Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Satisfy flatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

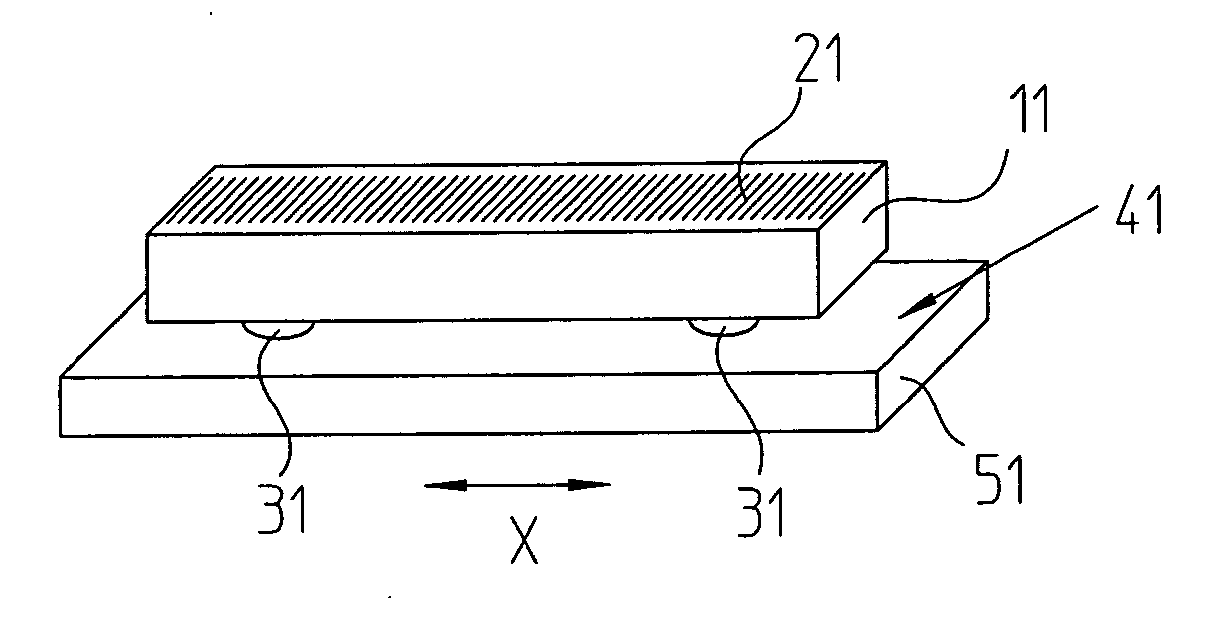

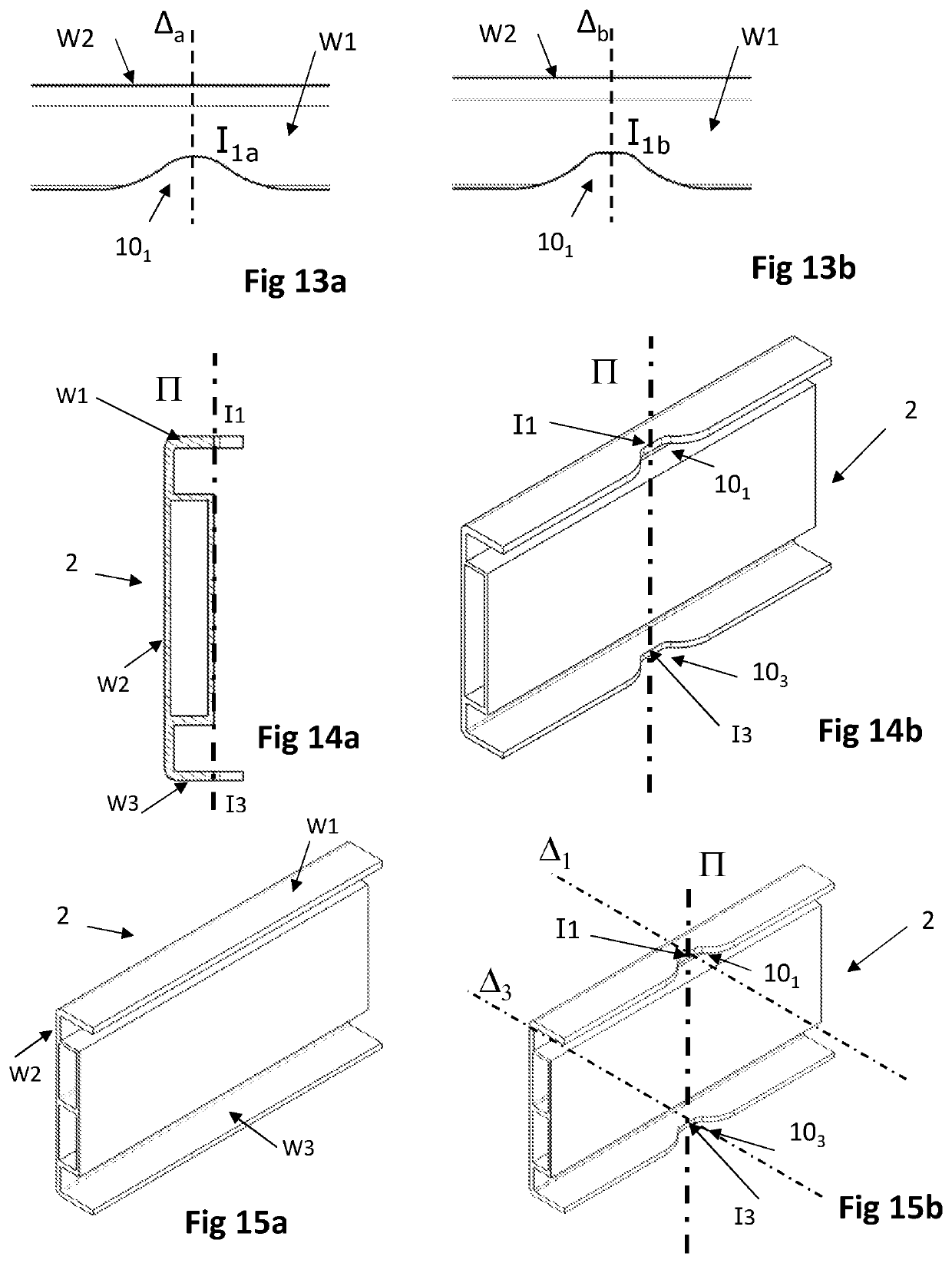

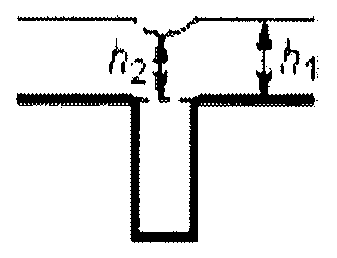

Method for attaching a scale to a carrier, a scale, and carrier having a scale

ActiveUS20070137059A1Eliminate the problemAvoid disadvantagesWalking sticksLaminationChemistryEngineering

A scale is attached to a carrier by optically contacting. The optically contacting bonds are formed by raised surface regions of the scale set apart from each other. Additional measures, such as the provision of adhesive surfaces, provide a rigid and vibration-resistant joint.

Owner:DR JOHANNES HEIDENHAIN GMBH

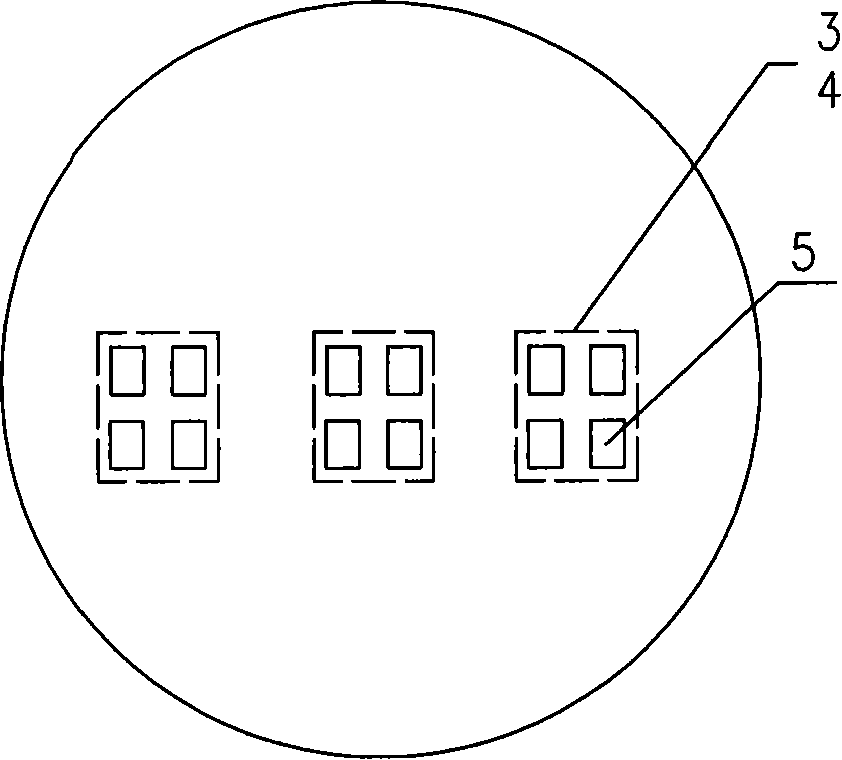

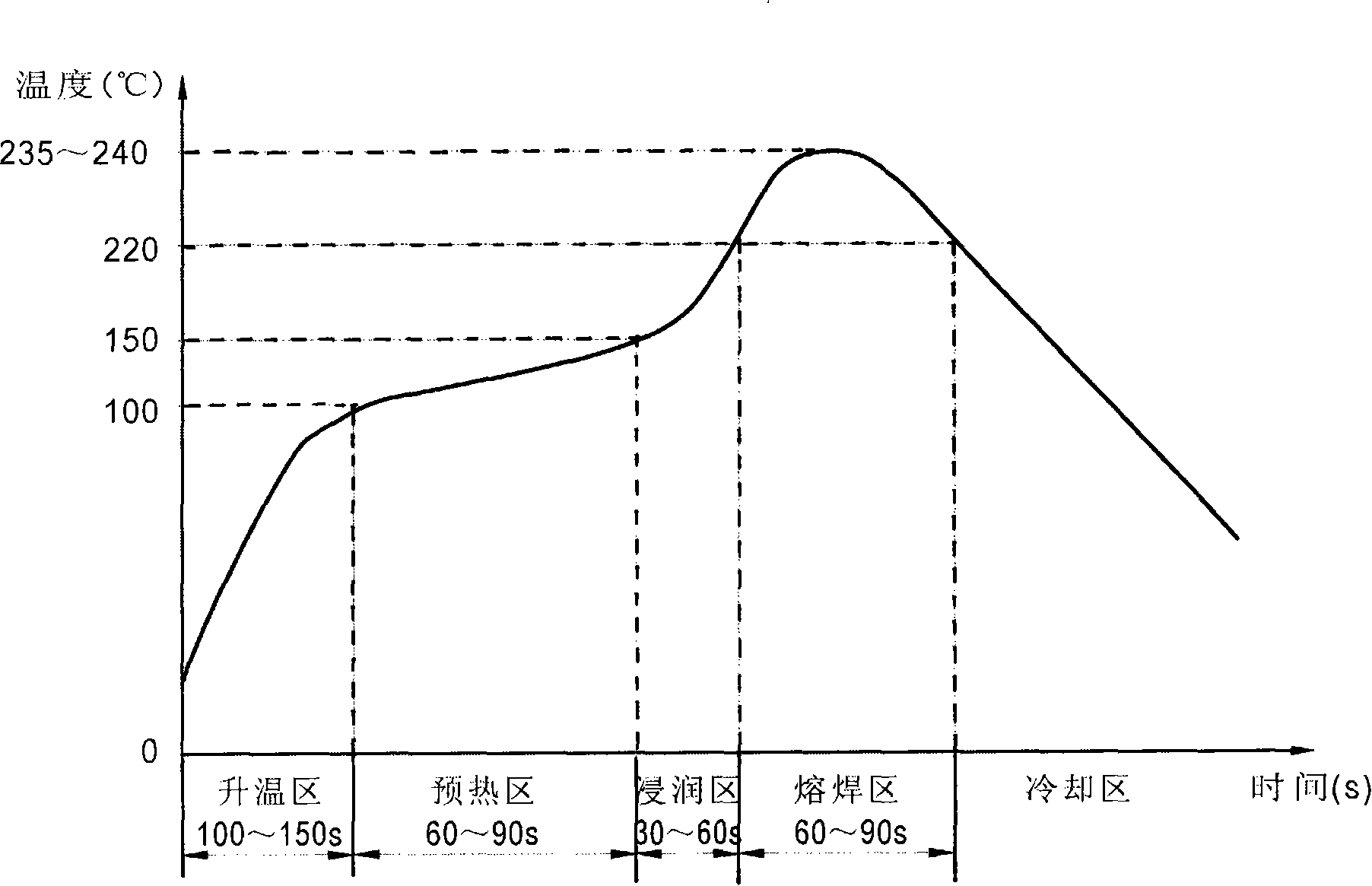

Solder tray local tin plating method on circuit board

InactiveCN101252815AImprove mechanizationReduce manufacturing costPrinted circuit assemblingTinningEngineering

The invention discloses a method for local tinning to the bonding pad on a circuit substrate, which enables lead-free tin plasma to be brushed to the spot welding position bonding pad of the circuit substrate through a steel mesh; the circuit substrate brushed with the lead-free tin plasma passes through the five areas of a reflow soldering machine for operating parameters in sequence, to form liquid tin coating covered in the entire spot welding position bonding pad, and after the circuit substrate cools, solid tin coating is formed in the spot welding position bonding pad. The invention utilizes the steel mesh to brush the lead-free tin plasma to the bonding pad of a common substrate, and utilizes the reflow soldering machine and depends on the wetting property of soldering flux, and the diffusion and the self positioning effect of the tin plasma to accomplish the tinning process of the bonding pad, the tin coating meets the process requirements of the thickness and the smoothness, and provides good basic conditions for the subsequent spot welding working procedure, and the manufacturer does not require to purchase special substrates for the substrate supplier, therefore, the production efficiency can be greatly improved, the qualified rate of the product can be increased, and the production cost of the enterprise can be reduced.

Owner:MORNSUN GUANGZHOU SCI & TECH

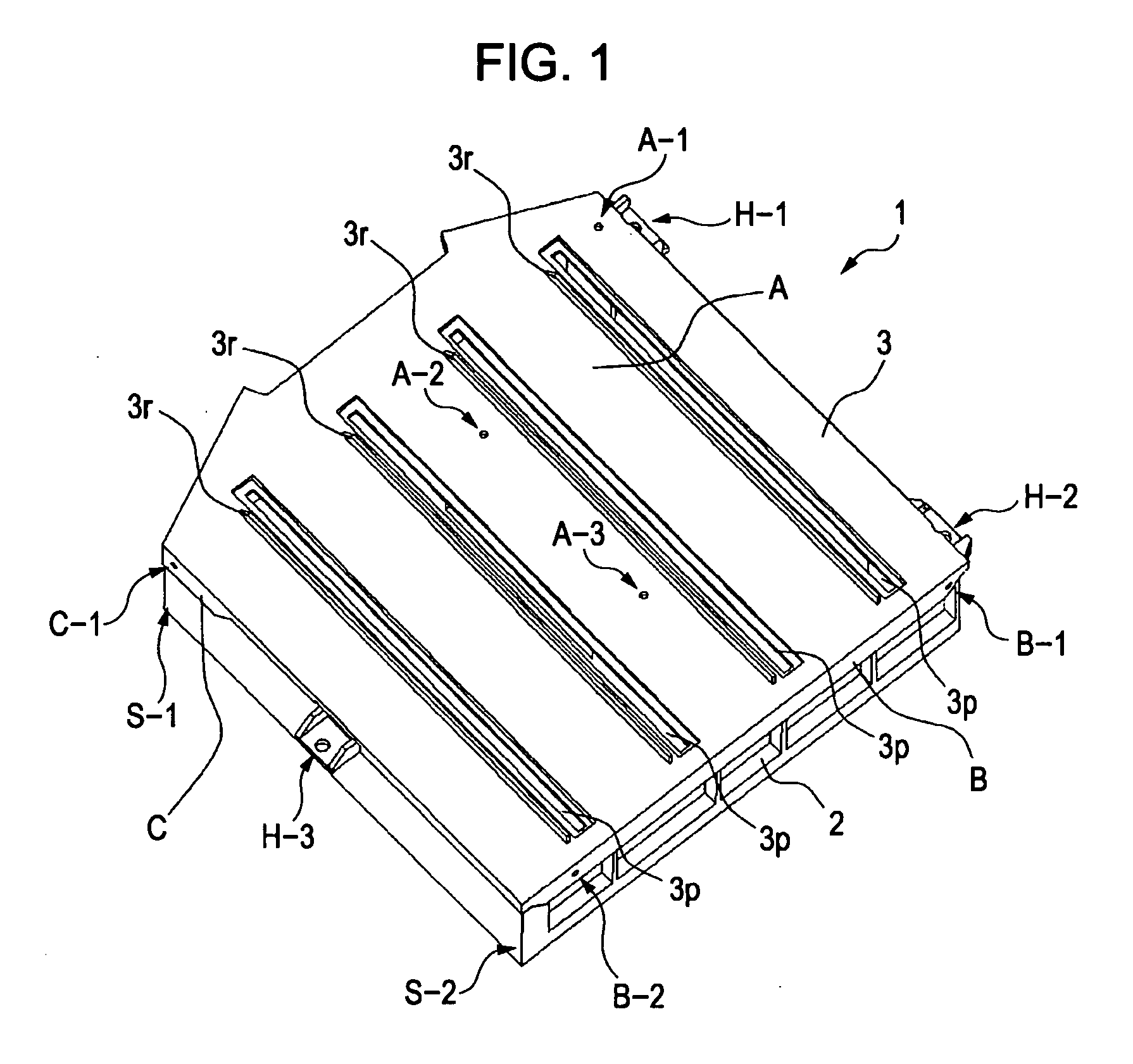

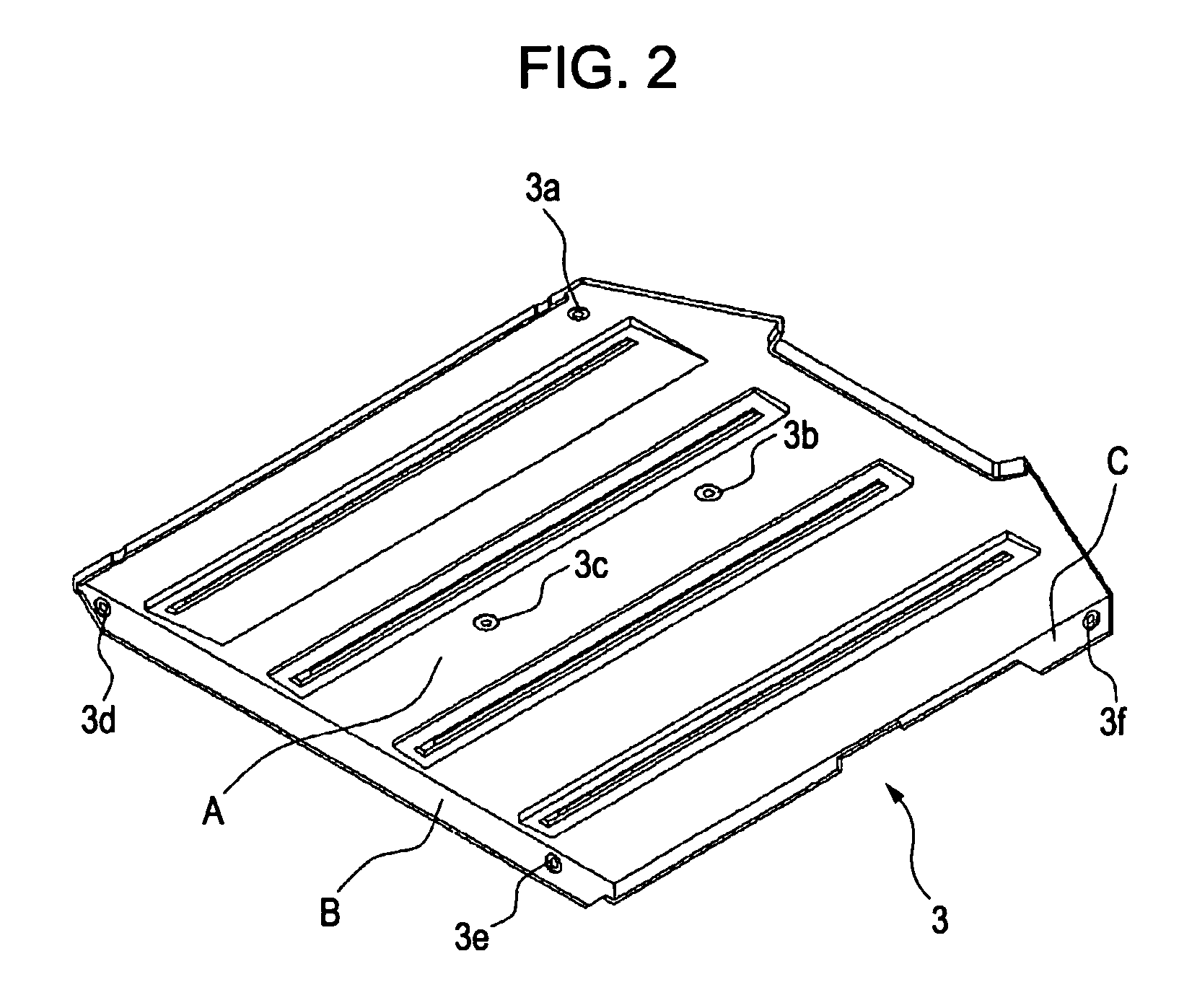

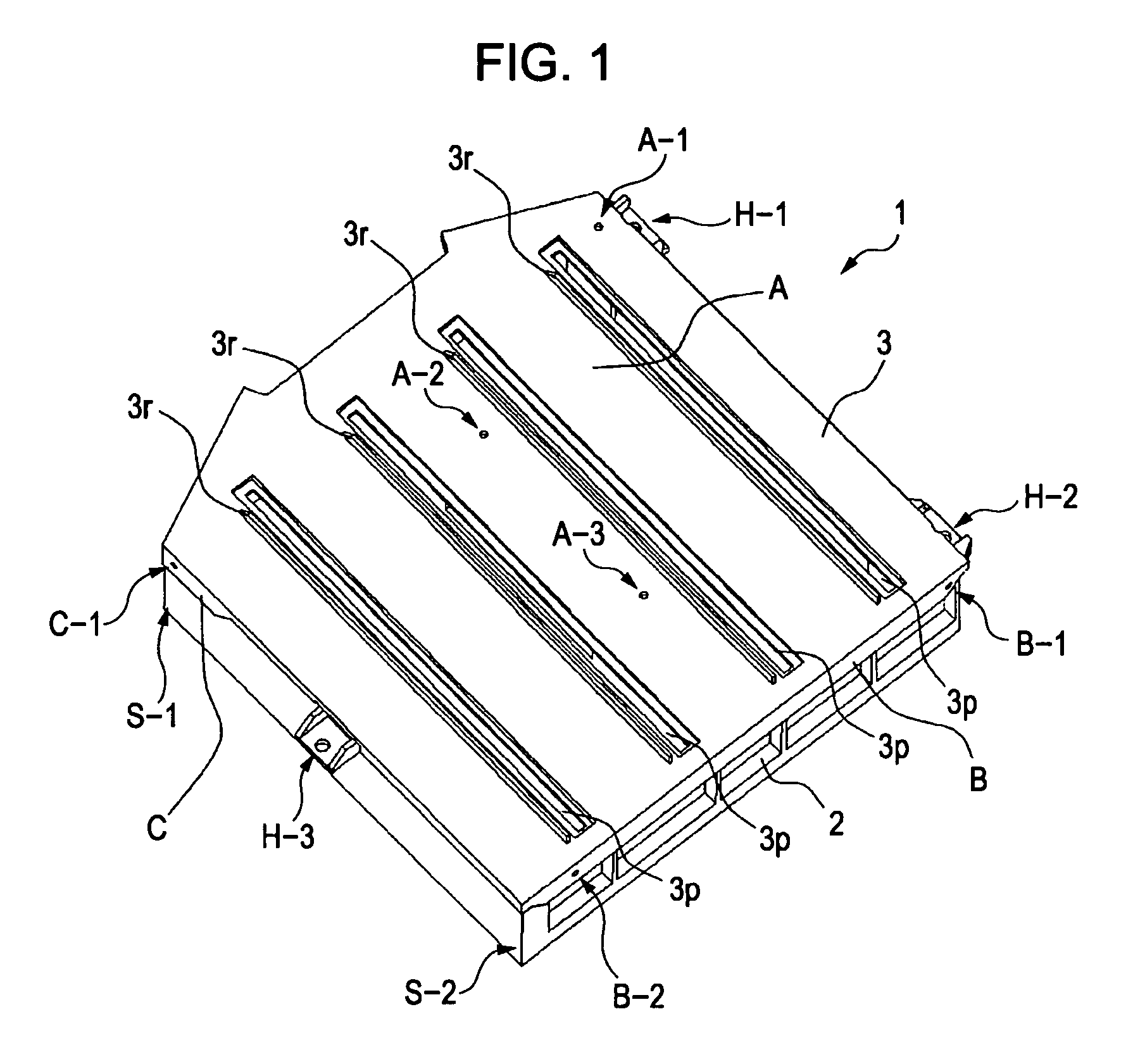

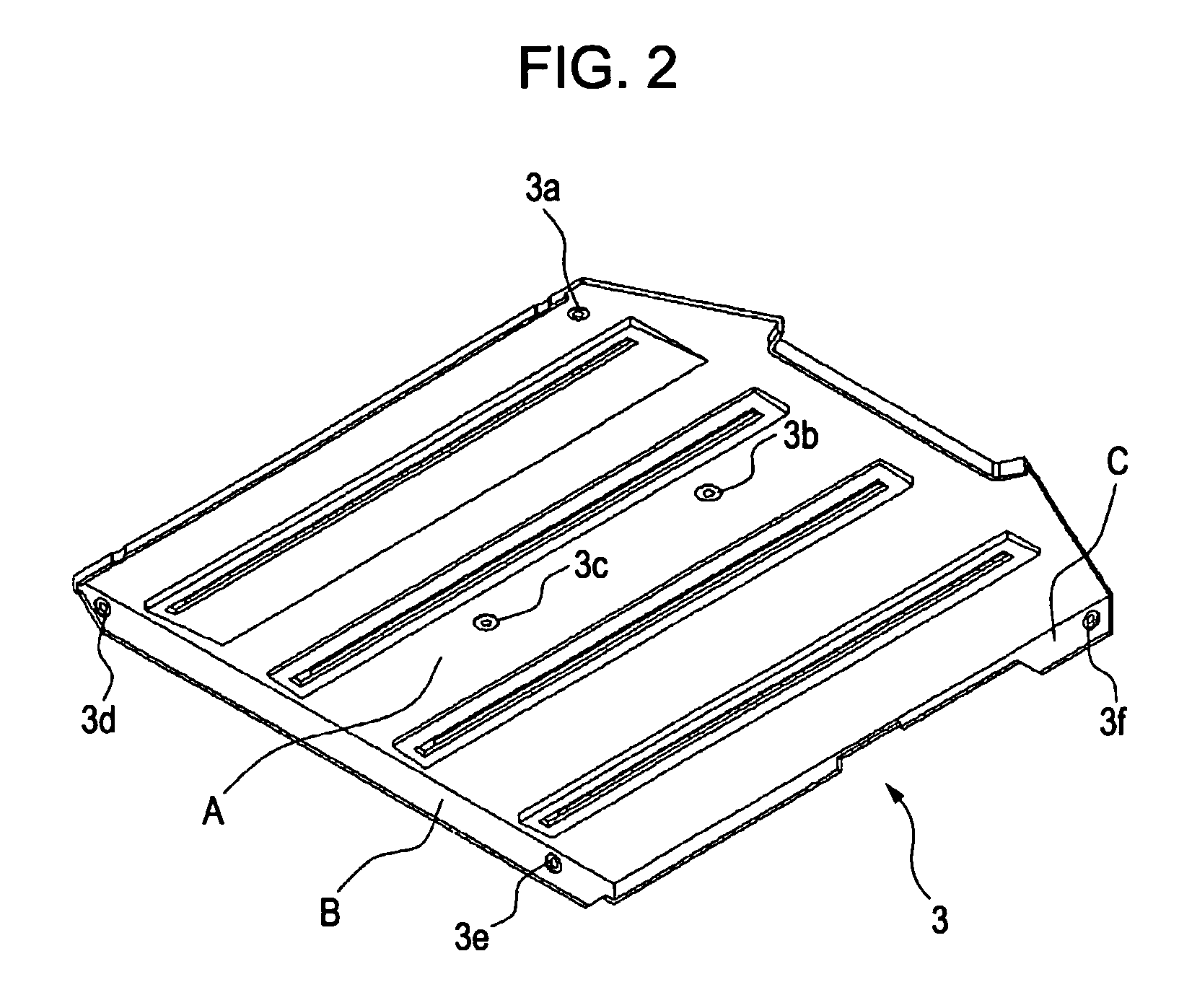

Optical unit and image forming apparatus

InactiveUS20060285170A1High rigiditySatisfactory flatnessDigitally marking record carriersInking apparatusEngineeringImage formation

At least one exemplary embodiment is directed to an optical unit adapted to irradiate image exposure light to an image carrier comprises a frame containing optical parts arranged therein and having an opening, and a cover adapted to cover the opening. The cover can be fixed by fixing members to the frame at three points in a first plane including the opening. The cover can further be fixed by fixing members to the frame at a second plane positioned on the frame and being adjacent to the first plane and at a third plane positioned on the frame and being not parallel to the second plane. Thus, an optical unit can be obtained which has high rigidity while, when the cover is attached to the opening, maintaining satisfactory flatness of the cover in a plane including the opening.

