Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Simply" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reconfigurable measurement system utilizing a programmable hardware element and fixed hardware resources

InactiveUS20030163298A1Easy to useSimplyError detection/correctionMeasurement arrangements for variableProgrammable hardwareComputer hardware

A system and method for configuring a device to perform a function, where the device includes a programmable hardware element and one or more fixed hardware resources. A program is stored which represents the function. A hardware configuration program is generated based on the program, specifying a configuration for the programmable hardware element that implements the function, and usage of the fixed hardware resources by the programmable hardware element in performing the function. A deployment program deploys the hardware configuration program onto the programmable hardware element, where, after deployment, the device is operable to perform the function, where the programmable hardware element directly performs a first portion of the function, and the programmable hardware element invokes the fixed hardware resources to perform a second portion of the function. An optional measurement module couples to the device and performs signal conditioning and / or conversion logic on an acquired signal for the device.

Owner:NATIONAL INSTRUMENTS

Integrated rainfall estimation method using x-band dual-polarimetric radar measurement data

ActiveUS20150145717A1Accurate estimateAccurately estimating rainfallRainfall/precipitation gaugesWeather condition predictionRainfall estimationEuclidean vector

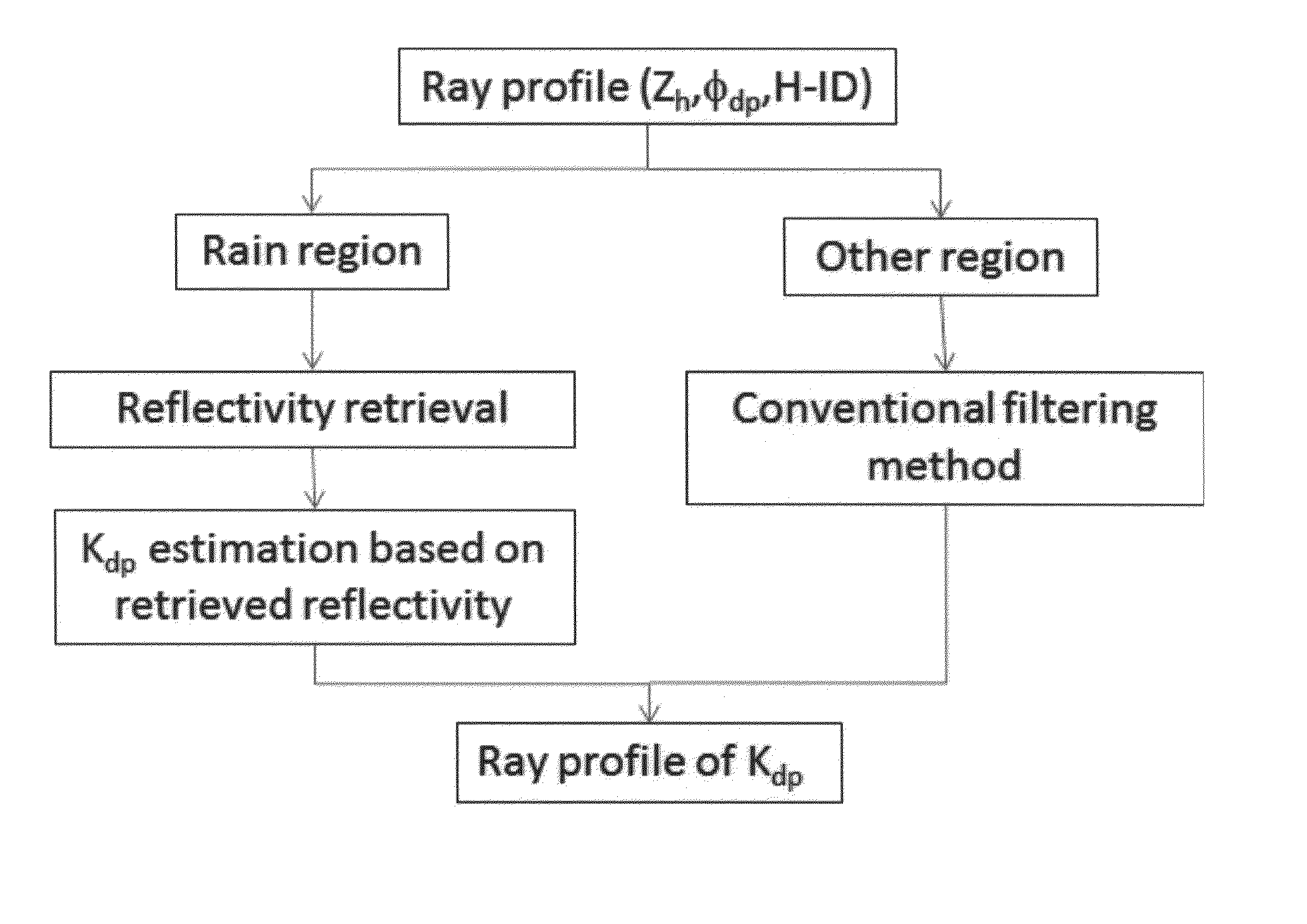

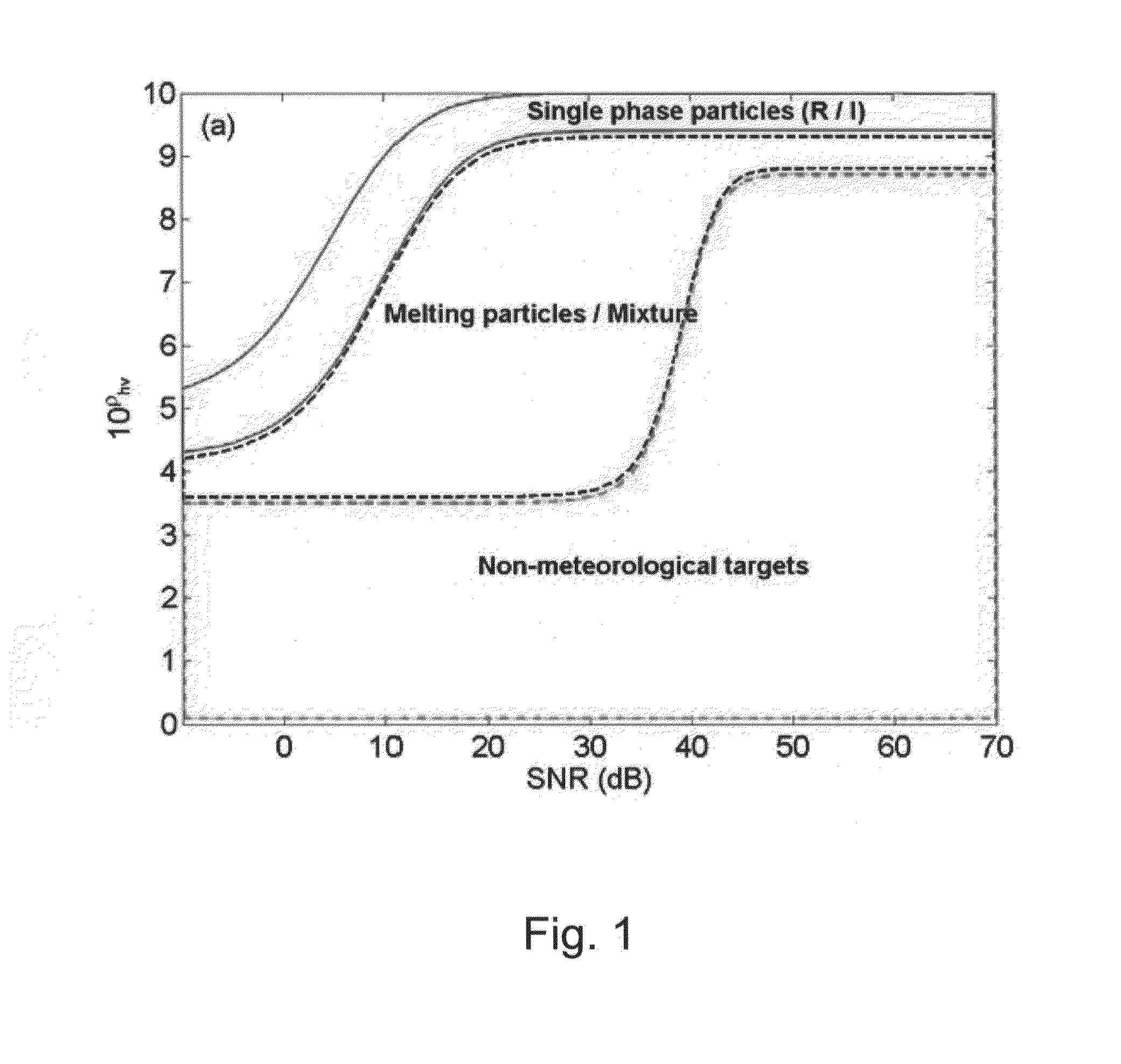

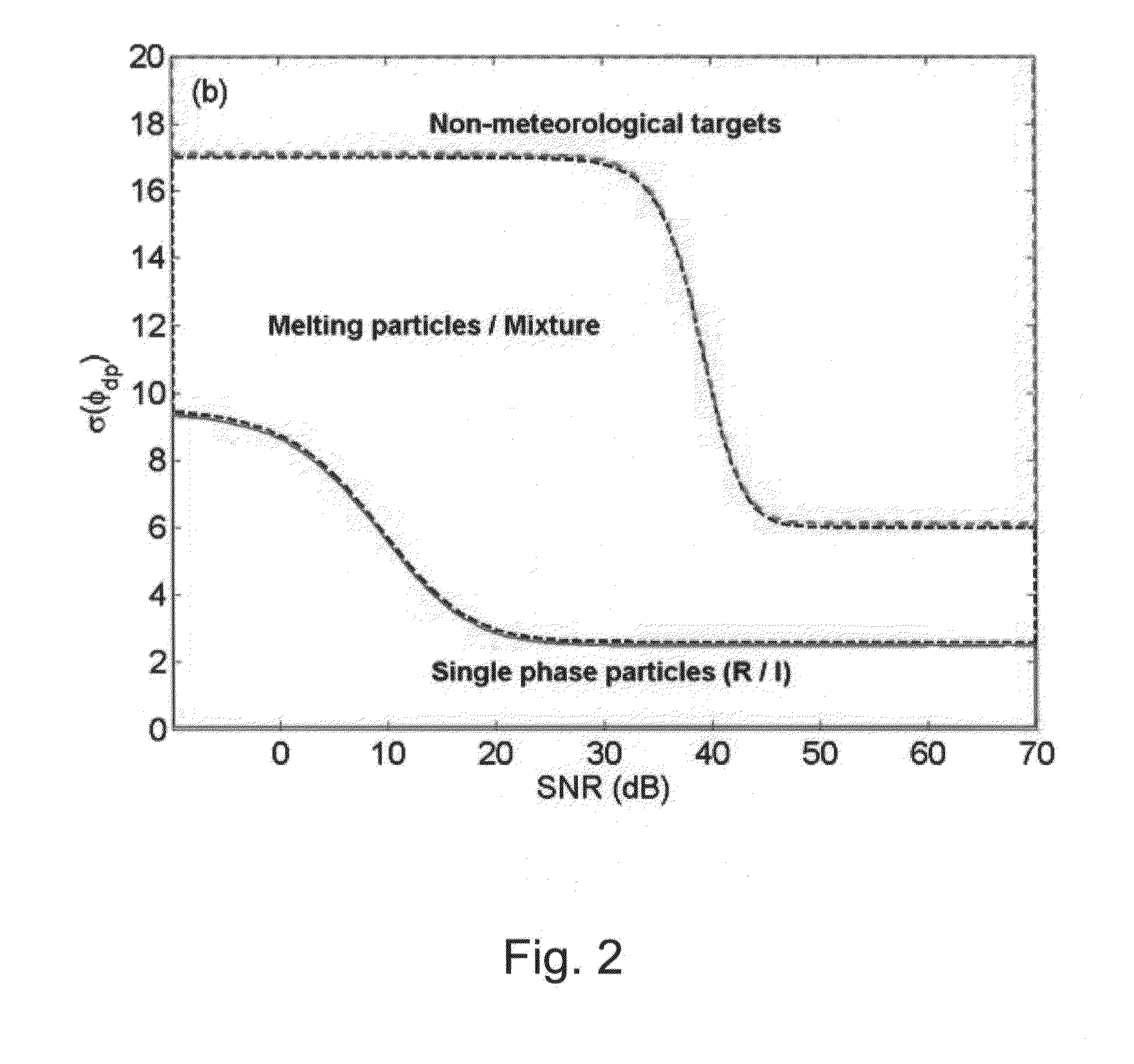

An integrated rainfall calculation method using X-band dual-polarimetric radar measurement data includes a precipitation classification step of classifying hydrometeors into four types of snow, rain / snow, rain and non-meteorological target through a fuzzy logic technique using a correlation coefficient (cross correlation coefficient, ρhv), features of a measured differential propagation phase (Ψdp(r)) or differential propagation phase (φdp) and a signal-to-noise ratio (SNR) as input variables (input feature vector); a specific differential phase calculation step of separately calculating a specific differential phase by applying a specific differential phase using a total difference of differential phase and signal-attenuation corrected reflectivity for the rain among the classified hydrometeors and applying a specific differential phase calculated using a filtering method for the other hydrometeors; and a rainfall calculation step of calculating rainfall by using a relation between the specific differential phase and the rainfall and using the separately calculated specific differential phase.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH

Apparatus and method for a wireless sensor to monitor barrier system integrity

Owner:BP CORP NORTH AMERICA INC

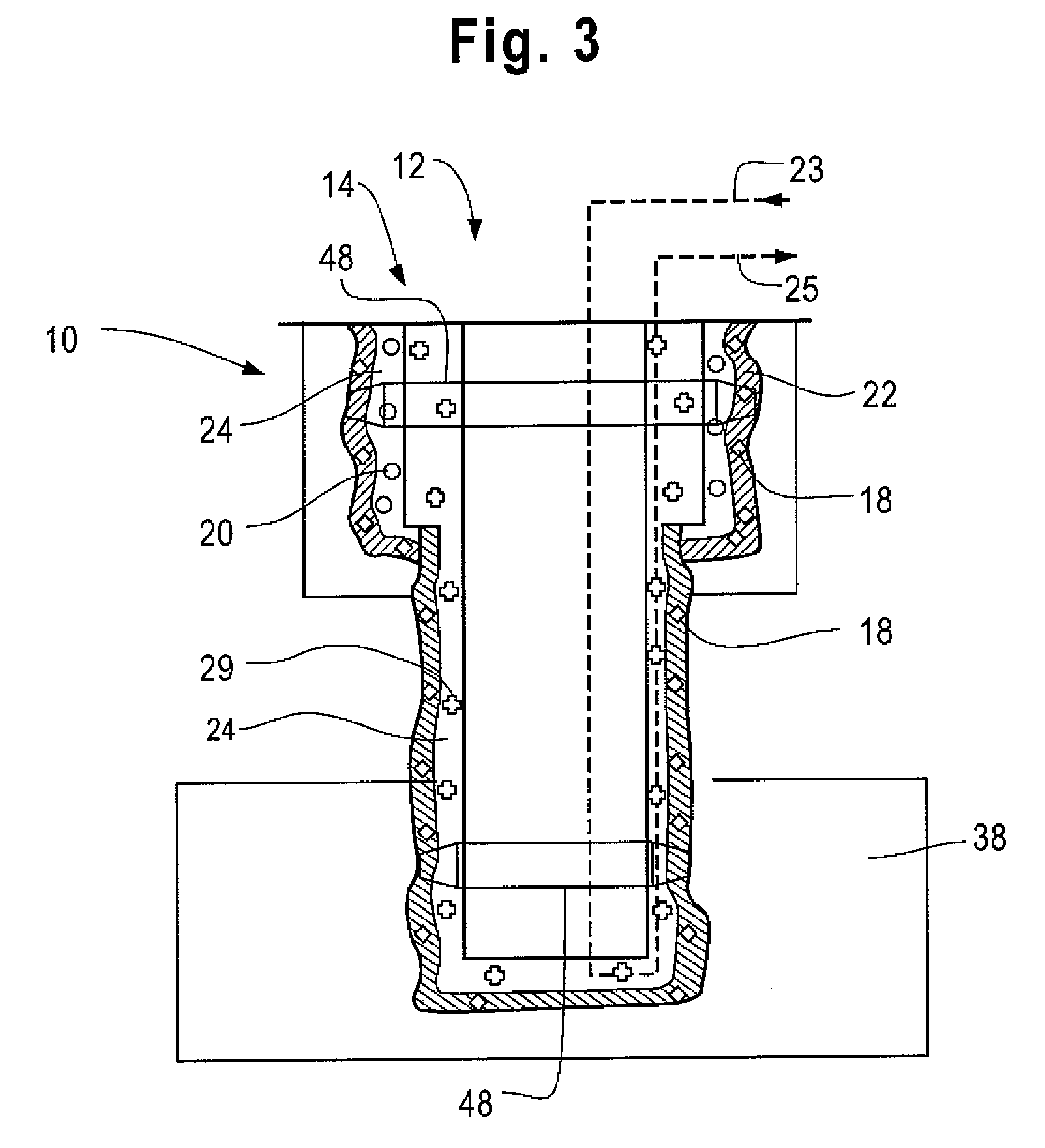

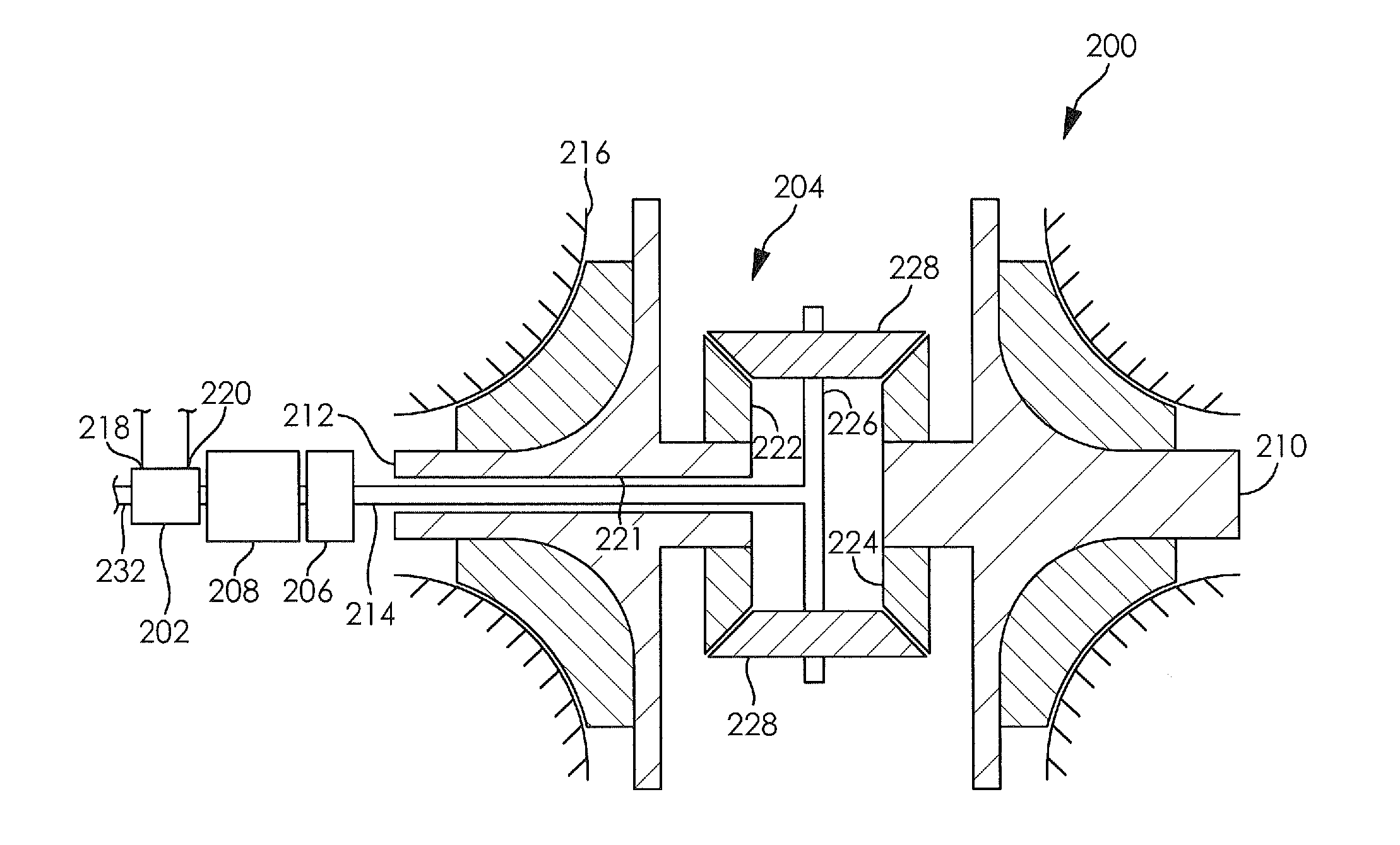

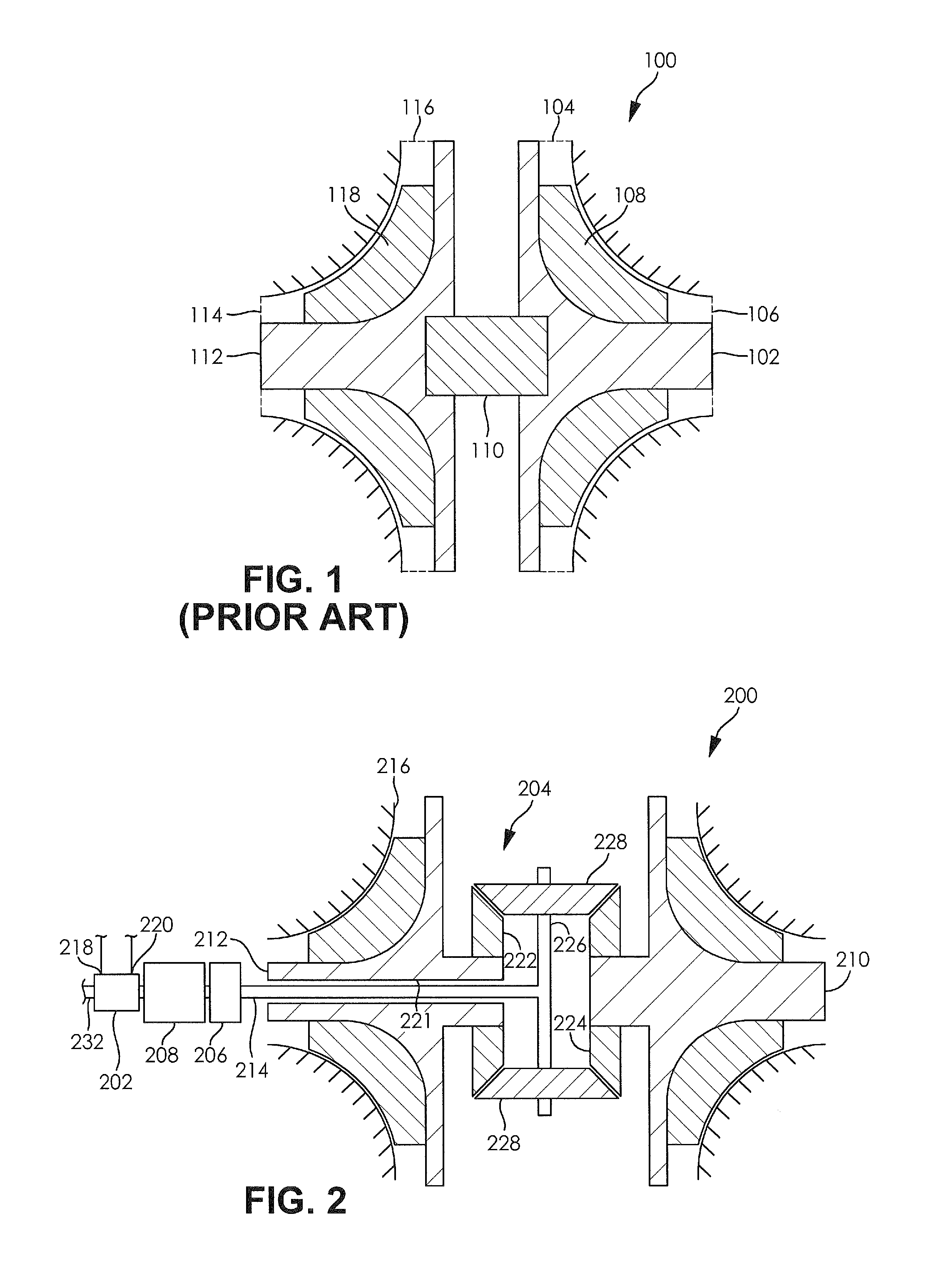

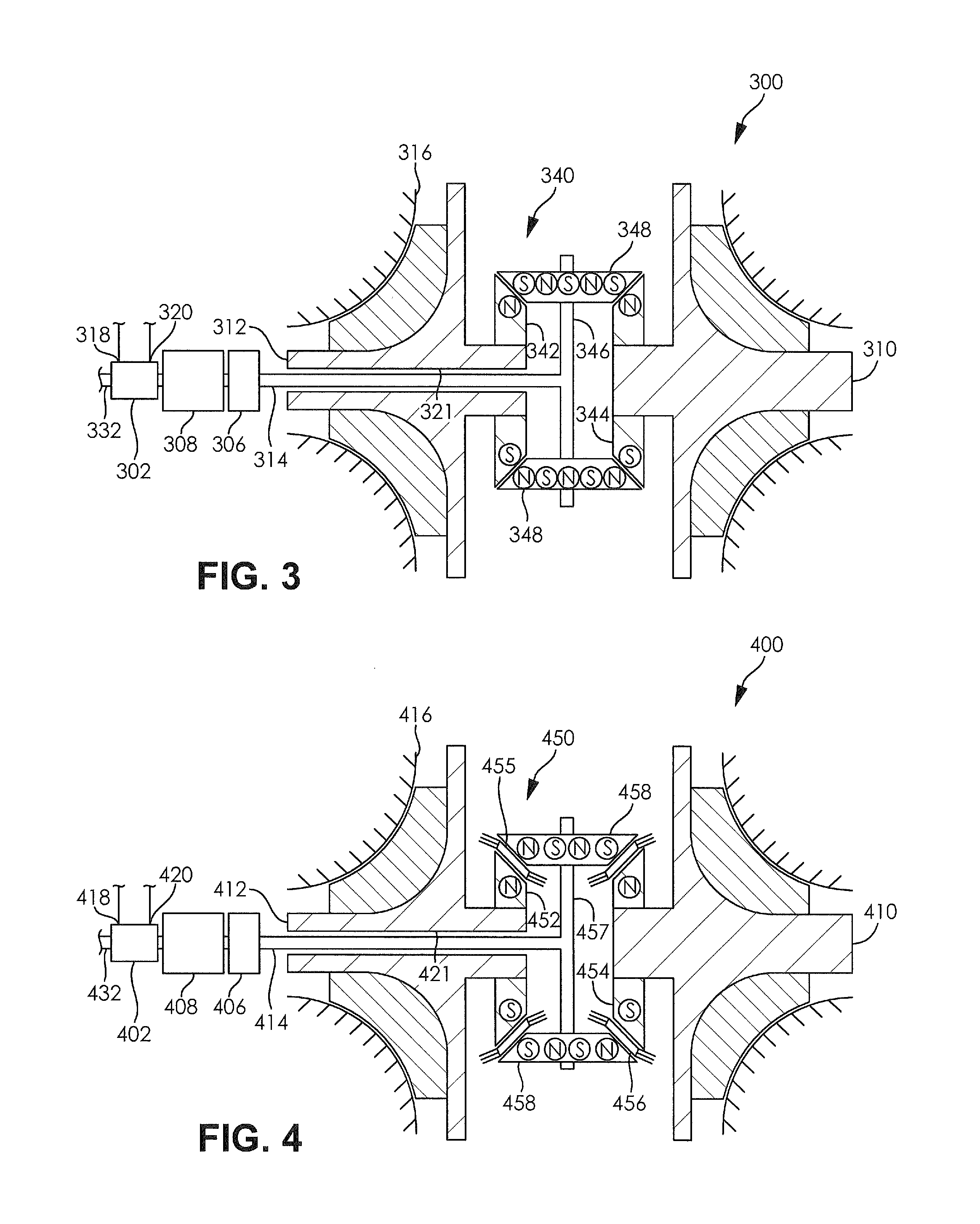

Internal combustion engine coupled turbocharger with an infinitely variable transmission

InactiveUS20140223901A1Reduces turbo lagImprove internal efficiencyInternal combustion piston enginesGas turbine plantsTurbochargerInternal combustion engine

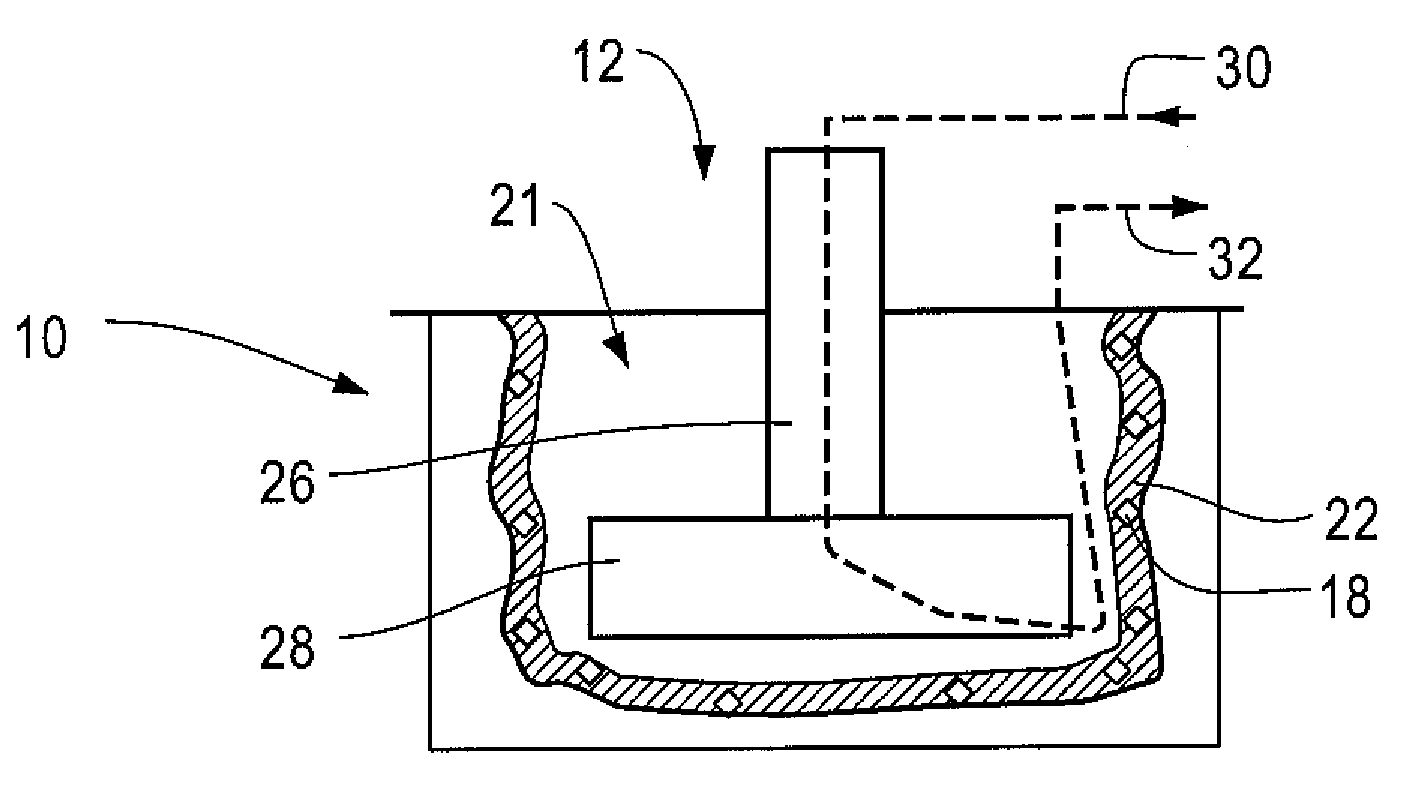

A turbocharger for use with an internal combustion engine is provided. The turbocharger comprises a differential device having a carrier portion, a compressor portion, and a turbine portion. The compressor portion is in driving engagement with a first portion of the differential device. The turbine portion is in driving engagement with a second portion of the differential device. The carrier portion of the differential device is in driving engagement with an infinitely variable transmission. The infinitely variable transmission is in driving engagement with the internal combustion engine. The turbocharger is simply controlled, reduces turbo lag, decreases a boost threshold of the turbocharger, and increases an efficiency of the internal combustion engine.

