Image supporting material, method for use thereof and image forming apparatus utilizing the same

a technology of image supporting material and image forming apparatus, which is applied in the field of image supporting material, can solve the problems of inability to obtain satisfactory image quality, low temperature fixing property, heat resistance and mechanical strength at the same time, and achieve the effects of improving image fixing property, regulating viscosity characteristics, and uniform luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

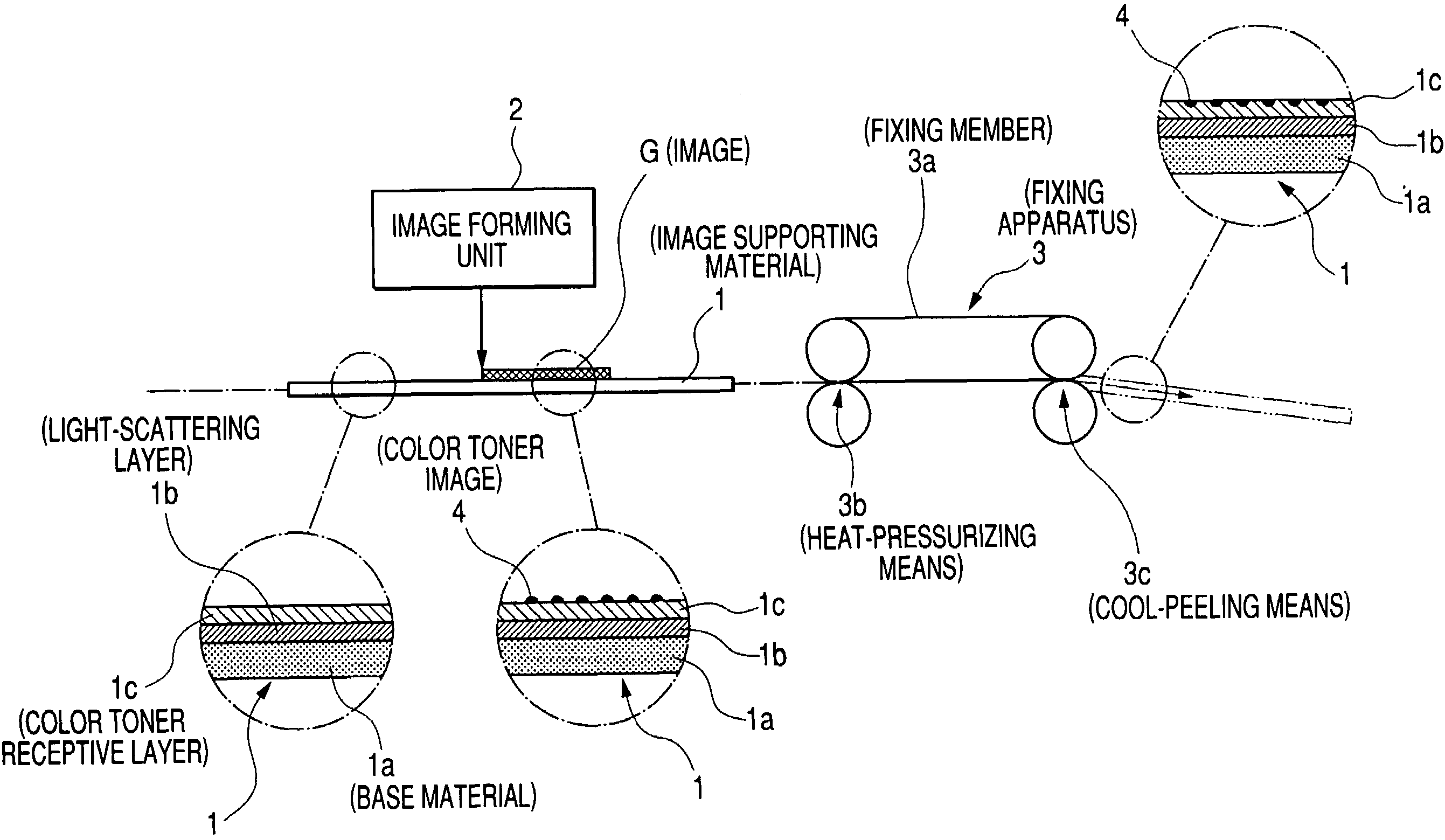

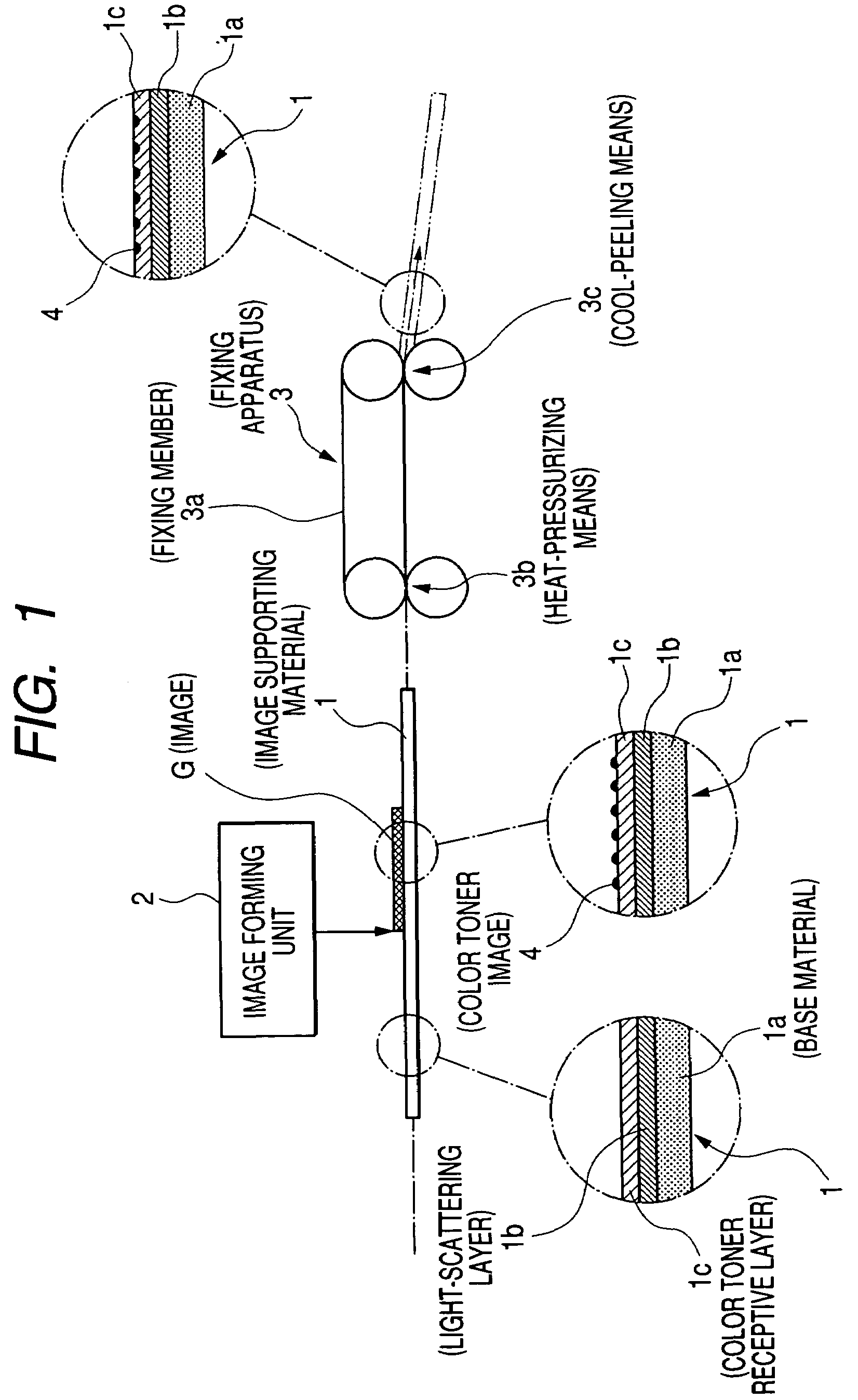

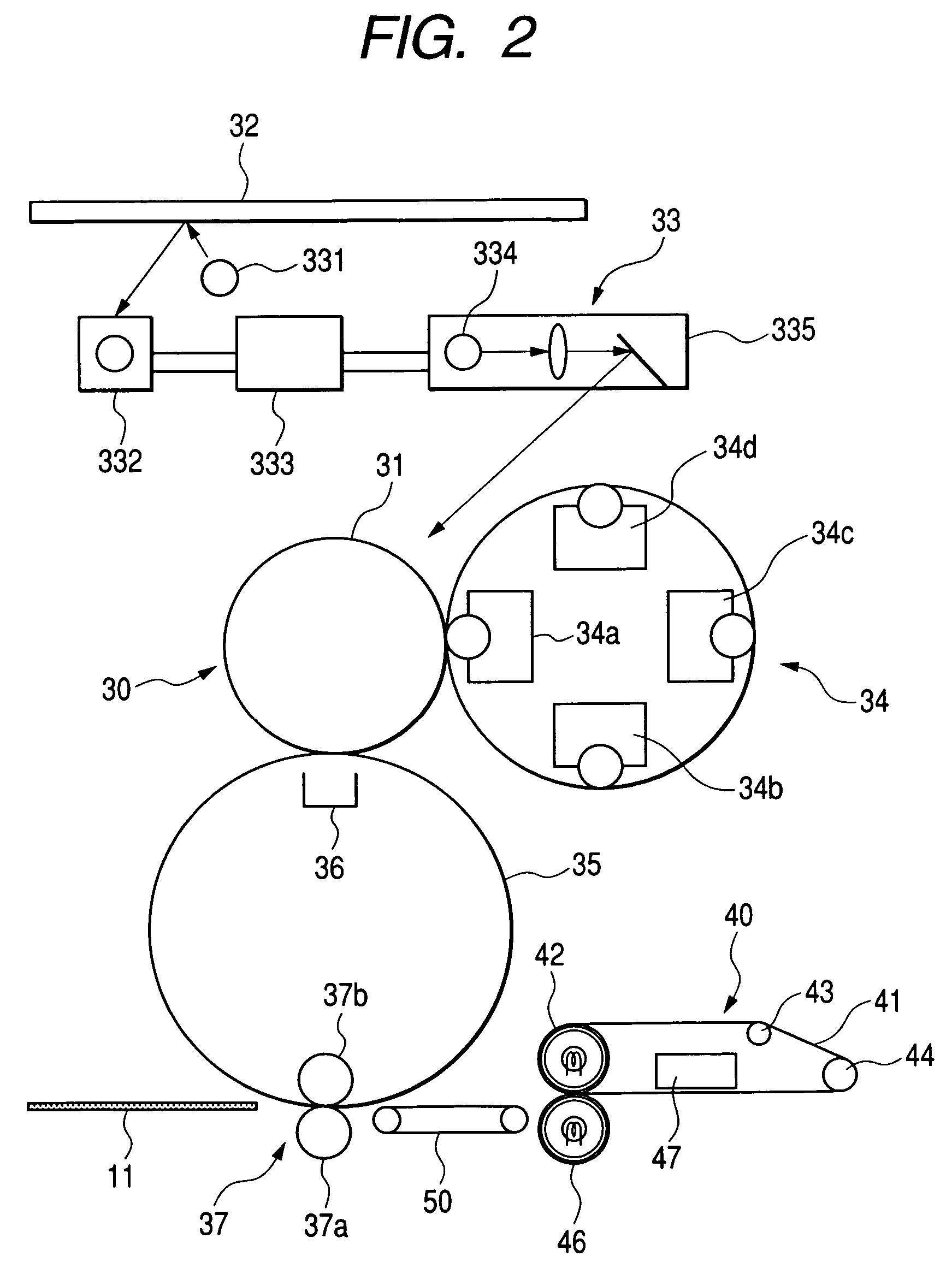

[0077]FIG. 2 shows an embodiment 1 of a color image forming apparatus embodying the present invention.

[0078]An image forming apparatus of the present embodiment shown in FIG. 2 is provided with an image forming unit 30 for forming, on an image supporting material 11, a color toner image 12 (cf. FIG. 6) formed for example by yellow, magenta, cyan and black color components, a fixing apparatus 40 for fixing the color toner image 12 formed by the image forming unit 30 on the image supporting material 11, and a conveying apparatus 50 for conveying the image supporting material 11 to the fixing apparatus 40.

