Quick register method for electronic-shaft gravure press

A technology of gravure printing machine and electronic axis, which is applied to the general parts of printing machinery, printing machines, rotary printing machines, etc. It can solve the problems of long and slow operation process, large automatic registration range and poor pre-registration accuracy. Achieve the effect of saving registration preparation time, improving pre-registration accuracy, and shortening registration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0025] This patent provides a variety of parallel schemes, and the different expressions belong to the improved scheme based on the basic scheme or the parallel scheme. Each scheme has its own unique characteristics.

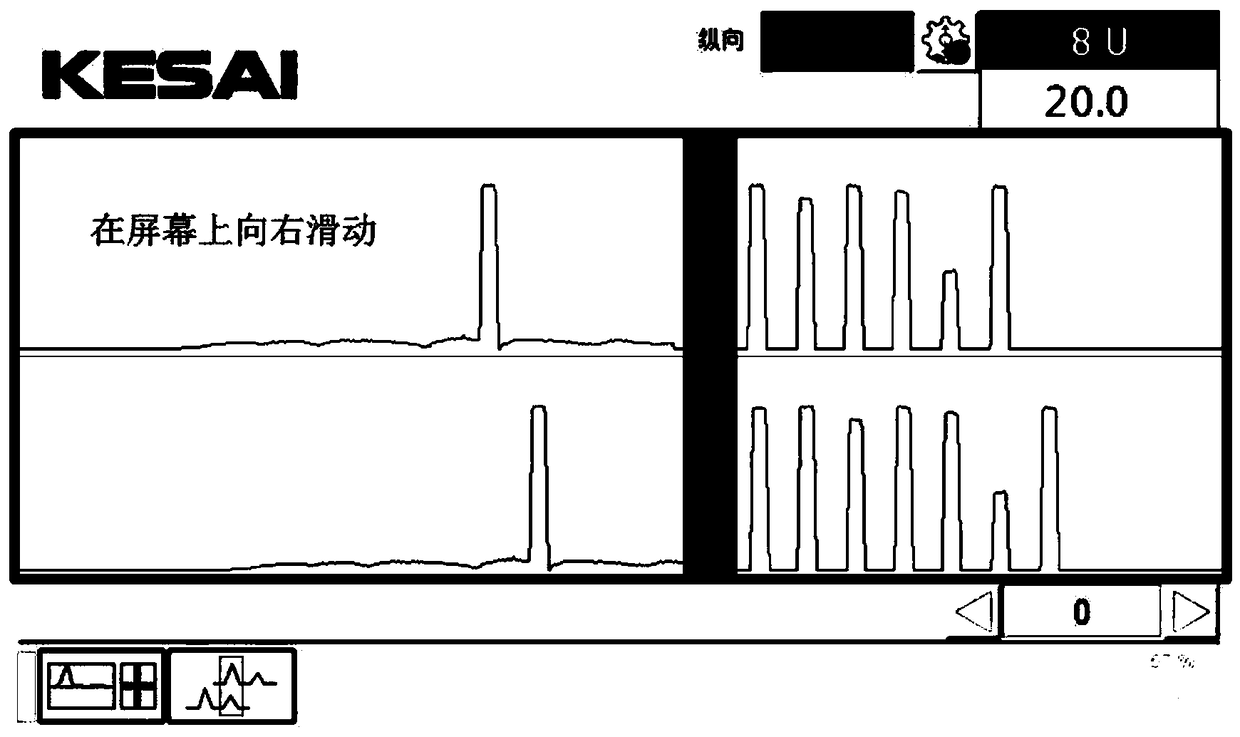

[0026] When the start-up printing speed does not exceed 50m / min and the pressure roller of the color group to be operated is in the pressed state, a rapid registration technology is carried out to realize overprinting in one step. This technology adopts the method of color mark detection after printing. By detecting the position of the color mark of the current color and the previous color, the phase difference between the two is calculated, and the ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com