Polisher for free curve flexibility of mold

A flexible polishing and free technology, which is applied in the field of polishing machines, can solve the problems of inability to carry out online control, low polishing efficiency, and low polishing quality, and achieve the effect of reducing gear meshing gap, reducing meshing gap, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

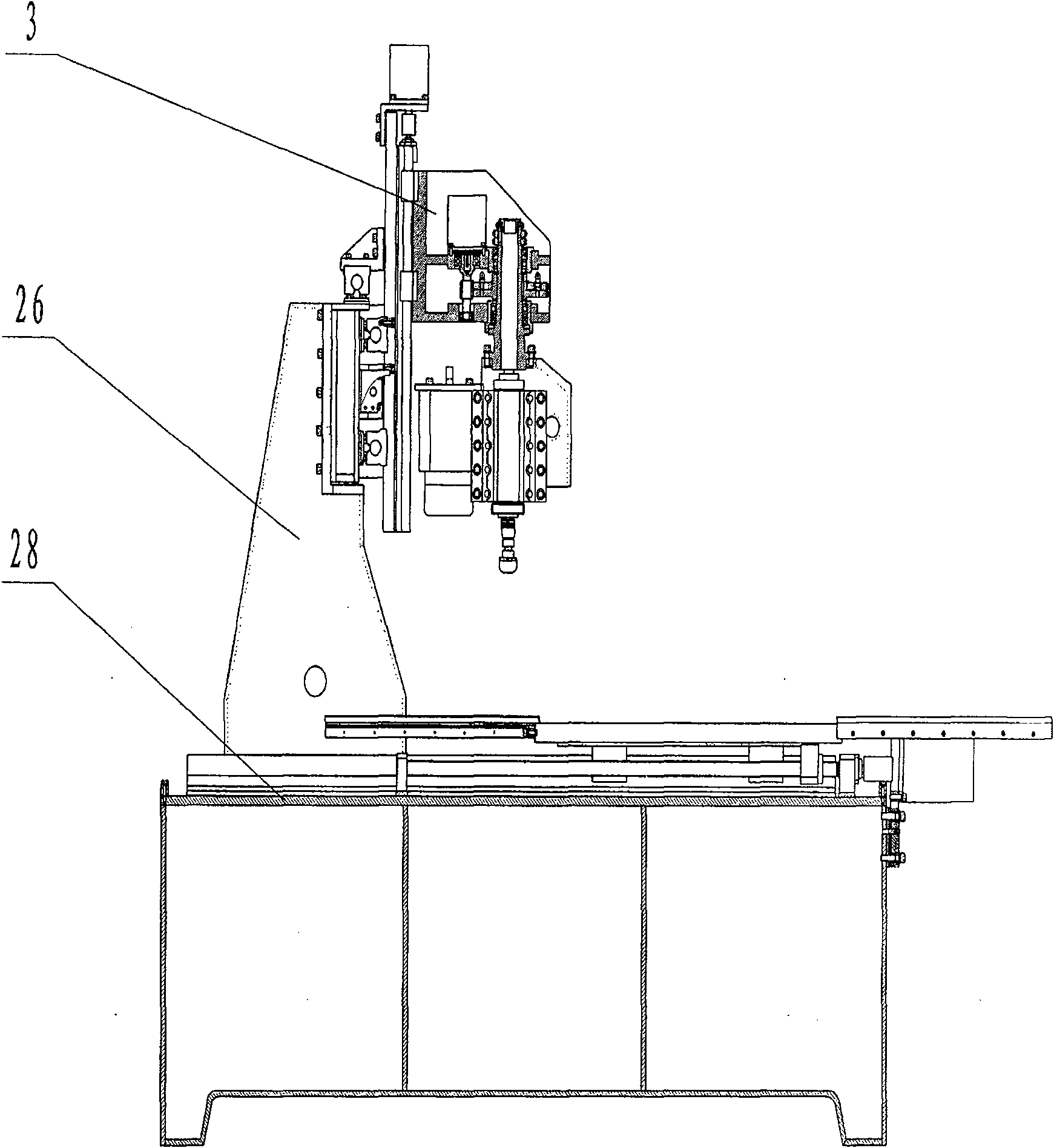

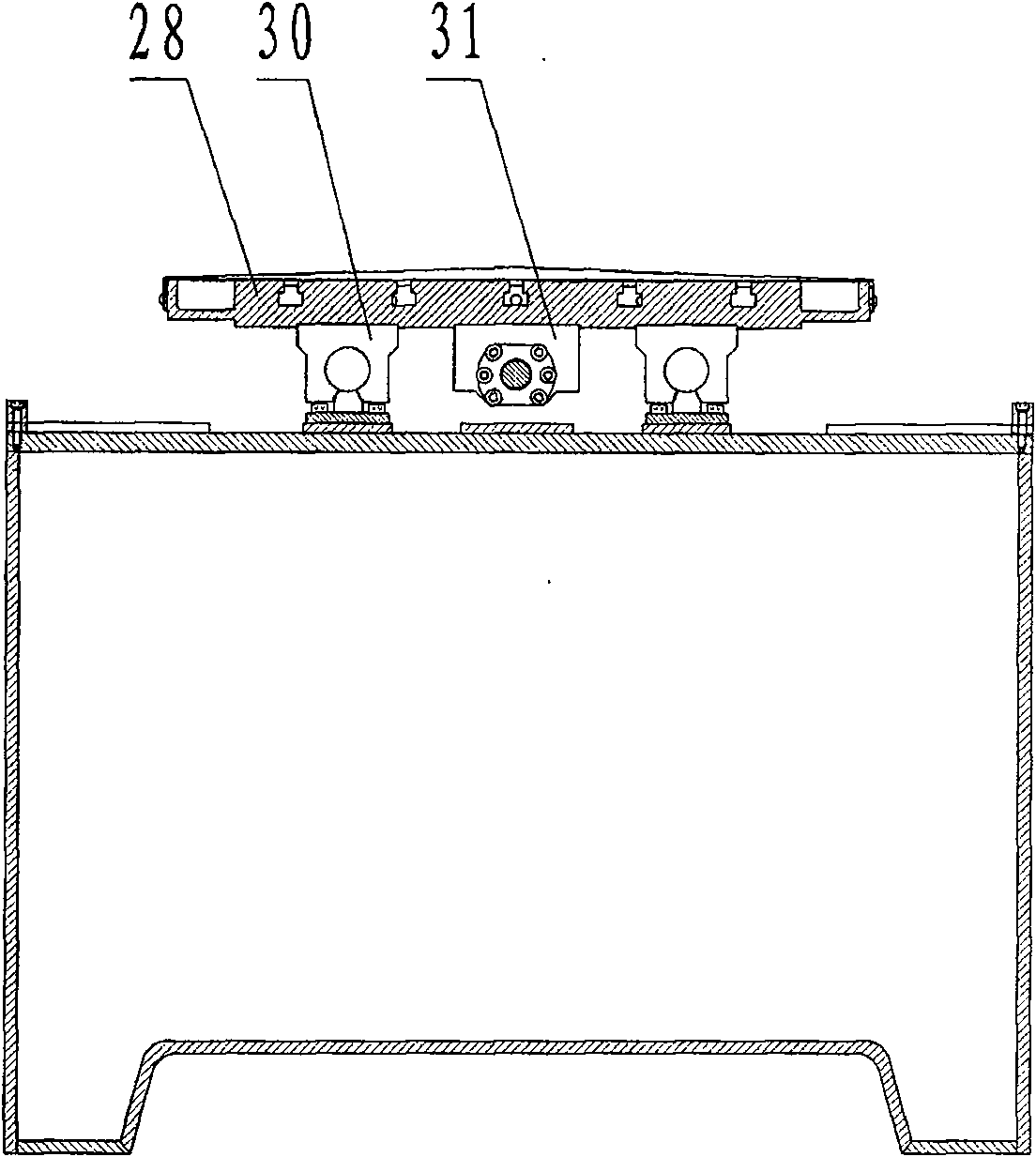

[0033] refer to Figure 1 to Figure 11 , a mold free-form surface flexible polishing machine, including a bed 26, a workbench 28, a motion mechanism and a grinding head part 3, the motion mechanism includes an X-axis transmission mechanism, a Y-axis transmission mechanism and a Z-axis transmission mechanism, and the The workbench 28 is installed on the bed 26 through the X-axis transmission mechanism, the Z-axis transmission mechanism is installed on the Y-axis transmission mechanism through the Z-axis support 8, and the Y-axis transmission mechanism is installed on the Y-axis support 8, The Y-axis support 8 is installed on the column support 1, and the column support 1 is installed on the workbench 28;

[0034] The X transmission mechanism includes an X-axis control motor 19, an X-axis ball screw 12, an X-axis guide rail slider 30 and two X-axis horizontal guide rails ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com