Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Satisfactory heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

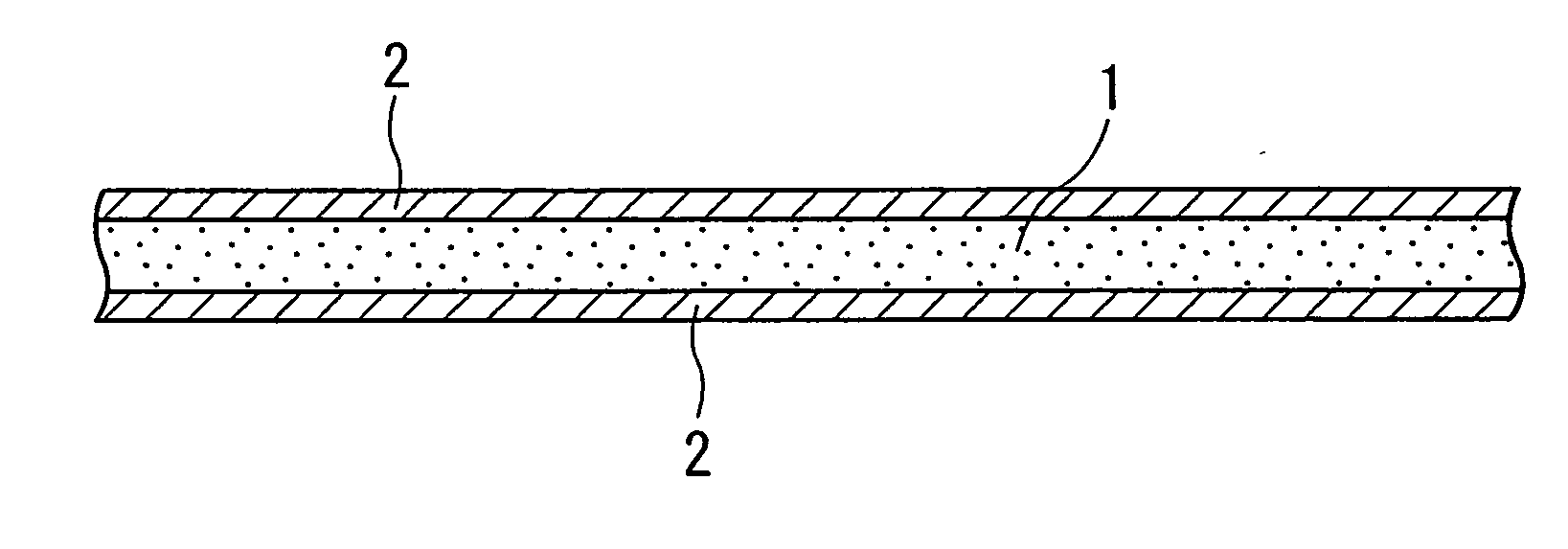

Pressure sensitive adhesive optical film and image viewing display

InactiveUS20030198807A1Avoid damageSmall valuePolarising elementsThin material handlingOptical thin filmImage View

A pressure sensitive adhesive optical film that has good reworkability, and further has excellent moisture heat resistance, and that gives neither foaming nor peeling under heated and humidified treatment is provided. A pressure sensitive adhesive optical film with a pressure sensitive adhesive layer laminated on at least one surface of an optical film, wherein a P0 gives a value of no more than 5 N / 25 mm, (where the pressure sensitive adhesive layer is attached on a glass plate, it is given an autoclave processing under a condition of 50° C.x5 atmx15 minutes, it is left under 23° C. ambient atmosphere for 30 minutes, and subsequently, the P0 of initial 90° peel strength at 23° C. and by a peeling speed of 300 mm / minute is determined), and a ratio (P1 / P0) of a P1 to a P0 is no less than 2 (where after the pressure sensitive adhesive layer is given the above-mentioned autoclave processing, it is furthermore given a heat-treatment at 80° C. for 2 hours, subsequently, it is left in 23° C. ambient atmosphere for 30 minutes, and the P1 of 90° peel strength after heating by a peeling speed of 300 mm / minute and at 23° C. is determined).

Owner:NITTO DENKO CORP

Laminate with fluoropolymer film and film-forming fluoropolymer

ActiveUS20070026222A1Maintain heat resistanceMaintaining non-stickinessSynthetic resin layered productsFlexible pipesPolymer sciencePhosphate

A functionalized fluoropolymer, preferably with phosphate functionality, can be coated on a metal oxide containing rubber substrate, which coating, after heating, results in a fluoropolymer-rubber substrate laminate without degradation of the rubber, and with good adhesion between the fluoropolymer and the rubber.

Owner:THE CHEMOURS CO FC LLC +1

Highly heat conductive silicone rubber composition, fixing roll and fixing belt

InactiveUS20050048296A1High thermal conductivitySatisfactory heat resistanceGroup 4/14 element organic compoundsShaft and bearingsThermal conductivityAddition reaction

A silicone rubber composition comprising (A) a normally liquid organopolysiloxane having at least two silicon atom-bonded alkenyl radicals, (B) a liquid organohydrogenpolysiloxane having at least two Si—H radicals, (C) a blend of two inorganic powders selected from three highly heat conductive inorganic powders which form 30% slurries at pH at least 8, 6 to less than 8, and less than 6, and (D) an addition reaction catalyst cures into a silicone rubber having a high thermal conductivity and heat resistance and is suited for fixing rolls or belts in copiers.

Owner:SHIN ETSU CHEM IND CO LTD

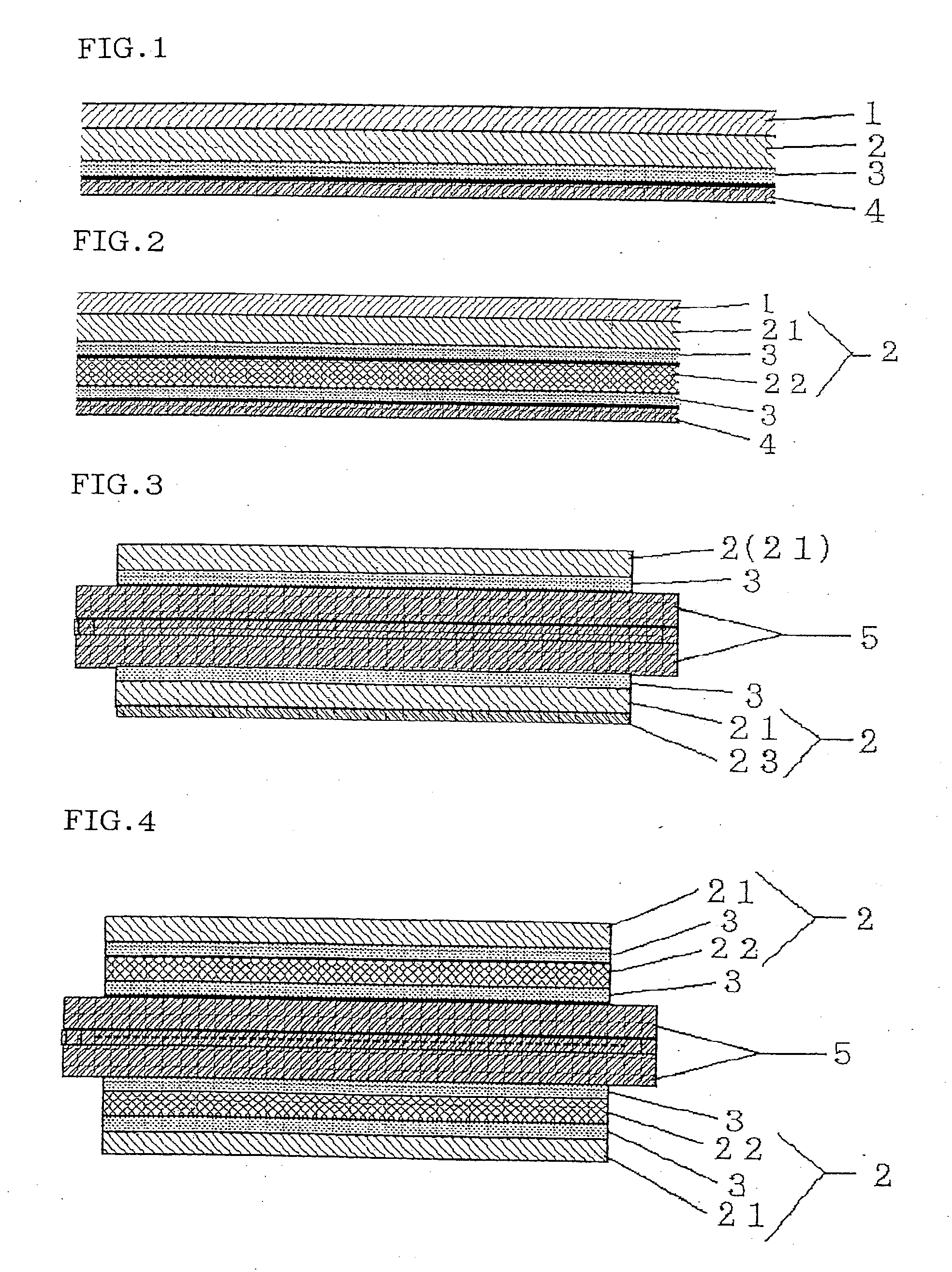

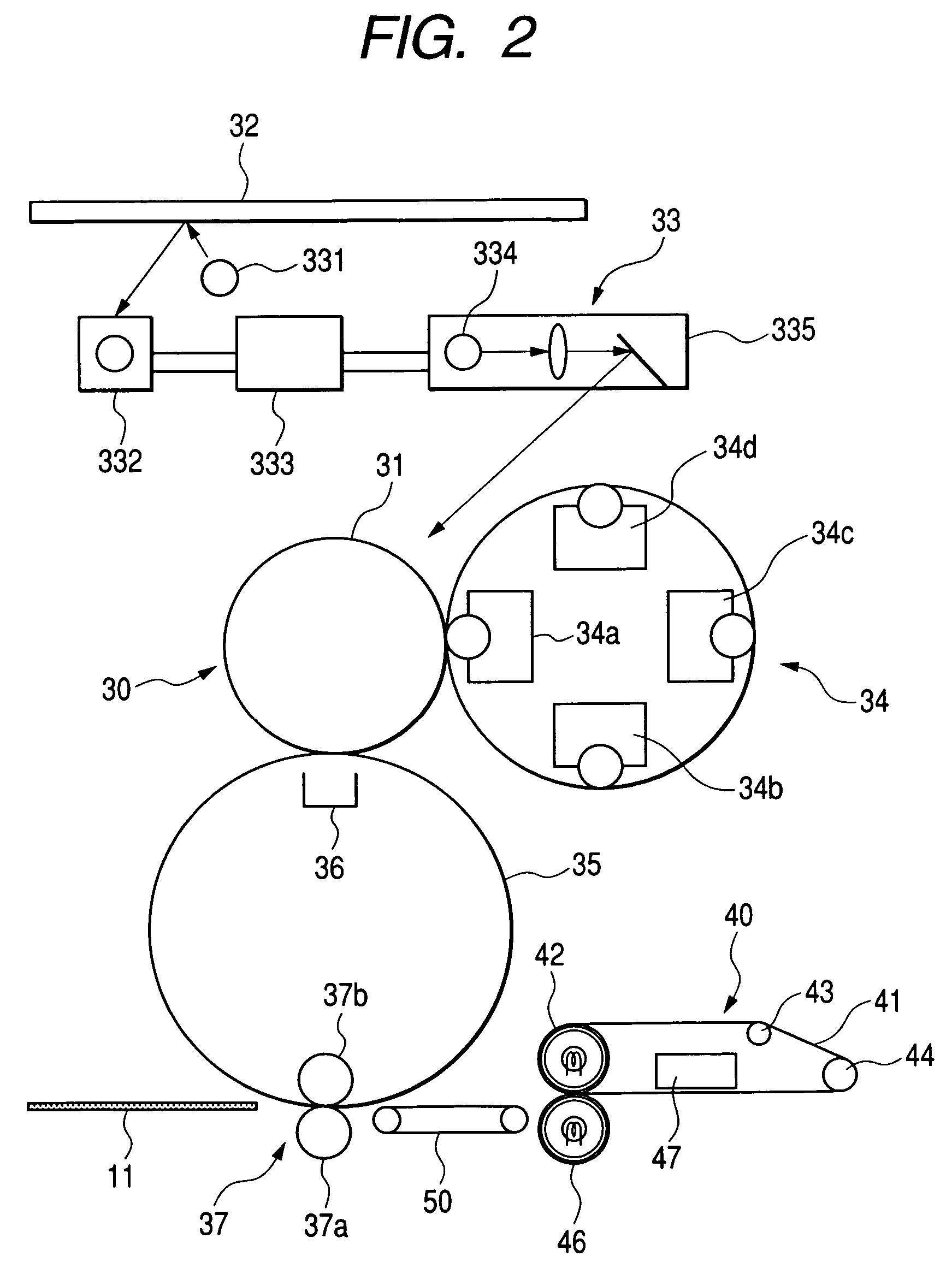

Heat fixing roll and fixing belt

ActiveUS20070135555A1Overcome lack of heat resistanceAdequate modulusShaft and bearingsSynthetic resin layered productsPolymer scienceSilicon

A heat fixing roll or belt having a silicone rubber layer which is formed by curing a silicone rubber composition comprising (A) 100 pbw of an organopolysiloxane having at least two silicon-bonded alkenyl radicals in a molecule, (B) 20-500 pbw of a metallic silicon powder having an average particle size of up to 100 μm, and (C) an effective amount of a curing agent. The silicone rubber layer has a high heat conductivity and long-term temperature durability.

Owner:SHIN ETSU CHEM IND CO LTD

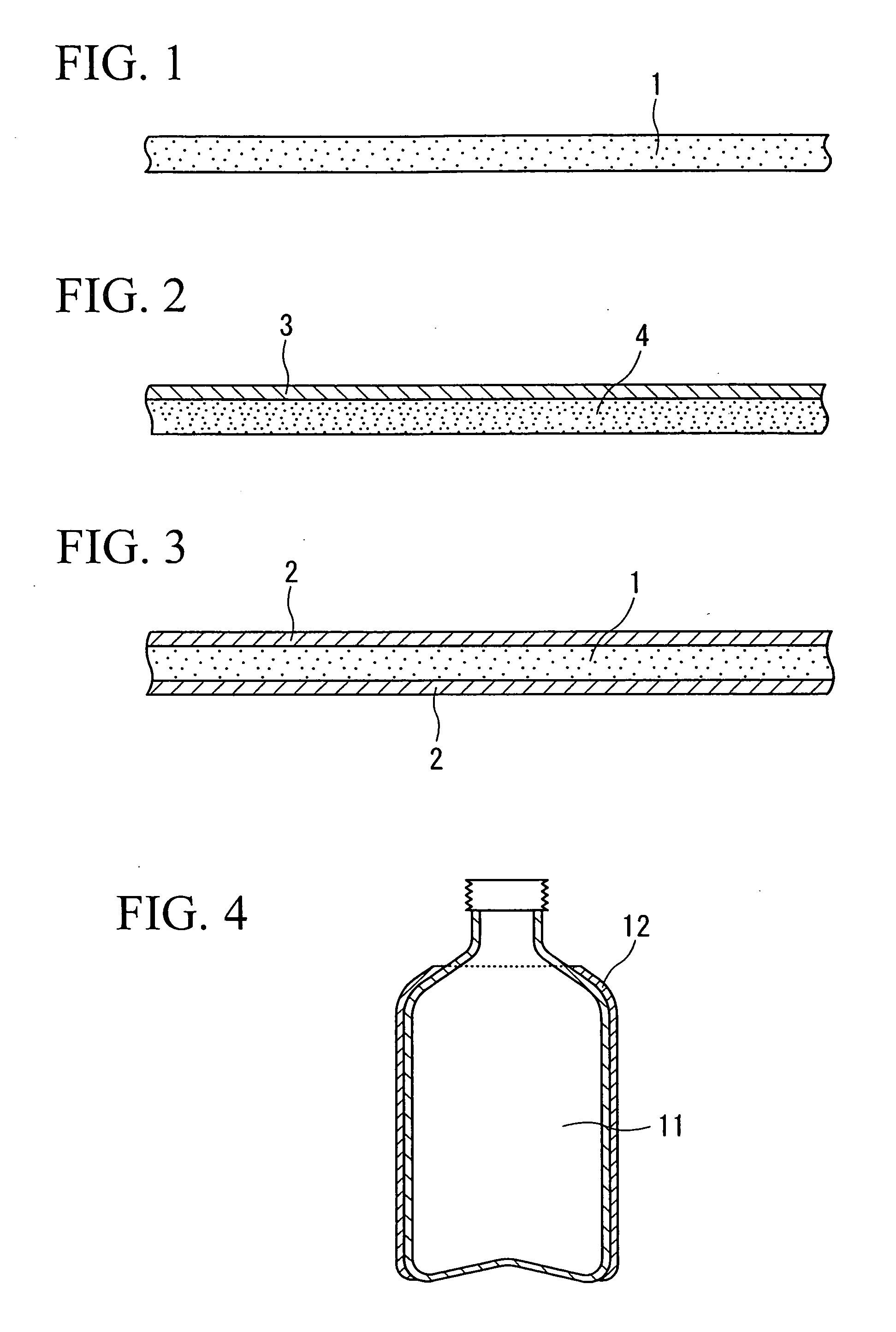

Foamed Film for Shrink Labels

InactiveUS20090294458A1Easy to bendSimplyBottlesSynthetic resin layered productsStatic friction coefficientEngineering

The present invention provides a foamed film for shrink labels which is capable of being accommodated by the new continuous attachment system for shrink labels, and in which a long foamed film for shrink labels is wound around the body of a container, and is cut at the inner-position where the film overlaps, after which the two ends of the resulting film unit are joined together to form a cylindrical shape, and this is subsequently heated to cause heat shrinkage of the film and to produce the label. The foamed film for shrink labels of the present invention is a film which stretches a blown film with an expansion ratio of 1.3 to 5 in the longitudinal direction (vertical direction or extrusion direction) so that the draw ratio is 1.5 to 4.0, which has properties such as a thickness of 120 to 300 μm, a tensile elastic modulus of 80 to 500 MPa, a static friction coefficient of 0.3 to 0.8, a coefficient of shrinkage of 15% or more at 90° C. and 30% or more at 120° C., and which is foamed and has shrinkability.

Owner:NISSEI CHEM +1

Resin composition

ActiveUS20170275453A1Improve the immunitySatisfactory heat resistanceSemiconductor/solid-state device detailsSolid-state devicesVinyl etherPolyvinylidene difluoride