Owner:CANON KK

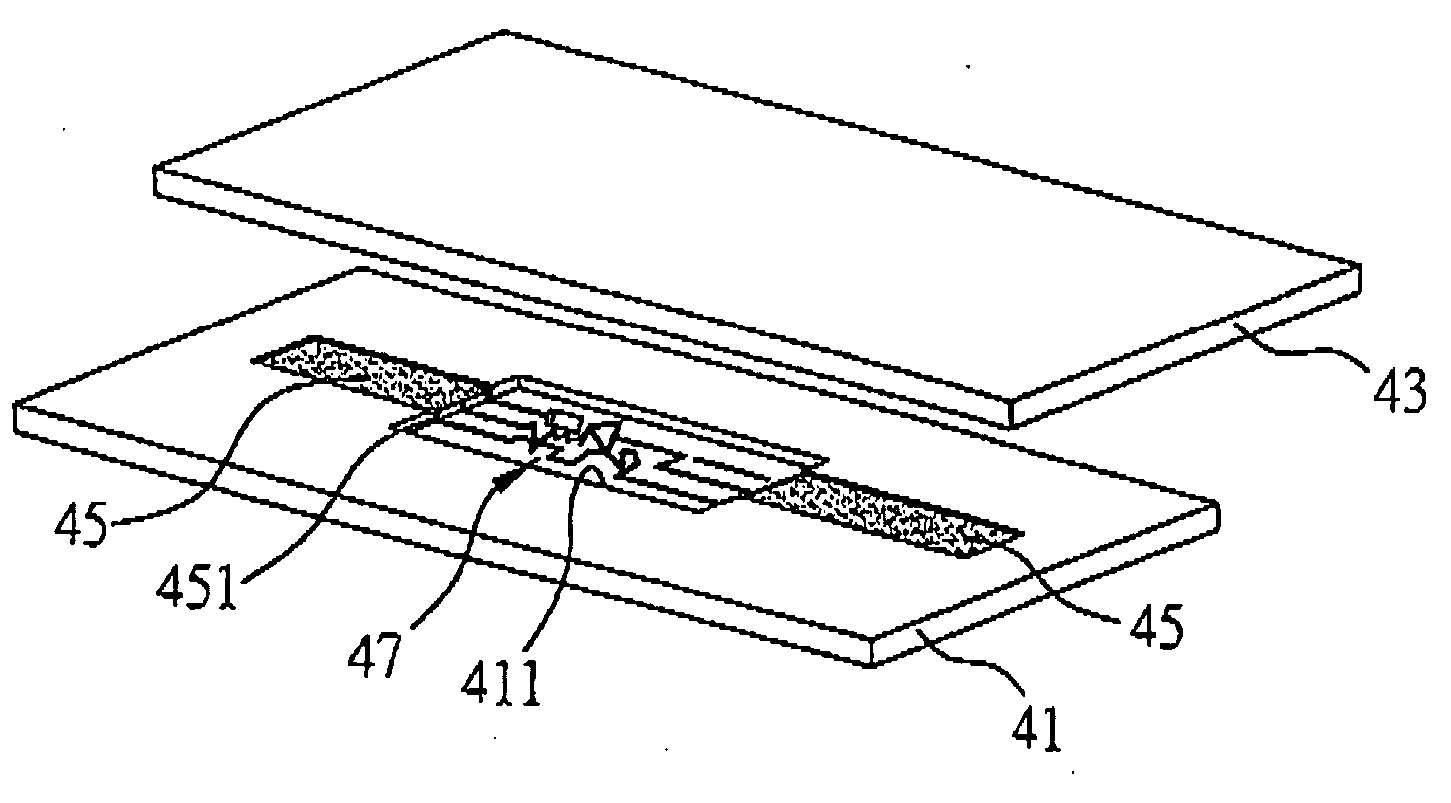

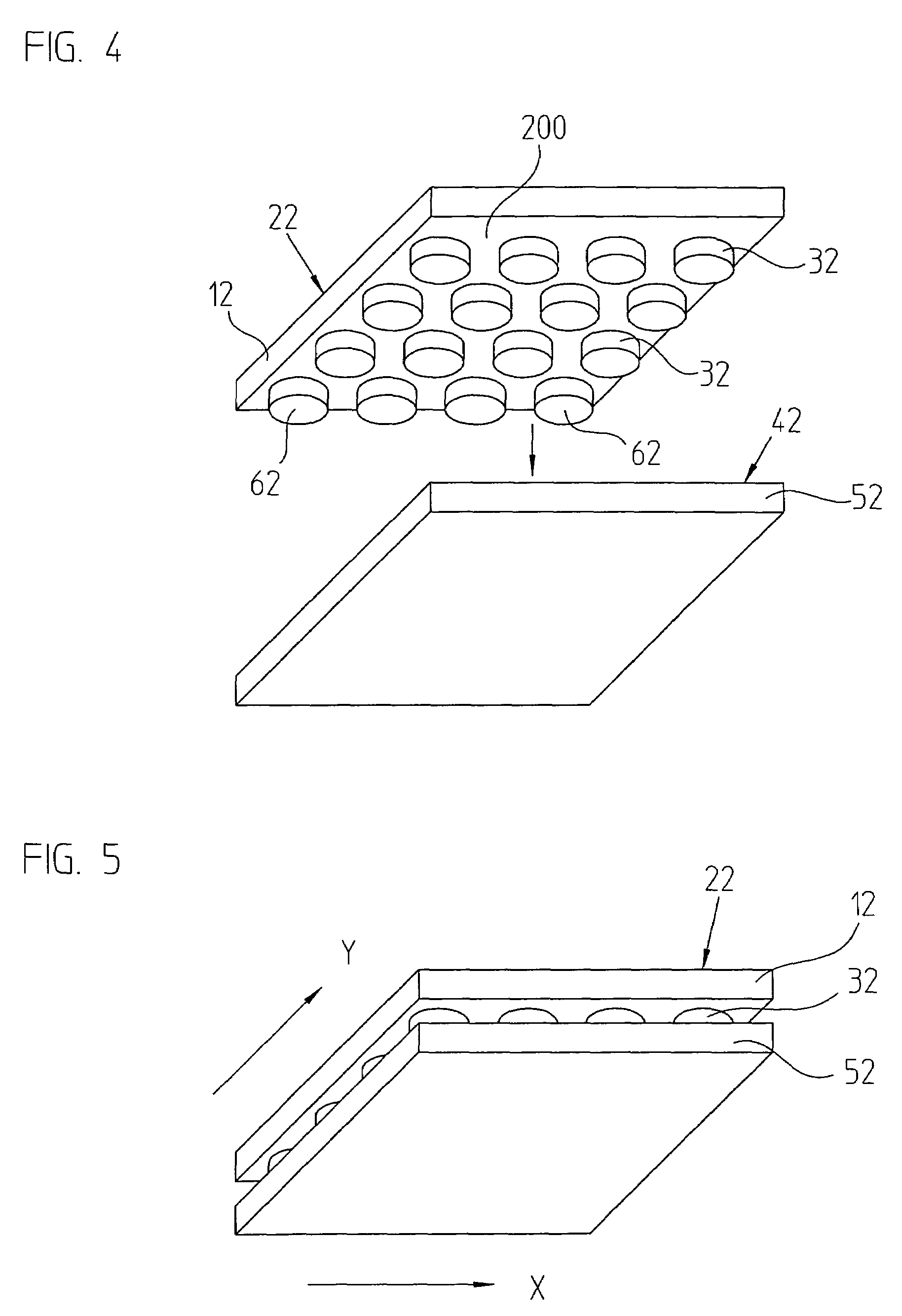

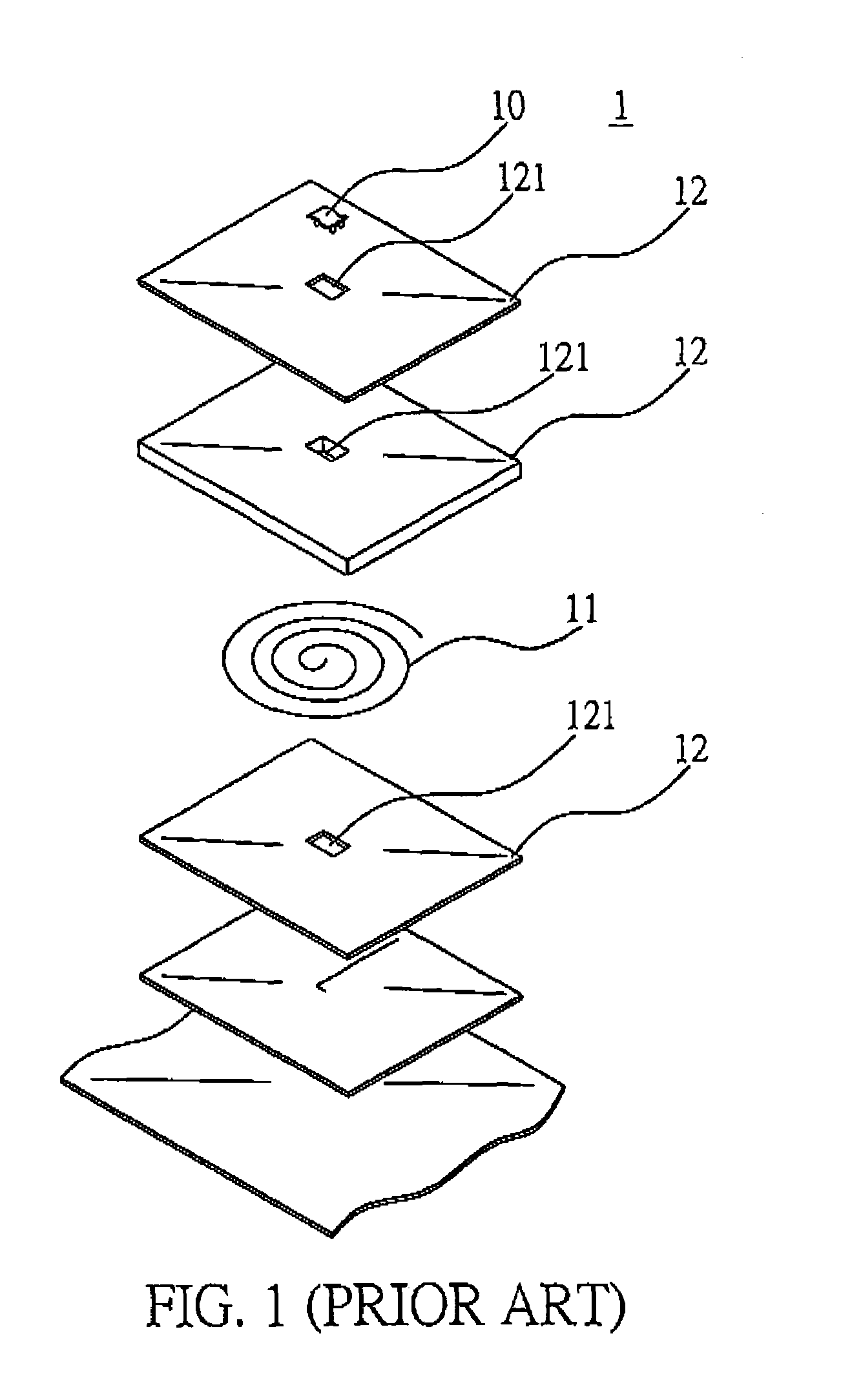

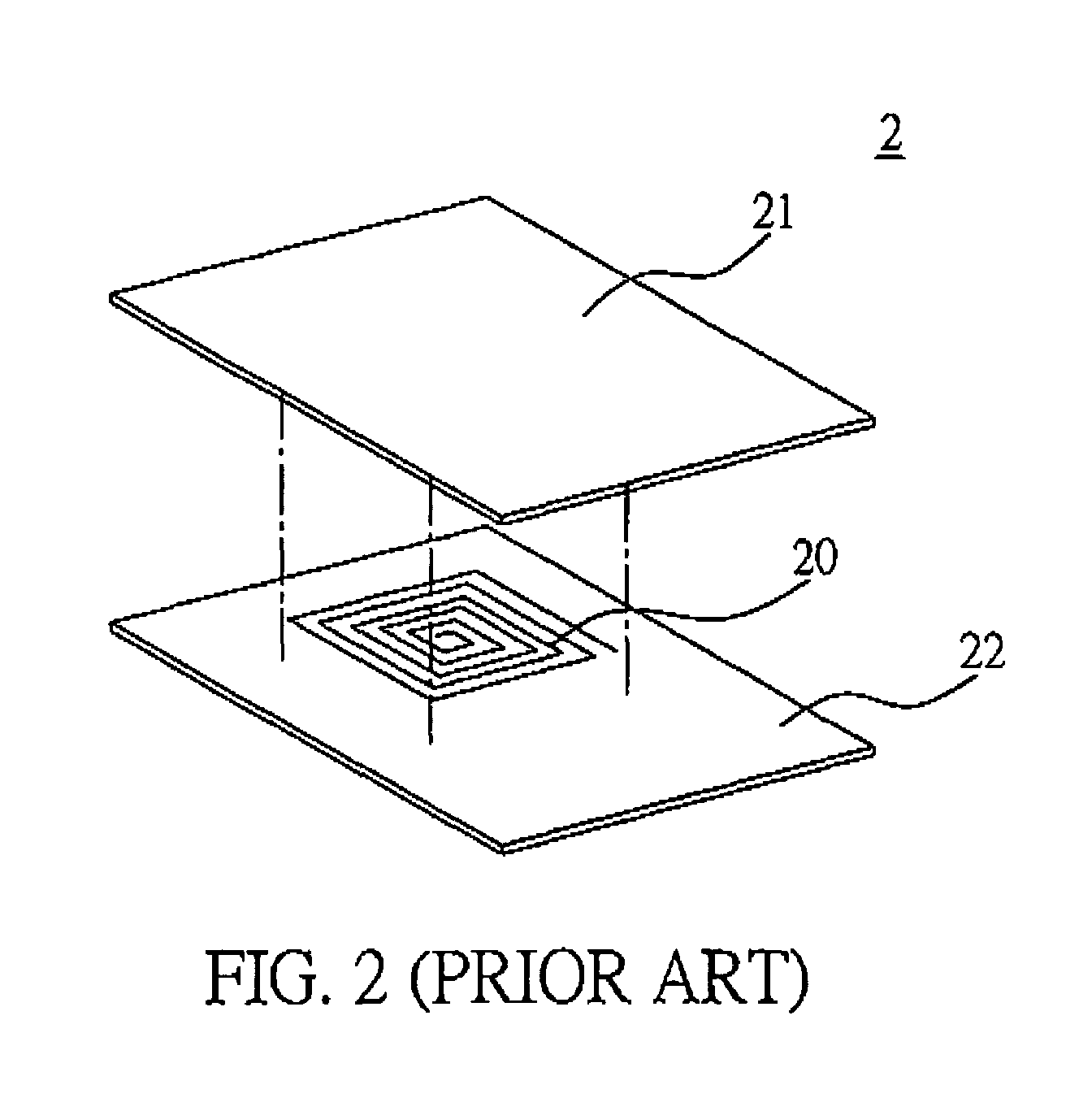

Flexible radio frequency identification label and method for fabricating the same

InactiveUS20070069899A1Improve product reliabilityExtended service lifeAntenna supports/mountingsLaminationPliabilityEngineering

A flexible radio frequency identification label and a method for fabricating the same are proposed. A first flexible protection layer is attached to a second flexible protection layer to form a closed space for receiving a radio frequency identification circuit. By such arrangement, a good flexibility can be provided by the flexible protection layers, and the closed space also enables the radio frequency identification circuit to be protected and isolated from the moisture in the outside environment, such that the circuit can be prevented from being oxidized and the service life of the product can be extended.

Owner:IND TECH RES INST

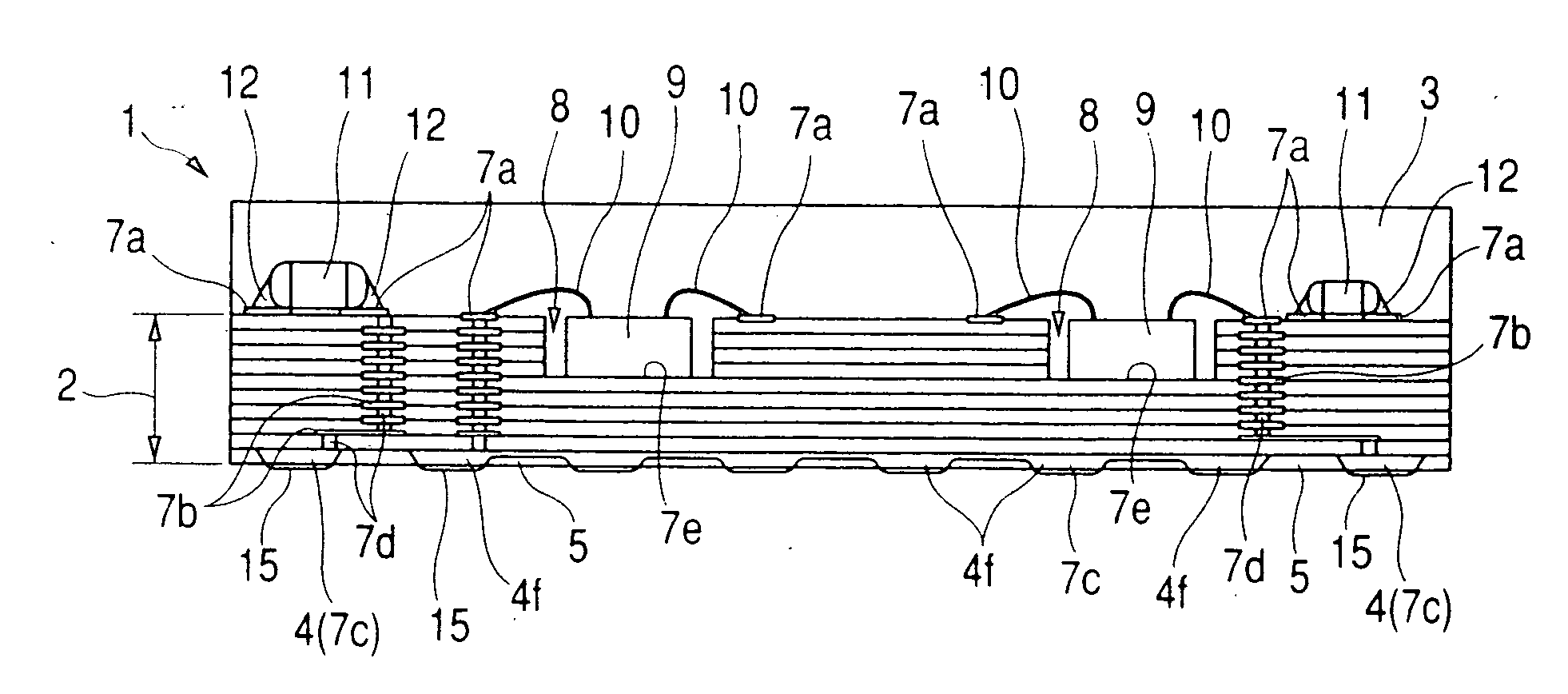

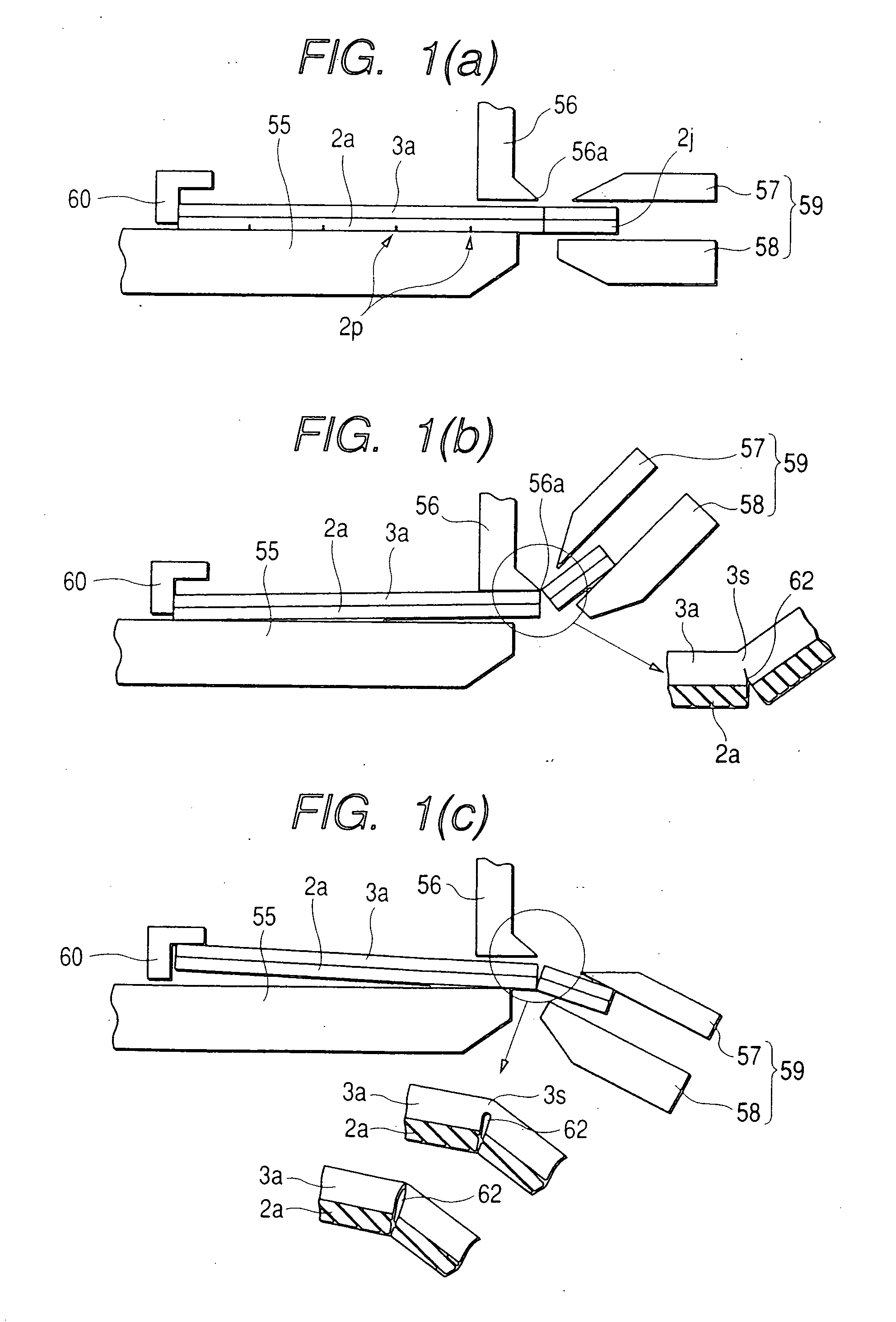

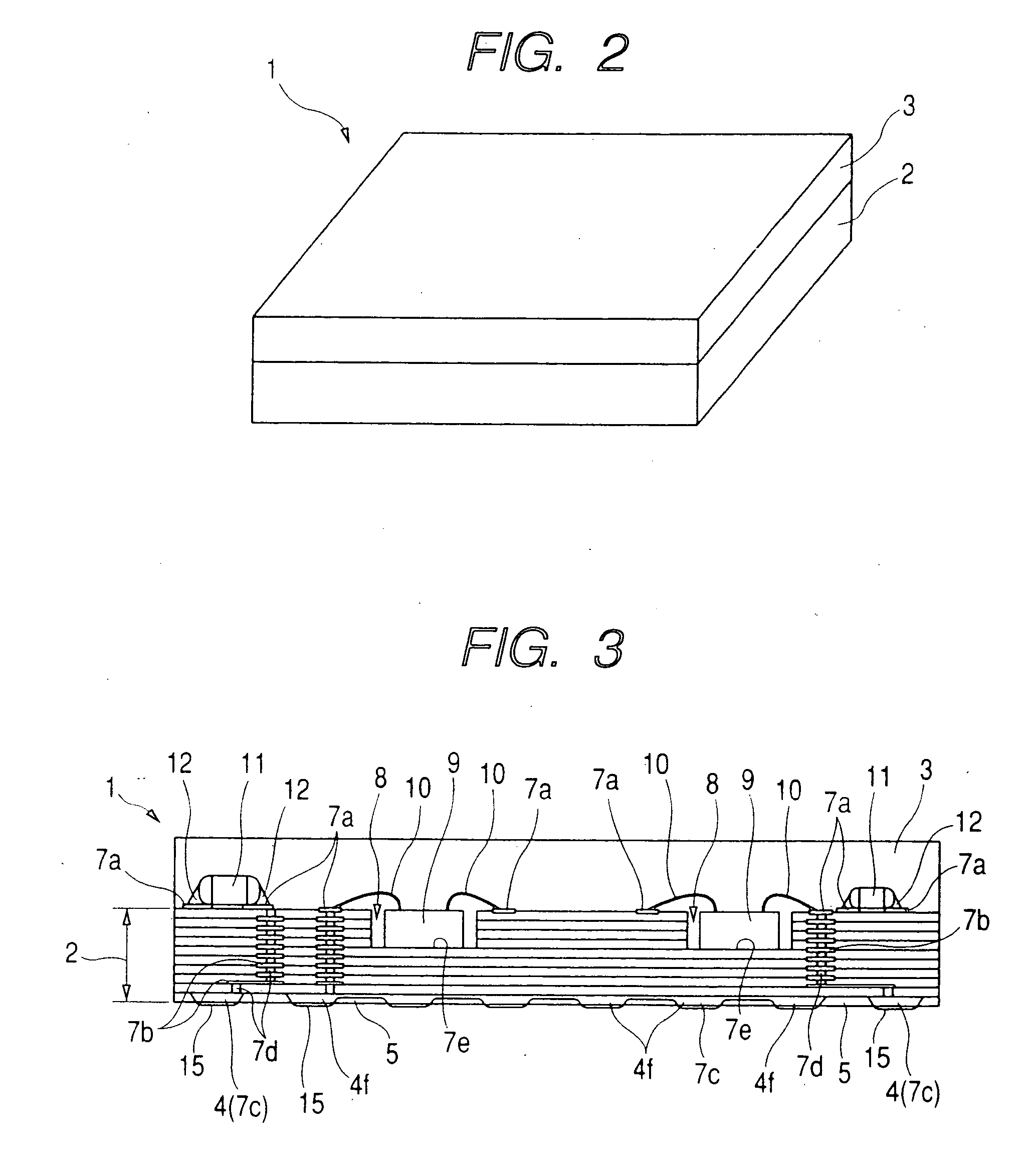

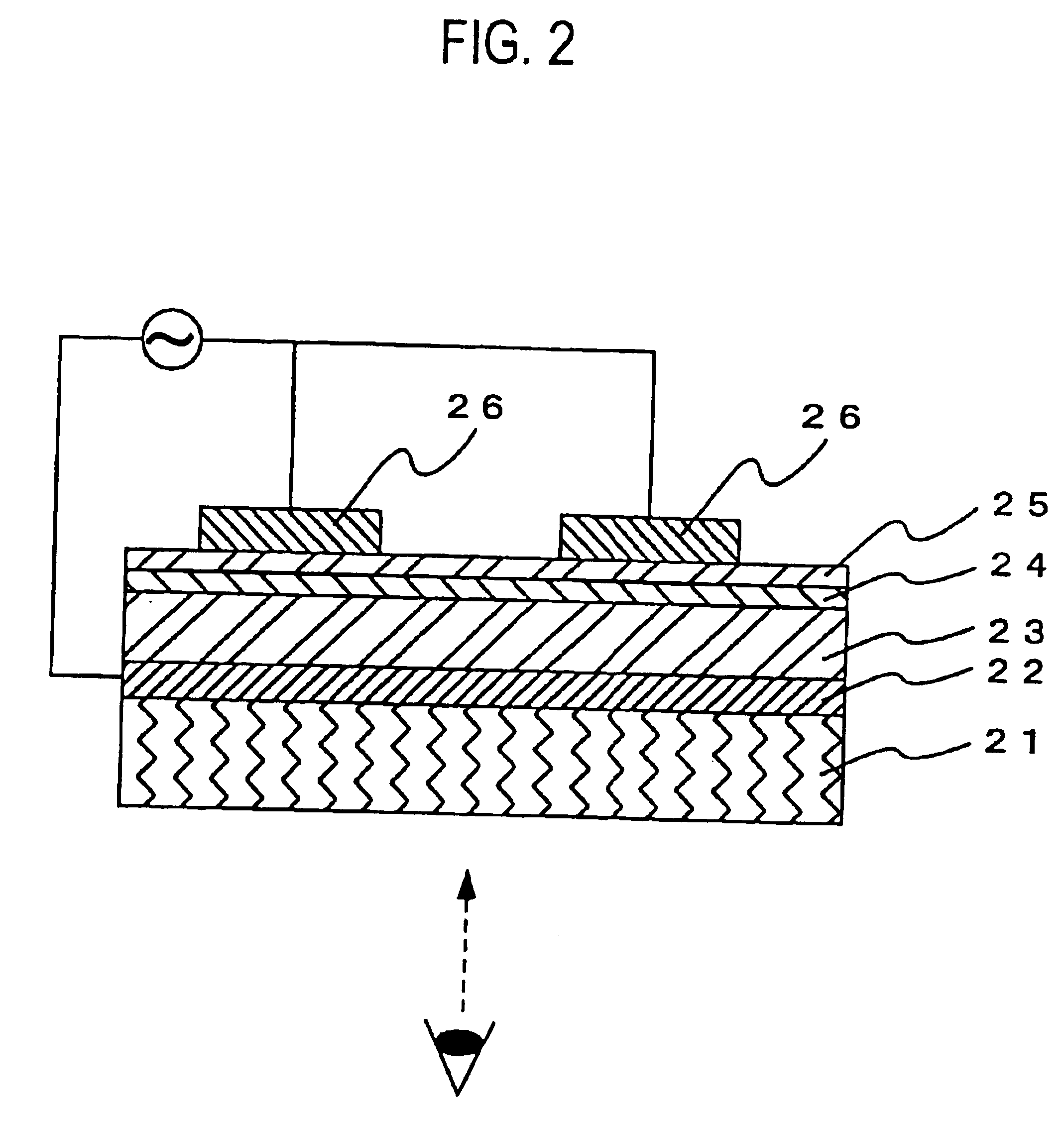

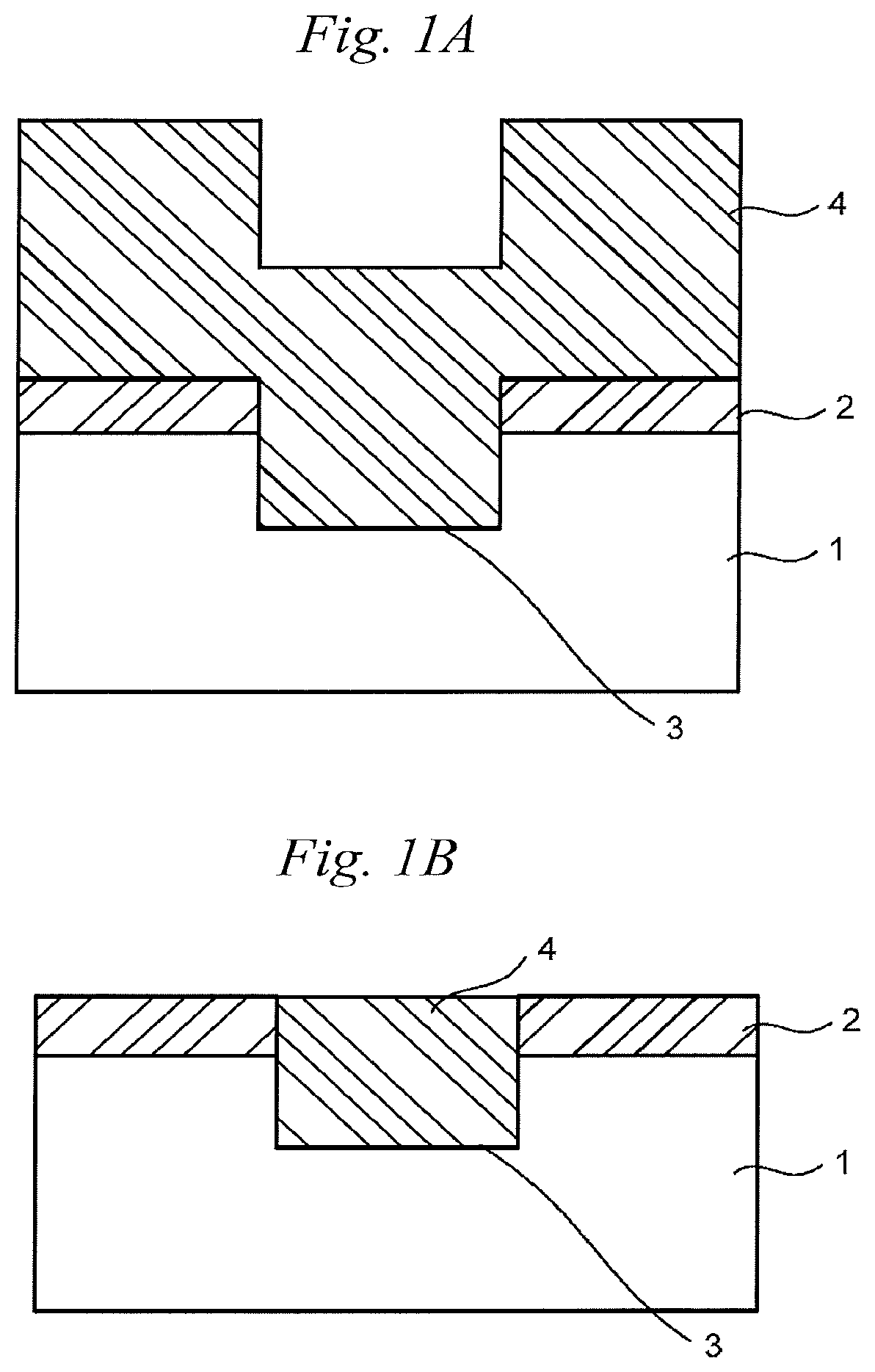

Manufacturing method of semiconductor device and semiconductor device

InactiveUS20070105283A1Satisfy flatnessReliable pickupSemiconductor/solid-state device detailsPrinted circuit aspectsDevice materialEngineering

In a dividing method according to the present invention, a wiring board formed of ceramic is forced up (upper swing) by a lower clamp claw of a clamper, and some of a protruded wiring board portion protruding from a conveying chute is pressed against a support body to perform a first division under bending stress. Thereafter, the upward-located clamper is rotatably swung (lower swing) downward to allow an upper clamp claw to press down the protruded wiring board portion, thereby performing a reverse division at the first division section again as a second division. Since the second division allows a tensile force to act on a remaining and thin non-divided resin portion, the non-divided resin portion is torn off. Thus, the perfect division is enabled. Fractionalizing is done by a one-row division and an individual division so that each semiconductor device is formed.

Owner:RENESAS TECH CORP

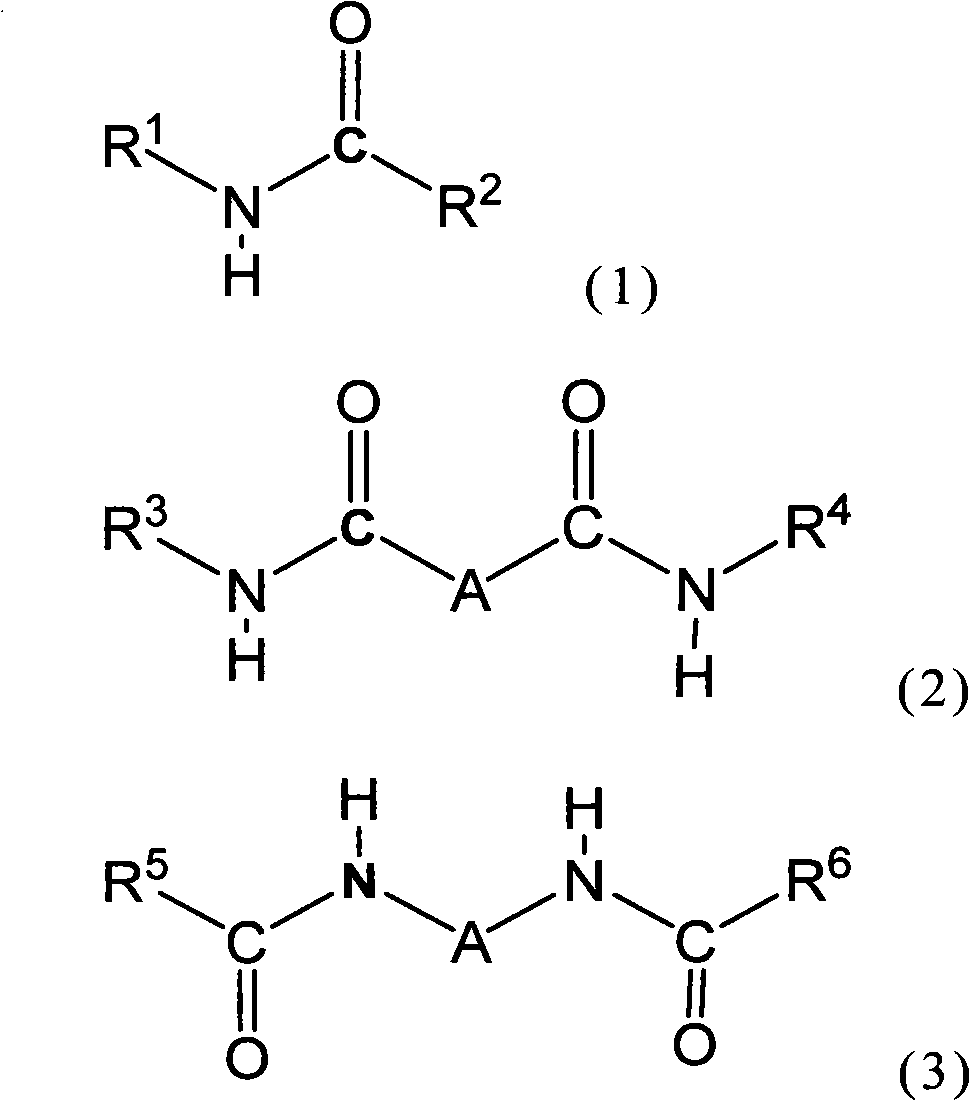

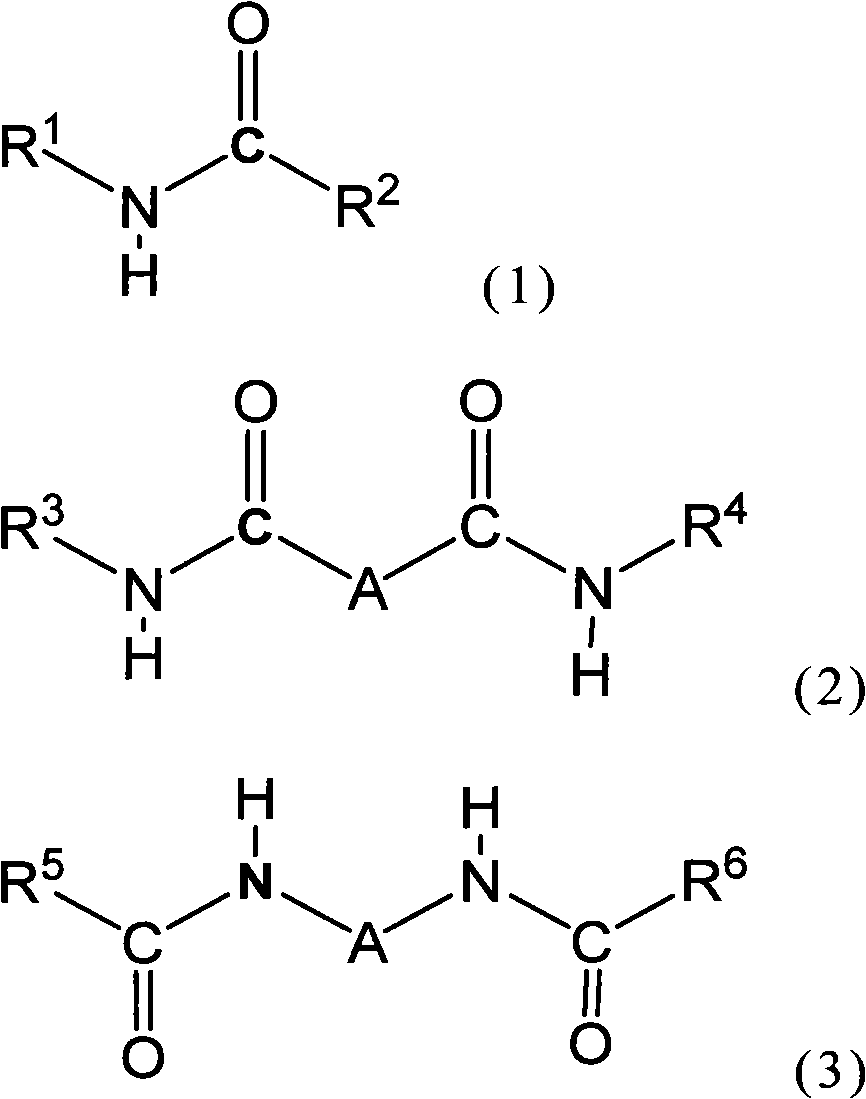

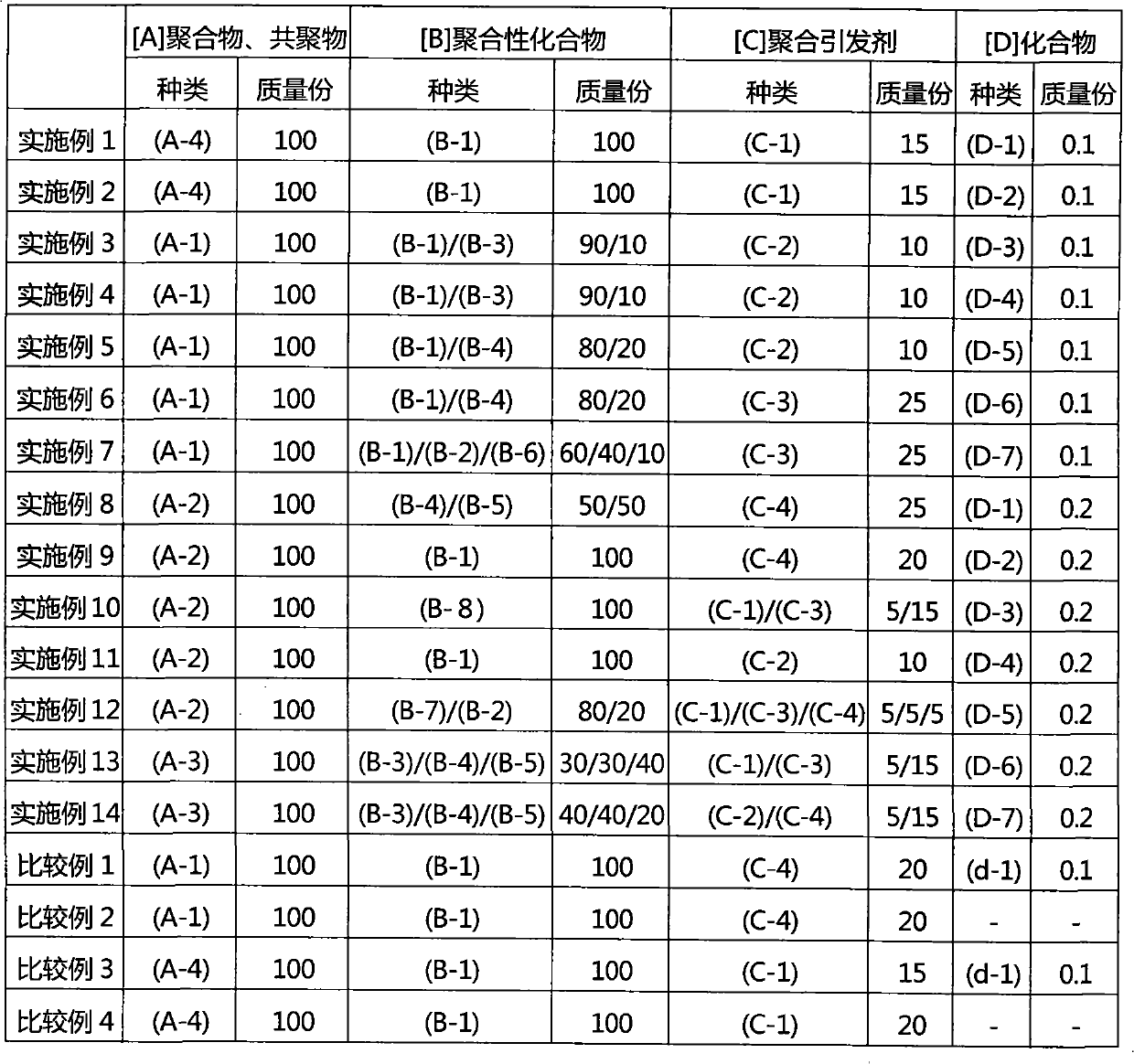

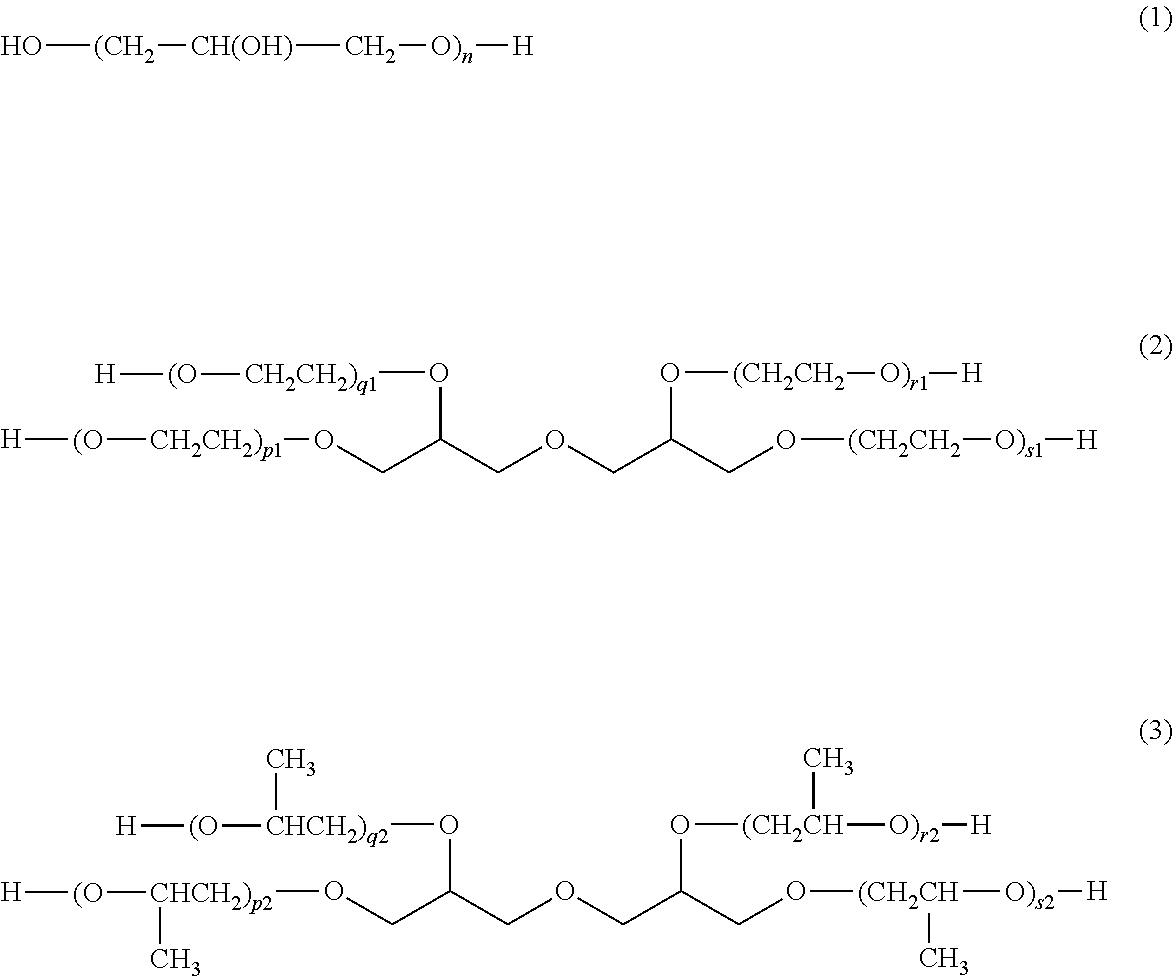

Radiation-sensitive resin composition, cured film, method for forming cured film, and display element

ActiveCN102269932AMeet heat resistanceSatisfies chemical corrosion resistanceSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusHeat resistanceRadiation sensitivity

The invention provides a radiation-sensitive resin composition, a cured film and a forming method thereof and a display element. The radiation-sensitive resin composition is excellent in both storage stability and low-temperature firing performance. Meanwhile, the radiation-sensitive resin composition is sufficient in radiation sensitivity. The curved film is excellent in heat resistance, chemical-corrosion resistance, transmittance, smoothness, voltage holding ratio and heat resistant linear expansion property. The radiation-sensitive resin composition is characterized by comprising [A] a polymer having epoxy groups, [B] a polymerizable compound having an ethylenic unsaturated bond, [C] a radiation-sensitive polymerization initiator, and [D] at least one compound selected from the following formula (1)-(3).

