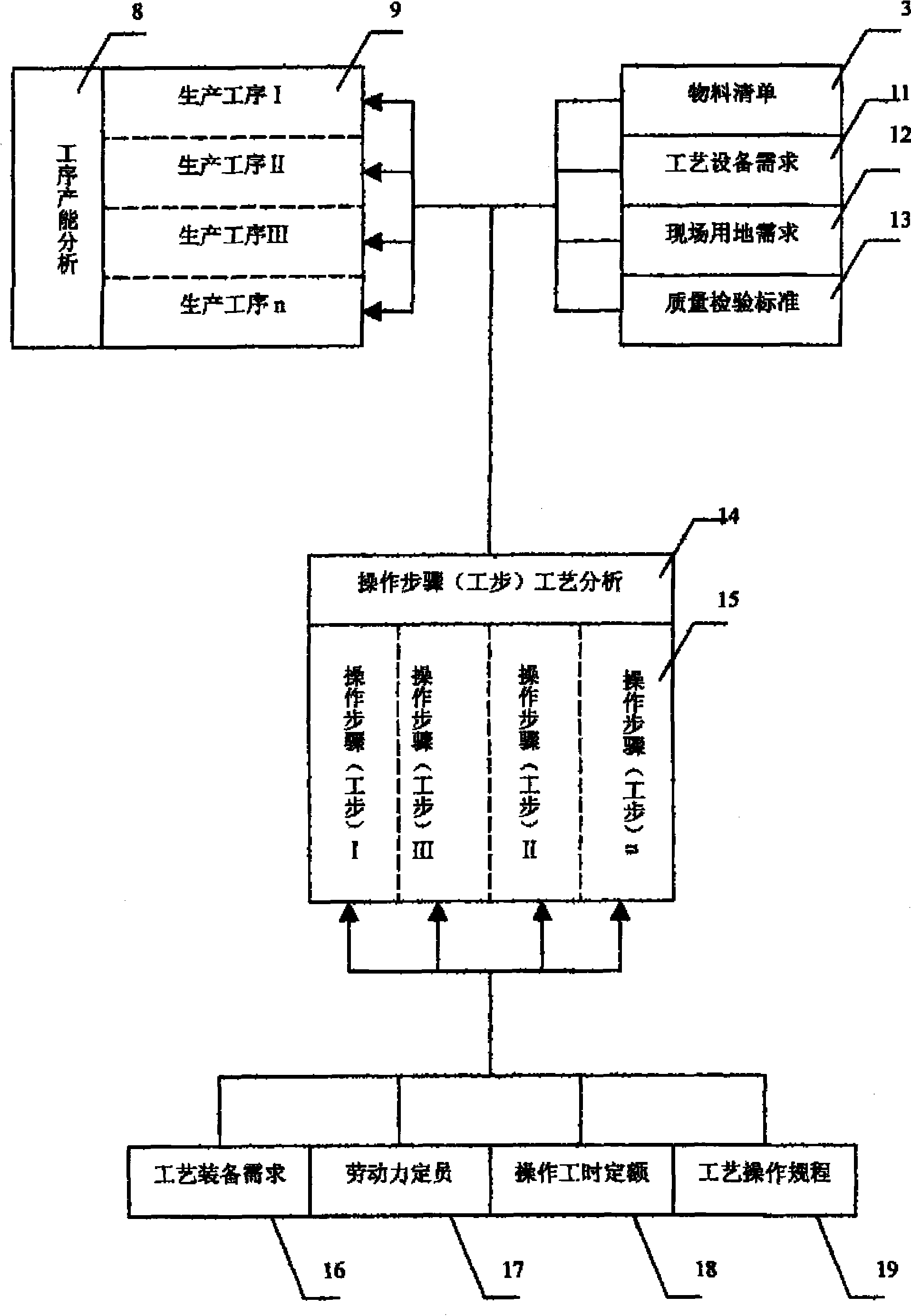

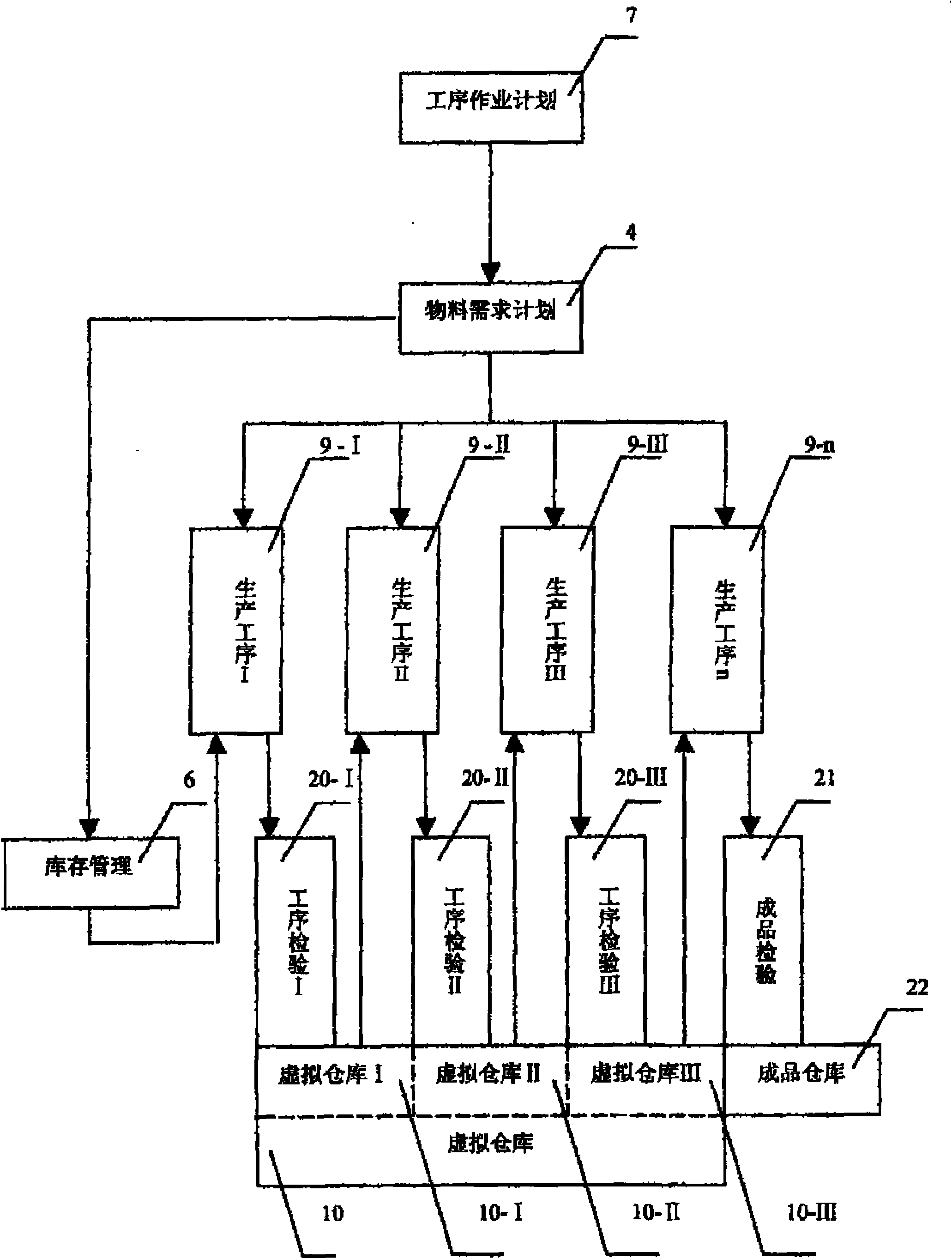

Technological analysis-based ERP production planning management software

InactiveCN101777169ARealize flexible managementIncrease profitResourcesAnalysis dataDynamic monitoring

The invention discloses technological analysis-based ERP production planning management software. On the basis of taking technological analysis data as a shared static data source of modules of a system, production procedures are used as basic units and set as virtual warehouses. Capacity requirements planning (CRP) performs the scheduling operation of a main production schedule (MPS) according to a procedure production capacity generated by the technological analysis data in operation steps (process steps) and generates production scheduling planning after verification and confirmation; and after corresponding material requirements are verified in a warehouse, a system generates procedure operational planning and production flows are dynamically monitored through the virtual warehouses. The production planning management changes the management mode that a production operational schedule (a production job order) is input after a production planer coordinates all departments and checks materials in the original ERP software, and makes up the breakpoints generated by an ERP information chain in process control, thereby improving value-added benefits of material flows, financial flows and information flows by workflows and effectively increasing the implementation success ratio of the software.

Owner:凌琳

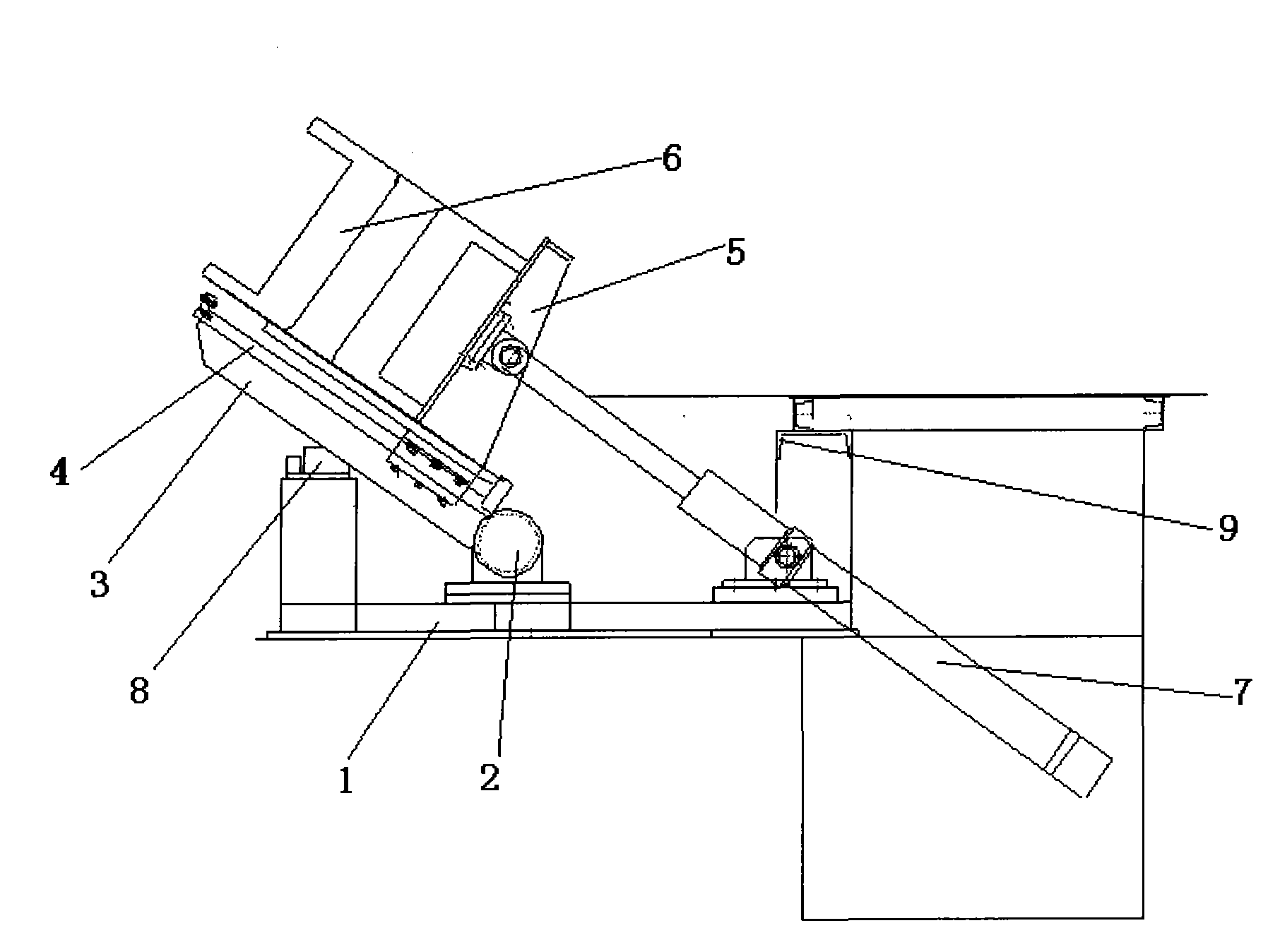

Hydraulic-driven automatic wire coil-loading device for frame winding machine

ActiveCN101916629ASimple structureImprove work efficiencyCable/conductor manufactureWinding machineEngineering

The invention discloses a hydraulic-driven automatic wire coil-loading device for a frame winding machine, which comprises a base frame, wherein, a fixed shaft is rotatablely arranged on the base frame and is fixedly equipped with a turnover support, the turnover support is equipped with a guide rail, the guide rail is equipped with a wire coil bracket in a sliding manner, and a wire coil is placed on the wire coil bracket; a hydraulic oil cylinder is arranged on the base frame through a hinged shaft, and the piston rod of the hydraulic oil cylinder is movably hinged with the bottom of the base frame; the front side of the turnover support is equipped with a turnover limit platform which is fixed on the base frame, and the turnover support rotates by taking the fixed shaft as an axle center until the support is contacted with the turnover limit platform; and the rear side of the wire coil bracket is equipped with a horizontal limit platform, and the rear end of the wire coil bracket is overlapped on the horizontal limit platform. Compared with the original technology, the hydraulic-driven automatic wire coil-loading device has simpler structure, lower cost, more convenient operation and higher operating efficiency.

