Self-crosslinkable polysiloxane-modified polyhydroxy polyurethane resin, process for producing said resin, resin material comprising said resin, and artificial leather produced utilizing said resin

一种多羟基聚氨酯、聚硅氧烷的技术,应用在人造革领域,能够解决性能差异、不充分等问题,达到耐热性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0103] (manufacture of modifier)

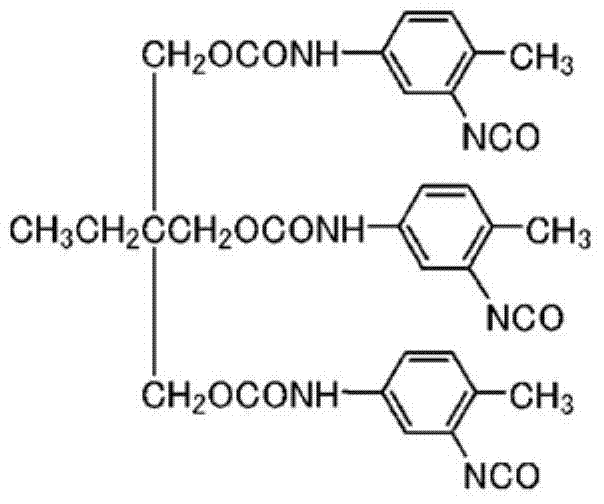

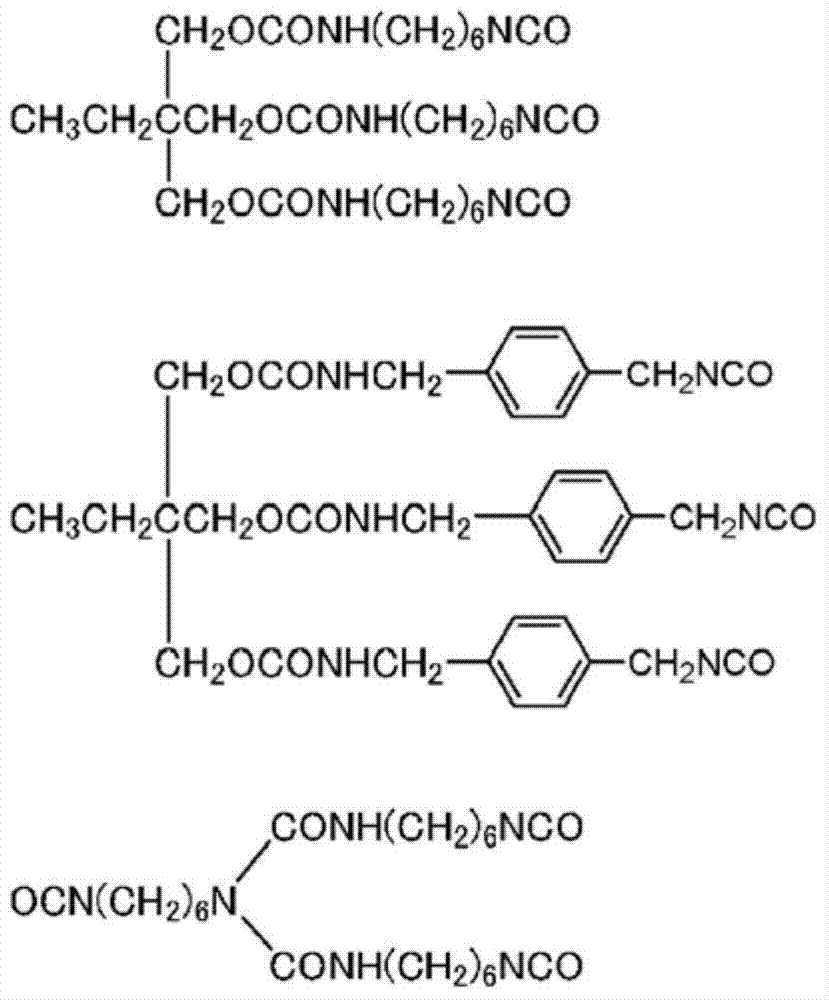

[0104] While mixing 100 parts of trimethylolpropane and hexamethylene diisocyanate tripolymer adduct [Coronate HL (trade name), Nippon Polyurethane Co., Ltd., NCO=12.9%, solid content 75%], ethyl acetate While fully stirring 24.5 parts at 100° C., 25.5 parts of ε-caprolactam were added and reacted for 5 hours. According to the infrared absorption spectrum of the modifier obtained (measured with FT-720 manufactured by Horiba Corporation. The same applies below.), at 2,270 cm -1 Absorption of free isocyanate groups remains. When the free isocyanate group was quantified, the theoretical value was 2.1% based on 50% of the solid content, whereas the actual measurement value was 1.8%. Therefore, the main structure of the above modifier is estimated to be the following formula.

[0105]

manufacture example 2

[0106] (manufacture of modifier)

[0107] While fully stirring 100 parts of an adduct of hexamethylene diisocyanate and water [Duranate 24A-100 (trade name), manufactured by Asahi Kasei Co., Ltd., NCO=23.0%], and ethyl acetate at 80°C, add methyl ethyl 32 parts of base ketoxime, reacted for 5 