Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Retain breathability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Finishing agent composition for cotton-silk fabrics and processing method of cotton-silk easy-care shirt

InactiveCN105133315AOvercome the defect of poor anti-slip performanceRetain moisture permeabilityVegetal fibresAnimal fibresAdditive ingredientMoisture permeability

The invention discloses a finishing agent composition for cotton-silk fabrics. The finishing agent composition comprises the following ingredients by weight: 120 to 180 parts of dihydroxy ethylene-urea resin, 10 to 60 parts of a powerful protecting agent, 10 to 50 parts of a smoothing agent, 30 to 80 parts of a softening agent, 10 to 25 parts of a catalyst, 5 to 10 parts of an anti-fraying agent, 1 to 5 parts of a penetrating agent, and 5 to 10 parts of a formaldehyde scavenger. The invention further provides a processing method of a cotton-silk easy-care shirt. The processing method of the cotton-silk shirt garment comprises the following steps: prewashing, drying, material spraying, pre-drying, pressing, baking, purified water washing, drying and moisture regaining, wherein the finishing agent composition is uniformly applied onto the cotton-silk easy-care shirt in the material spraying step. The finishing agent composition is used for finishing process of the cotton-silk fabrics, and can be used for overcoming the defect that the anti-sliding property of the cotton-silk fabrics is lowered after conventional easy-care treatment, reserving the own moisture permeability, air permeability and natural drapability of the cotton-silk fabrics, and enabling the cotton-silk fabrics to have relatively high easy-care property. Therefore, people can wear the shirt comfortably, and the shirt is easy to care. Moreover, the formaldehyde content of the finished cotton-silk easy-care shirt can be lower than the national standard.

Owner:NINGBO YOUNGOR TECH

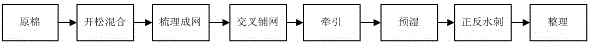

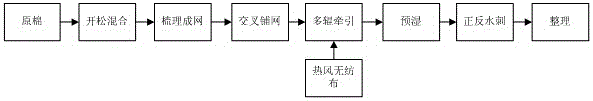

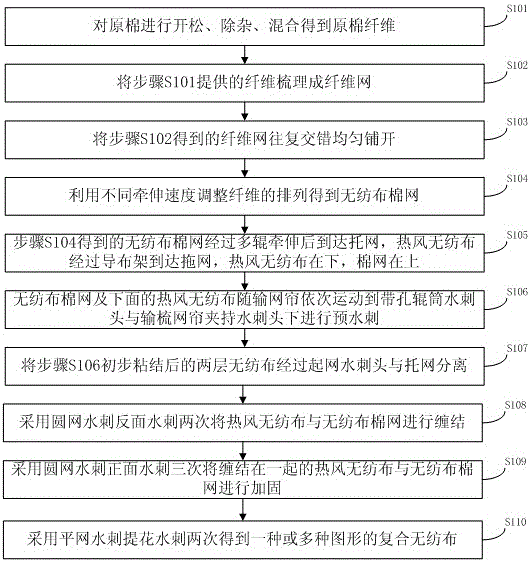

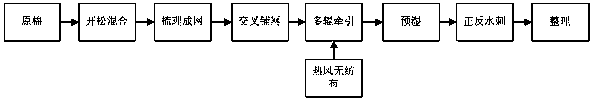

Compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric and production system thereof

ActiveCN106393945AComposite process advantagesRemove the phenomenon of bleedingLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

Processing technology for anti-wrinkling fabric of western-style clothes

InactiveCN107217489AImprove wrinkle resistanceRetain breathabilityBiochemical fibre treatmentWrinkle resistant fibresAnti wrinkleWrinkle

The invention discloses a processing technology for an anti-wrinkling fabric of western-style clothes. The processing technology specifically comprises the following steps: 1) by taking XLA fiber as a core yarn, externally coating cotton fiber and spinning into a covering yarn; 2) by taking the cotton fiber as a warp yarn and the covering yarn as a weft yarn, weaving a base cloth; 3) taking polyethylene glycol and citric acid at ratio of 1:(2-3) and performing esterification reaction for 2-3h at 130-140 DEG C, thereby acquiring an anti-wrinkling finishing agent; 4) putting the base cloth into a settling solution, dipping and settling, thereby acquiring the anti-wrinkling fabric of western-style clothes. The settling solution contains the following components in parts by weight: 6-8 parts of anti-wrinkling settling agent, 0.2-0.3 part of JFC, 0.5-0.6 part of catalyst, 0.1-0.2 part of active peptide and 98-100 parts of water. The processing technology has the beneficial effects that the fabric has excellent draping property, wrinkle resistance and air permeability, the western-style clothes wear more comfortable, the whiteness of the fabric is higher, the anti-wrinkling fabric is free from yellowing phenomenon and the washing resistance is excellent.

Owner:宁波市海曙区伊万卡农业科技有限公司

Bamboo fiber sock and yarn forming process thereof

InactiveCN102534904ARetain breathabilityRetain antimicrobial propertiesPanty-hoseYarnYarnTextile technology

The invention discloses a bamboo fiber sock and a yarn forming process of the bamboo fiber sock, and belongs to the technical field of the bamboo fiber textile technology. Main yarns of the bamboo fiber sock are 100 percent of bamboo fiber yarns, in addition, double-yarn splicing is carried out after the single-yarn twisting, and the bamboo fiber yarns are prepared through seven steps: loosening, combing, drawing, roving, spinning, dying and spooling. The bamboo fiber sock has high bamboo fiber content, the special functions of ventilation performance, antibacterial performance, deodorization performance and the like of the bamboo fiber are preserved for the maximum degree. In addition, the bamboo fiber sock has the advantages that the pilling is not easy to occur, the intensity is good, the color is vivid, the color difference is small, and the like.