Owner:JSR CORPORATIOON

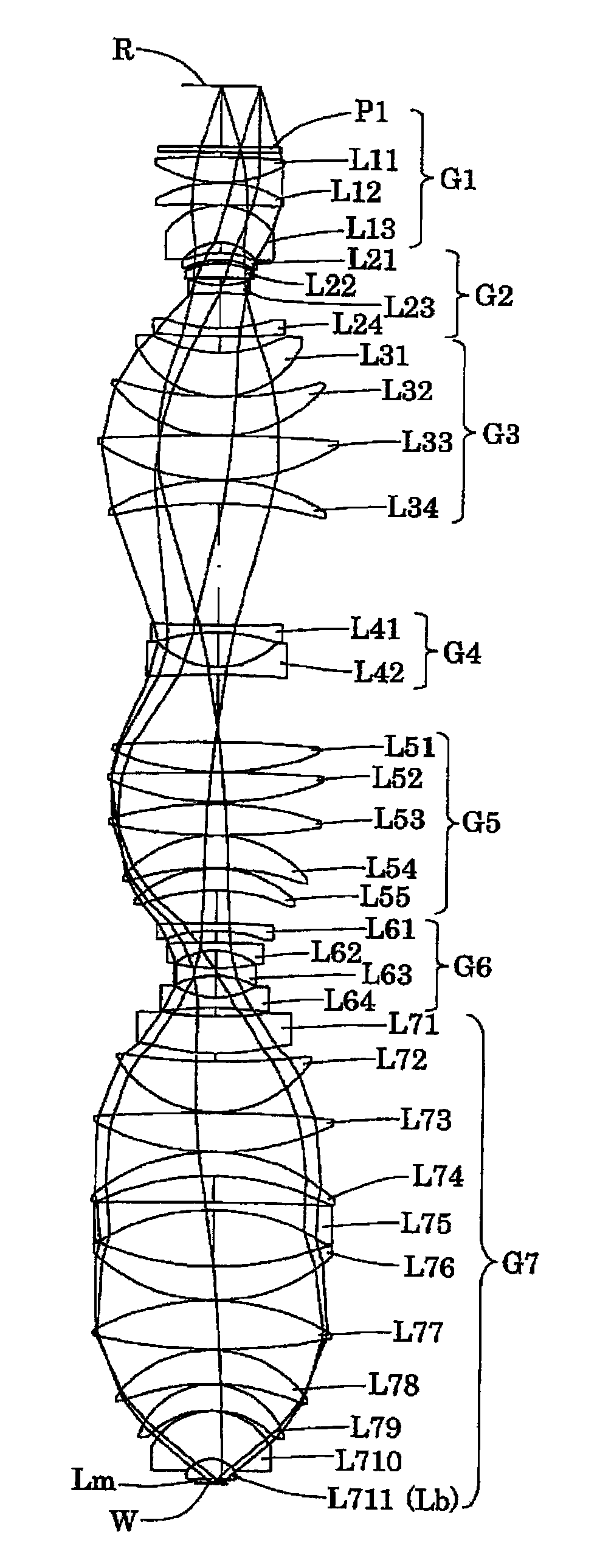

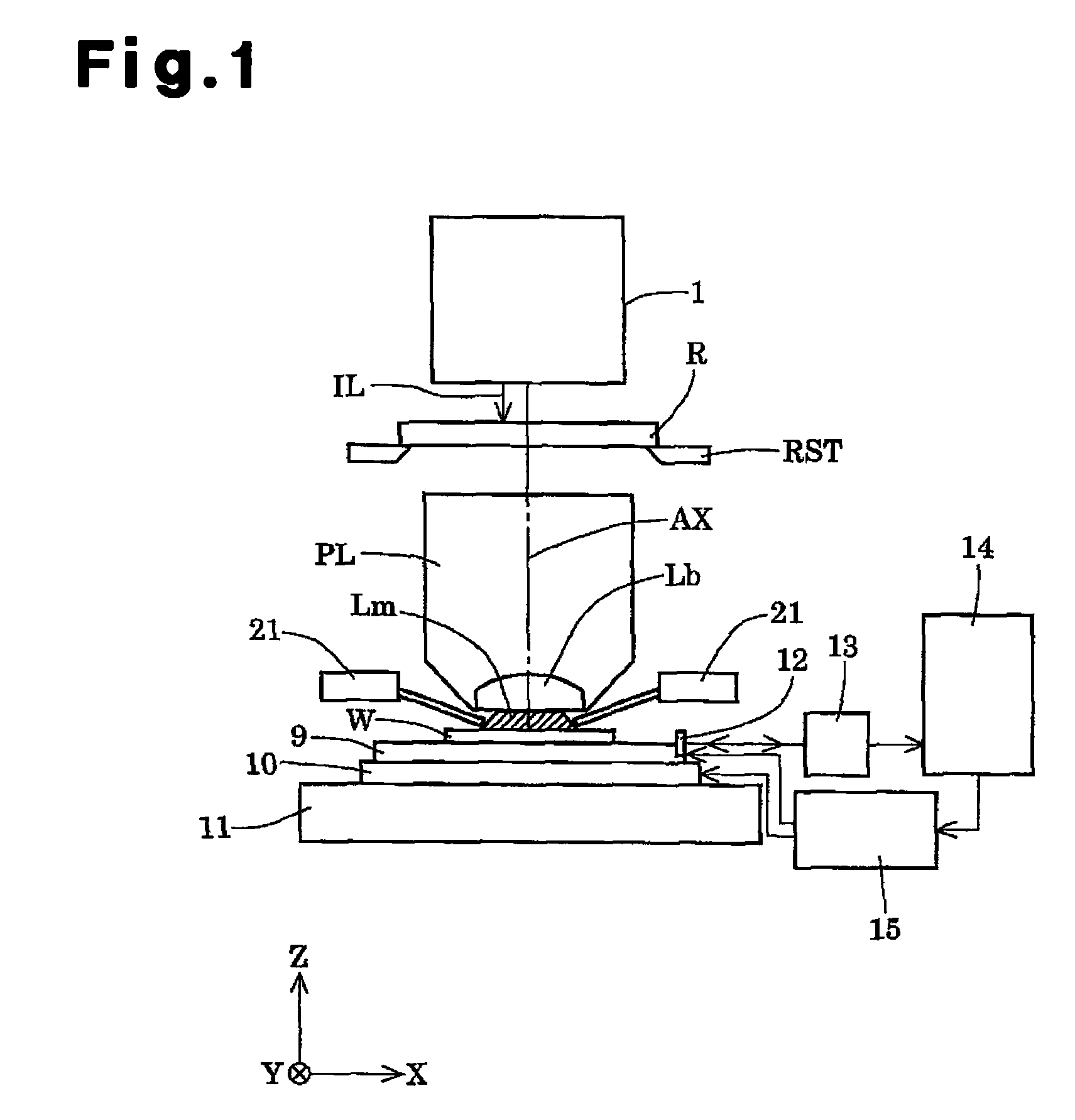

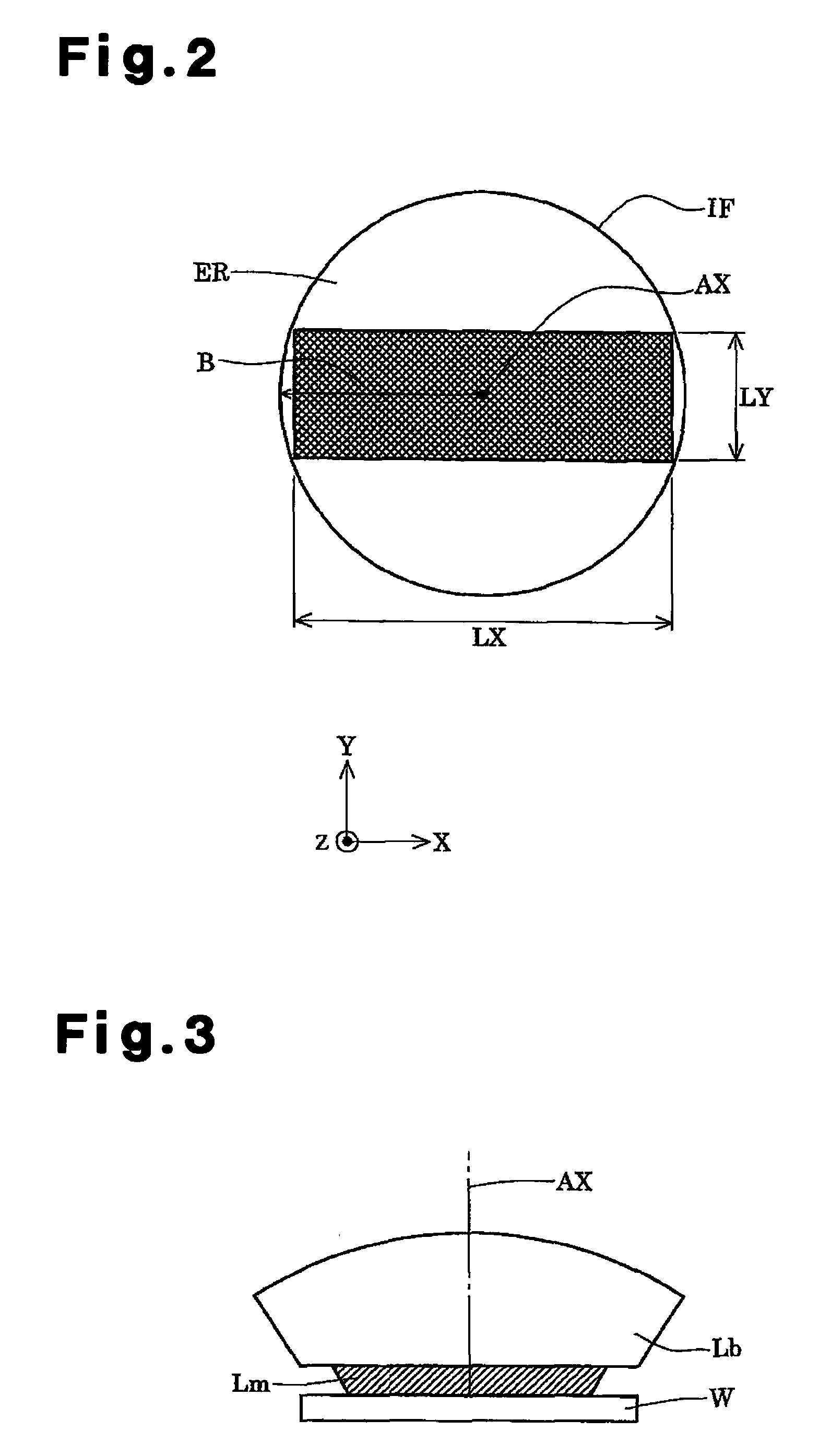

Projection optical system, aligner, and method for fabricating device

InactiveUS20090161087A1Satisfy flatnessInhibit overall enlargementPhotomechanical apparatusTelescopesOptical axisImage formation

A refractive projection optical system in which a large image side numerical aperture can be ensured by interposing liquid in the optical path to the image plane, and an image having good planarity can be formed while suppressing radial upsizing. The projection optical system comprising a first image forming system arranged in the optical path between a first plane (R) and a point optically conjugate to a point on the optical axis of the first plane, and a second image forming system arranged in the optical path between the conjugate point and a second plane. In the projection optical system, all optical elements having power are refractive optical elements. The optical path between the projection optical system and the second plane is fillable with liquid having a refractive index larger than 1.3.

