Welding robot capable of automatically identifying and tracking welding line

A welding robot and automatic identification technology, applied in the field of robots, can solve the problems of poor welding conditions, difficult to ensure welding quality, and threaten the safety of welding workers, so as to ensure welding quality, reduce labor intensity, and reduce auxiliary man-hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

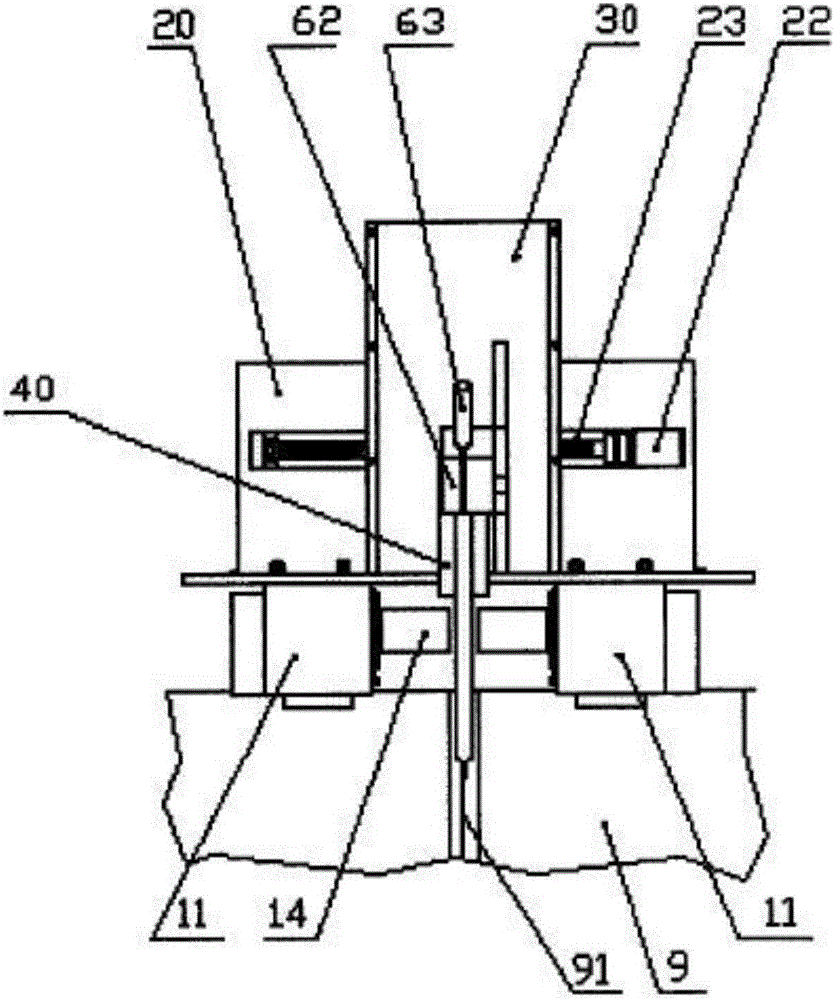

[0013] Embodiment: A welding robot that can automatically identify and track weld seams.

[0014] A kind of welding robot that the present invention designs can automatically identify and track welding seam (see figure 1 , 2 ), which is characterized in that it includes a trolley 1, a horizontal box body 20 and a vertical box body 30 installed on the trolley 1 at the rear and front respectively, horizontal and vertical tracking actuators 2 and 3, front vision sensors and rear vision Sensor 4 and 5, welding torch mechanism 6 and computer control system 7; Described trolley 1 comprises four permanent magnet wheels 12 and its driving mechanism 13 and drive motor 14 installed on the car body 11, and trolley 1 passes permanent magnet The wheels 12 can be attached to the surface of the welded pipe 9 to run smoothly; the horizontal and vertical tracking actuators 2 and 3 are connected with the connecting plate 8 and fixed on the upper surface of the trolley 1; the horizontal trackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com