Self-crosslinkable polyhydroxy polyurethane resin, resinaceous material that contains the resin, process for production of the resin, and imitation leather, surfacing material and weatherstrip material, using the resin

A technology of polyhydroxyurethane, manufacturing method, applied in the direction of polyurea/polyurethane coating, chemical instrument and method, synthetic resin layered product, etc. Achieves the effects of reducing global warming gases, excellent heat resistance, and excellent extinction effect due to problems such as poor chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0169] Hereinafter, specific manufacturing examples, examples, and comparative examples are given to explain the present invention in further detail, but the present invention is not limited to these examples. In addition, unless otherwise specified, "parts" and "%" in the following examples are quality standards.

[0170] (Production of modifier)

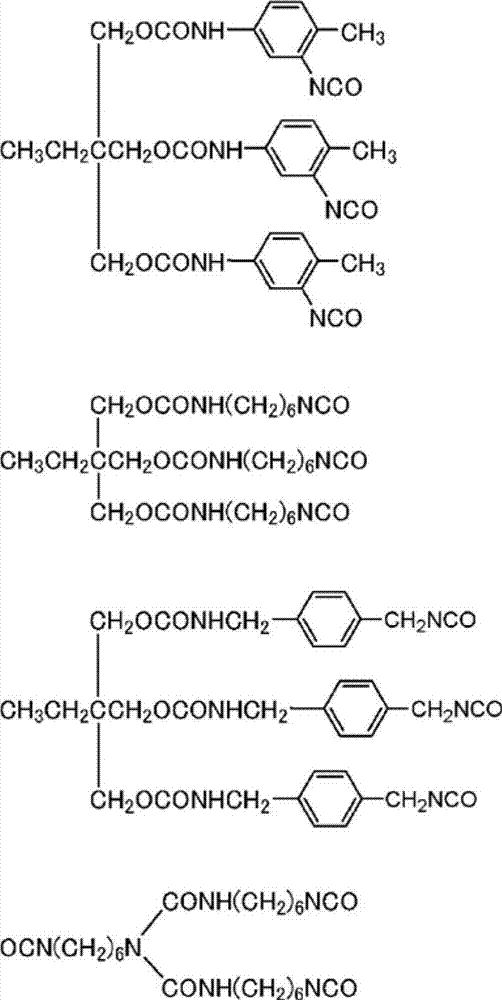

[0171] 100 parts of trimethylolpropane and hexamethylene diisocyanate tripolymer adduct [CoronateHL (trade name), manufactured by Nippon Polyurethane Co., Ltd., NCO=12.9%, solid content 75%], 24.5 parts of ethyl acetate While fully stirring at 100°C, 25.5 parts of ε-caprolactam was added and reacted for 5 hours. According to the infrared absorption spectrum of the modifier obtained (Horiba FT-720), at 2,270cm -1 Absorption due to free isocyanate groups remained at the place. When the free isocyanate groups were quantified, the theoretical value was 2.1% based on the solid content of 50%, compared to the actual measured value of 1.8%. ...

manufacture example 4

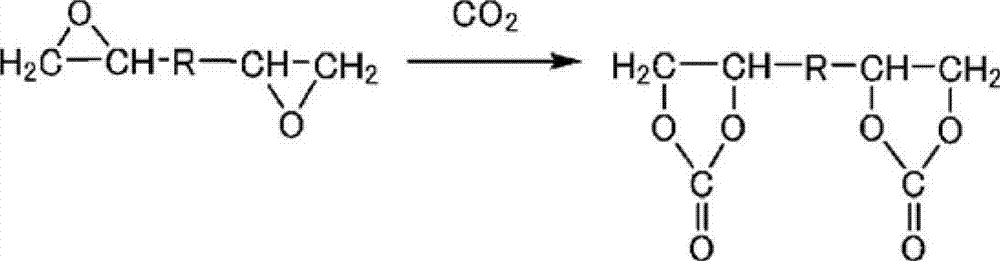

[0182] (Production of 5-membered cyclic carbonate compound)

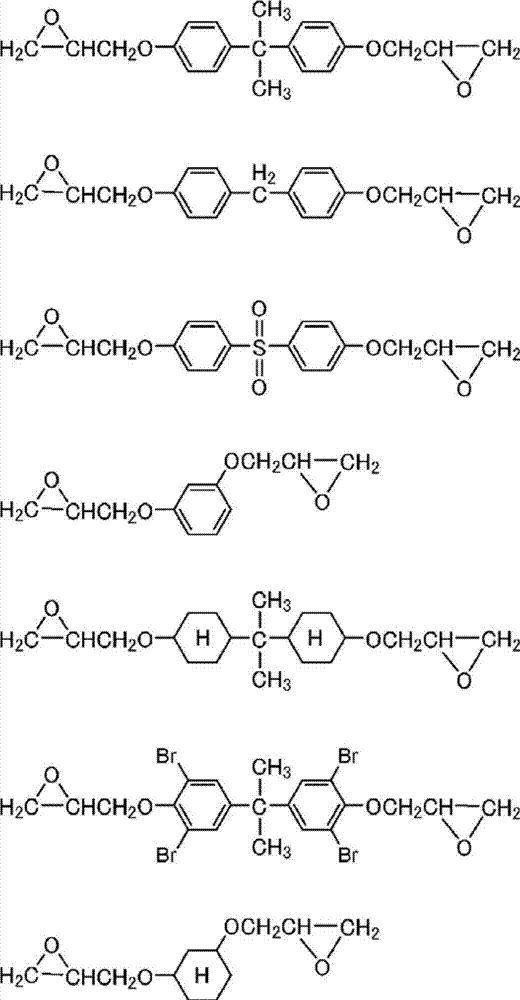

[0183] The divalent epoxy compound represented by the following formula A [epikote 828 (trade name), manufactured by Nippon Epoxy Co., Ltd., epoxy resin) is added to a reaction vessel equipped with a stirrer, a thermometer, a gas introduction tube, and a reflux condenser. Equivalent of 187g / mol] 100 parts, 100 parts of N-methylpyrrolidone, 1.5 parts of sodium iodide, and uniformly dissolve them.

[0184]

[0185] Then, while blowing carbon dioxide at a rate of 0.5 L / min, heating and stirring were performed at 80°C for 30 hours. After the reaction, while stirring at 300 rpm at high speed, the obtained solution was slowly added to 300 parts of n-hexane, the resulting powdery product was filtered with a filter, and washed with methanol to remove N-methylpyrrolidone and iodine Sodium. The powder was dried in a dryer to obtain 118 parts of a white powdery 5-membered ring cyclic carbonate compound (1-A) (yield 95%).

[0186]...

manufacture example 5

[0187] (Production of 5-membered cyclic carbonate compound)

[0188] The divalent epoxy compound [YDF-170 (trade name), manufactured by Toto Kasei Co., Ltd., epoxy equivalent 172 g / mol] represented by the following formula B was used instead of the divalent epoxy compound A used in Production Example 4, and Production Example 4 was reacted in the same manner to obtain 121 parts of white powdery 5-membered cyclic carbonate compound (1-B) (yield 96%).

[0189]

[0190] As in the case of Production Example 4, the product was confirmed by infrared absorption spectrum, GPC, and NMR. 20.3% of carbon dioxide was immobilized in the obtained 5-membered cyclic carbonate compound (1-B).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com