Owner:NIKON CORP

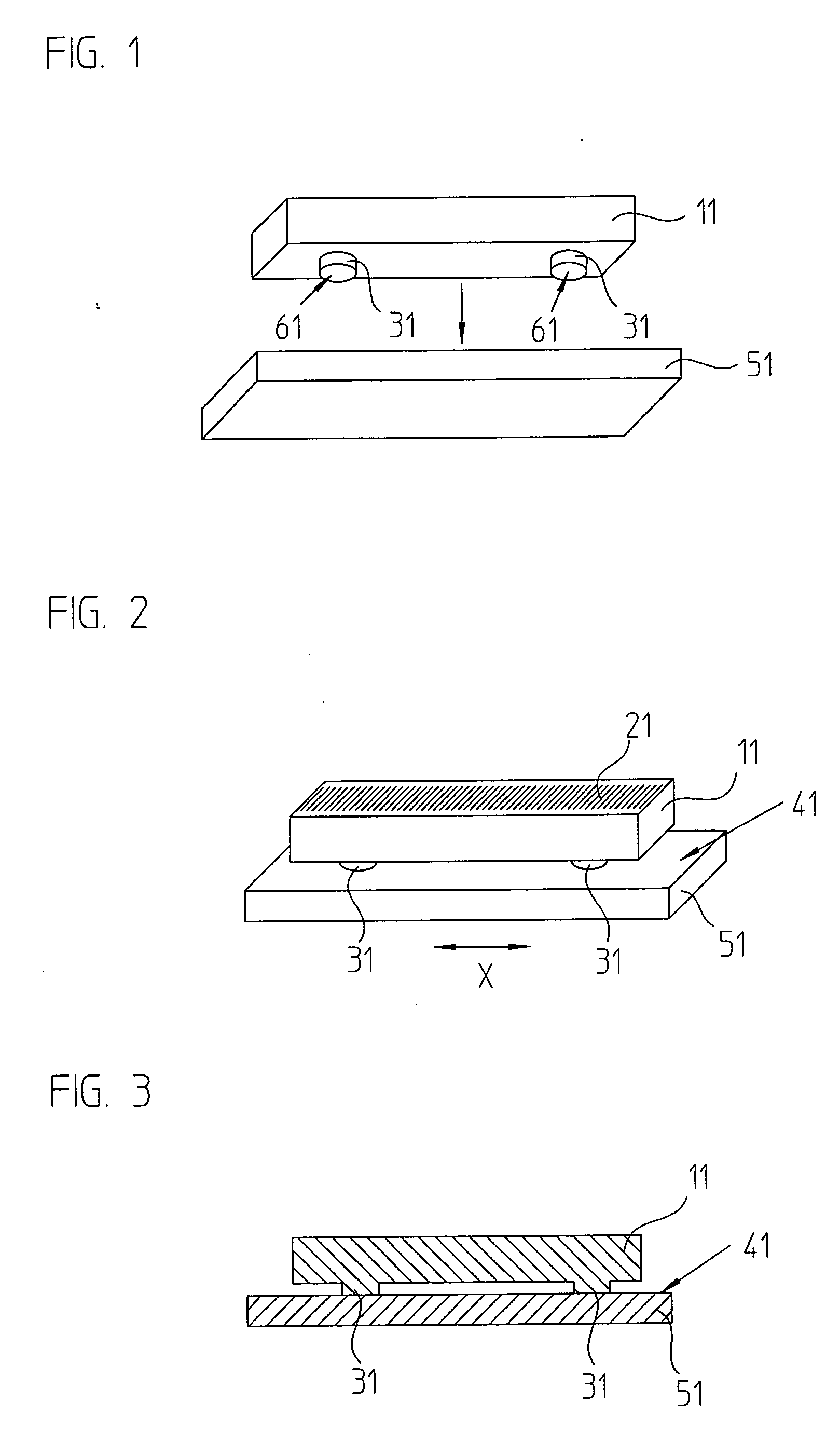

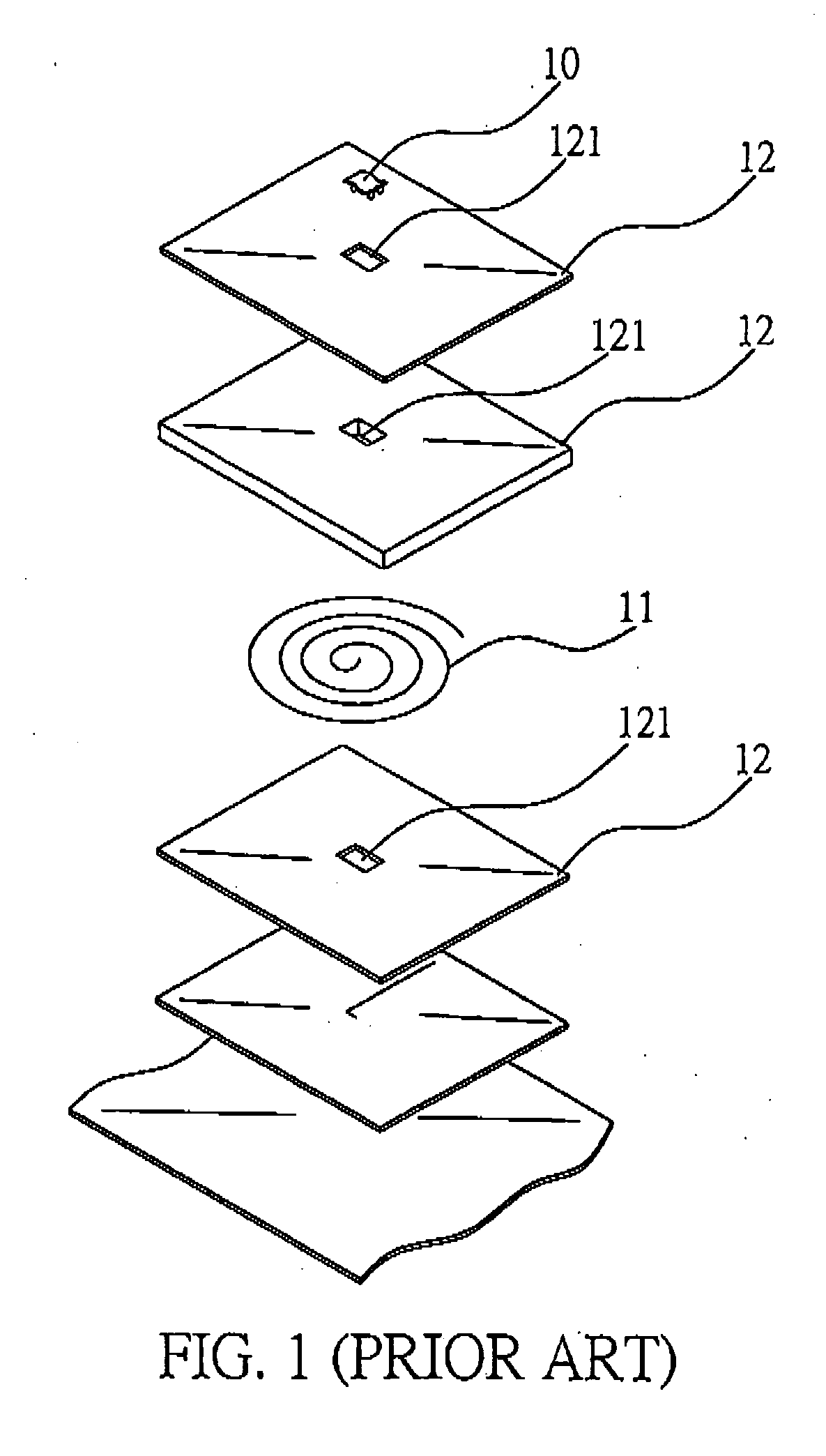

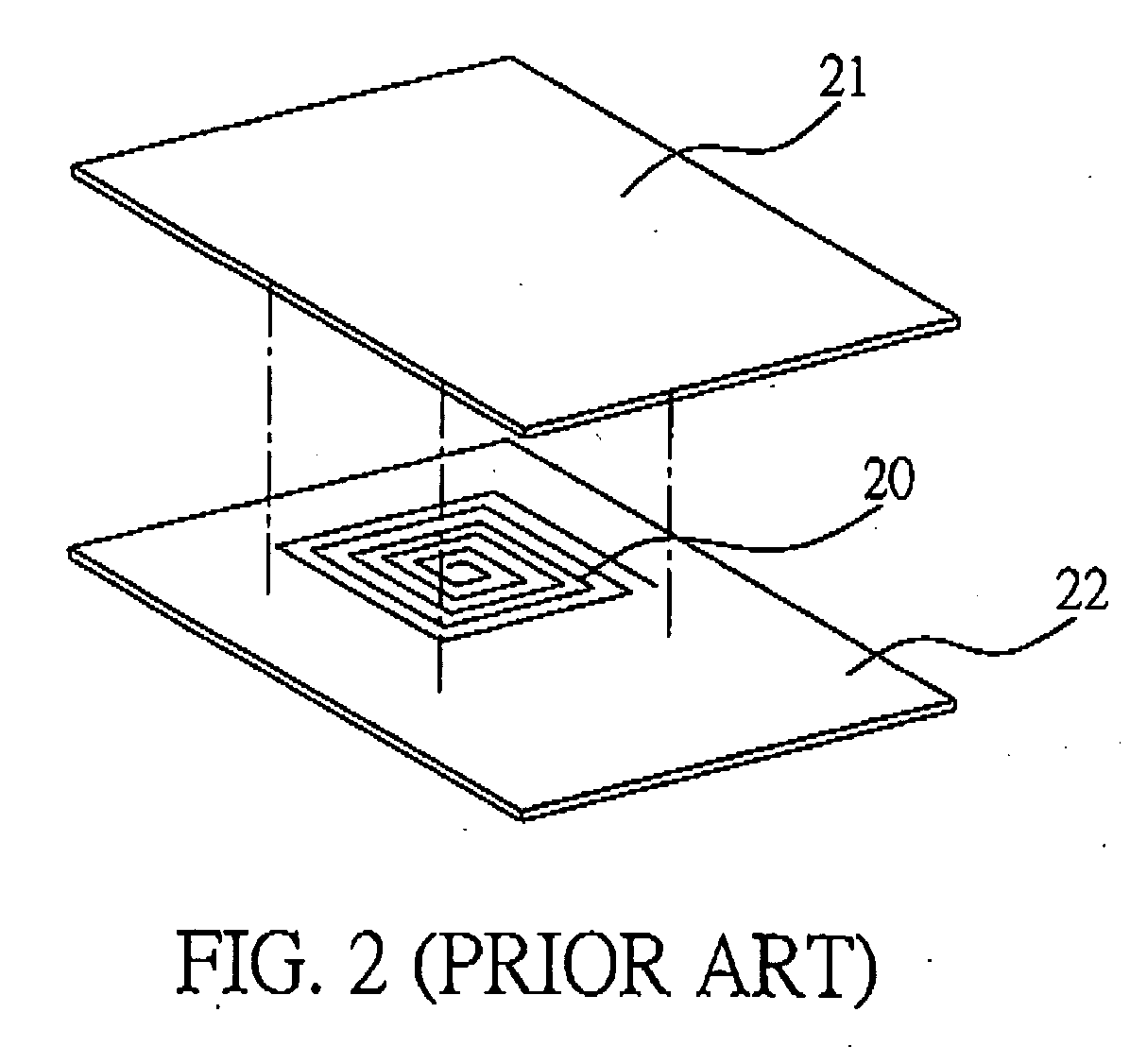

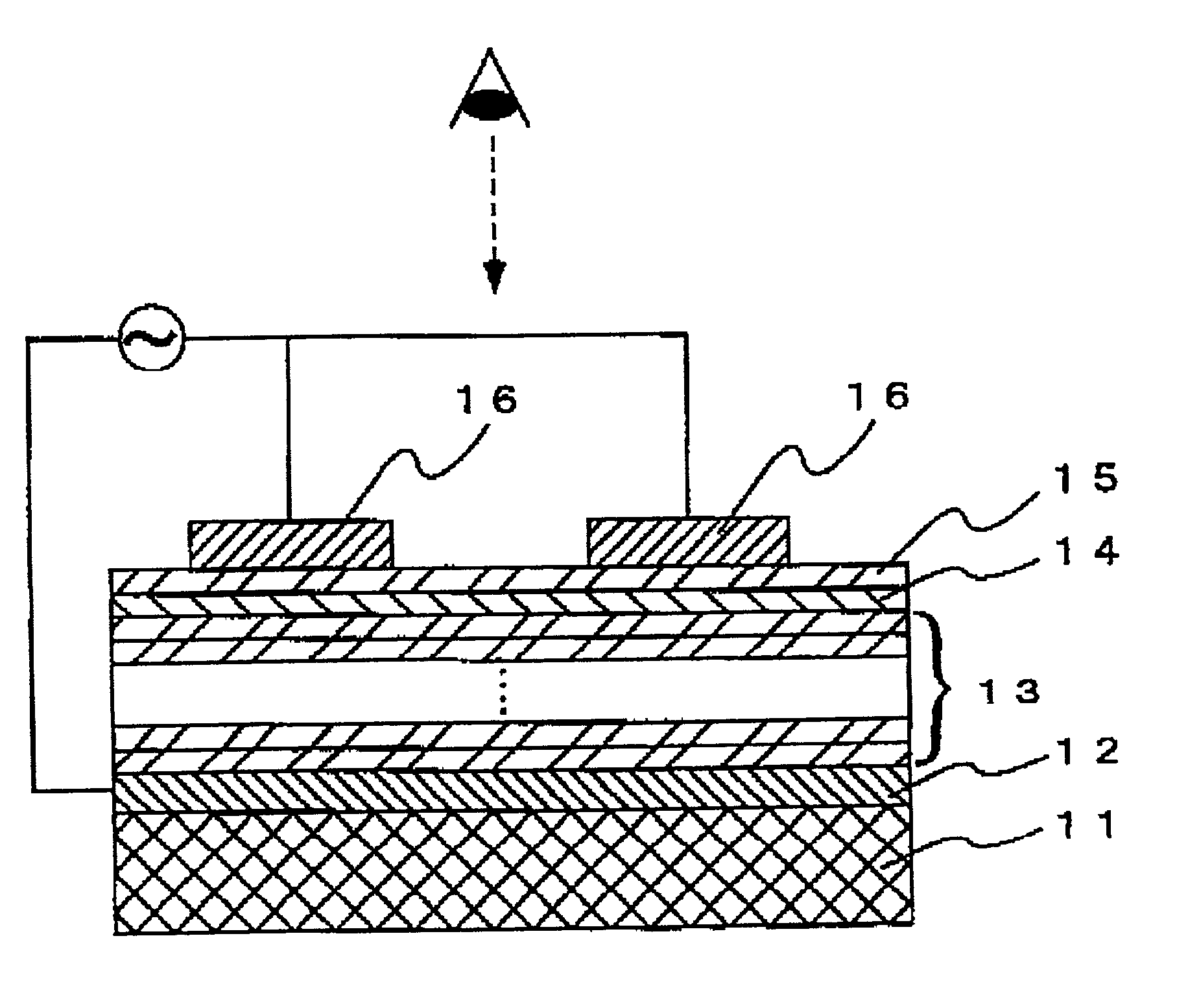

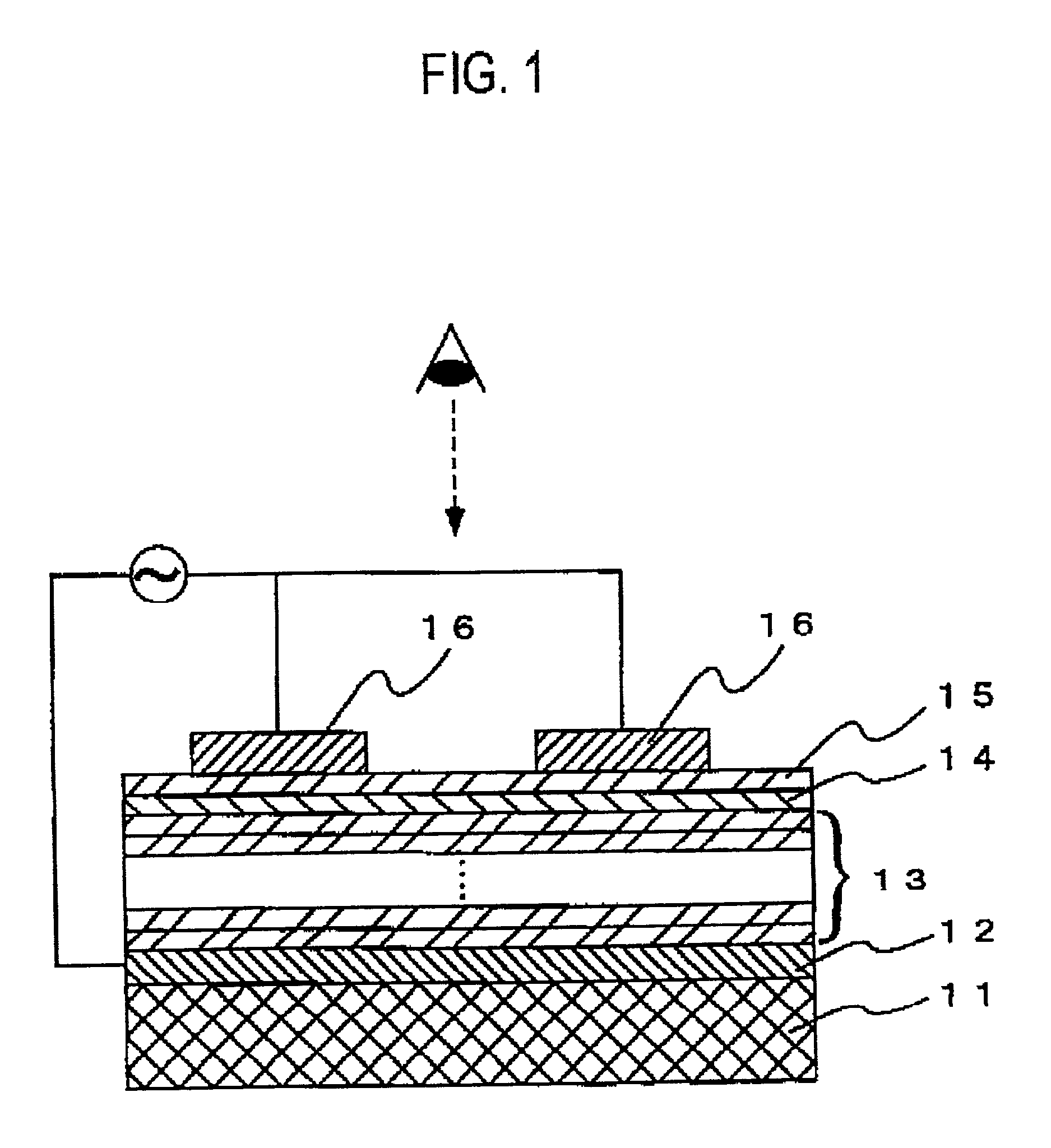

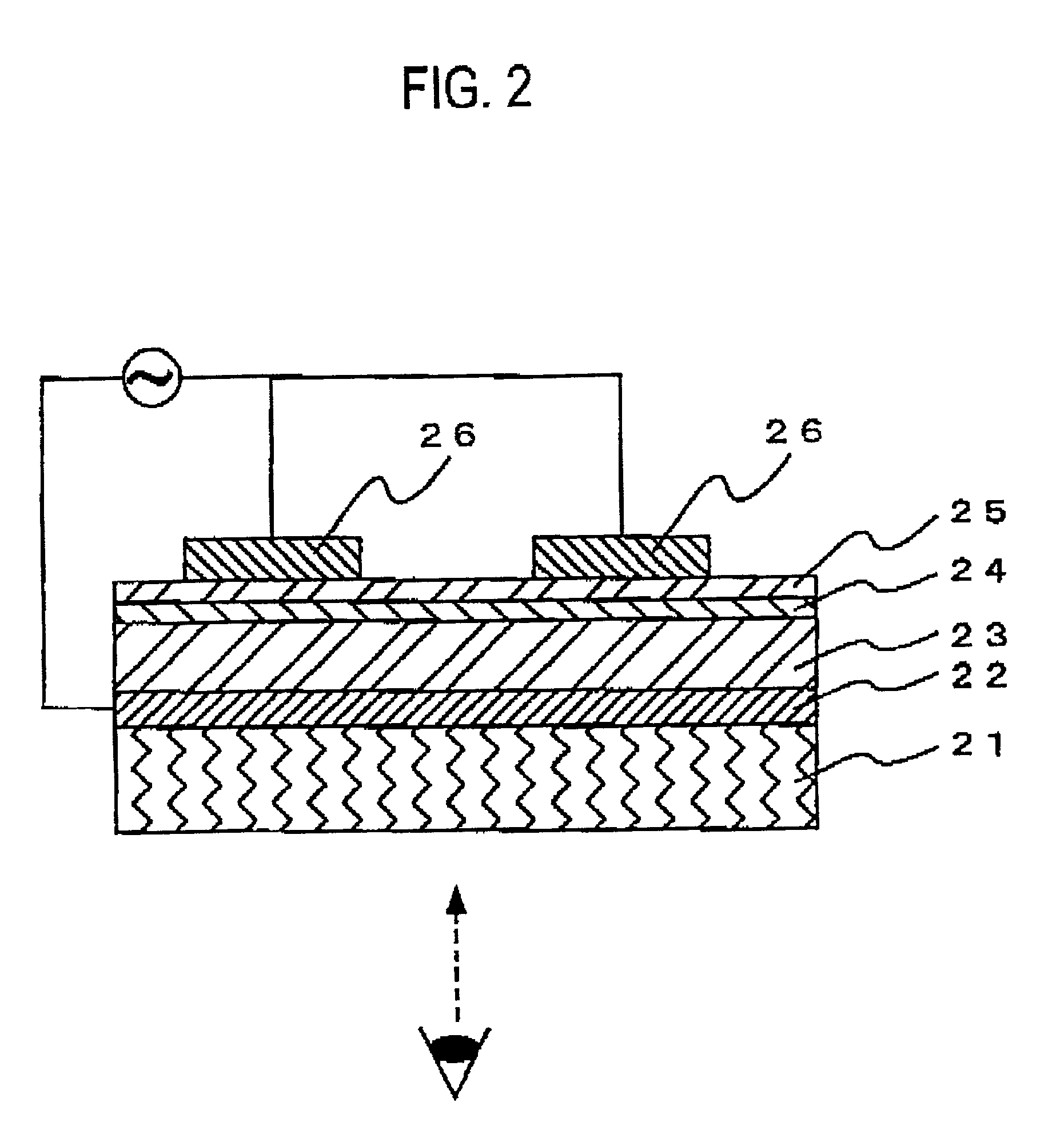

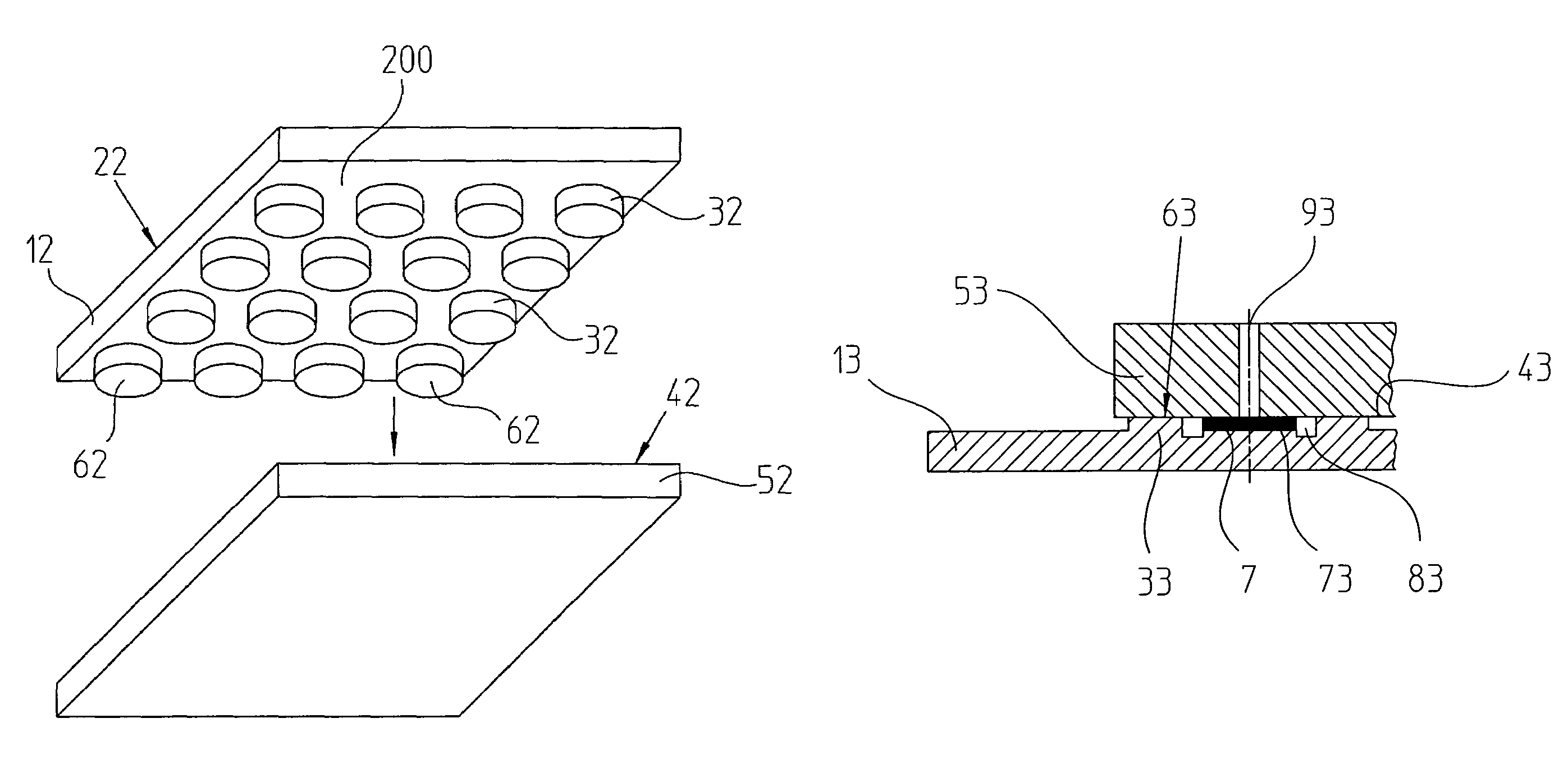

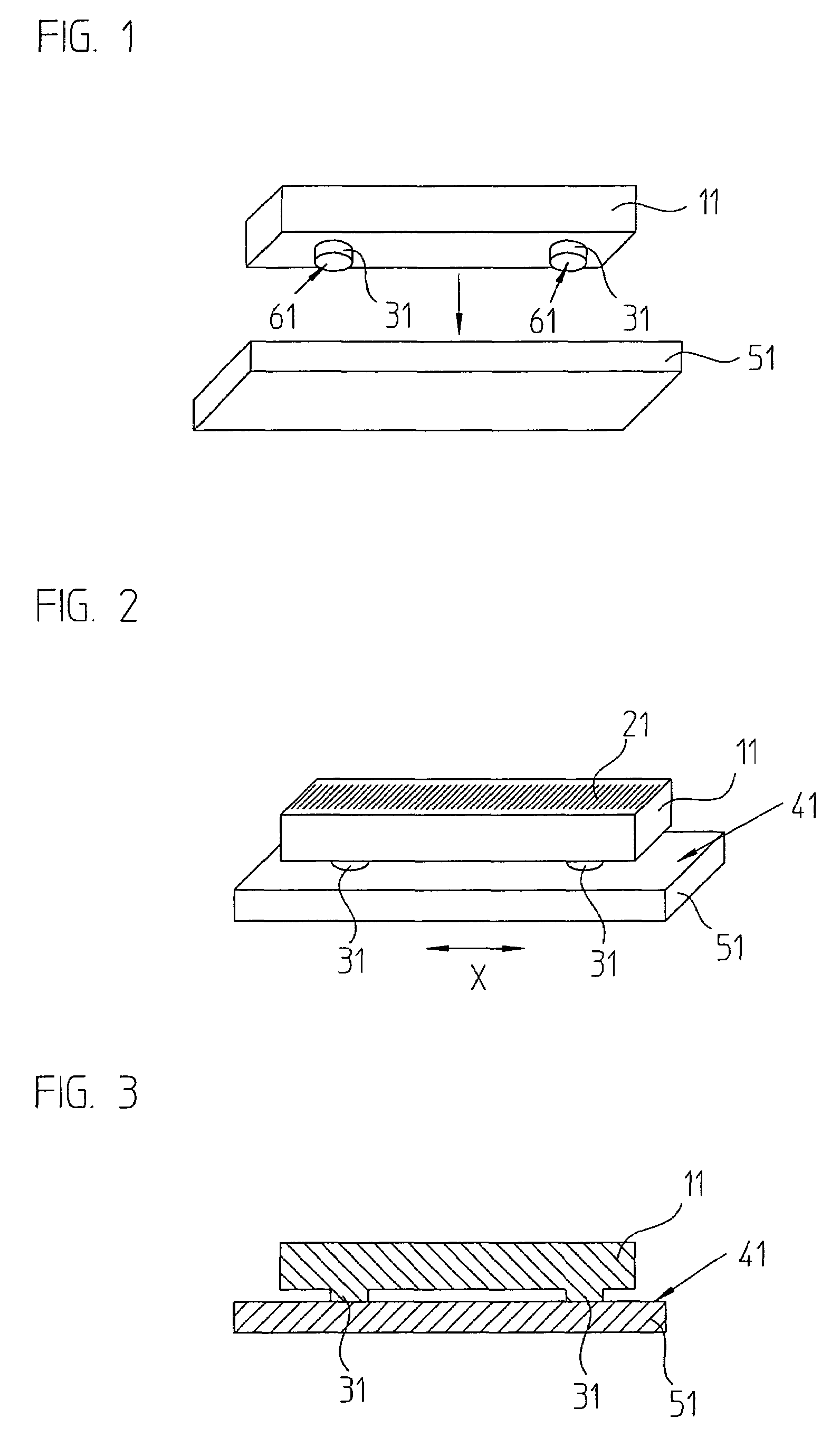

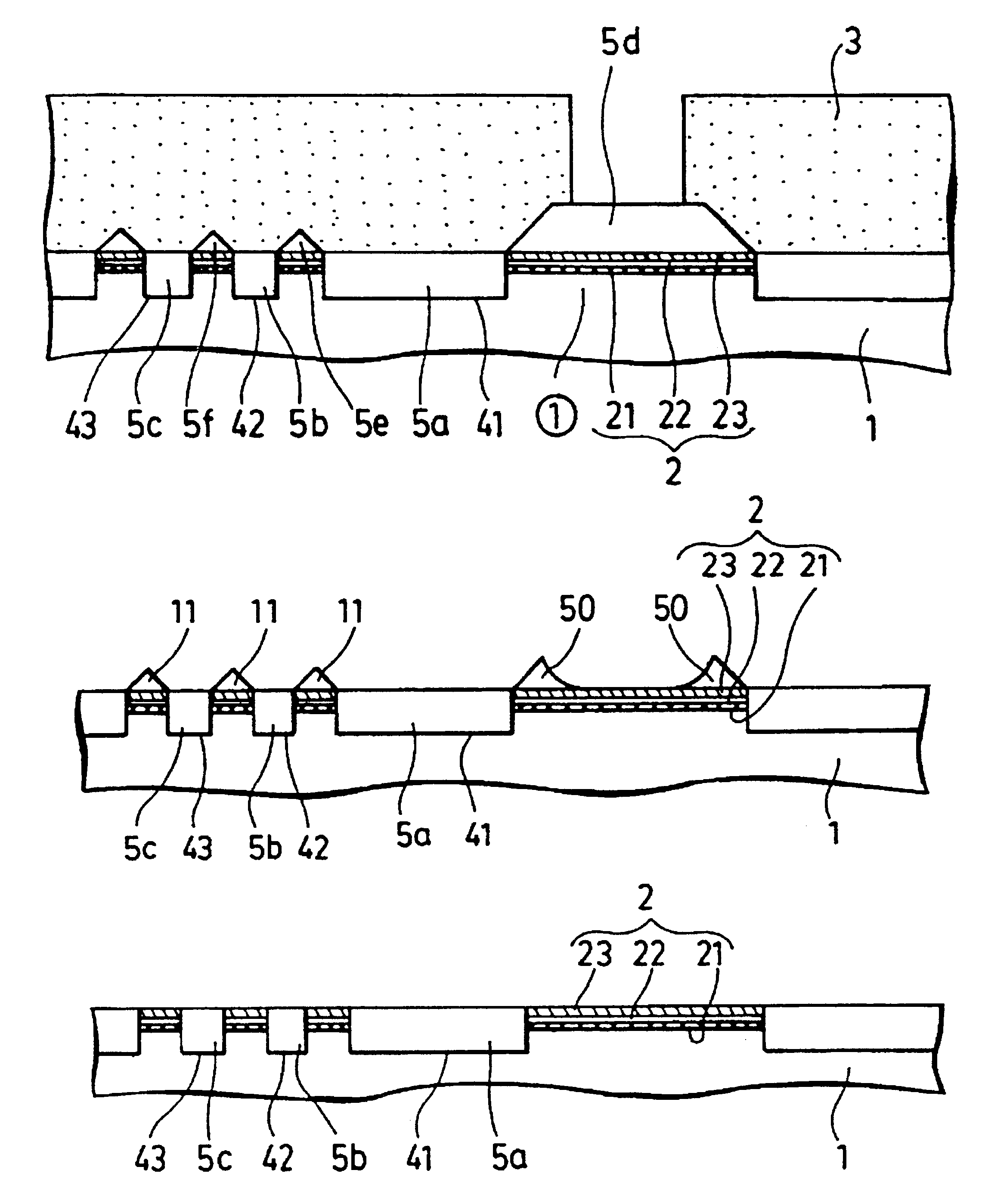

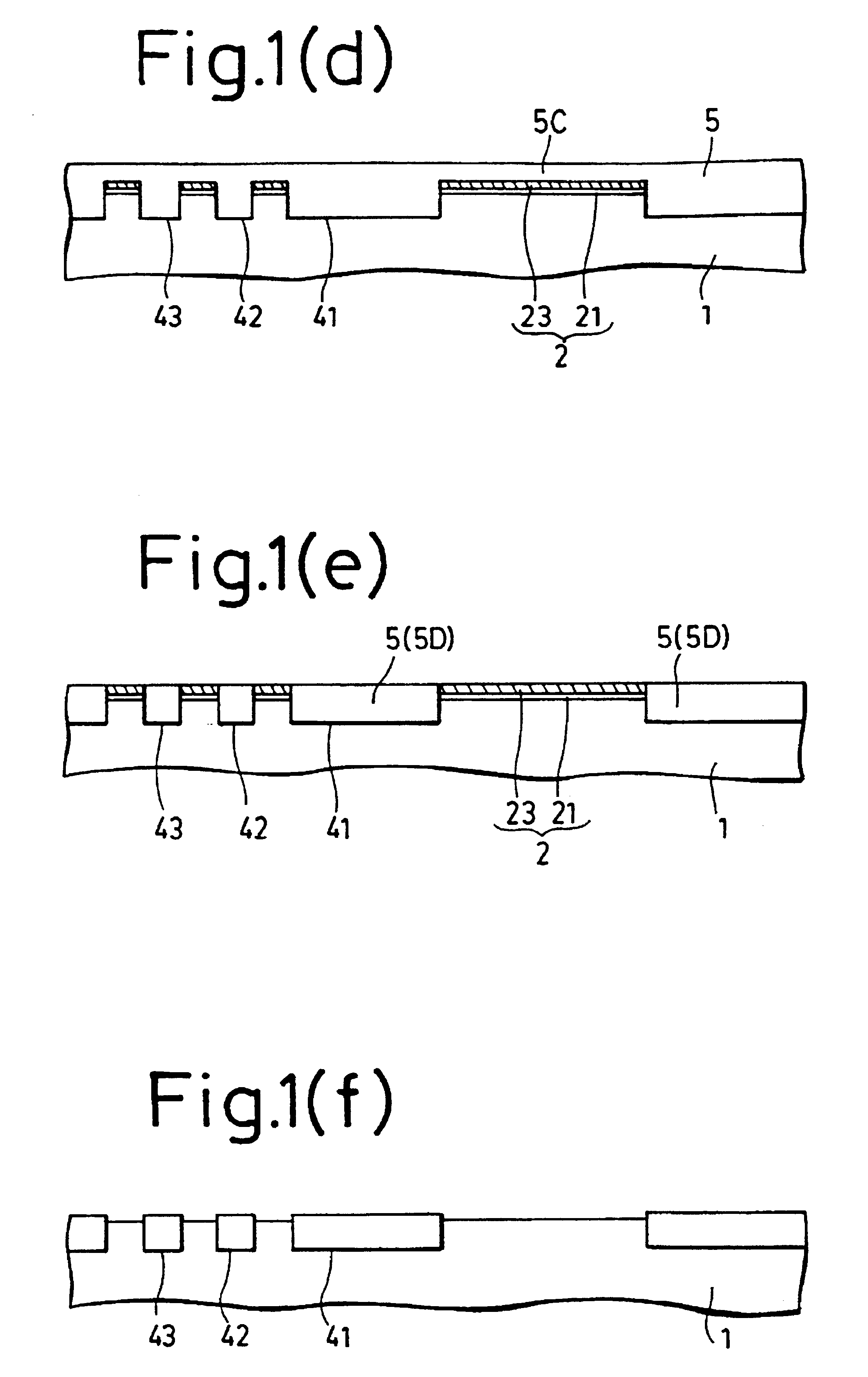

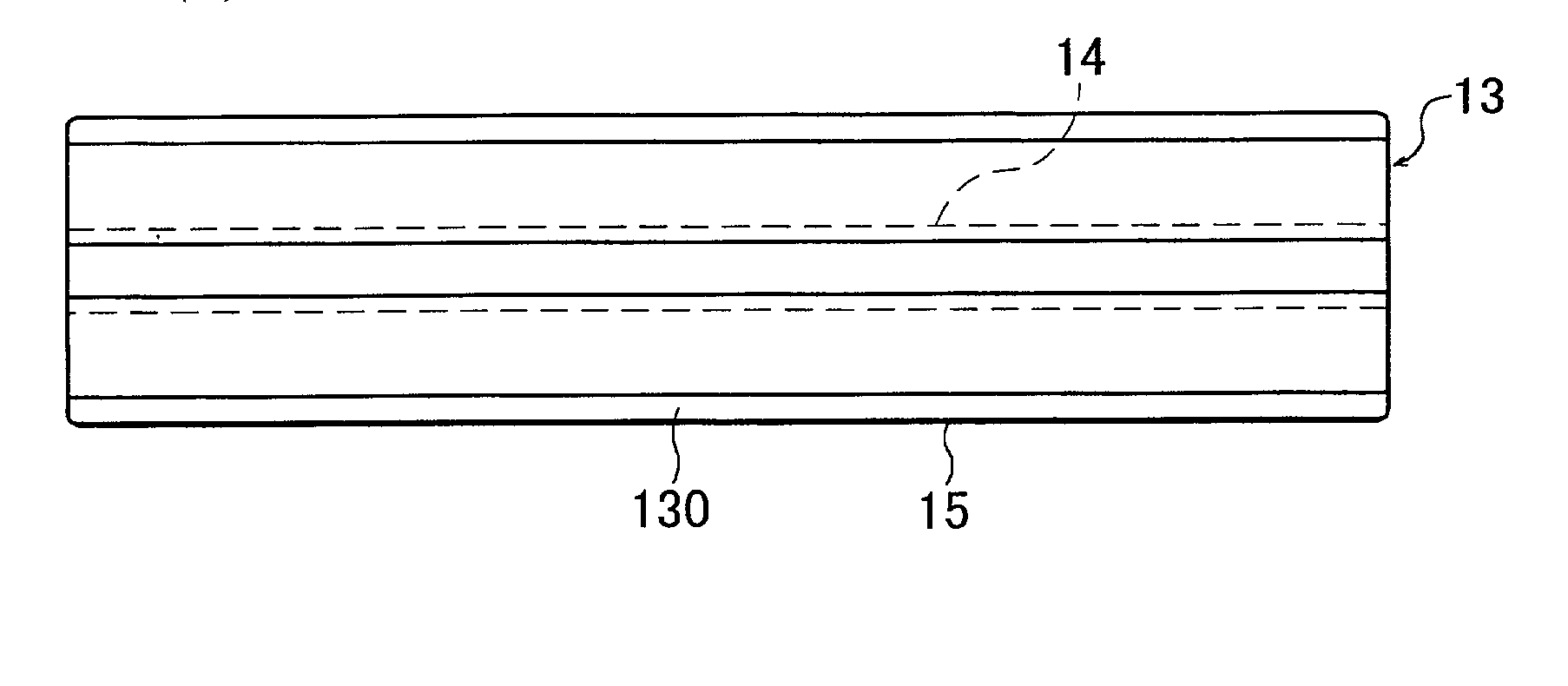

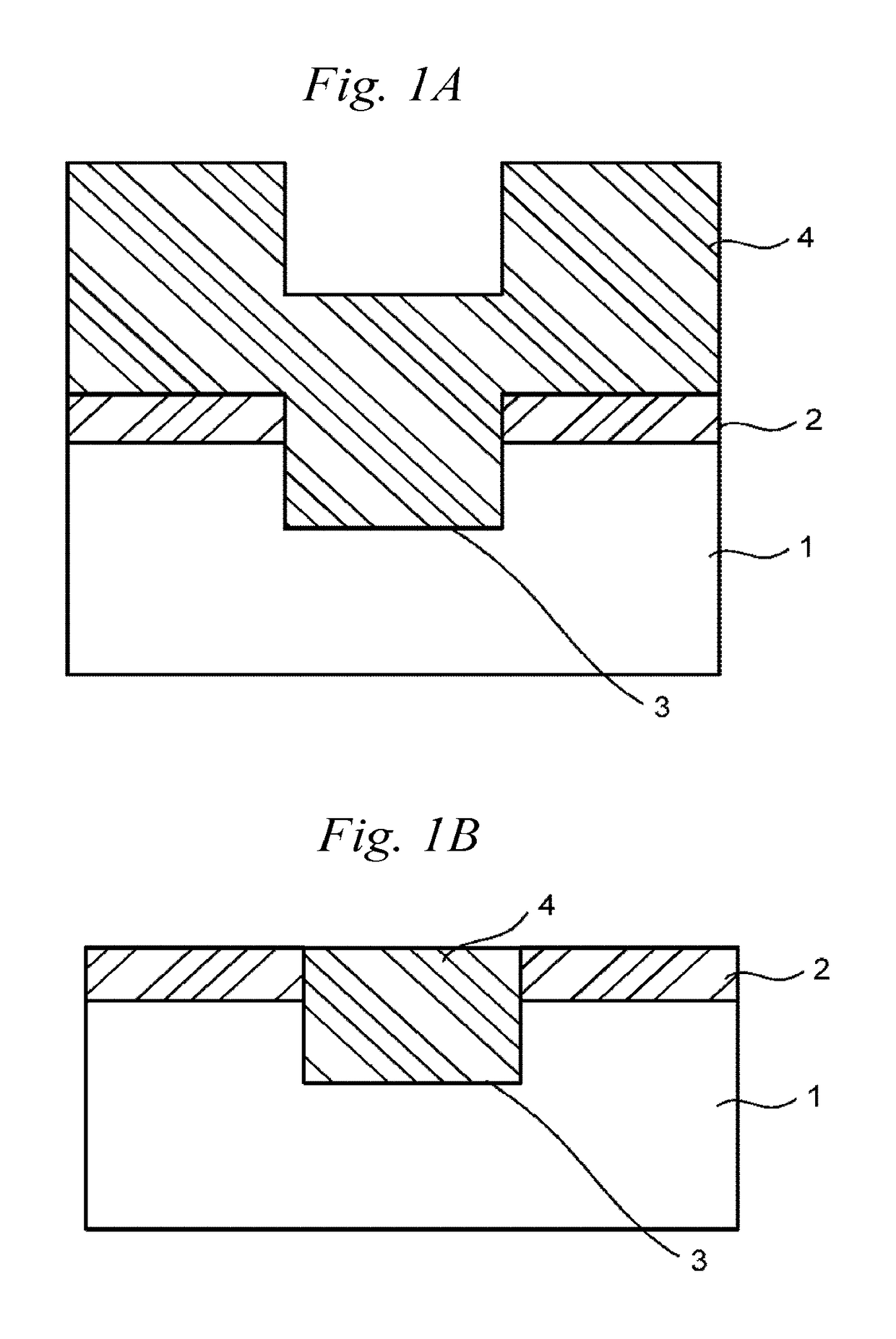

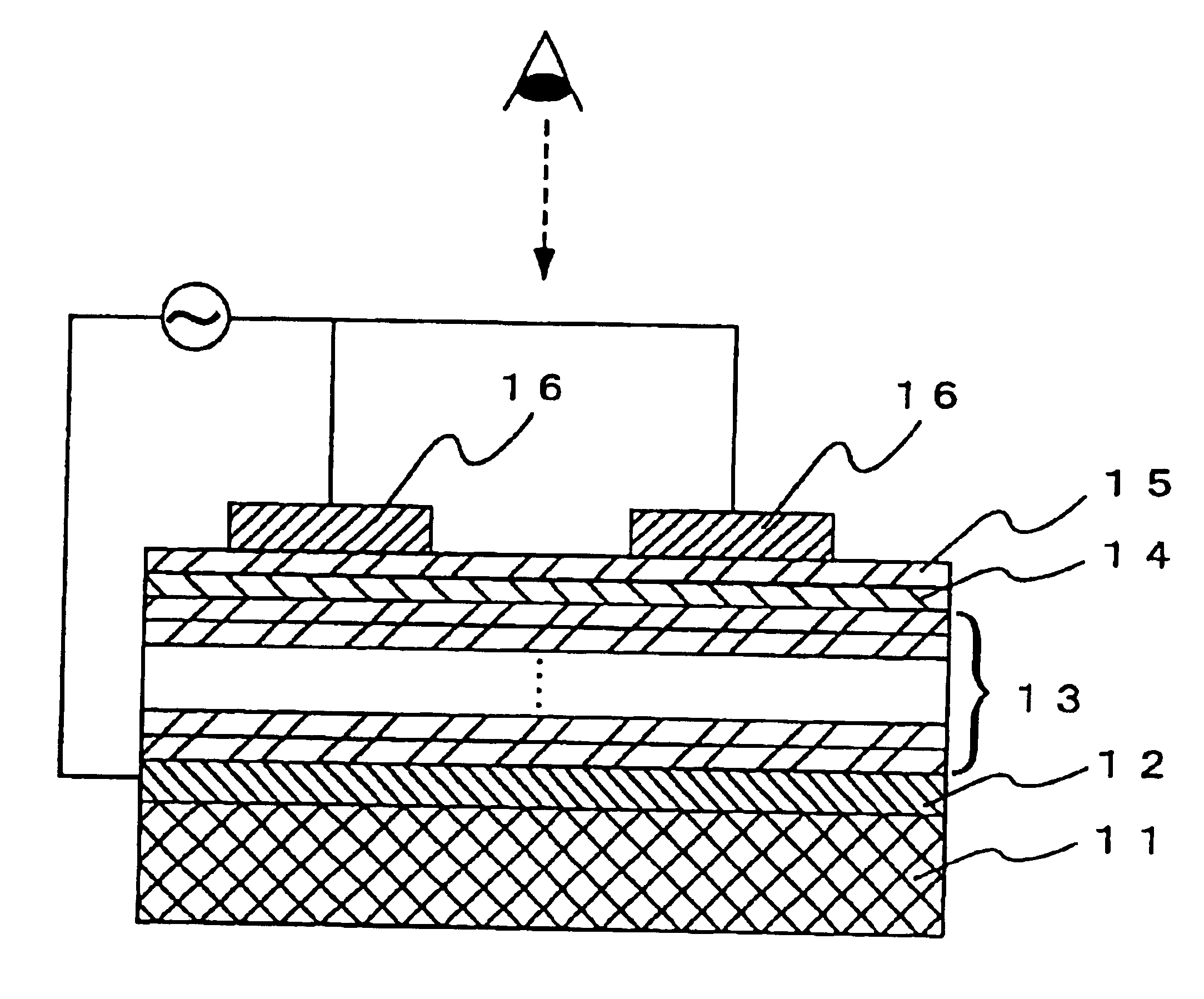

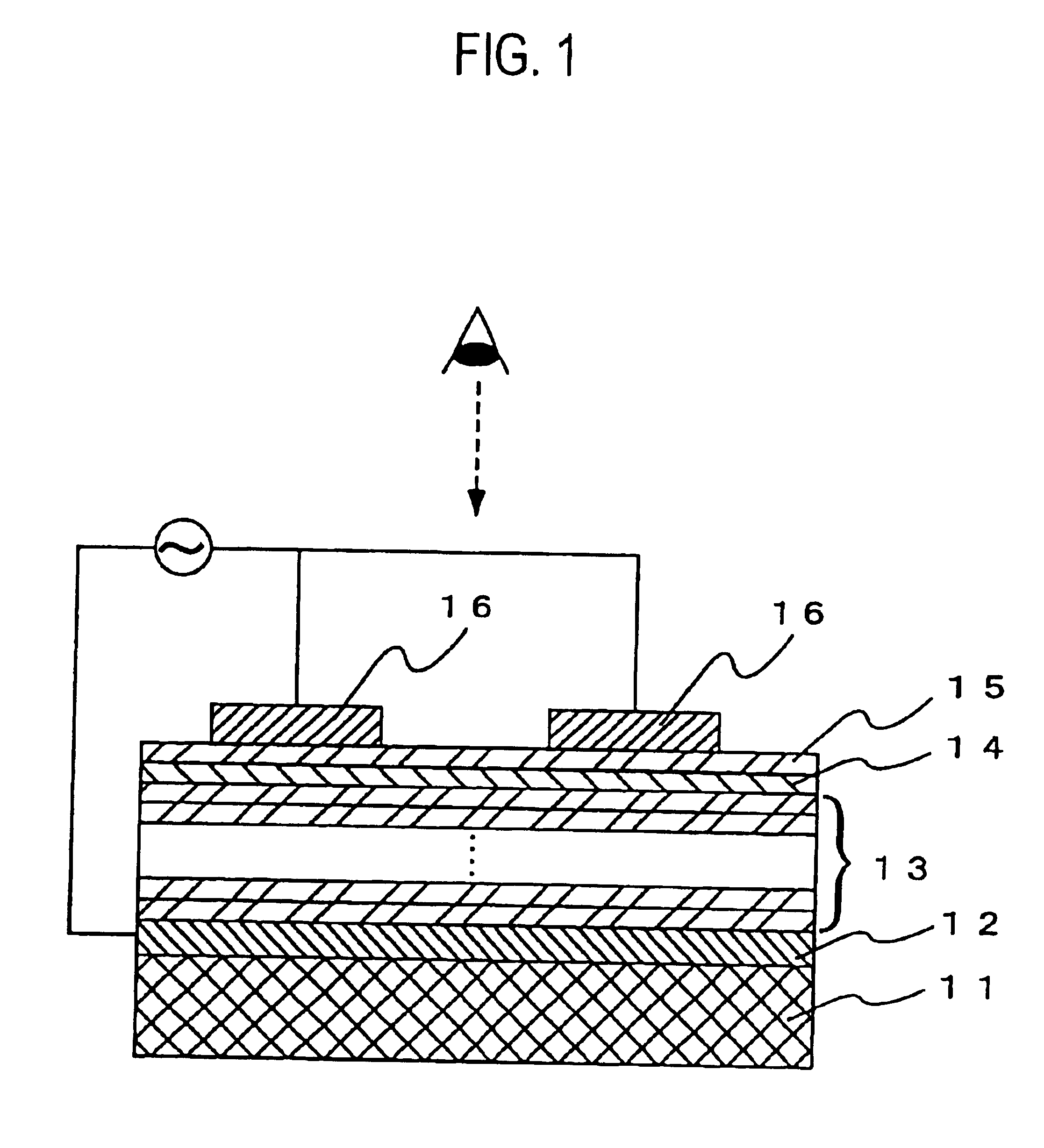

Thin-film el device, and its fabrication process

InactiveUS20020041147A1Easy to processImprove display qualityDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsDielectric layer

The invention has for its object to provide, without incurring any cost increase, a thin-film EL device in which a dielectric layer is corrected for non-flat portions to have a smooth surface, thereby ensuring enhanced display quality, and its fabrication process. This object is achieved by the provision of a thin-film EL device having at least a structure comprising an electrically insulating substrate (11), a lower electrode layer (12) stacked on the substrate according to a given pattern, a multilayer dielectric layer (13) formed thereon by repeating a solution coating-and-firing step plural times, and a light-emitting layer (14), a thin-film insulator layer (15) and a transparent electrode layer (16) stacked on the dielectric layer. The multilayer dielectric layer has a thickness of at least four times as large as a thickness of the electrode layer and 4 mum to 16 mum inclusive. The fabrication process is also provided.

Owner:IFIRE IP CORP

Method for attaching a scale to a carrier, a scale, and carrier having a scale

A scale is attached to a carrier by optically contacting. The optically contacting bonds are formed by raised surface regions of the scale set apart from each other. Additional measures, such as the provision of adhesive surfaces, provide a rigid and vibration-resistant joint.

Owner:DR JOHANNES HEIDENHAIN GMBH

Flexible radio frequency identification label and method for fabricating the same

InactiveUS7385512B2Good effectImprove protectionAntenna supports/mountingsLaminationEngineeringProtection layer

A flexible radio frequency identification label and a method for fabricating the same are proposed. A first flexible protection layer is attached to a second flexible protection layer to form a closed space for receiving a radio frequency identification circuit. By such arrangement, a good flexibility can be provided by the flexible protection layers, and the closed space also enables the radio frequency identification circuit to be protected and isolated from the moisture in the outside environment, such that the circuit can be prevented from being oxidized and the service life of the product can be extended.