Owner:合肥合宁电工设备有限公司

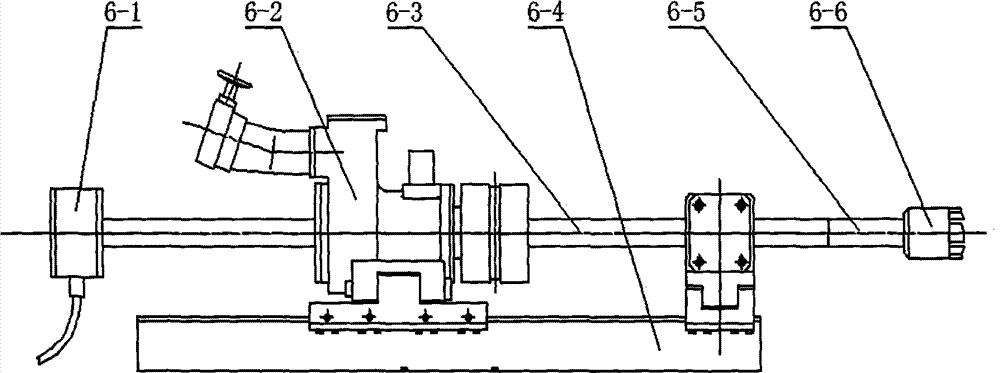

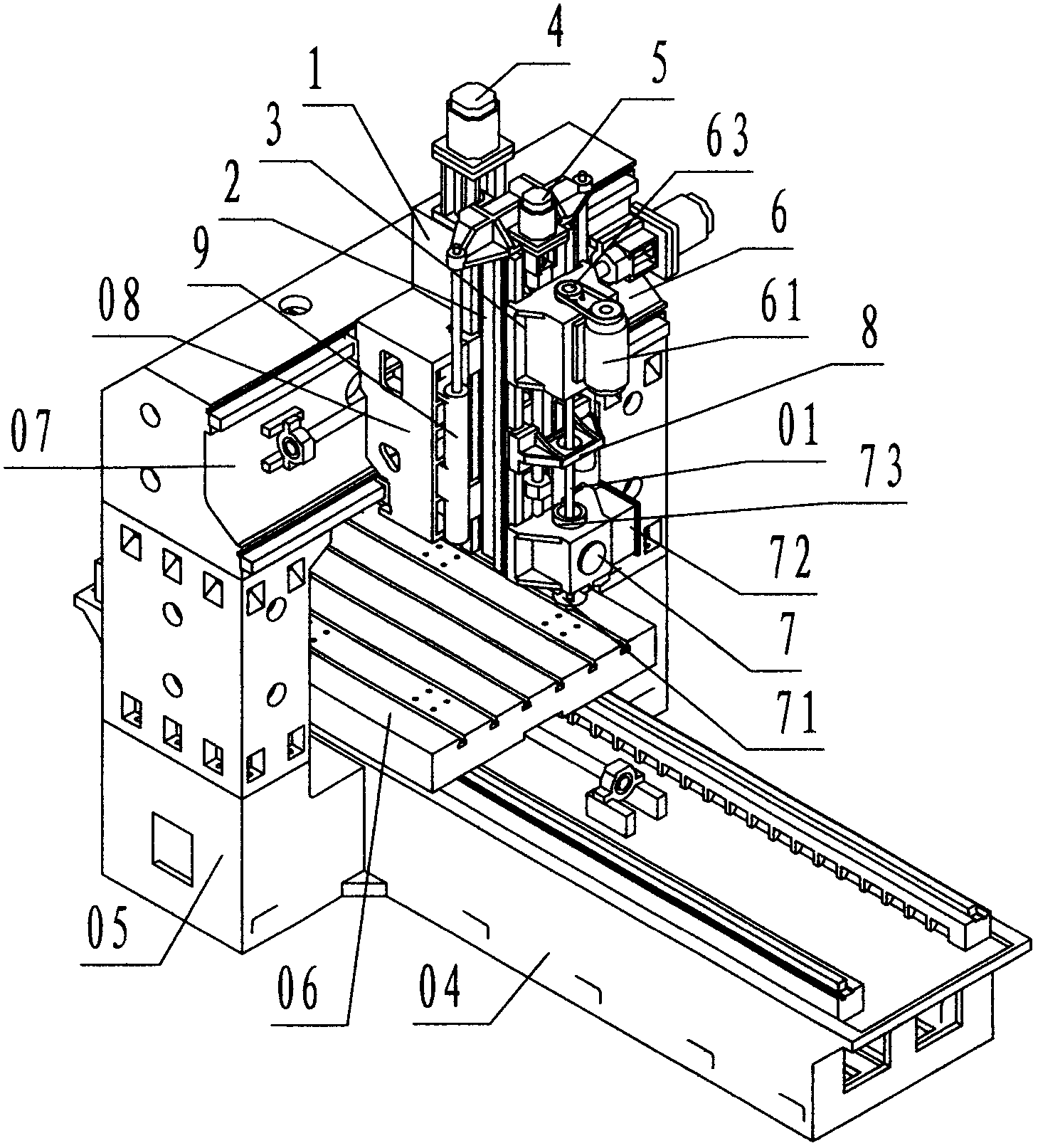

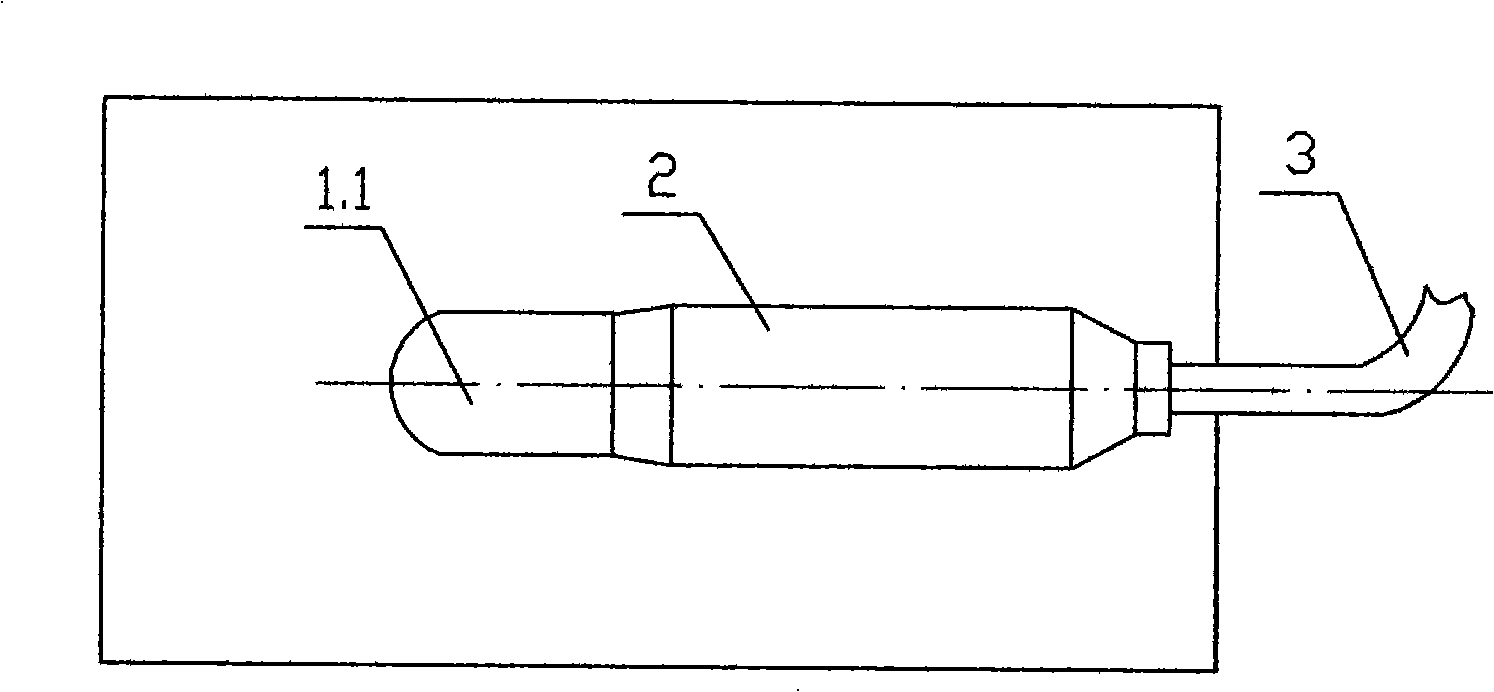

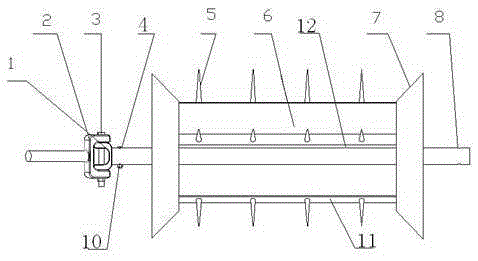

Vertical numerical-control deep hole drilling machine

InactiveCN103817363AAvoid "string vibration"Precise positioningFeeding apparatusLarge fixed membersNumerical controlEngineering

The invention discloses a vertical numerical-control deep hole drilling machine. The vertical numerical-control deep hole drilling machine comprises a fixed guide track (1), a movable guide track (2), a Z carriage (3), a movable track feeding motor (4), a movable track feeding lead screw (41), a Z carriage feeding motor (5), a Z carriage feeding lead screw (51), a drilling machine case (6), a positioning chip removing squeezer (7), a drill rod centre frame (8), a hydraulic stabilizer (9) and a deep hole drill bit (01). According to the technical scheme, a Z-axis perpendicular system is modified on the basis of the existing vertical numerical-control milling machine, shortcomings that in the prior art, a positioning and aligning process is troublesome, the workload is high, unproductive time is long, 'chord vibration' is easily caused during hole drilling, and the precision is not high are overcome, deep hole machining can be carried out by using a vertical hole drilling process, the drilling direction of a slender deep hole drill rod is consistent with the gravity action direction, 'chord vibration' is avoided, positioning and aligning are convenient when ultra-thin and deep holes are drilled, the unproductive time is short, and hole drilling precision meets requirements.

