Manufacturing method of semiconductor device and semiconductor device

a manufacturing method and technology of semiconductor devices, applied in the direction of printed circuit manufacturing, printed circuit aspects, non-metallic protective coating applications, etc., can solve the problems of degrading the sorbability of vacuum adsorption nozzles, hard surface of sealing resins, etc., and achieve satisfactory mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

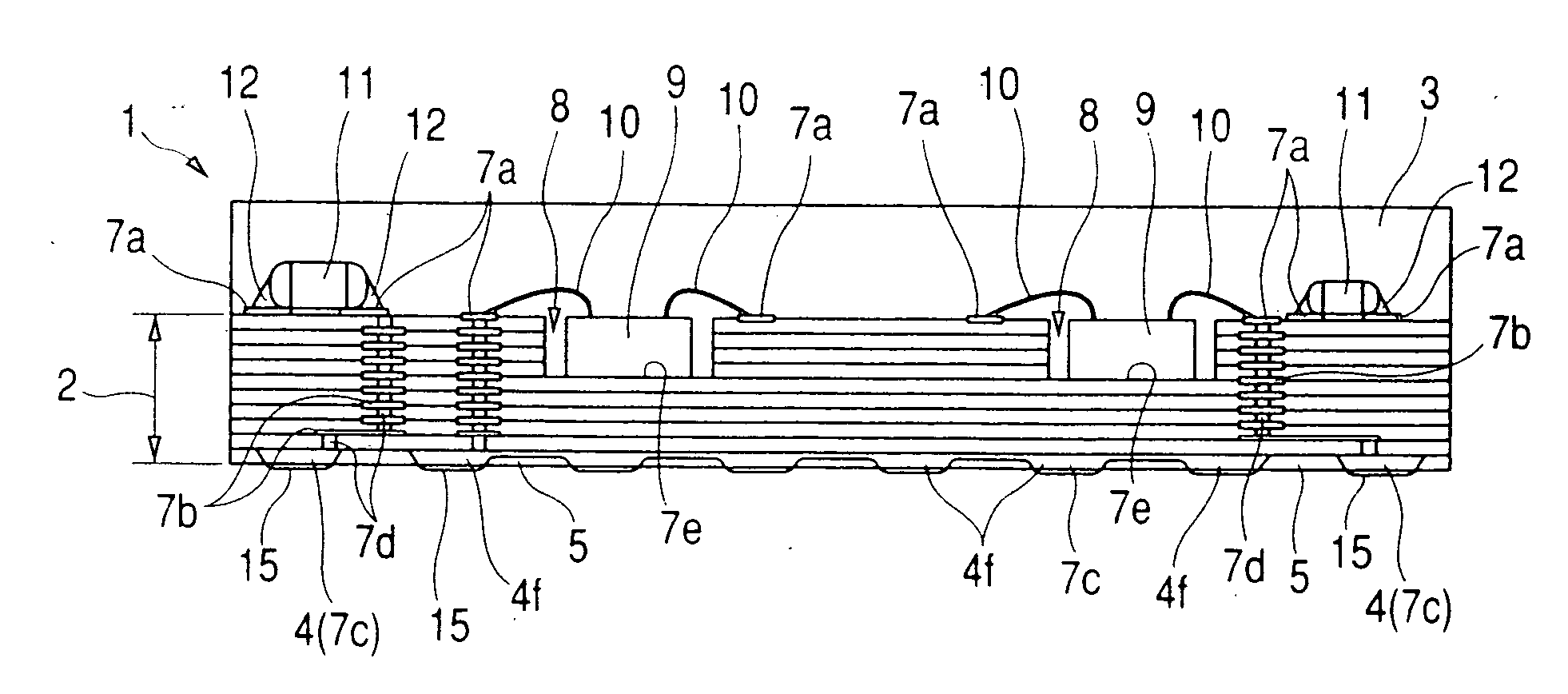

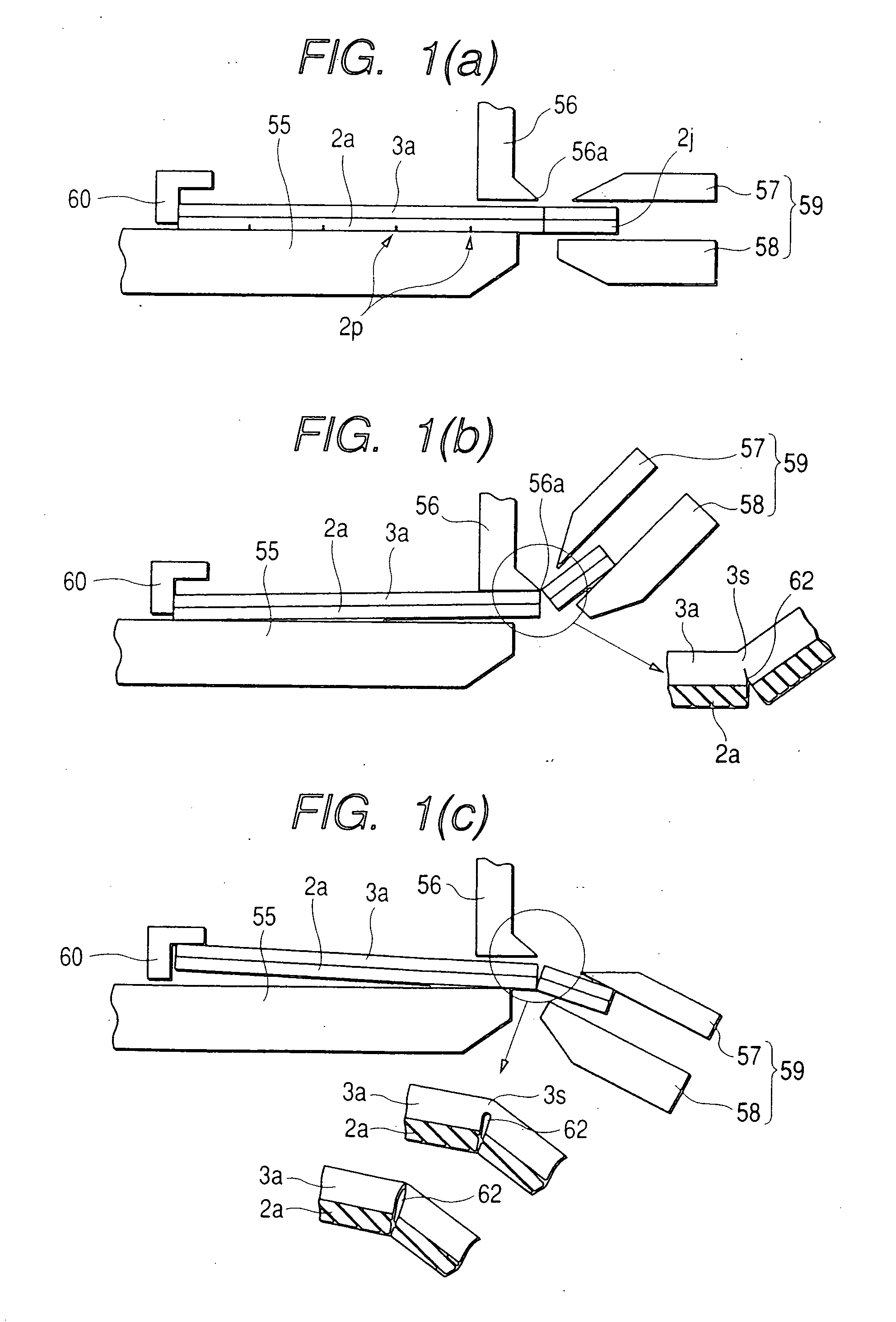

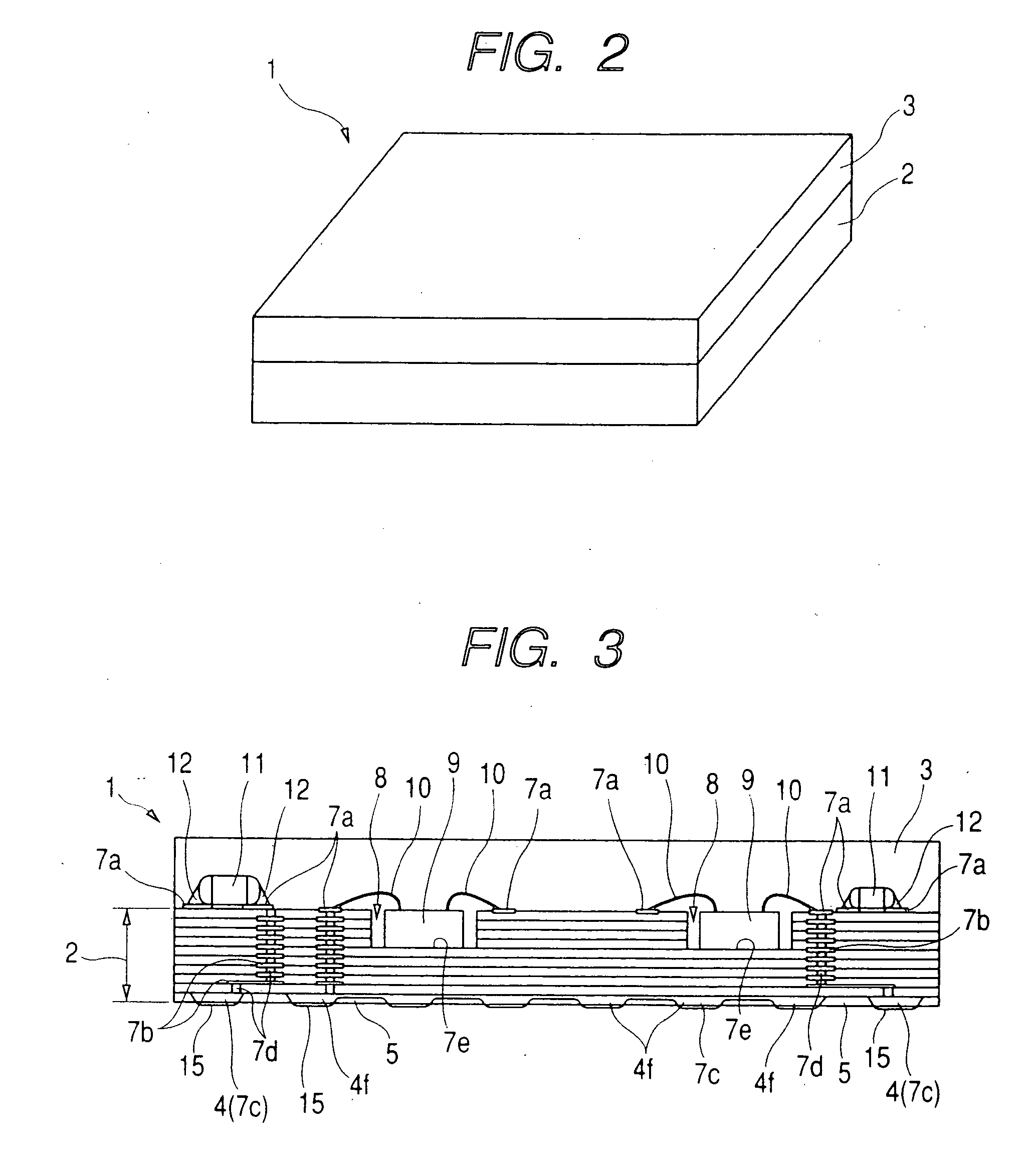

[0070] The first embodiment will explain an example in which the present invention is applied to the manufacture of a semiconductor device (hybrid integrated circuit device) built in a cellular phone. FIGS. 1 through 29 are drawings related to a method of manufacturing a semiconductor device, showing