Owner:DANA CORP

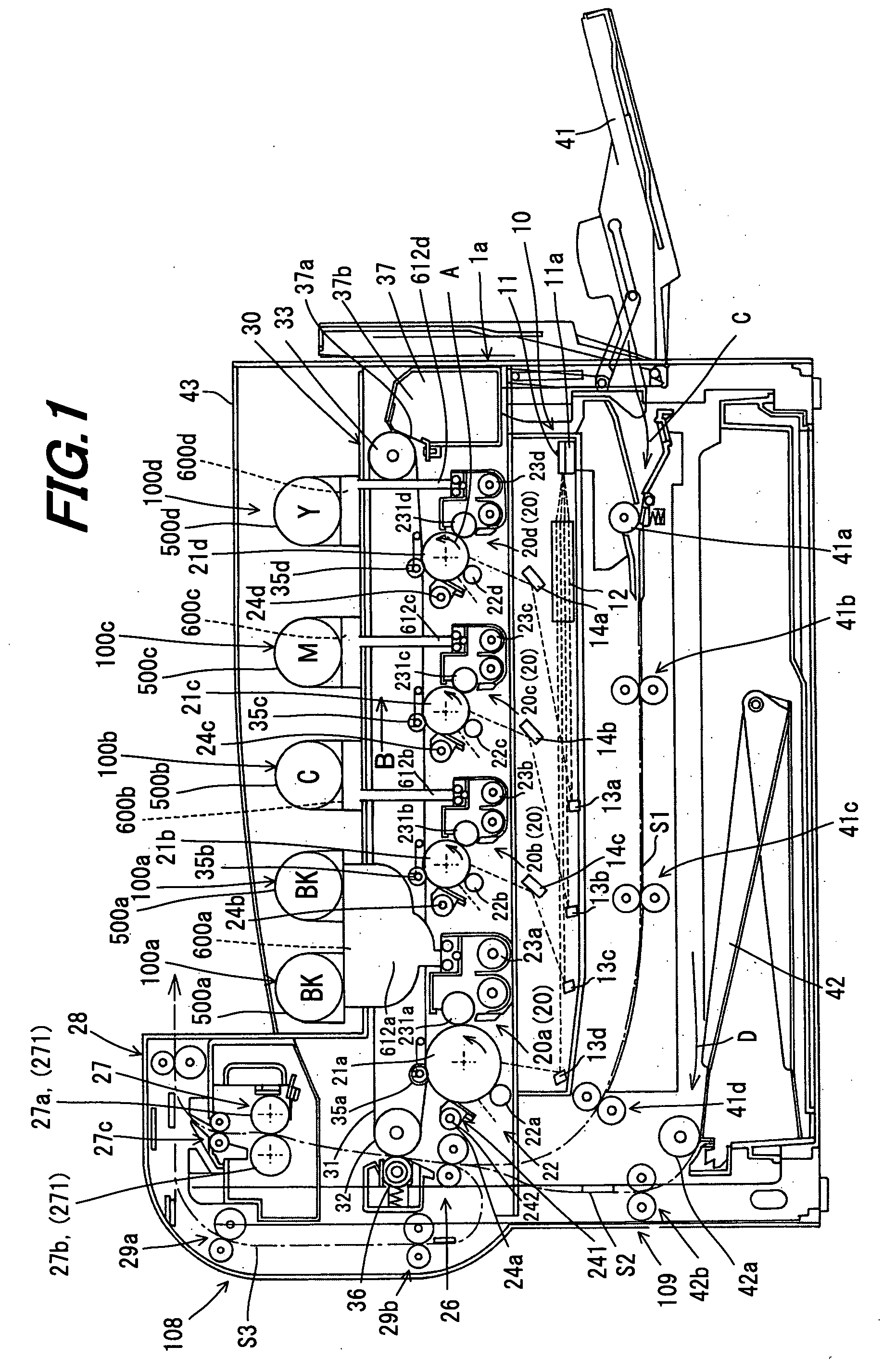

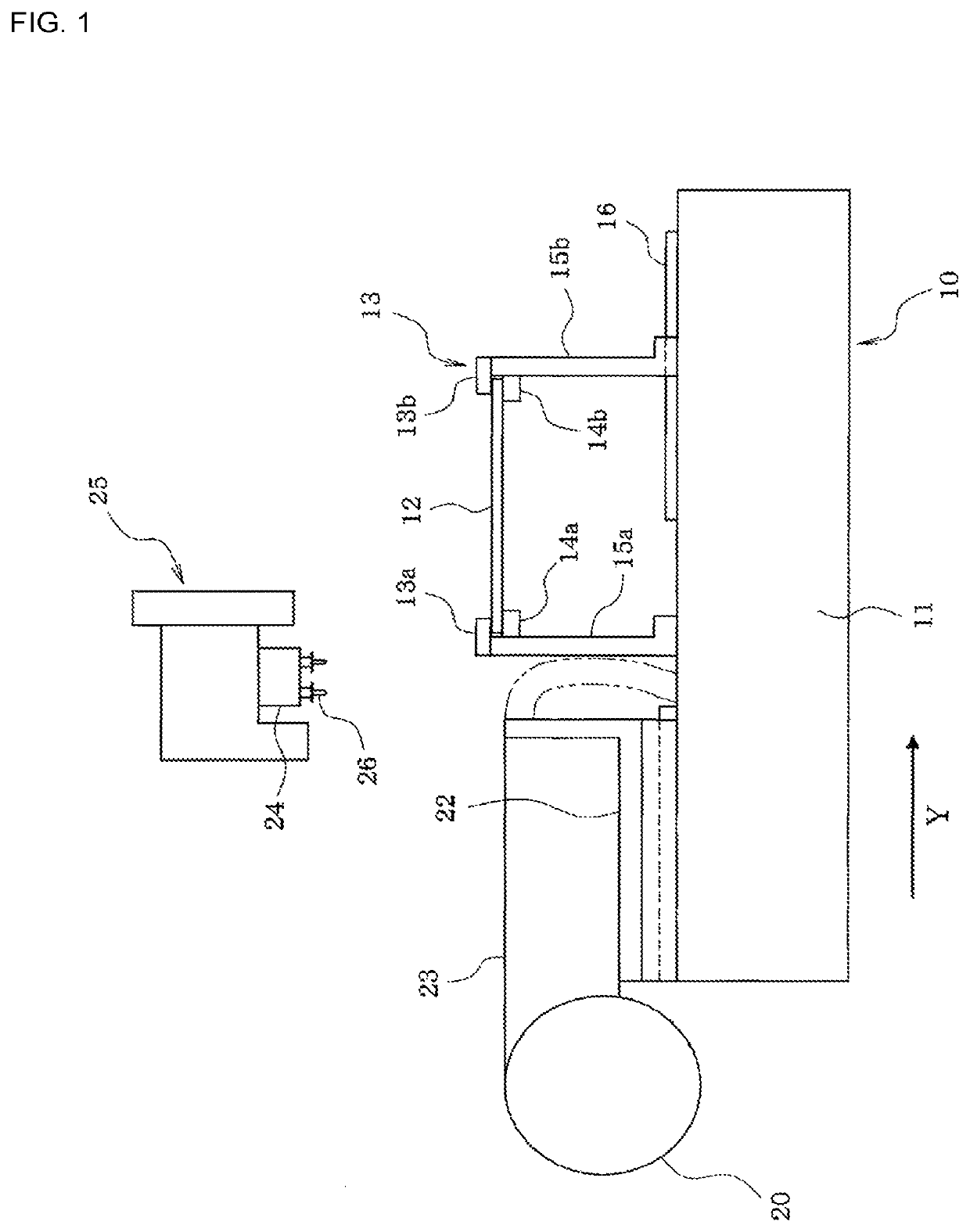

Carriage device and inkjet device

InactiveUS20110102504A1Easy to installShort timeInking apparatusPower drive mechanismsRotational axisEngineering

A carriage device includes a head unit, a printing head and a carriage. The head unit has a sub-plate attached to a head plate via an adjustment mechanism. The printing head is attached to the head plate via the sub-plate. The carriage retains the head unit. The adjustment mechanism includes a first-direction adjustment plate, a rotation position adjustment plate, and a pitch angle adjustment plate. The first-direction adjustment plate adjusts a position of the sub-plate with respect to the head plate in a first direction. The rotation position adjustment plate adjusts, in a predetermined plane, a rotation position of the sub-plate with respect to the head plate about a rotational axis that is normal to the predetermined plane. The pitch angle adjustment plate adjusts a pitch angle of the sub-plate with respect to the head plate, the pitch angle being in relation to the predetermined plane.

Owner:SEIKO EPSON CORP

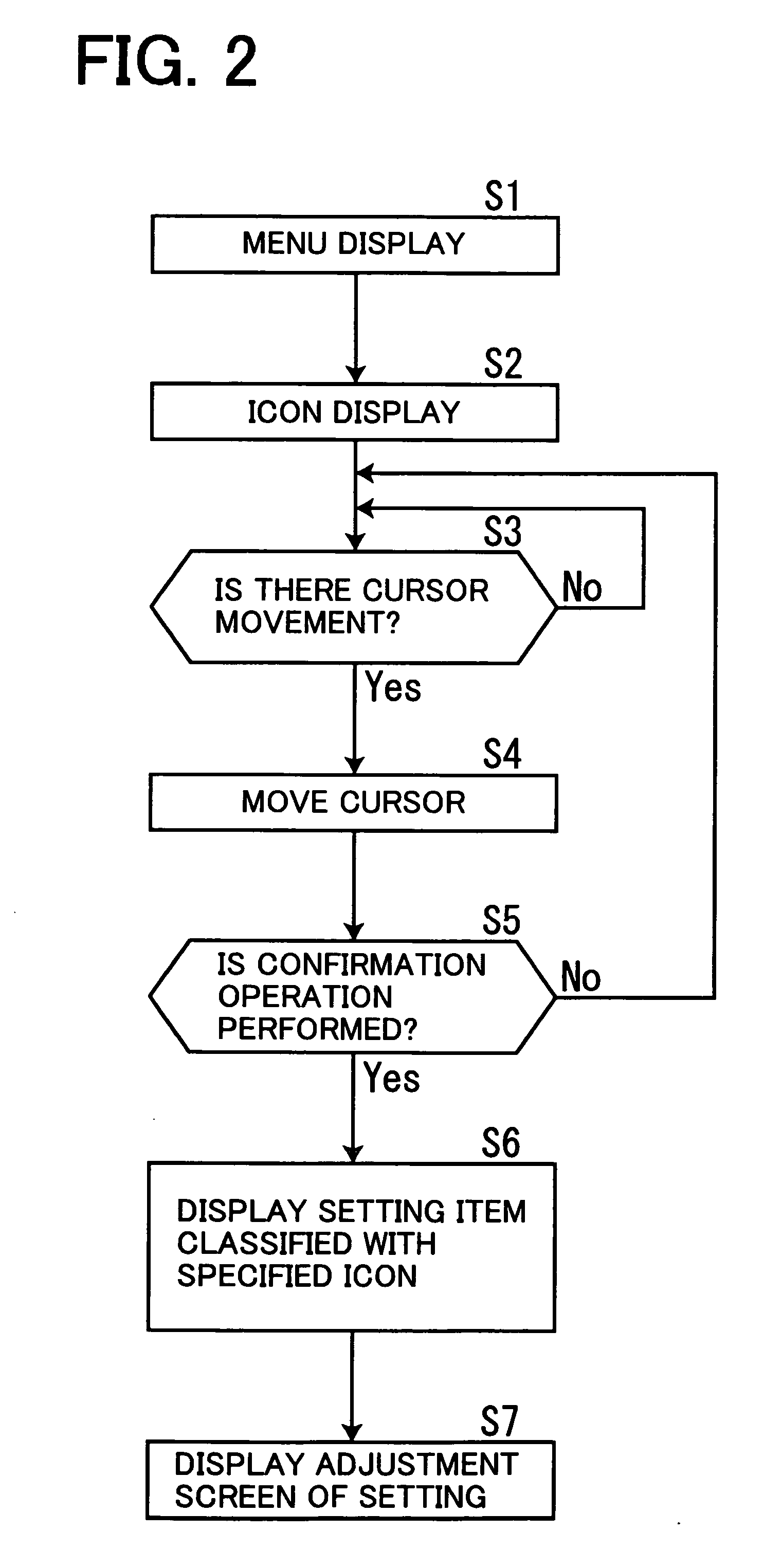

Simple item selecting method and electronic apparatus provided therewith

InactiveUS20060242601A1Easy to changeImprove visibilityTelevision system detailsSelective content distributionBackground colorElectronic equipment

To provide an electronic apparatus which allows a user to select a desired setting item easily on a menu screen for making settings of the electronic apparatus. A plurality of setting items of the electronic apparatus are divided based on predetermined classification and a plurality of icons 15 illustrating the classification are displayed. To improve viewability of the icons 15, icon frames 16 are used as backgrounds of the icons 15, and when the user selects an icon, a cursor 17 is used which explicitly specifies the icon being selected 15 and icon frame 16 by displaying them in a changed background color. Using these three components of the icons 15, icon frames 16 and cursor 17, the user can select a desired icon easily from among the icons 15 indicating the classification of many setting items of the electronic apparatus.

Owner:ORION ELECTRIC CO LTD

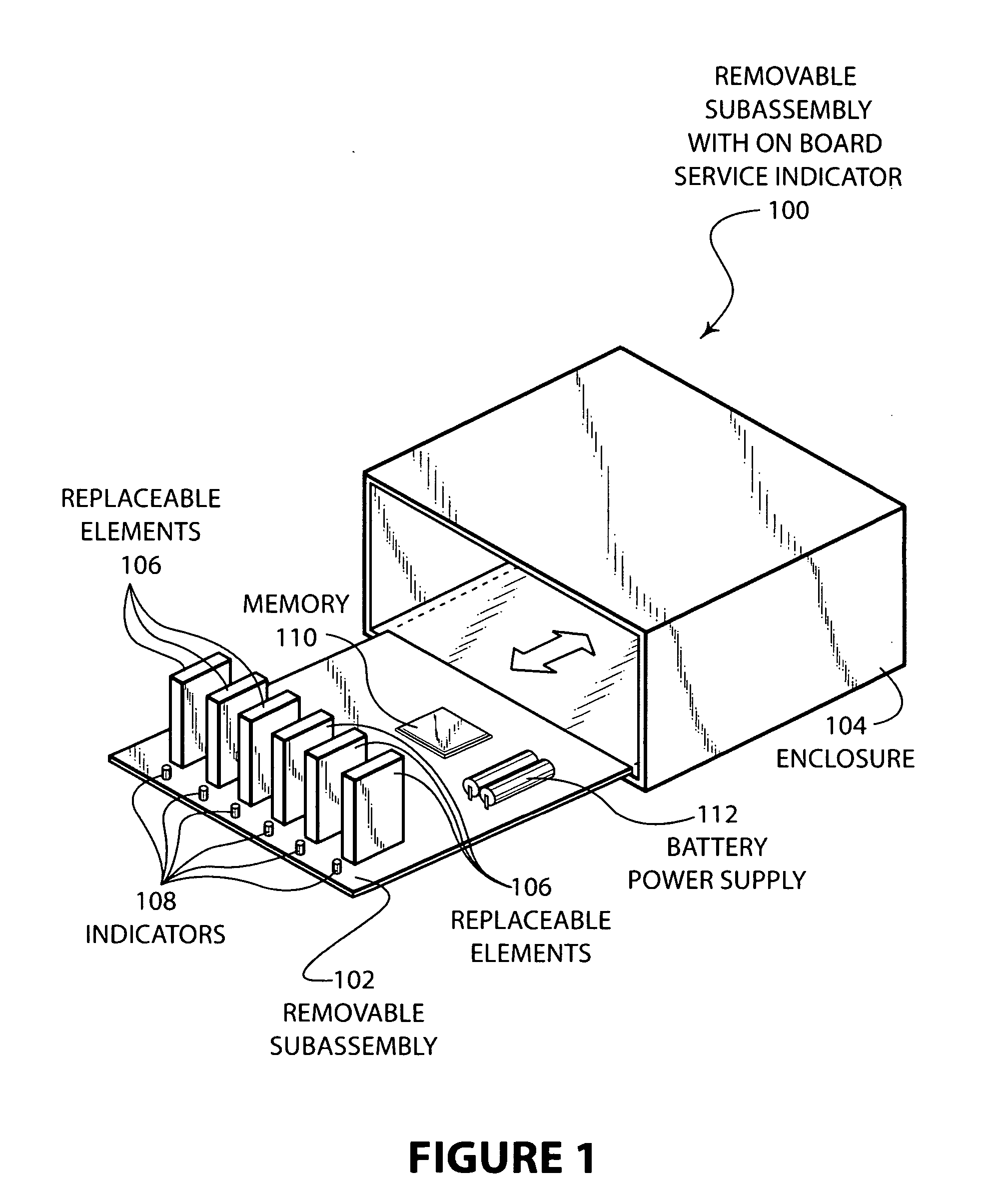

Onboard indicator

InactiveUS20050144508A1Simply and efficiently communicatingMinimize confusionError detection/correctionMemory systemsMaster controllerEmbedded system

A system and method for indicating the service status of serviceable elements of a subassembly stores the service status in a memory using a host controller. When the subassembly is removed from the host controller, the memory may be accessed using a second circuit and separate power supply, and indicators may be illuminated to indicate the service status of the elements.

Owner:NETWORK APPLIANCE INC

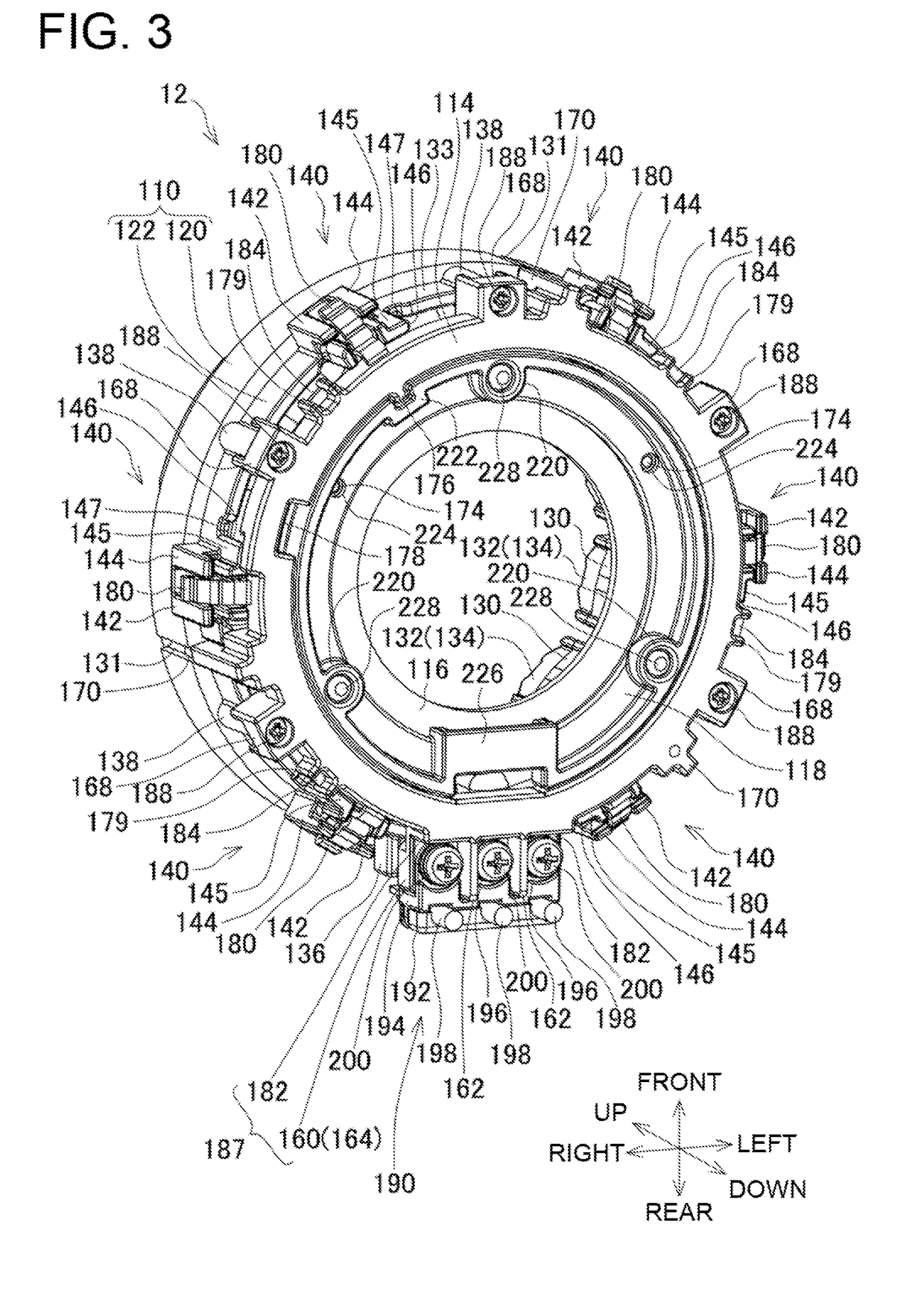

Power tool

InactiveUS20190001452A1Simply dealingSimplyWindings insulation shape/form/constructionMagnetic circuitEngineeringPower tool

It is intended to provide a power tool including a motor capable of simply dealing with even a complex coil connection structure.A hammer drill includes a plurality of coils, a stator holding the plurality of coils, a rotor that is rotatable with respect to the stator, and a terminal unit including a plurality of fusing terminals electrically connected to the plurality of coils.