Owner:FUJI ELECTRIC CO LTD

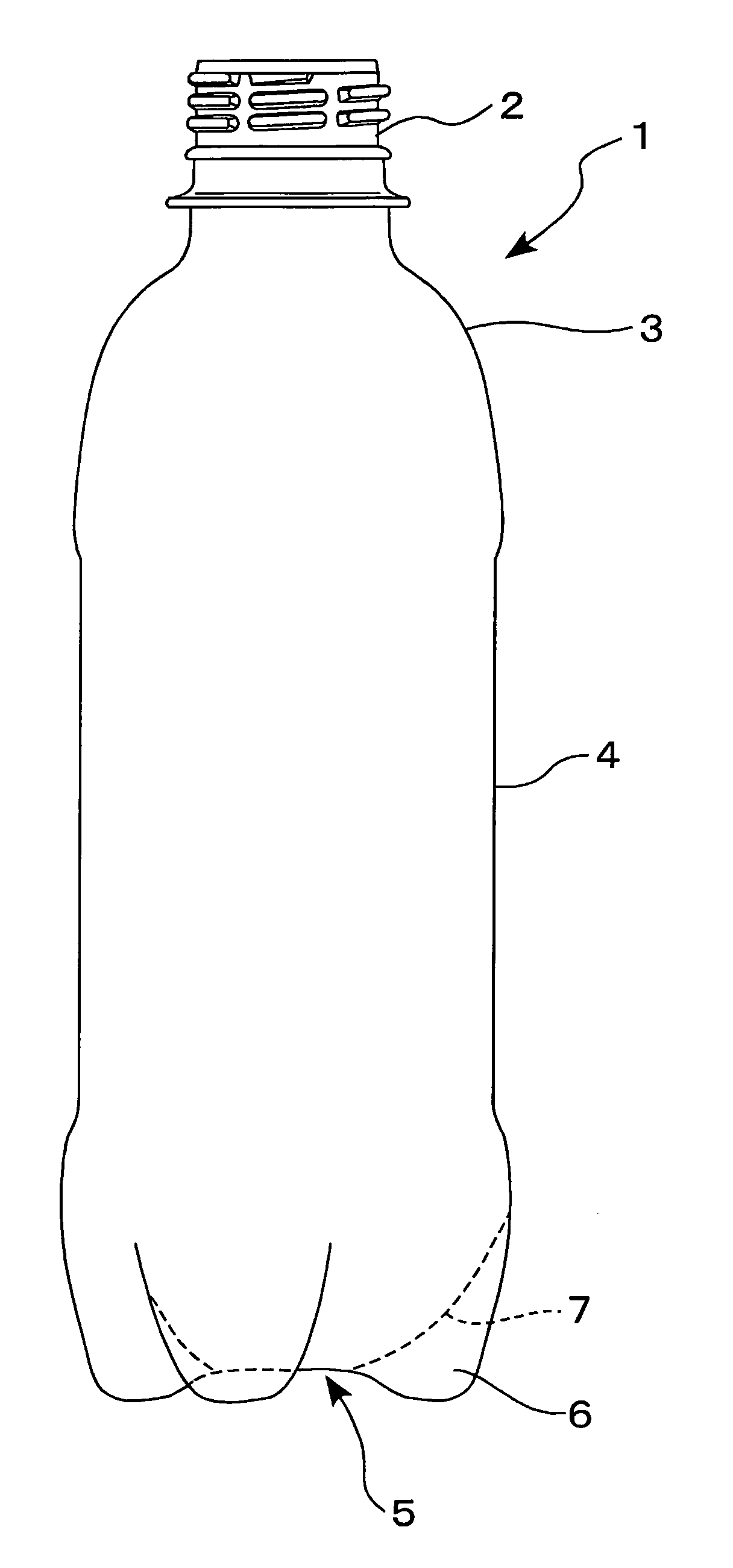

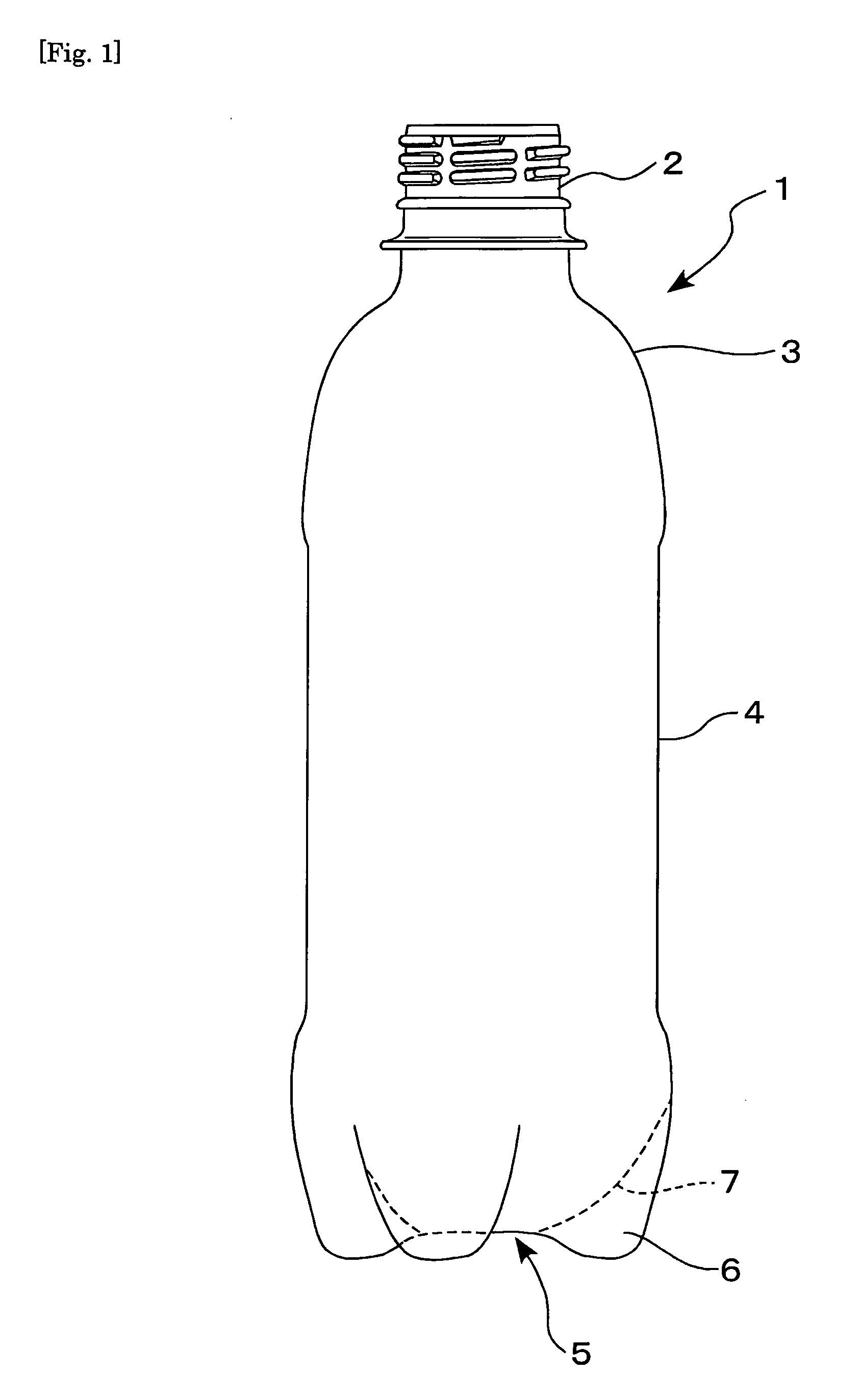

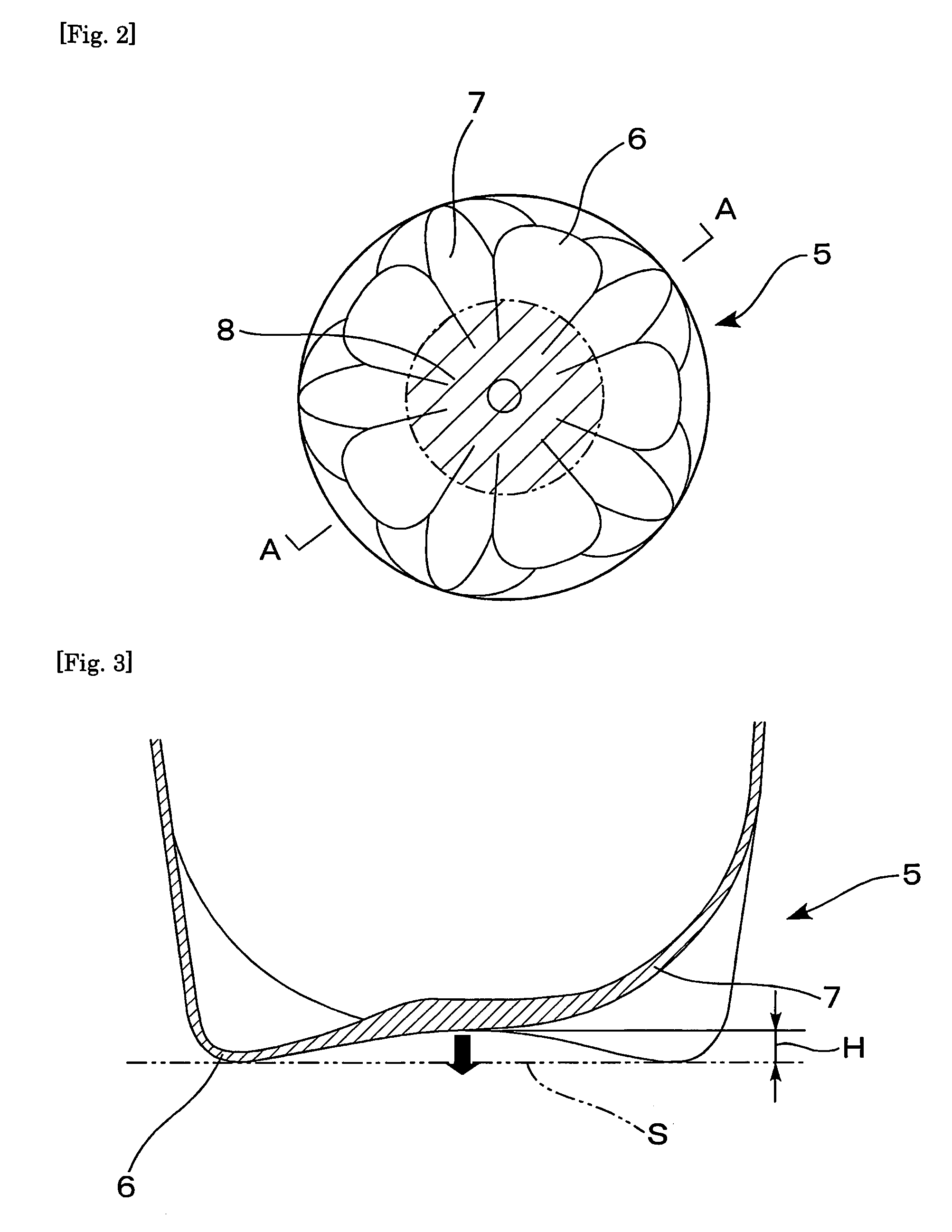

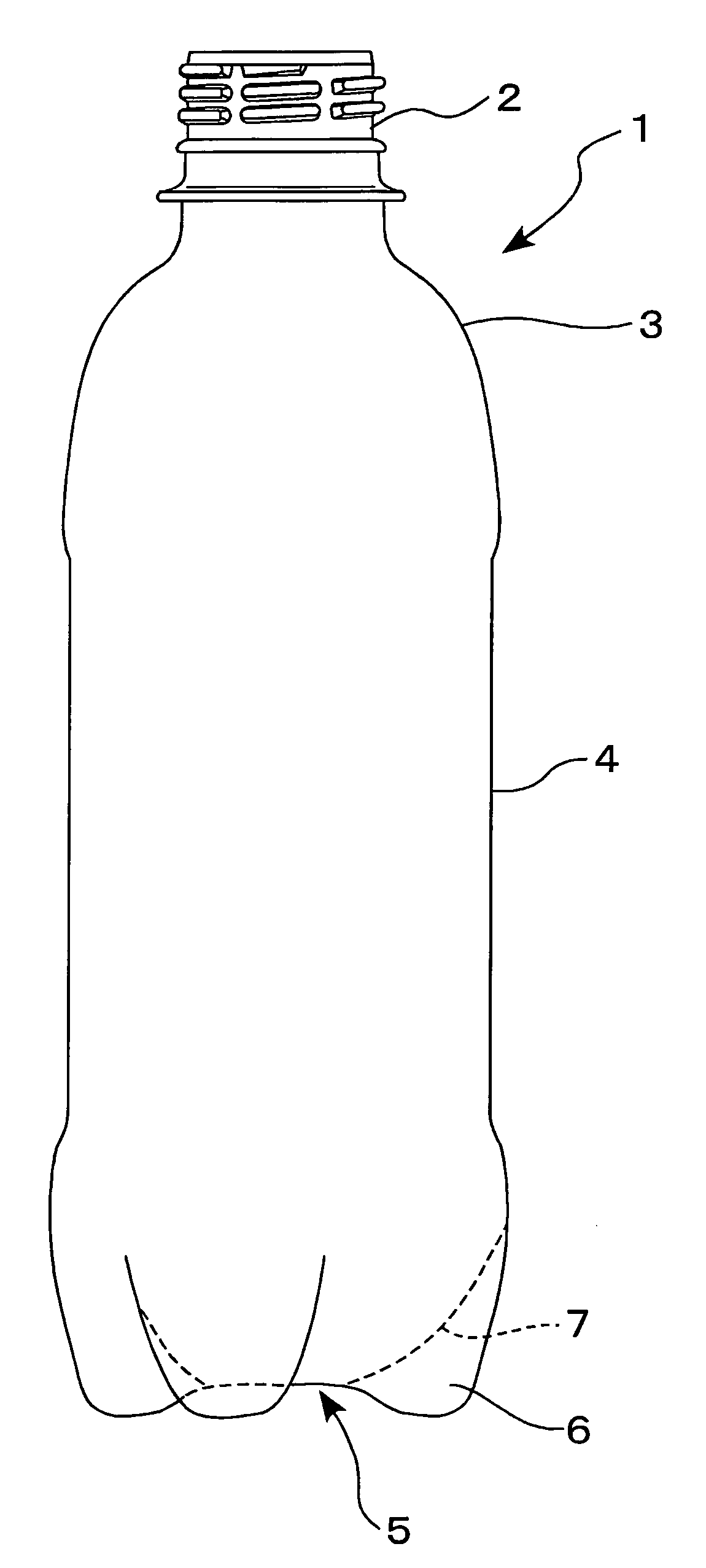

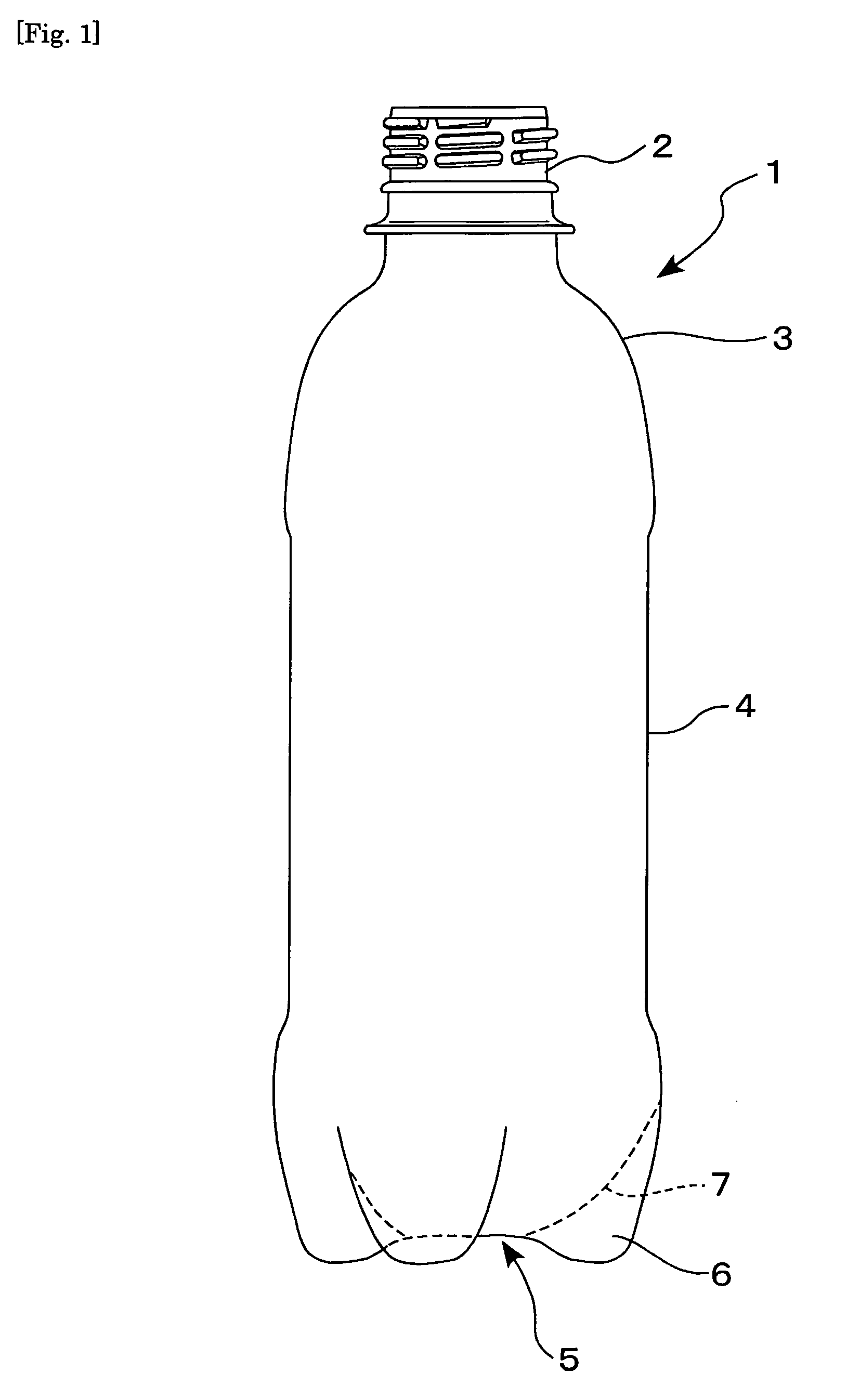

Polyester Resin and Heat and Pressure Resistant Plastic Bottle

InactiveUS20080274318A1Satisfactory heat resistanceResistant strengthEnvelopes/bags making machineryBottlesEngineeringHigh heat

This invention is intended to improve the heat resistance of PET bottles from a material aspect. A technical problem of this invention is to find a polyester resin which is suitable for heat and pressure resistant plastic bottles and which does not eat into productivity and is available at a low cost. The object of this invention is to provide a heat and pressure resistant plastic bottle that can be manufactured at a low cost and has pressure resistance at a high temperature and high impact strength. The means of fulfilling this object is a polyester resin comprising a major part of ethylene terephthalate units and containing at least one of minor copolymerizable components selected from a group consisting of isophthalic acid, cyclohexane dimethanol, and diethylene glycol, wherein three minor copolymerizable components have total content less than 3 mol. %.

Owner:YOSHINO KOGYOSHO CO LTD

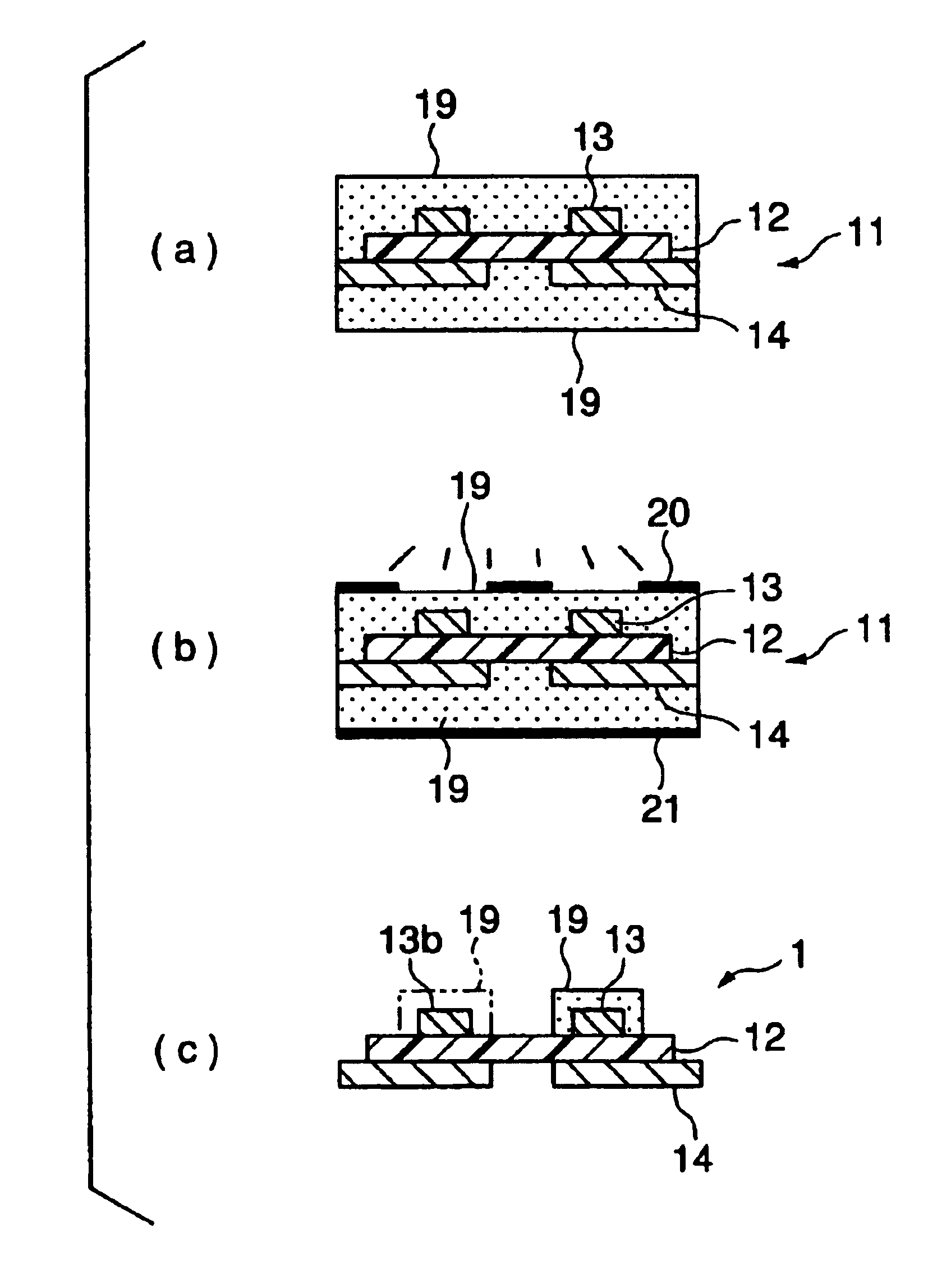

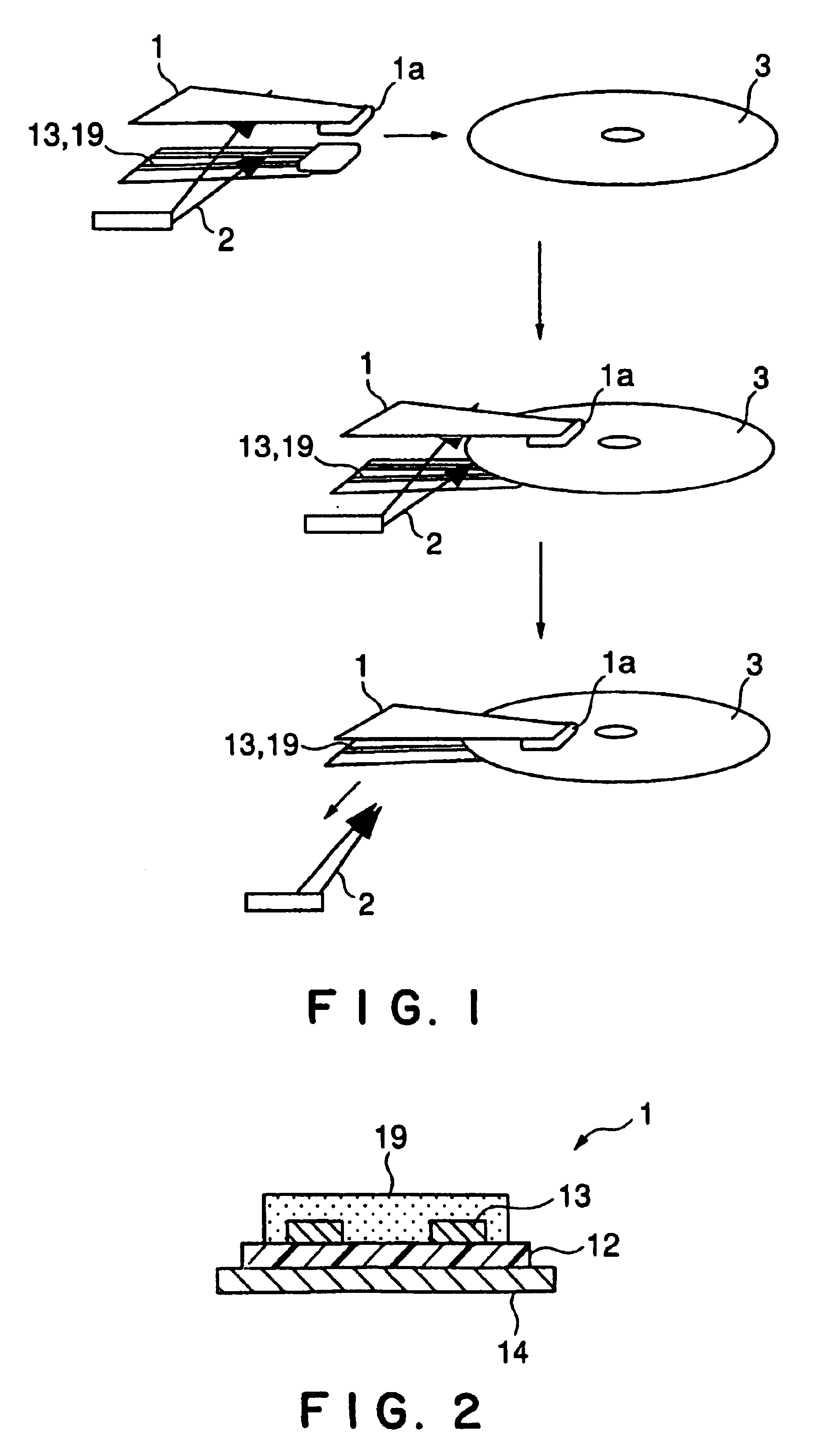

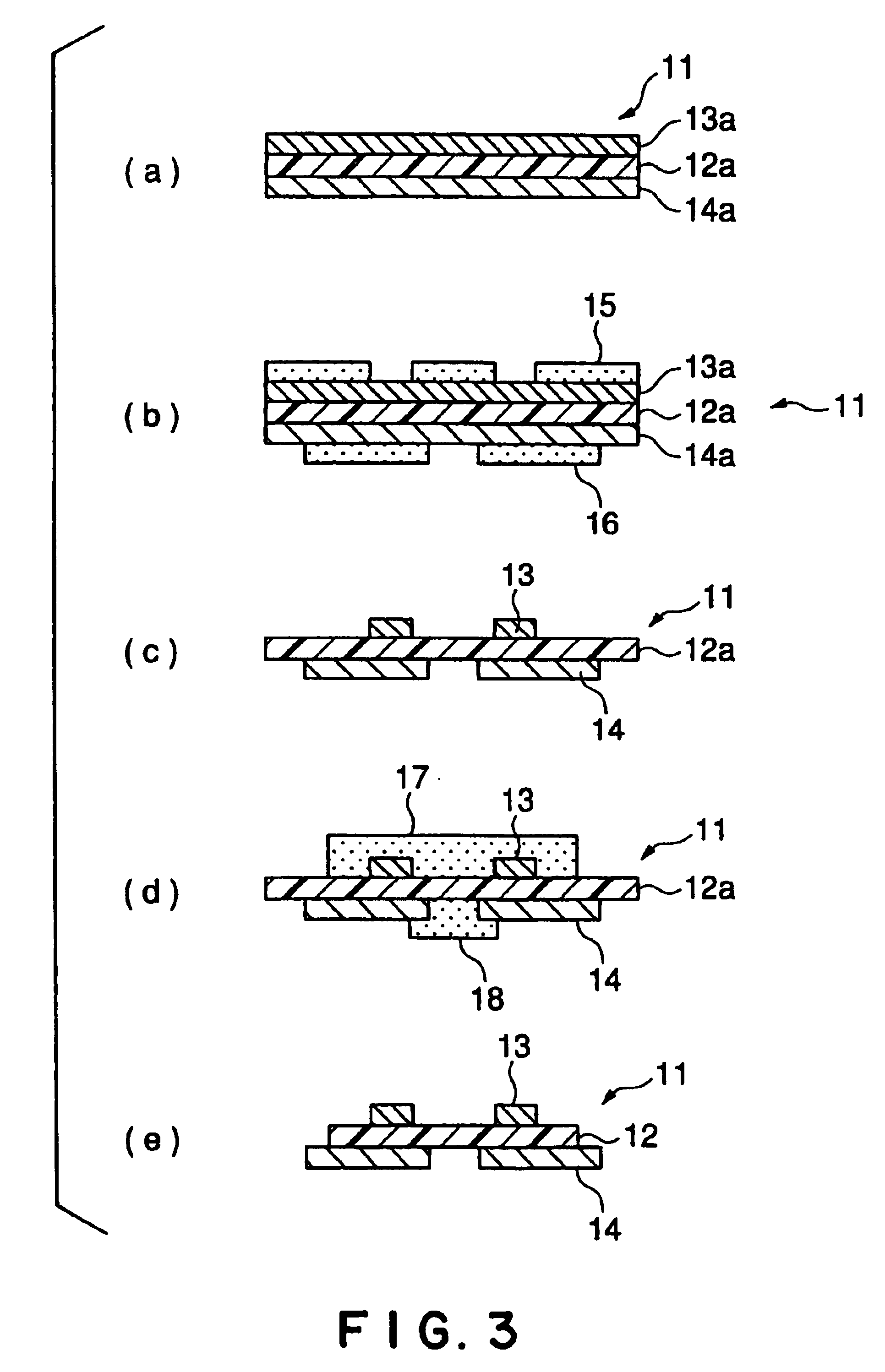

Magnetic head suspension with both protected wiring and unprotected wiring, in addition to terminals