Owner:IND TECH RES INST

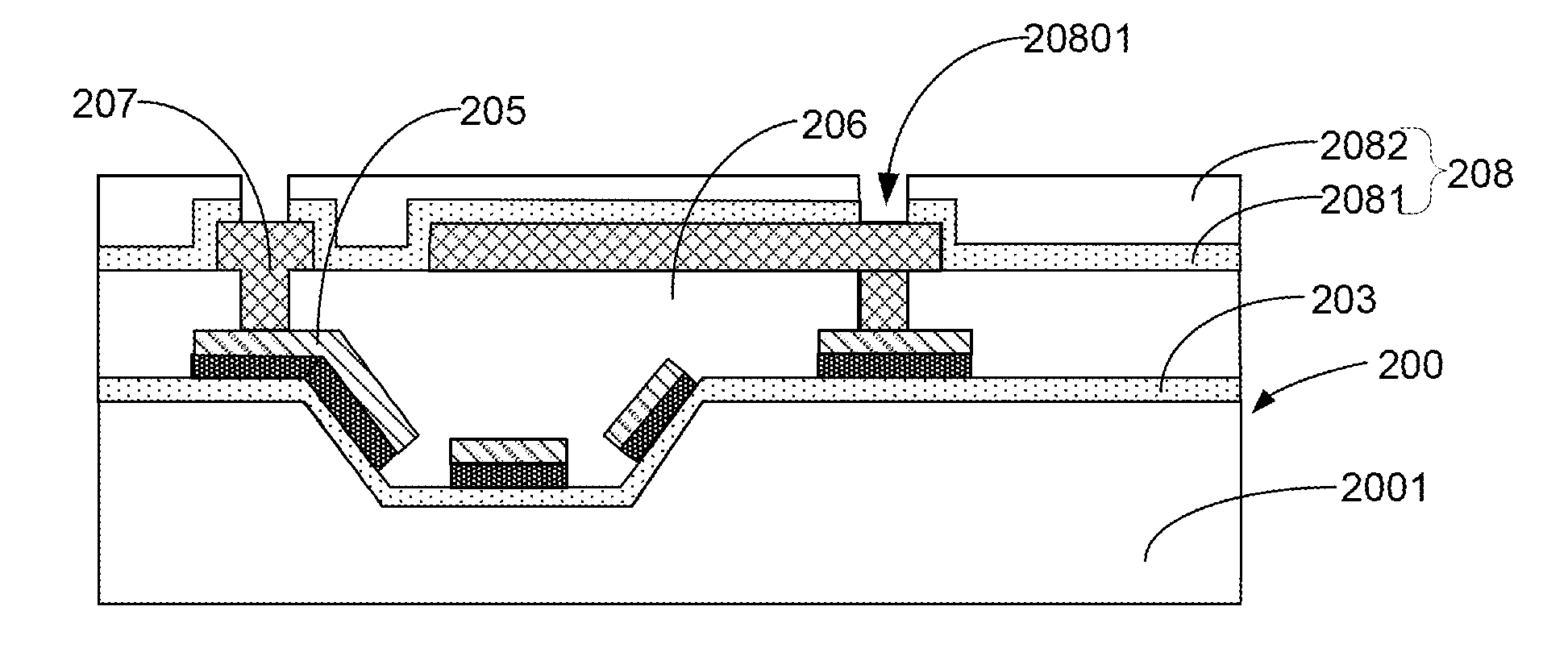

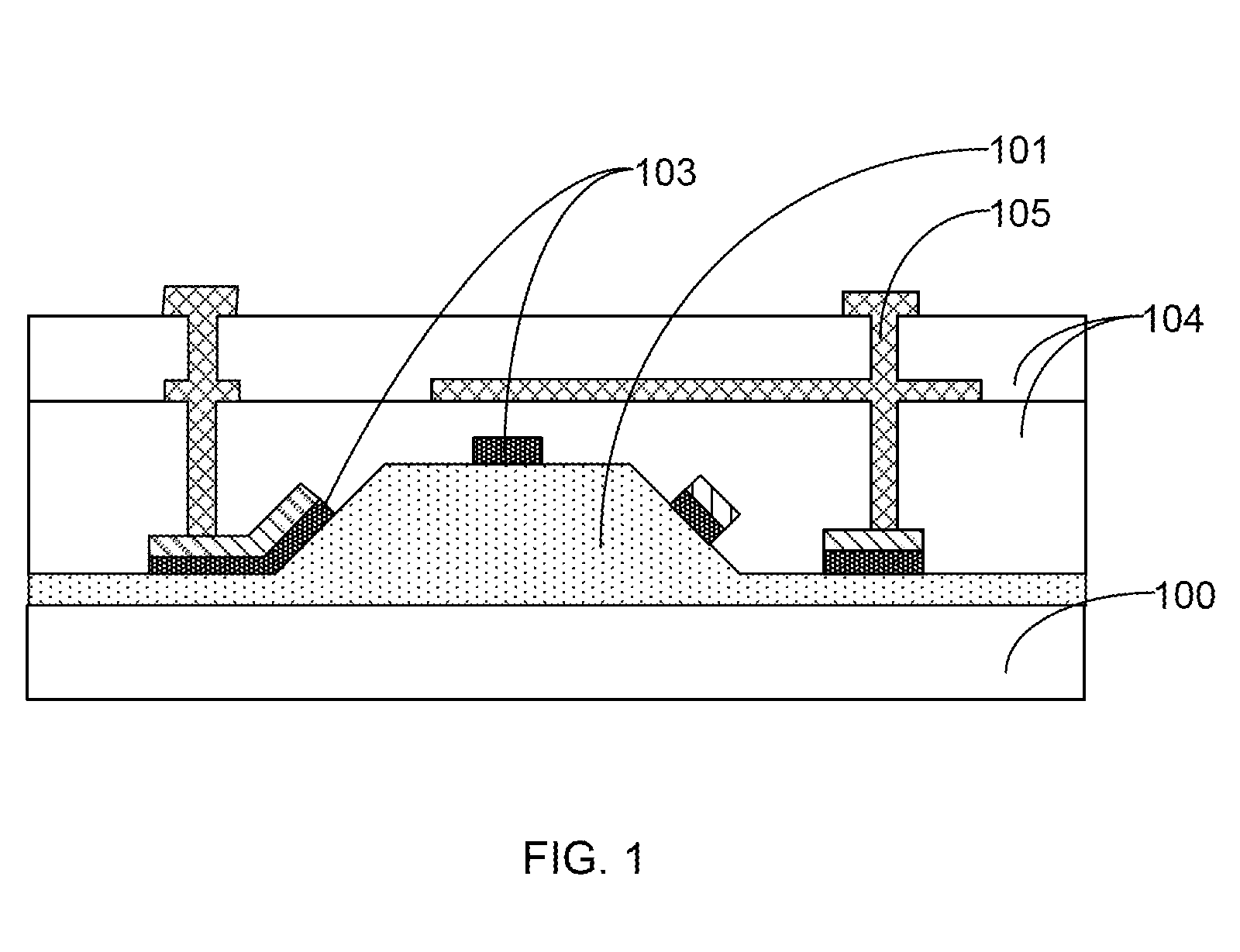

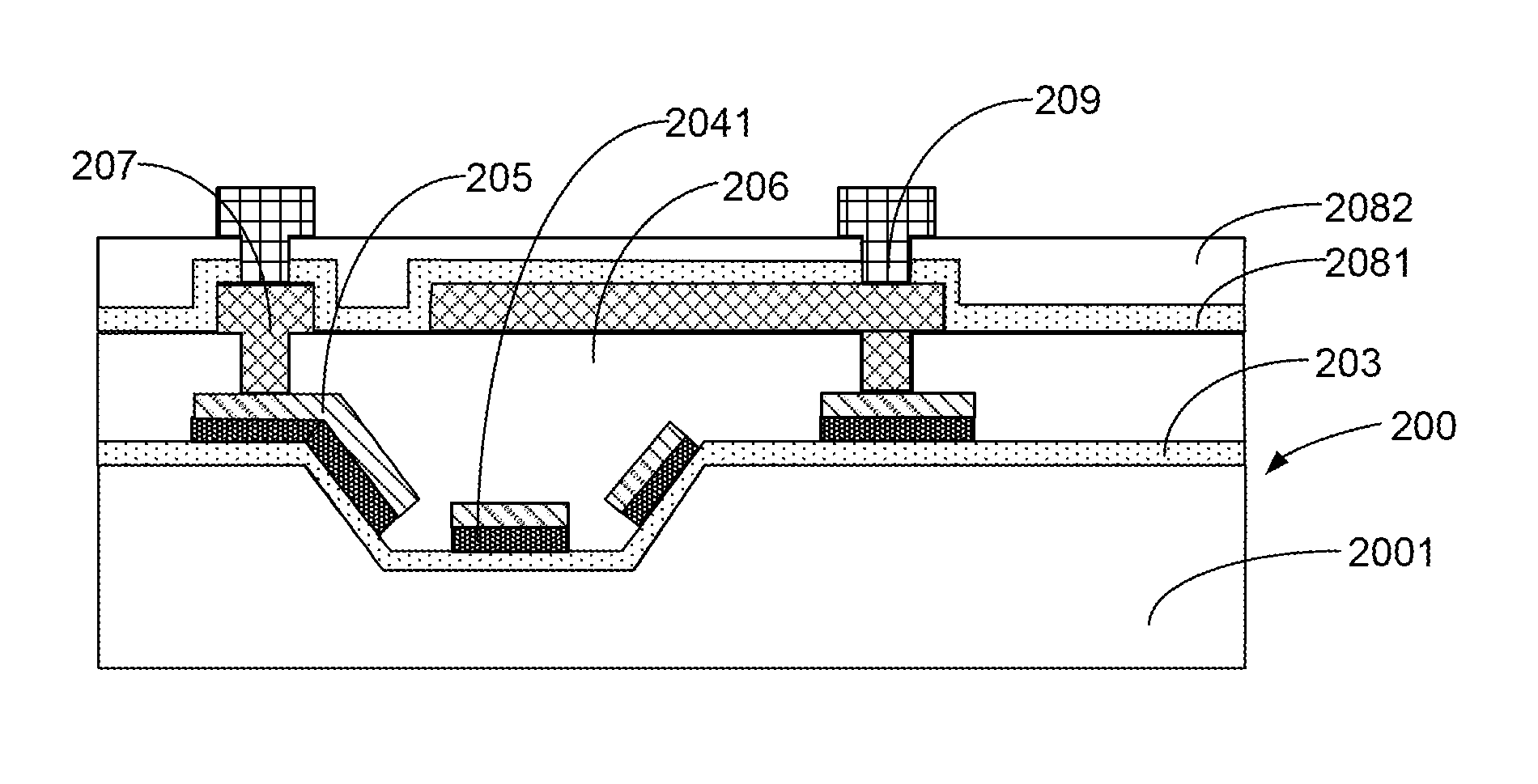

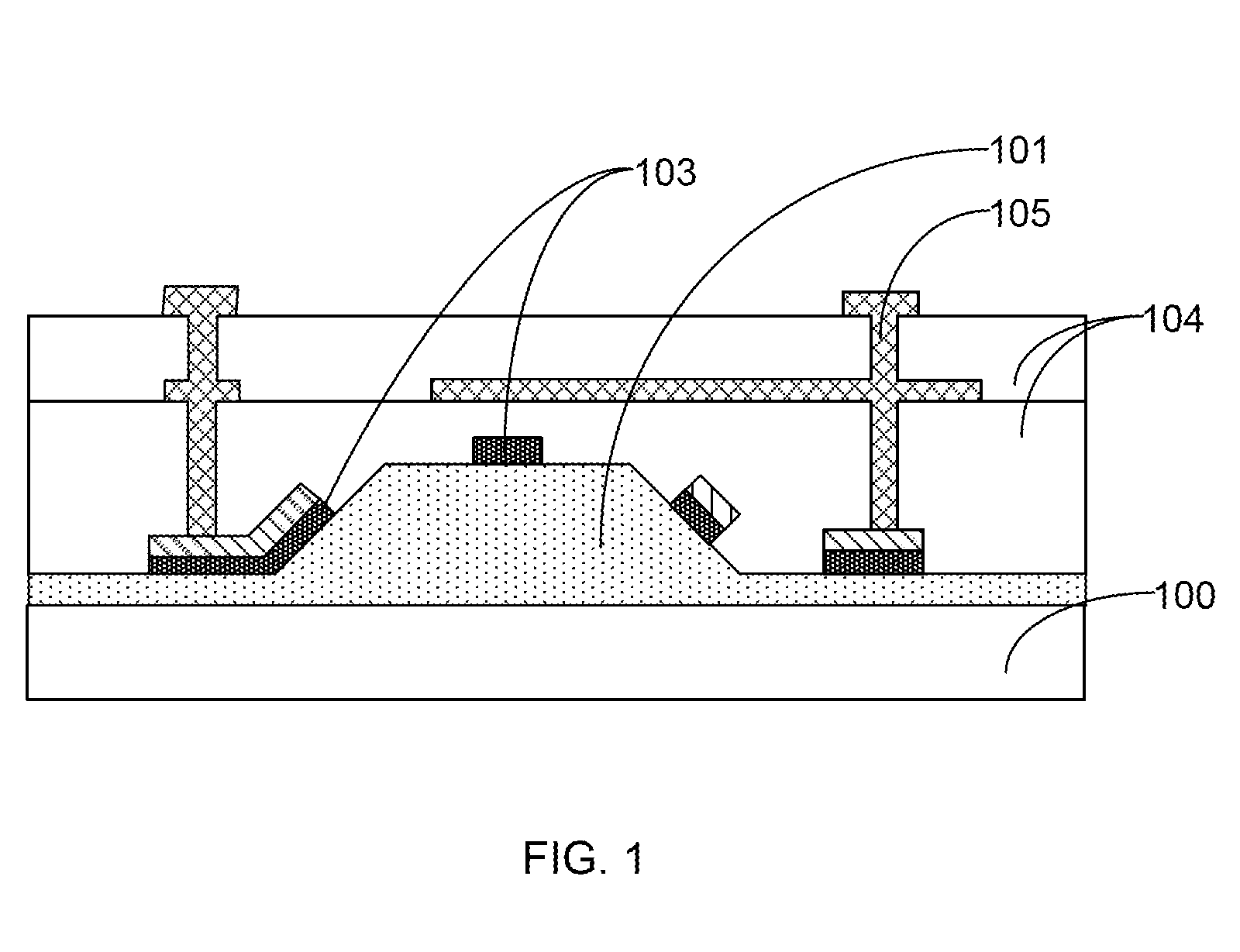

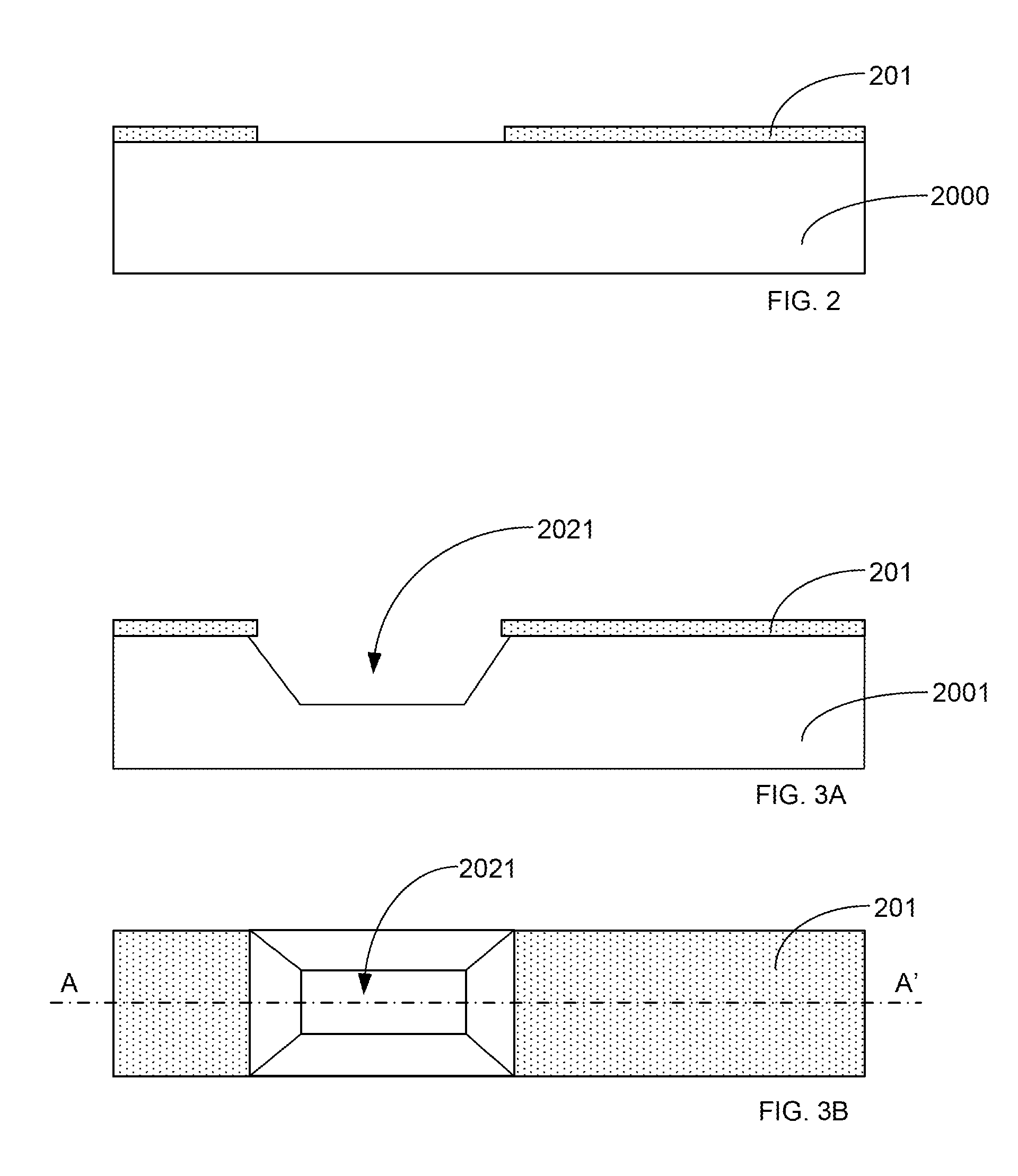

Magnetoresistive sensor, related manufacturing method, and related electronic device

ActiveUS20150349243A1Satisfactory controlSatisfactory surface flatnessMagnetic-field-controlled resistorsSolid-state devicesMagnetic reluctanceEngineering

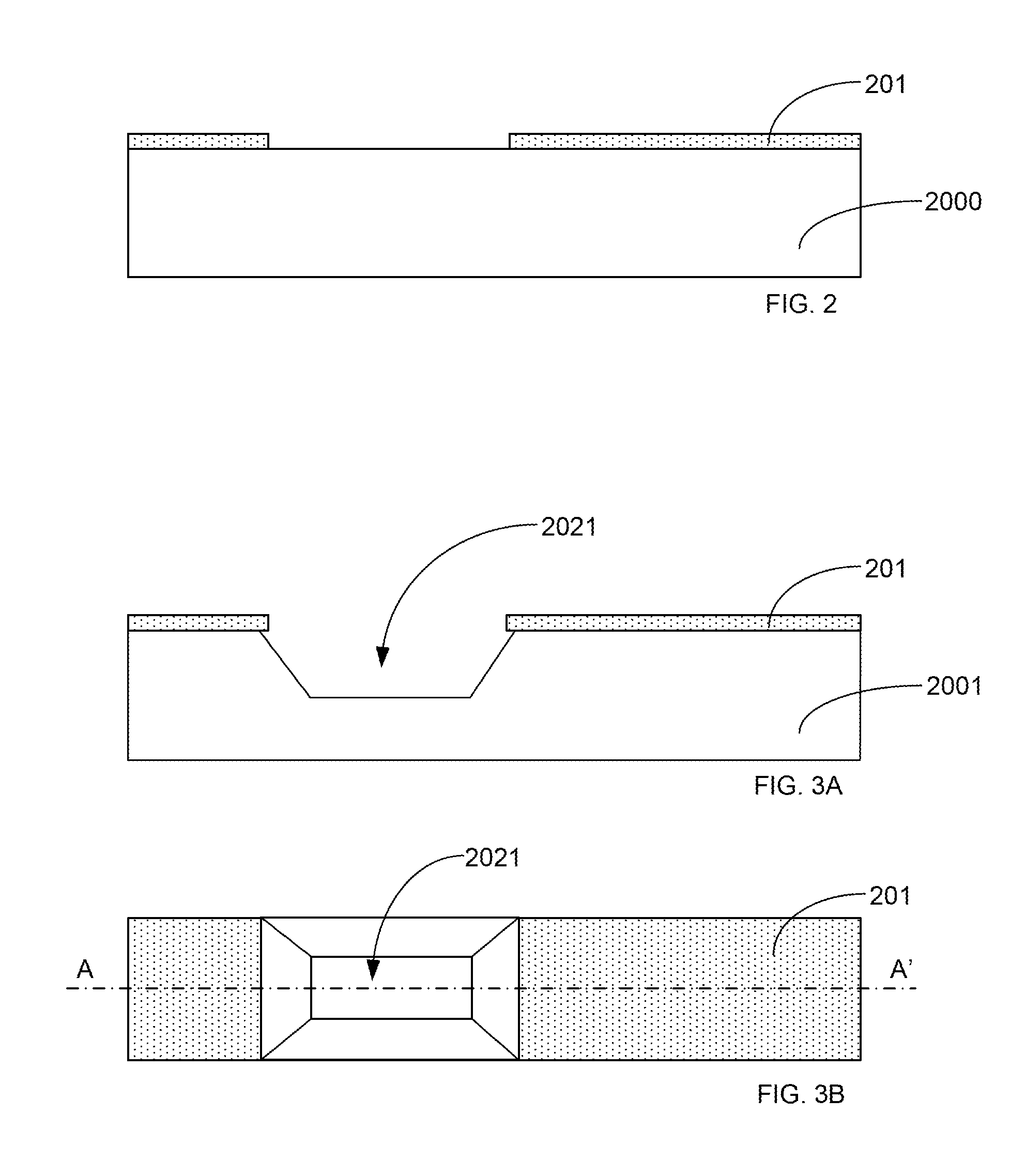

A method for manufacturing a magnetoresistive sensor may include the following steps: forming a trench structure in a substrate, wherein the step of forming the trench structure comprises performing a wet etching process on a substrate material member, wherein the trench structure has a first side, a second side, and a third side, wherein the second side is connected through the first side to the third side, wherein the second side is at a first obtuse angle with respect to a side of the substrate, and wherein the third side is at a second obtuse angle with respect to the side of the substrate; forming a first magnetic element on the first side of the trench structure; forming a second magnetic element on the second side of the trench structure; and forming a third magnetic element on the third side of the trench structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

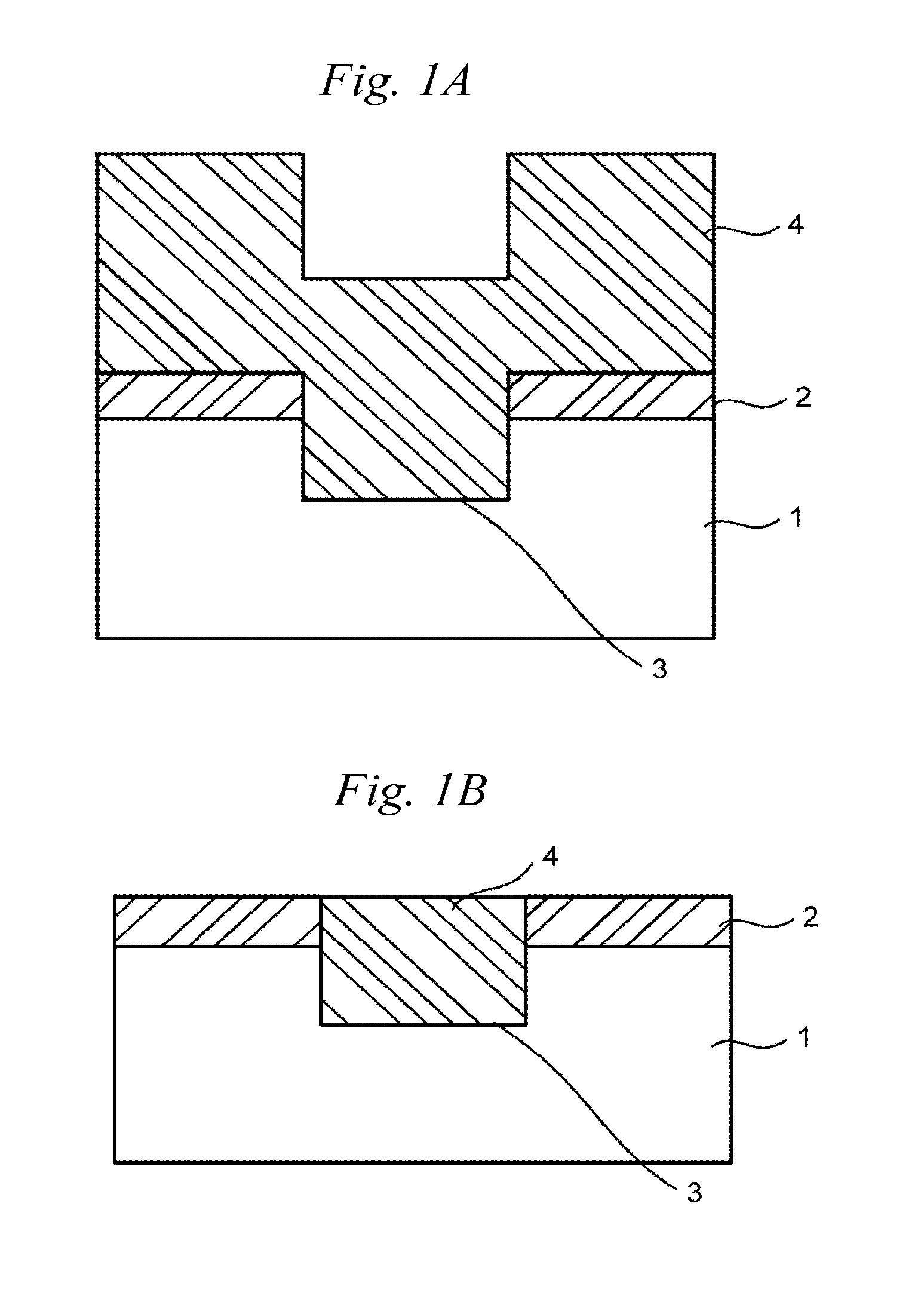

Method of forming trench isolation having polishing step and method of manufacturing semiconductor device

InactiveUSRE38363E1Satisfactory flattened shapeEasy to disassembleSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A method of forming trench isolation including a burying step of burying trenches by a deposition means for conducting etching and deposition simultaneously and a polishing step of flattening a burying material by polishing is conducted by disposing an isotropic etching step, a multi-layered etching stopper and a protrusion unifying structure. Polishing can be attained with satisfactory flatness uniformly or with no polishing residue even in a portion to be polished in which the etching stopper layer is distributed unevenly. The method can be applied to manufacture of a semiconductor device or the like.

Owner:SONY CORP

Optical unit and image forming apparatus

InactiveUS7830545B2Improve rigiditySatisfy flatnessDigitally marking record carriersInking apparatusImage formationEngineering

At least one exemplary embodiment is directed to an optical unit adapted to irradiate image exposure light to an image carrier comprises a frame containing optical parts arranged therein and having an opening, and a cover adapted to cover the opening. The cover can be fixed by fixing members to the frame at three points in a first plane including the opening. The cover can further be fixed by fixing members to the frame at a second plane positioned on the frame and being adjacent to the first plane and at a third plane positioned on the frame and being not parallel to the second plane. Thus, an optical unit can be obtained which has high rigidity while, when the cover is attached to the opening, maintaining satisfactory flatness of the cover in a plane including the opening.

Owner:CANON KK

Magnetoresistive sensor, related manufacturing method, and related electronic device

ActiveUS9450178B2Satisfactory controlSatisfy flatnessMagnetic-field-controlled resistorsSolid-state devicesEngineeringElectron

A method for manufacturing a magnetoresistive sensor may include the following steps: forming a trench structure in a substrate, wherein the step of forming the trench structure comprises performing a wet etching process on a substrate material member, wherein the trench structure has a first side, a second side, and a third side, wherein the second side is connected through the first side to the third side, wherein the second side is at a first obtuse angle with respect to a side of the substrate, and wherein the third side is at a second obtuse angle with respect to the side of the substrate; forming a first magnetic element on the first side of the trench structure; forming a second magnetic element on the second side of the trench structure; and forming a third magnetic element on the third side of the trench structure.

Owner:SEMICON MFG INT (SHANGHAI) CORP

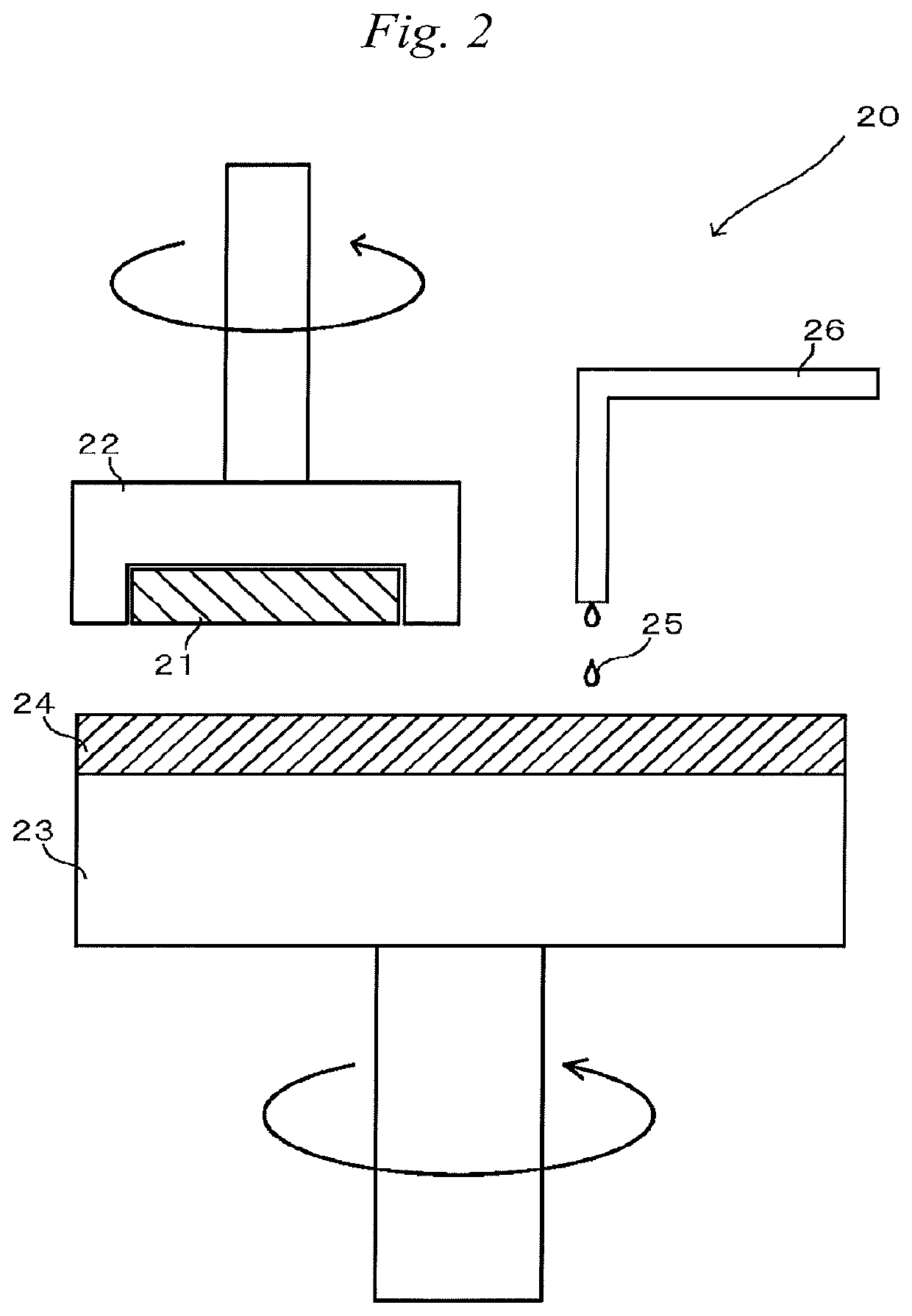

Polishing agent, polishing method and method for manufacturing semiconductor integrated circuit device

ActiveUS20160237316A1Low removal rateHigh removal rateSemiconductor/solid-state device manufacturingPolishing compositions with abrasivesOrganic acidCerium(IV) oxide

The present invention relates to a polishing agent including: cerium oxide particles; a water-soluble polyamine; potassium hydroxide; at least one selected from an organic acid and a salt thereof; and water, in which the polishing agent has a pH of 10 or more, a polishing method using the polishing agent, and a method for manufacturing a semiconductor integrated circuit device.