hours. According to the obtained infrared absorption spectrum of the modifier, at 2,270cm -1 Absorption of free isocyanate groups remained at the position, and when the free isocyanate groups were quantified, the theoretical value was 2.9% based on 50% solid content, while the actual measurement value was 2.6%. Therefore, the main structure of the above modifier is estimated to be the following formula.

[0108]

manufacture example 3

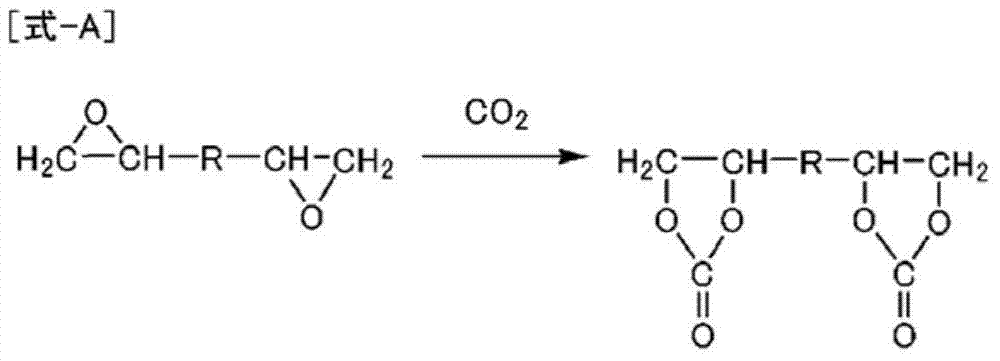

[0109] (Manufacture of five-membered ring cyclic carbonate compound)

[0110] Add the divalent epoxy compound [Epicoat828 (trade name), Japanese epoxy resin (KK) system shown in formula A in the reaction vessel that is equipped with stirrer, thermometer, gas introduction pipe and reflux condenser; Epoxy equivalent 187g / mol], 100 parts of N-methylpyrrolidone, and 1.5 parts of sodium iodide were uniformly dissolved.

[0111]

[0112] Thereafter, while bubbling carbon dioxide at a rate of 0.5 liter / minute, the mixture was heated and stirred at 80° C. for 30 hours. After the reaction was finished, the obtained solution was slowly added while stirring at a high speed at 300rpm in 300 parts of normal hexane, and the powdery product generated was filtered with a filter, and washed with methanol to remove N-methylpyrrolidone and sodium iodide. The obtained powder was dried in a drier to obtain 118 parts of a five-membered ring cyclic carbonate compound (1-A) as a white powder (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com