InactiveUS6894875B2Good chemical resistanceMeet heat resistanceDisposition/mounting of recording headsRecord information storageEpoxyAcrylic resin

A magnetic head suspension includes an insulating base (12), wiring parts (13) formed on one surface of the insulating base (12) including a conductive metal layer, an elastic metal plate (14) provided on the other surface of the insulating base (12), and a wiring protecting layer (19) covering the wiring parts (13). The wiring protecting layer (19) is formed by subjecting a dry film containing an epoxy resin, an acrylic resin and a polymer containing aromatic rings to exposure and developing processes.

Owner:DAI NIPPON PRINTING CO LTD

Thermocurable Polyimide Resin Composition

InactiveUS20090305046A1Low coefficient of water absorptionSatisfactory heat resistancePrinted circuit aspectsPrinted circuit manufactureSolventChemistry

A thermosetting polyimide resin composition which, when used in an adhesive layer of a metal-clad laminate, is able to be manufactured by only the solvent removal without requiring an imidation step reaching 300° C. or higher and is thermosetting, a cured material of which is excellent in adhesive properties, low in coefficient of water absorption and satisfactory in heat resistance is provided.A thermosetting polyimide resin composition including a polyimide resin having a repeating unit or units having a specified structure and a compound having two or more polymerizable double bonds in one molecule thereof; a film containing the subject thermosetting polyimide resin composition and a metal-clad laminate including an adhesive layer composed of the subject thermosetting polyimide resin composition.

Owner:MITSUBISHI GAS CHEM CO INC

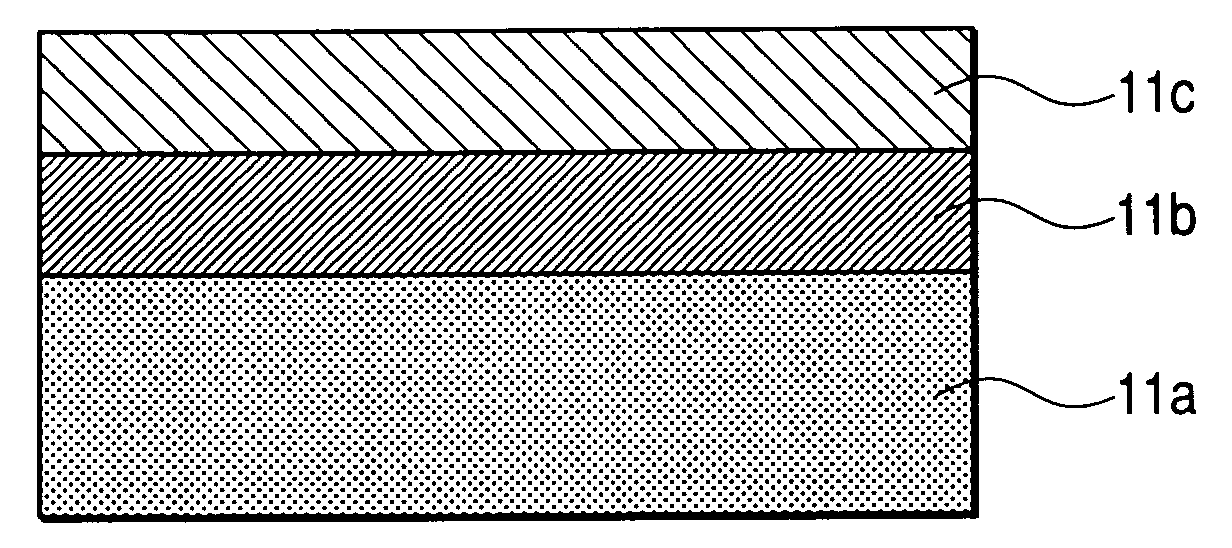

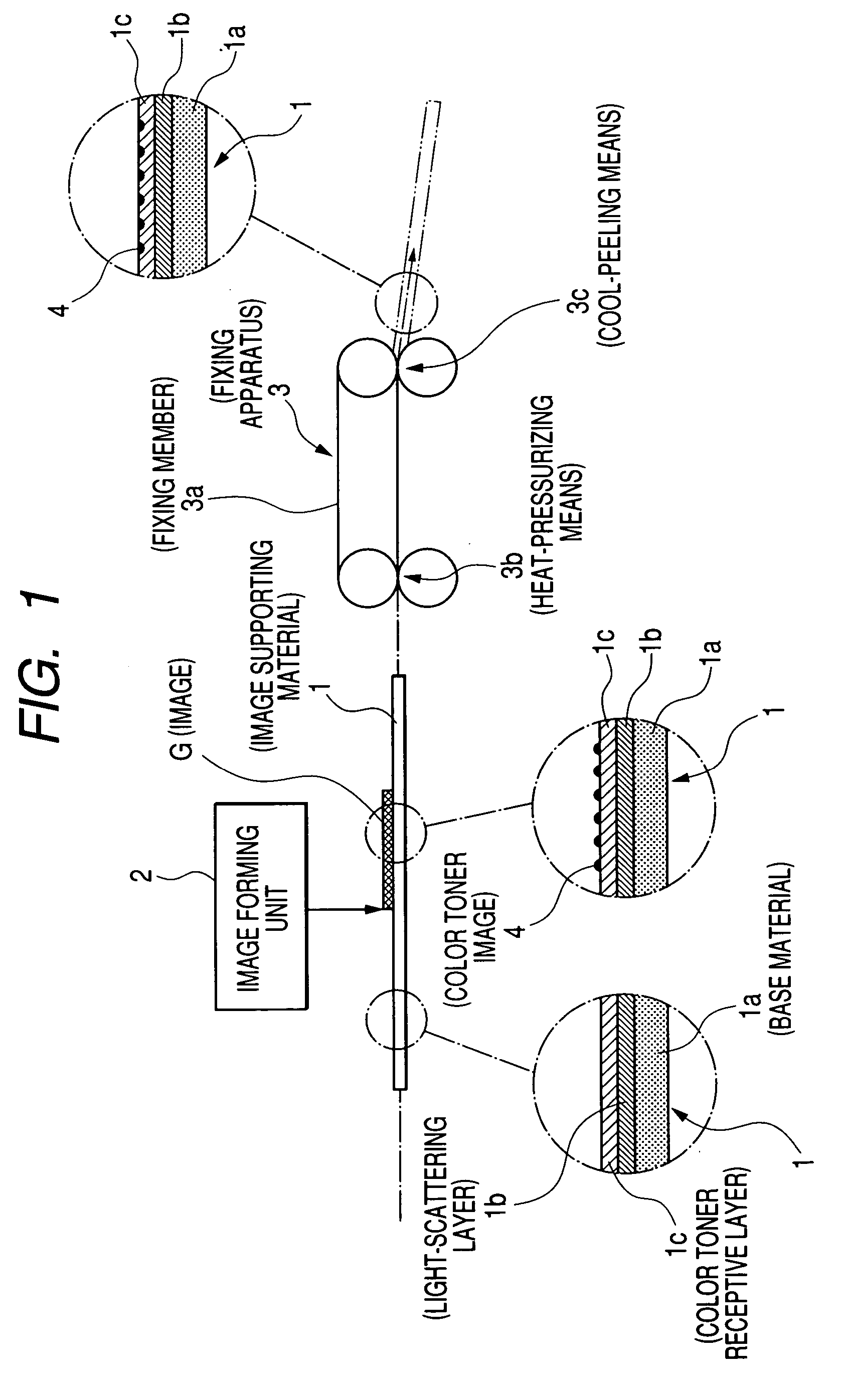

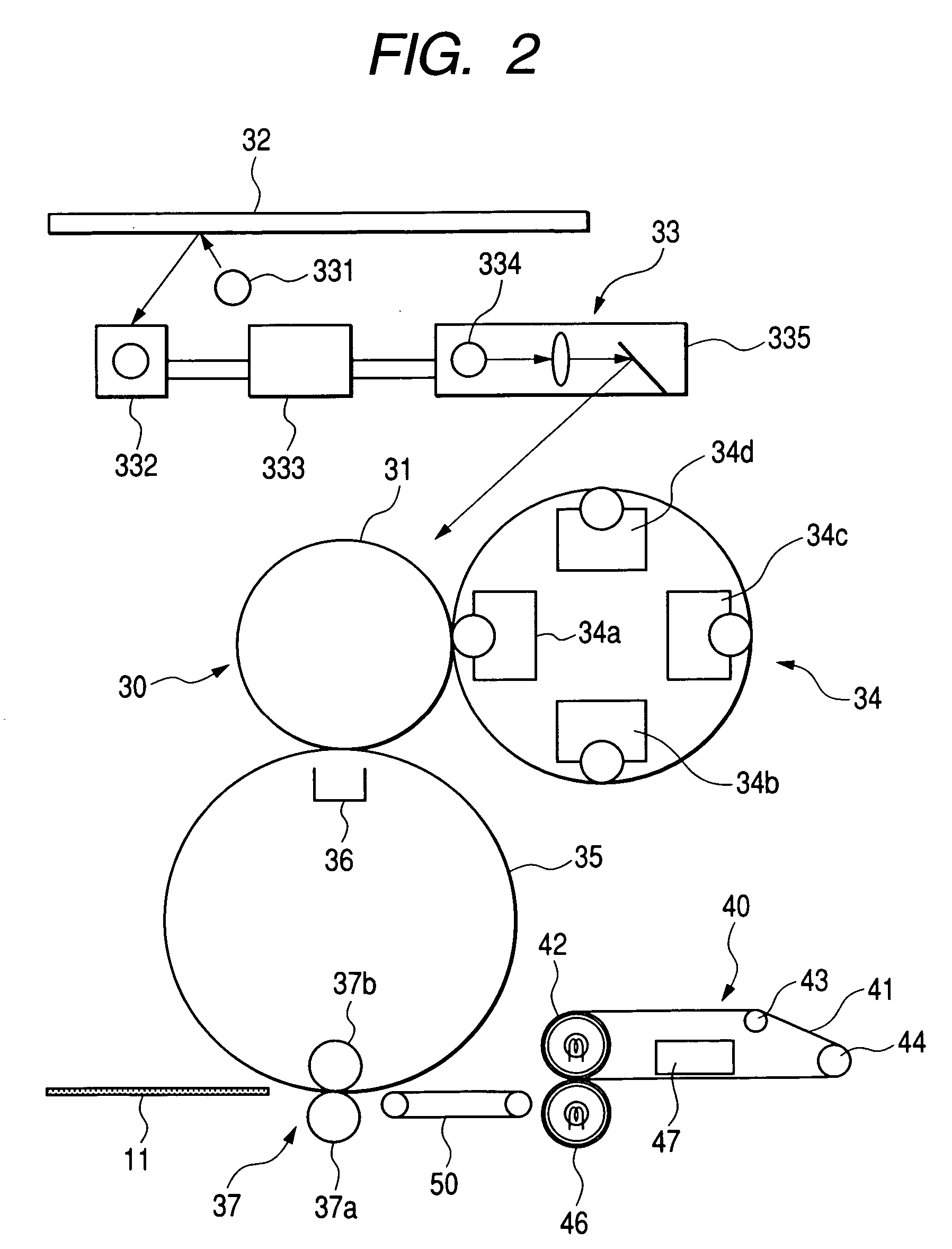

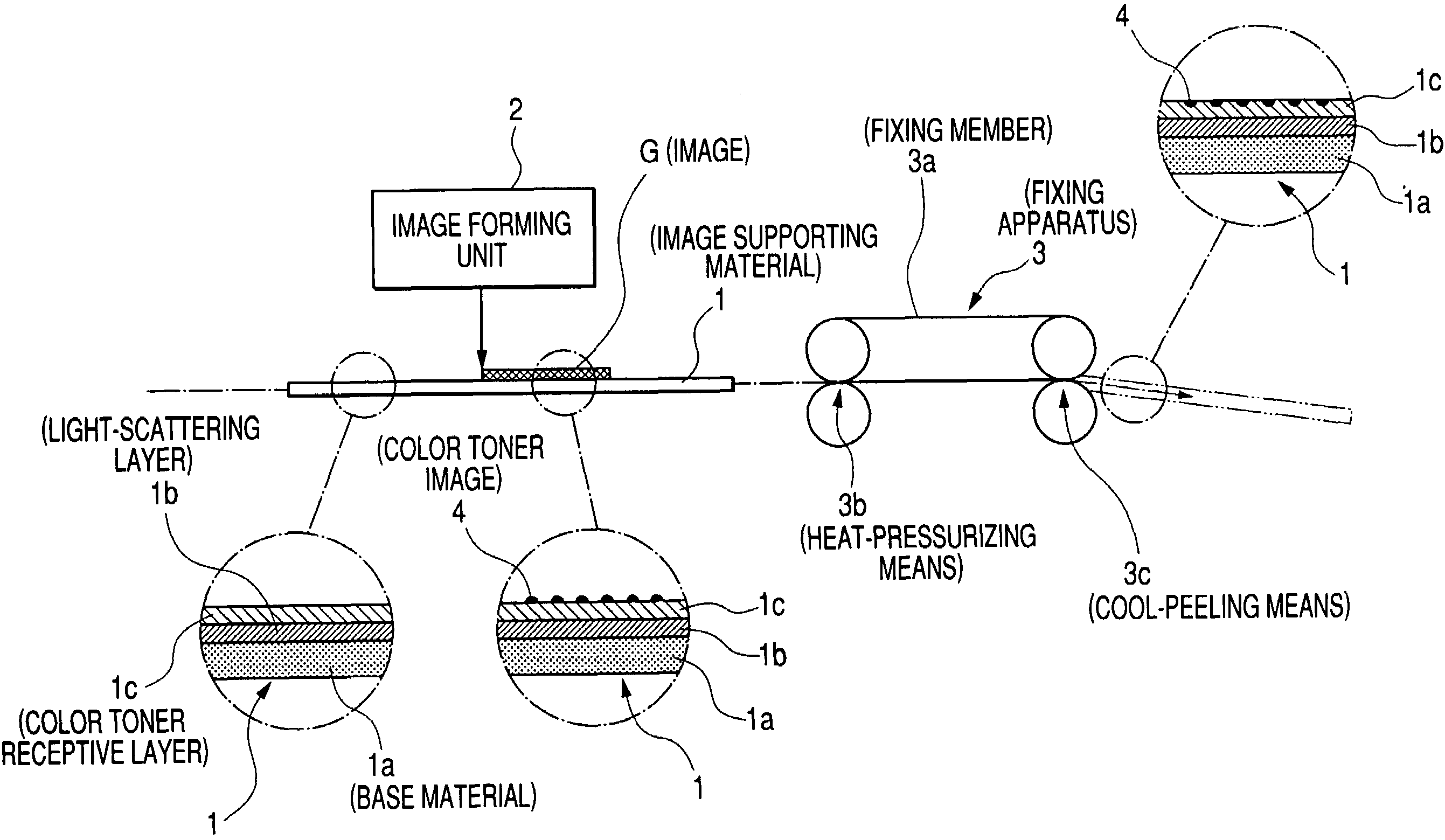

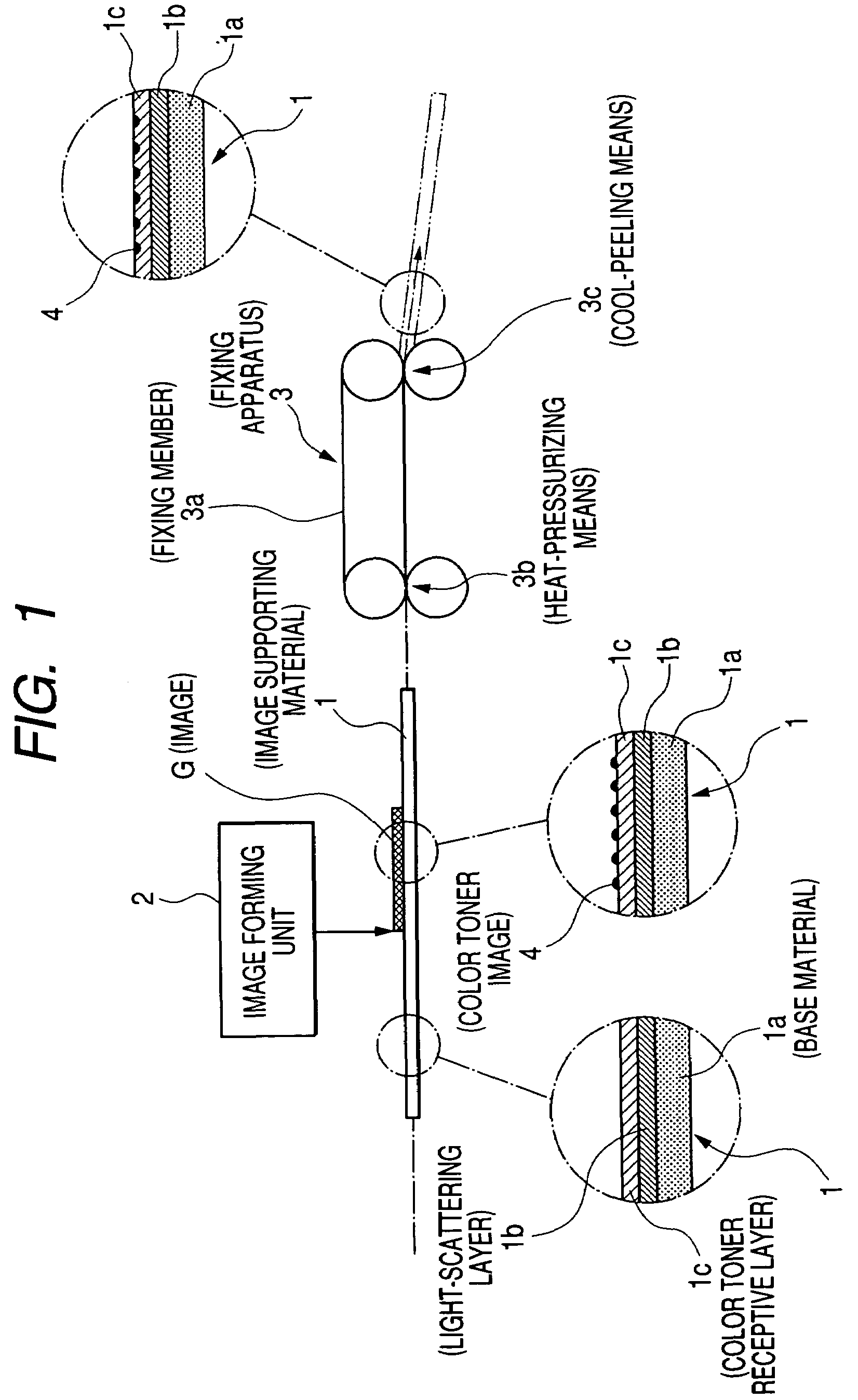

Image supporting material, method for use thereof and image forming apparatus utilizing the same

ActiveUS20050214485A1High glossSatisfactory heat resistanceDecorative surface effectsSpecial ornamental structuresPolyolefinImage formation

The present invention provides an image supporting material for fixably supporting a color toner image, the material including a base material, a light scattering layer provided on the base material and containing a white pigment and a thermoplastic resin, and a color toner receptive layer provided on the light scattering layer and containing at least a thermoplastic resin, wherein the thermoplastic resin in the light scattering layer is constituted of a polyolefin or a polyolefinic copolymer having a temperature, at which viscosity becomes 5×103 Pa·s, of 100° C. or higher, and the thermoplastic resin in the color toner receptive layer is constituted of a resin obtained by melt mixing of a crystalline polyester resin and an amorphous resin and having a temperature, at which viscosity becomes 103 Pa·s, equal to or higher than 65° C. but lower than 80° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