[0079]In the present embodiment, the image supporting material 11 at least includes, as shown in FIG. 3A on a base paper 11a of a basis weight of 100 to 250 gsm, a light scattering layer 11b of a thickness of 20 to 50 μm containing a white pigment in an amount of 20 to 40 wt. %, and thereon a color toner receptive layer 11c of a thickness of 5 to 20 μm containing at least a thermoplas...

example 1

Color Image Forming Apparatus

[0335]As the image forming apparatus, there was employed the image forming apparatus shown in FIG. 2. An image forming process speed was 160 mm / sec except for the fixing process. A weight ratio of the toner and the carrier, a charging potential of the photosensitive member, an exposure amount and a developing bias were so regulated as to obtain a development amount of the color toner of 0.5 mg / cm2 in a solid image area.

Color Toner Developer

[0336]The color toner developer X was employed.

Image Supporting Material

Base Paper

[0337]A base of a thickness of 150 μm formed with pulps was employed.

Light Scattering Layer

[0338]One hundred parts by weight of polyethylene resin were mixed with 25 parts by weight of titanium dioxide (KA-10, particle size: 300-500 nm, manufactured by Titan Kogyo Co.), charged in a melt extruder heated at 200° C., discharged from a T-die and laminated to a flame treated surface of the base paper by nipping between a nip roller and a cool...

example 2

[0356]A color image was prepared in the same manner as in Example 1, except that the color toner receptive layer was changed in the following manner.

Color Toner Receptive Layer

[0357]40 parts by weight of the crystalline polyester resin B and 60 parts by weight of the amorphous polyester resin I were subjected to a melt-mixing for 10 minutes in an extrusion kneader heated at 240° C., and pellets prepared therefrom were charged in a melt extruder heated at 170° C., discharged from a T-die and laminated to the base paper, bearing the light scattering layer, by nipping between a nip roller and a cooling roller to obtain a color toner receptive layer of a thickness of 20 μm. In the melt-mixing of the resins, T0=230° C. at t0=5 minutes. The color toner receptive layer had T1 of 78° C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature Tb | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| temperature T1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com