Owner:MAKITA CORP

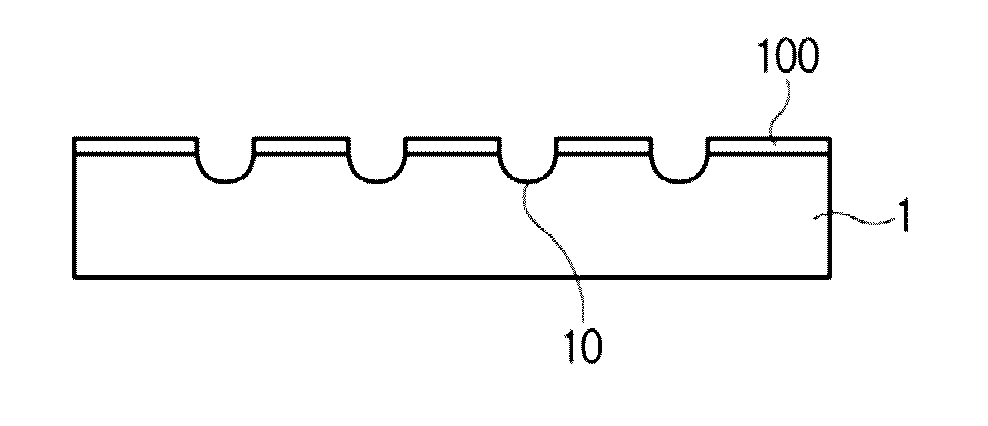

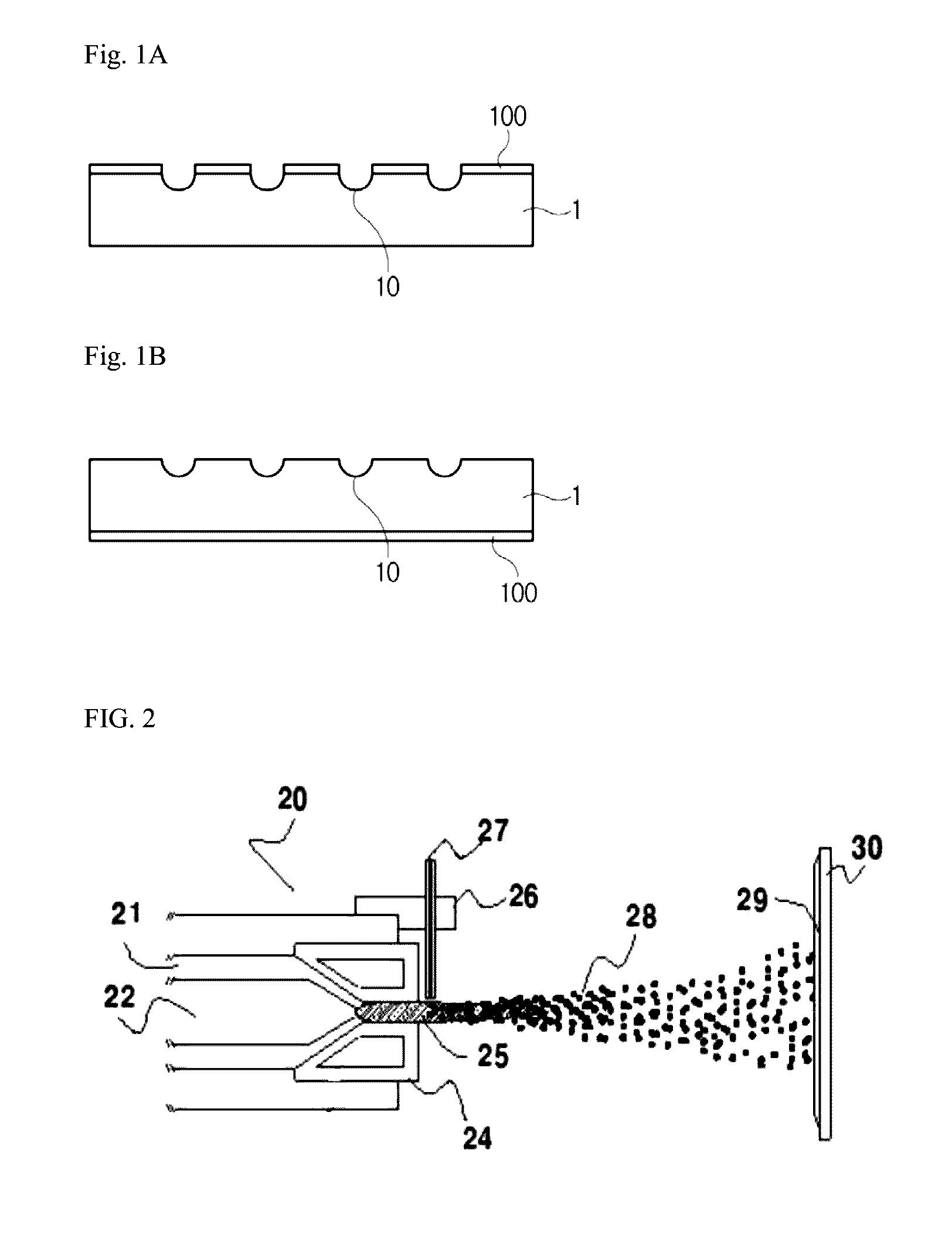

Biosensor and usage thereof

ActiveUS20120061259A1SimplyAccurately measureImmobilised enzymesBioreactor/fermenter combinationsWorking electrodeReaction layer

A biosensor for quantifying an analyte in a sample and usage thereof are provided. The biosensor includes an insulative substrate, a cover, a sample supply port, an electrode system including at least a working electrode, a counter electrode and a third electrode, and a reaction layer at least formed over the working electrode. The third electrode, used for estimating whether the amount of the sample is sufficient, is disposed nearer to the sample supply port than the counter electrode is. Whether the amount of the added sample is sufficient is estimated by comparing the electrical current value detected between the working electrode and the counter electrode with the electrical current value detected between the working electrode and the third electrode. This invention has a simple structure and produces accurate measurements.

Owner:LEADWAY HK

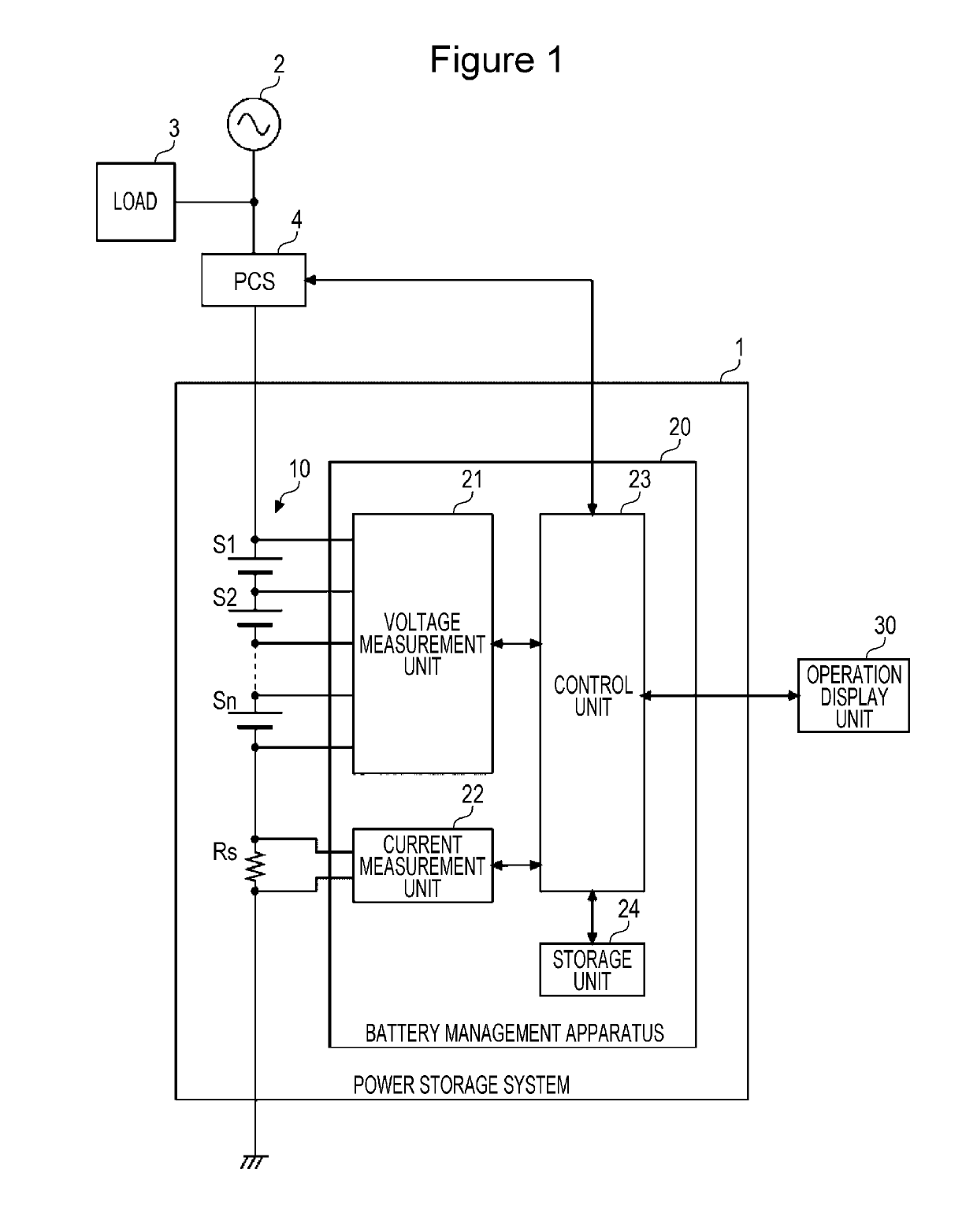

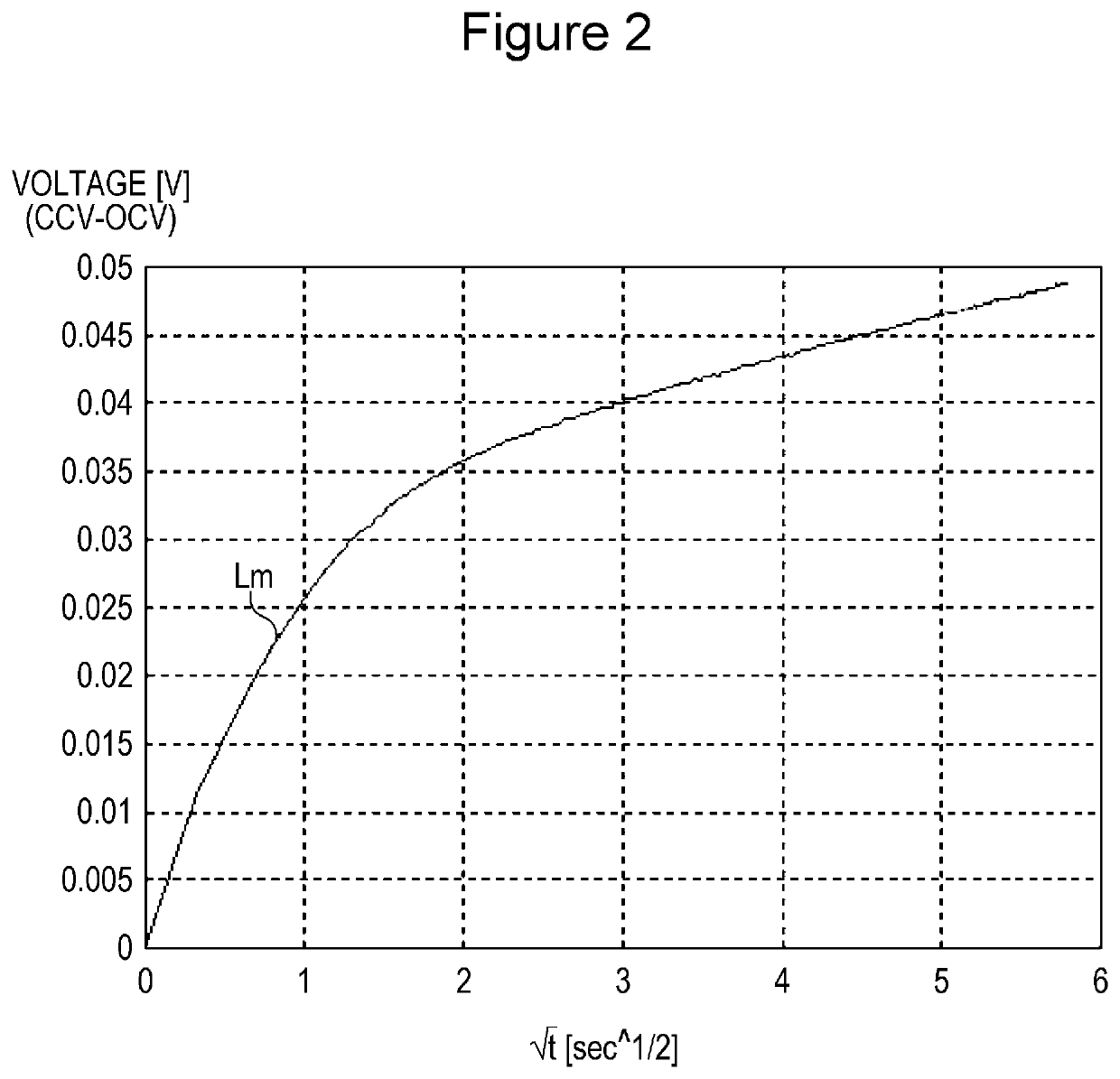

Battery diagnosis method, battery diagnosis program, battery management apparatus, and power storage system

ActiveUS20190170831A1Low costSimplyCharge equalisation circuitCurrent/voltage measurementDiffusion resistanceElectrical battery

A control unit in a battery management apparatus discharges constant direct current from a battery for a predetermined time period or charges the battery with the constant direct current for the predetermined time period to diagnose a state of the battery. A change point is identified where a rise in voltage given by subtracting open circuit voltage of the battery from measured voltage of the battery is varied from a curved line shape to a straight line shape with respect to transition of an increase of a value in which an elapsed time since start of charge-discharge is defined as a square root of time. A rise in voltage from the voltage when the charge-discharge is started to the change point is identified as a rise in voltage caused by resistance components of electrolyte, a negative electrode, and a positive electrode of the battery and a rise in voltage after the change point is identified as a rise in voltage caused by a diffusion resistance component of the battery.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Attachable dry erase shopping list

A clipboard for keeping lists of items for purchases is described. The clipboard includes a dry-erase board, a paper pad, a holder for a dry-erase marker, a holder for an ink pen, a plurality of magnets for holding the clipboard to a ferro-magnetic surface, and a folding board having a clip for attaching to the clipboard to a shopping cart handled. The clip is configured to enable tilting the clipboard with mounted on a shopping cart handle. The clipboard can be moved from a refrigerator, carried to a store, and then clipped onto a shopping cart.

Owner:SANTORE REBECCA

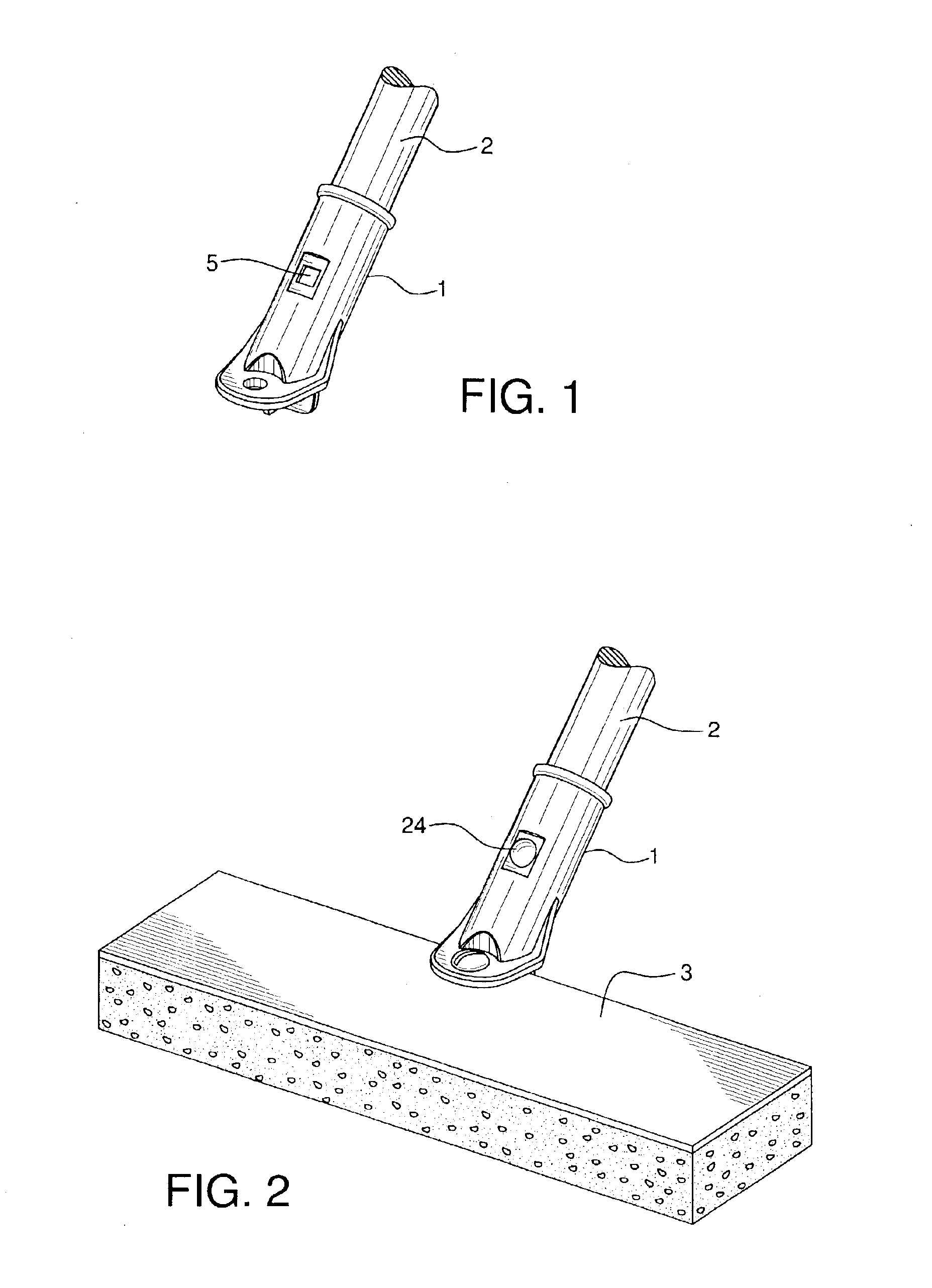

Handle connector

InactiveUS6872026B2Easy to receiveMaintain integrityBrush bodiesBristle carriersDie castingEngineering

A handle connector for securing the head of a cleaning tool to its handle is formed as a unitary integral body, preferably of die-cast construction. The connector has two distal ends. At one end, there is an opening for receiving a handle. The other end of the connector extends outwardly and is configured to mate with the head of a broom, mop, or similar manual tool. The body of the connector includes a floating web comprising a substantially flat section and laterally flanking slots. A bolt and wing nut are provided for joining the handle to the connector. As the wing nut is manually tightened against the connector, it applies a compressive force against the flat section of web, which flexes inward in relation to the handle, ultimately contacting the outside surface of the handle. Continued manual tightening ensures for a tight fit between handle and connector and rigidly secures the joint between these tool components.