Owner:葛林钢

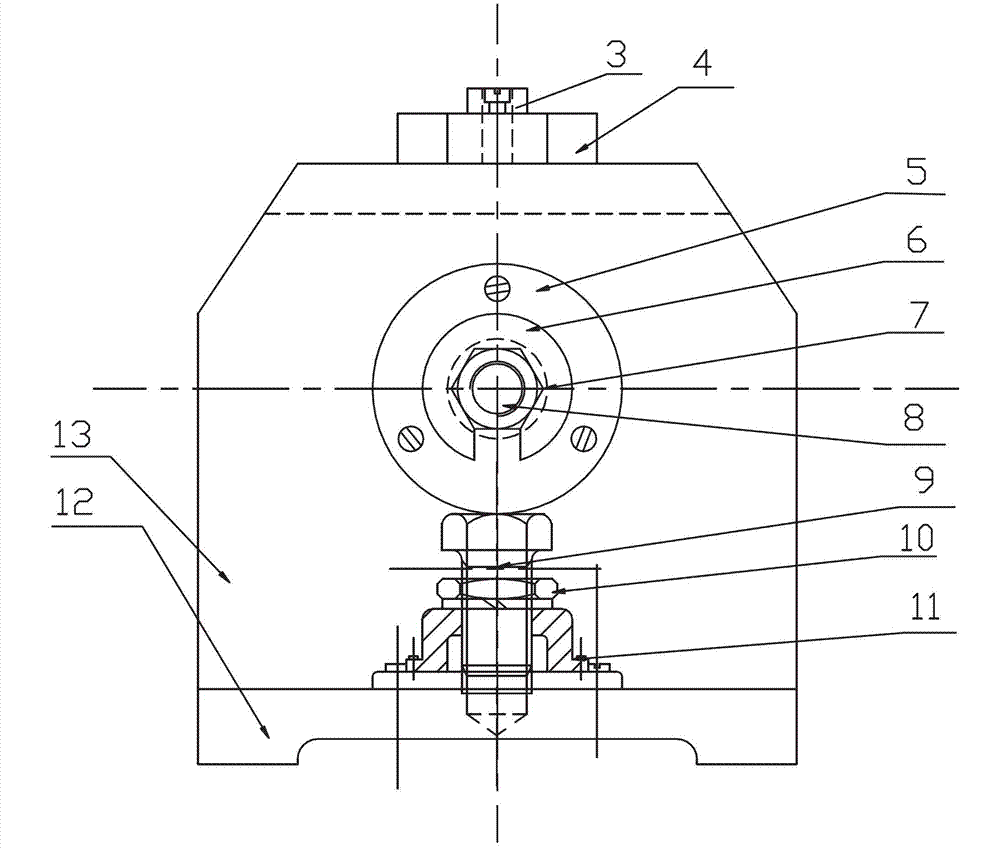

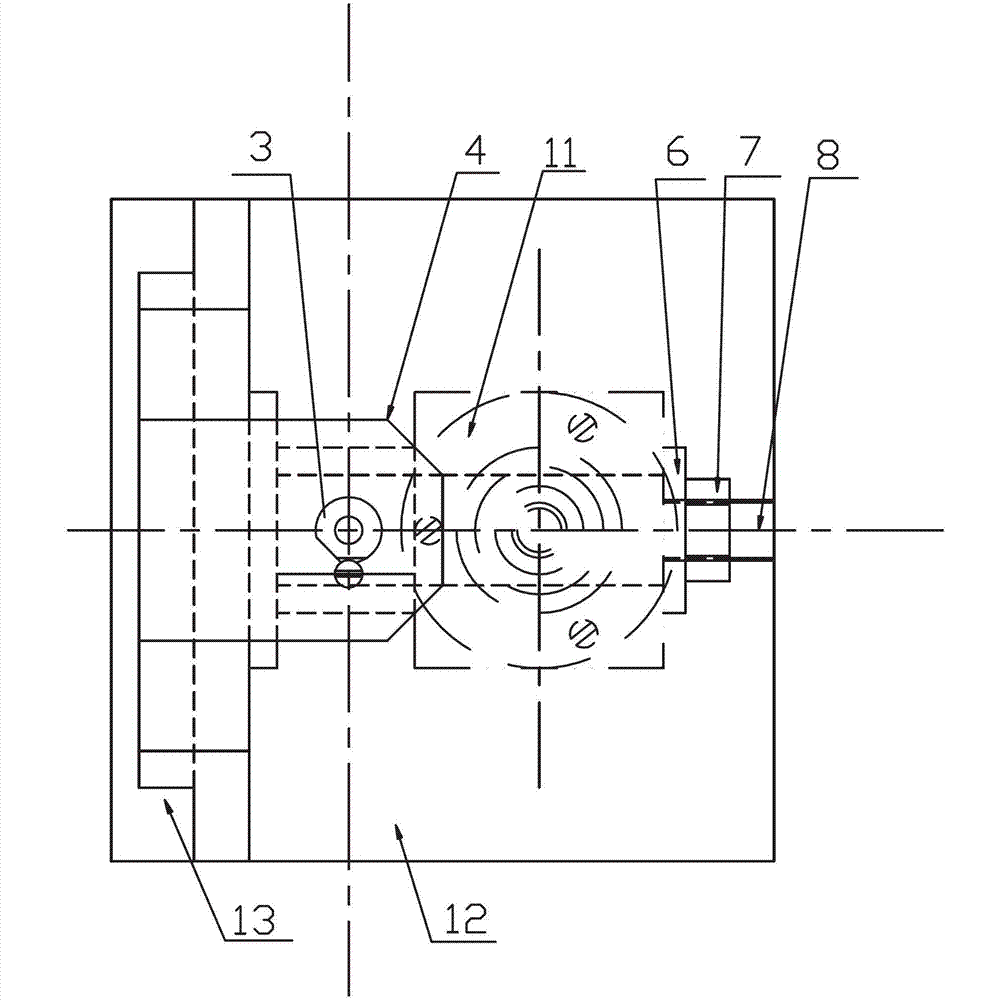

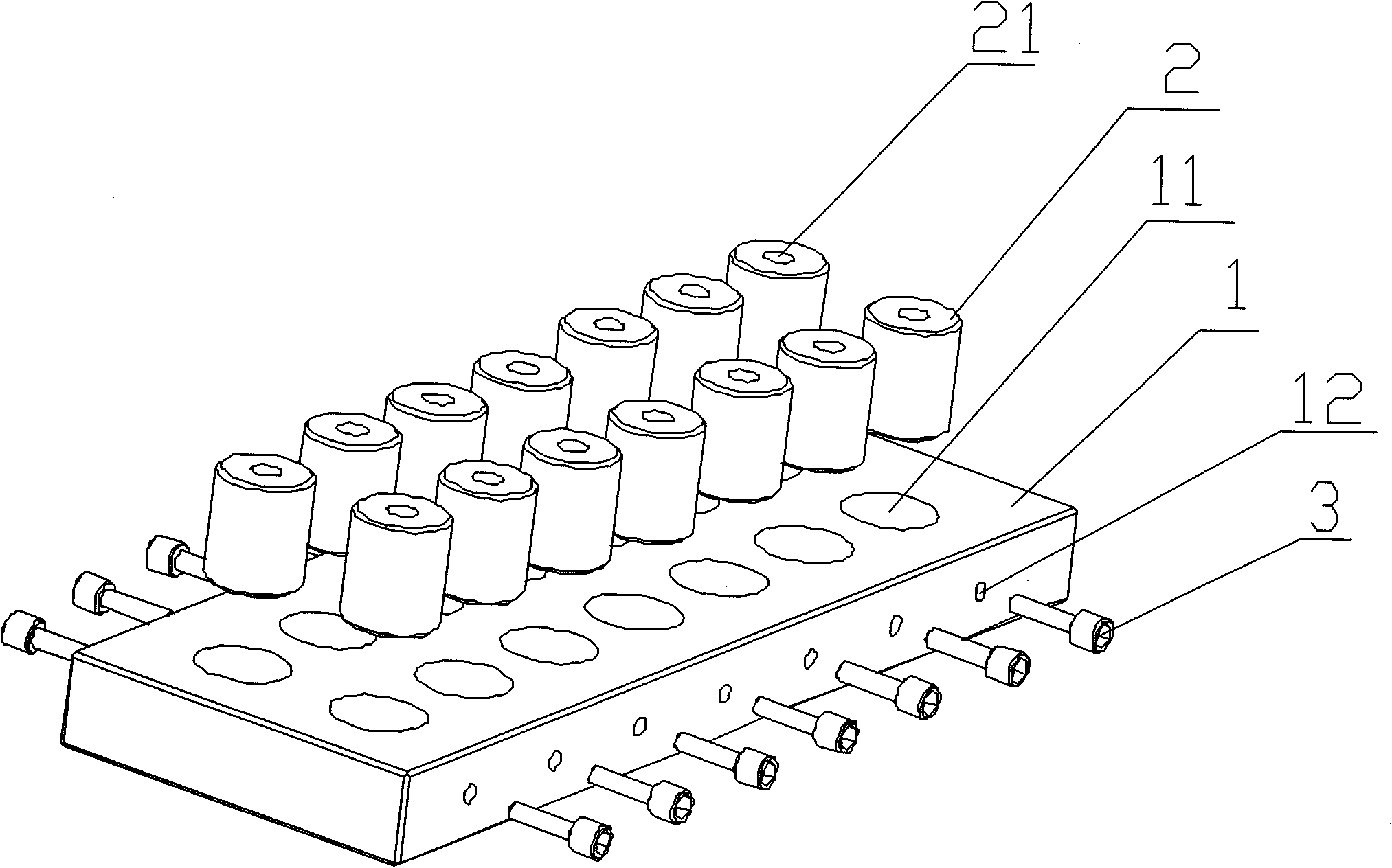

Novel radial hole joint fixture suitable for multi-model number drills

InactiveCN102896506AReduce auxiliary man-hoursReduce labor intensityPositioning apparatusDrill jigsEngineeringSupport plane

The invention discloses a novel radial hole joint fixture suitable for multi-model number drills. The fixture comprises a pedestal, a supporting frame and a fixture body used for clamping a workpiece to be processed, wherein the supporting frame is fixed on the pedestal, and a drill plate is fixed on the top end of the supporting frame through a screw and a locating pin; and the fixture body comprises an axial fixture and a radial telescopic fixture, the axial fixture is arranged on the supporting frame, and the radial telescopic fixture is arranged on the pedestal. By means of the mode, the novel radial hole joint fixture disclosed by the invention can reduce the technical demand on workers, reduce the labor intensity of the workers, guarantee safe production and improve the labor productivity; and the novel radial hole joint fixture can be quickly and conveniently used for producing new products to shorten the production preparation period and reduce the production cost.

Owner:SUZHOU VOCATIONAL UNIV

Adjustable lever drilling die clamp

ActiveCN102729064ALow technical requirementsReduce labor intensityDrilling/boring measurement devicesPositioning apparatusEngineering

Owner:SUZHOU VOCATIONAL UNIV

Positioning hole jig used in slow-silk thread cutting machine

ActiveCN101870021AImprove installation stabilityLow cost of reuseAutomatic control devicesFeeding apparatusEngineering

The invention discloses a positioning hole jig used in slow-sill thread cutting machine, which is characterized by comprising a positioning hole plate and a tool-setting bushing, wherein the positioning plate is provided with plural-numbered positioning holes used for clamping workpieces; the tool-setting bushing and the positioning hole are matched with each other; the positioning hole plate is also provided with locking screws for fixing the workpieces. In the invention, the positioning hole plate which can be provided with plural-numbered workpieces is adopted and each positioning hole is provided with a tool-setting bushing, thus ensuring the clamping state of the simulation workpieces to enable the tool setting to be more accurate; and the locking screws are adopted to fix the workpieces, thus increasing installation stability of the workpieces. The invention has the advantages of simple structure, convenient operation, little nonproductive time, and low cost due to recycling of consumable items. The invention is worth being popularized and used.

Owner:JOUDER PRECISION INDAL KUSN

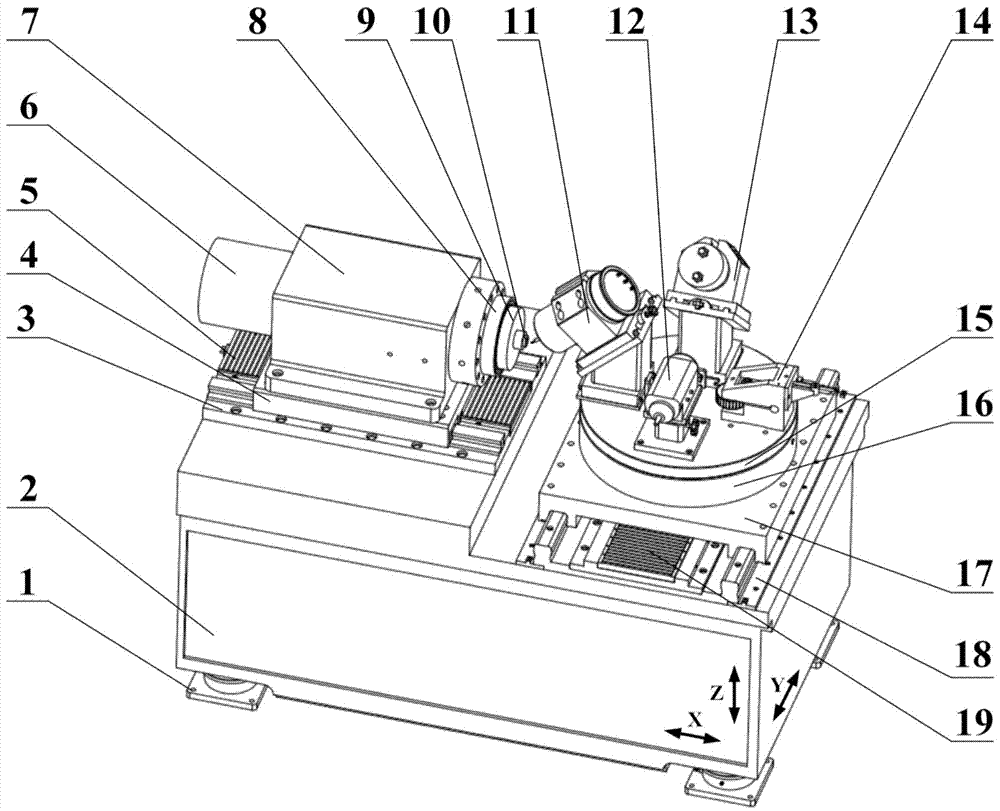

Precise machining machine tool for small-caliber rotating shaft symmetrical optical curved elements

InactiveCN107457570ARealize compensation processingImprove controllabilityMeasurement/indication equipmentsOther manufacturing equipments/toolsRotary stageRotational axis

The invention discloses a precise machining machine tool for small-caliber rotating shaft symmetrical optical curved elements. The precise machining machine tool is provided with a machine body with a vibration reducer. A first slide table driven by a first linear motor is mounted on one side of the machine body, and is provided with a workpiece main shaft. Correspondingly, a second slide table driven by a second linear motor is mounted on the other side of the machine body, and is provided with a first rotating table; and an inclined shaft fine milling device, an inclined shaft electroheological polishing device, a single-point diamond turning device and a detecting device are annularly arranged on the rotating table. The precise machining machine tool is fast and convenient in switching of different machining modes, can perform the in-situ measurement and the compensation machining on workpieces, and achieves good controllability of machining paths; the workpieces are once clamped in the machining process, so that the accumulated errors are reduced, the auxiliary labor hours are reduced, and the machining precision and the machining efficiency are improved; and the precise machining machine tool adapts to machining and detection of the workpieces with different surface shapes and multiple materials, and can effectively prevent the interference phenomenon between cutters and the workpieces in machining of concave surfaces of the workpieces.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

One-way wire cut electrical discharge machining method circularly utilizing electrode wire

InactiveCN105562854AAvoid commutation stripesReduce time consumptionElectrical-based machining electrodesEngineeringElectrical discharge machining

A one-way wire cut electrical discharge machining method circularly utilizing an electrode wire comprises a forward wire walking step and a reverse wire walking step. The wire walking direction of the forward wire walking step is opposite to that of the reverse wire walking step. In the forward wire walking step, discharge cutting machining is conducted during wire walking, and in the reverse wire walking step, the discharge cutting machining is suspended during wire walking. By means of the method, the utilization rate of the electrode wire can be increased, and meanwhile the machining precision can be improved.