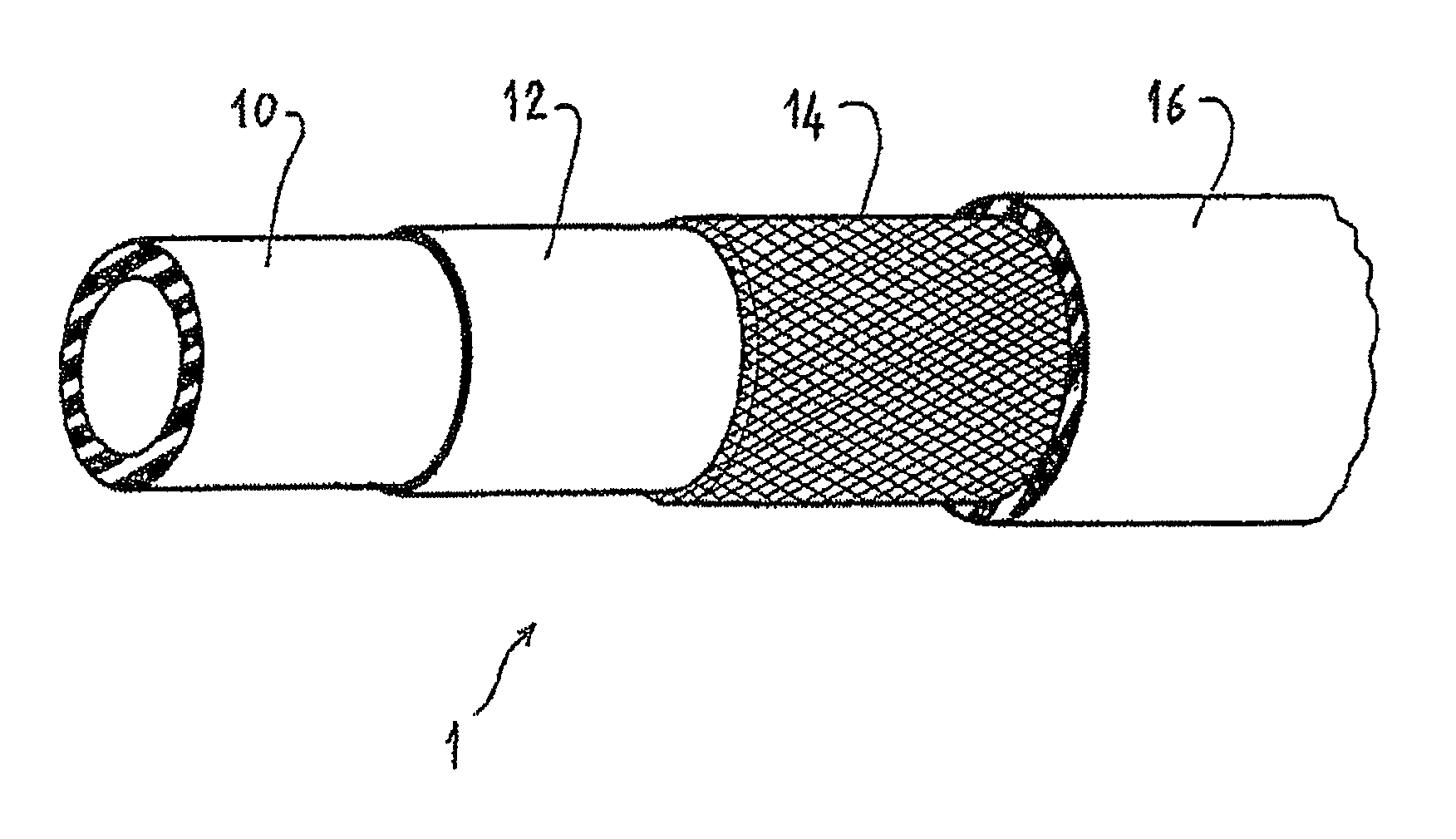

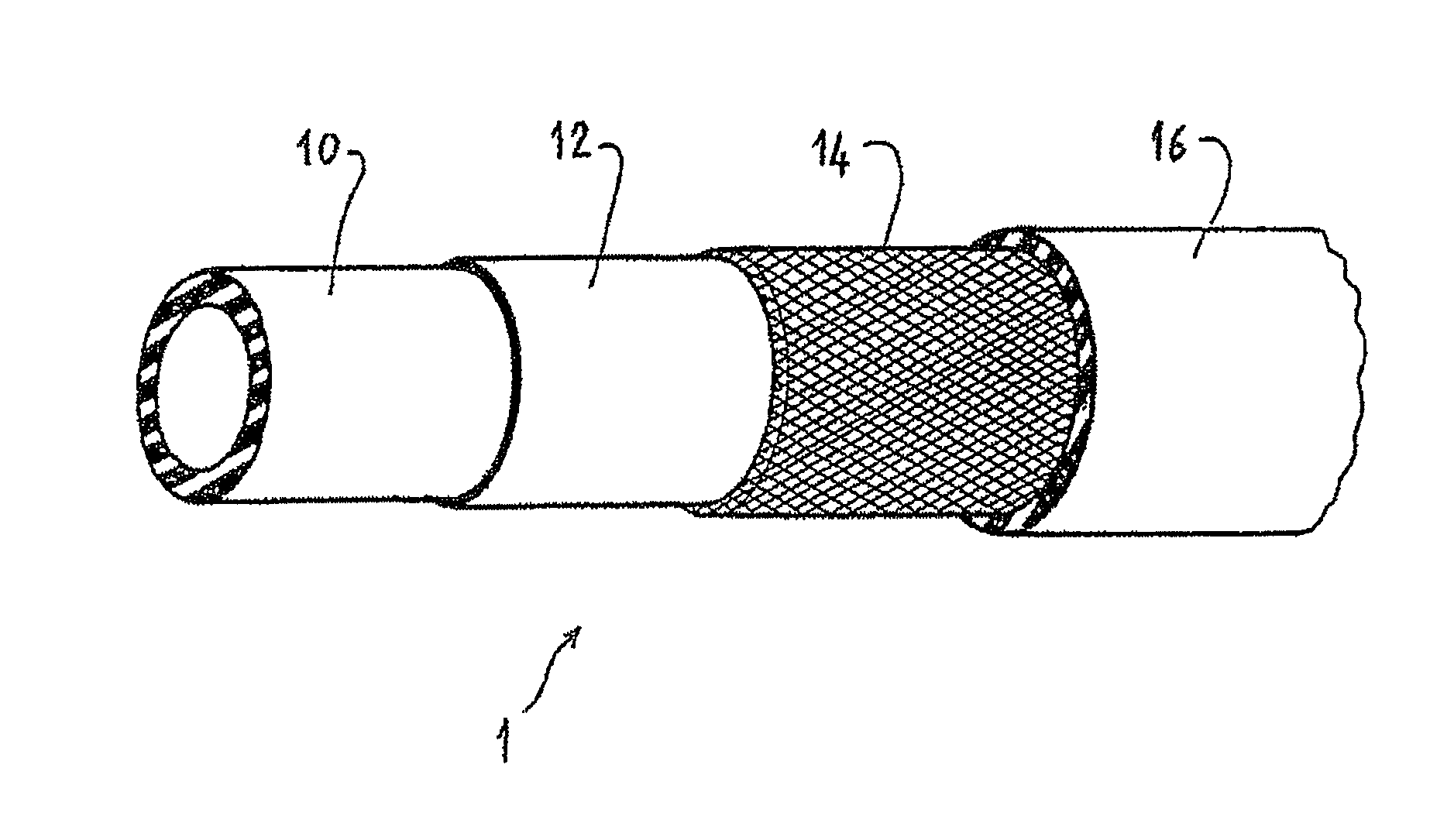

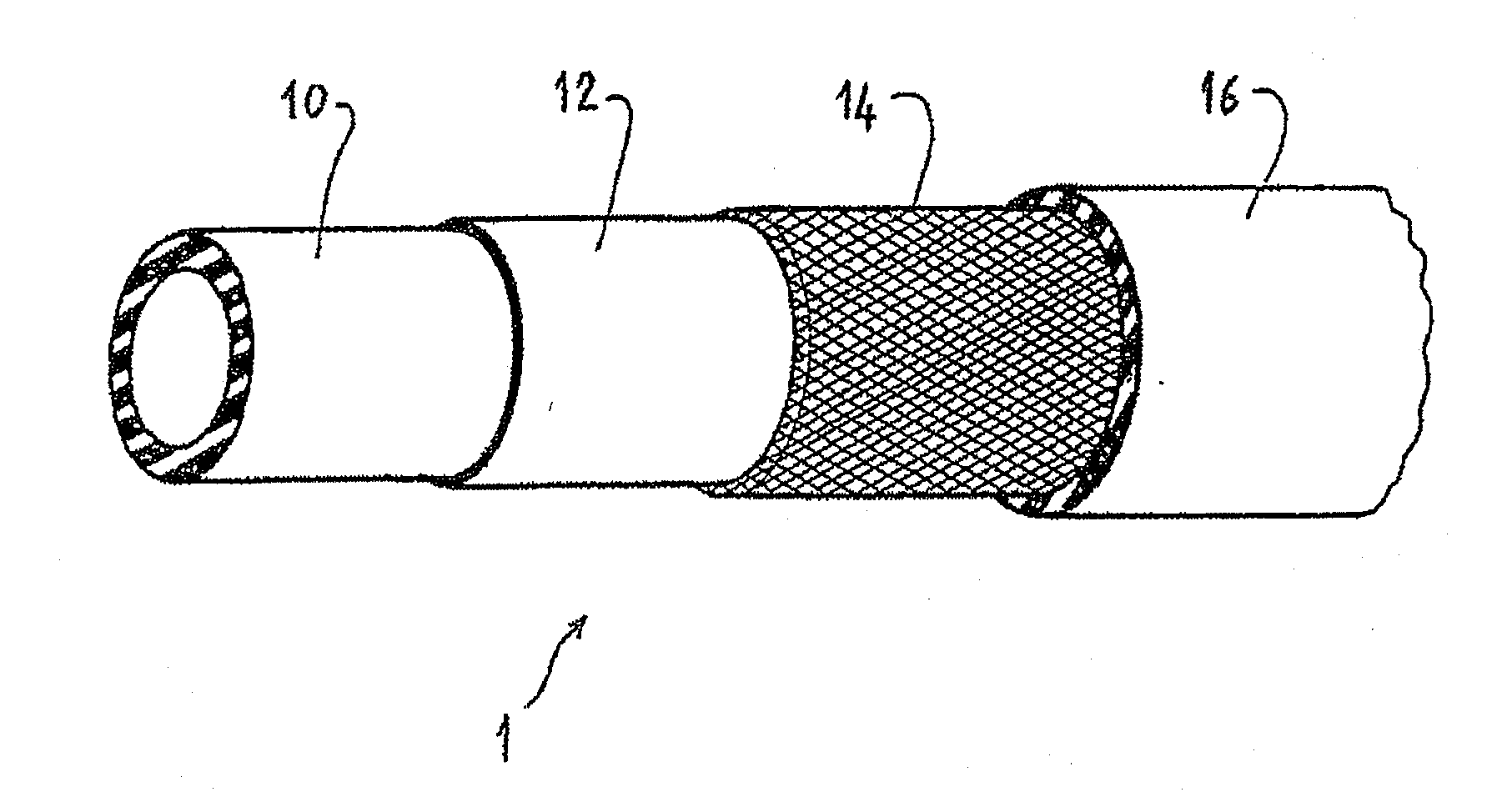

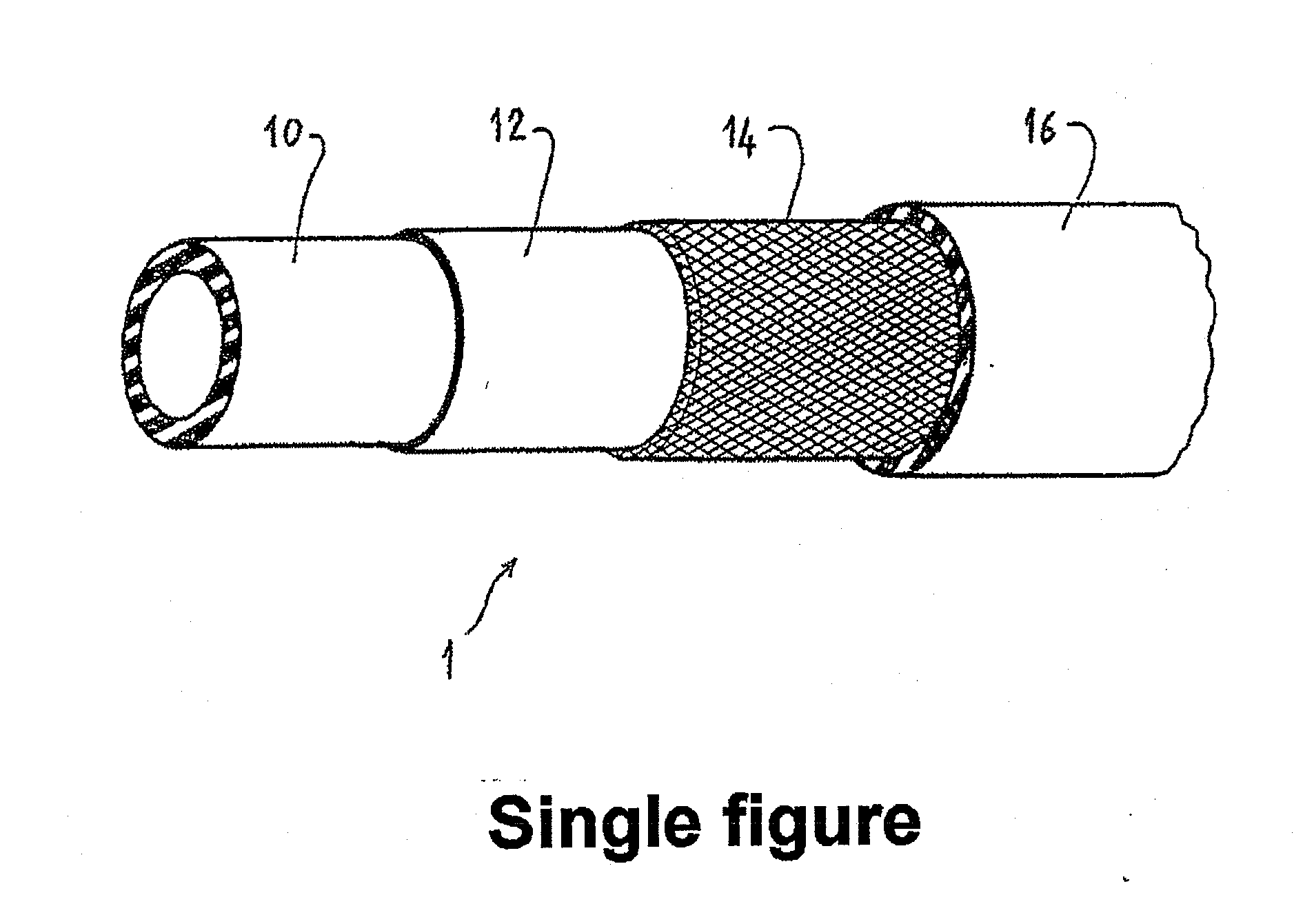

Pipe for the air intake circuit of a motor vehicle engine, and circuit incorporating the same

ActiveUS8449961B2Satisfactory heat resistanceMechanical strengthCombustion-air/fuel-air treatmentSynthetic resin layered productsElastomerYarn

The present invention relates to a pipe usable for an air intake circuit of a motor vehicle engine, and to this air intake circuit in particular for the intake of air at the outlet of a turbocompressor that comprises at least one such pipe.This pipe (1) comprises at least one inner elastomer layer (10), one outer elastomer layer (16), one intermediate elastomer layer (12) and one reinforcing structure (14) which is situated between the intermediate and outer layers and which comprises yarns based on an aliphatic polyester, such as a PET, each intermediate and outer layer being formed from a composition based on at least one acrylate copolymer (ACM).According to the invention, said composition is crosslinked by means of a system chosen from the group consisting of those based on at least one soap combined with sulfur, with a urea derivative and those based on a thiadiazole.

Owner:HUTCHINSON SA

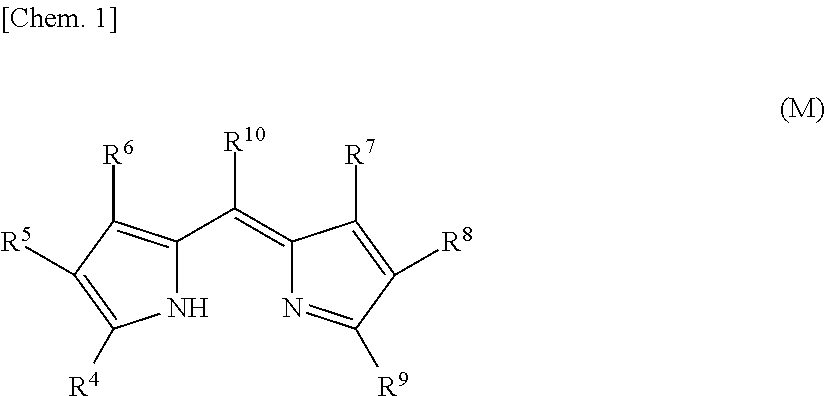

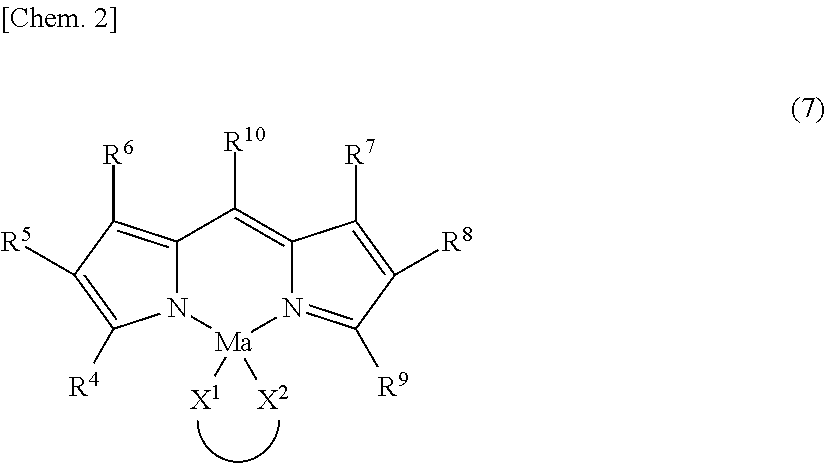

Coloring composition, coloring radiation-sensitive composition, color filter and solid-state imaging device

ActiveUS20140154616A1Meet heat resistanceExcellent developabilityPhotosensitive materialsOrganic dyesOrganic solventHeat resistance

Disclosed is a coloring composition with satisfactory heat resistance, no discoloration, excellent developability, and no development residues on a substrate and pixels of other colors, providing, a coloring composition for a color filter including (A) a polymer having a dye skeleton and (B) an organic solvent, wherein the content of an unreacted monomer component having the dye skeleton which is capable of forming (A) the polymer having the dye skeleton is less than or equal to 1 mass % with regard to (A) the polymer having the dye skeleton.