Owner:安吉县上墅针织厂

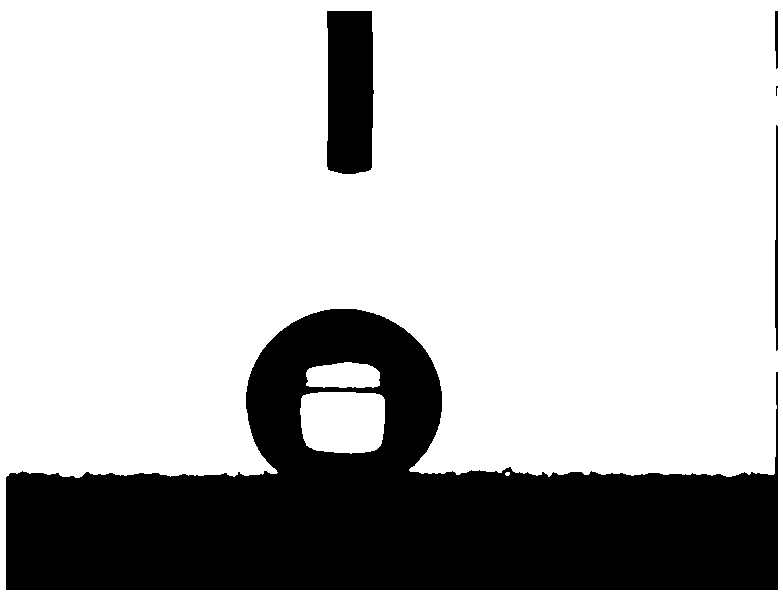

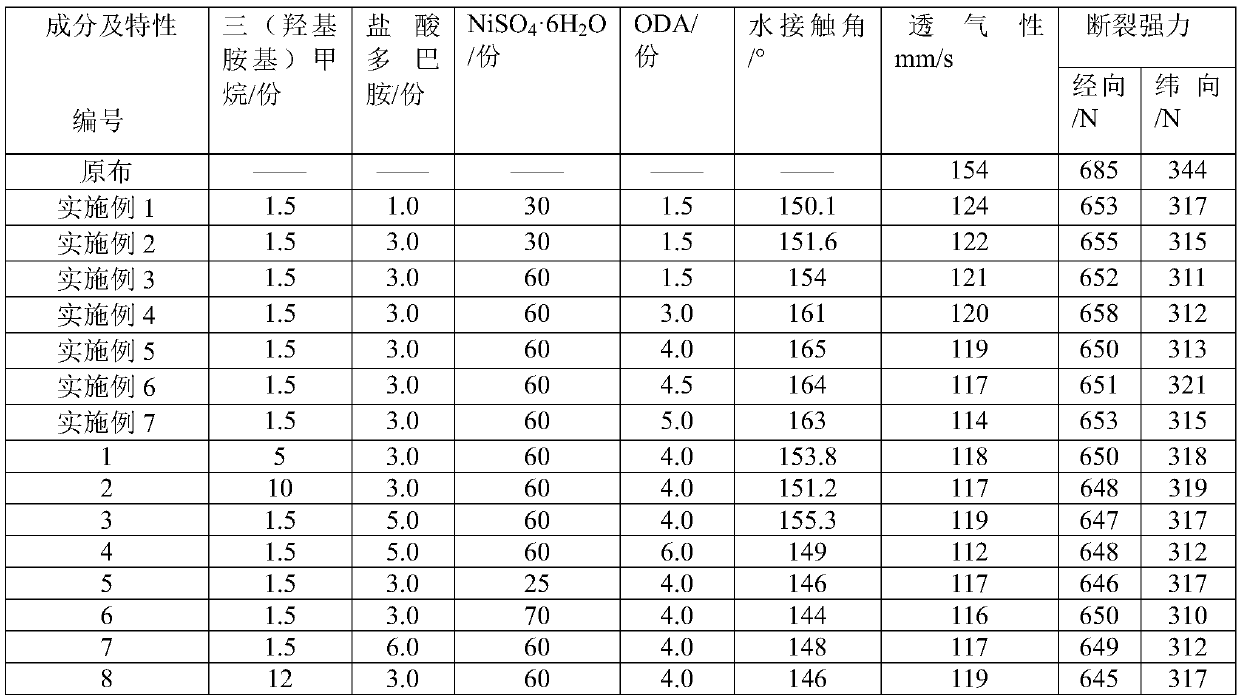

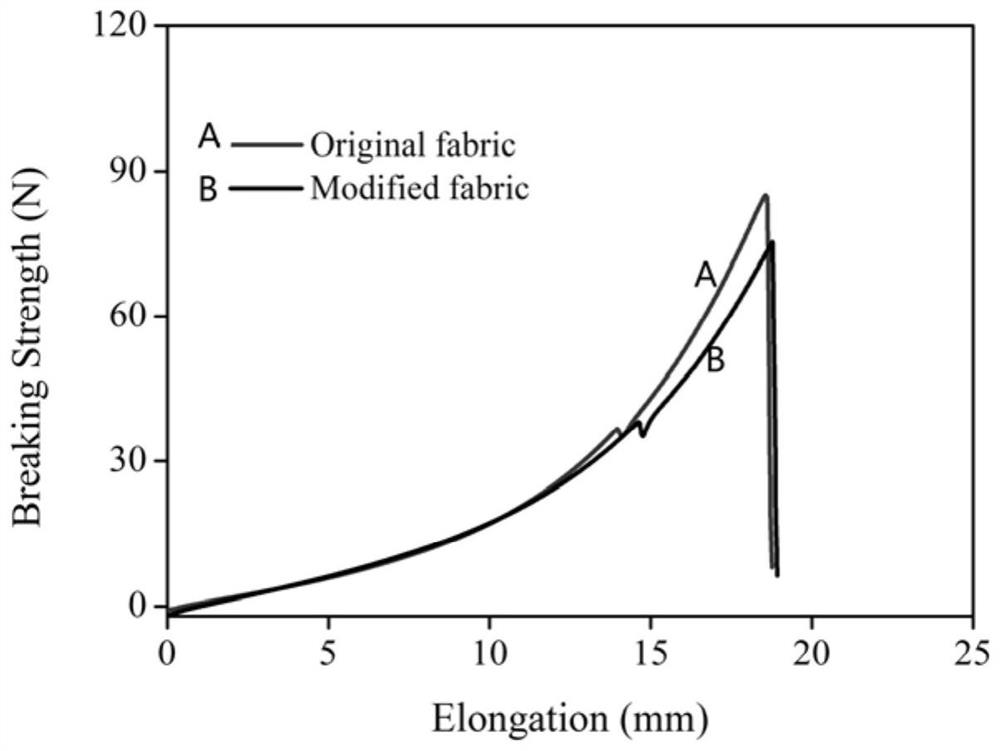

Wearing-resistant super-hydrophobic fabric and preparation method thereof

ActiveCN109610179ARetain breathabilityWarp and weft strong retentionUltrasonic/sonic fibre treatmentLiquid repellent fibresSurface energyChemistry

The invention discloses a wearing-resistant super-hydrophobic fabric and a preparation method thereof and belongs to the field of super-hydrophobic fabrics. The preparation method comprises the following steps: firstly, on the basis of dopamine, and under oxygen and weak alkali conditions, carrying out a self-polymerization reaction so as to obtain a poly-dopamine buffer liquid, and depositing thedopamine on the surface of a fabric; secondly, carrying out roughening treatment on the surface of the fabric by using a nickel sulfate solution; and finally treating the surface of the fabric with alow surface energy substance, namely octadecylamine, thereby obtaining the super-hydrophobic fabric. The contact angle of the prepared super-hydrophobic fabric is up to 165 degrees, after 1000 timesof friction, the super-hydrophobic property is still maintained, high wearing resistance is achieved, the application range of the fabric can be greatly increased, and requirements of different fieldscan be met; and in addition, the strength in warp and weft directions of the fabric can be maintained, and application of the fabric is barely affected.