Owner:ASAHI GLASS CO LTD

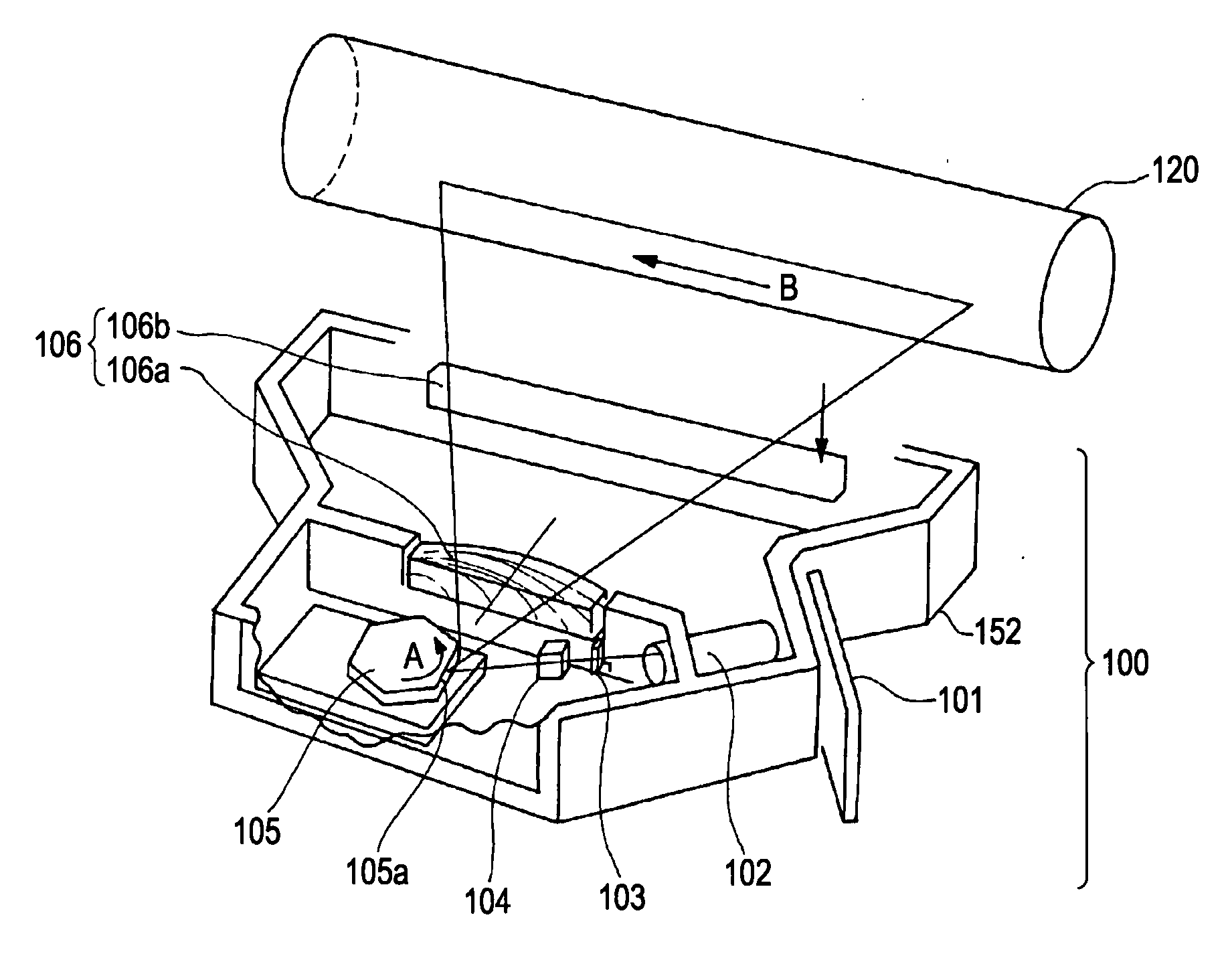

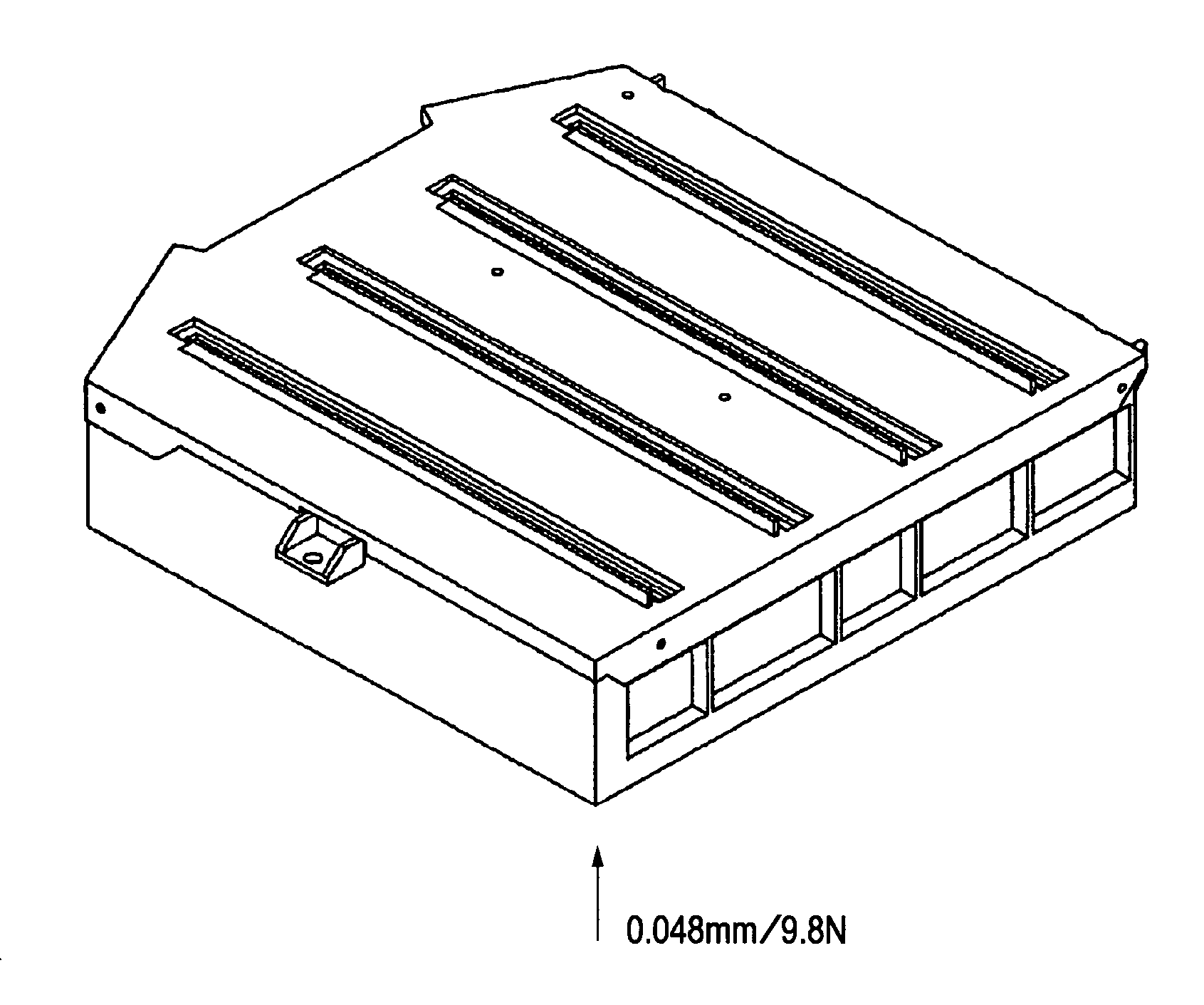

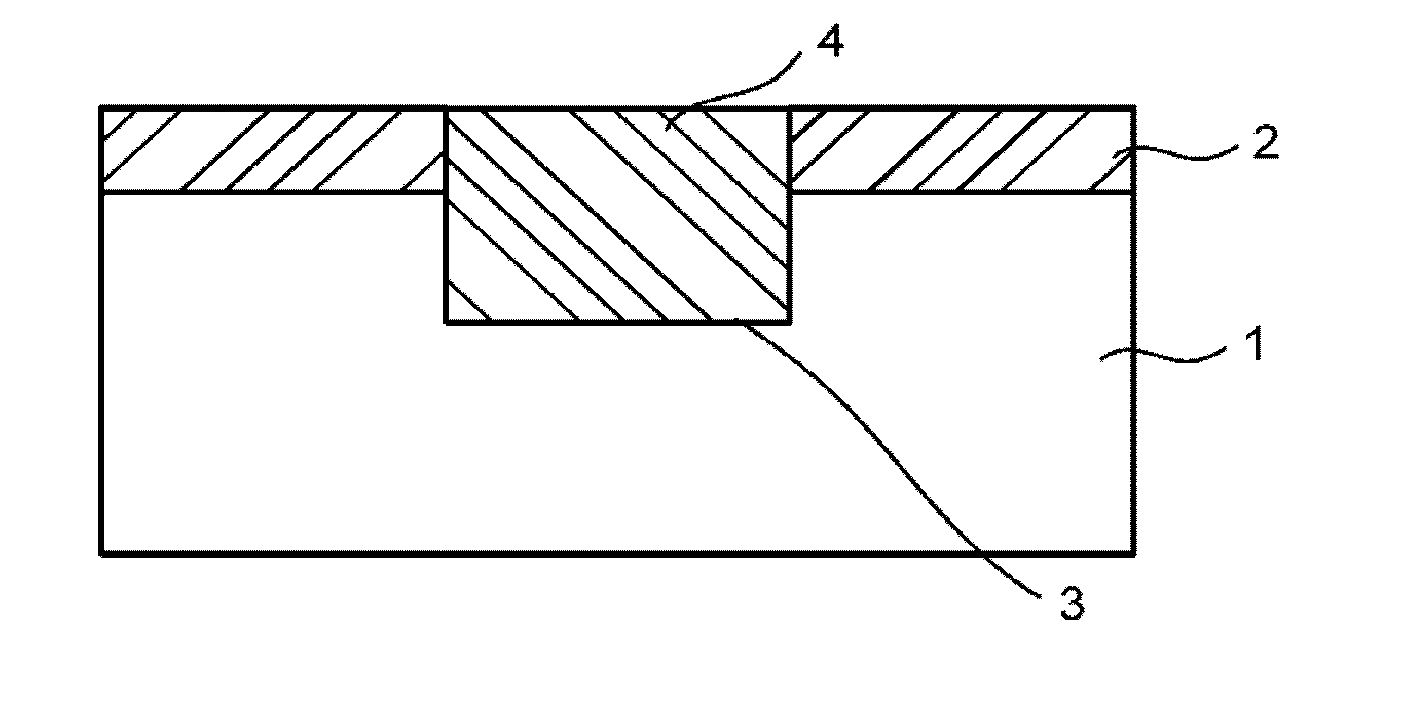

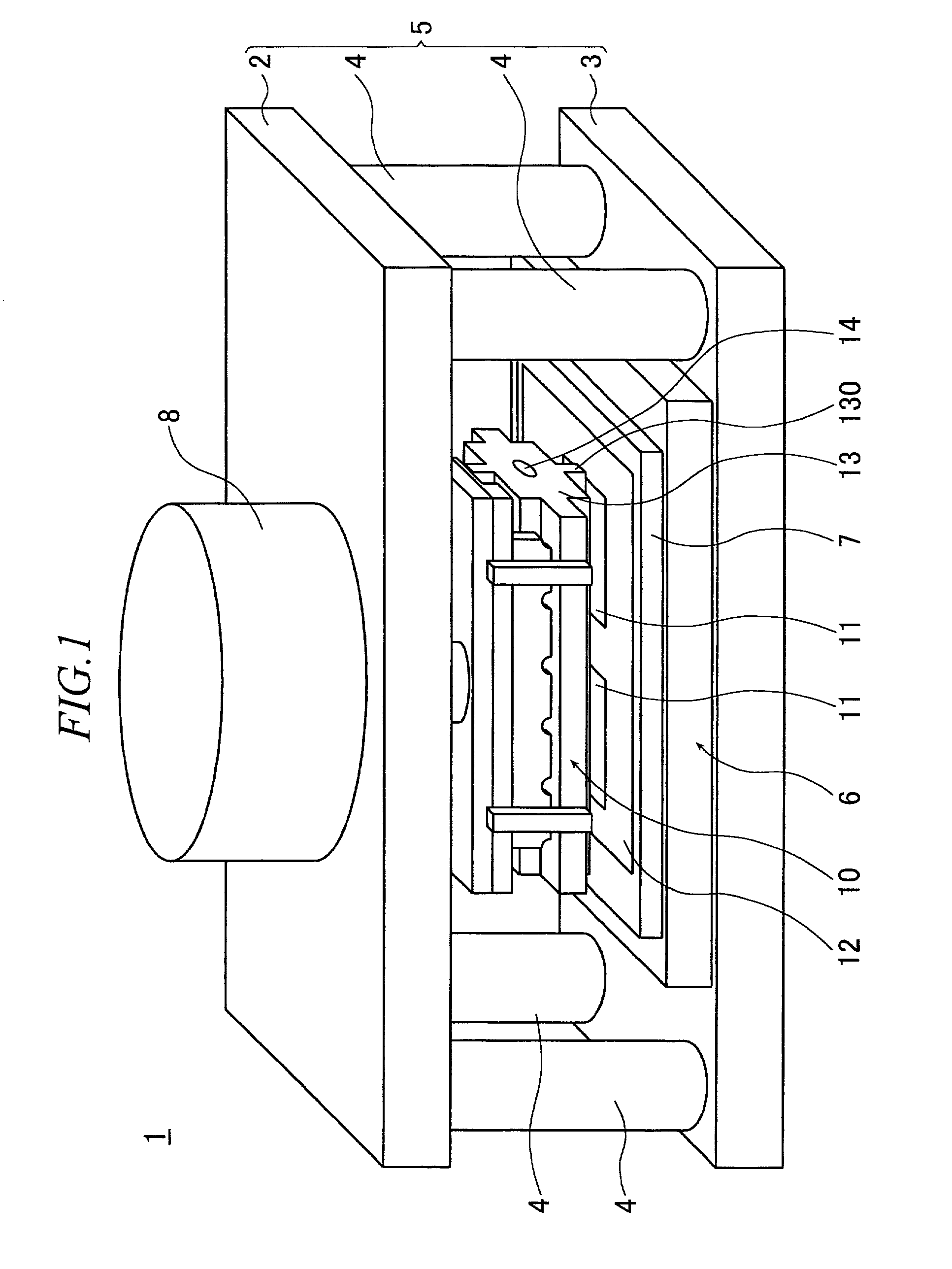

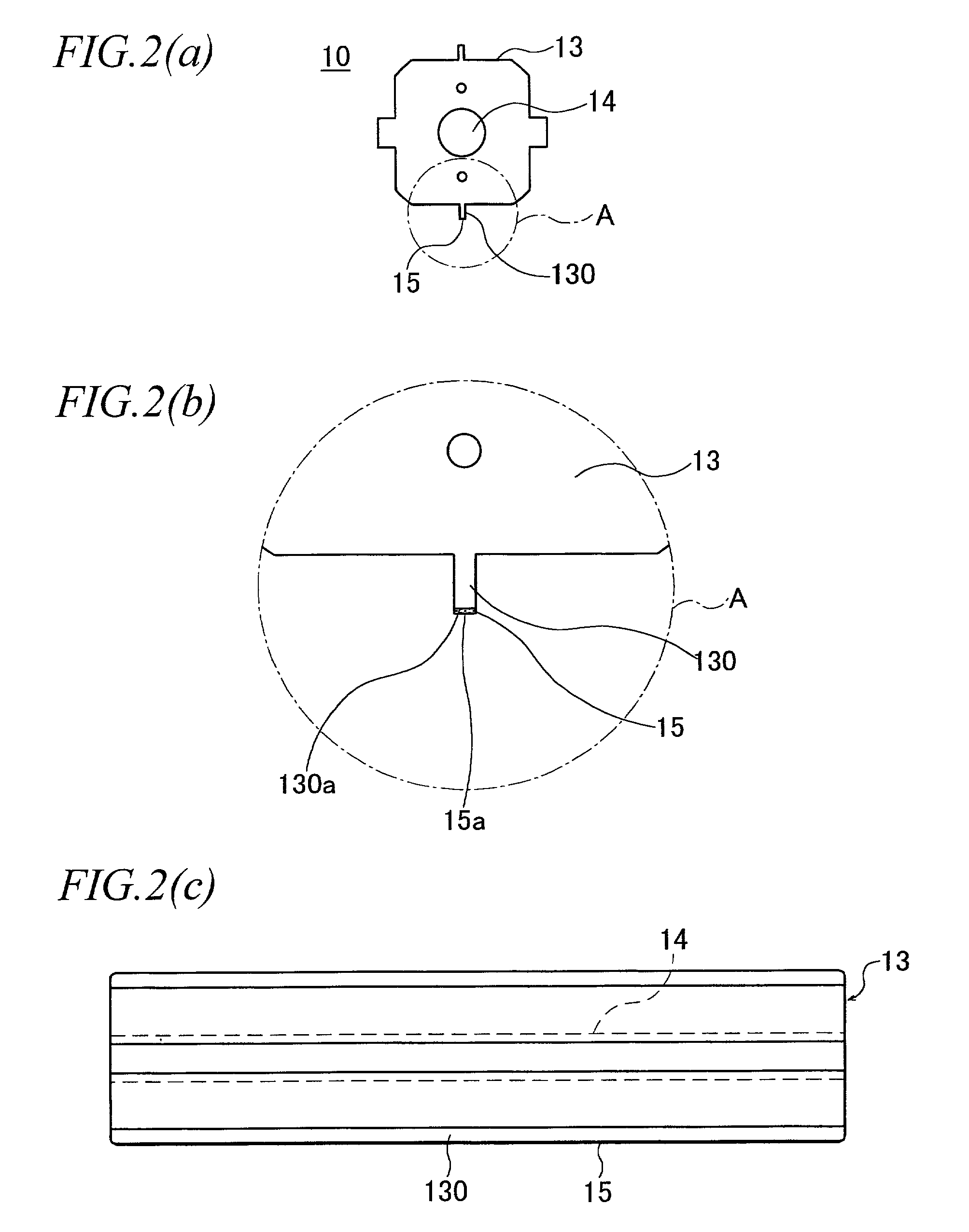

Thermocompression bonding device and bonding head thereof

InactiveUS20020124933A1Increase productionSatisfy flatnessPrinted circuit assemblingSemiconductor/solid-state device manufacturingThermocompression bondingHot pressing

The thermocompression-bonding head (10) of the thermocompression-bonding apparatus (1) according to the present invention has a ceramic layer (15) having a predetermined thickness on the contact part (130a) of the pressing member (130) of the head body (13). The difference between the thermal expansion coefficient of the head body (13) and the thermal expansion coefficient of the ceramic layer (15) is within the range of ±30% at a temperature of 400° C. or less.

Owner:NAGAOKA TSUTOMU

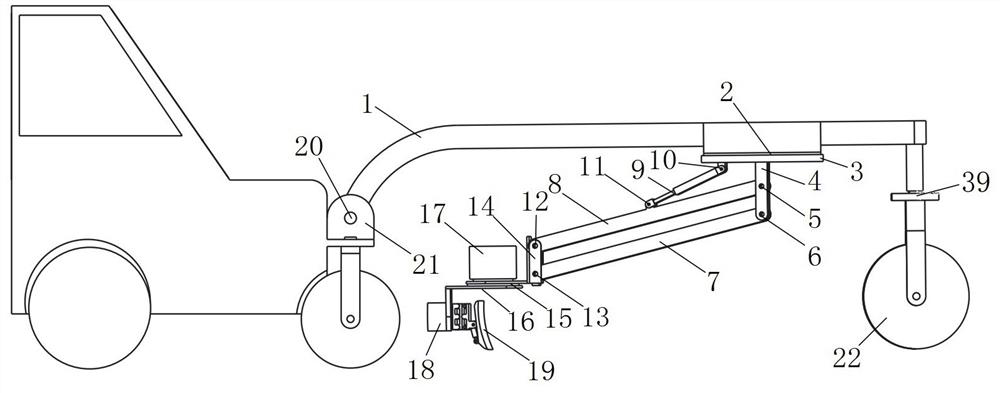

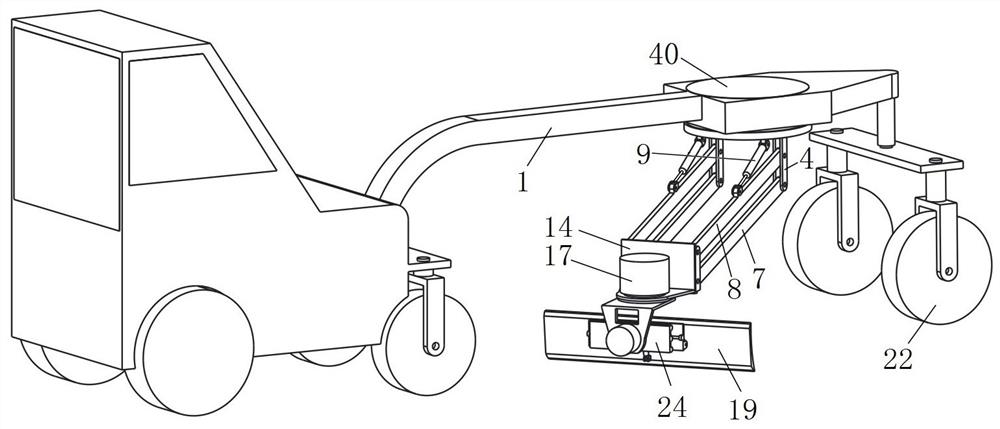

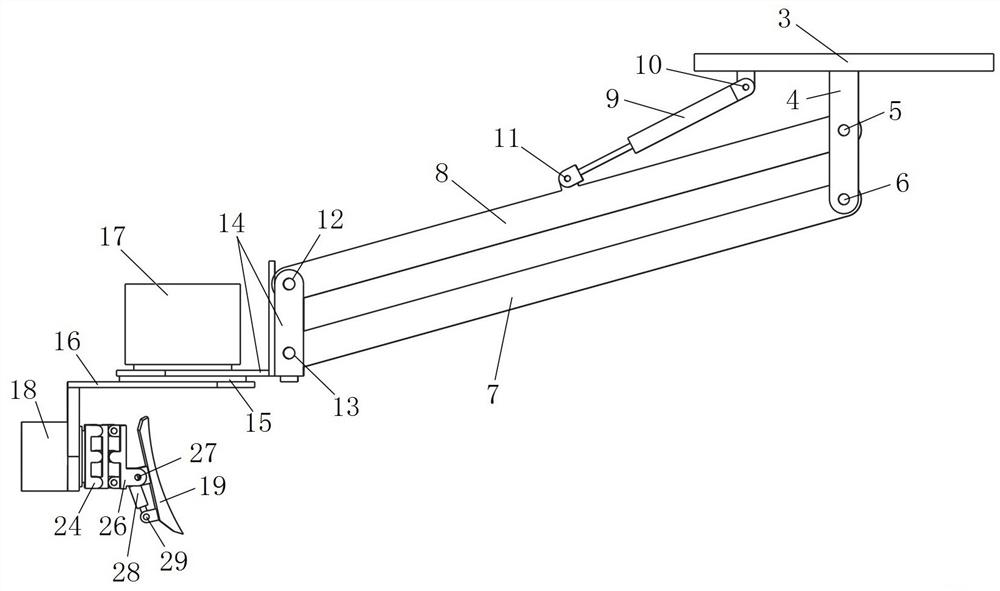

Land leveler scraping working device based on rotary translation mechanism

PendingCN113309159AEasy to operate and controlPrecise Draw ControlMechanical machines/dredgersMachineIndustrial engineering

The invention discloses a land leveler scraping working device based on a rotary translation mechanism. The land leveler scraping working device comprises a machine frame, a first rotary table, a translation mechanism, a second rotary table and a scraper knife mechanism, the first rotary table is installed on the machine frame through a rotary pair and can rotate relative to the machine frame, the translation mechanism is a planar double-connecting-rod four-rod mechanism and forms a parallelogram structure, the translation mechanism comprises a longitudinal beam, a first connecting rod, a second connecting rod and a movable platform, the longitudinal beam is fixedly installed on the first rotary table, the two ends of the first connecting rod and the second connecting rod are connected with the longitudinal beam and the movable platform, and the movable platform can translate relative to the first rotary table under the driving action of a first linear driver; the second rotary table is mounted on the movable platform through a revolute pair and can rotate relative to the movable platform; the scraper knife mechanism can realize lateral movement and rotation of a scraper knife. According to the land leveler scraping working device, six-degree-of-freedom movement of the scraper knife can be achieved during operation, and compared with an existing land leveler, the land leveler scraping working device is good in flexibility, low in movement coupling degree, free of spherical hinges and better in rigidity and stability.

Owner:SHANDONG JIAOTONG UNIV

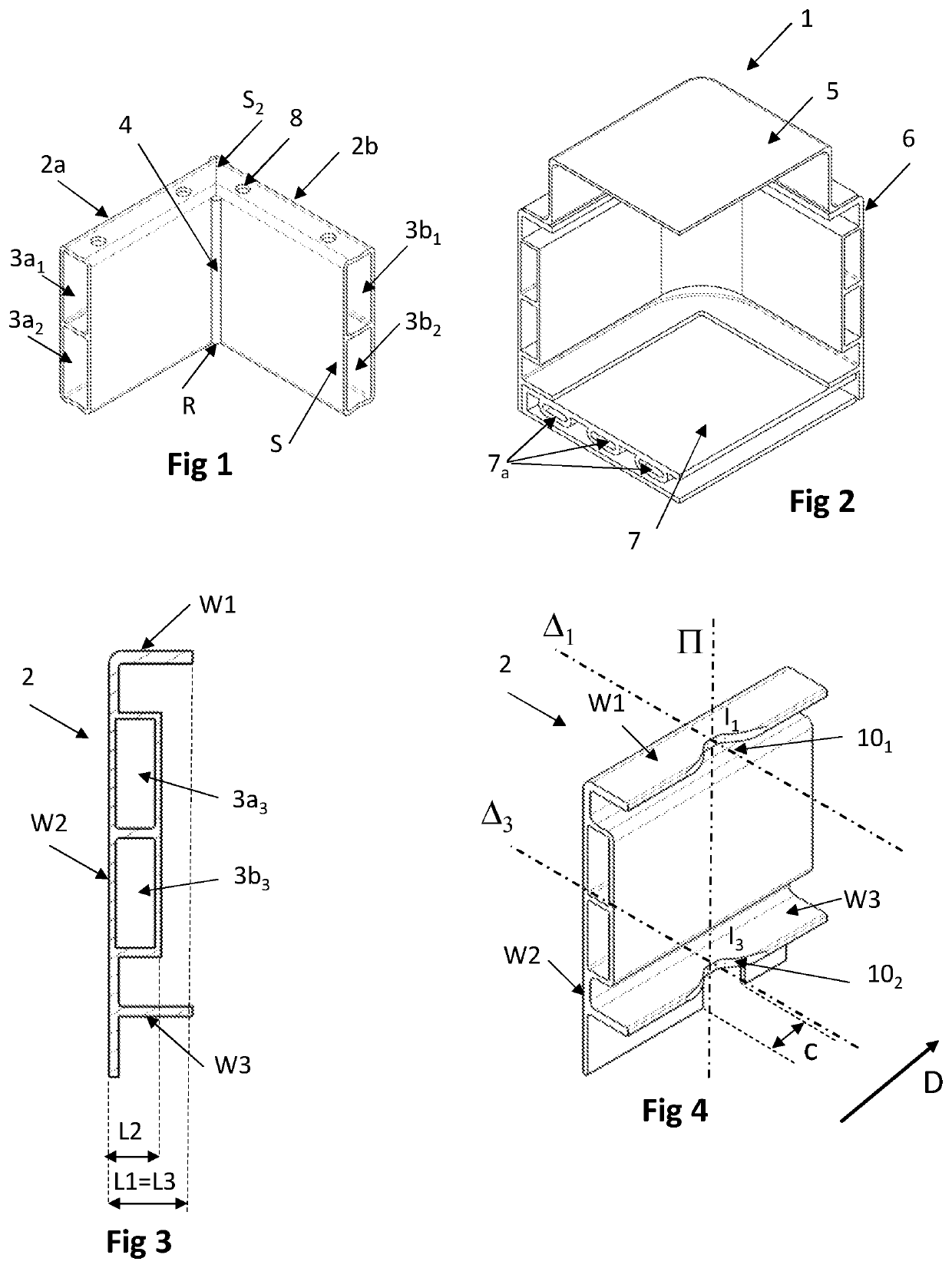

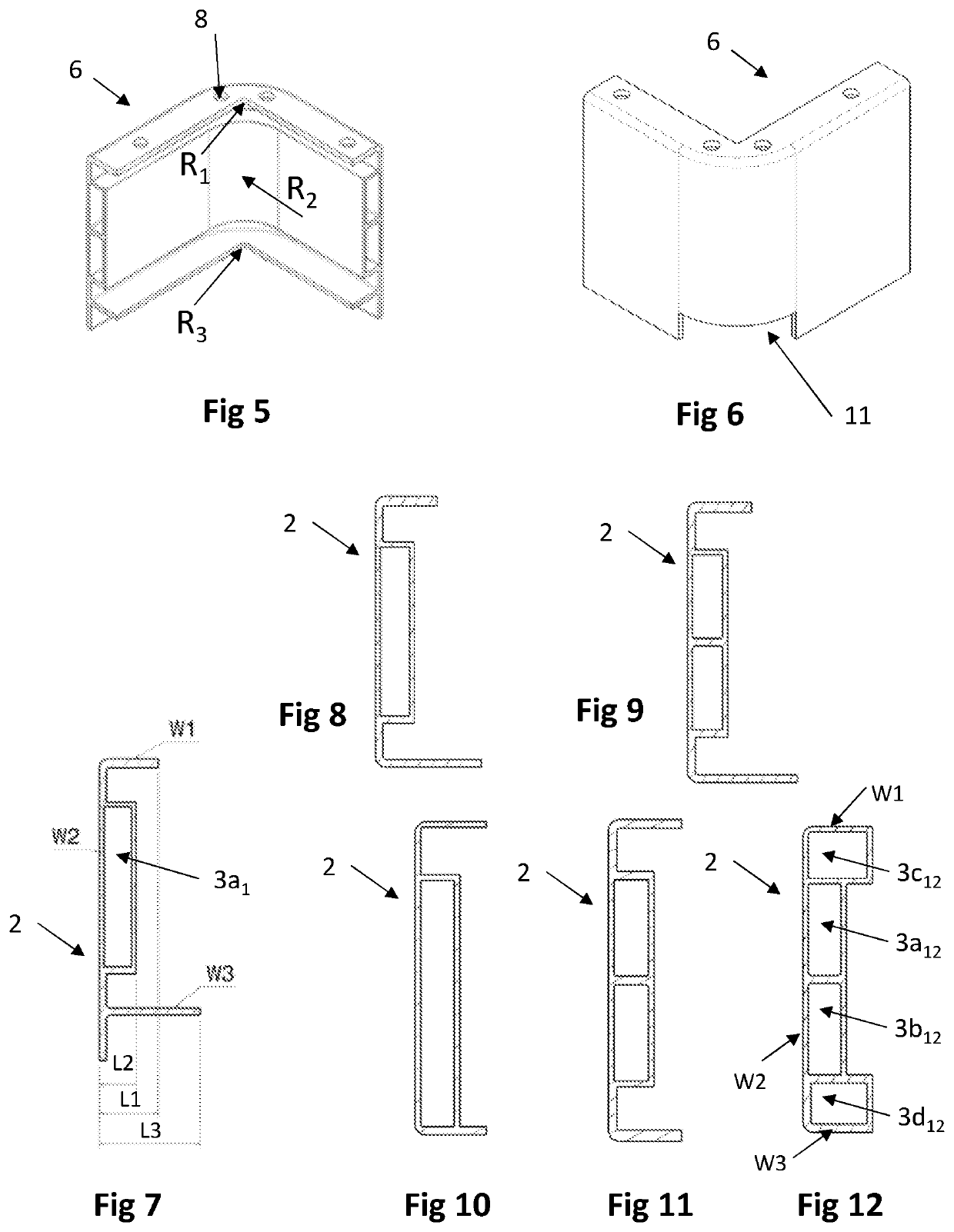

Battery box for electric vehicles

ActiveUS20200130516A1Satisfy flatnessOptimize volumeElectric propulsion mountingPropulsion using engine-driven generatorsElectric-vehicle batteryElectrical battery

A battery box for electric or hybrid motor vehicles, comprising a peripheral frame which has a generally convex polygonal shape, a bottom part and a top cover; the bottom part being joined to a lower surface of the peripheral frame, said peripheral frame comprising at least an aluminum extruded element, bent in a single direction in at least a position along the extrusion longitudinal direction according an angle wherein said bent aluminum extruded element at the said position presents at least two different inner radii of curvatures.

Owner:CONSTELLIUM SINGEN

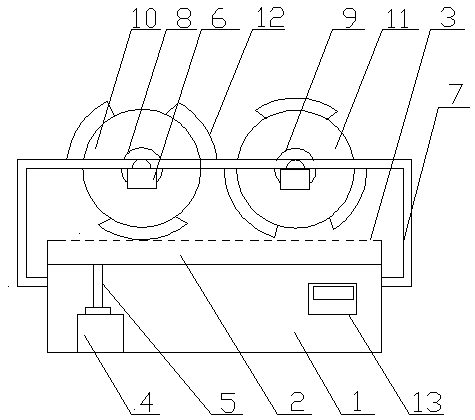

Carton cutting device

InactiveCN109049834AEffective movementEffective placement movePaper-makingBox making operationsCartonElectric machinery

The invention provides a carton cutting device. The carton cutting device includes a base, a cutting table is arranged on the base, air intake small holes distributed evenly are formed in the surfaceof the cutting table, a vacuum pump is arranged in the base, a PVC tube is connected with the vacuum pump and connected to the inner cavity of the cutting table, a bracket is arranged at the upper endof the base, and symmetrical motor supporting brackets are arranged on the bracket; and a first motor and a second motor are arranged on the motor supporting brackets respectively, the output end ofthe first motor is connected with a left rolling roller, the output end of the second motor is connected with a right rolling roller, cutting blades are arranged on the left rolling roller and the right rolling roller, a control end is arranged on the front end face of the base, the first motor, the second motor, the vacuum pump are electrically connected with the control end, the cutting blades on the left rolling roller and the right rolling roller are arrayed in a staggered mode, and the vacuum pump is connected with the PVC tube through a threaded air pipe connector. Therefore, a carton iscut through the combination of the gravity and a cutting knife to obtain a flat cutting opening, and the smoothness of the cutting edge is met.