Owner:QUICKIE MFG

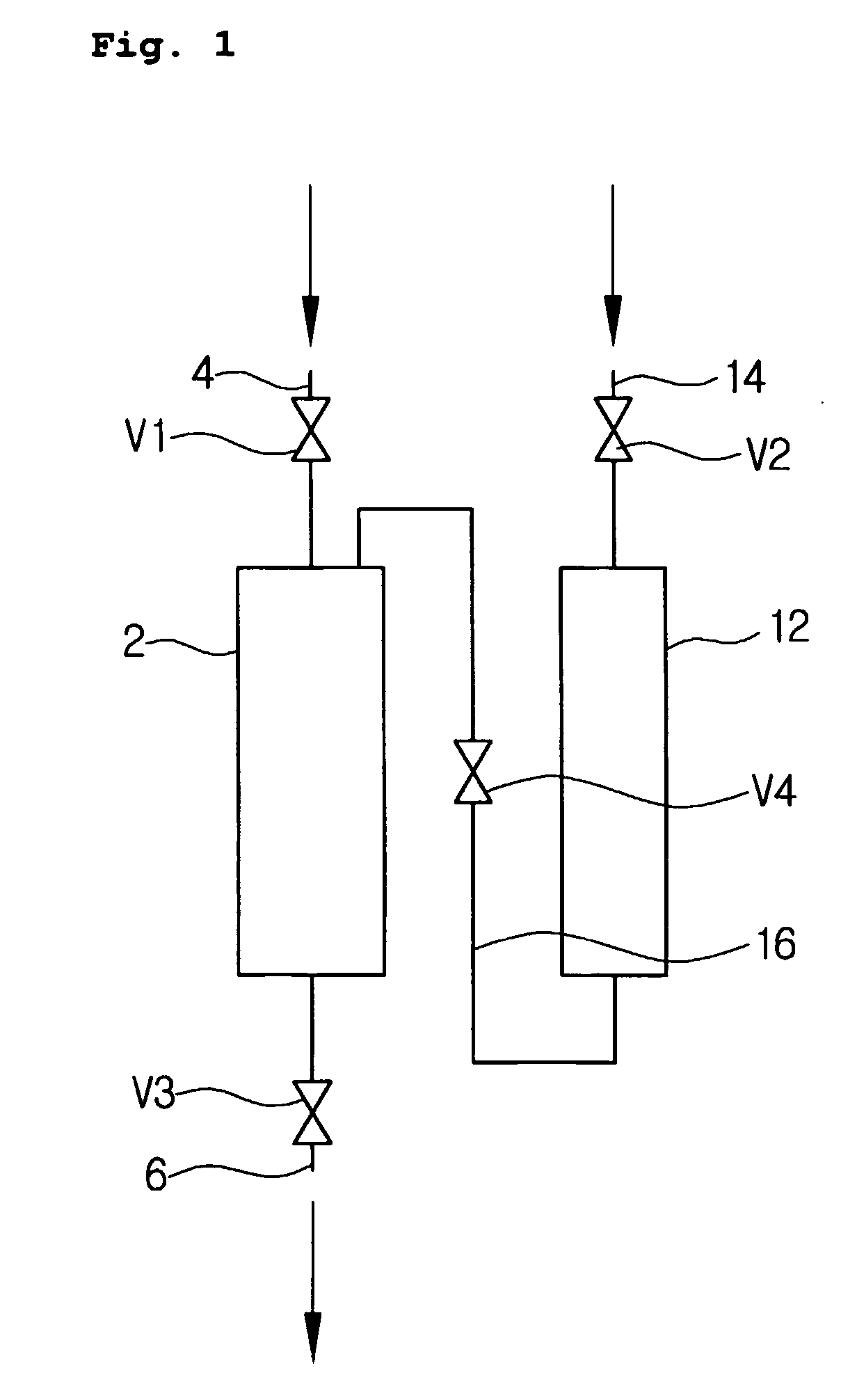

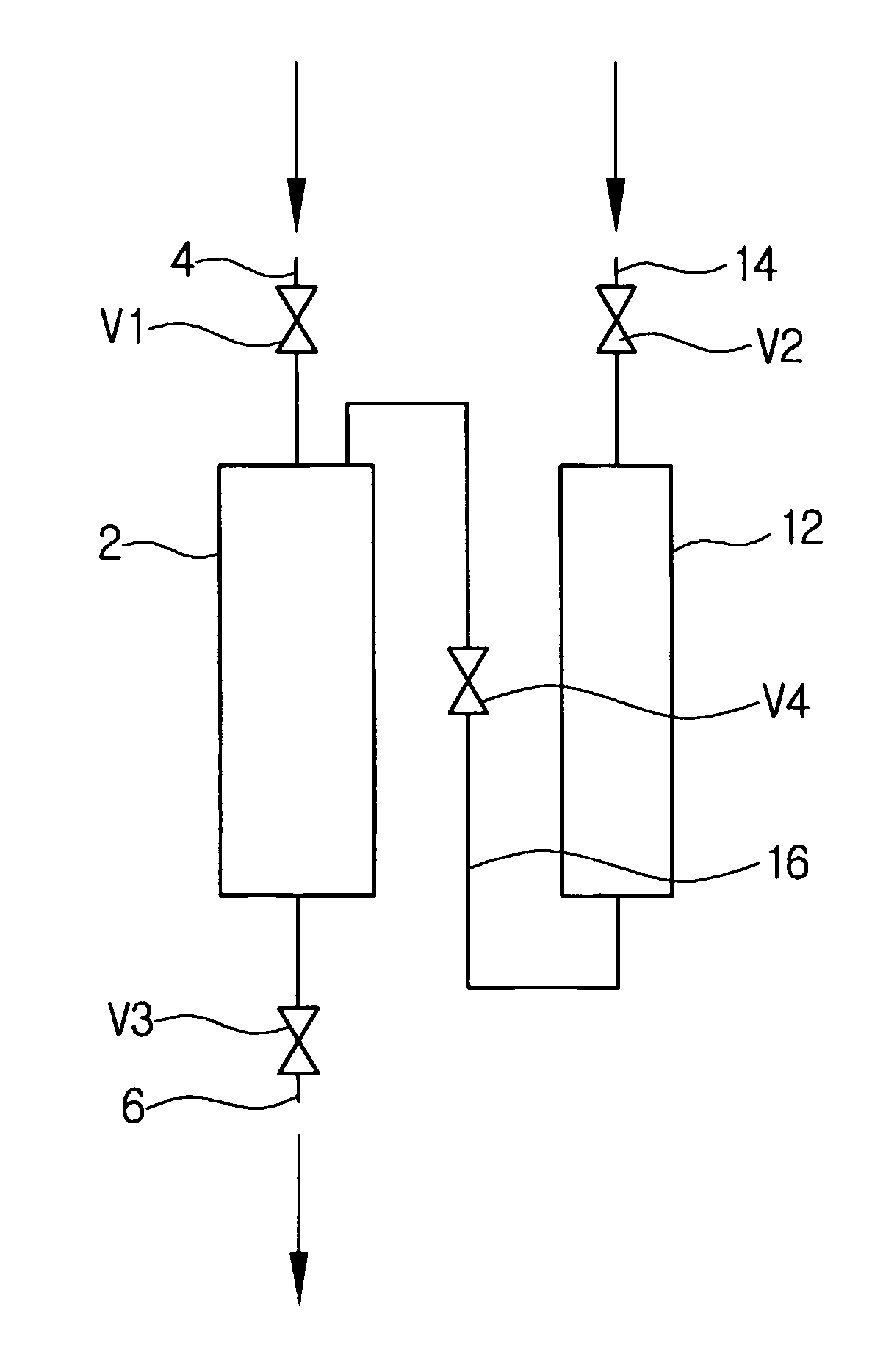

Water softener

InactiveUS7285220B2Fast supplySmall sizeIon-exchanger regenerationScale removal and water softeningWater softeningSoft water

Disclosed is a water softener capable of producing soft water at various temperatures and facilitating the regeneration of an ion exchange resin thereof. The water softener includes a water softening tank in which an internal region containing therein the ion exchange resin is partitioned into a plurality of water softening regions which are individually assigned into a predetermined temperature; a regeneration tank integrated with the water softening tank into a single body and containing the regeneration material of the ion exchange resin; a cold / hot control valve to supply raw water to a selected one of the plurality of water softening regions according to the temperature of the raw water to rapidly supply the soft water at a desired temperature to a user; and a regeneration valve to facilitate the periodic regeneration of the ion exchange resin through a simple manual operation.

Owner:SEUNG GWANG CO LTD

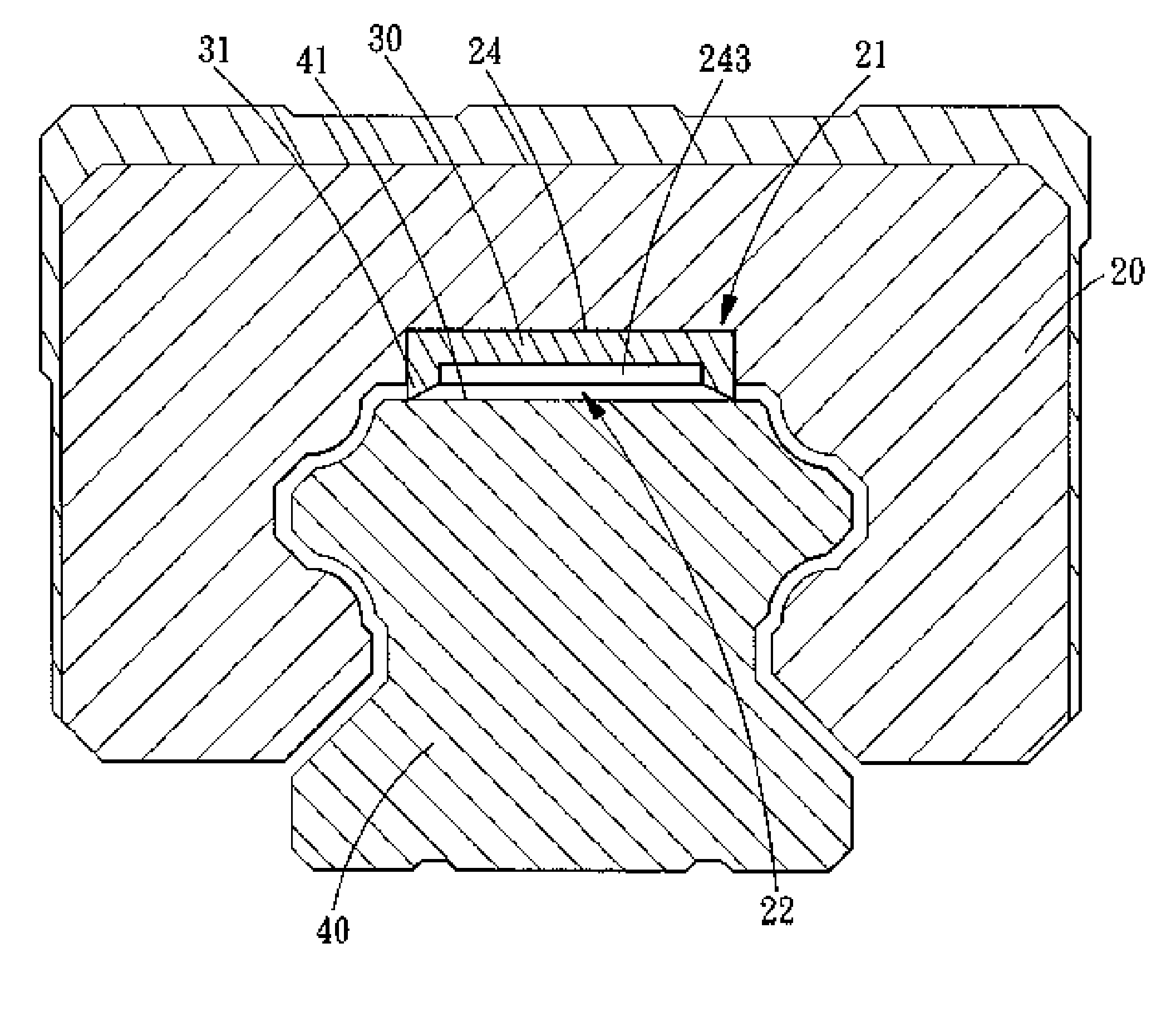

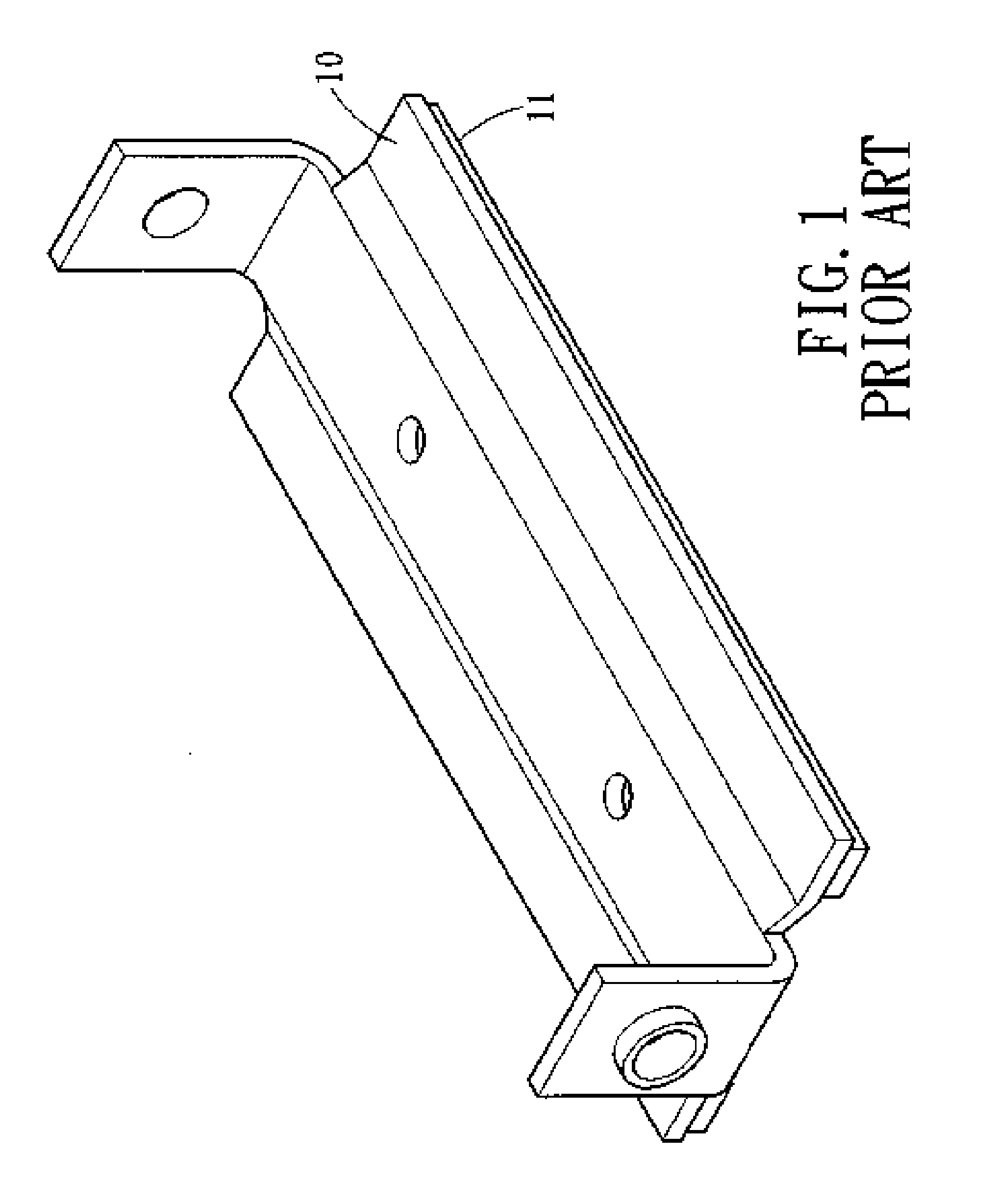

Anti-dust structure for a sliding block of a linear guideway

InactiveUS20070215245A1Simple structureLow costLinear bearingsWood working safety devicesEngineeringSteel ball

An anti-dust structure for a sliding block of a linear guideway comprises a sliding block and a flexible anti-dust strip. A positioning groove is formed in the inner surface of the sliding block and located correspondingly to the upper steel ball groove. The flexible anti-dust strip has a plurality of lip portions that protrude out of the positioning groove, and the lip portions come into contact with the top surface of the rail. In this way, the flexible anti-dust strip can scrape off the grease and dust accumulated on the top surface of the rail at all times, preventing the dust and grease entering the upper steel ball groove via the top surface of the rail, and thus obtaining a better anti-dust function and ensuring the service life of the linear guideway.