Owner:南通鹏翔织造有限公司

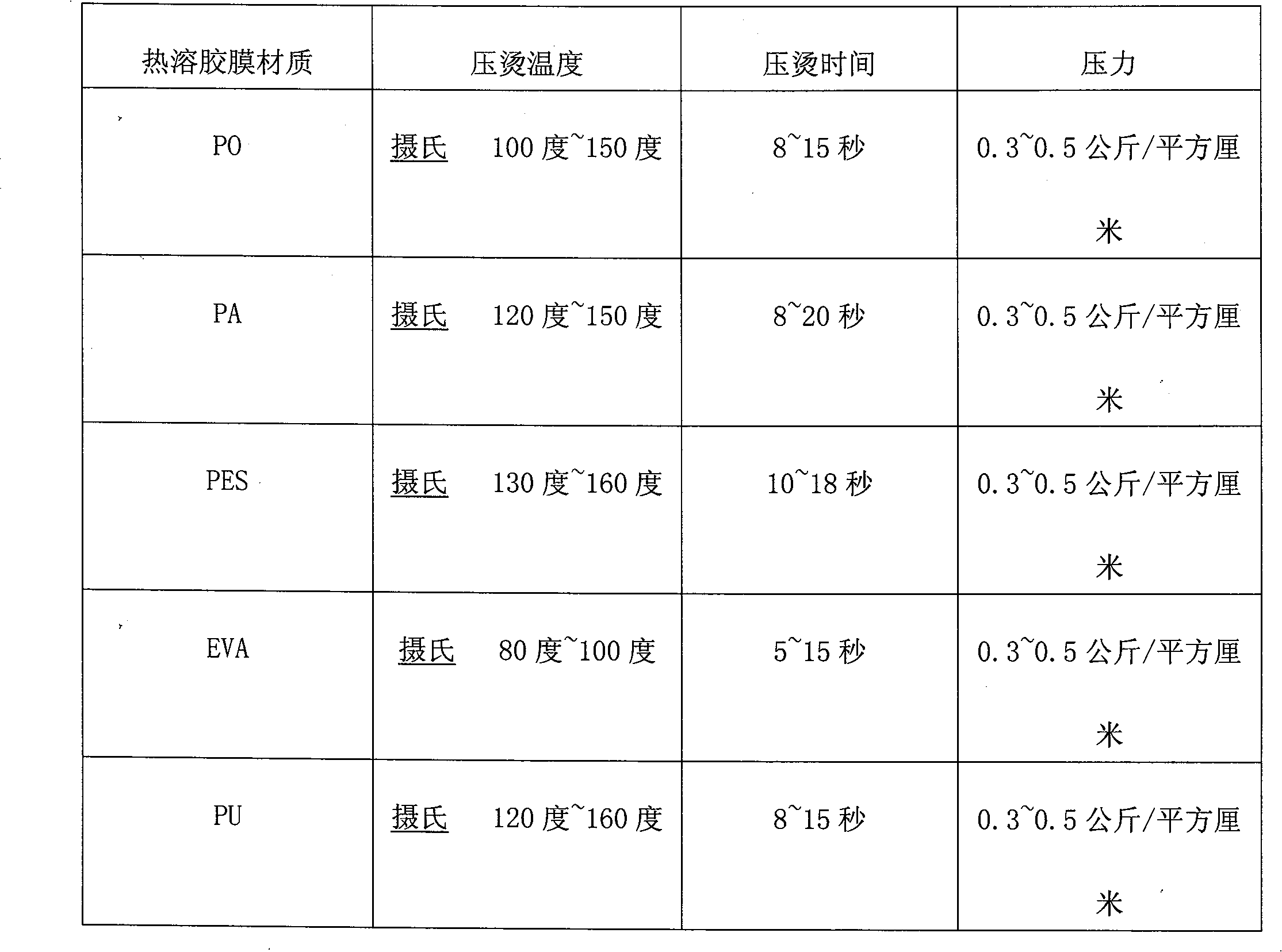

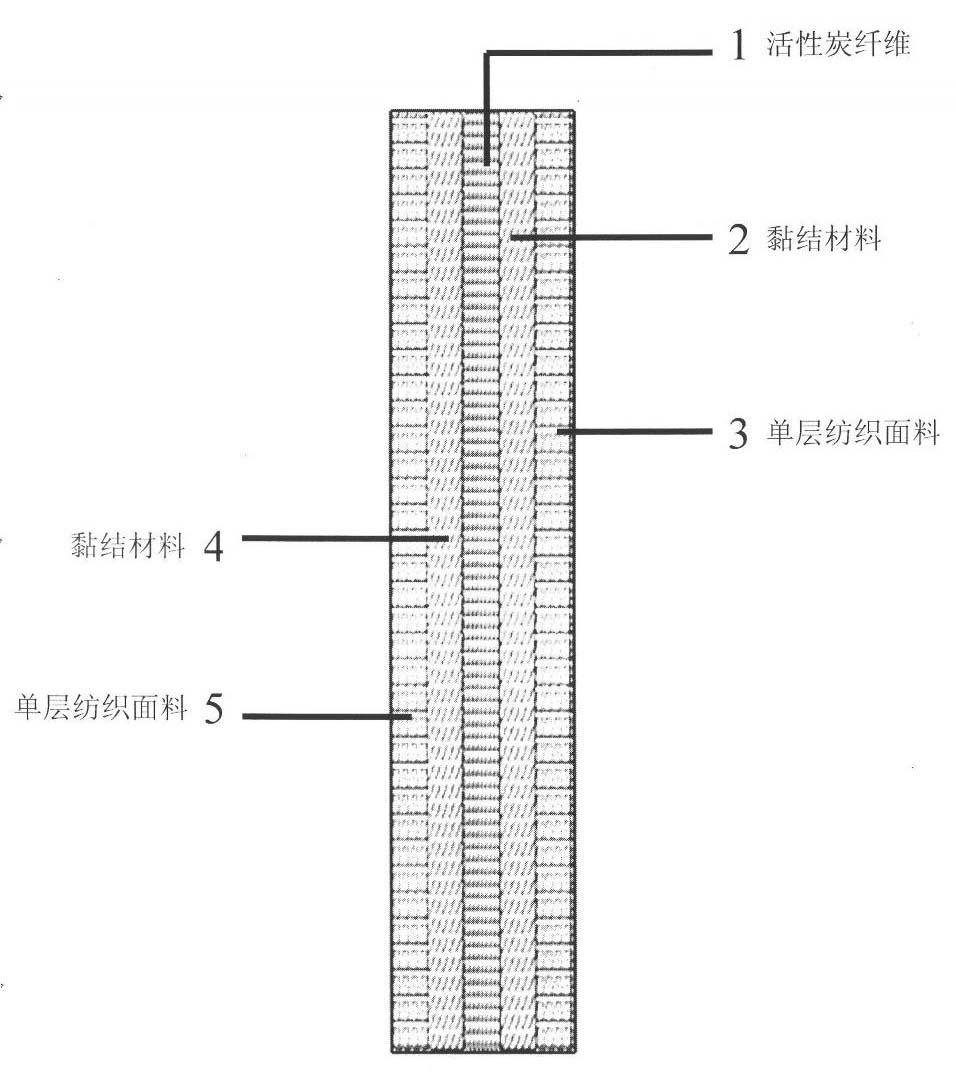

Preparation method of multi-layered textile fabric capable of purifying air

The invention relates to a preparation method of a multi-layered textile fabric capable of purifying air. The method comprises the following steps that: activated carbon fiber is adopted as the middle layer of the fabric, bonding material layers are respectively covered on the upper surface and the lower surface of the activated carbon fiber, single-layered textile fabric layers are singly added on the surface of the upper layered bonding material and the lower layered bonding material, and finally the textile fabric in a five-layered structure is formed. The fabric in the structure can not only prevent the defects of low activated carbon fiber strength, easy fall-off, no wear resistance, poor spinning property and easy external drilling of activated carbon fiber yarn, but also keeps the absorption property of harmful gases, and embodies the characteristics of practicality, durability, aesthetics, permeability, wear resistance and large contact area with the air of the textile fabric. The preparation method is as follows: solid bonding material is combined with the single-layered textile fabric and the activated carbon fiber to prepare the fabric by hot melting after a certain pressure is applied, or liquid bonding material is combined with the single-layered textile fabric and the activated carbon fiber to prepare the fabric by glue transfer after a certain pressure is applied.

Owner:沈靖

Preparation method and application of unilateral sensitive flexible film with micro-nano composite structure

InactiveCN112986334AImprove breathabilityRetain breathabilityMaterial impedanceMaterial resistanceConductive polymerIn situ polymerization

The invention discloses a preparation method and application of a unilateral sensitive flexible film with a micro-nano composite structure. A hydrophobic microporous membrane is used as a substrate and a template, a surfactant is used as a structure regulator, and a protonic acid doped conductive polymer sensitive material with a nanoparticle structure is deposited on one side of the hydrophobic microporous membrane through an in-situ polymerization method to prepare the conductive polymer / microporous membrane composite flexible membrane. A gas or humidity sensor prepared by using the single-side sensitive flexible film with the micro-nano composite structure as a sensing element has the advantages of flexibility, bendability, breathability, health, sensitive response, simple process, low cost, good product consistency and repeatability and the like; the product can be applied to the fields of flexible electronic devices, wearable intelligent equipment, portable medical instruments and the like.