Owner:BEIJING DONGXING LUBRICANT CO LTD

Aggregate machinery for machining large-sized mechanical components

InactiveCN101497162AImprove efficiencyImprove machining accuracyOther manufacturing equipments/toolsMechanical componentsAgricultural engineering

The invention discloses a combined machine tool for processing large mechanical parts, which comprises a numerical control system, a main worktable, a vertical lathe worktable, a portal frame, a vertical boring and milling head component, a left horizontal boring and milling head and a right horizontal boring and milling head, wherein the vertical lathe worktable is arranged in a center hole of the main worktable; in the portal frame, upper ends of a gantry right upright post and a gantry left upright post are fixedly or movably connected with a gantry beam, and lower ends of the two upright posts are in assembly connection with guide rail platforms at two sides of the main worktable through an upper right guide rail and an upper right guide rail groove, a lower right guide rail and a lower right guide rail groove, an upper left guide rail and an upper left guide rail groove, a lower left guide rail and a lower left guide rail groove; the vertical boring and milling head component comprises a vertical boring and milling head bracket and a vertical boring and milling head, and is in assembly connection with the gantry beam through a linear guide rail and a linear guide rail groove; right and left horizontal boring and milling head outer shells of the right and left horizontal boring and milling heads pass through rectangular through holes in the middle of the two upright posts from two sides of the portal frame respectively and pass through right and left horizontal boring and milling head brackets to form sliding connection; and the right and left horizontal boring and milling heads can be lifted vertically and moved transversely.

Owner:JILIN TIANLIN IND & TRADE

Material feeding type plastering device

The invention discloses a fed type plasterer, belonging to construction tools. The plasterer comprises a flat, a flow valve and a feeding hose, wherein, the flat is a rectangular component with a thin wall; the bottom surface of the flat is a smooth plane; the middle of the flat is concave upward in the length direction to form a material cavity; the top of the material cavity bends and gradually shrinks into a hollow throat; one end of the flow valve is connected with the hollow throat while the other end is connected with the feeding hose; and the outer wall of the flow valve is provided with a hand switch with a normal close structure. When the plasterer is used, the outer wall of the flow valve is held by hands; the feeding hose is connected and introduced mortar, the bottom surface of the flat faces toward a construction surface, the hand switch is pressed to control the feeding amount of the mortar, the plasterer make rubbing and leveling operations during moving process. The plasterer has the advantages of continuous feeding, nonproductive time conservation, high construction efficiency and low labor intensity, is particularly suitable for extensive constructions.

Owner:ZHENGTAI GRP

Welding robot capable of automatically identifying and tracking welding line

InactiveCN106312398AReduce labor intensityReduce auxiliary man-hoursWelding/cutting auxillary devicesAuxillary welding devicesComputer control systemEngineering

The invention belongs to the technical field of robots, and provides a welding robot capable of automatically identifying and tracking a welding line. The welding robot comprises a walking vehicle, a horizontal box body, a vertical box body, a horizontal and vertical tracking execution mechanism, a front vision sensor, a rear vision sensor, a welding gun mechanism and a computer control system; the horizontal box body and the vertical box body are arranged on the walking vehicle in a rear and front manner, the horizontal and vertical tracking execution mechanism is connected with a connecting plate and is fixedly arranged on the upper surface of the walking vehicle, the front vision sensor is mounted on the front side of the vertical box body, and a computer can be connected with the front vision sensor, the rear vision sensor, the walking vehicle and the horizontal and vertical tracking execution mechanism through cables, wherein the front vision sensor and the rear vision sensor can obtain the geometrical shape and the position information of the welding line. According to the welding robot, the geometrical shape of the welding line can be automatically identified, the pipeline welding bead number, the layer number and the tracking motion of the walking vehicle can be automatically planned through the computer, and stability and optimization of the welding quality can be ensured.

Owner:谢克庆

Mining partial cold-supply device

InactiveCN1737336AReduce auxiliary man-hoursSimplify auxiliary processesTunnel/mines ventillationMobile vehicleIce storage

This invention relates to a mining local cool supply device, which comprises an ice storage tank and a water storage tank in the mobile vehicle, interconnected with air cooler through agent circulating pipe, wherein the agent circulating pipe is multilayer dish type heat-exchanger rig when it passes the ice storage tank, and connected with the bore-hole pump when it passes the water storage tank. By said technique, the cool supply device below the well can discharge condensation heat, and the pump does not need to do explosion-proof process; besides, the system does not need to process corrosion prevention. The invention is fit for supplying cool in mining, underground installation and tunneling operation place.

Owner:HUNAN UNIV OF SCI & TECH

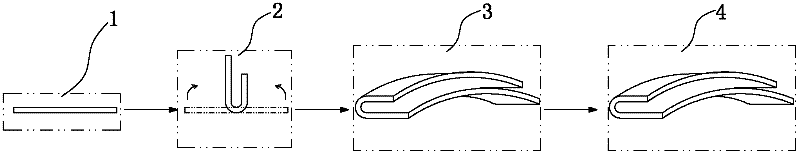

Progressive die molding process for arc-shaped sheet metal component with U-shaped cross-section

The invention relates to a progressive die molding process for an arc-shaped sheet metal component with a U-shaped cross-section, which is characterized by comprising the following procedures: 1) punching a positioning hole; 2) punching two horizontal border holes; 3) punching a vertical hole for communicating the two horizontal border holes to form a free edge; 4) punching a vertical positioningslot; 5) bending the free edge upwards for 90 degrees; 6) bending the 90-degree bent edge inwards for 45 degrees; 7) bending the 45-degree bent edge inwards for 45 degrees; 8) punching a horizontal compensation hole; 9) cutting the edge; 10) pressuring to form an arc shape; 11) carrying out forming correction; and 12) cutting auxiliary parts at the two ends to form a final product. By adopting the procedures, the product processing can be completed by one worker with one device, and the product processing cost can be reduced; and the positioning hole is used as a positioning benchmark, and nomanual positioning and clamping is needed. On one hand, the auxiliary working hours are reduced, the labor intensity is lowered, and the production efficiency is increased. On the other hand, the product processing accuracy is improved, the product forming quality is ensured, and the process is particularly suitable for production of large quantities of products.

Owner:天津市津兆机电开发有限公司

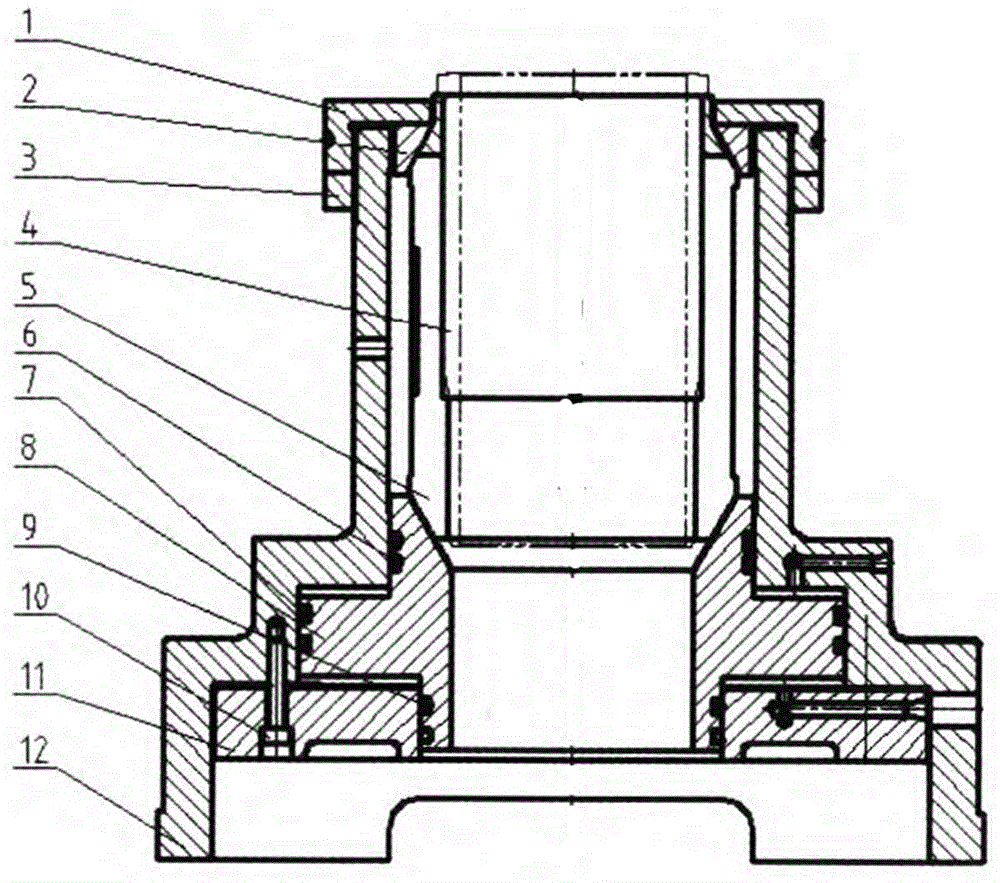

Fine boring fixture in cylinder jacket machining

InactiveCN105619108ASmall roundness errorReduce labor intensityPositioning apparatusMetal-working holdersEngineeringCircular surface

The invention discloses a fine boring fixture in cylinder jacket machining, and relates to the field of machining, in particular to the fine boring fixture in cylinder jacket machining. The fine boring fixture comprises a fixture body; an inner cavity of the fixture body is a three-step-shaped; the middle inner cavity is an oil cylinder; a hollow piston is mounted in the oil cylinder; the upper part of an inner hole of the piston is a conical surface; a middle sealing groove is formed in the outer circular surface of the piston; an upper outer circle of the piston is matched with the lower part of the upper cavity wall of the fixture body; an upper sealing groove is formed in the upper outer circle of the piston; the lower part of the inner cavity of the fixture body is connected with a cylinder cover through a bolt; a lower outer circle of the piston is matched with an inner circle of the cylinder cover; a lower sealing groove is formed in the outer circular surface of the lower part of the piston; sealing rings are arranged in the sealing grooves; and an expansion sleeve with upper and lower surfaces as conical surfaces is additionally mounted in the upper cavity of the fixture body. The fine boring fixture is convenient to operate and stable in operation, improves the roundness and the coaxiality of the inner hole of a cylinder jacket, shortens the assistance time, and relives the labor intensity of workers.

Owner:陕西天财工程造价咨询有限公司

Gantry double-knife multi-axis CNC cutting and carving machine

ActiveCN104924466BSimple structureQuality improvementWorking accessoriesStone-like material working toolsNumerical controlEngineering

Provided is a gantry type double-blade multi-axis numerical control cutting-carving all-in-one machine, comprising a gantry structure of a main machine base, a stand columns and a top beam, and a cross beam, a translation workbench, and power head assemblies. The machine is characterized in that the number of the power head assemblies is two. A first power head assembly and a second power head assembly do rotary motion respectively through two same worm gear rotation executive devices, and are respectively connected with a left cross-shaped sliding plate and a right cross-shaped sliding plate through a linear guide rail pair, and are respectively driven by a hydraulic mechanism and are slidably cooperated up and down along the linear guide rail pair. The left cross-shaped sliding plate and the right cross-shaped sliding plate are arranged on two sides of the cross beam, and are slidably cooperated with the cross beam through a cross-shaped sliding plate drive device. The cross beam is slidably cooperated along the stand columns in an up-down manner through a cross beam elevating device which is arranged on the top beam. The translation workbench is hinged with an auxiliary rotary workbench. The auxiliary rotary workbench is cooperated with the translation workbench through an auxiliary rotary workbench shaft, and is locked by a locking device. Single machine can complete all processes, and can complete a plurality of processes by one-time assembling. The machine is high in processing precision and high in work efficiency.