Owner:FUJIFILM CORP

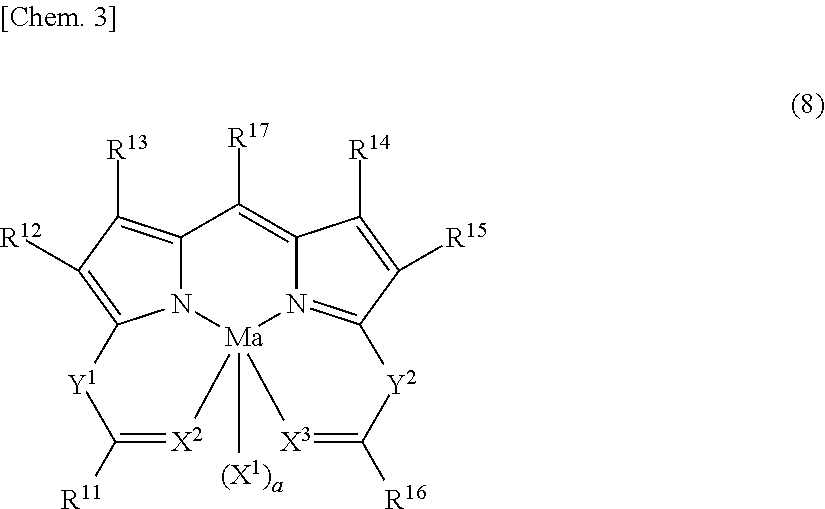

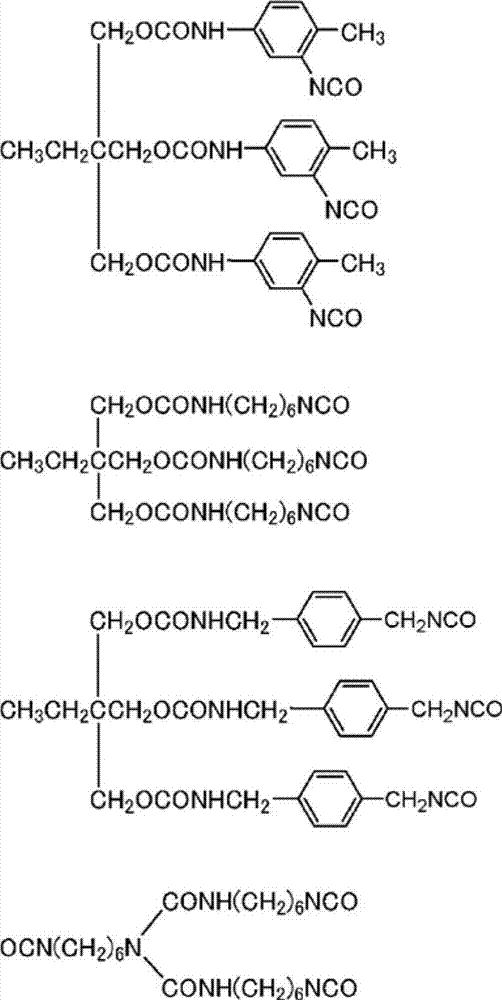

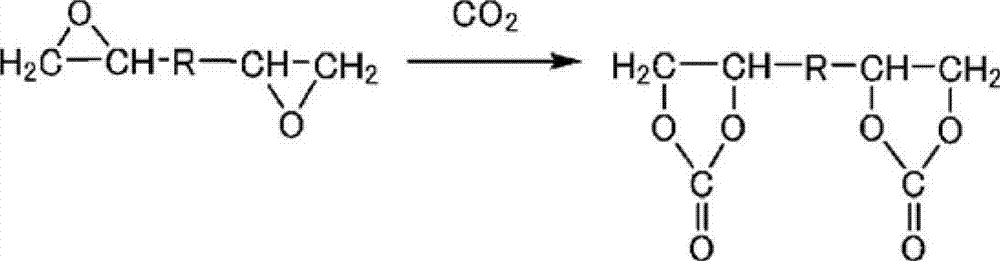

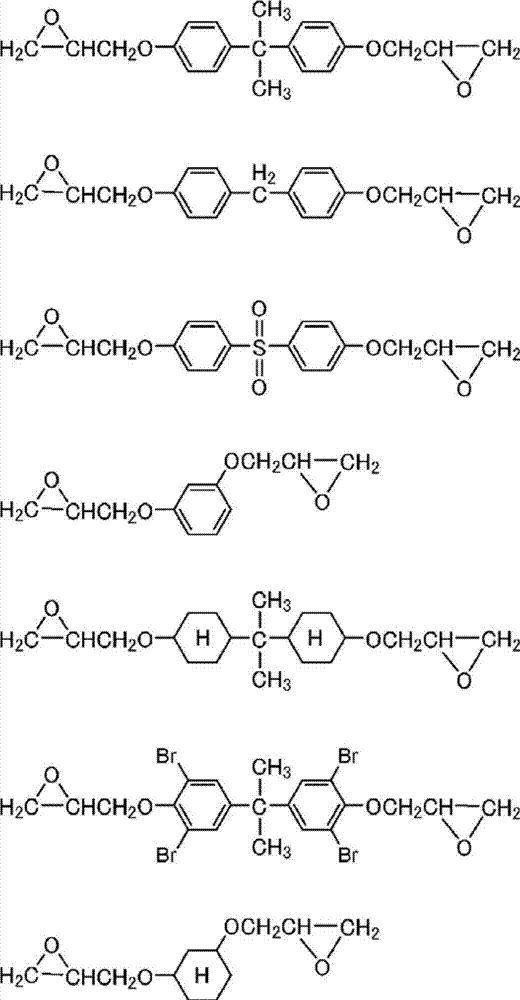

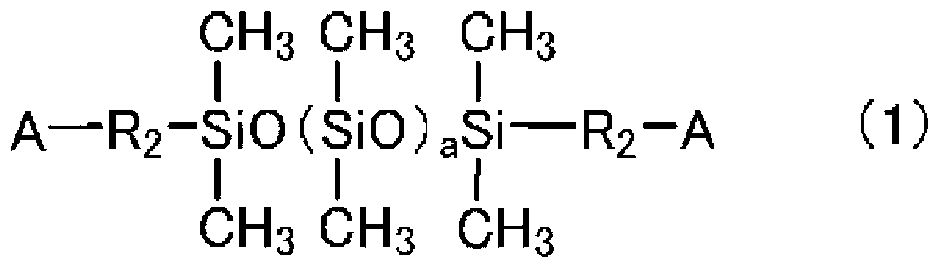

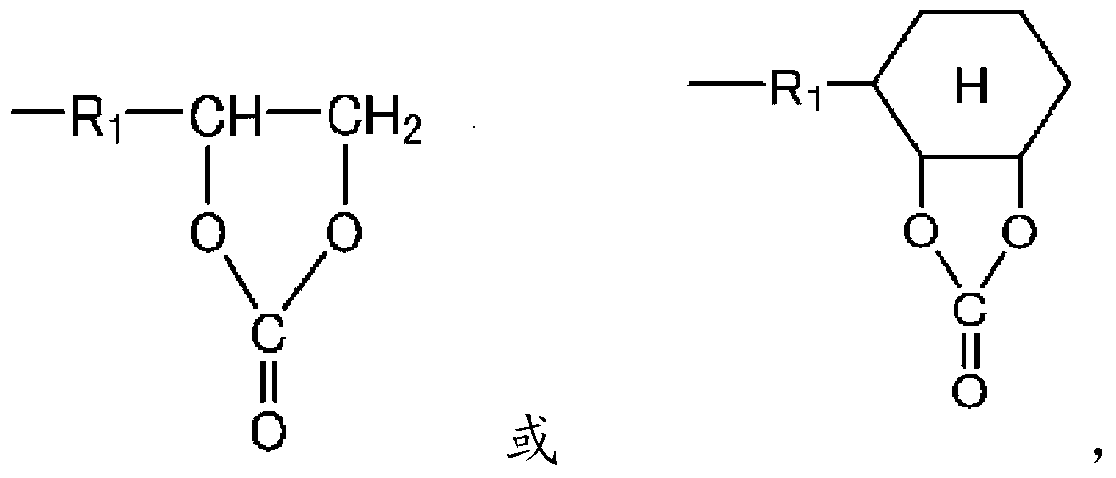

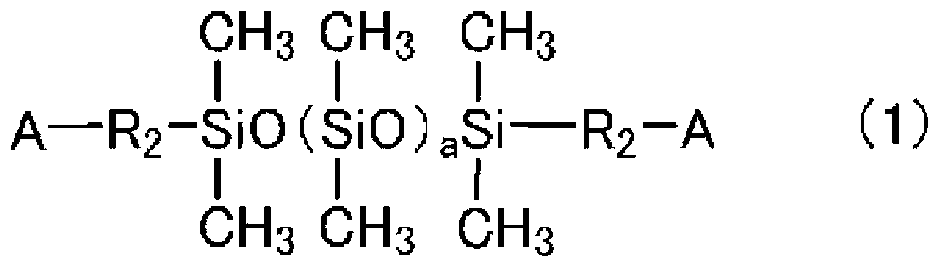

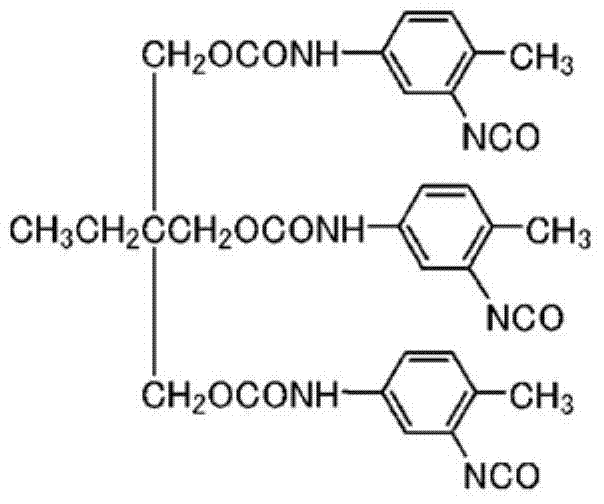

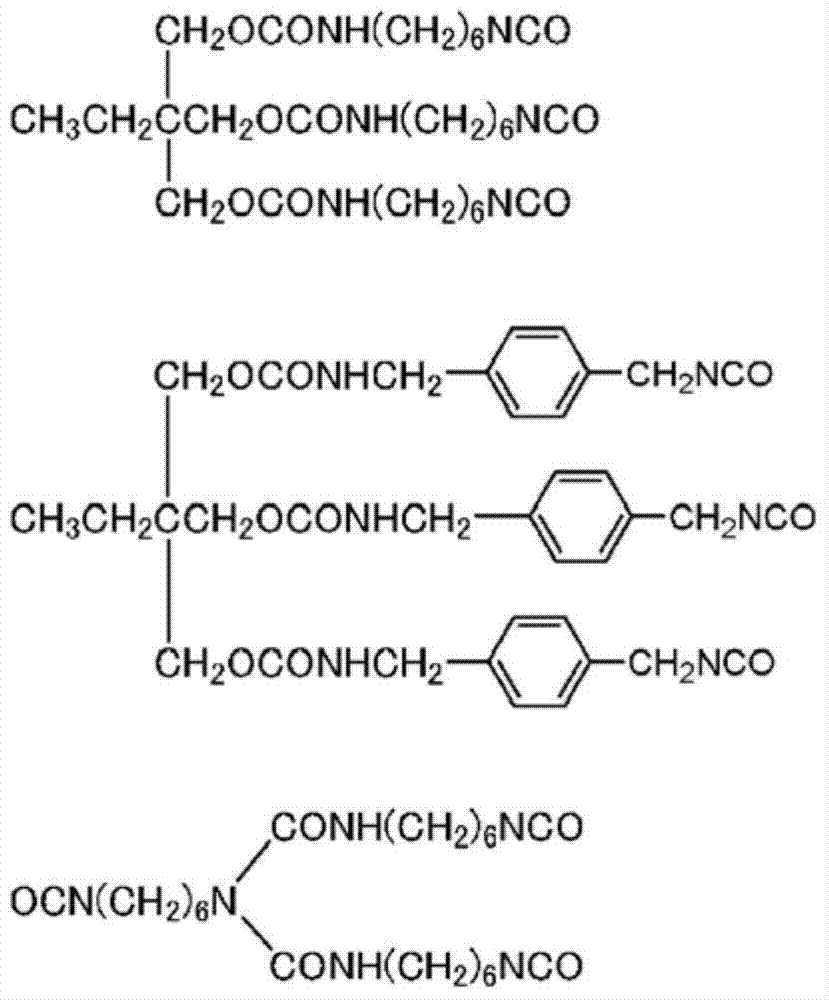

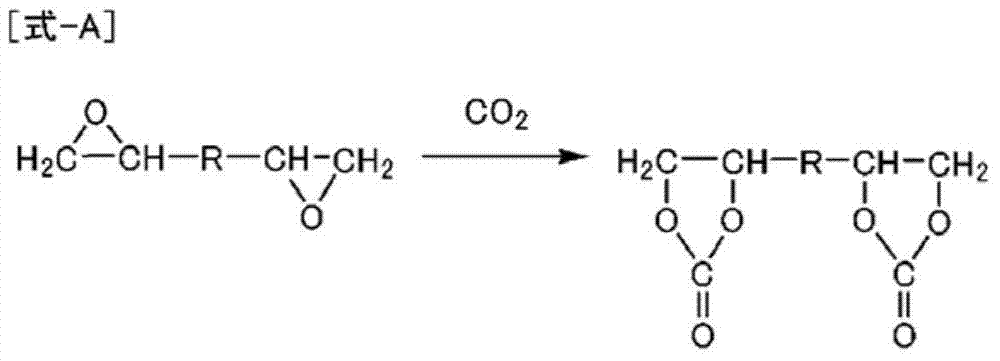

Self-crosslinkable polyhydroxy polyurethane resin, resinaceous material that contains the resin, process for production of the resin, and imitation leather, surfacing material and weatherstrip material, using the resin

ActiveCN102958978AEfficient use ofSatisfactory heat resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsPolyolefinSilicone oil

A self-crosslinkable polyhydroxy polyurethane resin which is prepared by the reaction of a five-membered cyclic carbonate compound and an amine compound and which has masked isocyanate groups in the structure; a process for the production of the polyhydroxy polyurethane resin; an imitation leather obtained by filling or laminating a base fabric with a resin composition that comprises the polyhydroxy polyurethane resin as the main component; a surfacing material made of a thermoplastic polyolefin resin, which includes a thermoplastic polyolefin resin sheet and a top coat layer formed on the sheet either directly or with a primer layer interposed therebetween and in which the top coat layer is a layer formed from a resin composition that comprises the polyhydroxy polyurethane resin as the main component; and a weatherstrip material which comprises the polyhydroxy polyurethane resin and a specific diorgano- polysiloxane and / or a specific silicone oil as the main components.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

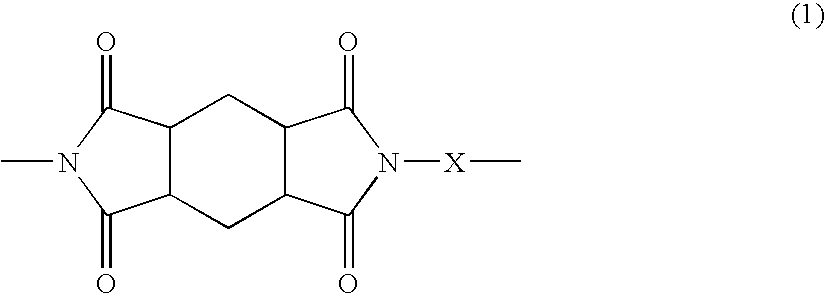

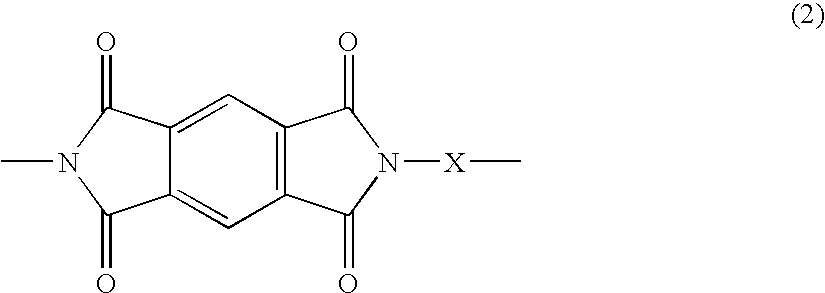

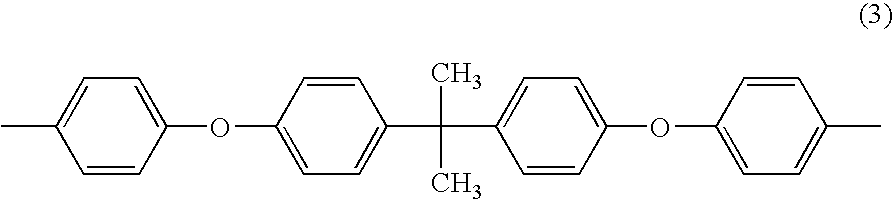

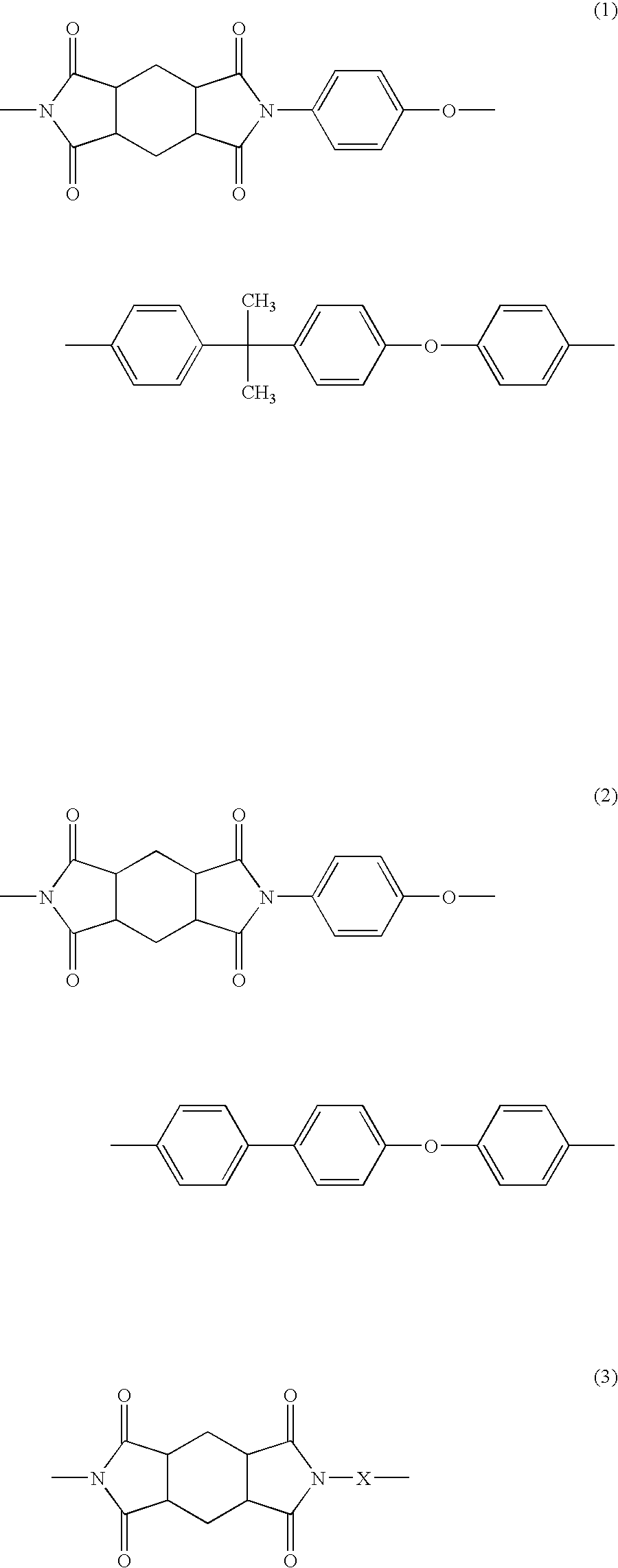

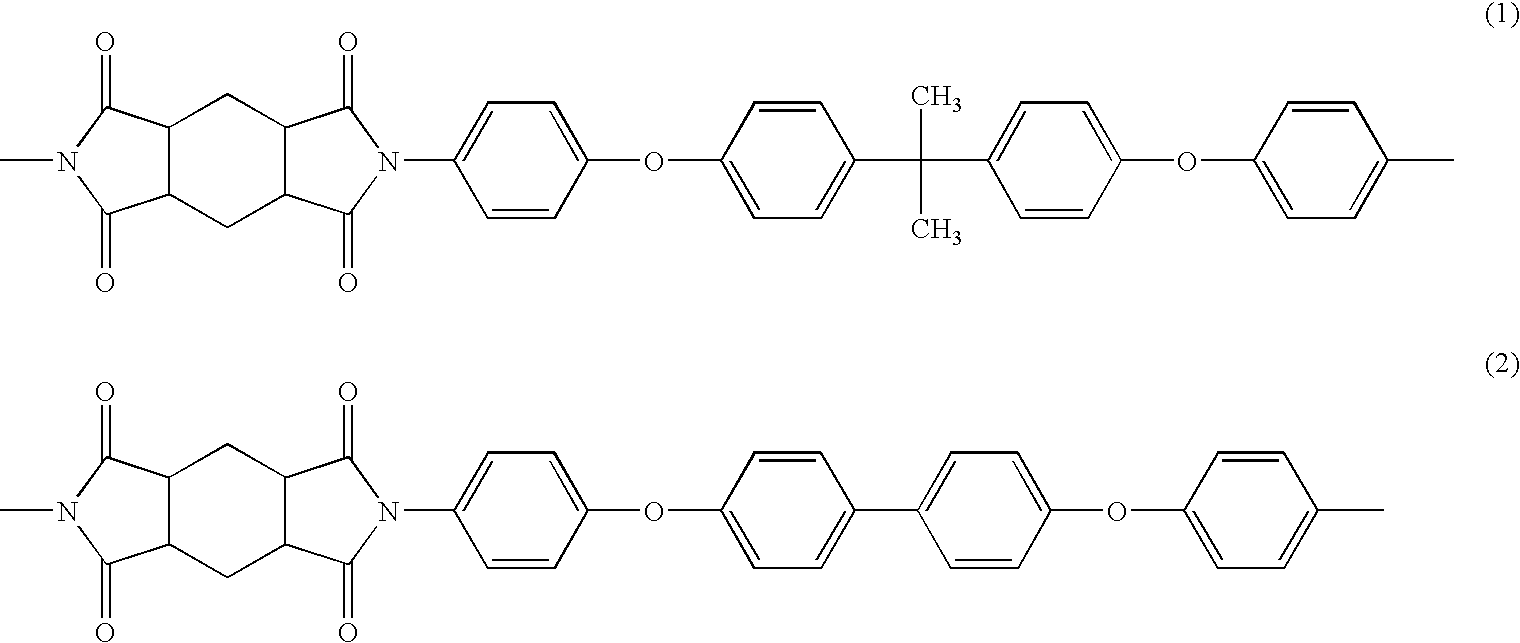

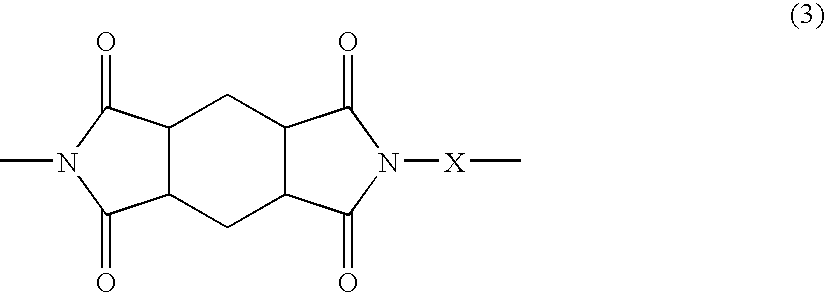

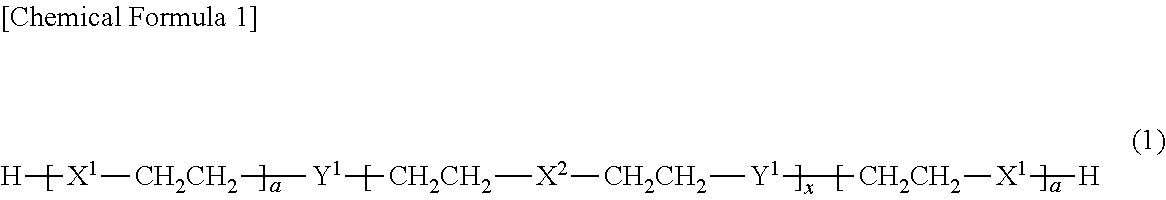

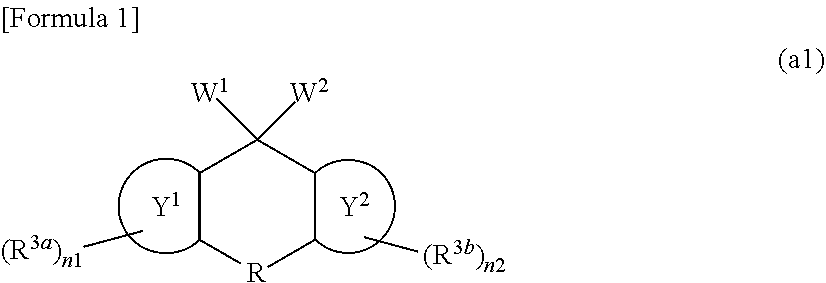

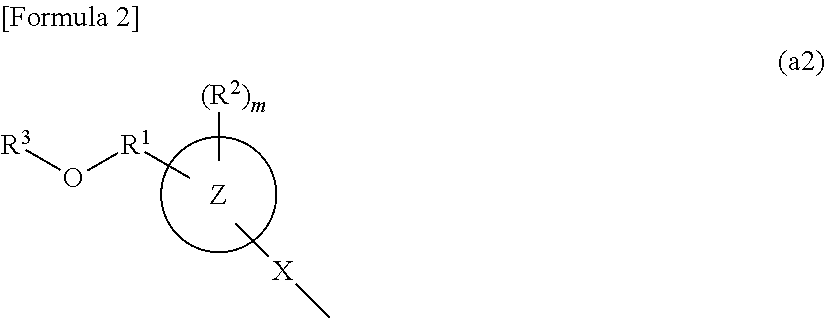

Polyimide resin

InactiveUS20090291259A1Improve adhesionReduction factorSynthetic resin layered productsPretreated surfacesSolubilityHeat resistance

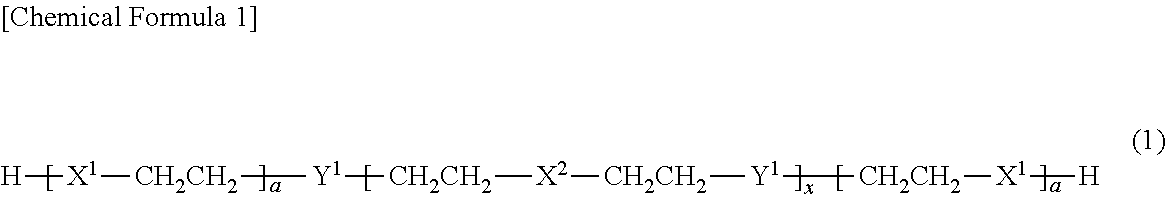

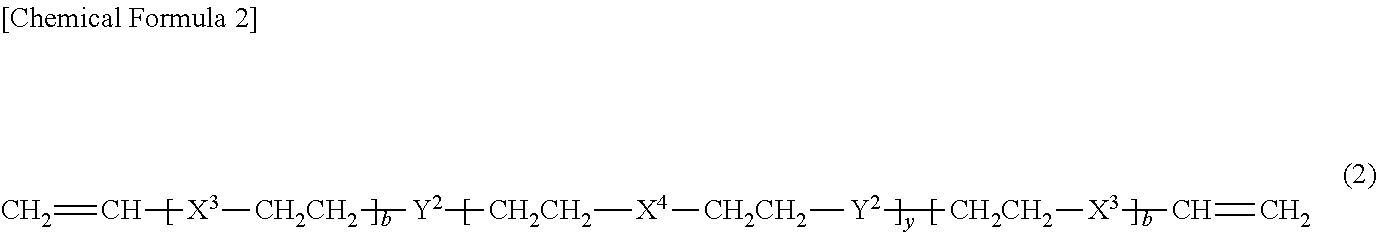

A polyimide resin which is satisfactory in solvent solubility and heat resistance, has a low coefficient of water absorption and is excellent in adhesive properties and a method for manufacturing the same, a film containing the subject polyimide resin and a metal-clad laminate including an adhesive layer composed of the subject polyimide resin are provided.The polyimide resin is a polyimide resin containing a molecule having a repeating unit represented by a structure of any one of the following formulae (1) to (3) in a specified proportion, whose molecular end is capped by an end-capping agent.