Owner:ZHEJIANG UNIV

High-strength waterproof ventilated composite dressing and preparation method thereof

ActiveCN111513925AImprove waterproof performanceGood antifoulingNon-adhesive dressingsPlastersPolymer scienceWound.exudate

The invention discloses a high-strength waterproof ventilated composite dressing and a preparation method thereof. The high-strength waterproof ventilated composite dressing comprises an outer layer and an inner layer, wherein the outer layer is a polytetrafluoroethylene film; the inner layer is hydrogel; the polytetrafluoroethylene film has a pore canal structure; and the polytetrafluoroethylenefilm is in composite connection with the hydrogel on the inner layer through graftd hydrophile macromolecular compounds. The high-strength waterproof ventilated composite dressing prepared by the preparation method disclosed by the invention adopts a puffed polytetrafluoroethylene film as the outer layer structure, so that the dressing has favourable waterproof and anti-fouling performance; the situation that bacteria deeply enter a wound can be effectively prevented by the special pore canal structure, and wound infection is effectively avoided; and besides, the wound transudate and perspiration on the skin can also be quickly evaporated through the special pore canal structure; and the composite dressing reserves the good performance of the puffed polytetrafluoroethylene, so that the dressing can meet the requirements of wound processing under battlefield and field complex condition.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

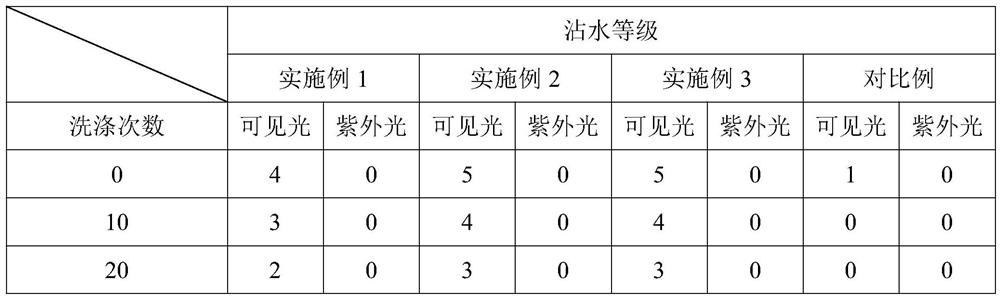

Waterproof and breathable water sportswear fabric and preparation method thereof

InactiveCN112900085ARetain breathabilityConsider water resistanceBiochemical fibre treatmentFibre typesHydrophilic monomerFiber

The invention provides a preparation method of a waterproof and breathable water sportswear fabric, and belongs to the field of functional fabric preparation. The water sportswear fabric comprises a surface layer prepared from a waterproof and breathable fabric, and the waterproof and breathable fabric is formed by interweaving waterproof and breathable fibers as warp yarns and weft yarns; the preparation method of the waterproof and breathable fabric comprises the following steps of S1, doping nano-zinc oxide or nano-titanium oxide into polymer resin, and spinning into fibers; S2, conducting KH570 surface active site modification; S3, grafting a methacrylic acid hydrophilic monomer; S4, grafting an azobenzene segment; and S5, grafting a hydrophobic segment; and then manufacturing into a fabric. The fibers are subjected to graft modification and then interwoven into the fabric, the breathability of the fabric can be kept while the waterproof performance is obtained, and a hydrophilic segment, a photosensitive heterogeneous segment and the hydrophobic segment are sequentially grafted to the resin fibers through graft modification to construct the hydrophilic-hydrophobic reversible conversion waterproof fabric.

Owner:宁波共振运动科技有限公司

Softener of lotus root fiber and use method of softener

InactiveCN109629239AIncrease contentKeep the anti-odor functionBiochemical treatment with enzymes/microorganismsGrip property fibresAmylaseCellulose

The invention discloses a softener of lotus root fiber. The softener is prepared from, by weight, 40-50 parts of a pyroligneous liquor, 4-10 parts of butanediol, 8-12 parts of lauryl sodium sulfate, 10-20 parts of sulfoacid, 3-8 parts of cellulose, 1-3 parts of lithium chloride, 2-4 parts of amylase and 400-500 parts of water. The softener of the lotus root fiber has the advantages that the softening effect is good, an isolating membrane cannot be formed on the surface of the lotus root fiber, and the lotus root fiber treated by the softener can improve the comfort of a wearing fabric to the greater extent.