Owner:蔡崇友

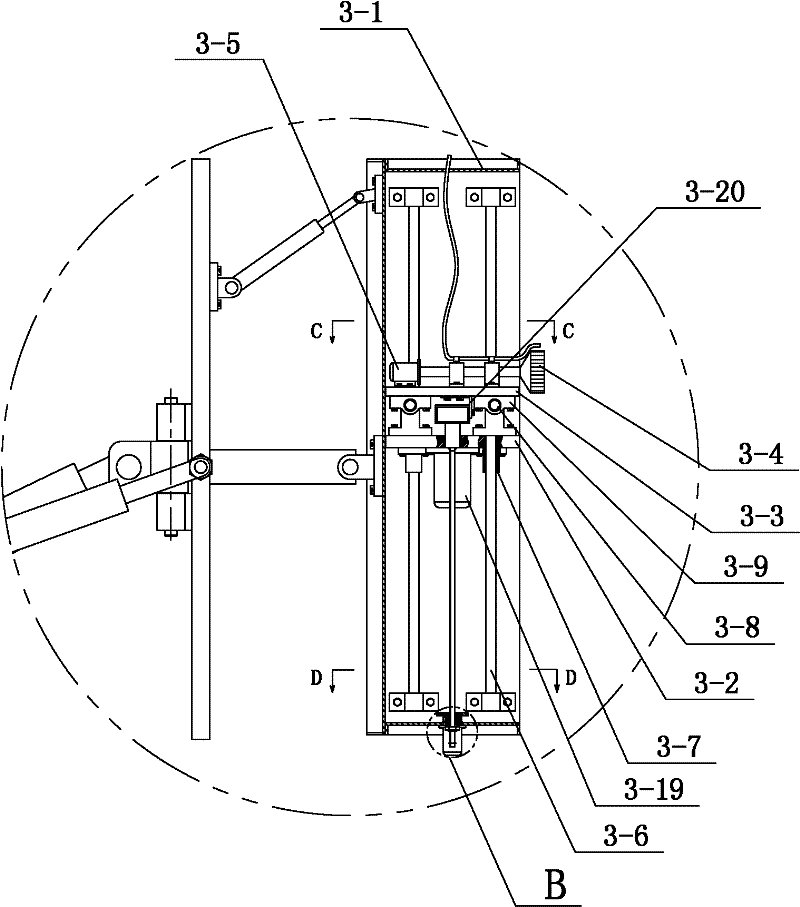

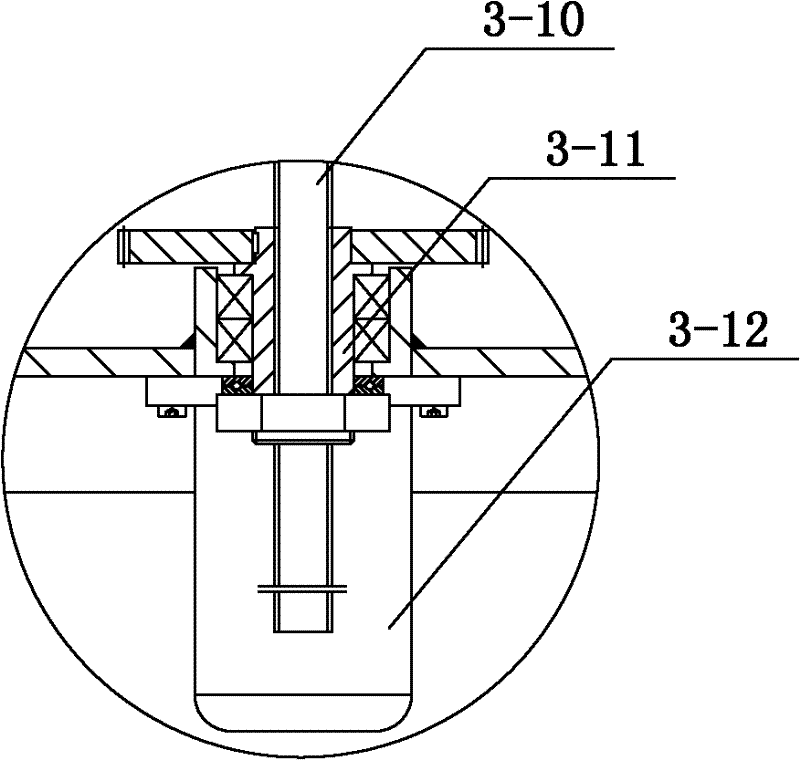

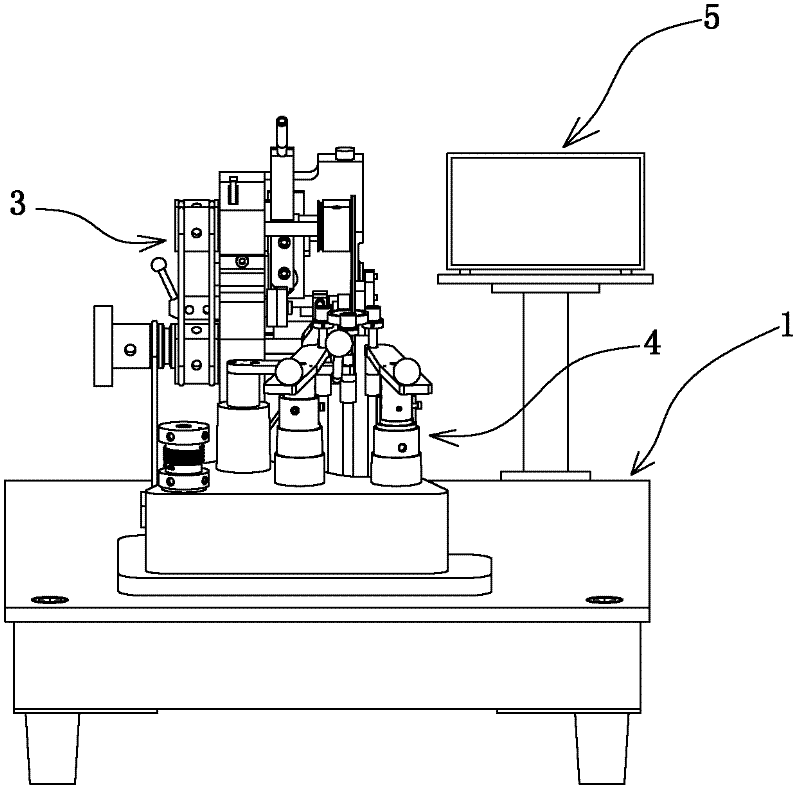

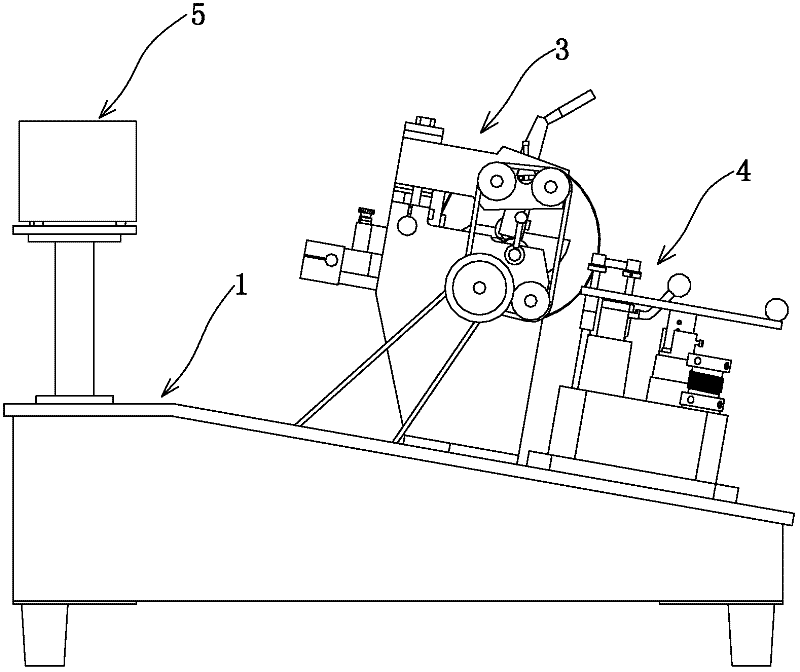

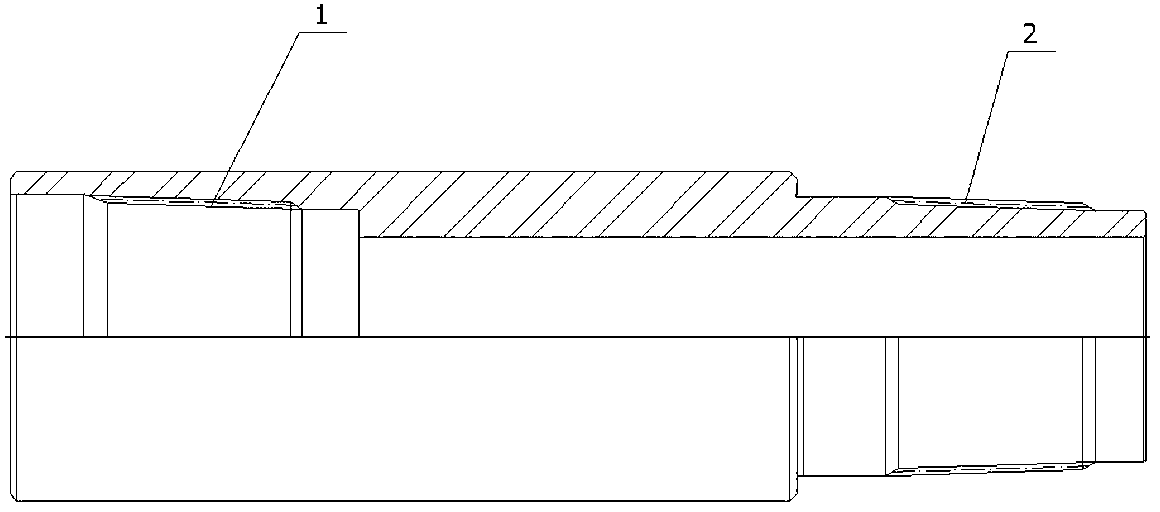

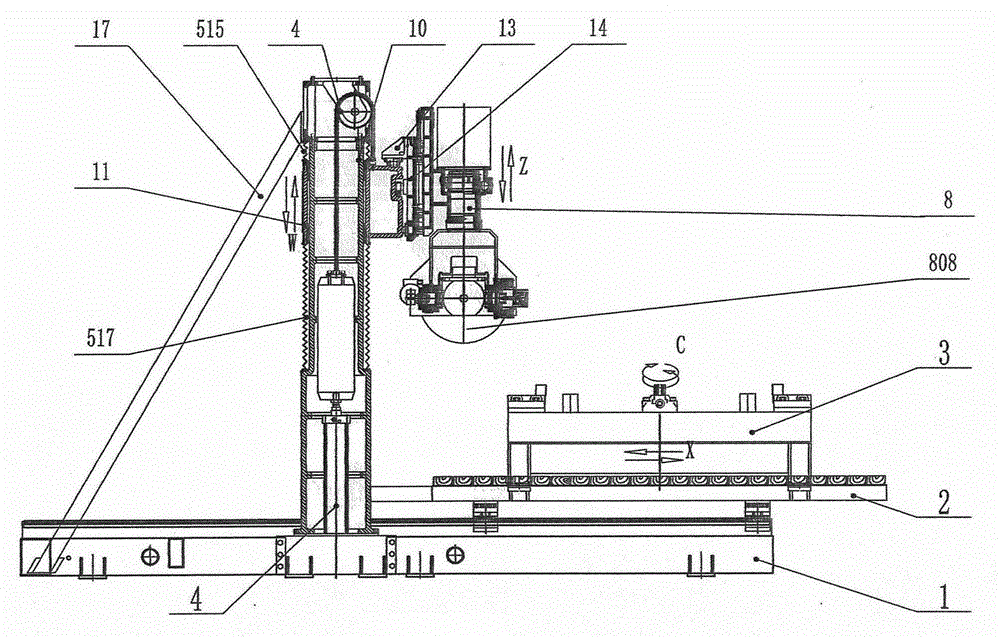

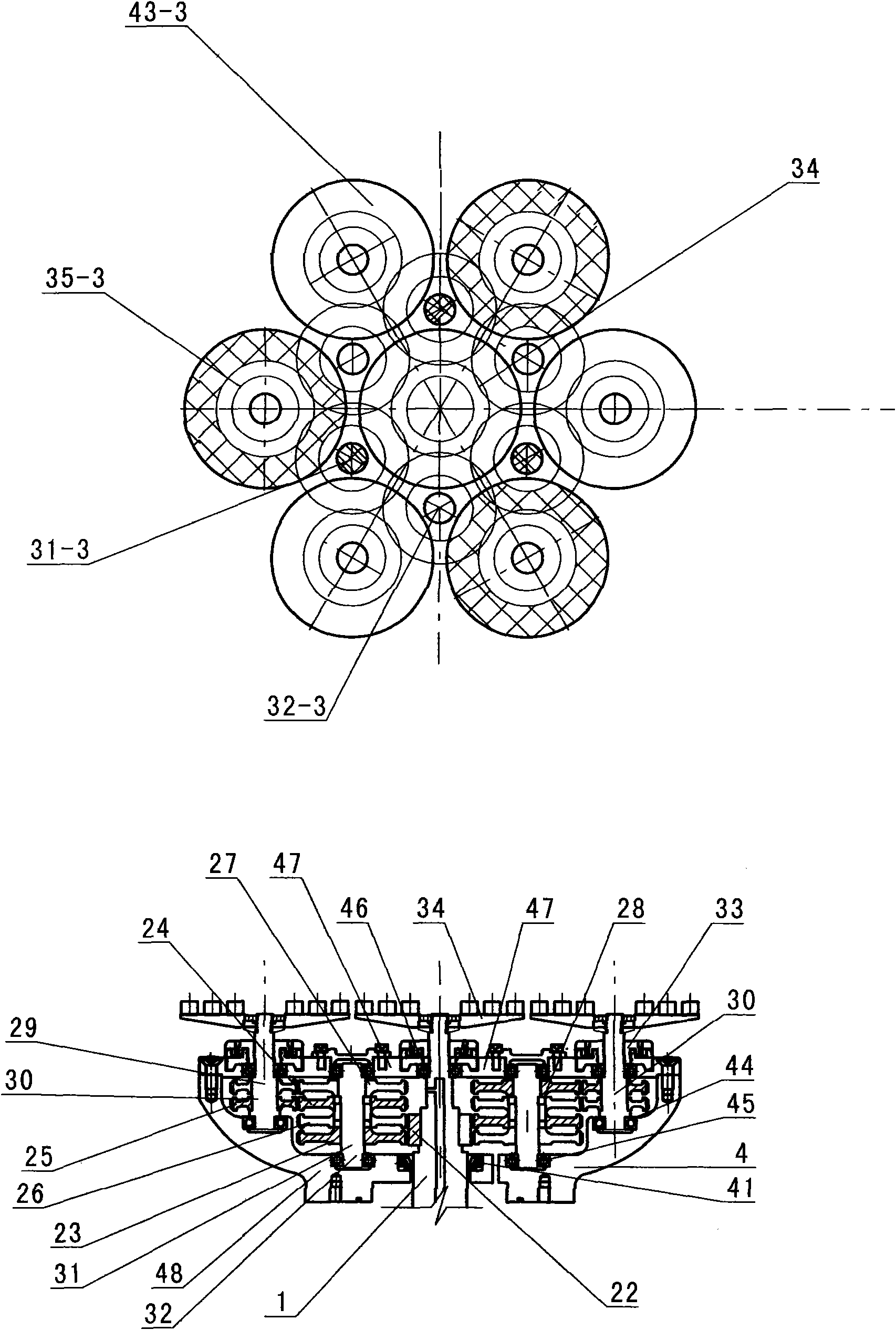

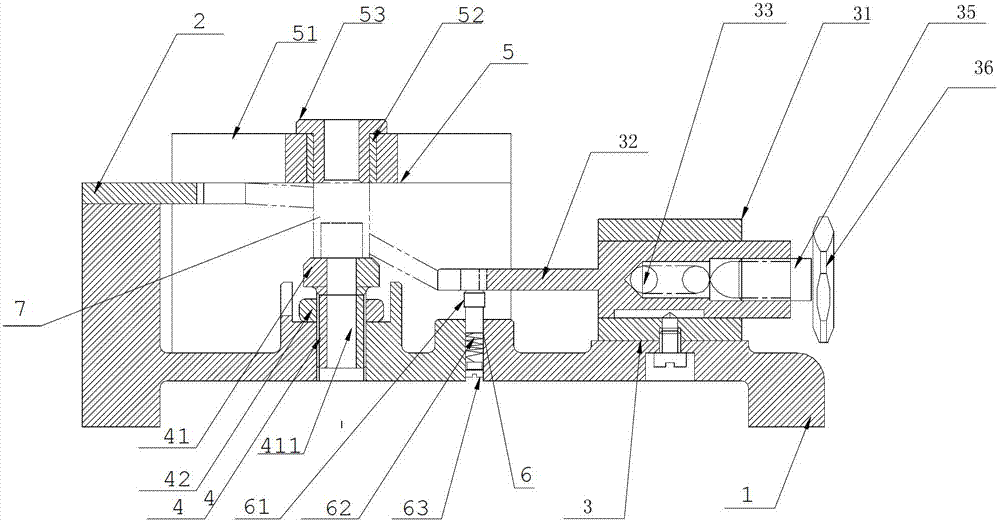

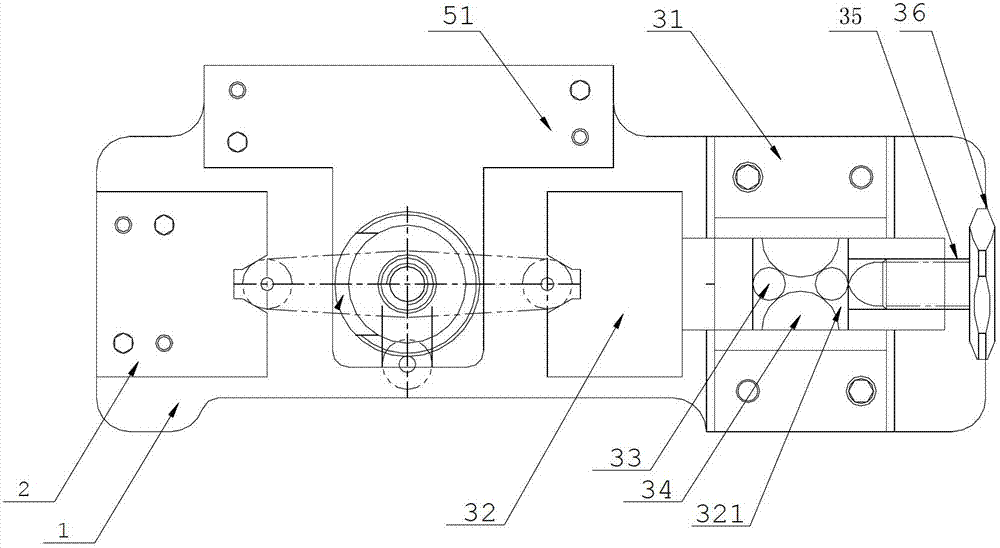

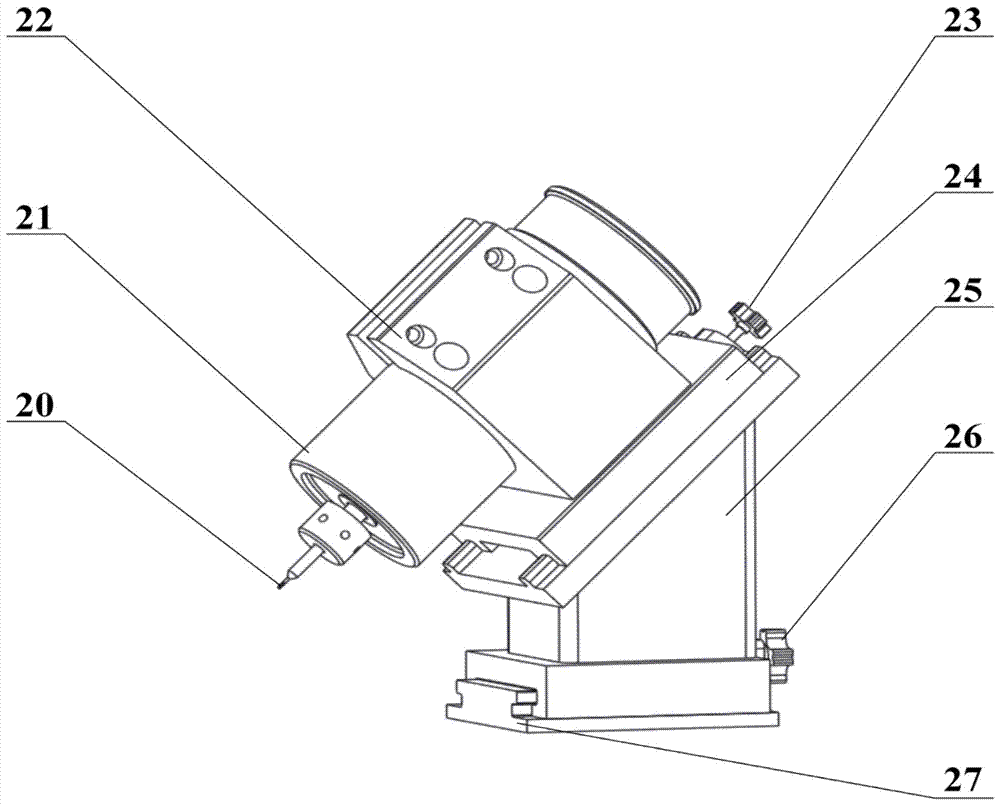

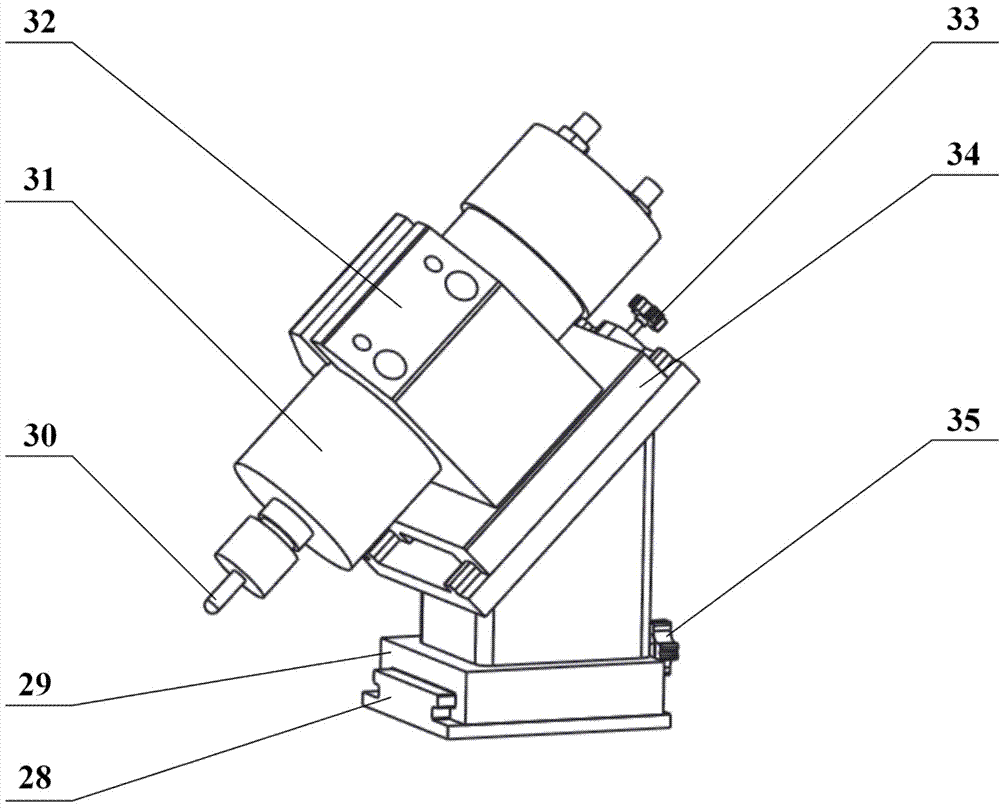

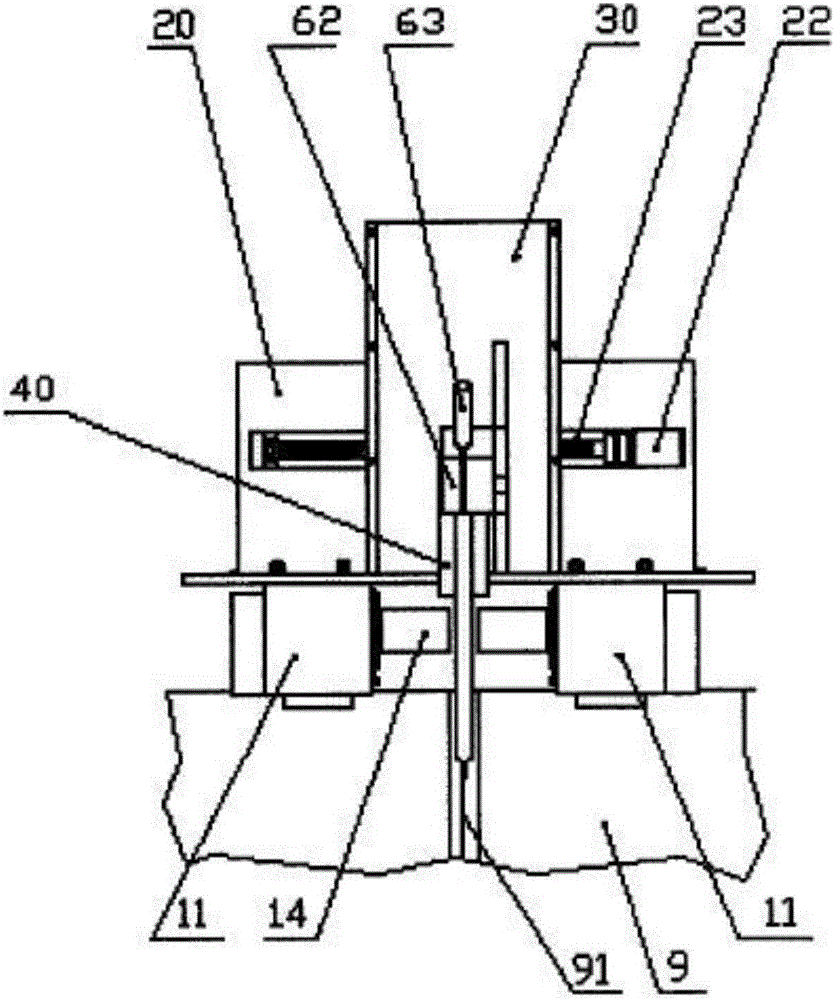

