Tube structure wood mold

A wood mold and cylinder technology, used in wood processing appliances, casting equipment, manufacturing tools, etc., can solve the problems of difficult to control the moisture content of wood, cracking of wood molds, and high consumption, so as to reduce wood consumption and avoid cracking. , the effect of reducing the processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

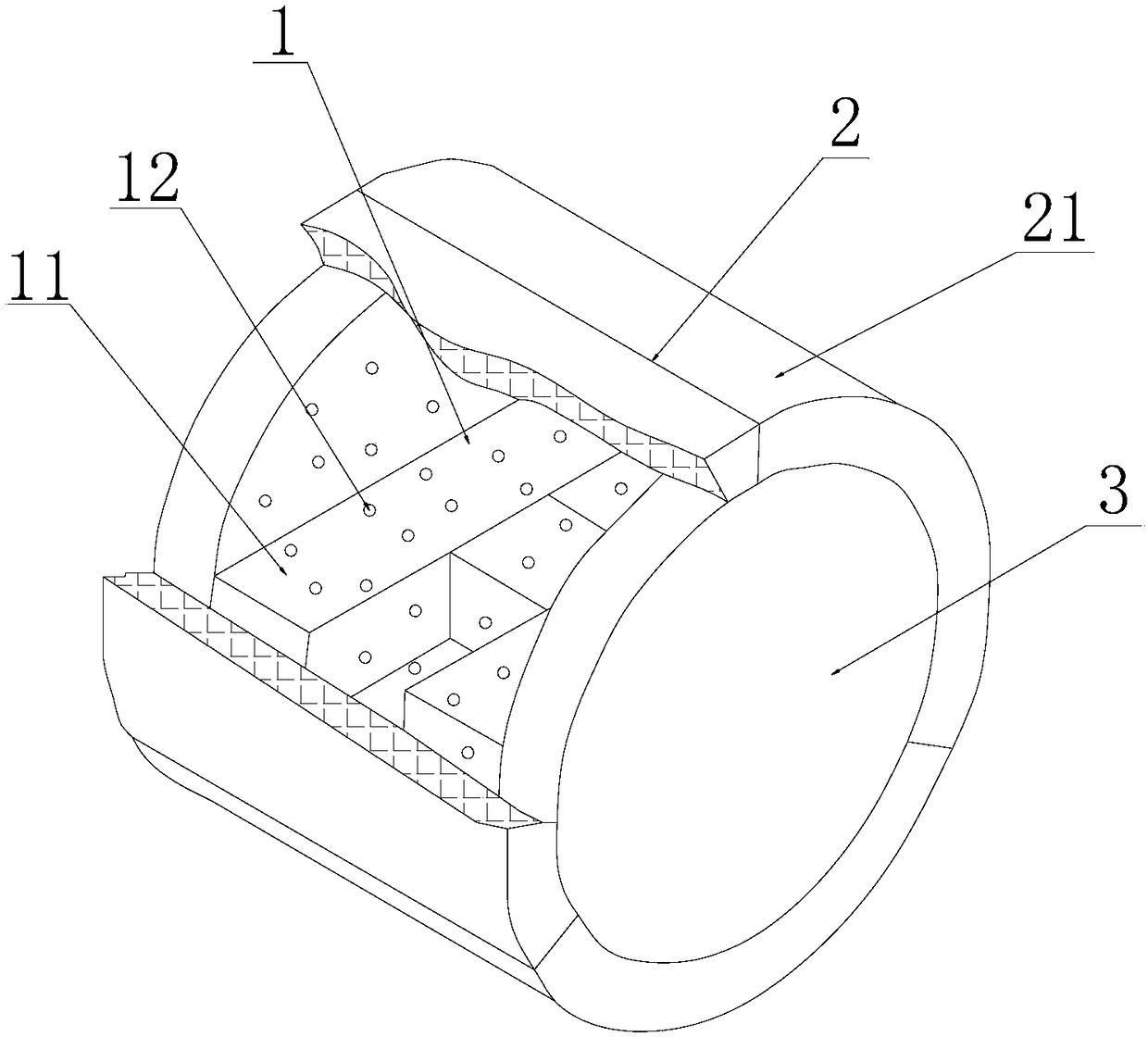

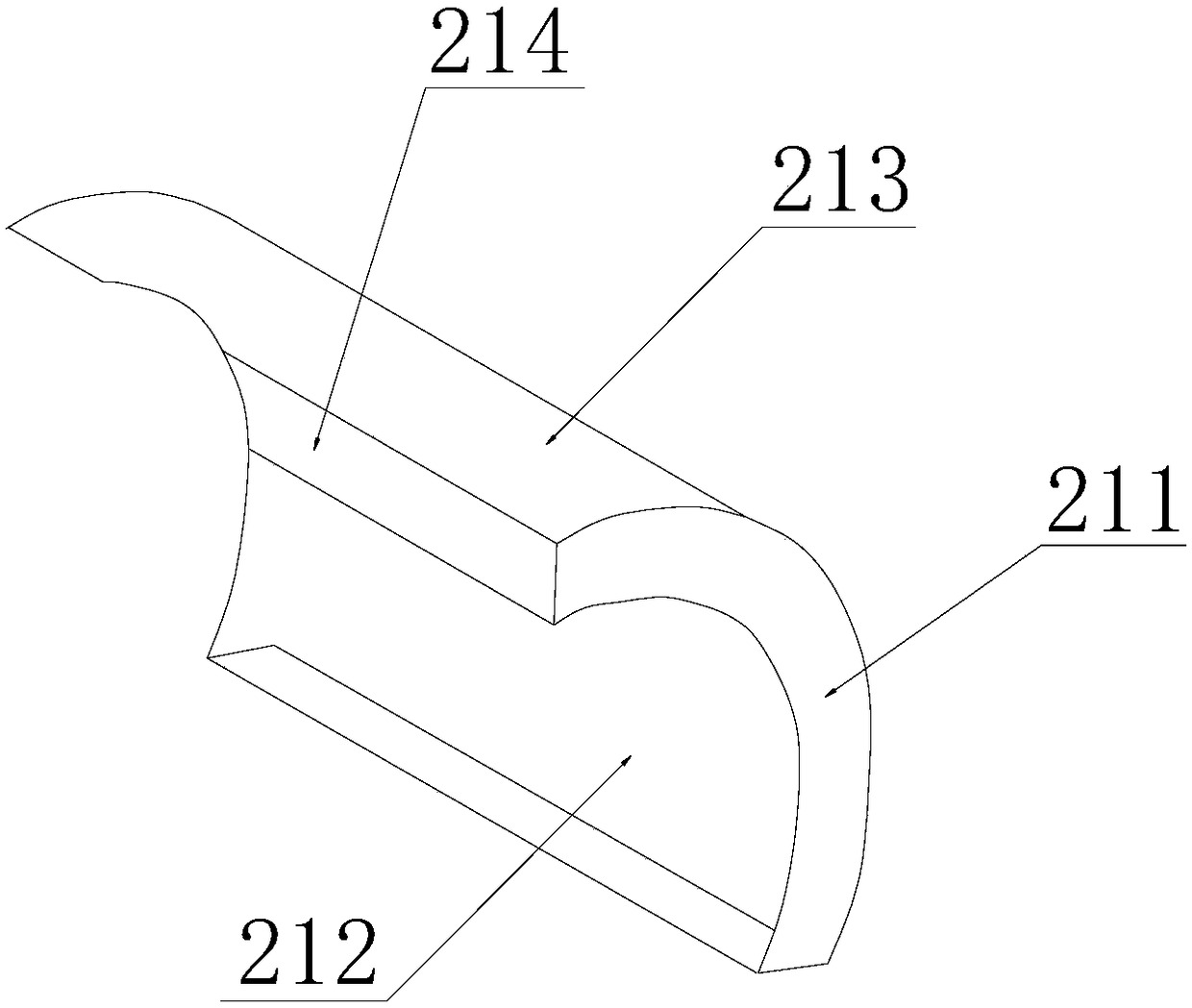

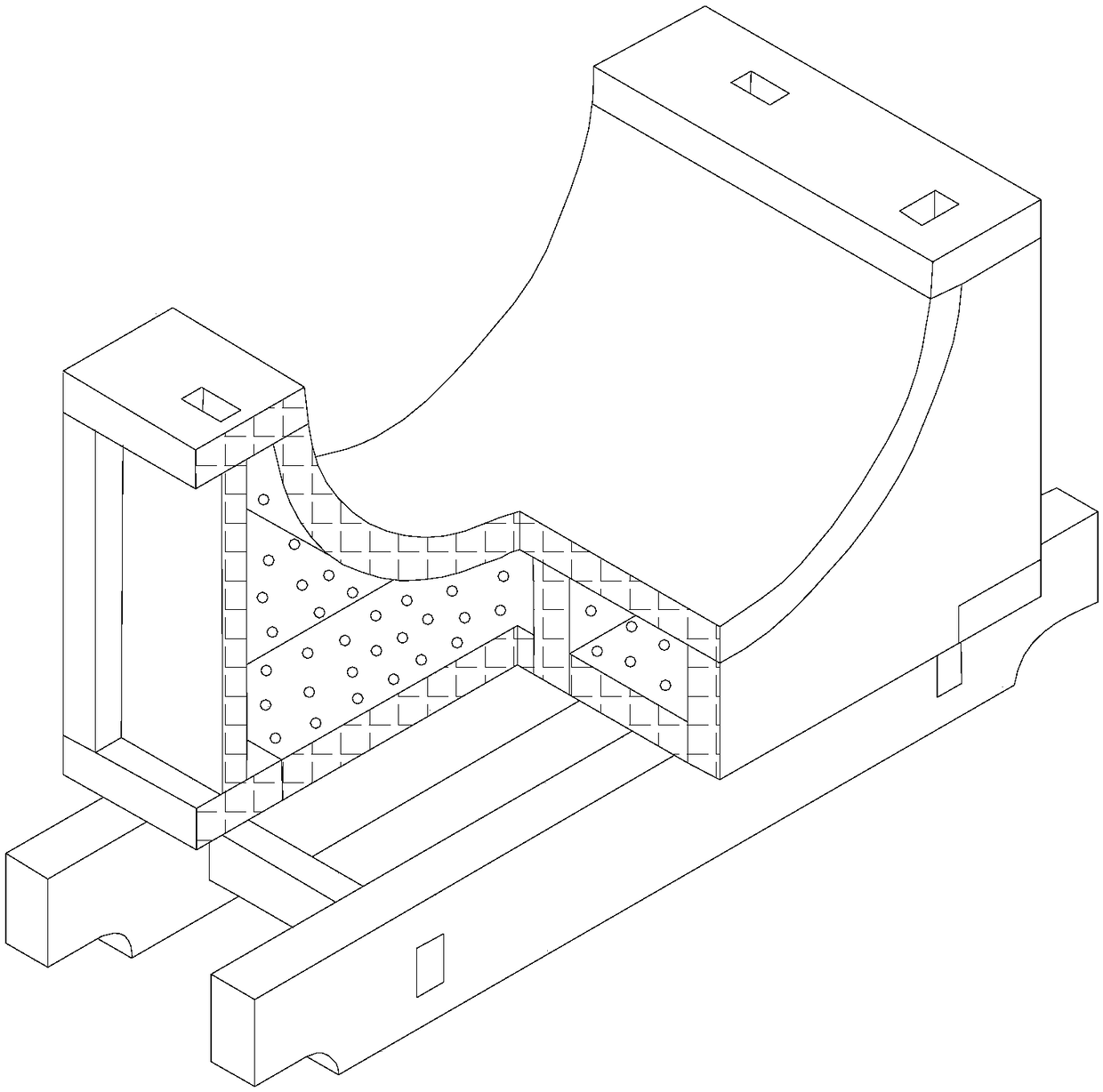

[0015] refer to figure 1 and figure 2 , Embodiment 1 of a wooden formwork with a cylindrical structure of the present invention, comprising a skeleton part 1, an outer edge part 2 and an end face part 3, the outer edge part 2 is a hollow cylindrical structure as a whole, and the outer edge part 2 The two ends of the end face 3 are provided with a disc-shaped structure that is compatible with the inner diameter of the cylinder of the outer edge part 2, and the cylinder formed between the outer edge part 2 and the inner wall of the end face 3 The body space is a skeleton part 1, and several solid wood skeletons 11 are arranged inside the skeleton part 1, and foamed plastic fillers 12 are also arranged inside the skeleton part 1, and the solid wood skeletons 11 and foamed plastic fillers 12 are mutually matched and filled in the skeleton. within part 1. The outer edge portion 2 includes several arc plates 21, and the arc plates 21 include an arc plate body 211, an arc plate in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com