Owner:MITSUBISHI GAS CHEM CO INC

Heat fixing roll and fixing belt

ActiveUS7537838B2Overcome lack of conductivityAdequate modulusShaft and bearingsSynthetic resin layered productsSiliconPolymer chemistry

A heat fixing roll or belt having a silicone rubber layer which is formed by curing a silicone rubber composition comprising (A) 100 pbw of an organopolysiloxane having at least two silicon-bonded alkenyl radicals in a molecule, (B) 20-500 pbw of a metallic silicon powder having an average particle size of up to 100 μm, and (C) an effective amount of a curing agent. The silicone rubber layer has a high heat conductivity and long-term temperature durability.

Owner:SHIN ETSU CHEM CO LTD

Pipe for the Air Intake Circuit of a Motor Vehicle Engine, and Circuit Incorporating the Same

ActiveUS20110303318A1Meet heat resistanceSatisfactory mechanical strengthCombustion-air/fuel-air treatmentSynthetic resin layered productsYarnElastomer

The present invention relates to a pipe usable for an air intake circuit of a motor vehicle engine, and to this air intake circuit in particular for the intake of air at the outlet of a turbocompressor that comprises at least one such pipe.This pipe (1) comprises at least one inner elastomer layer (10), one outer elastomer layer (16), one intermediate elastomer layer (12) and one reinforcing structure (14) which is situated between the intermediate and outer layers and which comprises yarns based on an aliphatic polyester, such as a PET, each intermediate and outer layer being formed from a composition based on at least one acrylate copolymer (ACM).According to the invention, said composition is crosslinked by means of a system chosen from the group consisting of those based on at least one soap combined with sulfur, with a urea derivative and those based on a thiadiazole.

Owner:HUTCHINSON SA

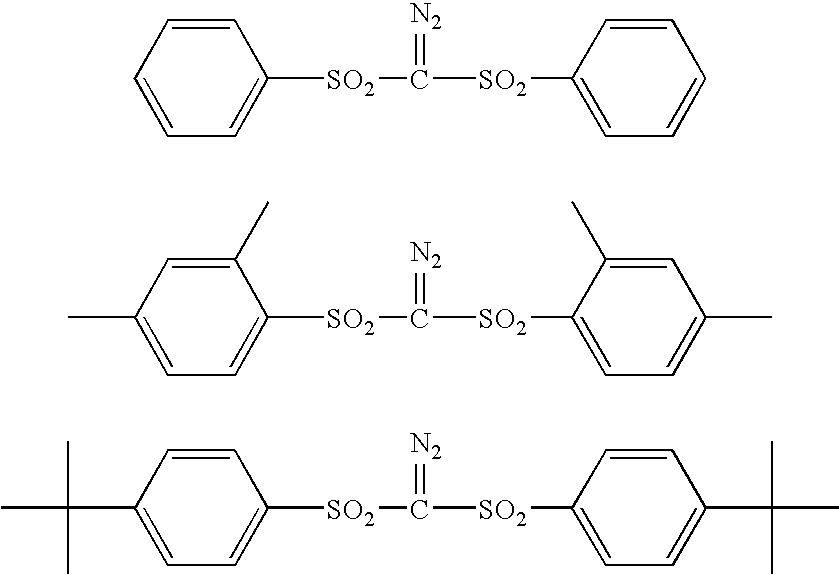

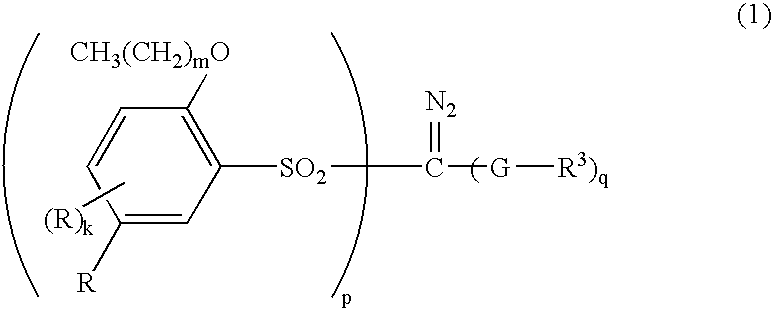

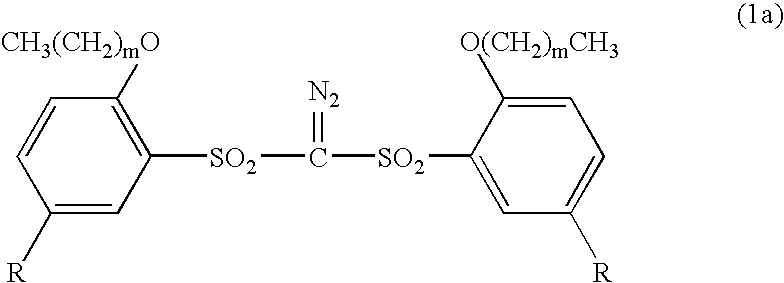

Sulfonyldiazomethanes, photoacid generators, resist compositions, and patterning process

ActiveUS7109311B2Satisfactory heat resistanceClear processMonoazo dyesOrganic chemistryResistMicrofabrication

A chemical amplification type resist composition comprising a specific benzenesulfonyldiazomethane containing a long-chain alkoxyl group at the 2-position on benzene ring has many advantages including improved resolution, improved focus latitude, minimized line width variation or shape degradation even on long-term PED, minimized debris left after coating, development and peeling, and improved pattern profile after development and is thus suited for microfabrication.

Owner:SHIN ETSU CHEM IND CO LTD

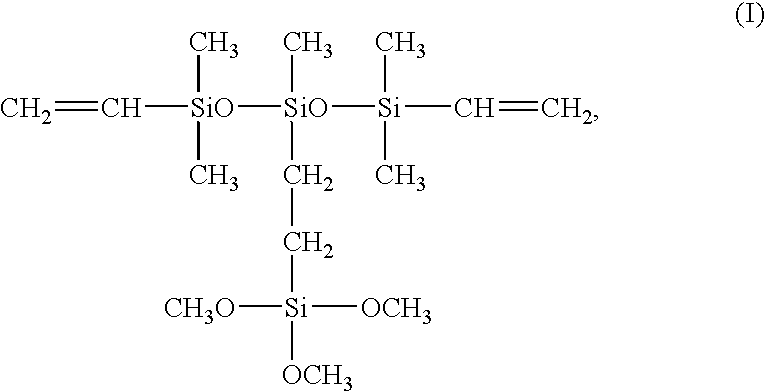

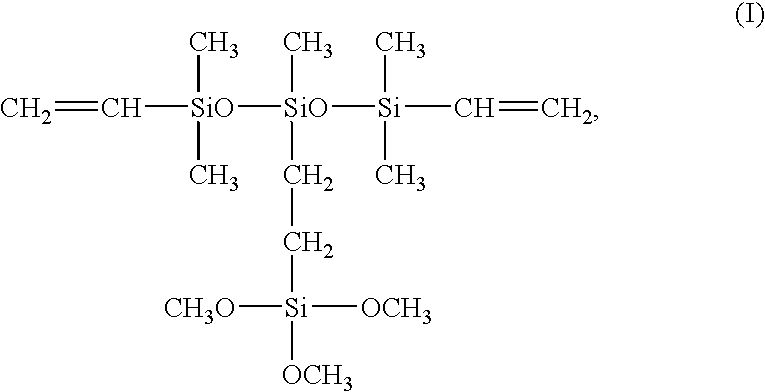

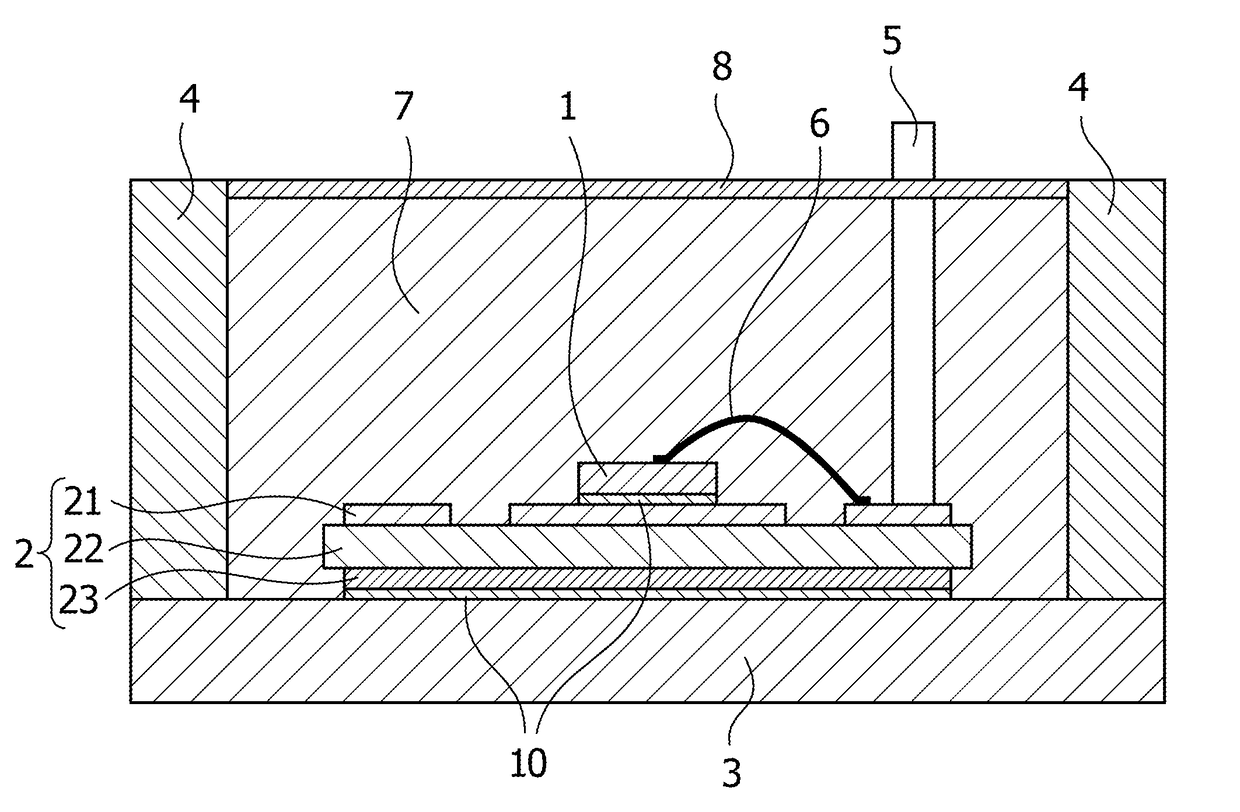

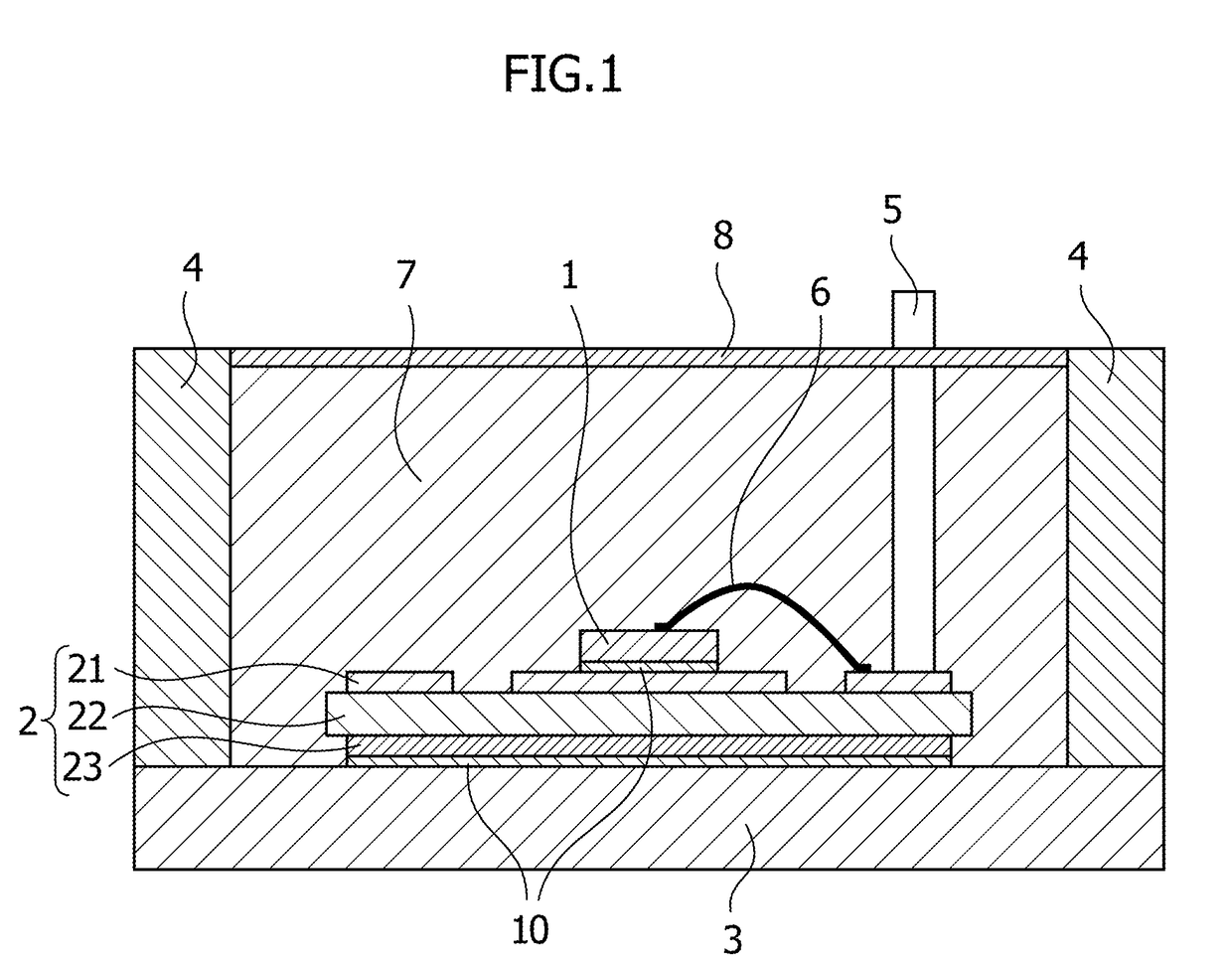

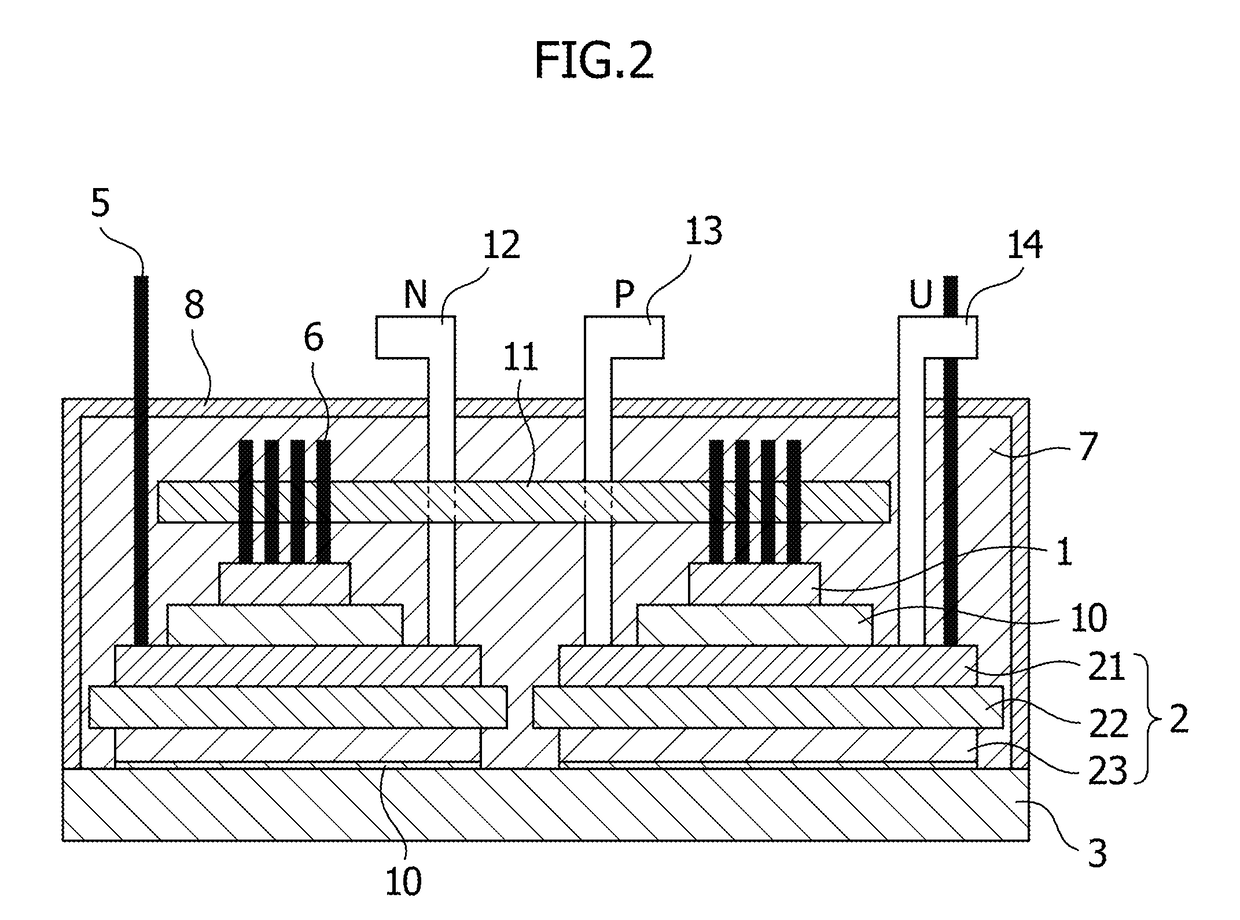

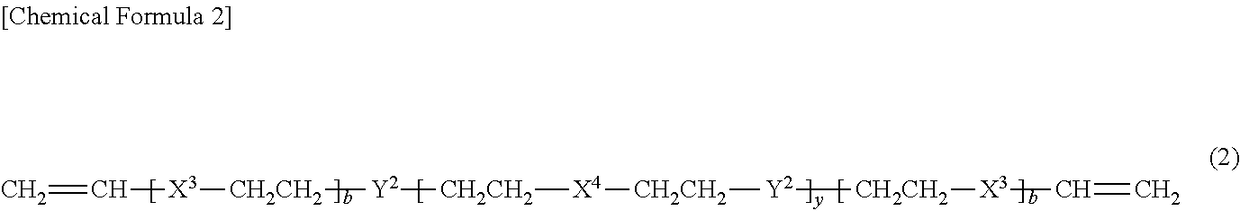

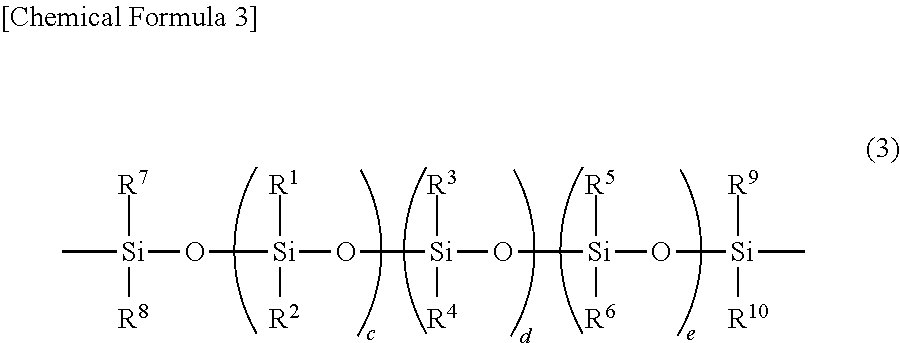

Curable composition for semiconductor encapsulation

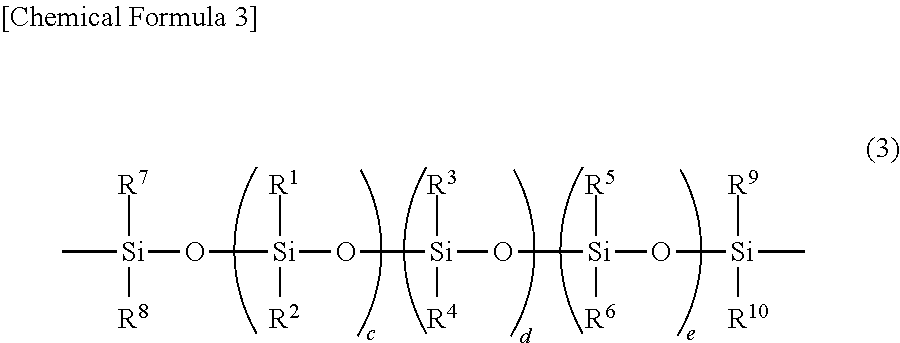

InactiveUS20120126435A1Excellent in heat resistance and electrical insulation propertySatisfactory heat resistanceLayered productsSemiconductor/solid-state device detailsHeat resistanceSemiconductor package

Provided are a curable composition for semiconductor encapsulation which produces a cured product that is excellent in heat resistance, electrical insulation properties at high temperatures, flexibility and heat cycle resistance, and a semiconductor device encapsulated by curing this curable composition. Specifically, there is provided a curable composition for semiconductor encapsulation containing, as component (A), a particular SiH group-containing siloxane compound; as component (B), a particular vinyl group-containing siloxane compound; as component (C), a compound having at least three SiH groups or at least three vinyl groups; and as component (D), a hydrosilylation catalyst.