Owner:WUHU JINMAO PACKAGE PROD

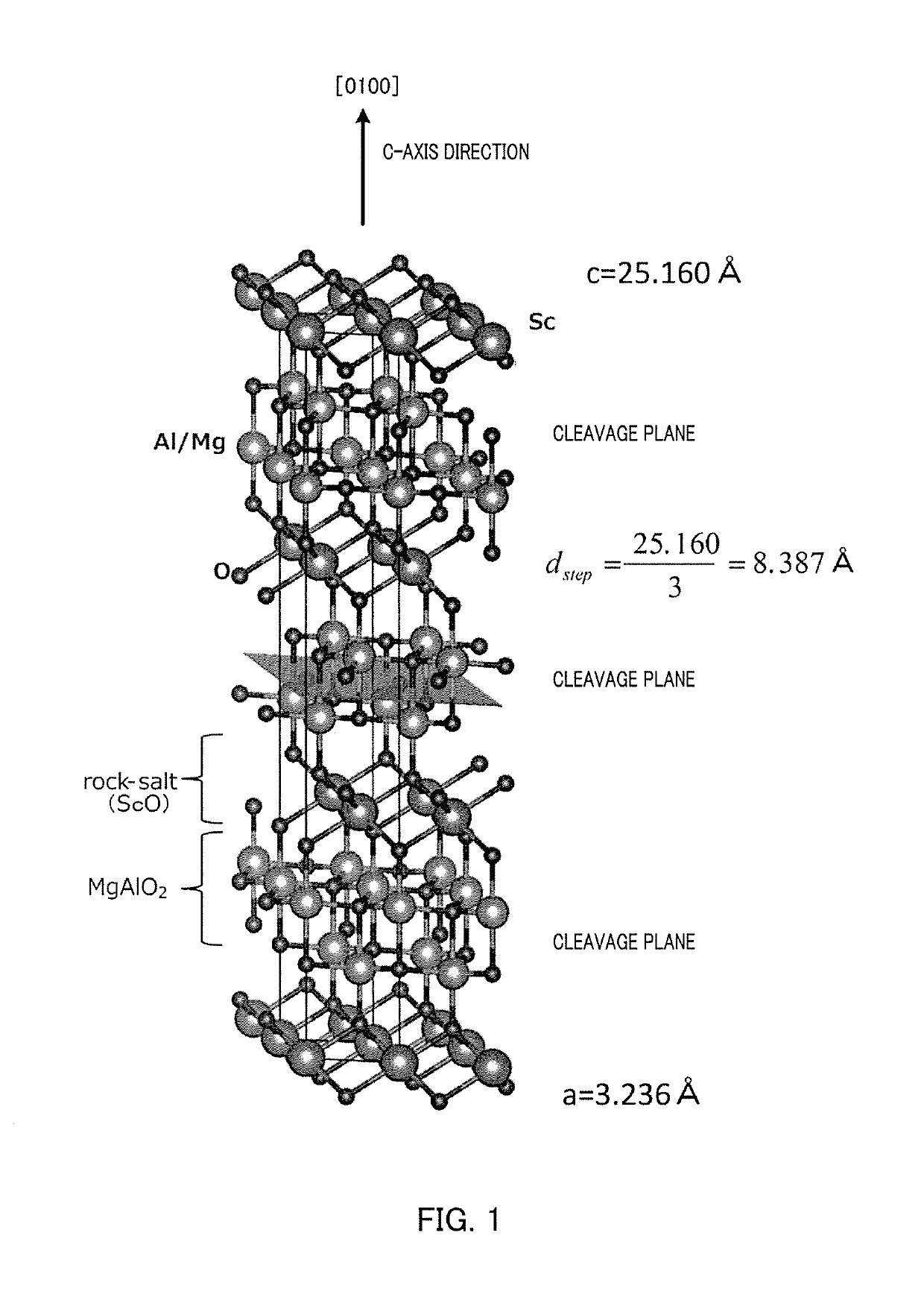

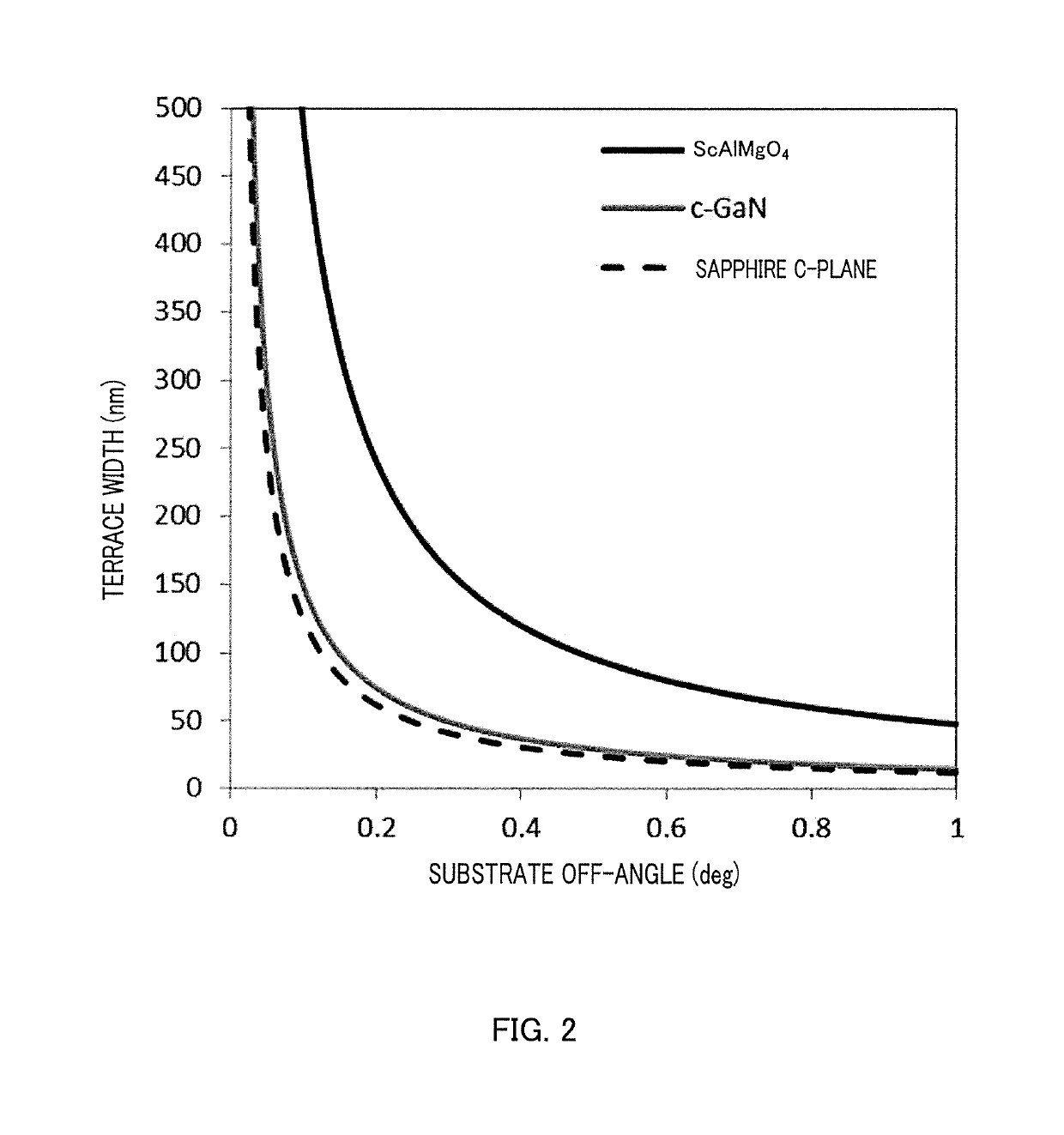

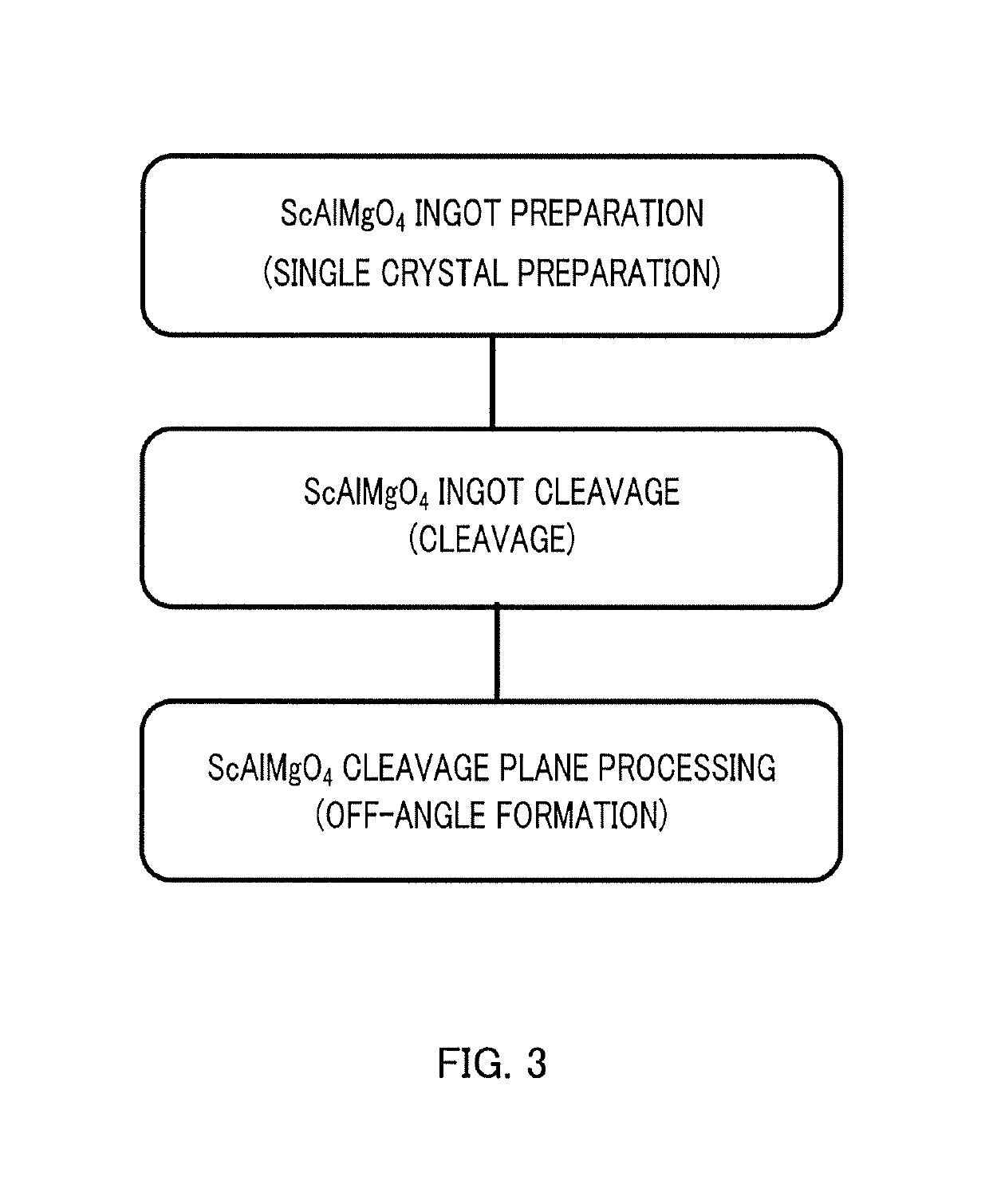

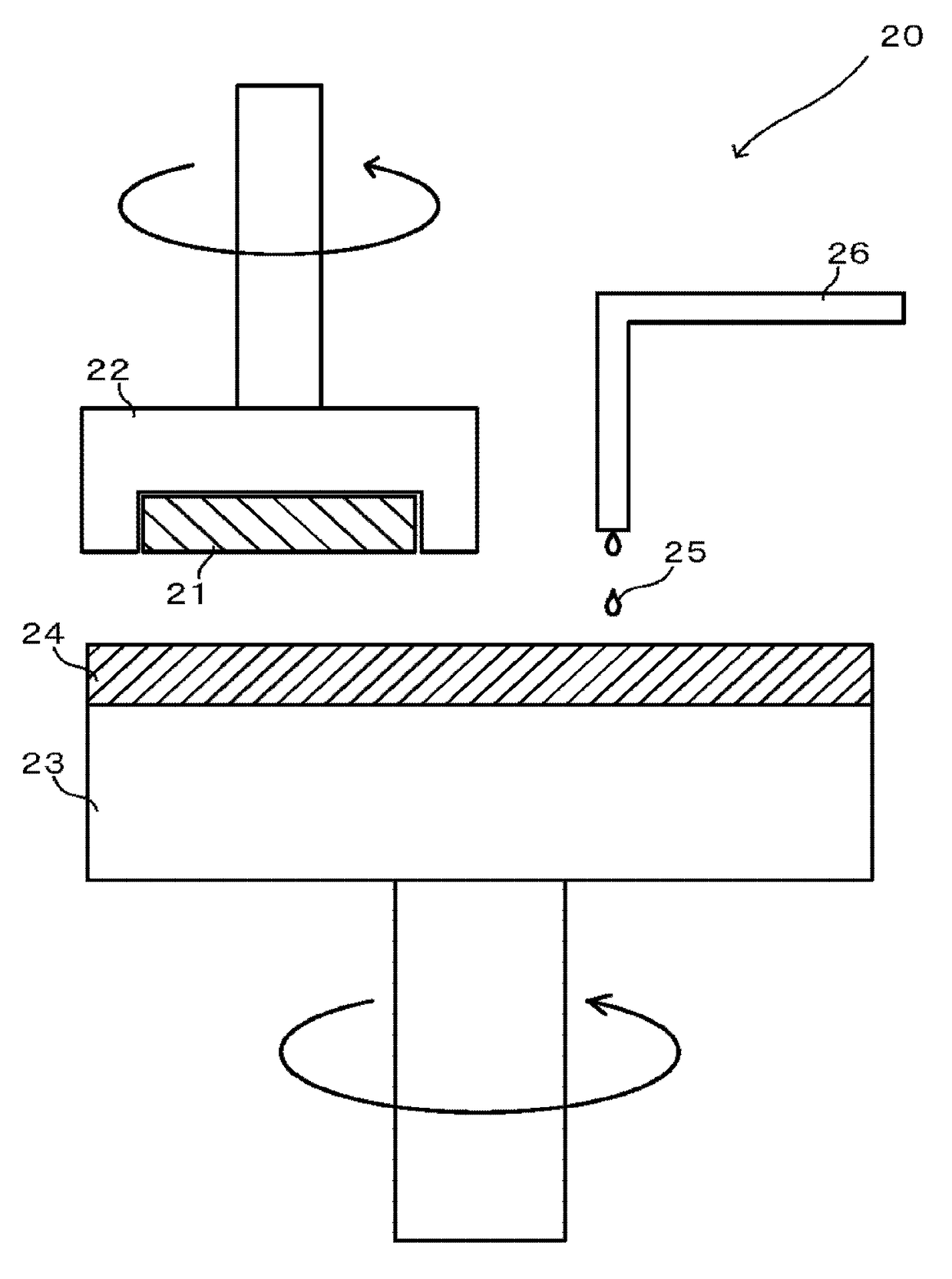

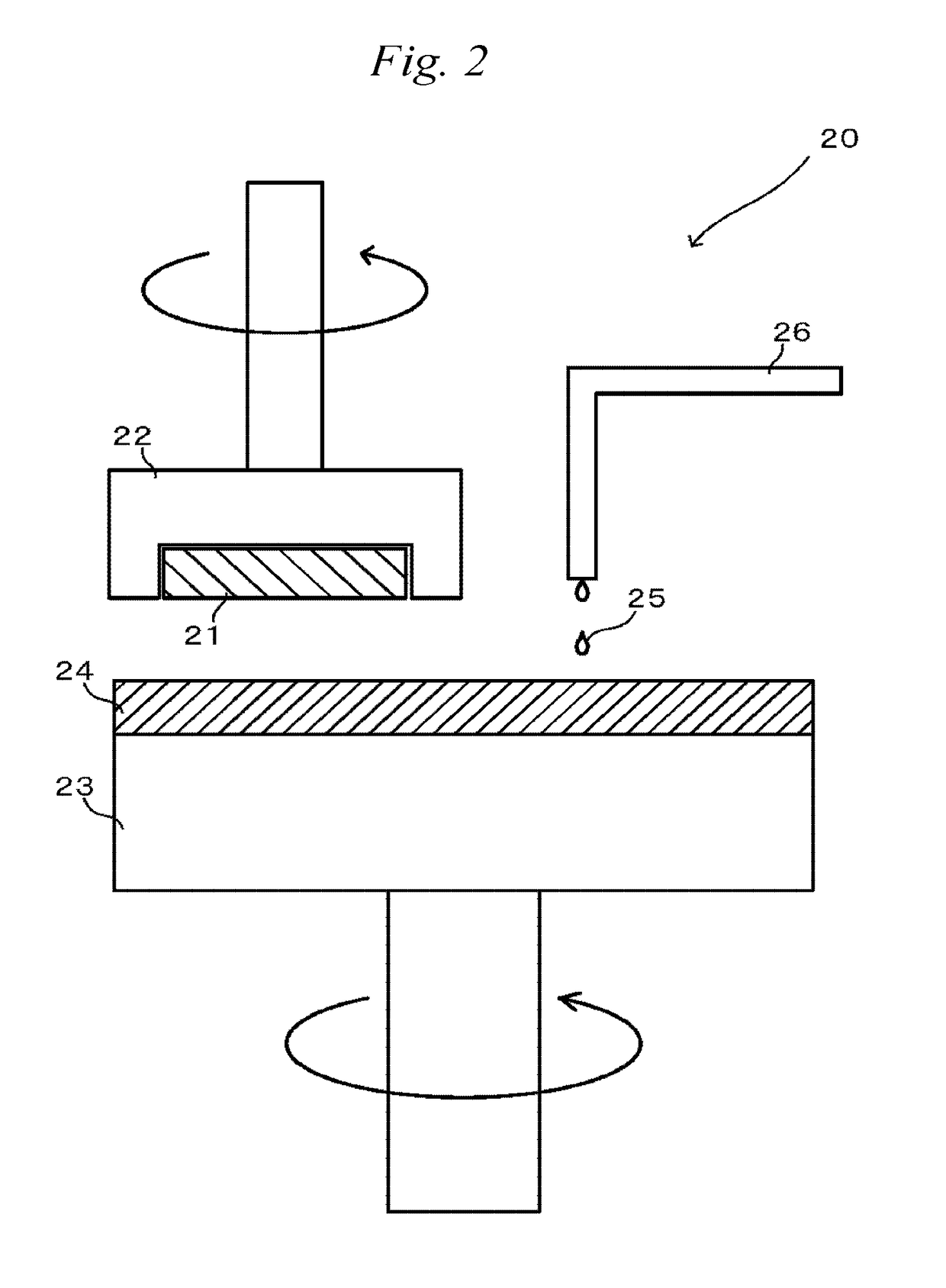

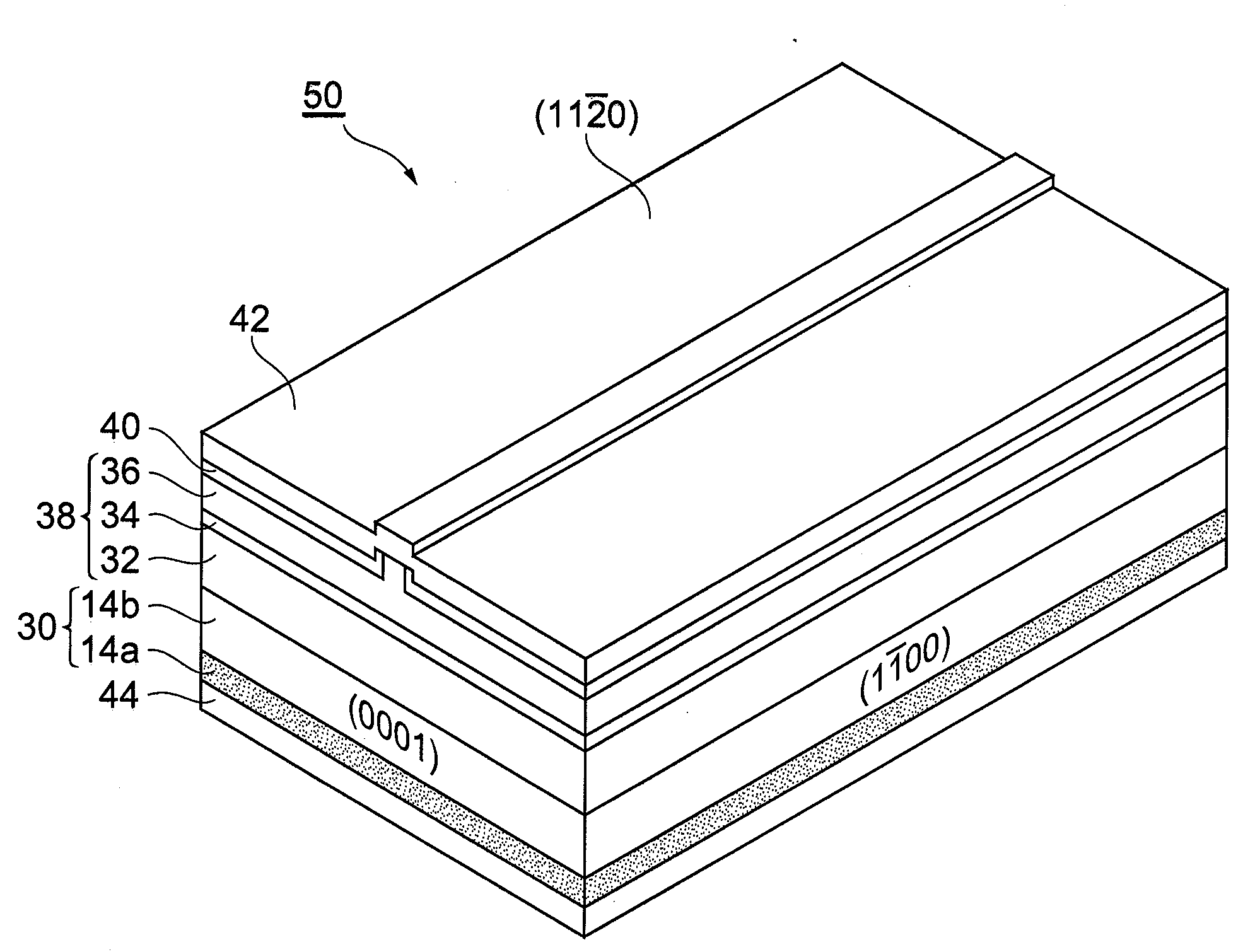

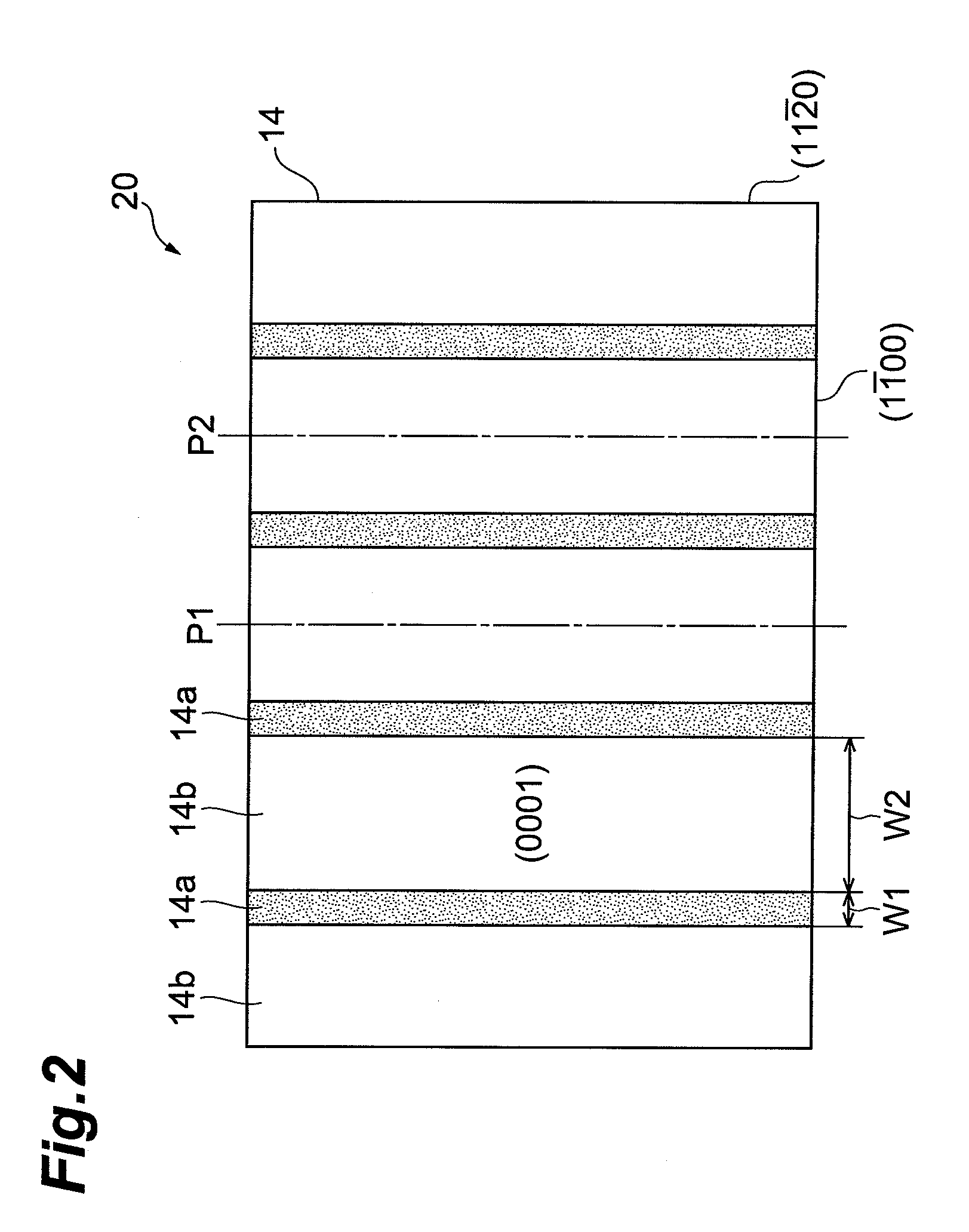

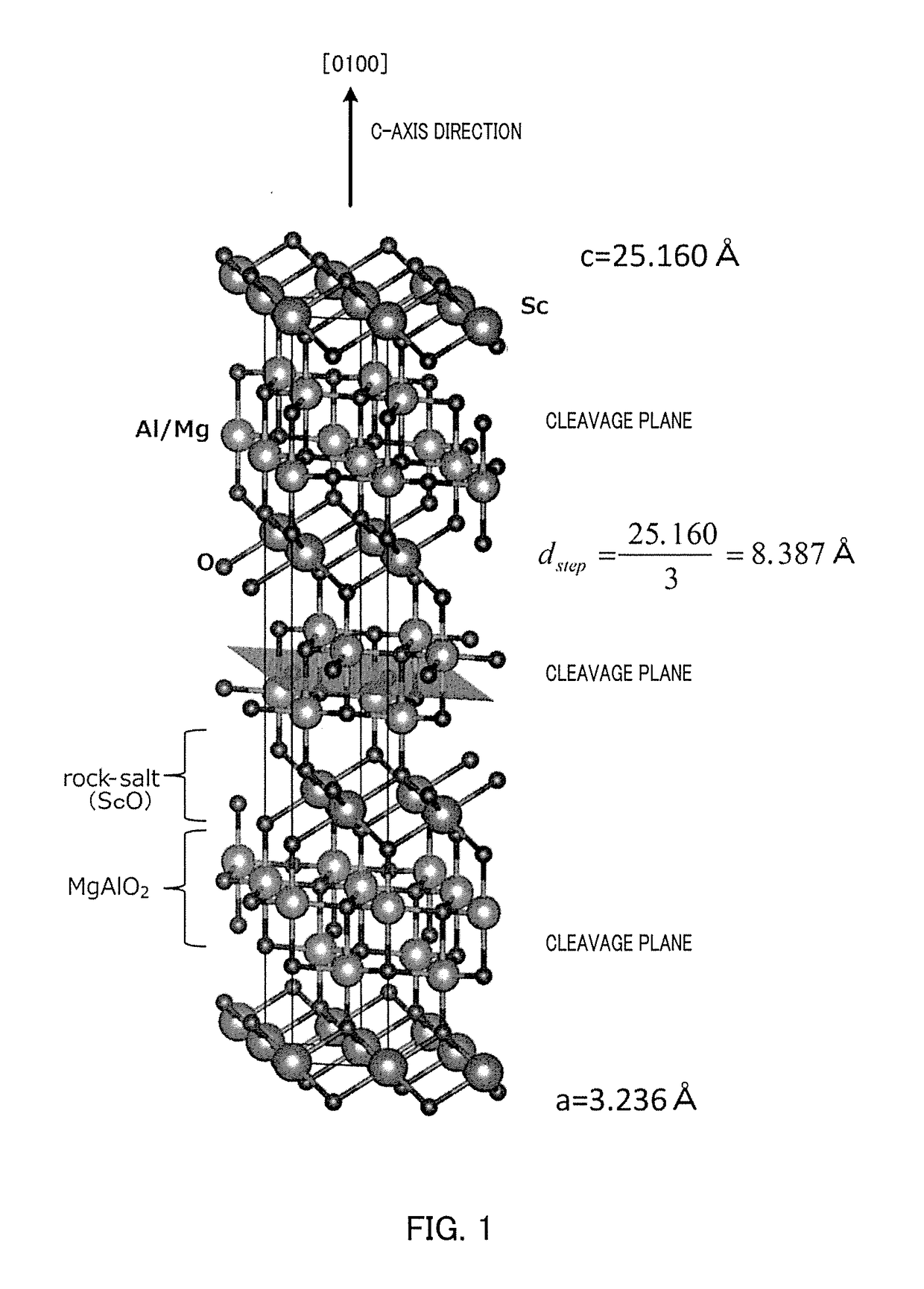

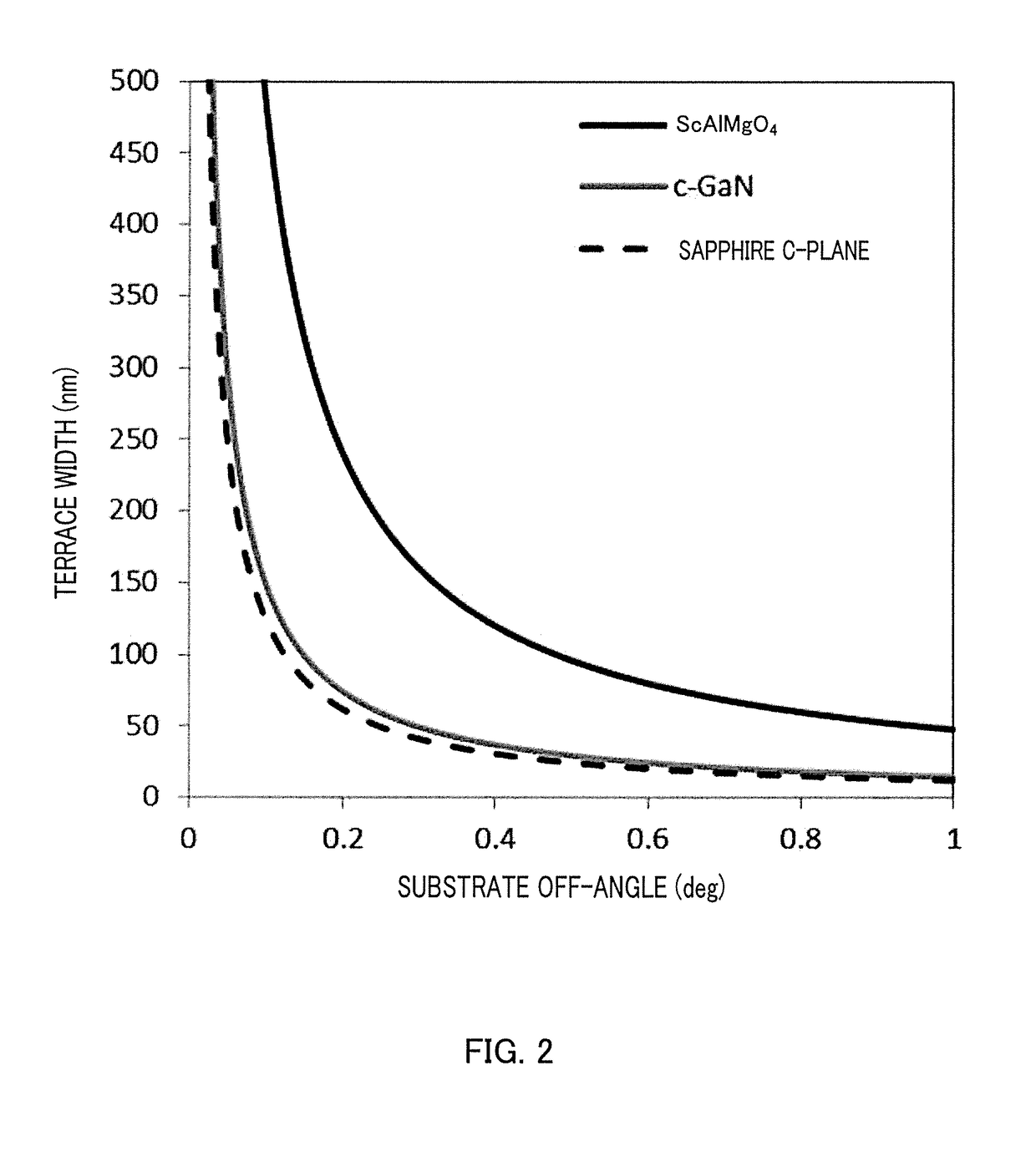

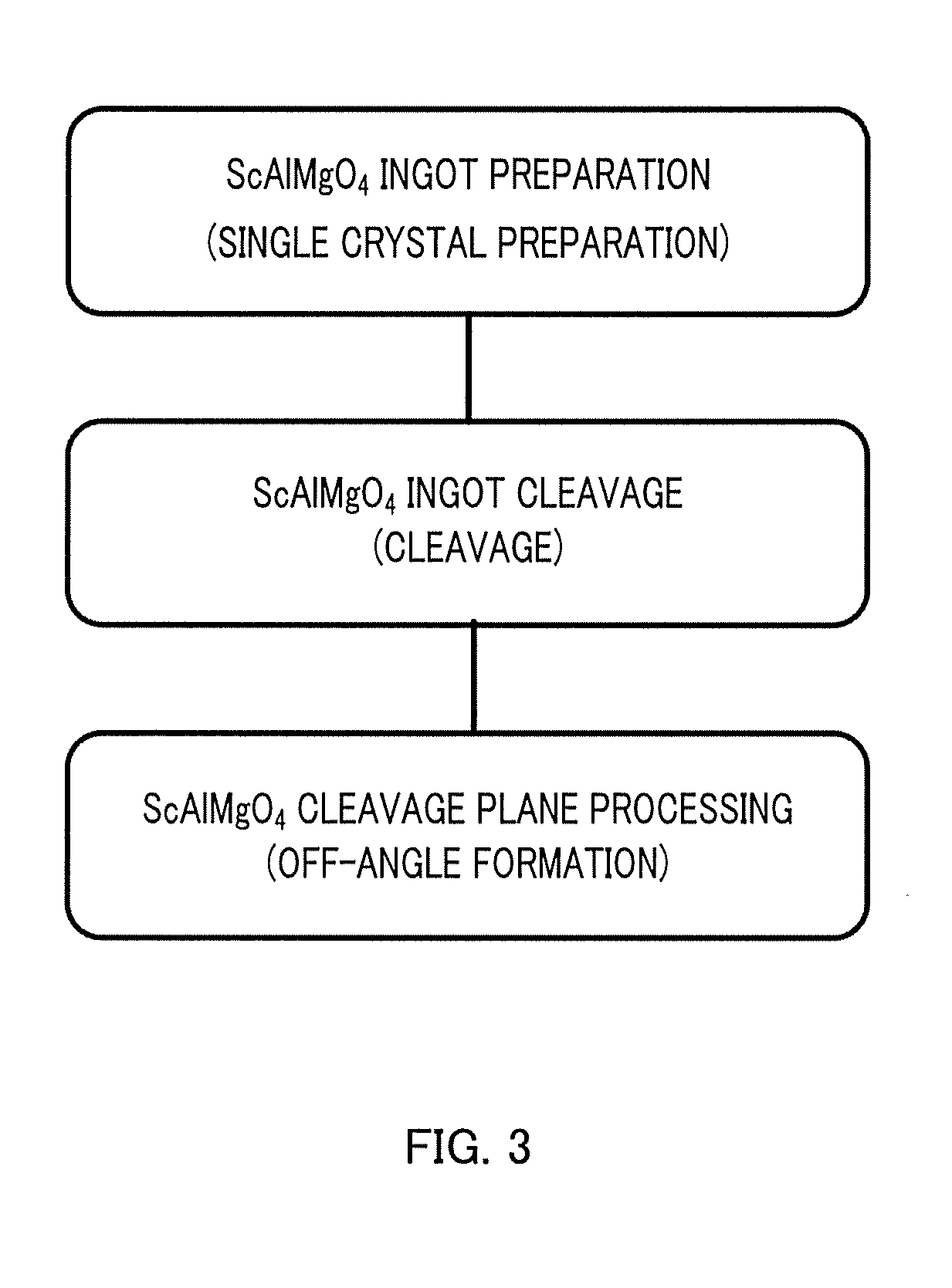

RAMO4 substrate and nitride semiconductor apparatus

ActiveUS10411154B2Satisfactory crystallinitySatisfy flatnessOptical wave guidancePolycrystalline material growthLanthanideSingle crystal

An RAMO4 substrate including a single crystal represented by a general formula RAMO4, wherein R represents one or more trivalent elements selected from a group consisting of Sc, In, Y, and lanthanide elements, A represents one or more trivalent elements selected from a group consisting of Fe(III), Ga, and Al, and M represents one or more divalent elements selected from the group consisting of Mg, Mn, Fe(II), Co, Cu, Zn, and Cd, in which a main plane of the RAMO4 substrate has an off-angle a tilted θa° with respect to an M-axis direction from a C-plane and 0.05°≤|θa|≤0.8° is satisfied.

Owner:PANASONIC CORP

Polishing agent, polishing method and method for manufacturing semiconductor integrated circuit device

ActiveUS9803107B2Low removal rateHigh selectivitySemiconductor/solid-state device manufacturingPolishing compositions with abrasivesOrganic acidPotassium hydroxide

The present invention relates to a polishing agent including: cerium oxide particles; a water-soluble polyamine; potassium hydroxide; at least one selected from an organic acid and a salt thereof; and water, in which the polishing agent has a pH of 10 or more, a polishing method using the polishing agent, and a method for manufacturing a semiconductor integrated circuit device.

Owner:ASAHI GLASS CO LTD

Thin-film EL device, and its fabrication process

InactiveUS6809474B2Easy to processImprove display qualityDischarge tube luminescnet screensElectroluminescent light sourcesOptoelectronicsDielectric layer

The invention has for its object to provide, without incurring any cost increase, a thin-film EL device in which a dielectric layer is corrected for non-flat portions to have a smooth surface, thereby ensuring enhanced display quality, and its fabrication process. This object is achieved by the provision of a thin-film EL device having at least a structure comprising an electrically insulating substrate (11), a lower electrode layer (12) stacked on the substrate according to a given pattern, a multilayer dielectric layer (13) formed thereon by repeating a solution coating-and-firing step plural times, and a light-emitting layer (14), a thin-film insulator layer (15) and a transparent electrode layer (16) stacked on the dielectric layer. The multilayer dielectric layer has a thickness of at least four times as large as a thickness of the electrode layer and 4 mum to 16 mum inclusive. The fabrication process is also provided.

Owner:IFIRE IP CORP

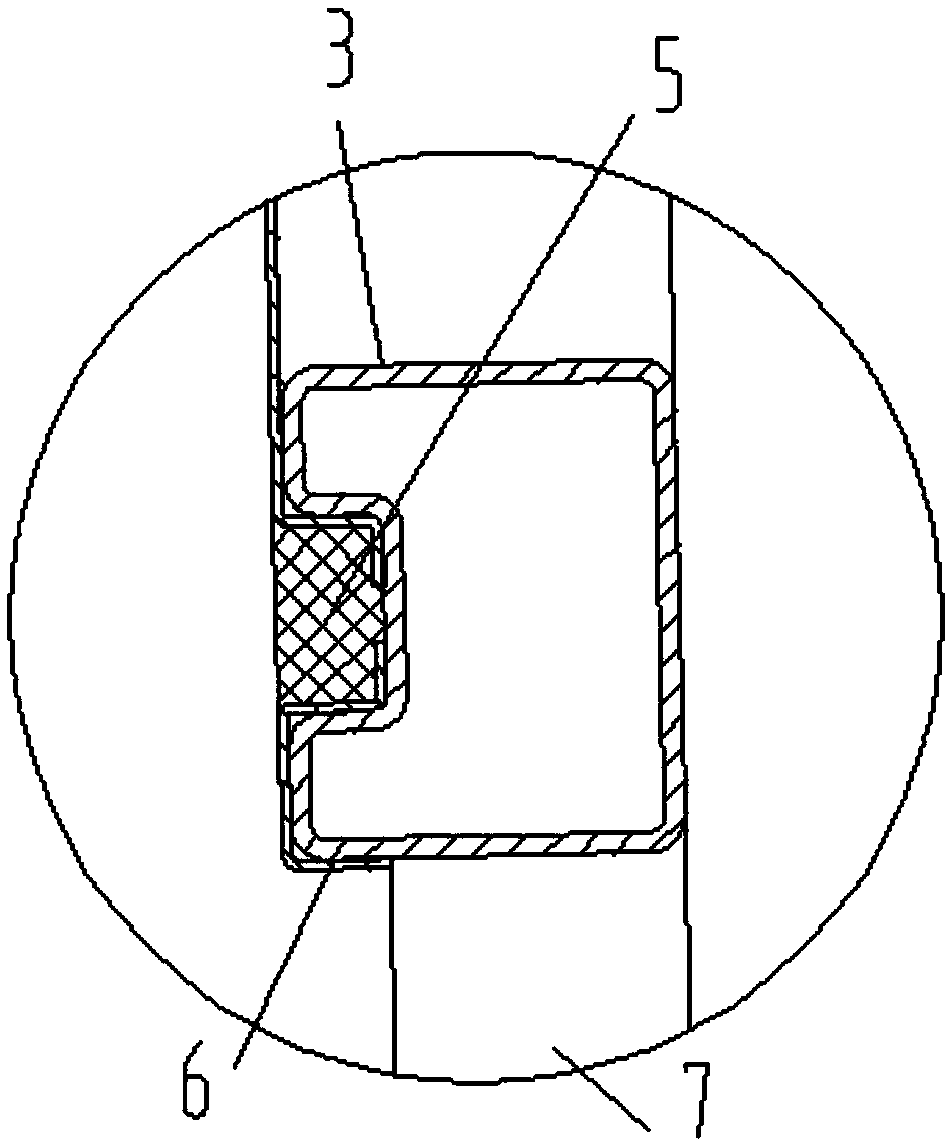

Rolling skin of a passenger car

PendingCN109050683ASatisfy flatnessImprove aestheticsSuperstructure connectionsPassenger vehicle superstructuresEngineeringWaist line

The invention discloses rolling skin for passenger vehicles, comprises a vehicle body skeleton, wherein the vehicle body skeleton is provided with a side window lower beam and a waist beam, a middlesection rolled skin is fixed on the side window lower beam and the waist beam, and also comprises lower section rolled skin; the cross section of the side window lower beam is a P-shaped special-shaped pipe structure, the cross section of the waist beam is a rectangular pipe structure, and a groove is arranged on one end surface of the waist beam; The middle-section rolled skin is welded with thecar body skeleton along the missing corners of the side window lower beam and the grooves of the waist beam; The lower rolled skin is welded with the car body skeleton along the groove of the waist beam. The invention not only satisfies the smoothness of the surface of the vehicle body, but also displays the waist line on the exterior shape of the vehicle body, and improves the aesthetics of the vehicle.