Owner:湖州鑫瑞辰纺织科技有限公司

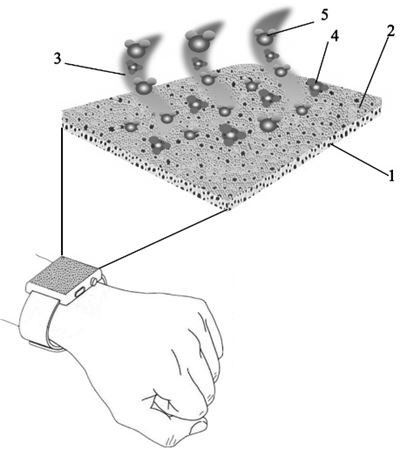

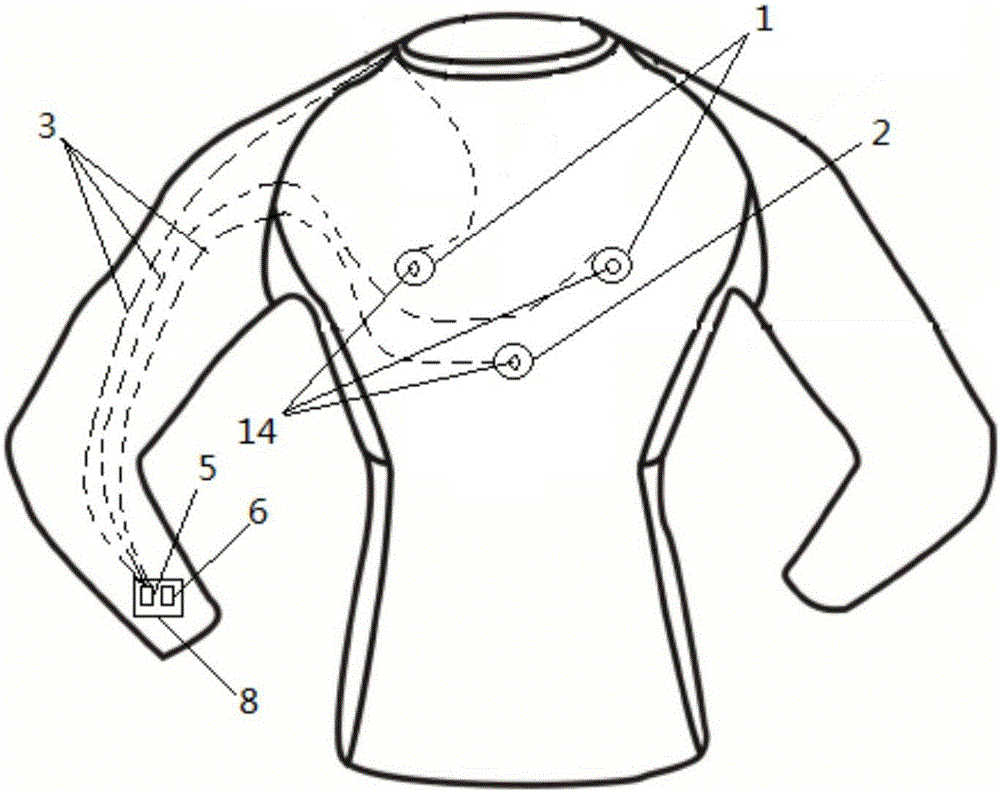

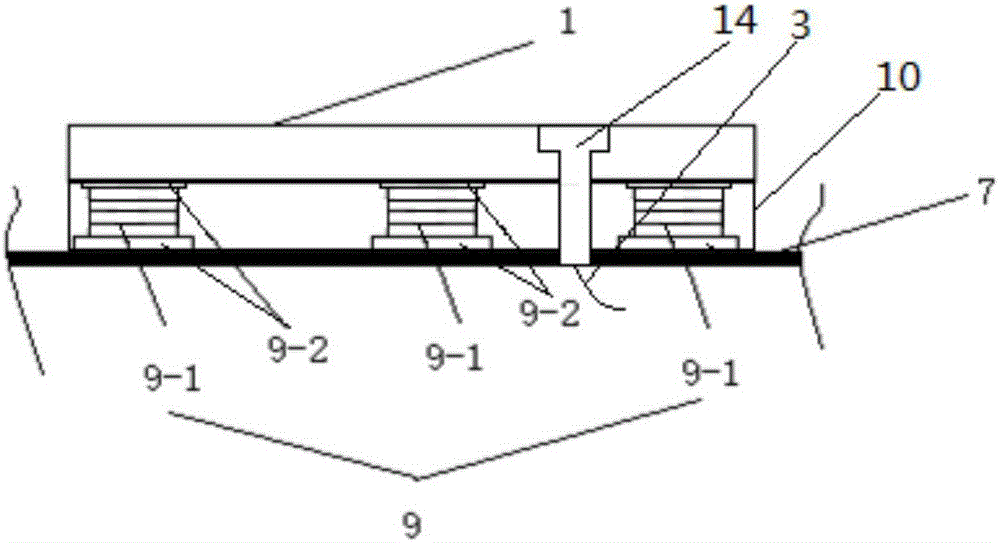

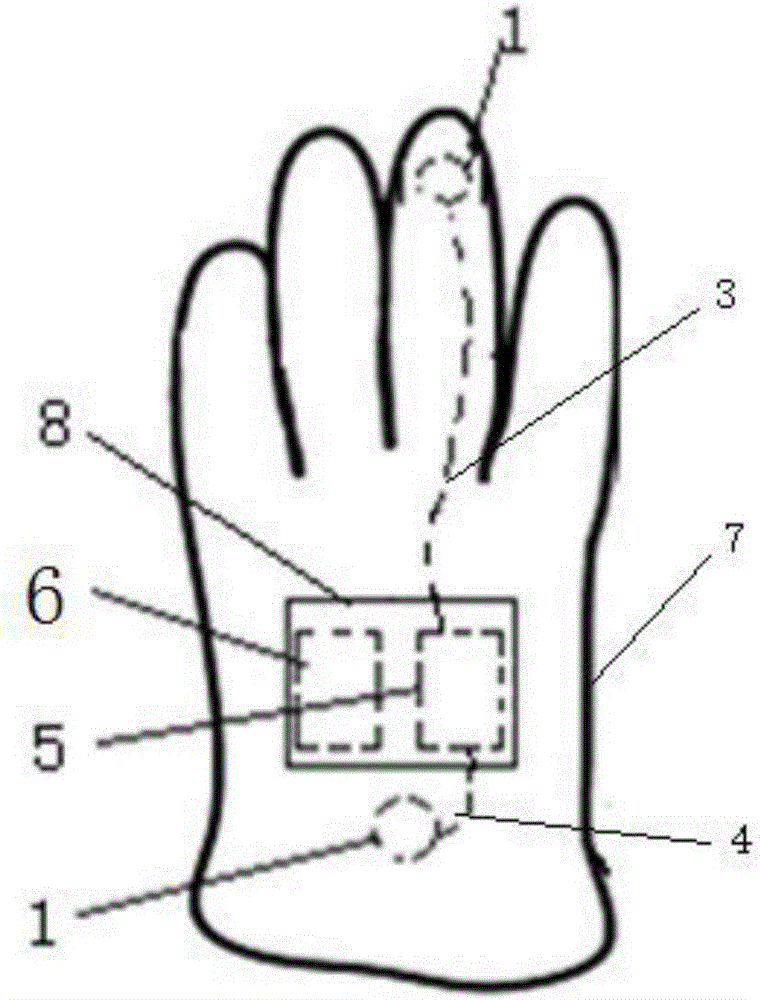

Biological information acquisition device, smart garment and smart gloves

PendingCN106137179AEasy to collectDoes not affect movementDiagnostic recording/measuringSensorsBiological bodyEngineering

The invention discloses a biological information acquisition device, a smart garment and smart gloves. The biological information acquisition device is applied to a wearable article and comprises a biological information acquisition assembly arranged on the wearable article, a main control unit arranged on the wearable article and conductive yarn for connecting the biological information acquisition assembly and the main control unit, wherein at least part of the biological information acquisition assembly is fixed in the position, corresponding to a to-be-monitored part of a living body, of the wearable article; after the main control unit is electrically connected with the biological information acquisition assembly through the conductive yarn, at least part of the conductive yarn penetrates the wearable article. Compared with the prior art, the biological information acquisition device can acquire biological information of the living body conveniently, and the conductive yarn can be changed adaptively along with the form of the wearable article, so that the practicability and the comfort of the wearable article can be improved greatly under the condition that actions of the living body are not affected.

Owner:SHANGHAI UNIV OF ENG SCI

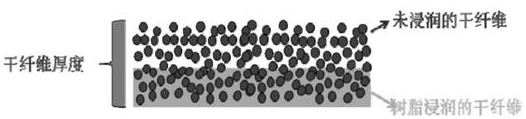

Semi-impregnated prepreg preparation method and prepreg structure

ActiveCN113199666AReduce gas residueEnsure stabilityGlass/slag layered productsCoatingsPolymer chemistryYarn

The invention relates to the technical field of formed composite materials, in particular to a semi-impregnated prepreg preparation method and a prepreg structure. The semi-impregnated prepreg preparation method comprises the following steps that low gram weight gluing is carried out on a first glue film; high-gram-weight gluing is carried out on a second glue film; the first glue film and the second glue film which