Owner:ADEKA CORP

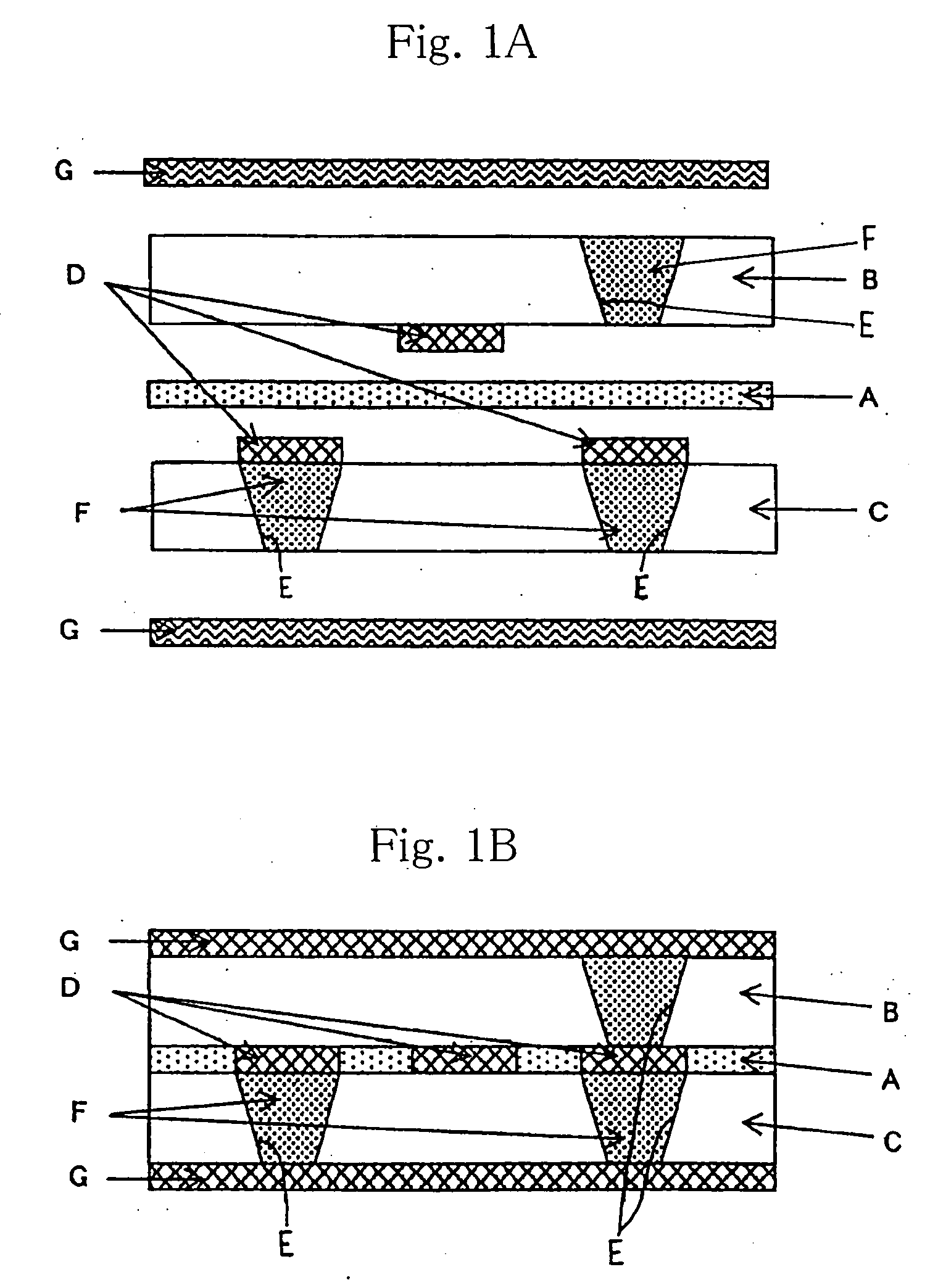

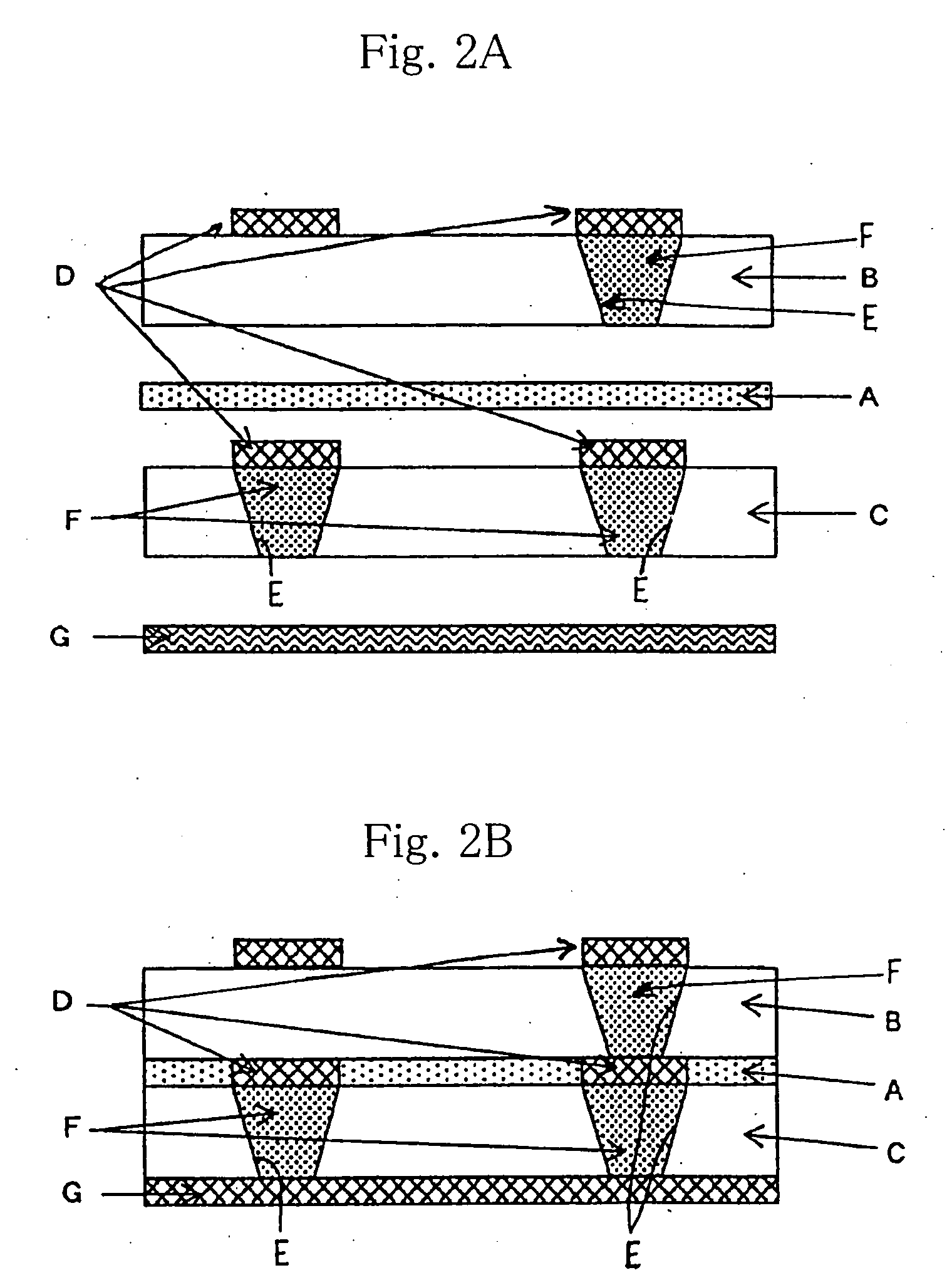

Multi-layer circuit board and method of making the same

InactiveUS20090107624A1High density surface mountingSimple manufacturing processManual label dispensersPrinted circuit secondary treatmentOptoelectronicsLow melting point

A method of making a multi-layer circuit board that has a first film and at least two more films, second and third films, each being made of a thermoplastic polymer capable of forming an optically anisotropic melt phase, the first film having a low melting point, the second and third films having respective melting points higher than the melting point of the first film and at lest one of the second and the third films having a circuit pattern thereon, and the first to third films are thermo compressed together with the first film interposed between the second and third films. This method entails causing at least one of the circuit patterns on one of the second and third films to contact an opposing surface of the other of the second and third films through the first film during the thermo compression bonding of the first to third films.

Owner:KURARAY CO LTD

Polyolefin resin composition for hot melt adhesive, hot melt adhesive film, and laminate

InactiveUS20170009110A1Solve the lack of adhesionImprove heat resistanceGraft polymer adhesivesPolyolefinHot melt

A polyolefin resin composition for hot melt adhesives includes 5 to 95% by weight of (A) an ethylene-α-olefin copolymer having a melting point of at least 100° C. but not more than 140° C.; and 5 to 95% by weight of (B) an ethylene-α-olefin copolymer having a melting point of at least 70° C. but less than 100° C.

Owner:KANEKA CORP

Polyester resin and heat and pressure resistant plastic bottle

InactiveUS7959997B2Satisfactory heat resistanceResistant strengthEnvelopes/bags making machineryBottlesEngineeringPEG-terephthalate

This invention is intended to improve the heat resistance of PET bottles from a material aspect. A technical problem of this invention is to find a polyester resin which is suitable for heat and pressure resistant plastic bottles and which does not eat into productivity and is available at a low cost. The object of this invention is to provide a heat and pressure resistant plastic bottle that can be manufactured at a low cost and has pressure resistance at a high temperature and high impact strength. The means of fulfilling this object is a polyester resin comprising a major part of ethylene terephthalate units and containing at least one of minor copolymerizable components selected from a group consisting of isophthalic acid, cyclohexane dimethanol, and diethylene glycol, wherein three minor copolymerizable components have total content less than 3 mol. %.

Owner:YOSHINO KOGYOSHO CO LTD

Self-crosslinking polysiloxane-odified polyhydroxy polyurethane resin, resin material containing same, method for producing same, artificial leather comprising same, and thermoplastic polyolefin skin material comprising same

ActiveCN103270071AReduce environmental adaptabilityReduce environmental adaptation productsPolyurea/polyurethane coatingsWoven fabricsPolyolefinHeat resistance

The invention provides a self-crosslinking polysiloxane-modified polyhydroxy polyurethane resin which has a polysiloxane segment and a masked isocyanate group in the structure thereof and is derived from a reaction between a five-membered cyclic carbonate polysiloxane compound represented by general formula (1) and an amine compound. The invention also provides a method for producing the same. According to the invention, with respect to a polyhydroxy polyurethane resin, the application of which has not progressed in the prior art, a novel self-crosslinking polyhydroxy polyurethane resin which is capable of providing a product or the like having excellent smoothness, abrasion resistance, chemical resistance, non-adhesiveness, heat resistance, etc., and is useful in terms of reduction of greenhouse gas and therefore is environmentally responsive can be provided.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

Self-crosslinkable polysiloxane-modified polyhydroxy polyurethane resin, process for producing said resin, resin material comprising said resin, and artificial leather produced utilizing said resin

ActiveCN103597003ASatisfied with smoothnessSatisfactory non-adhesivePolyurea/polyurethane coatingsWoven fabricsHeat resistancePolyresin

A problem is to provide, in the field of polyhydroxy polyurethane resins the development of applications of which has not moved ahead by conventional technologies, a self-crosslinking polyhydroxy polyurethane resin, which enables to provide products, such as imitation leathers, excellent in abrasion resistance, chemical resistance, heat resistance and the like, and moreover, which is useful from the viewpoint of a reduction in greenhouse gas, contains carbon dioxide incorporated and fixed therein, and is responsive to environmental conservation. Provided are a self-crosslinking, polysiloxane-modified, polyhydroxy polyurethane resin having masked isocyanate groups in a structure of a polysiloxane-modified, polyhydroxy polyurethane resin derived from a reaction of a 5-membered cyclic carbonate compound and an amine-modified polysiloxane compound and having polysiloxane segments therein; a production process of the self-crosslinking resin; a resin material containing the self-crosslinking resin; and an imitation leather composed of a base fabric and a resin composition composed of the self-crosslinking resin as its principal component and impregnated in or laminated on the base fabric.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

Polyimide film

InactiveUS20110178266A1Satisfactory heat resistanceInduce mobilityPrinted circuit aspectsEngineeringFlexible electronics

Disclosed is a polyimide film, which is very transparent and very resistant to heat and thus undergoes little dimensional change under thermal stress, and is suitable for use in transparent conductive films, TFT substrates, flexible printed circuit boards and so on.

Owner:KOLON IND INC

Curable composition for semiconductor encapsulation

InactiveUS8470937B2Excellent in heat resistance and electrical insulation propertySatisfactory heat resistanceLayered productsSemiconductor/solid-state device detailsHeat resistanceSemiconductor package

Provided are a curable composition for semiconductor encapsulation which produces a cured product that is excellent in heat resistance, electrical insulation properties at high temperatures, flexibility and heat cycle resistance, and a semiconductor device encapsulated by curing this curable composition. Specifically, there is provided a curable composition for semiconductor encapsulation containing, as component (A), a particular SiH group-containing siloxane compound; as component (B), a particular vinyl group-containing siloxane compound; as component (C), a compound having at least three SiH groups or at least three vinyl groups; and as component (D), a hydrosilylation catalyst.

Owner:ADEKA CORP

Curable composition, cured film, display panel or OLED light, and method for producing cured product

ActiveUS20190031818A1Satisfactory curabilitySatisfactory heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingChemistryCationic polymerization