Owner:HIWIN TECH

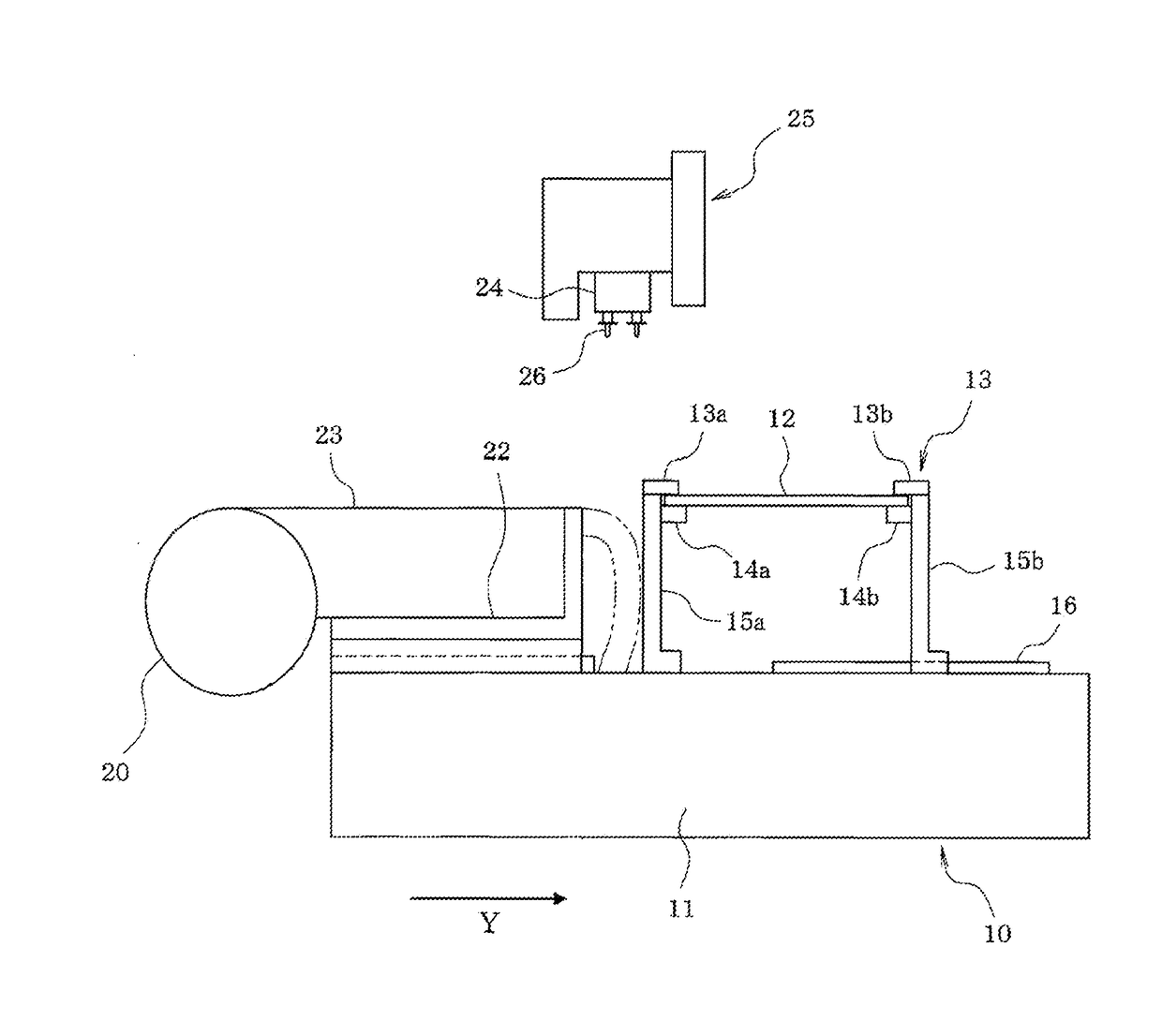

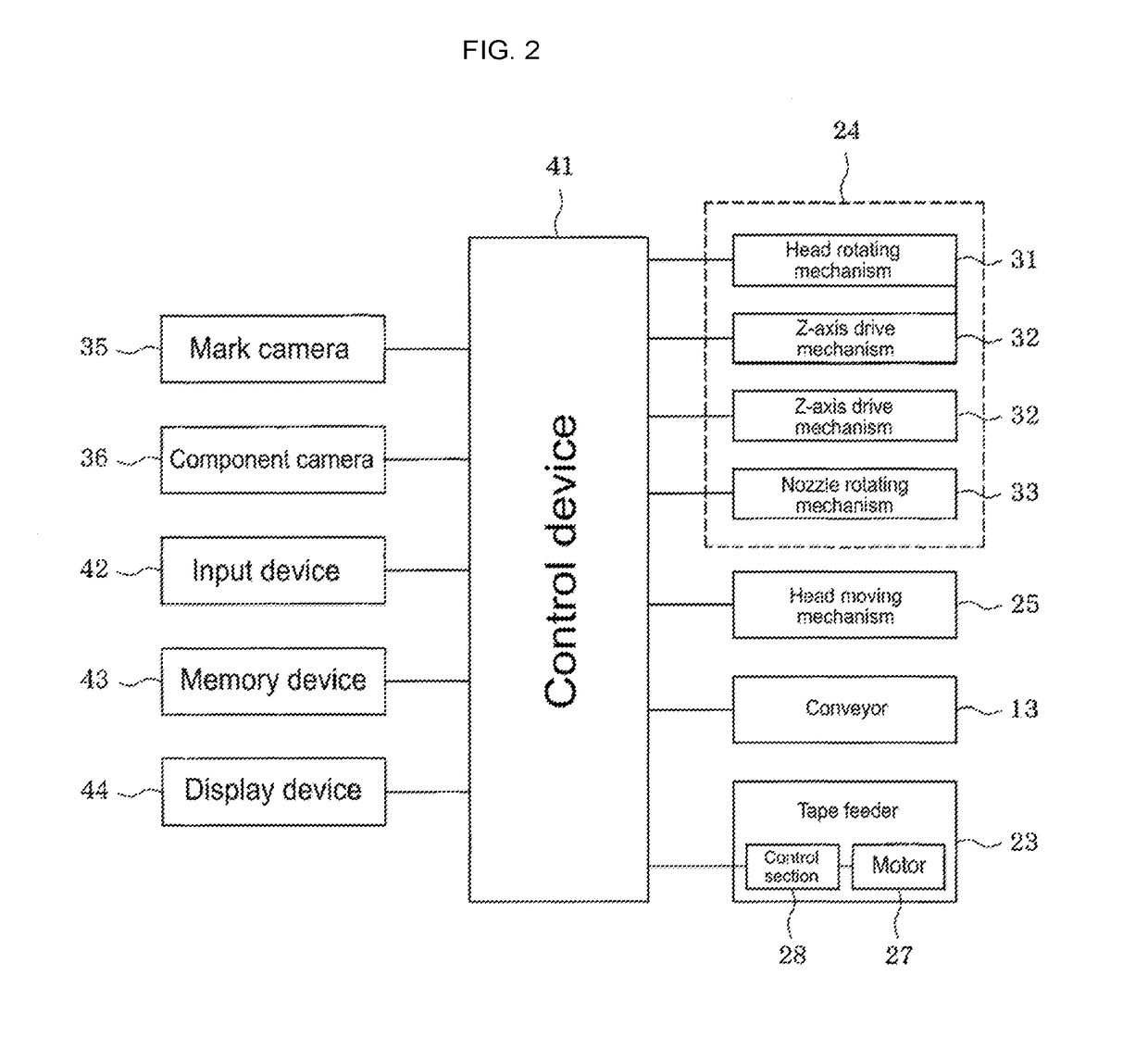

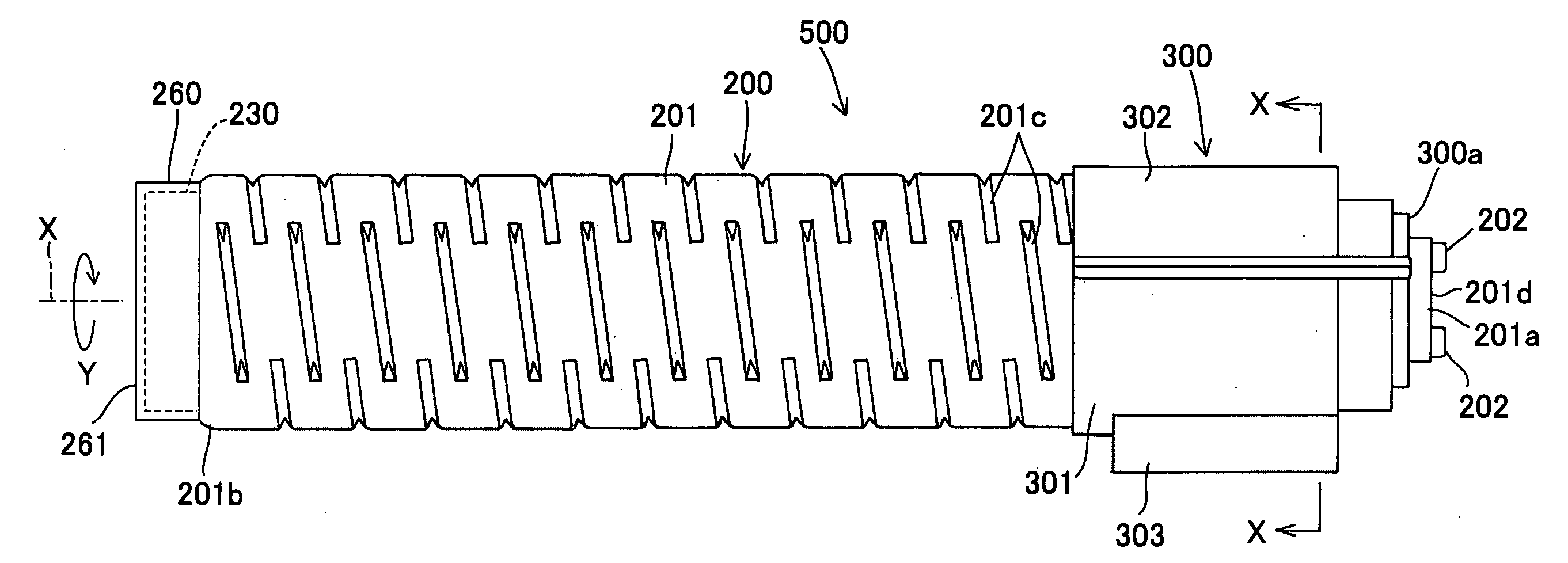

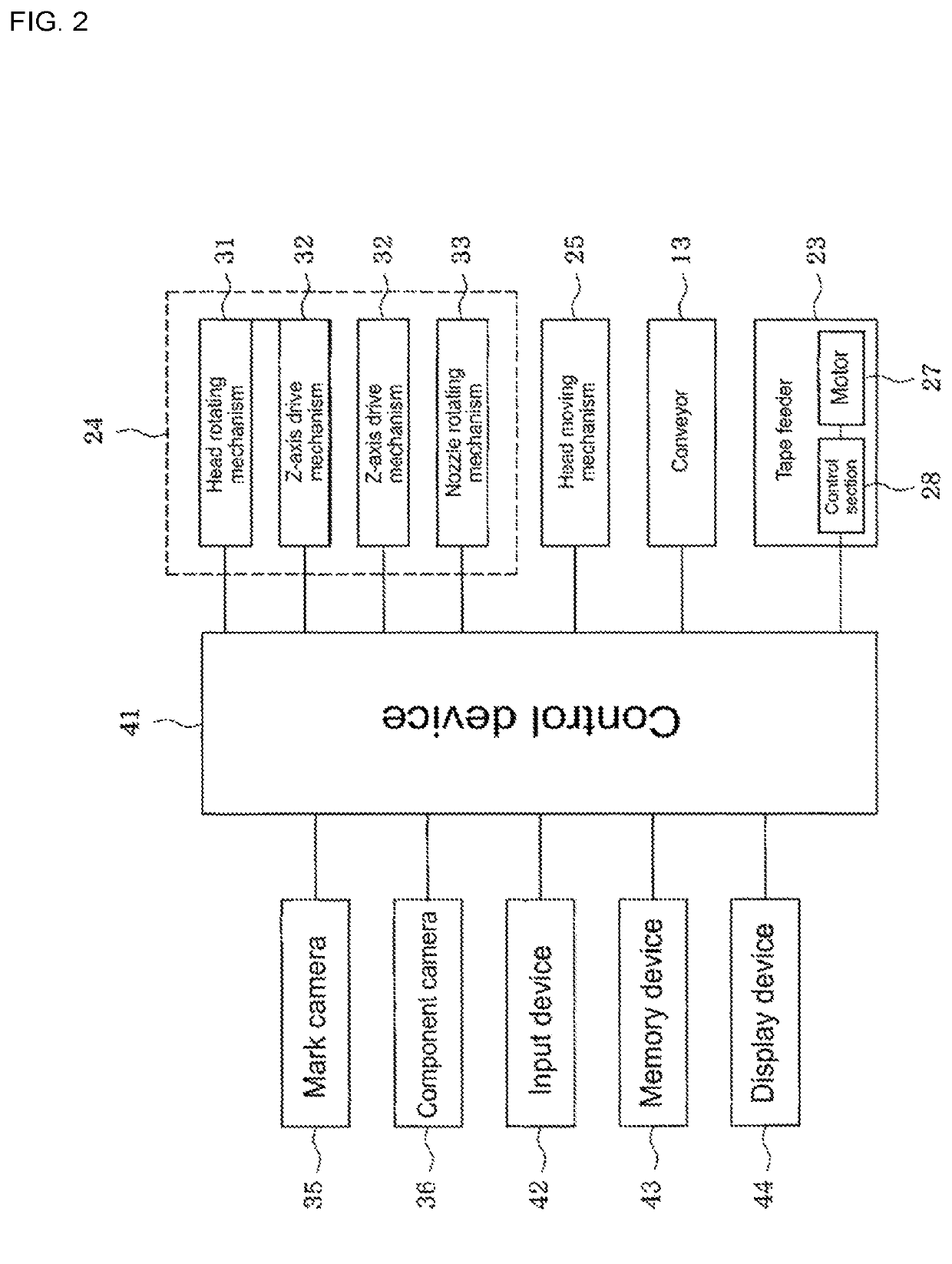

Component pickup position correction system and component pickup position correction method for a rotary head type component mounter

ActiveUS20170311493A1Improve productivityPrecise positioningElectrical componentsEngineeringCorrection method

In a rotary head type component mounter, before using two suction nozzles of rotary head to pick up the leading components in component supply tape set in two tape feeders, rotary head is moved in the XY directions by head moving mechanism and rotated by head rotating mechanism such that the pickup points of the two suction nozzles are positioned on two straight lines and extending in the tape feeding direction of each tape feeder passing through the ideal pickup points of the leading components of the two tape feeders, and the leading components are fed to component pickup positions and that are the pickup points of the suction nozzles on the two straight lines. Then, the two suction nozzles of rotary head are lowered simultaneously to pick up the two component simultaneously using the two suction nozzles.

Owner:FUJI MASCH MFG CO LTD

Toner container and toner loading method

A toner bottle that is composed of a main part, a toner loading portion, a bottle cap that can hermetically close and open a toner loading opening in the toner loading portion, and a bottle-side toner discharge port. This toner bottle is constructed such that the bottle cap that encloses the toner loading opening has a locking projection which can limit the rotation in the loosening direction while the toner loading portion has a cap locking projection which will engage the locking projection and can limit the rotation in the loosening direction.

Owner:SHARP KK

Internal combustion engine coupled turbocharger with an infinitely variable transmission

InactiveUS9404414B2Decreases a boost threshold of the turbochargerImprove internal efficiencyInternal combustion piston enginesGas turbine plantsTurbochargerInternal combustion engine

A turbocharger for use with an internal combustion engine is provided. The turbocharger comprises a differential device having a carrier portion, a compressor portion, and a turbine portion. The compressor portion is in driving engagement with a first portion of the differential device. The turbine portion is in driving engagement with a second portion of the differential device. The carrier portion of the differential device is in driving engagement with an infinitely variable transmission. The infinitely variable transmission is in driving engagement with the internal combustion engine. The turbocharger is simply controlled, reduces turbo lag, decreases a boost threshold of the turbocharger, and increases an efficiency of the internal combustion engine.

Owner:DANA CORP

Onboard indicator

InactiveUS7194578B2SimplyEfficiently communicating the statusError detection/correctionMemory systemsEmbedded system

A system and method for indicating the service status of serviceable elements of a subassembly stores the service status in a memory using a host controller. When the subassembly is removed from the host controller, the memory may be accessed using a second circuit and separate power supply, and indicators may be illuminated to indicate the service status of the elements.

Owner:NETWORK APPLIANCE INC

Heat exchanger plate for transition liquid phase bonding

InactiveUS20160370134A1Low costQuality improvementMetal working apparatusLaminated elementsBonding processEngineering

A heat exchanger includes a plurality of plates bonded by transition liquid phase (TLP) bonding. Since the plates are bonded by the transition liquid phase bonding a good bonding portion may be formed reducing defects therein, thereby enabling the heat exchanger to have a high quality. In addition, since the bonding process is performed under a mild condition, it is possible to easily employ a bonding condition and more improve production efficiency.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Component pickup position correction system and component pickup position correction method for a rotary head type component mounter

ActiveUS10531601B2Precise positioningSimplyElectrical componentsEngineeringElectrical and Electronics engineering

In a rotary head type component mounter, before using two suction nozzles of rotary head to pick up the leading components in component supply tape set in two tape feeders, rotary head is moved in the XY directions by head moving mechanism and rotated by head rotating mechanism such that the pickup points of the two suction nozzles are positioned on two straight lines and extending in the tape feeding direction of each tape feeder passing through the ideal pickup points of the leading components of the two tape feeders, and the leading components are fed to component pickup positions and that are the pickup points of the suction nozzles on the two straight lines. Then, the two suction nozzles of rotary head are lowered simultaneously to pick up the two component simultaneously using the two suction nozzles.

