Self-crosslinking polysiloxane-odified polyhydroxy polyurethane resin, resin material containing same, method for producing same, artificial leather comprising same, and thermoplastic polyolefin skin material comprising same

A polyhydroxyurethane, thermoplastic polyolefin technology applied to products with excellent heat resistance, involving an interior for automobiles, to obtain slipperiness, non-adhesion, abrasion resistance, and chemical resistance field, can solve the problem of insufficient, etc., and achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0155] Hereinafter, the present invention will be described in more detail with reference to specific production examples, examples, and comparative examples, but the present invention is not limited to these examples. In addition, unless otherwise specified, "part" and "%" in each of the following examples are based on mass.

[0156] (Manufacturing of Modifier)

[0157]On one side, 100 parts of trimethylolpropane and hexamethylene diisocyanate trimer adduct (CORONATEHL (trade name), manufactured by Nippon Polyurethane Co., Ltd., NCO=12.9%, solid content 75%), and 24.5 parts of ethyl acetate While fully stirring at 100°C, 25.5 parts of ε-caprolactam was added and reacted for 5 hours. According to the infrared absorption spectrum of the modifier obtained (measured with Horiba FT-720, the same applies below), at 2,270 cm -1 Absorption due to the appearance of free isocyanate groups on the surface, and when the free isocyanate groups are quantified, the theoretical value is 2....

manufacture example 4

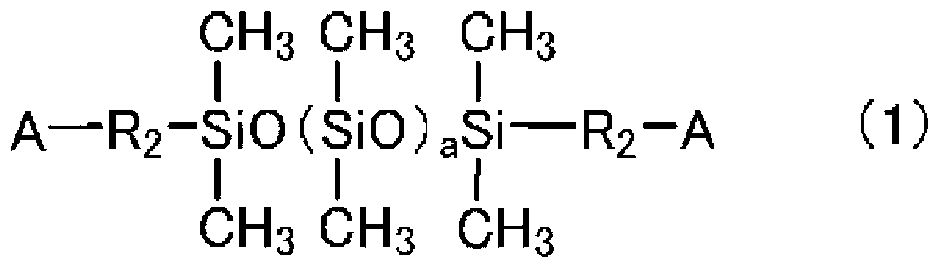

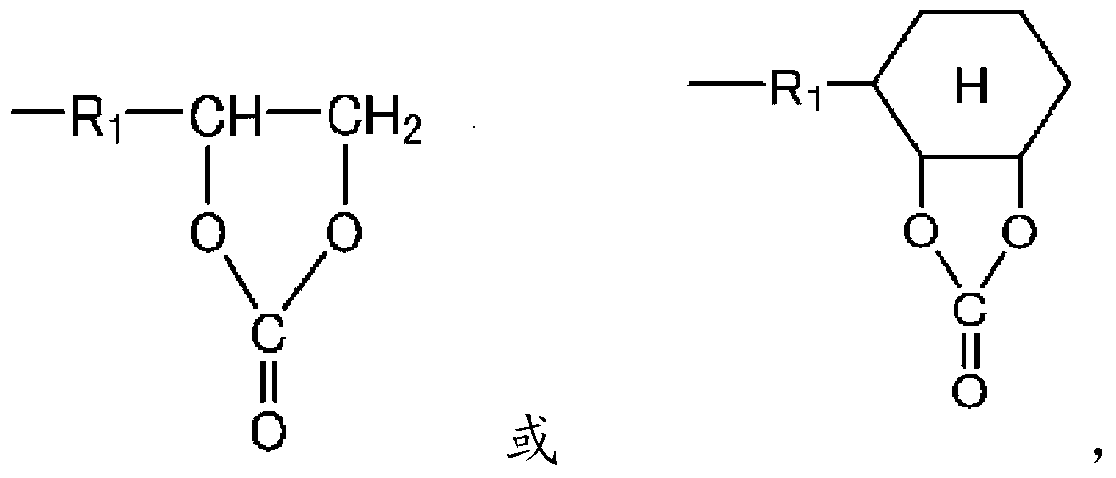

[0165] (Manufacture of 5-membered cyclic carbonate polysiloxane compound)

[0166] In a reaction vessel equipped with a stirrer, a thermometer, a gas introduction tube, and a reflux cooler, a divalent epoxy-modified polysiloxane represented by the following formula A (manufactured by Shin-Etsu Chemical Co., Ltd., X-22-163 ( trade name); epoxy equivalent 198g / mol) 100 parts, N-methylpyrrolidone 100 parts, sodium iodide 1.2 parts, and dissolve uniformly. Thereafter, the mixture was heated and stirred at 80°C for 30 hours while passing carbon dioxide at a rate of 0.5 liter / min.

[0167]

[0168] (a is the value when the molecular weight reaches 396)

[0169] After completion of the reaction, 100 parts of n-hexane was added to the obtained solution to dilute it, and then, using a separating funnel, it was washed three times with 80 parts of pure water to remove N-methylpyrrolidone and sodium iodide. The n-hexane solution was dehydrated with magnesium sulfate and then concent...

manufacture example 5

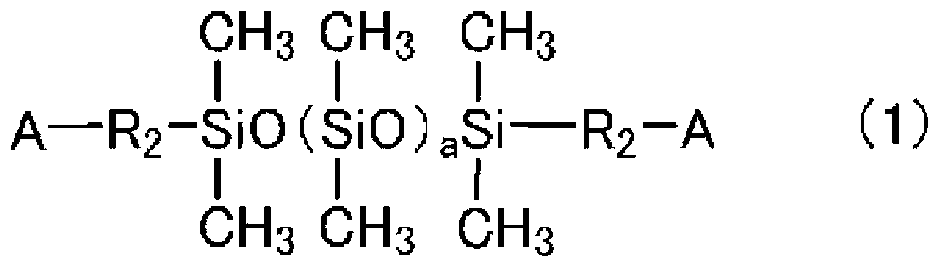

[0171] (Manufacture of 5-membered cyclic carbonate polysiloxane compound)

[0172] The divalent epoxy-modified polysiloxane B represented by the following formula B (Shin-Etsu Chemical Co., Ltd., KF-105 (trade name); epoxy equivalent 485 g / mol) was used instead of the one used in Production Example 4. Divalent epoxy-modified polysiloxane A was reacted in the same manner as in Production Example 4 except that, to obtain 99 parts of a colorless and transparent liquid 5-membered ring carbonate polysiloxane compound (1-B) (Yield 91%).

[0173]

[0174] (a is the value when the molecular weight reaches 970)

[0175] The product was confirmed by infrared absorption spectrum, GPC, and NMR. In the obtained 5-membered ring cyclic carbonate polysiloxane compound (1-B), 8.3% of carbon dioxide was immobilized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com