are coated with glue are attached to the two side faces of a fiber layer, and hot press molding is conducted; and an air guide layer is attached to the hot-pressed first glue film. By improving the prepreg hot-pressing process in the prior art, the gluing parameters are controlled when the first glue film and the second glue film are glued, a structure with an upper micro-infiltration layer, a middle dry yarn layer and a bottom infiltration layer is formed, and the micro-infiltration layer has air permeability; and compared with the prior art, the ventilation continuity of a semi-impregnated prepreg base material is reserved, gas residues in the vacuum-pumping curing process of a thick and heavy product laying layer are reduced, the stability of dry yarns in the semi-impregnated prepreg base material is ensured, and the phenomena of twisting, slippage and dispersion of the dry yarns in the laying process are reduced.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Cotton fabric with different functions on two sides and preparation method thereof

ActiveCN112012011AImprove safety performanceGood durabilityStain/soil resistant fibresBiochemical fibre treatmentComposite materialAnti bacterial

The invention relates to a cotton fabric with different functions on two sides. One side of the fabric is an antibacterial finishing layer, and the other side of the fabric is an antifouling finishinglayer. The antibacterial finishing layer is made of polymethacryloyloxyethyl trimethyl ammonium chloride; and the antifouling finishing layer is made of polyethylene glycol-400 (PEG-400). The antibacterial finishing layer in the cotton fabric with different functions on the two sides is a non-skin contact layer and can effectively kill various bacteria and prevent bacterial adhesion, and the antifouling finishing layer is a skin contact layer and can prevent skin secretion adhesion, so that bacterial nutrition channels are cut off, and mildness and no irritation to the skin are guaranteed. The cotton fabric with the different functions on the two sides has efficient antibacterial capacity, excellent bacterial adhesion prevention capacity and excellent skin secretion pollution prevention capacity, is mild and non-irritant to the skin and has high safety.