Owner:FUJI CORP

Water softener

InactiveUS20050235821A1Small sizeSimply performIon-exchanger regenerationScale removal and water softeningIon exchangeRaw water

Disclosed is a water softener capable of producing soft water at various temperatures and facilitating the regeneration of an ion exchange resin thereof. The water softener includes a water softening tank in which an internal region containing therein the ion exchange resin is partitioned into a plurality of water softening regions which are individually assigned into a predetermined temperature; a regeneration tank integrated with the water softening tank into a single body and containing the regeneration material of the ion exchange resin; a cold / hot control valve to supply raw water to a selected one of the plurality of water softening regions according to the temperature of the raw water to rapidly supply the soft water at a desired temperature to a user, and a regeneration valve to facilitate the periodic regeneration of the ion exchange resin through a simple manual operation.

Owner:SEUNG GWANG CO LTD

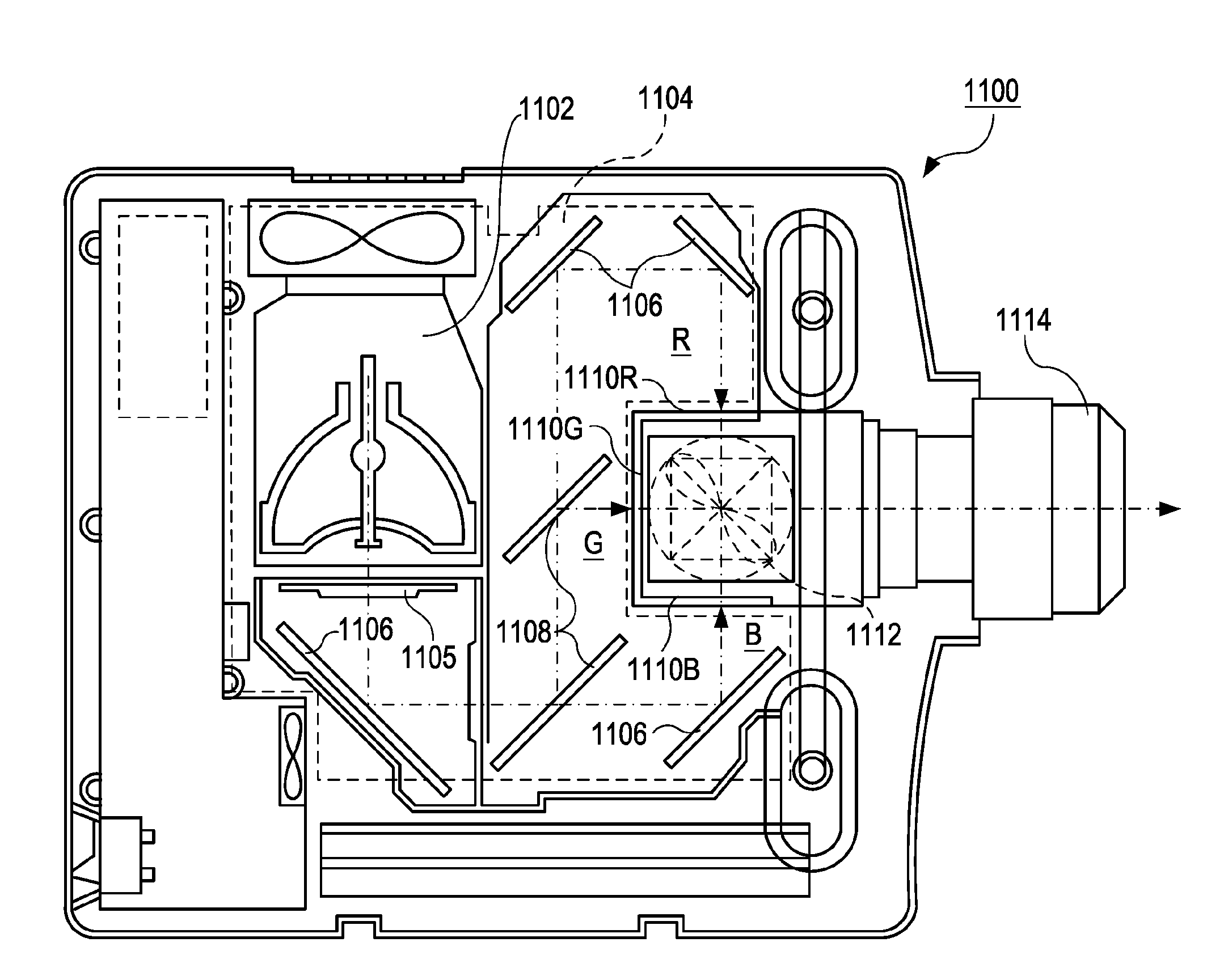

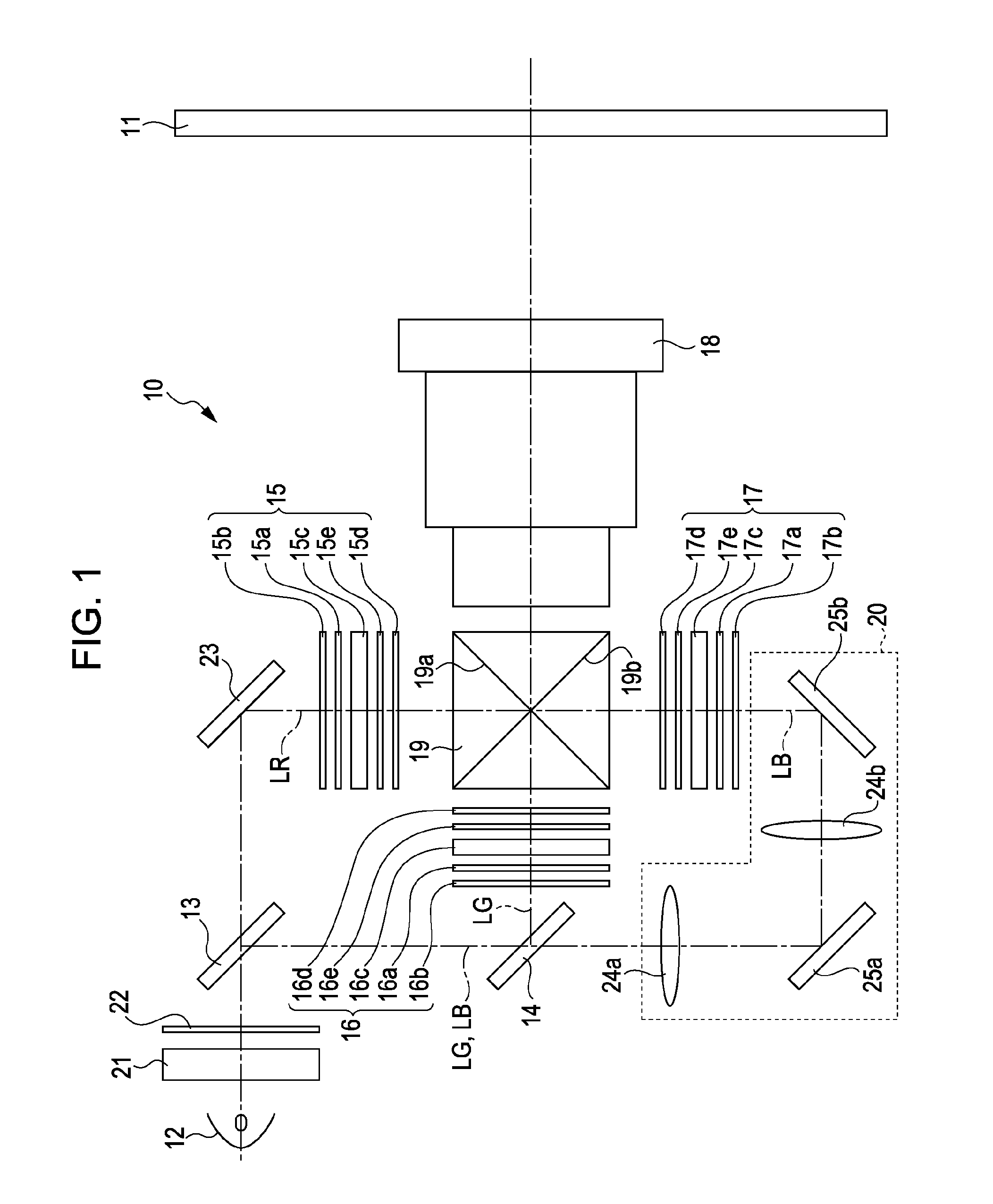

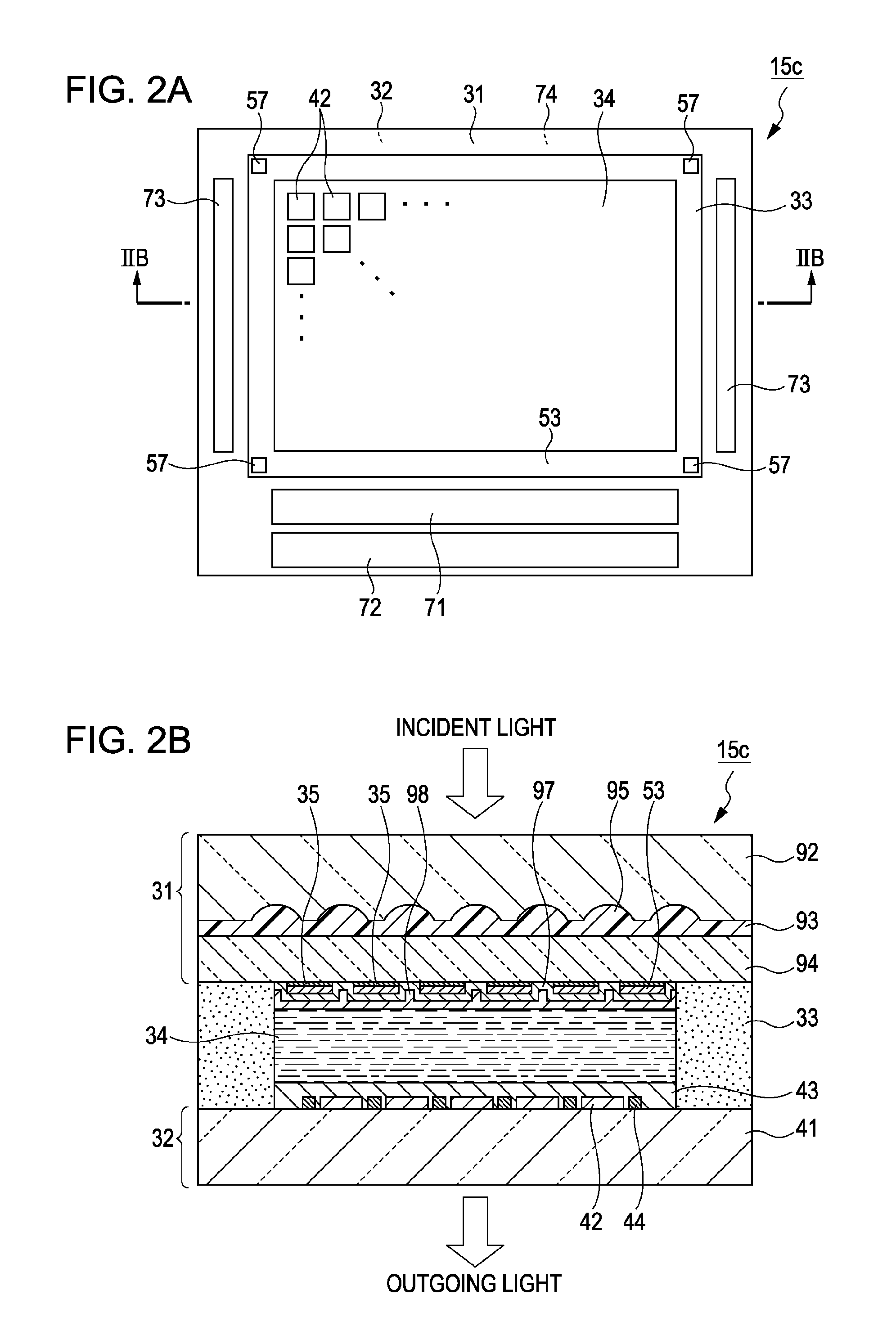

Liquid crystal device and projector

InactiveUS20090231499A1Increase contrastImprove accuracyColor television detailsNon-linear opticsPhase differencePolarizer

A liquid crystal device includes a liquid crystal panel, a pair of polarizers and a phase plate. The phase plate is formed by a supply direction of an inorganic material to the substrate surface set such that a ratio of a front phase difference, which is produced when light is incident along a normal direction of the phase plate, and a first phase difference, which is produced when light is incident along a first direction different from the normal direction, falls within a predetermined range.

Owner:SEIKO EPSON CORP

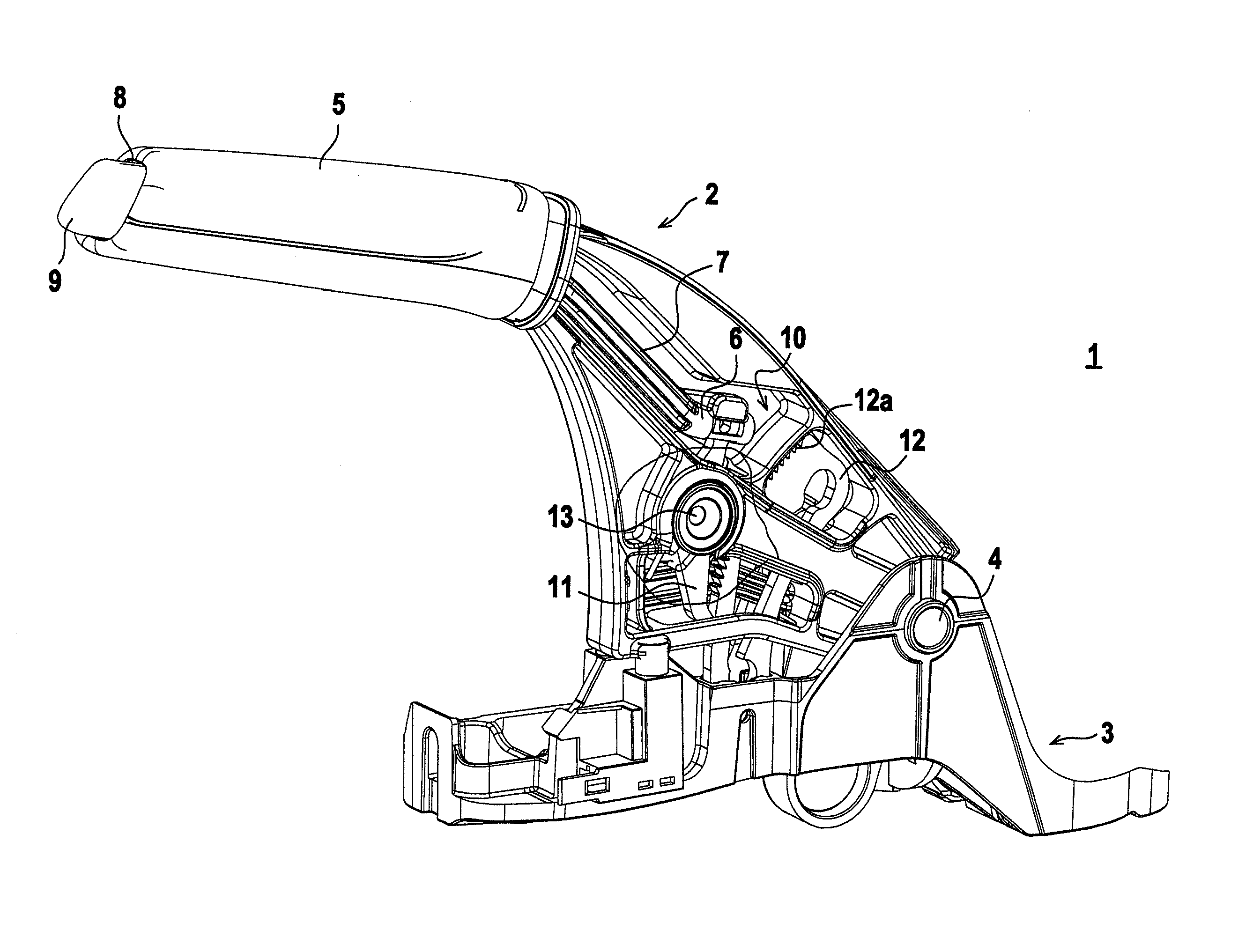

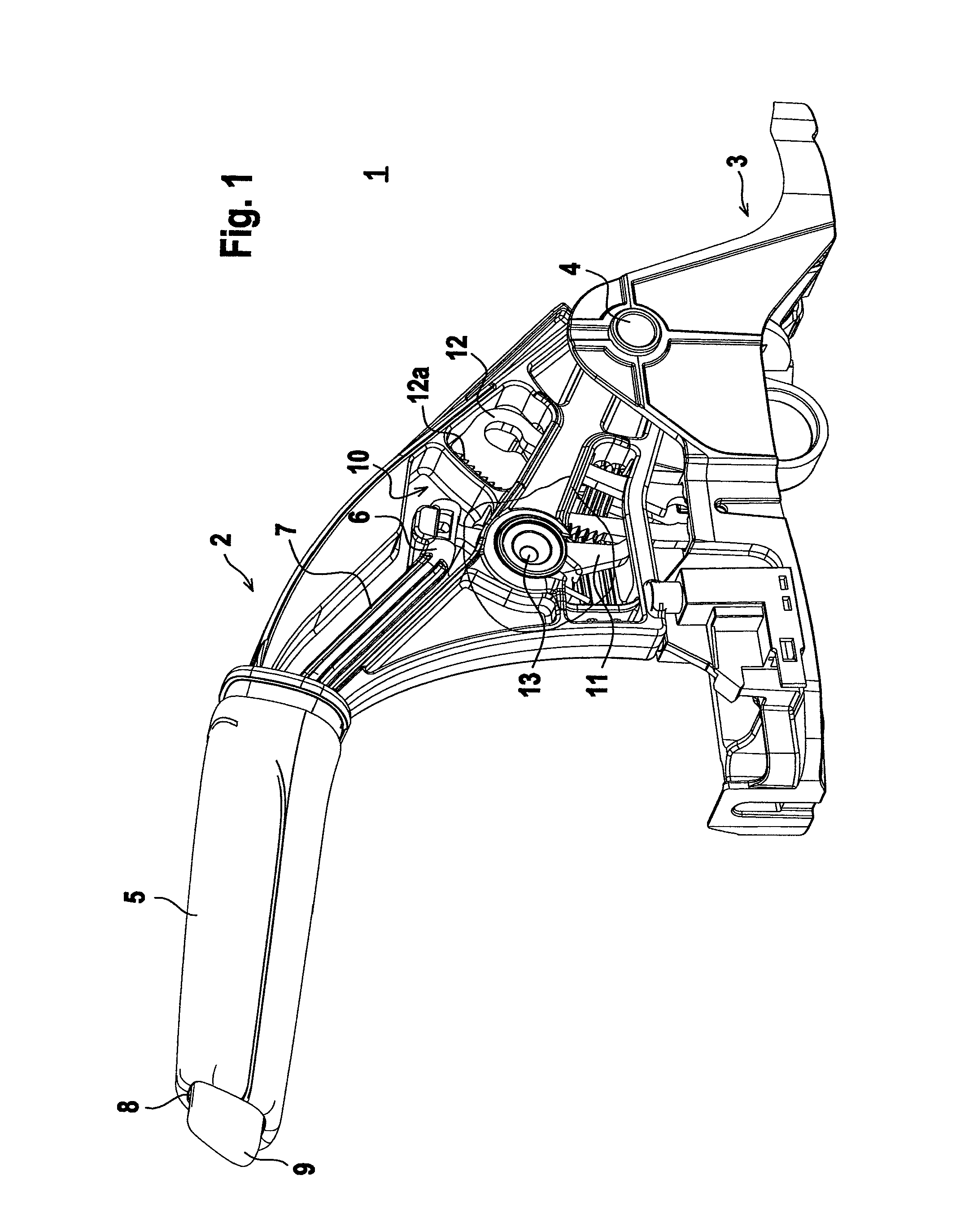

Operating mechanism for a parking brake

InactiveUS20100326228A1Optimal designSave on installation costsControlling membersMechanical apparatusStructural unitEngineering