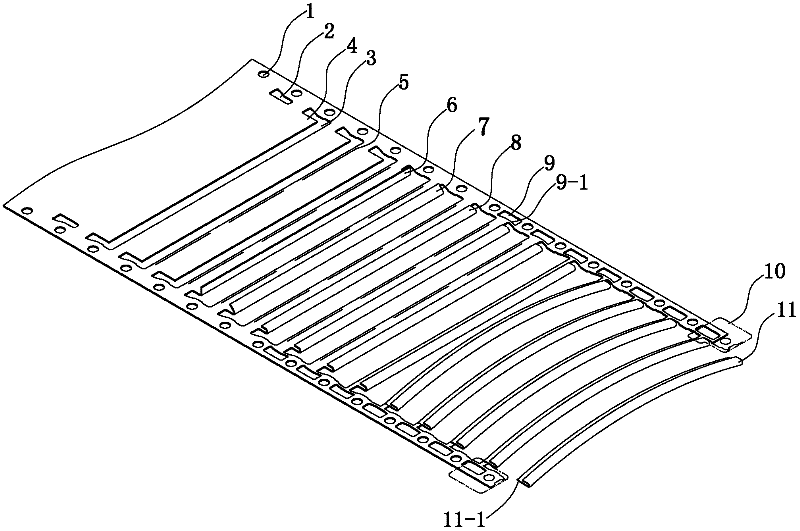

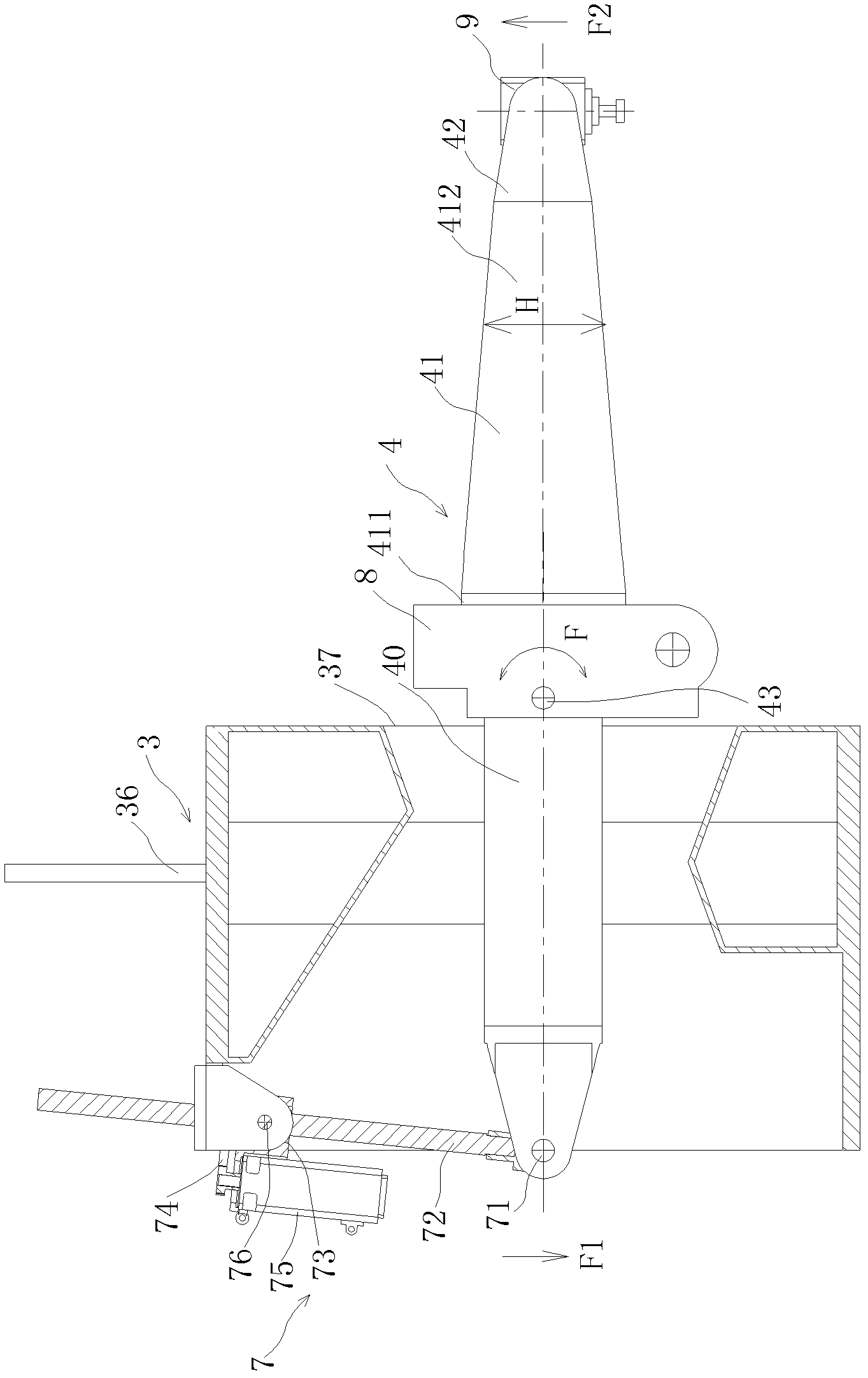

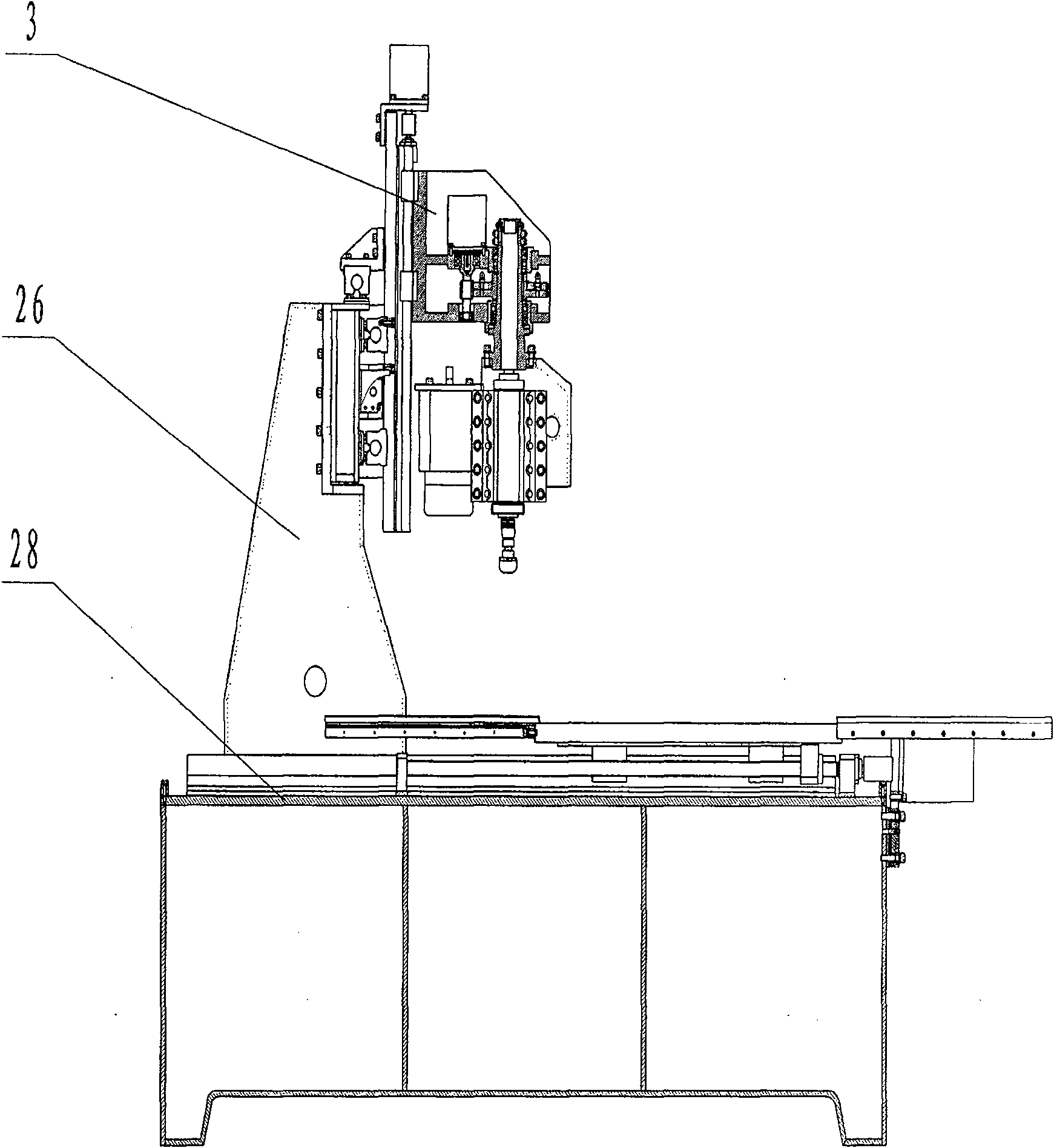

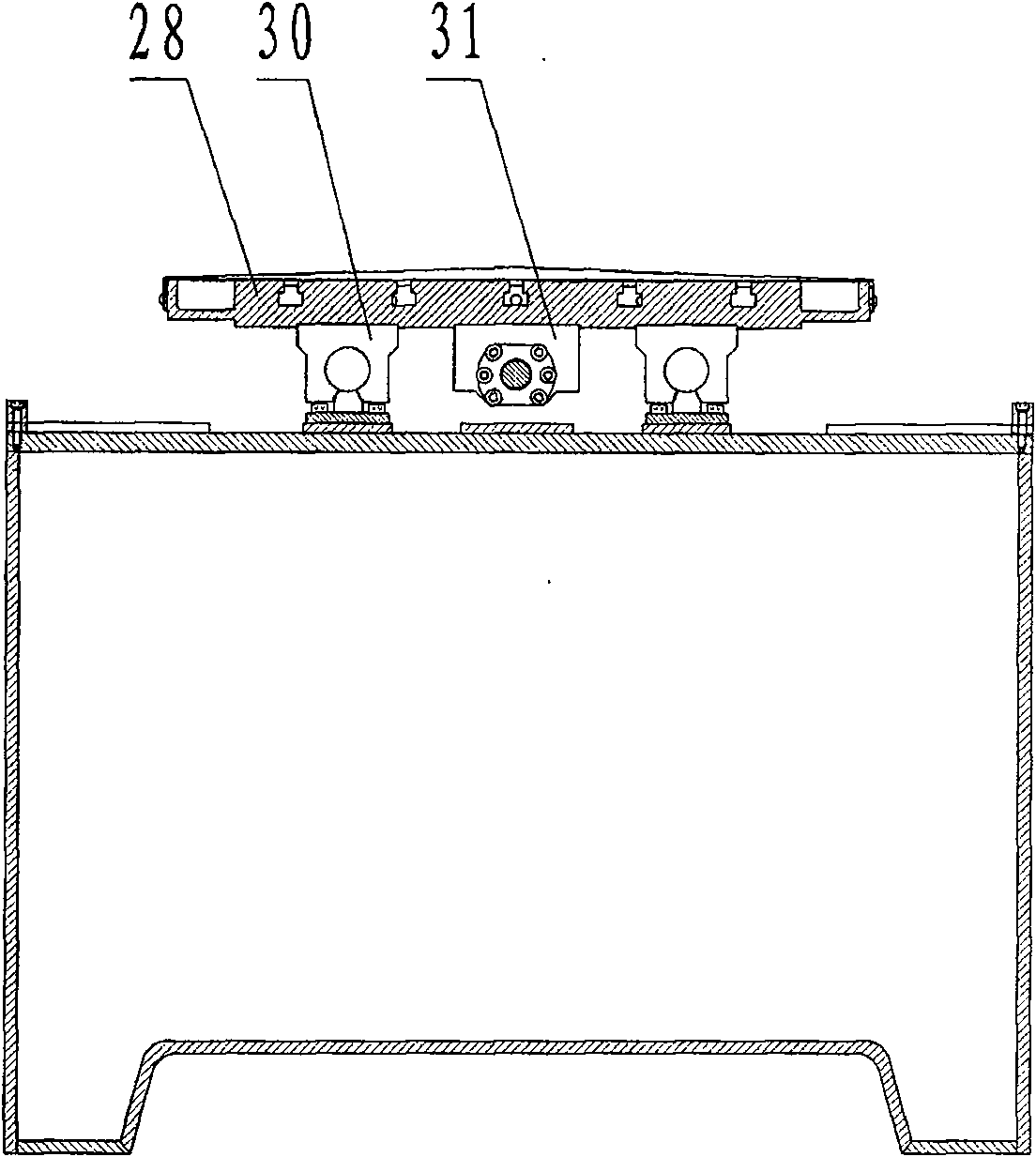

Processing machine tool for integrated propeller

ActiveCN102405118BReduce labor intensityReduce auxiliary man-hoursMachine tool componentsWorkpiecesPropellerEngineering

A processing machine tool for an integrated propeller includes a planar turntable (1); a stand (2) which is provided at a side of the planar turntable (1) and can move relative to it; a frame (3) which is provided on the stand (2) and can slide up and down; a mechanical arm (4) which is provided on the frame (3) and can swing up and down; a front processing arm (41) which is provided on the mechanical arm (4) and can turn about its own axis; and a spindle head (9) provided on the front processing arm (41). The invention can avoid the processing error caused by the overturning and repeated location of a workpiece, and the problem of the discontinuous round corners of vane surface at both sides thereof.