the first embodiment of the present invention, and a semiconductor manufacturing apparatus. FIGS. 2 through 7 are drawings related to the semiconductor device manufactured by the first embodiment. FIGS. 1(a) to 1(c) and FIGS. 8 through 29 are drawings related to the semiconductor manufacturing apparatus.

[0071] As shown in FIG. 2, the semiconductor device (hybrid integrated circuit device) 1 manufactured by the semiconductor device manufacturing method according to the present embodiment comprises, in appearance, a module substrate 2 constituted of a square-shaped low temperature calcined laminated substrate, and an encapsulator or encapsulating body 3 formed of an insulating resin that...

second preferred embodiment

[0174] A second embodiment shows an example in which in a semiconductor manufacturing apparatus, the division of a wiring board is made satisfactory and the position to divide the wiring board can be set accurately. FIGS. 30(a) and 30(b) is a typical view illustrating a cutting mechanism for cutting a substrate covered with a resin layer and its cut state.

[0175] As described in the first embodiment, the surface of the resin layer 3a formed by printing is low in flatness due to an undulation or the like. When the undulation is large, a resin layer 3a is not brought into contact with a fulcrum 56a of a support body 56 when a protruded wiring board portion 2j of a substrate 2a is forced up, and a top portion 142 of an undulation 141 comes into contact with the lower surface of the support body 56, as shown in FIG. 31. It has turned out that since the position to which a dividing force is applied, does not correspond to the position of the fulcrum 56a in such a case, the division does ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com