An operating mechanism for a parking brake includes a manual brake lever pivotably coupled to a bearing block and a locking device adapted to lock the manual brake lever into a position. The locking device includes a detent arranged on the manual brake lever and adapted to pivot around a pivoting axis, the detent having a bore, a locking segment connected to the bearing block, a spring element adapted to hold the detent into a locking position on the locking segment, and a connecting element adapted to secure the detent on the manual brake lever. The connecting element and the spring element jointly form a single structural unit adapted for insertion into the bore in the detent during installation of the detent on the manual brake lever.

Owner:DIETZ AUTOMOTIVE

Battery diagnosis method, battery diagnosis program, battery management apparatus, and power storage system

ActiveUS11275122B2SimplyLow costCharge equalisation circuitCurrent/voltage measurementElectrical batteryControl theory

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

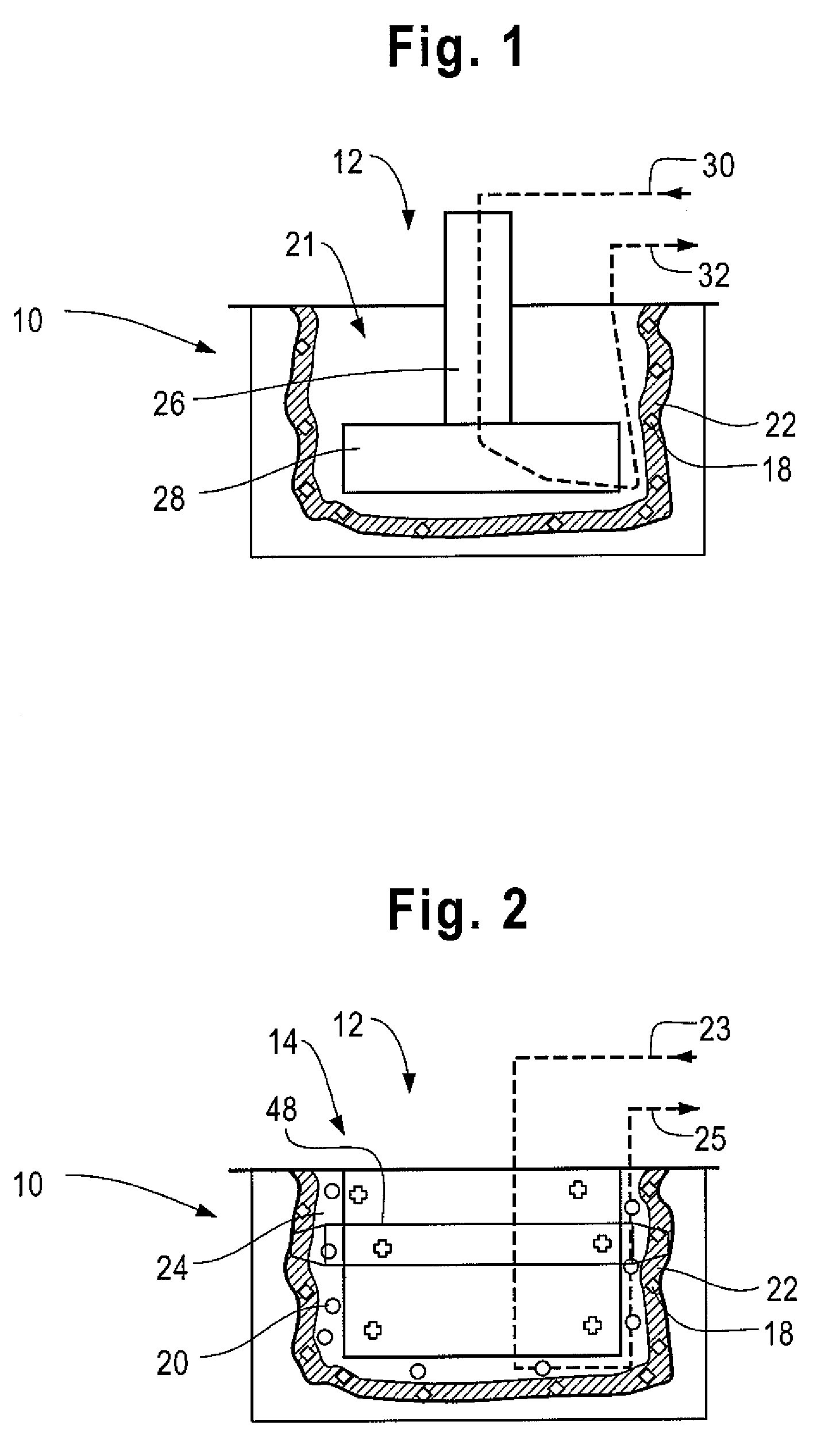

Seal-tight grommet and method of producing same

The invention relates to a sealing device for a chamber partition, the partition having an orifice enabling a strand of conductor wires to pass between the outside and the inside of the chamber. The device includes a plug through which passes the strand, and an apparatus to keep the plug pressed against the partition. The conductor wires can be kept away from one another inside the plug to ensure the seal-tightness of the plug itself. Advantageously, the plug is pressed into a void of a counter-form, the internal shape of the void substantially complementing an external shape of the plug. The form / counter-form assembly provides for a perfect seal-tightness.

Owner:THALES SA

Friction-assisted tube fabrication method

A friction assisted tube fabrication method is disclosed. The friction assisted tube fabrication includes a set of methods such as a friction assisted tube forming, a friction assisted tube extrusion, and a friction assisted tube straining method. A metal object, for example, a deformable tube is simply deformed into the tube using a mandrel. The metal object with an initial diameter is forced across the slope of the mandrel with an angle. The mandrel is configured to rotate while forcing the metal object to deform into the tube with the desired radius. While rotating the mandrel, a friction is generated due to contact between the tube and the mandrel, thereby generating thermal energy to heat a deformation area of the tube for simply and easily softening and forming into the desired shape with accuracy diameter, and dimensions using a nominal pressing force without additional equipment and power.

Owner:HOSSEINI SEYYED HADI +1

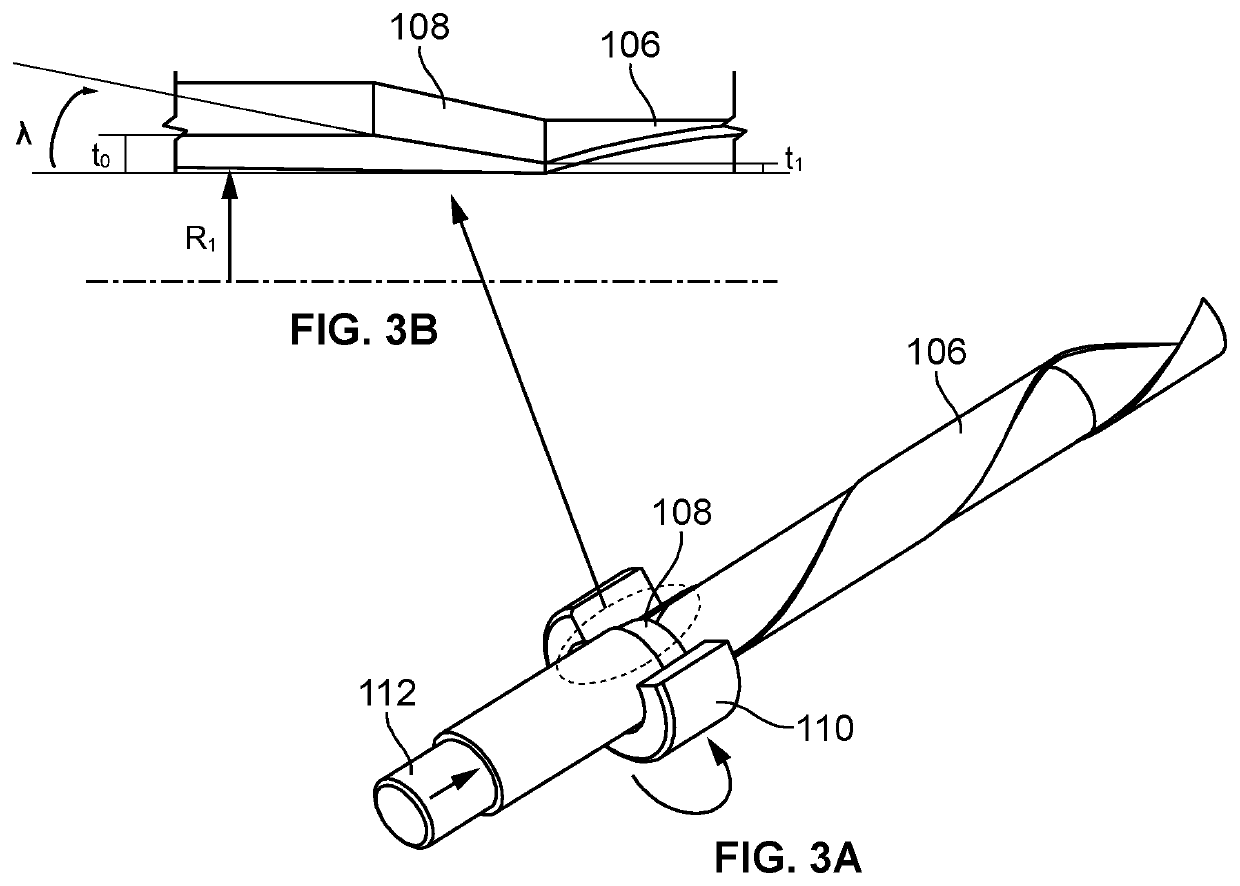

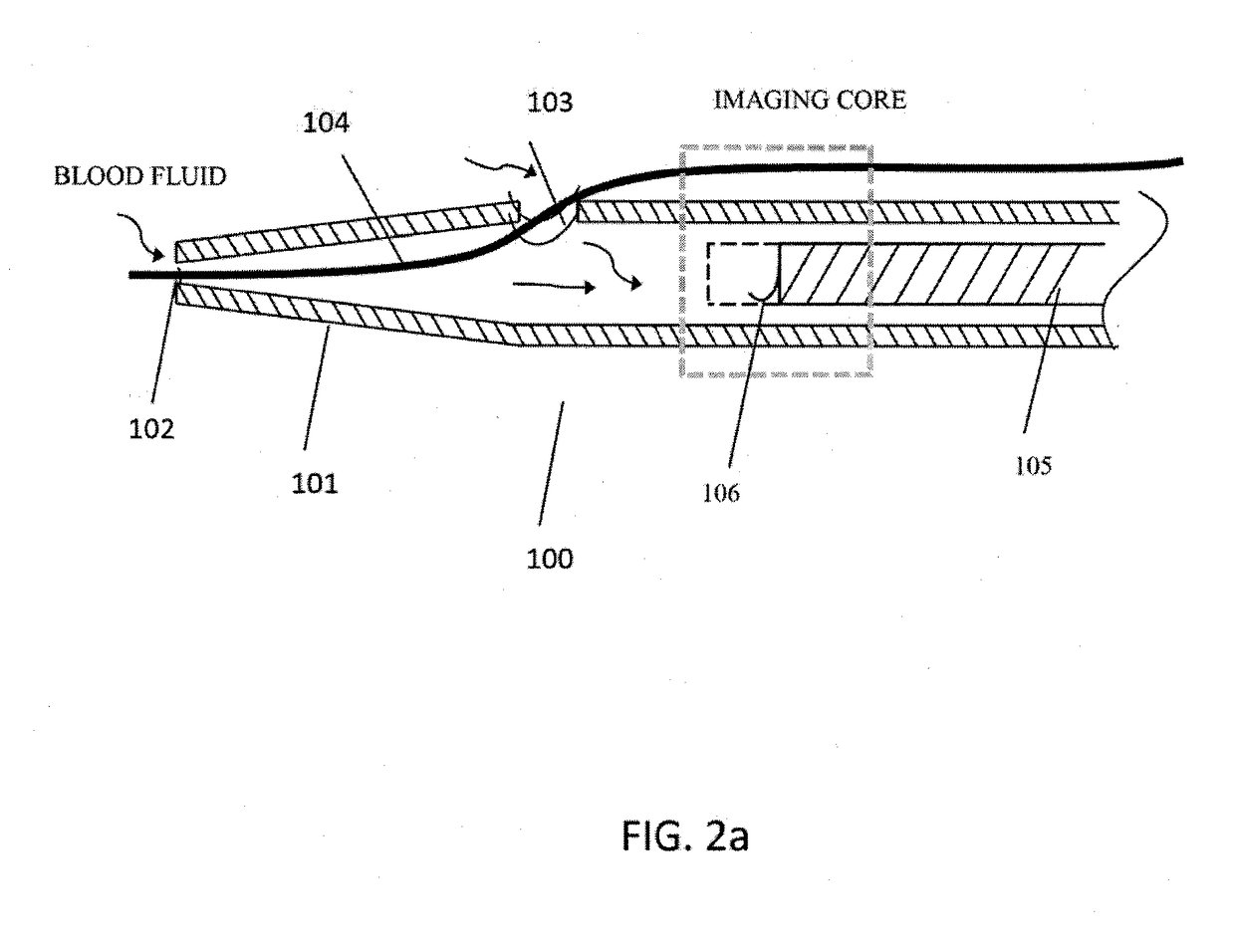

Imaging and/or pressure measurement catheter and method for use thereof

InactiveUS20170188834A1SimplyOperation efficiency can be improvedCatheterDiagnostic recording/measuringPressure senseCatheter

Exemplary apparatus and method for obtaining information regarding at least one sample can be provided. For example, at least one optical data-obtaining first arrangement can be used which is configured to obtain data for the at least one sample based on a first light radiation provided from the sample(s). At least one pressure-sensing second arrangement can also be used which is configured to measure a pressure of at least one fluid that is provided at or near the sample(s) based on a second light radiation. In addition, e.g., a housing third arrangement can at least partially enclose the first and second arrangements.

Owner:THE GENERAL HOSPITAL CORP

Process for preparing vitis vinifera pip extract and pharmaceutical composition for preventing or treating rheumatoid arthritis comprising the same

InactiveUS20100173028A1SimplyMinimizing residual solventBiocideAntipyreticVitis viniferaAdditive ingredient

The present invention provides an improved process for preparing a Vitis vinifera pip extract. And also, the present invention provides a pharmaceutical composition for preventing or treating rheumatoid arthritis including the Vitis vinifera pip extract as an active ingredient.

Owner:THE CATHOLIC UNIV OF KOREA IND ACADEMIC COOPERATION FOUND +1

Liquid crystal device and projector

InactiveUS7864277B2Expand the allowable rangeIncrease contrastColor television detailsNon-linear opticsPhase differencePolarizer

A liquid crystal device includes a liquid crystal panel, a pair of polarizers and a phase plate. The phase plate is formed by a supply direction of an inorganic material to the substrate surface set such that a ratio of a front phase difference, which is produced when light is incident along a normal direction of the phase plate, and a first phase difference, which is produced when light is incident along a first direction different from the normal direction, falls within a predetermined range.

Owner:SEIKO EPSON CORP

Operating mechanism for a parking brake

InactiveUS8667862B2Save on installation costsShorten the timeControlling membersMechanical apparatusDetentEngineering

An operating mechanism for a parking brake includes a manual brake lever pivotably coupled to a bearing block and a locking device adapted to lock the manual brake lever into a position. The locking device includes a detent arranged on the manual brake lever and adapted to pivot around a pivoting axis, the detent having a bore, a locking segment connected to the bearing block, a spring element adapted to hold the detent into a locking position on the locking segment, and a connecting element adapted to secure the detent on the manual brake lever. The connecting element and the spring element jointly form a single structural unit adapted for insertion into the bore in the detent during installation of the detent on the manual brake lever.

Owner:DIETZ AUTOMOTIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com