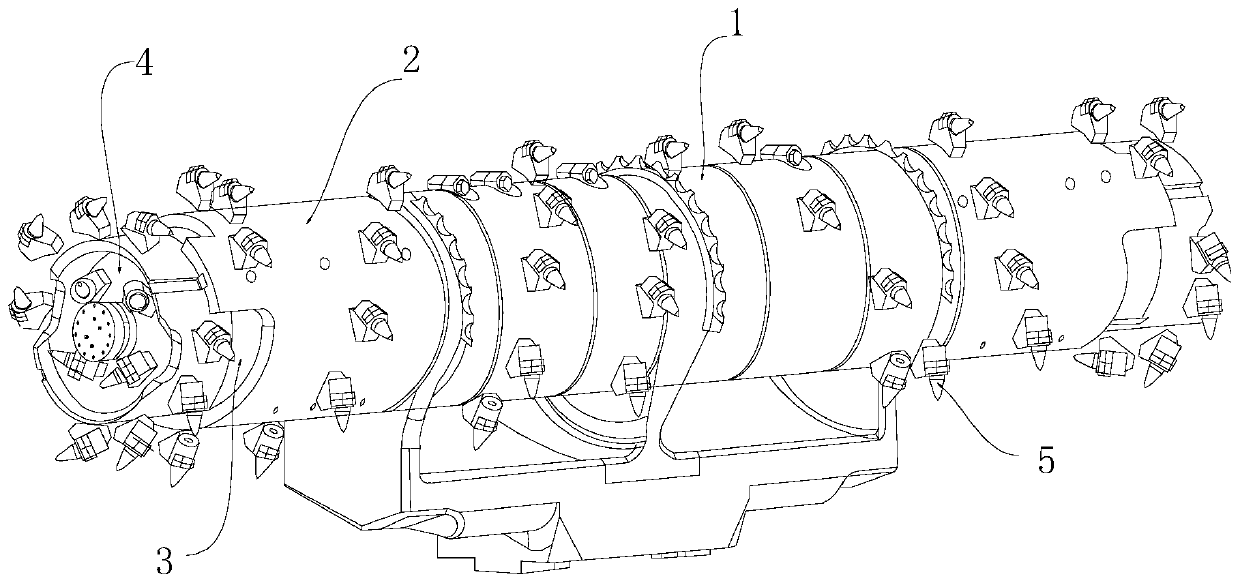

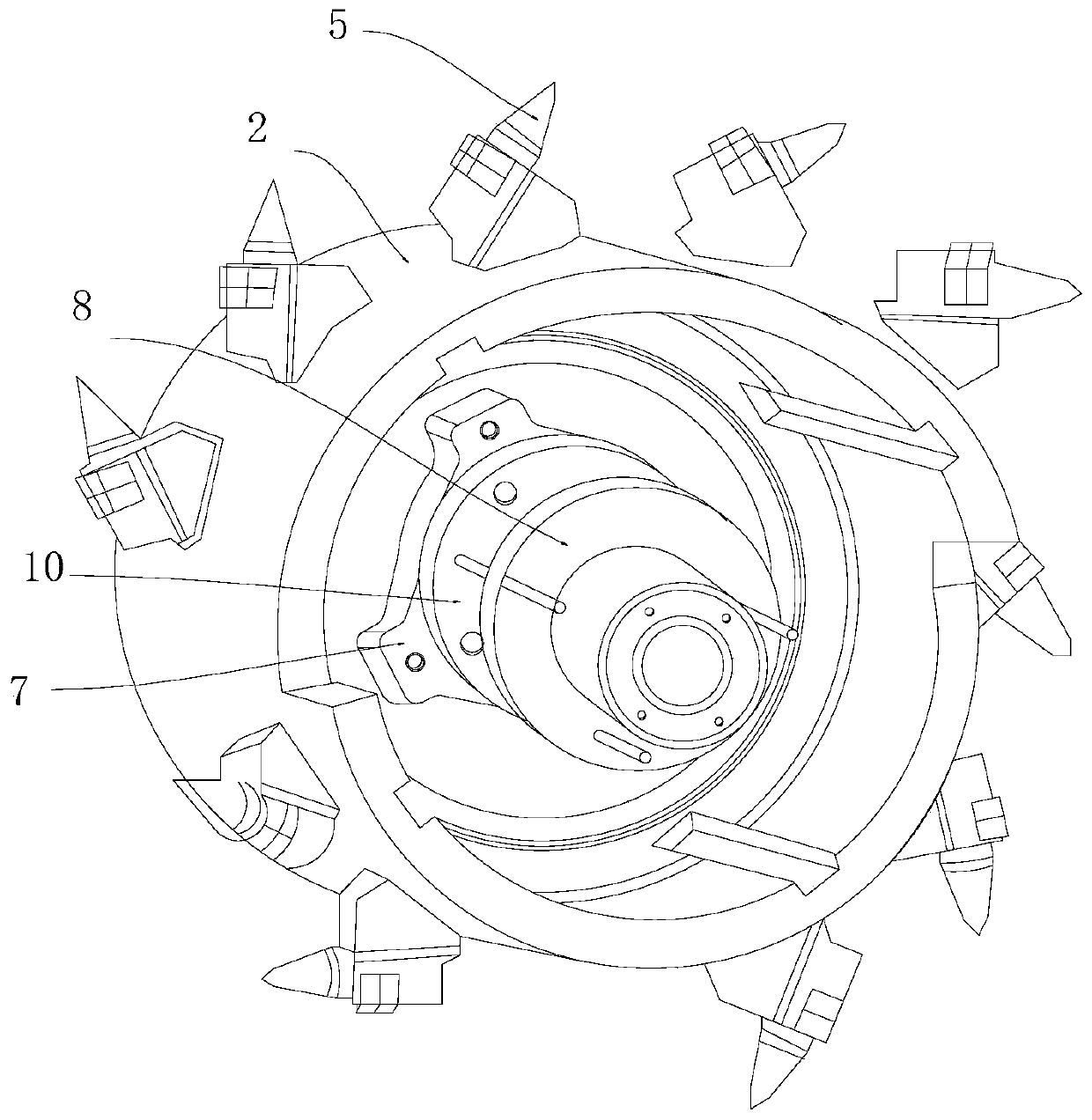

Roadheader cutting drum

InactiveCN110761787AImprove structural strengthHigh positioning accuracyDriving meansCutting machinesCoalRock breaking

The invention discloses a roadheader cutting drum, and belongs to the field of excavation machinery. The roadheader cutting drum includes an inner cutting drum body, outer cutting drum bodies arrangedon both sides of the inner cutting drum body, accommodating grooves formed in both sides of the outer cutting drum body and telescopic cutting drum bodies arranged in the accommodating grooves and slidably connected with the outer cutting drum bodies; and a plurality of groups of rock breaking teeth are arranged on the outer sides of the inner cutting drum bodies, the outer cutting drum bodies and the telescopic cutting drum bodies correspondingly. The telescopic cutting drum bodies are internally provided with fixed seats, and mounting seats are arranged at the groove bottoms of the accommodating grooves. Telescopic oil cylinders are arranged on the mounting seats, and the output ends of the telescopic oil cylinders are fixedly connected with the fixed seats. The roadheader cutting drumenables the telescopic oil cylinders on both sides of the outer cutting drum bodies to be improved from an exposed installation mode to a built-in installation mode, so that the telescopic oil cylinders are effectively protected and the structural strength of both sides of the outer cutting drum bodies is increased, and the coal mine driving efficiency and tunneling quality are improved.

Owner:北京道思克矿山装备技术有限公司

Rotator for well cleaning with clearance seal and labyrinth seal

PendingCN112317150AReduce the risk of failureScientific and reasonable structure designEngine sealsHollow article cleaningEngineeringStructural engineering

The invention relates to a rotator for well cleaning with clearance seal and labyrinth seal, and belongs to the technical field of deep well cleaning. The rotator for well cleaning with clearance sealand labyrinth seal comprises a rotator body, wherein a water spraying channel is formed in the side face of the rotator body in the radial direction; a bush is embedded in the rotator body; a plurality of grooves are formed in the inner wall of the bush in the circumferential direction and are in clearance fit; the single-side clearance of the grooves is smaller than the diameter of water molecules; a high-pressure water channel is formed in shaft rod in the axial direction; a high-pressure water side channel communicating with the high-pressure water channel is formed in the side face of theshaft rod in the radial direction; the high-pressure water side channel communicates with a water spraying channel; a connector connected with a high-pressure water conveying device is arranged at the end of the shaft rod; and the two ends of the rotator body are in threaded connection with cover-shaped nuts to fix the bush from the end parts. The rotator for well cleaning with clearance seal andlabyrinth seal provided by the invention is scientific and reasonable in structural design, easy to manufacture, convenient to assemble and disassemble and safe and reliable to use, auxiliary workinghours are reduced on the premise that the cleaning effect and the cleaning quality are guaranteed, shutdown caused by blockage of the rotator is avoided, the risk of well cleaning failure is reduced,and the well cleaning efficiency is greatly improved.

Owner:中冶沈勘工程技术有限公司

Seedling stage mulching film recycling film winding roll

InactiveCN105284219AReduce auxiliary man-hoursImprove recycling efficiencyGatherer machinesEngineeringMechanical engineering

The invention discloses a seedling stage mulching film recycling film winding roll which comprises a film winding roll disc shaft. The film winding roll disc shaft is sleeved with a film winding column, gear racks are evenly arranged on the surface of the film winding column, and film winding shaft discs are fixedly arranged on the two sides of the film winding column and are fixed with the film winding roll disc shaft. After mulching film recycling work is completed, fast film unloading is facilitated, auxiliary work time in the mulching film recycling process is shortened, and the mulching film recycling efficiency is improved. Different from previous mulching film recycling machines, the discs of the film winding roll are arranged to be of a conical structure, in the film winding process, the film is collected inwards, and the phenomenon that the shaft is clamped by the film in the film winding process is avoided. The seedling stage mulching film recycling film winding roll is simple in structure, convenient to operate and high in practicality.

Owner:GUIZHOU UNIV

Mechanical clamping device of coiled wide-width material

The invention provides a mechanical clamping device of a coiled wide-width material. The device is characterized by comprising a power side clamping device, a driven side clamping device and a papertube; the power side clamping device comprises a body I, a sliding sleeve and a protruded key; the driven side clamping device comprises a body II, the sliding sleeve and the protruded key; the papertube pushes the sliding sleeve to move towards the body I and the body II, and the sliding sleeve drives the protruded key to move; and the protruded key extends out of the outer surface of the sliding sleeve to be in contact with the inner surface of the paper tube to realize fixing of the paper tube in a tensioning mode. According to the power side clamping device, the driven side clamping device, a cooperative mode between the sliding sleeve, the protruded key, the body I and the body II is adopted, the axial-direction fixing of the paper tube, through the power side clamping device and thedriven side clamping device, is changed into the radial-direction fixing, so that the paper tube end part is prevented from cracking caused by the fact that the paper tube end part is clamped throughthe axial force, under the condition that the paper tube is fixedly clamped, the risk of cracking of the paper tube end part is reduced, the winding precision is improved, and the winding quality isensured.

Owner:CHANGZHOU YONGSHENG NEW MATERIALS EQUIP CO LTD

Polisher for free curve flexibility of mold

InactiveCN100593457CAchieve polishTo achieve the purpose of polishingPolishing machinesGrinding drivesEngineeringGrinding wheel

The invention relates to a flexible die polishing machine for freeform curved face, comprising a bed and a worktable. The invention is characterized in that, the polishing machine also comprises a movement mechanism and a grinding wheel head component; the movement mechanism comprises an X axis transmission mechanism, a Y axis transmission mechanism and a Z axis transmission mechanism; the worktable is arranged on the bed through the X axis transmission mechanism; the Z axis transmission mechanism is arranged on the Y axis transmission mechanism through a Z axis bearing; the Y axis transmission mechanism is arranged on a Y axis bearing; the Y axis bearing is arranged on an upright column bearing; the upright column bearing is arranged on the worktable. The flexible die polishing machine for freeform curved faces has the advantages of good suitability for various curved surfaces; high polishing efficiency and quality; easy realization of precise partial correction of surface shape.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com