Owner:TOKYO OHKA KOGYO CO LTD

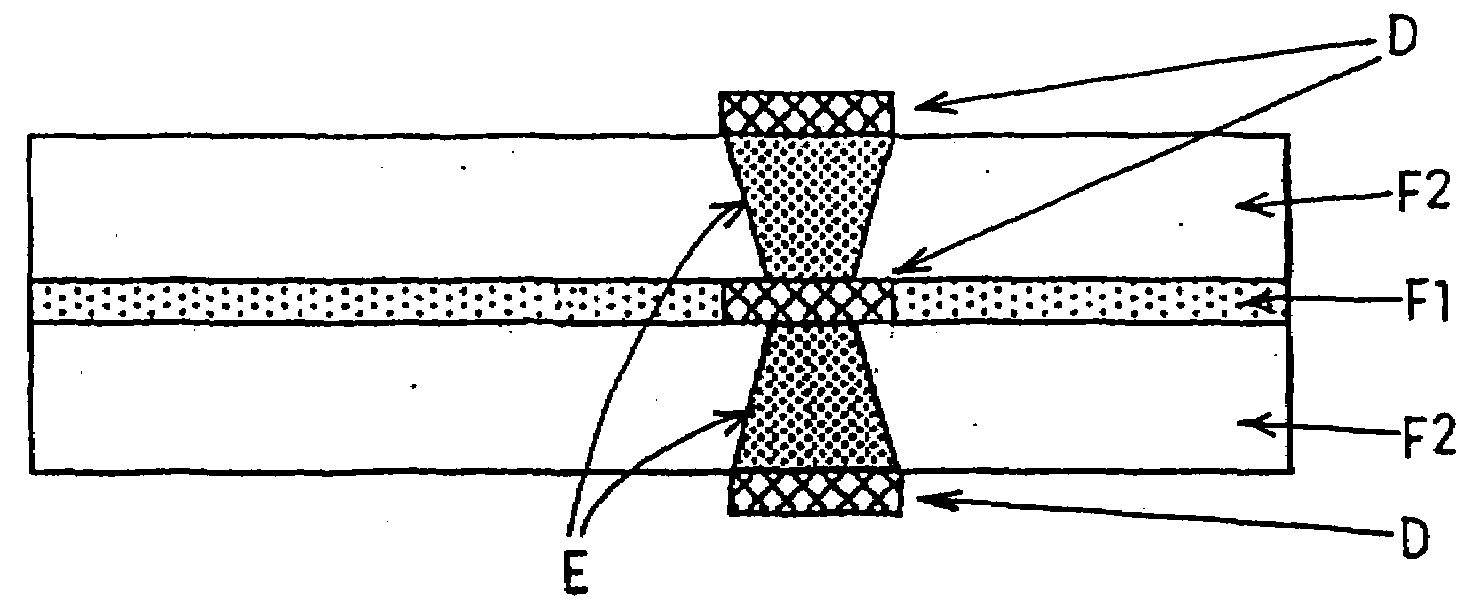

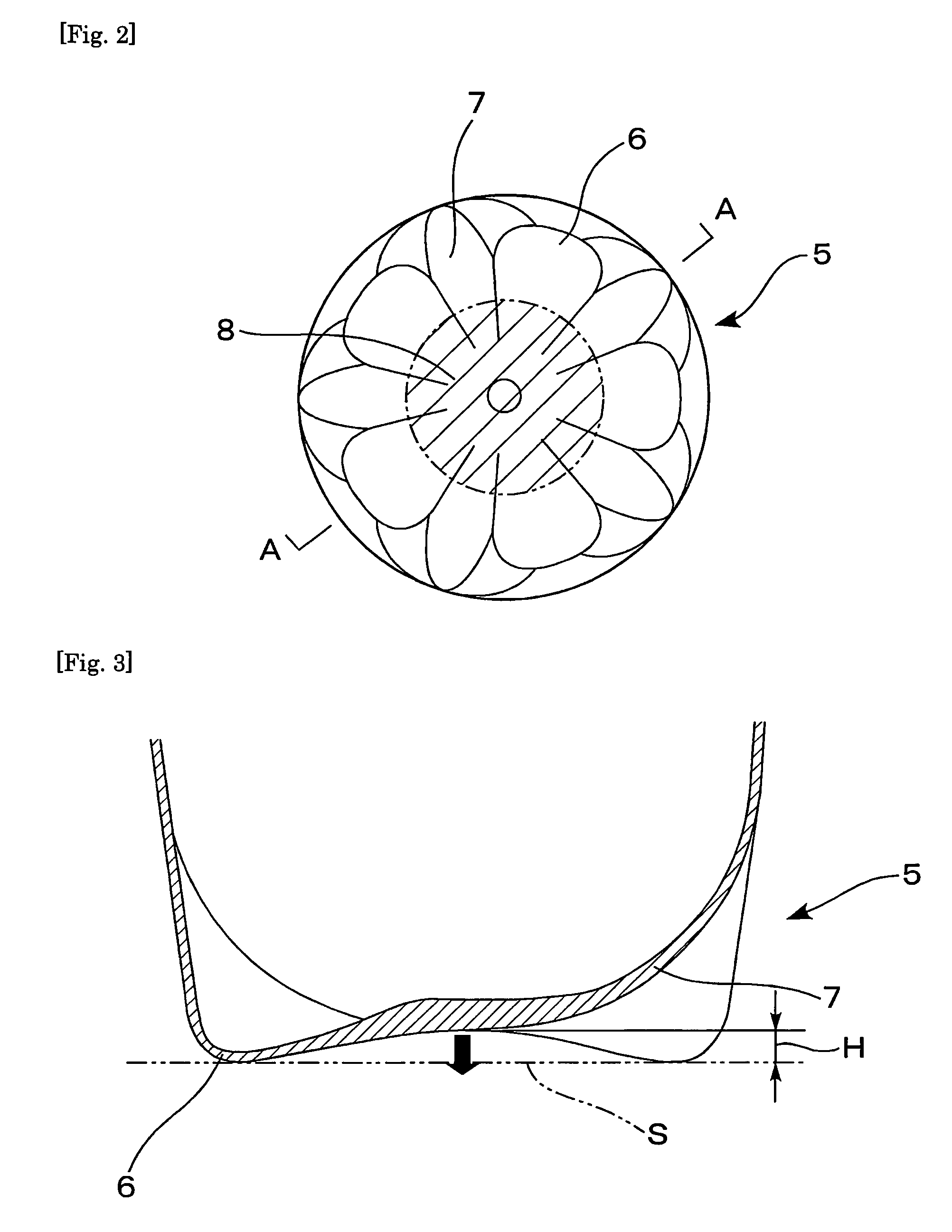

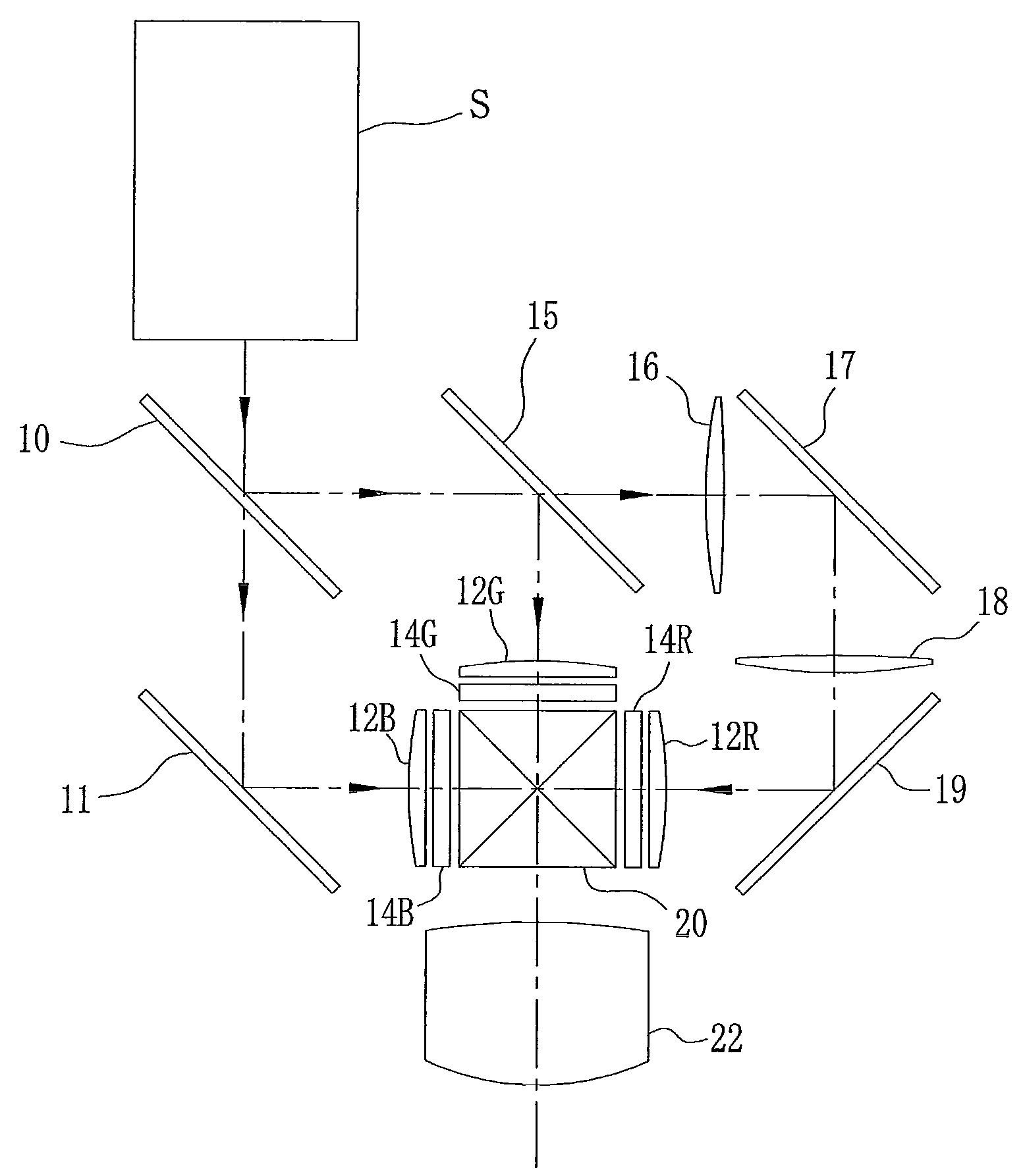

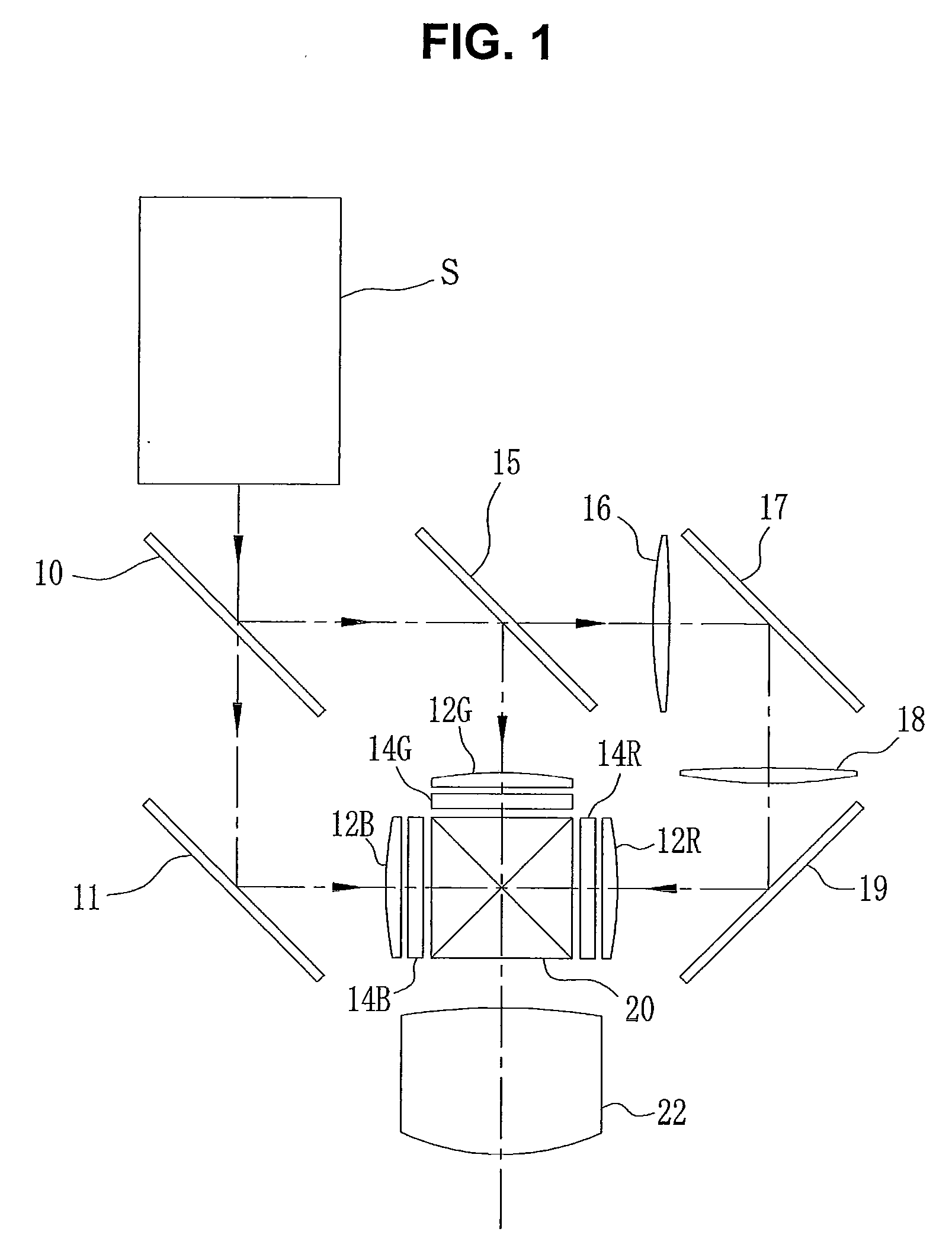

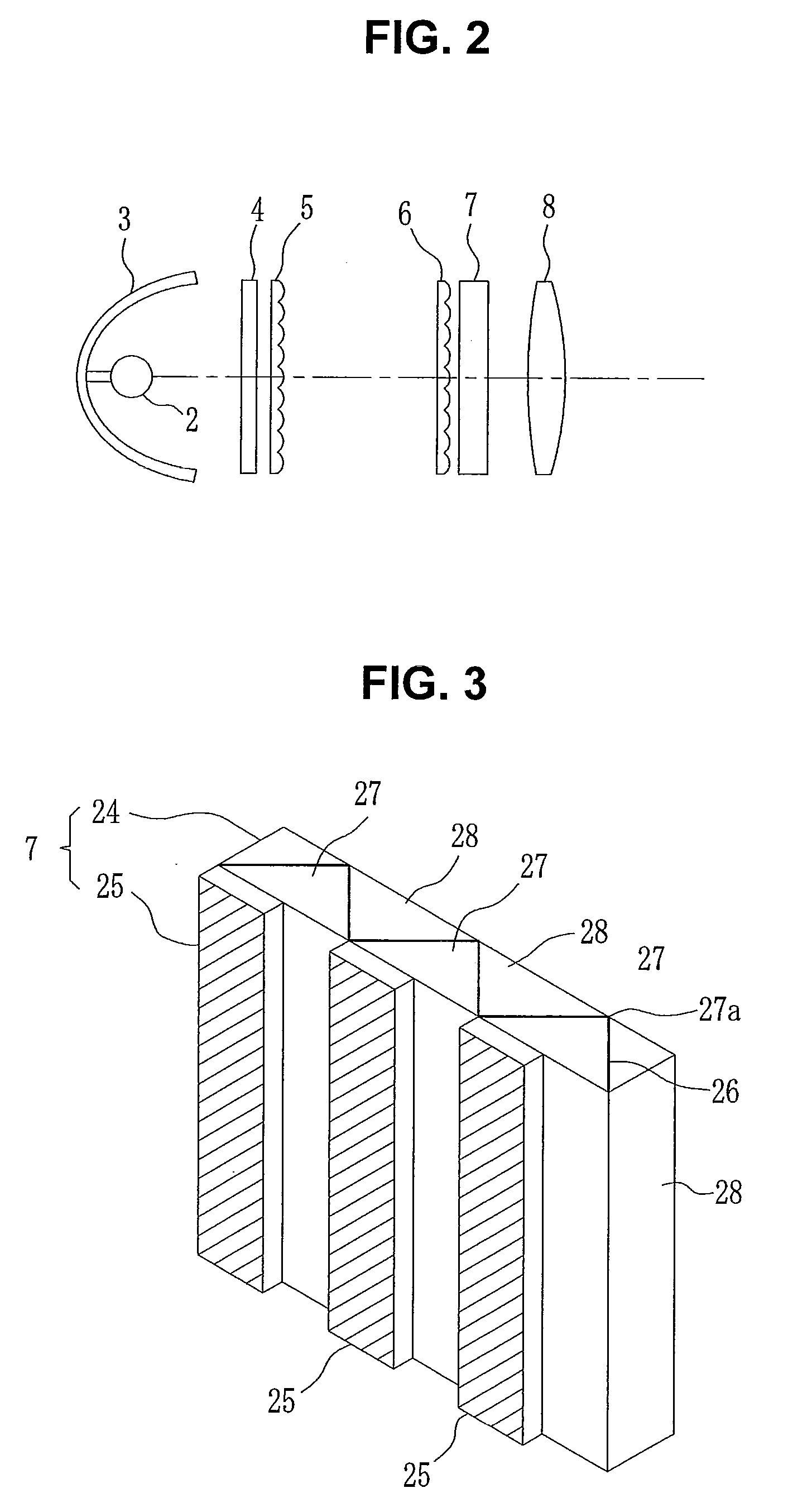

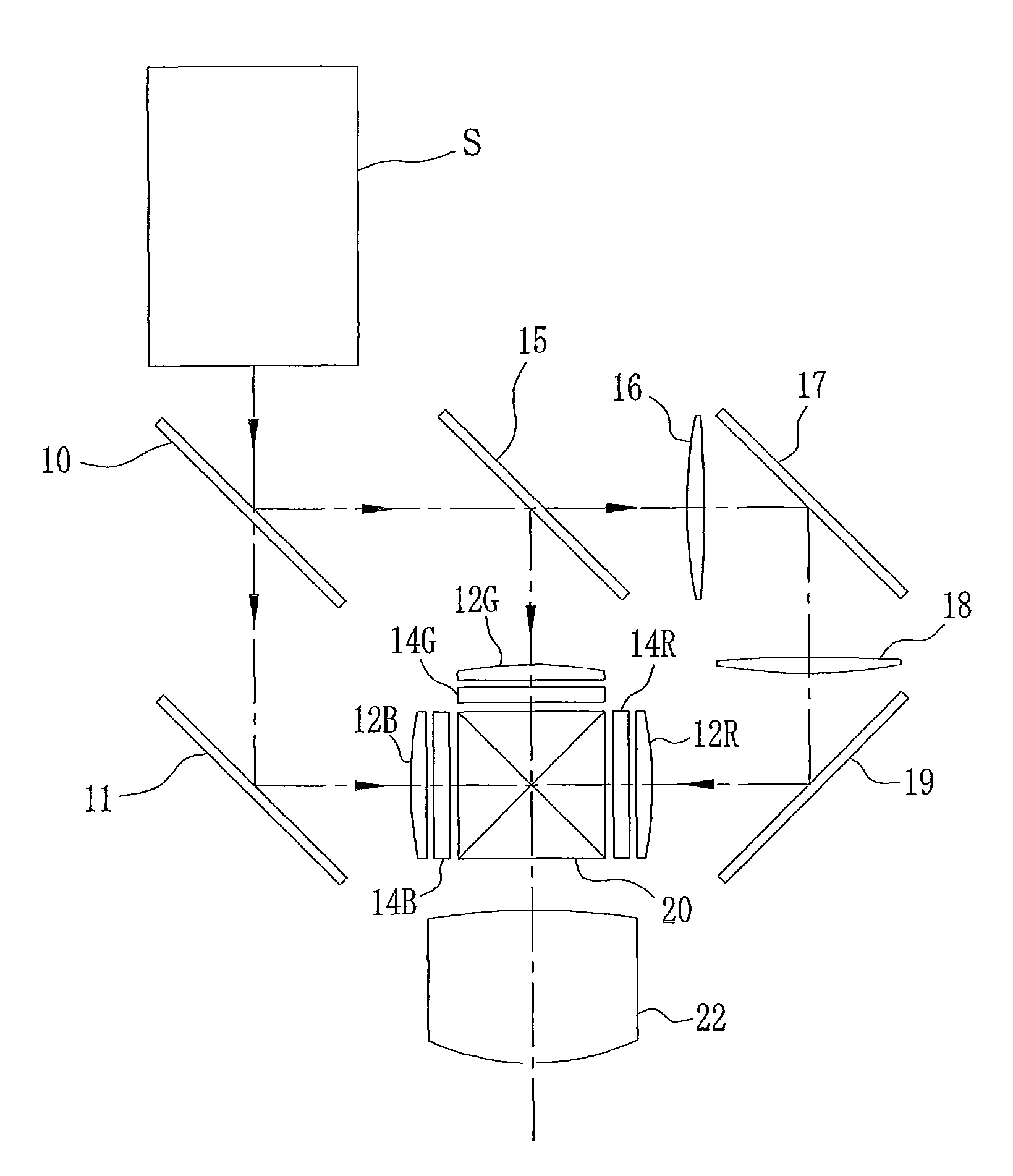

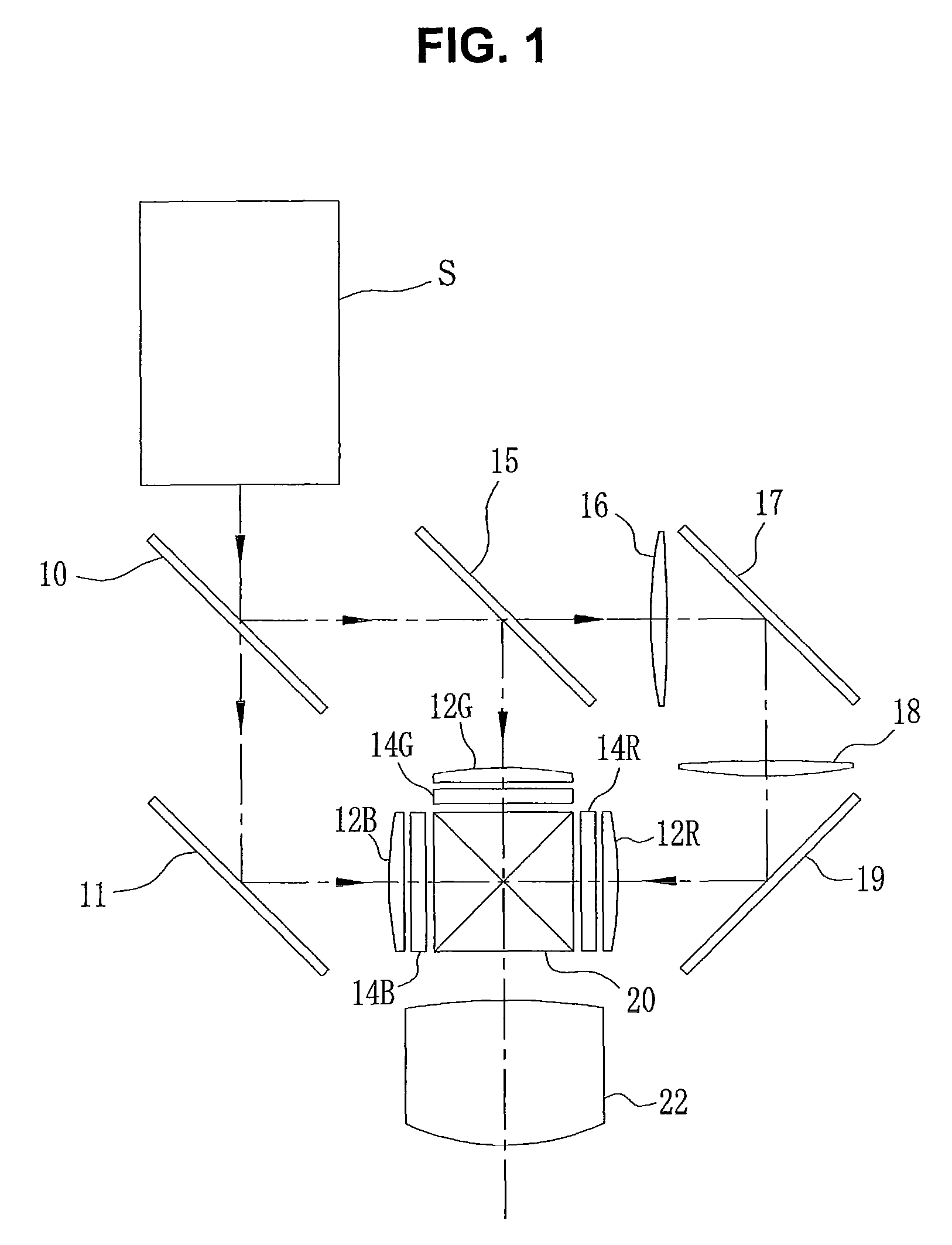

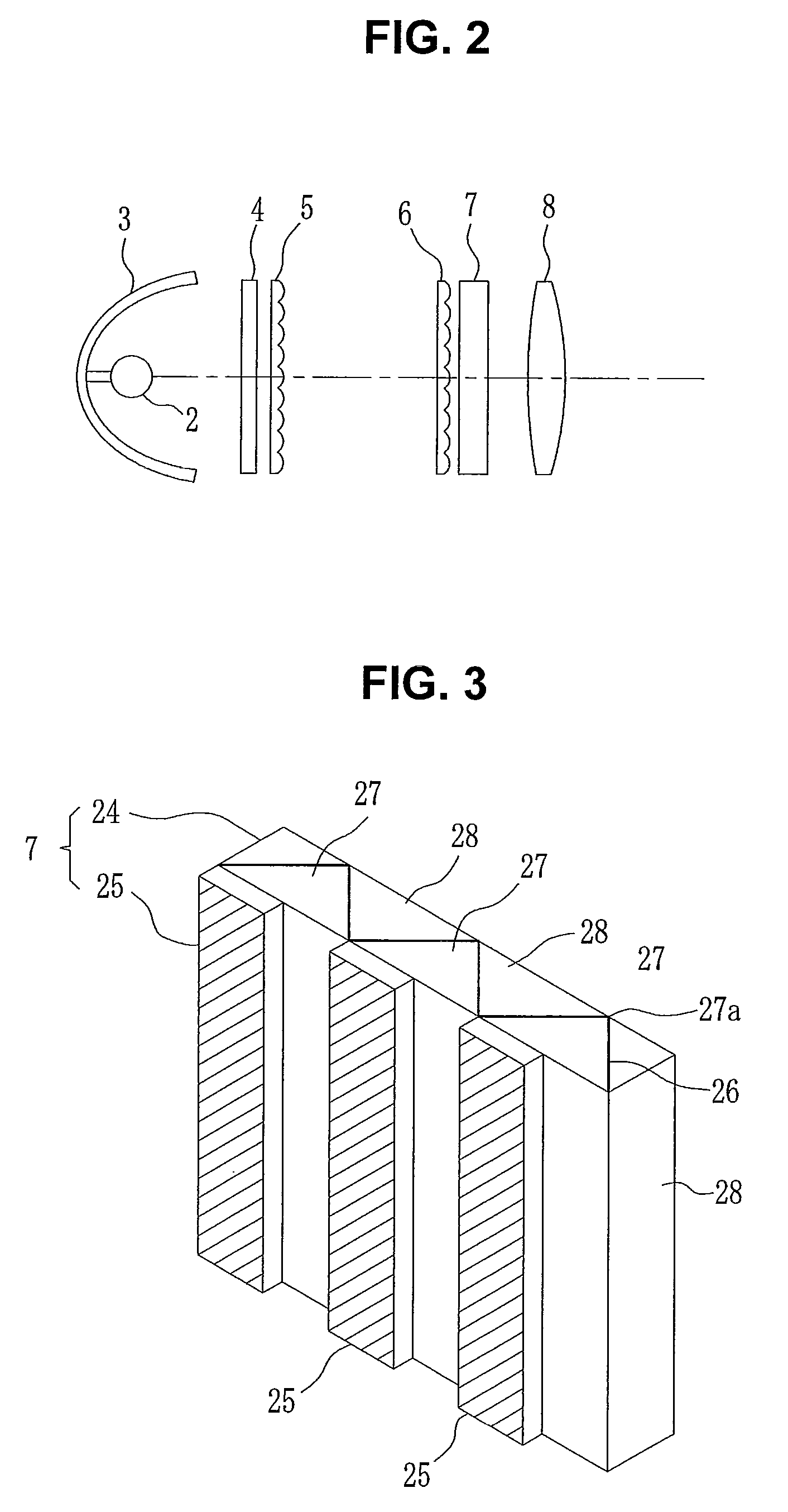

Polarization conversion element, polarized light illumination optical element, and liquid crystal projector

InactiveUS20090296008A1Satisfactory heat resistanceSuppress manufacturing costStatic indicating devicesProjectorsPhase differencePolarization beam splitter

A prism sheet is bonded to the bottom faces of rectangular prisms constituting a polarization beam splitter array. In the front face of the prism sheet, a plurality of rectangular prism elements are arranged in parallel to each other and a phase difference compensation film is formed on the surface. The edge lines of the rectangular prism elements are inclined at 45 degrees relative to the edge lines of the rectangular prisms. Linear polarized light of S-polarization component reflected by a polarized light separation film is reflected twice sequentially in a phase difference compensation film formed in a pair of oblique faces of the rectangular prism elements, so that the polarization direction is rotated by 90 degrees and then the light reenters the rectangular prism. Then, the light is transmitted through the polarized light separation film and then extracted from the rectangular prism.

Owner:FUJIFILM CORP

Rubber-like articles and rubber-like material-containing articles

InactiveUS20070117931A1Improve heat resistanceGood weather resistanceHydrocarbon by hydrogenationHydrocarbonsHydrogenWeather resistance

Rubber-like or rubber-like-material-containing articles contain or are made from hydrogenated natural polyisoprenoids or modified products thereof. These rubber-like or rubber-like-material-containing articles include a rubber-like elastic article made from a hydrogenated natural polyisoprenoid or a modified product thereof. A polymer obtained by reacting a natural polyisoprenoid with hydrogen in a solvent in the presence of a hydrogenation catalyst, for example, can be used as the hydrogenated natural polyisoprenoid. The hydrogenated natural polyisoprenoid preferably has a degree of hydrogenation of 50% or more. The hydrogenated natural polyisoprenoid preferably has a weight-average molecular weight of 20×104 or more and a molecular-weight distribution of 2.0 or more. The rubber-like or rubber-like-material-containing articles have excellent heat resistance and weather resistance, and are also excellent in view of resources and environment, because they use plant-derived raw materials.

Owner:NITTA CORP +1

Polarization conversion element, polarized light illumination optical element, and liquid crystal projector

InactiveUS8031288B2Satisfactory heat resistanceSuppress manufacturing costStatic indicating devicesProjectorsPhase differencePolarization beam splitter

A prism sheet is bonded to the bottom faces of rectangular prisms constituting a polarization beam splitter array. In the front face of the prism sheet, a plurality of rectangular prism elements are arranged in parallel to each other and a phase difference compensation film is formed on the surface. The edge lines of the rectangular prism elements are inclined at 45 degrees relative to the edge lines of the rectangular prisms. Linear polarized light of S-polarization component reflected by a polarized light separation film is reflected twice sequentially in a phase difference compensation film formed in a pair of oblique faces of the rectangular prism elements, so that the polarization direction is rotated by 90 degrees and then the light reenters the rectangular prism. Then, the light is transmitted through the polarized light separation film and then extracted from the rectangular prism.

Owner:FUJIFILM CORP

Image supporting material, method for use thereof and image forming apparatus utilizing the same

ActiveUS7267864B2High glossSatisfactory heat resistanceDecorative surface effectsSpecial ornamental structuresPolyolefinImage formation

The present invention provides an image supporting material for fixably supporting a color toner image, the material including a base material, a light scattering layer provided on the base material and containing a white pigment and a thermoplastic resin, and a color toner receptive layer provided on the light scattering layer and containing at least a thermoplastic resin, wherein the thermoplastic resin in the light scattering layer is constituted of a polyolefin or a polyolefinic copolymer having a temperature, at which viscosity becomes 5×103 Pa·s, of 100° C. or higher, and the thermoplastic resin in the color toner receptive layer is constituted of a resin obtained by melt mixing of a crystalline polyester resin and an amorphous resin and having a temperature, at which viscosity becomes 103 Pa·s, equal to or higher than 65° C. but lower than 80° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com