A machining method for a floating gearbox of a self-elevating multifunctional service platform

A service platform and gear box technology, applied in the direction of transmission boxes, components with teeth, etc., can solve the problems of floating gearboxes that are bulky and cannot meet the one-time machining of floating gearboxes, so as to reduce requirements and reduce Improvement of processing time and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below through embodiments in conjunction with the accompanying drawings.

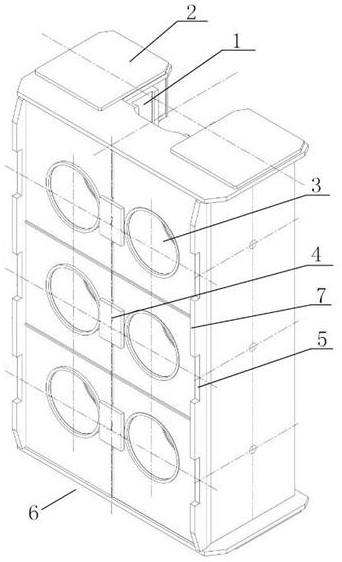

[0045] Please refer to the name of each part of the floating gearbox 6 figure 1 , the machining method of the floating gearbox 6 includes the following operations:

[0046] First, cylinder end processing

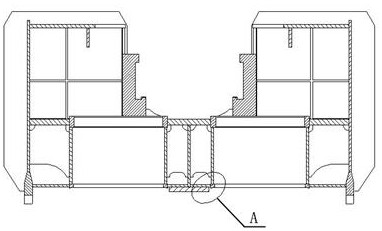

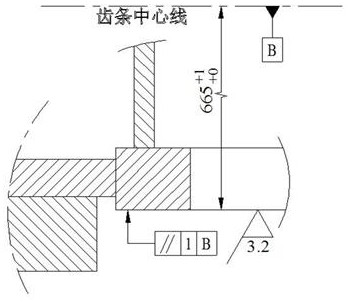

[0047] The spindle of the machine tool measures the machining allowance from the center line of the rack back to the end face of the support hole 3, installs a φ300 milling cutter on the spindle, and processes six end faces at one time to ensure the design size mm, and the end face of the supporting round hole 3 is used as the reference plane for subsequent processing, such as figure 2 , image 3 shown;

[0048] Second, positioning plate 4 processing

[0049] Based on the end face of the supporting round hole 3, the processing amount of the intermediate positioning plate 4 is detected according to the digital display and the depth g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com