Land leveler scraping working device based on rotary translation mechanism

A technology for working devices and graders, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc. It can solve the difficulties of high-precision motion control, poor blade flexibility, and small movement space, etc. problem, to achieve the effect of easy control of blade inclination angle, good dynamic performance and meeting construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

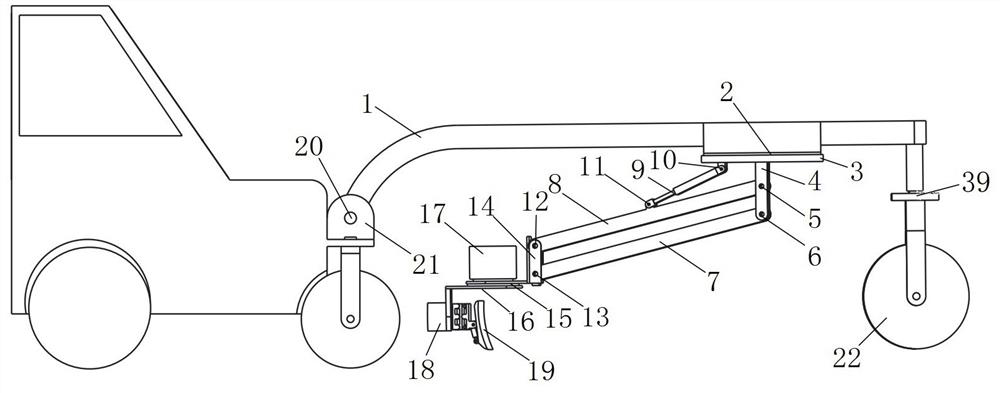

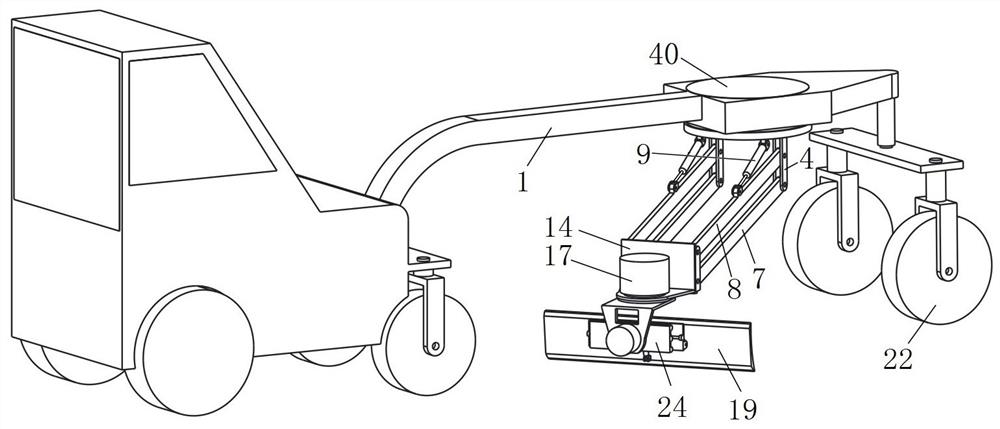

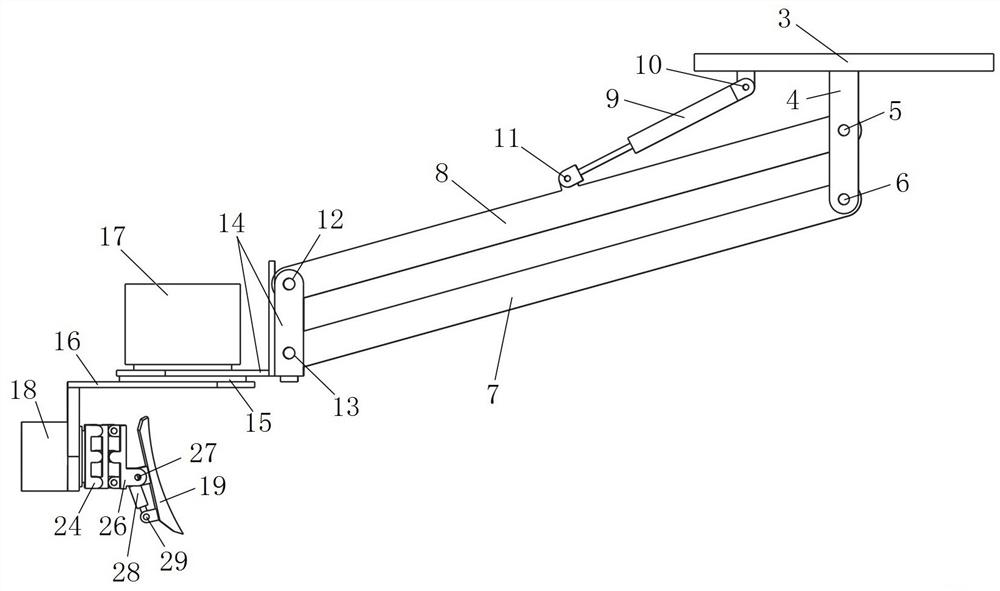

[0040] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

[0041] control figure 1 , figure 2 , image 3 , Figure 4 , a soil scraping device for a grader based on a rotary translation mechanism, including a frame 1, a first rotary table 3, a translation mechanism, a second rotary table 16, and a blade mechanism. One end of the frame 1 is connected to the front vehicle The frame 22 is connected, and the other end is connected with the rear frame 21. The first turntable 3 is installed on the frame 1 through the first rotating pair 2 and driven by the first driving element 40, which is hydraulic Under the driving action of the motor or motor, the first turntable 3 can rotate relative to the frame 1, and cooperate with the translation mechanism to realize the extraction of the blade mechanism.

[0042] control figure 2 , Figure 5 , Figure 6 , when the existing motor grader relies on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com