Owner:NANJING GOLDEN DRAGON BUS

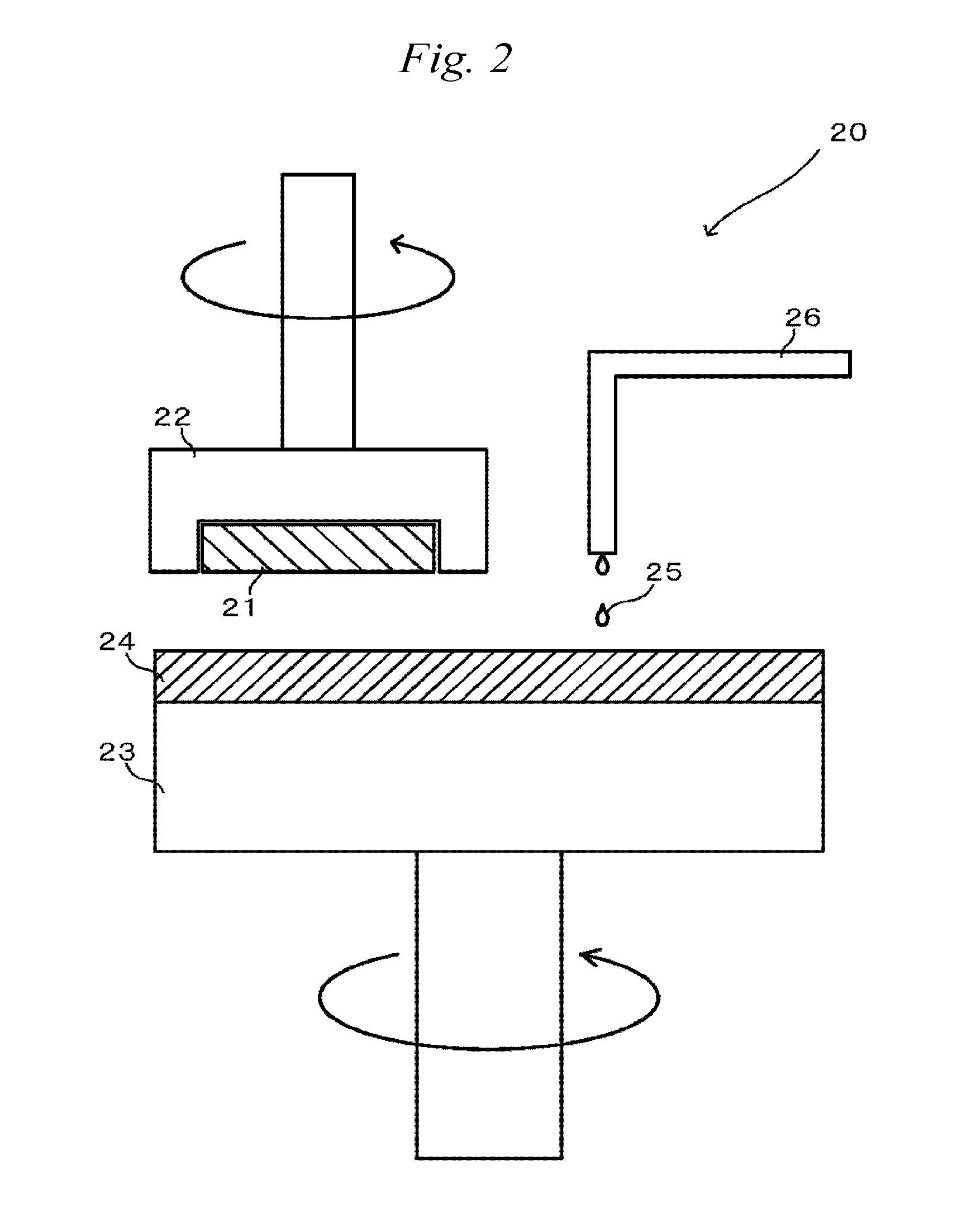

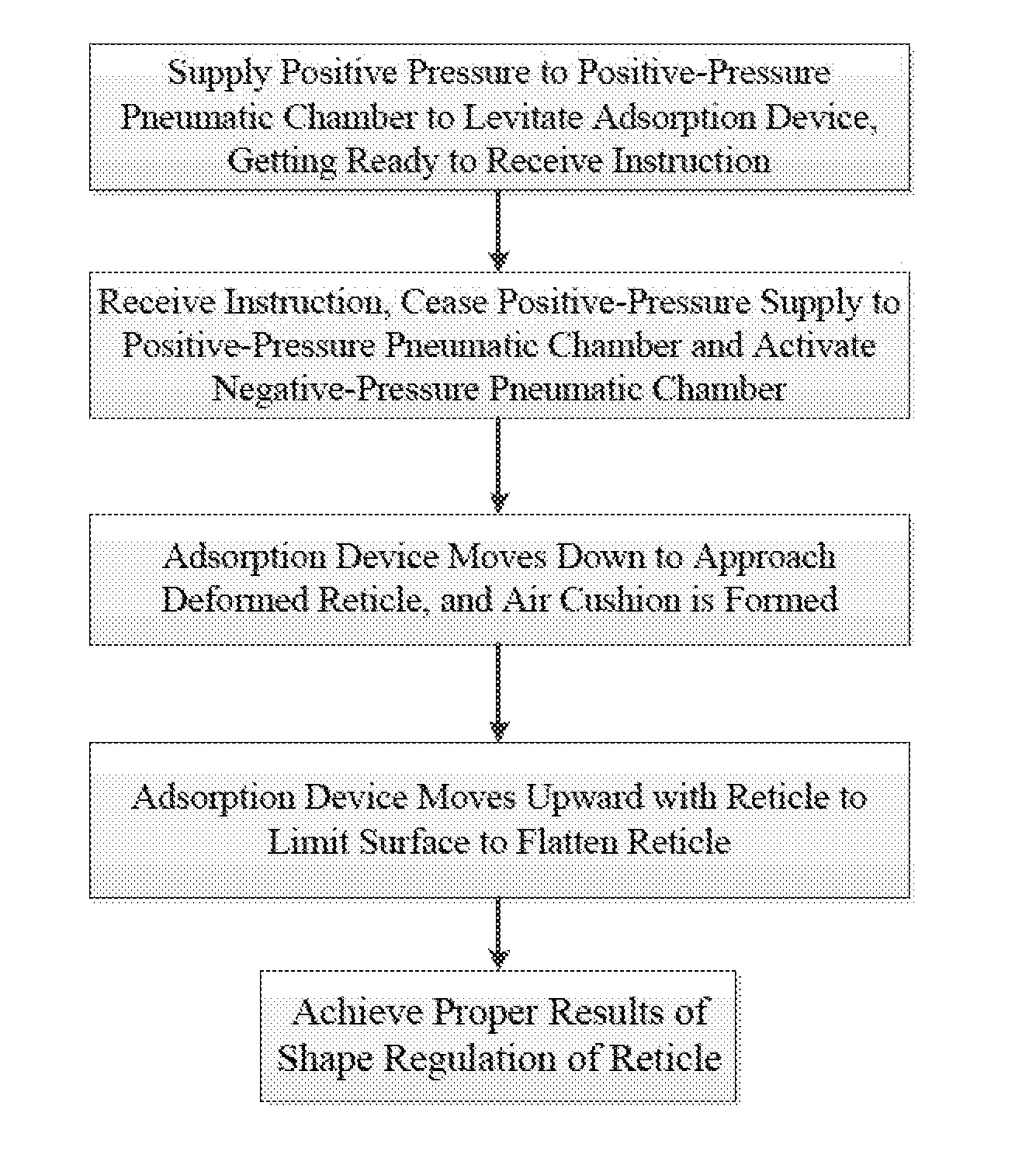

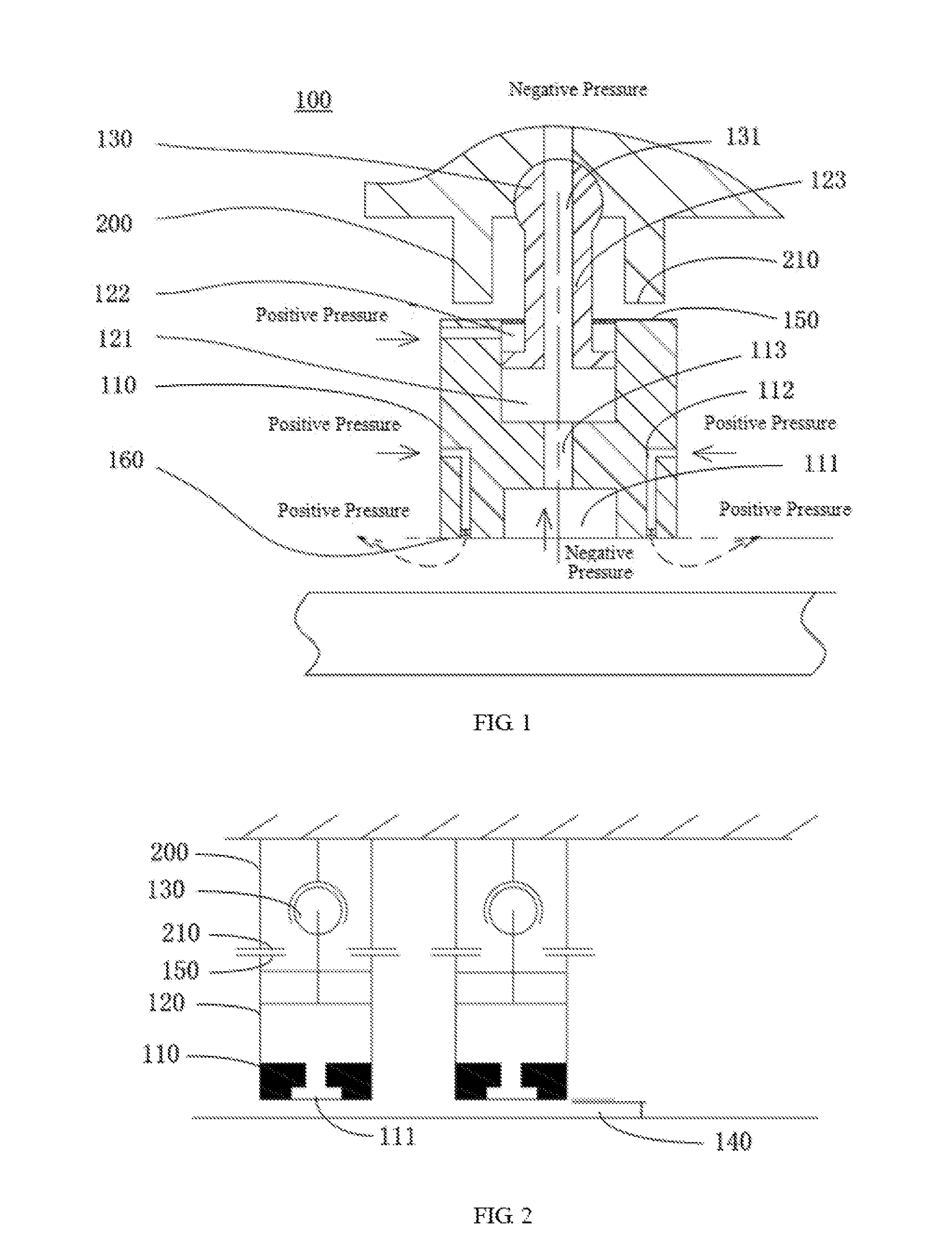

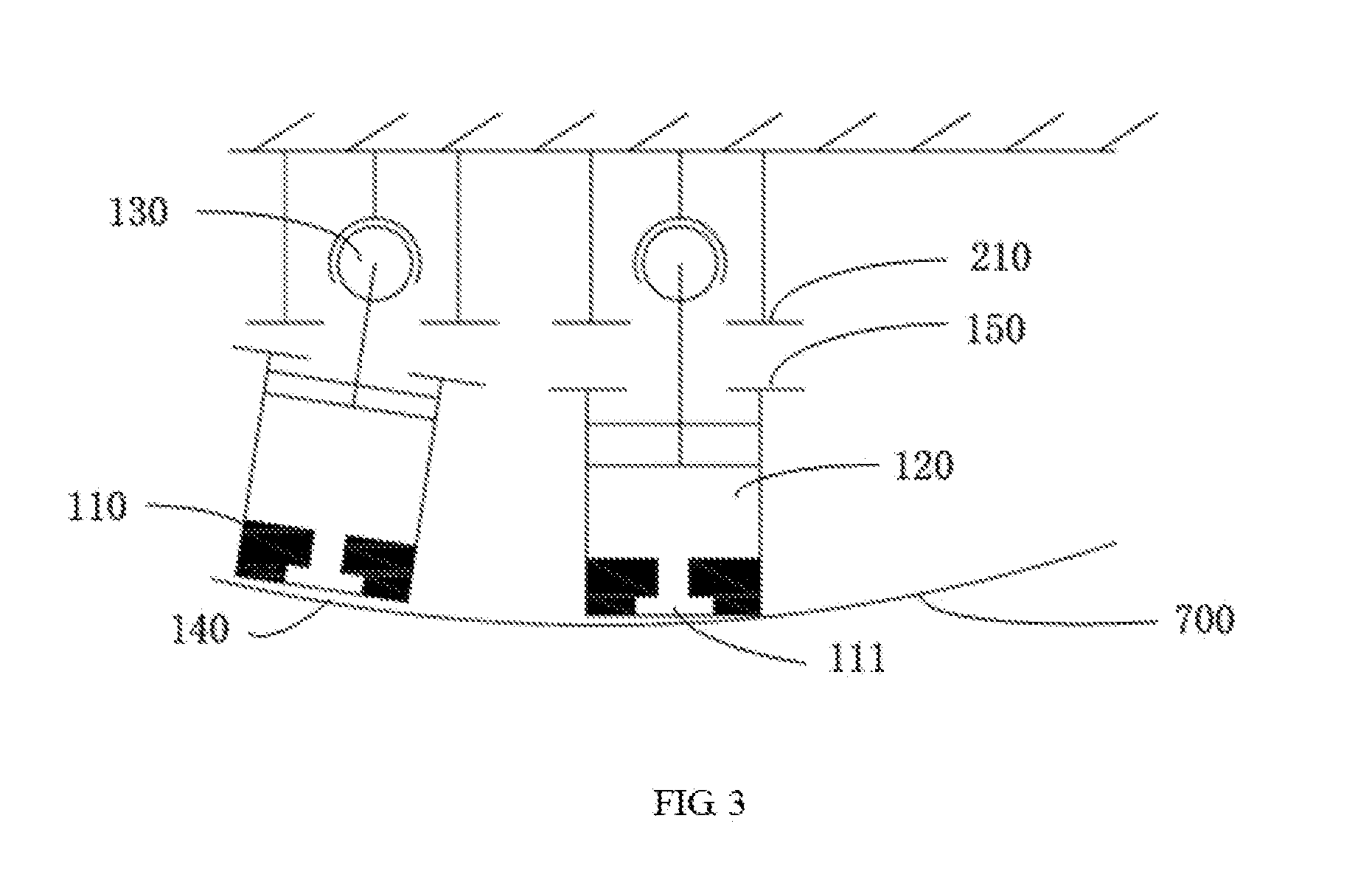

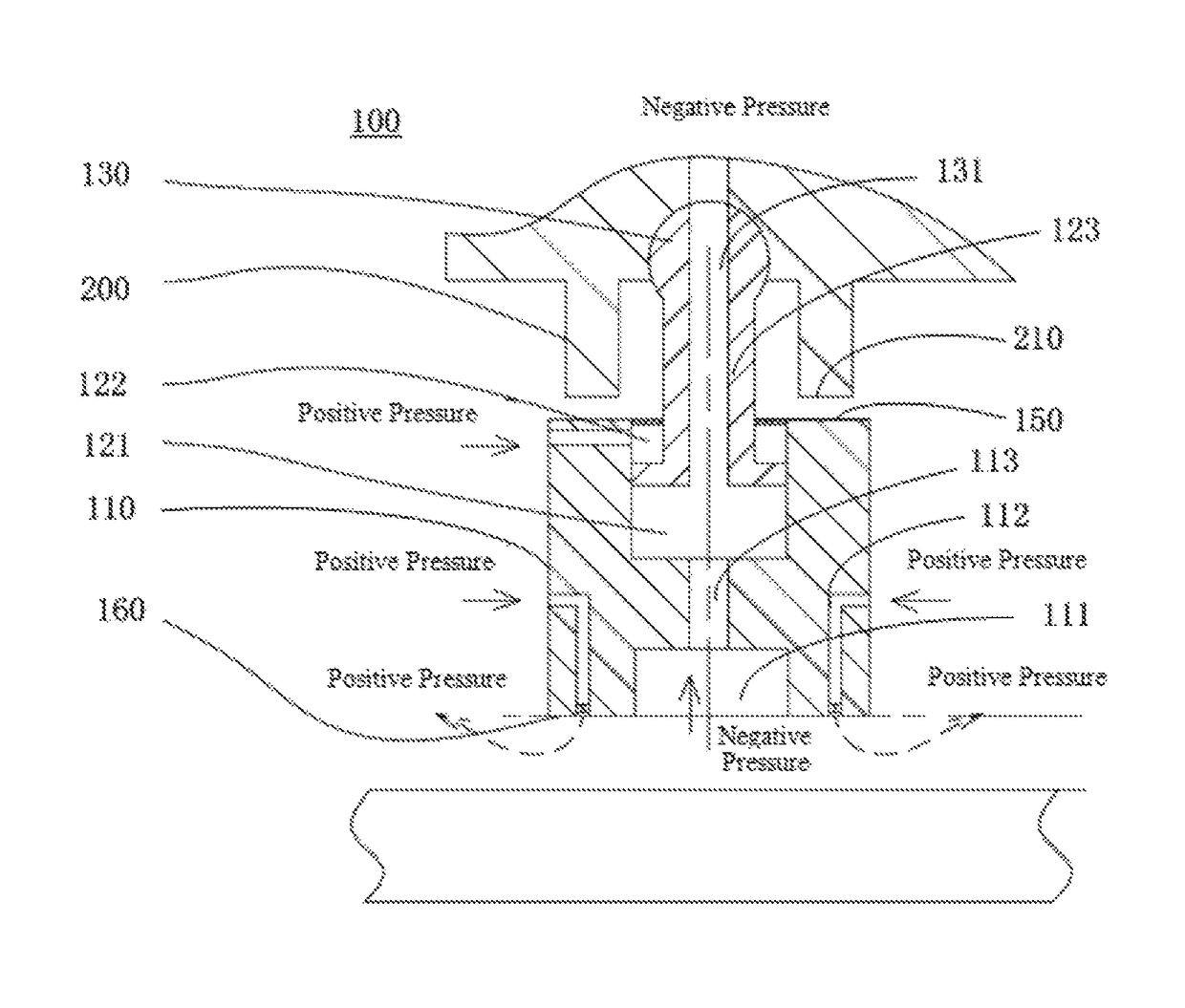

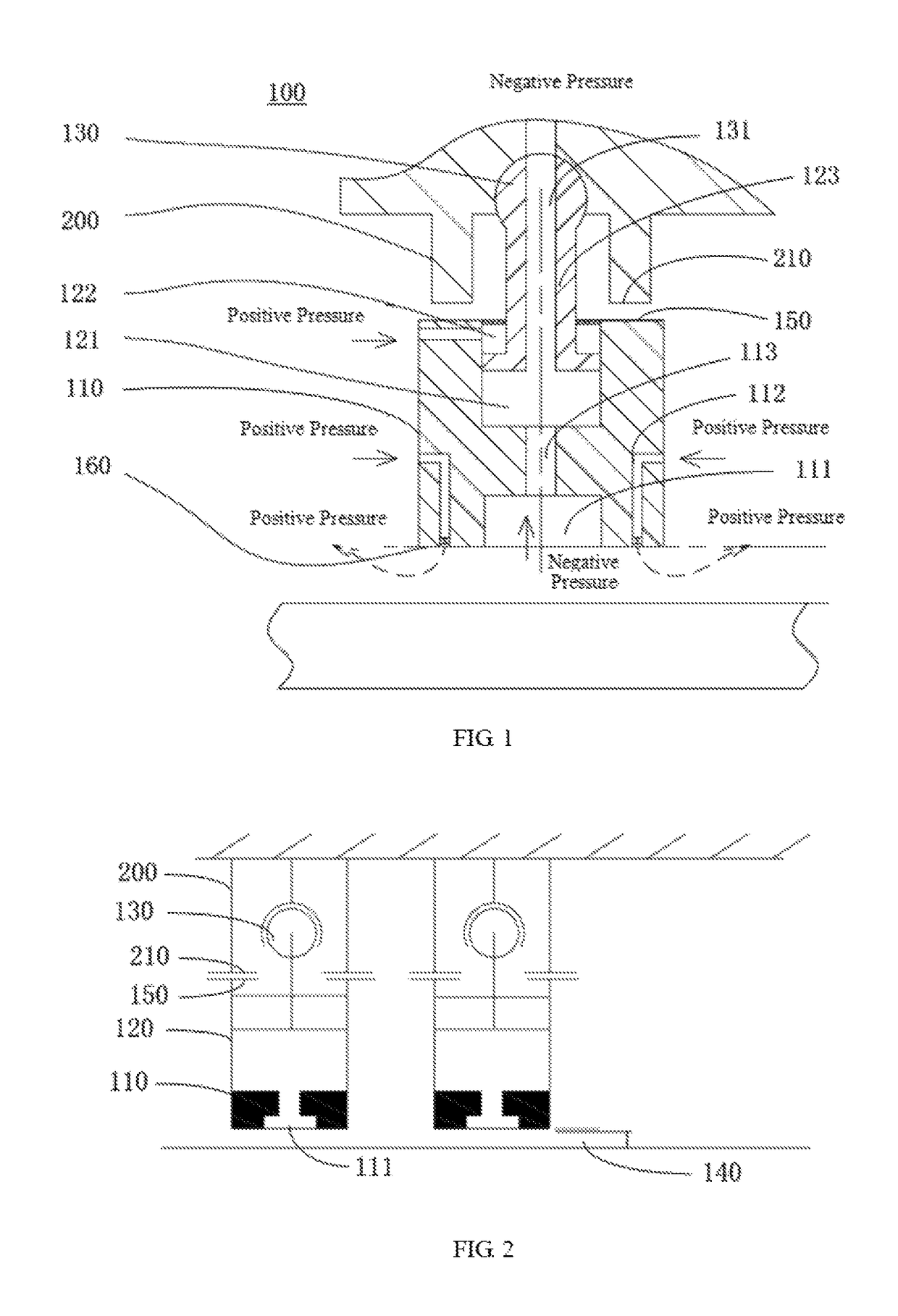

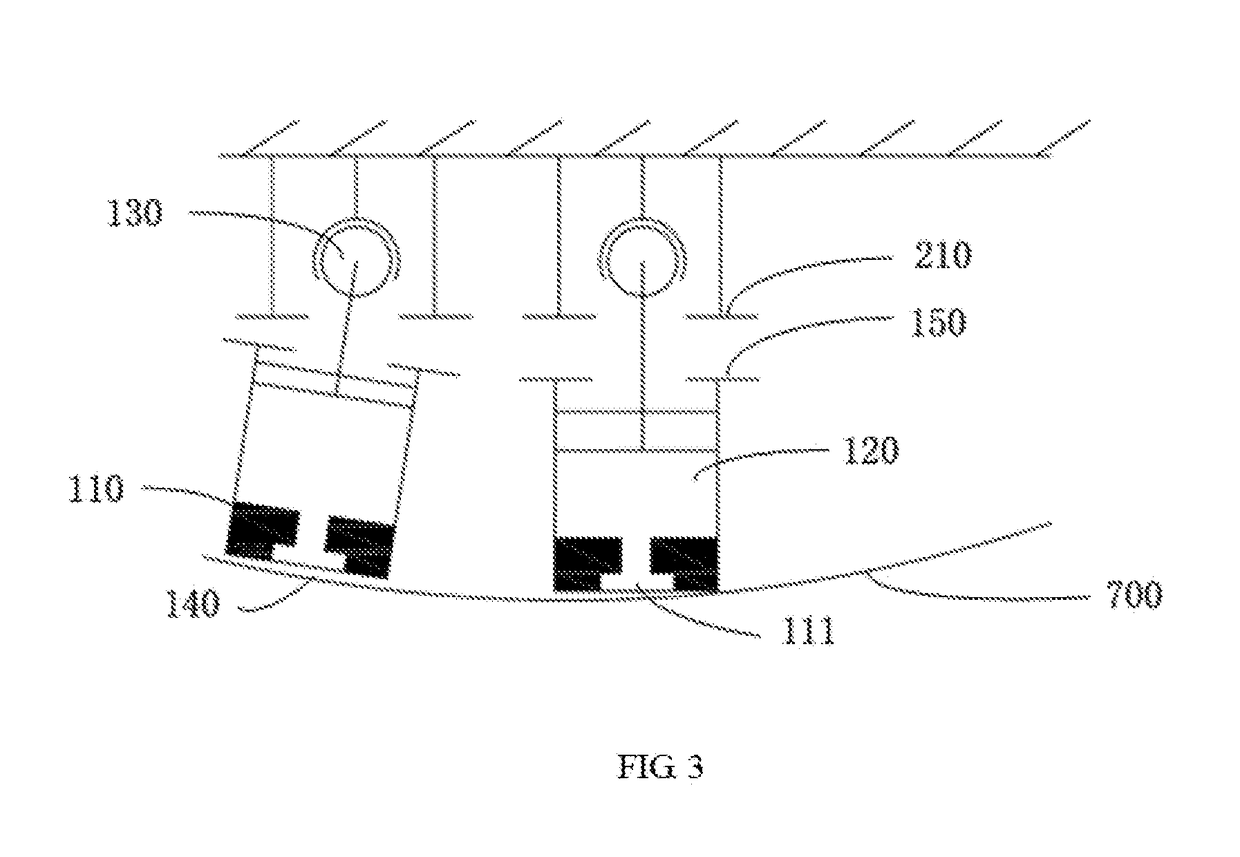

Reticle Shape Regulation Device and Method, and Exposure Apparatus Using Same

ActiveUS20160147163A1Satisfy flatnessEasy to createPhotomechanical exposure apparatusMicrolithography exposure apparatusPositive pressureEngineering

A reticle shape regulation device includes: an adsorption device having an upper surface and a lower surface; and a limit mechanism having a limit surface. The adsorption device is movable relative to the limit mechanism at least in a vertical direction. The upper surface of the adsorption device faces toward and is engagable with the limit surface. The lower surface of the adsorption device defines a vacuum chamber that is configured for communication with a negative-pressure source so as to adsorb the reticle by a negative pressure. The lower surface of the adsorption device further defines at least one positive-pressure outlet that is in communication with a positive-pressure source and is configured to supply a continuous positive-pressure air flow between the lower surface of the adsorption device and the reticle during the adsorption of the reticle. The positive-pressure air flow is so controlled as to form an air cushion between the lower surface of the adsorption device and the reticle while allowing the adsorption of the reticle by the adsorption device. This can correct deformations of the reticle, thus enabling satisfactory flatness thereof during an exposure process, and can easily create vacuum and an air cushion between a deformed reticle and the adsorption device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

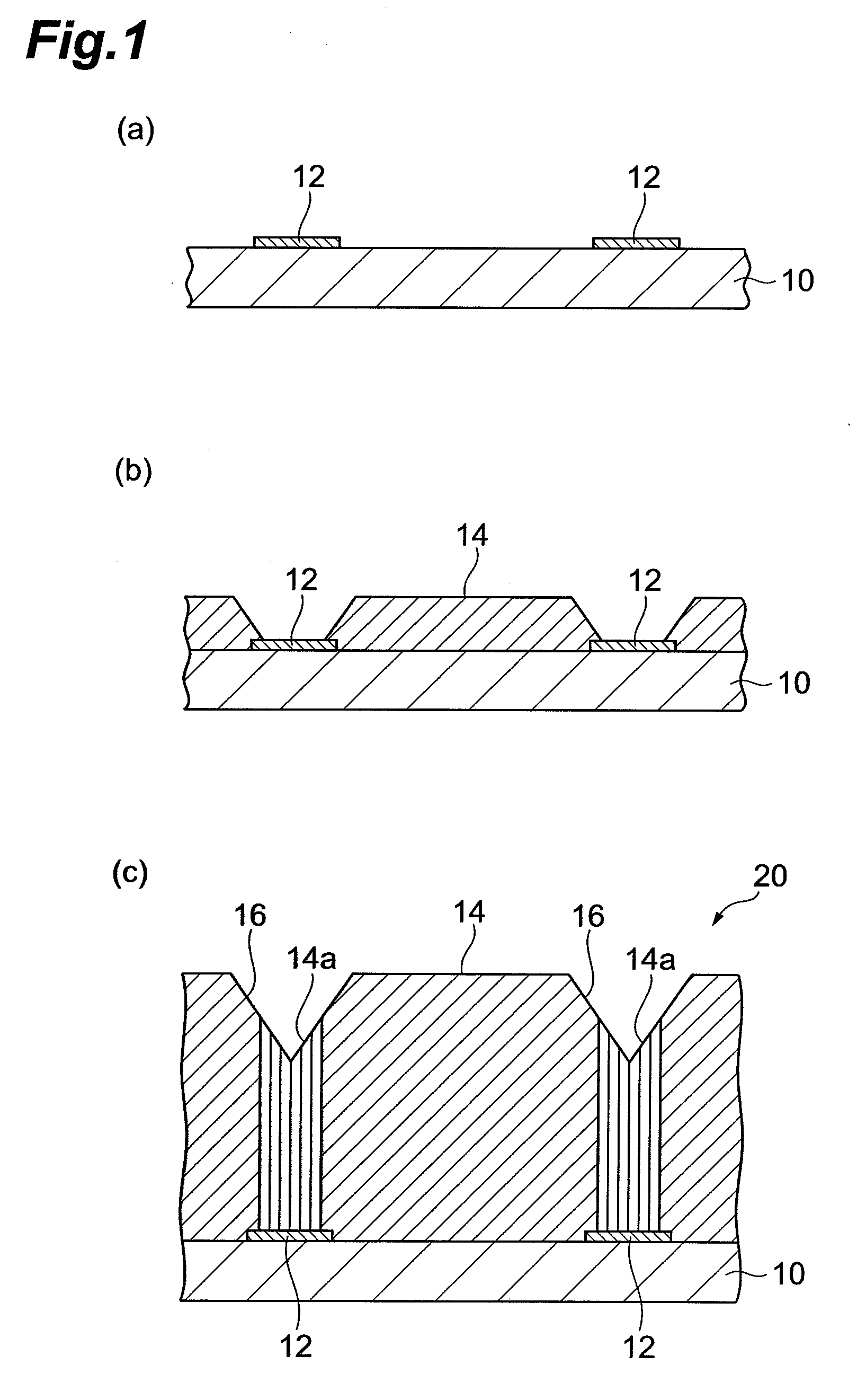

Method of manufacturing semiconductor light-emitting element

InactiveUS20080299694A1Lower electrical resistivityCarrier concentrationLaser detailsSemiconductor/solid-state device manufacturingBulk crystalSingle crystal substrate

In a semiconductor laser manufacturing method, a GaN single-crystal substrate is formed by slicing a GaN bulk crystal, grown on a c-plane, parallel to an a-plane which is perpendicular to the c-plane. In this substrate, crystal defects extending parallel to the c-axis direction do not readily exert an influence, and degradation of element characteristics due to crystal defects can be suppressed. Further, because the a-plane is a nonpolar plane, improved light emission efficiency and longer wavelengths can be achieved compared with the c-plane, which is a polar plane. Hence a semiconductor laser manufacturing method of this invention enables further improvement of the element characteristics of the semiconductor laser to be fabricated.

Owner:SUMITOMO ELECTRIC IND LTD

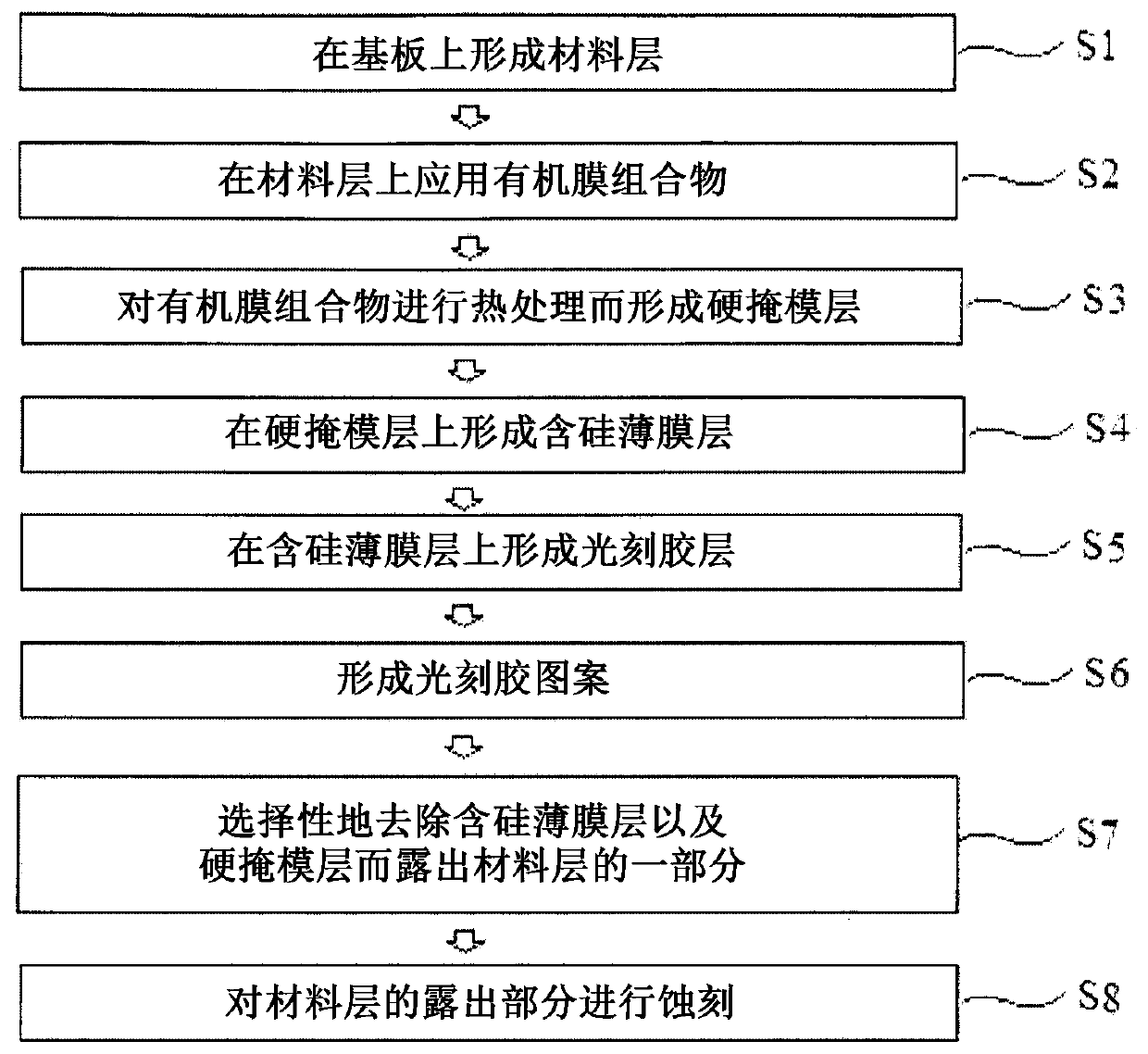

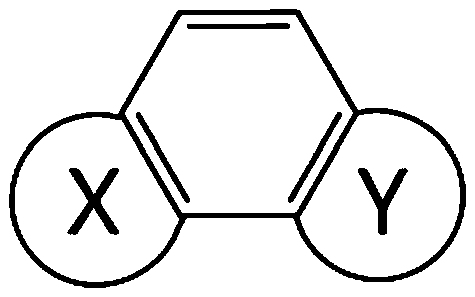

Polymer, organic film composition, and method for forming pattern

PendingCN111295409AImprove heat resistanceImprove corrosion resistanceSemiconductor/solid-state device manufacturingPhotosensitive materials for photomechanical apparatusOrganic filmPolymer science

The present invention relates to: a polymer comprising a moiety represented by the following chemical formula 1; an organic film composition comprising the polymer; and a method for forming a patternby using the organic film composition. [Chemical Formula 1] In chemical formula 1, X and Y are respectively and independently a five-membered ring group containing at least one hetero atom.

Owner:SAMSUNG SDI CO LTD

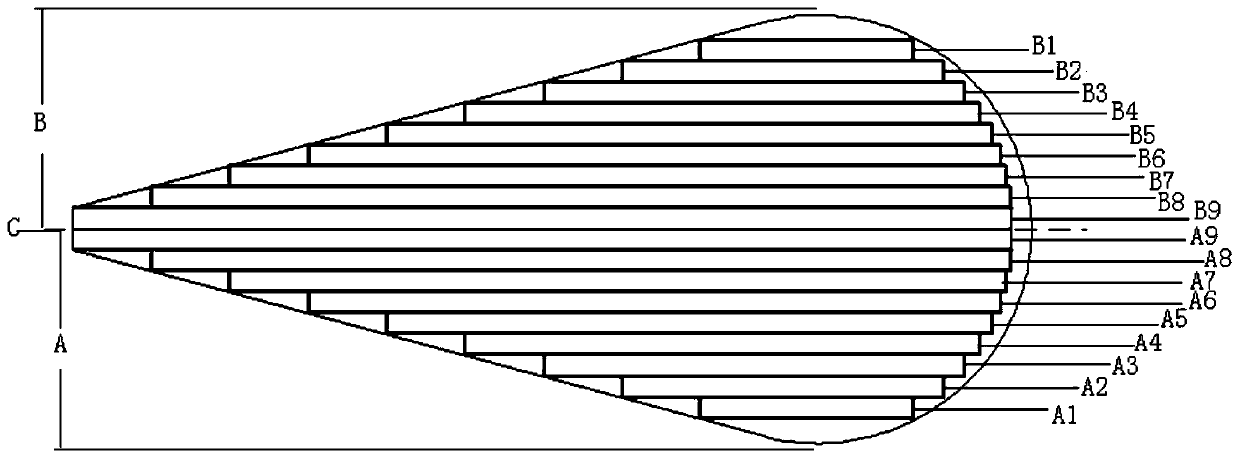

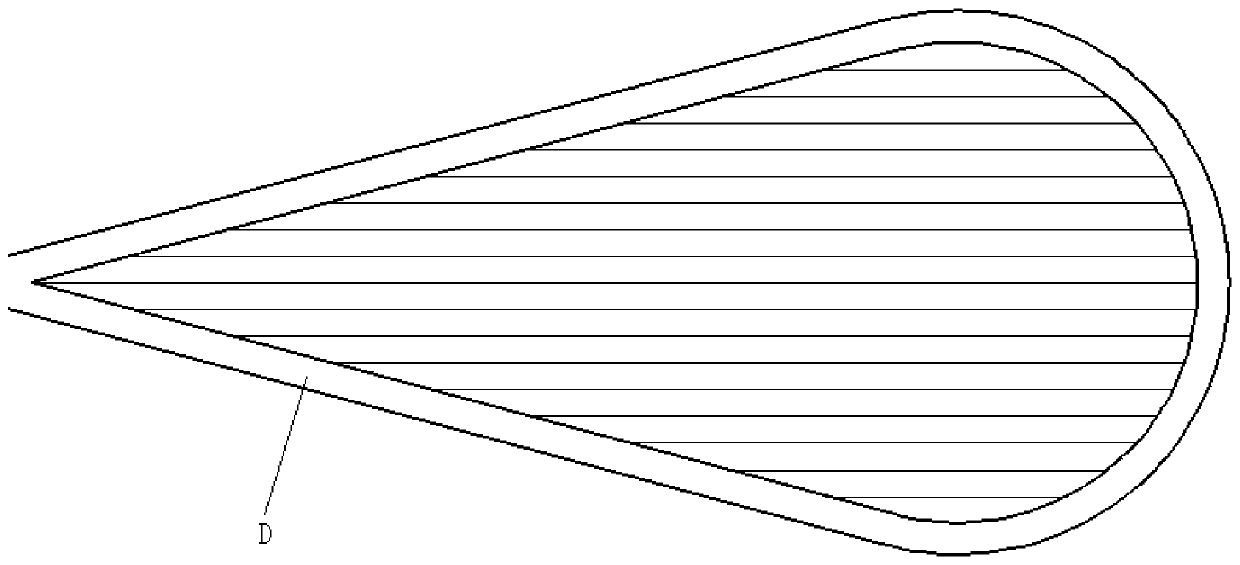

Large-area asphalt square gangplank paving construction method

ActiveCN110055866AImprove paving efficiencyReduce adverse effectsRoads maintainenceRoad surfaceAdverse effect

The invention provides a large-area asphalt square gangplank paving construction method. The method includes the following steps that plates are divided, so that a plate division map is obtained; hotjointing board paving areas are paved; cold jointing board paving areas are paved with cold jointing boards; outer arc-shaped paving areas are paved; and paving areas on the two sides of the center line are paved. The method has the advantages that the provided large-area asphalt square gangplank paving construction method is provided, through reasonable division of the paving plate division map and adoption of the gangplank paving construction method, the adverse effects caused by manual paving and the cold joint condition can be effectively reduced, large-area bituminous pavement paving efficiency is high, and the design requirements for the flatness, the degree of compaction and the like are met.

Owner:中交一公局第五工程有限公司 +1

Reticle shape regulation device and method, and exposure apparatus using same

ActiveUS9760025B2Satisfy flatnessEasy to processPhotomechanical exposure apparatusMicrolithography exposure apparatusPositive pressureEngineering

A reticle shape regulation device includes: an adsorption device having an upper surface and a lower surface; and a limit mechanism having a limit surface. The adsorption device is movable relative to the limit mechanism at least in a vertical direction. The upper surface of the adsorption device faces toward and is engagable with the limit surface. The lower surface of the adsorption device defines a vacuum chamber that is configured for communication with a negative-pressure source so as to adsorb the reticle by a negative pressure. The lower surface of the adsorption device further defines at least one positive-pressure outlet that is in communication with a positive-pressure source and is configured to supply a continuous positive-pressure air flow between the lower surface of the adsorption device and the reticle during the adsorption of the reticle. The positive-pressure air flow is so controlled as to form an air cushion between the lower surface of the adsorption device and the reticle while allowing the adsorption of the reticle by the adsorption device. This can correct deformations of the reticle, thus enabling satisfactory flatness thereof during an exposure process, and can easily create vacuum and an air cushion between a deformed reticle and the adsorption device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Polishing agent, polishing method, and liquid additive for polishing

ActiveUS10570314B2High removal rateHigh selectivityOxygen/ozone/oxide/hydroxideOrganic chemistryOrganic acidIonic polymerization

The present invention relates to a polishing agent including: metal oxide particles; an organic acid having a monodentate ligand; a nonionic polymer; and water, in which the polishing agent has a pH of from 3.0 to 7.0, and the nonionic polymer includes at least one selected from the group consisting of polyglycerin, polyoxyethylene polyglyceryl ether and polyoxypropylene polyglyceryl ether.

Owner:AGC INC

Ramo4 substrate and nitride semiconductor apparatus

ActiveUS20180342644A1Satisfactory crystallinity and flatnessHigh performanceOptical wave guidancePolycrystalline material growthChemistryLanthanide

An RAMO4 substrate including a single crystal represented by a general formula RAMO4, wherein R represents one or more trivalent elements selected from a group consisting of Sc, In, Y, and lanthanide elements, A represents one or more trivalent elements selected from a group consisting of Fe(III), Ga, and Al, and M represents one or more divalent elements selected from the group consisting of Mg, Mn, Fe(II), Co, Cu, Zn, and Cd, in which a main plane of the RAMO4 substrate has an off-angle a tilted θa° with respect to an M-axis direction from a C-plane and 0.05°≤|θa|≤0.8° is satisfied.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com