Owner:ZHEJIANG SCI-TECH UNIV

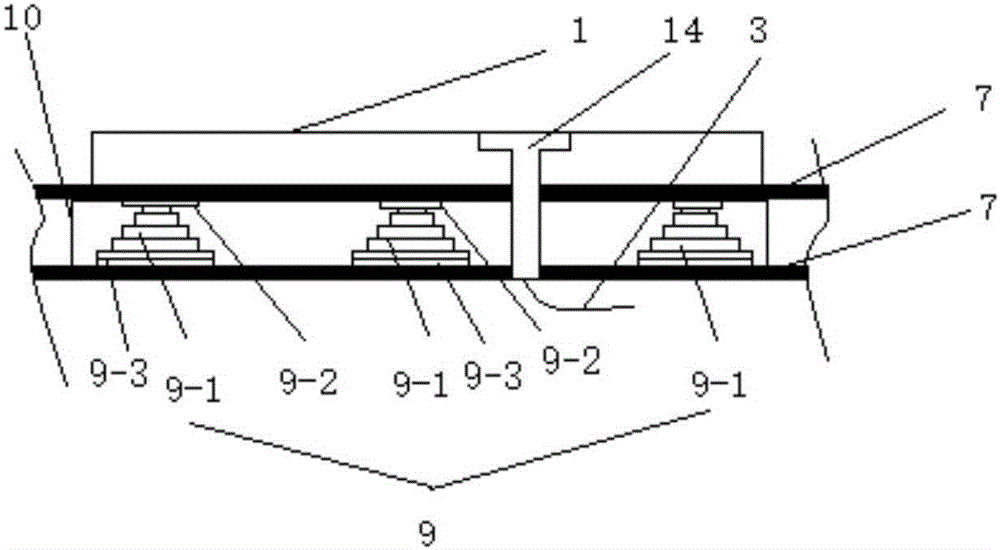

Bioelectrical signal monitoring device, monitoring garment and monitoring gloves

PendingCN106137180AAccurate monitoringRetain comfortEvaluation of blood vesselsSensorsBiological bodyExcitation temperature

The invention discloses a bioelectrical signal monitoring device applied to a wearable article. The bioelectrical signal monitoring device comprises a bioelectrical signal monitoring assembly, a memory metal assembly and a main control unit, wherein the bioelectrical signal monitoring assembly and the memory metal assembly are arranged on the wearable article, and at least part of the bioelectrical signal monitoring assembly is fixed in the position, corresponding to a to-be-monitored part of the living body, of the wearable article and connected with the memory metal assembly; the excitation temperature of the memory metal assembly is lower than the temperature of the to-be-monitored living body; when the living body wears the wearable article, the memory metal assembly is excited and deforms towards the bioelectrical signal monitoring assembly to prop the bioelectrical signal monitoring assembly against the to-be-monitored part of the living body. Compared with the prior art, the bioelectrical signal monitoring assembly can be tightly attached to the to-be-monitored part of the living body under the action of the memory metal assembly without aid of external force, and bioelectrical signals of the living body can be monitored precisely for a long time through the main control unit.

Owner:SHANGHAI UNIV OF ENG SCI

Production method of argil flowerpot

InactiveCN106747294ARetain breathabilityAffect resilienceReceptacle cultivationClaywaresFree coolingToughness

The invention relates to a production method of an argil flowerpot, which comprises the steps of raw material treatment, blank treatment and forming. Most of a raw material used is red soil; the material is convenient and economic; the mass production is facilitated; added glassy water facilitates forming of the argil flowerpot; a production process is simple; the fired flowerpot reserves air permeability of the argil; a mold shape can be adjusted to change a shape of the flowerpot in a forming process; the flowerpot is heated and then cooled naturally in a firing process; on the one hand, the energy consumption can be reduced; on the other hand, natural cooling can avoid influence of temperature jump on toughness of the flowerpot in the cooling process, so that the naturally cooled flowerpot is good in toughness and high in yield; the flowerpot is soaked in the glassy water in a coloring process; air holes in the surface of the flowerpot can be sealed temporarily to facilitate coloring; the flowerpot is colored uniformly; the surface is smooth and clean; and the manufacturing of the technical flowerpot is facilitated.

Owner:梅州市泰丰陶瓷有限公司

Preparation method for protective structure of concrete bridge anti-collision wall

InactiveCN102674887BSmall water absorptionRetain breathabilityBuilding insulationsSocial benefitsSurface layer

Owner:DALIAN TIANLU ANTI CORROSION ENG

A composite method of hot-air non-woven fabric and cotton non-woven fabric and its production system

ActiveCN106393945BRetain softnessRetain water absorptionLamination ancillary operationsLaminationPulp and paper industryNonwoven fabric

The invention discloses a compounding method of hot air through nonwoven fabric and all cotton nonwoven fabric, and belongs to the technical field of nonwoven fabric production. The method comprises the following steps: taking hot air through nonwoven fabric as the bottom layer, laminating a nonwoven fabric-cotton mesh on the hot air through fabric, and carrying out pre-wetting and front-back spunlace laminating to obtain the product. According to the method, a spunlace method is used to replace chemical adhering to compound chemical fiber nonwoven fabric and all cotton spunlace nonwoven fabric; the advantages of all cotton nonwoven fabric such as softness, water absorbing property, breathability, and the like, are preserved, at the same time, the advantages of hot air through nonwoven fabric such as high filling power, good elasticity, soft hand feeling, strong warm keeping performance, air penetrating and water penetrating performance, and the like are also preserved; moreover, the glue leakage is prevented, and the peeling strength meets the requirement.

Owner:WINNER MEDICAL (HUANGGANG) CO LTD

Coating decoration method for making high-grade waxing leather from low-grade leather

ActiveCN102827966BImprove waxing effectLow toxicityLeather manufacturingLeather surface finishingDefect repairLower grade

The invention relates to the technical field of a leather coating decoration method, and provides a coating decoration method for making high-grade waxing leather from low-grade leather with the advantages that the process is simple, the operation is convenient, used solvents have low toxicity, the natural attributives of softness, ventilation and the like of real leather are maintained, and the qualification rate is high. The method mainly comprises the following steps of leather blank preparation, defect repair, baking, plate pressing, polishing, mechanical foaming, falling, toggling, top coating, beating softening and sand plate pressing.

Owner:XINGYE LEATHER TECH CO LTD

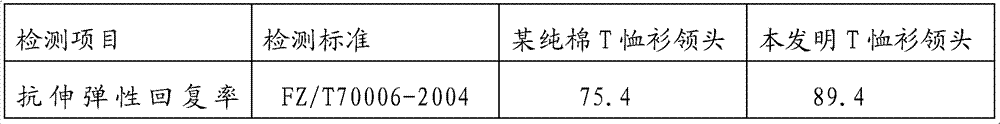

Cotton coated yarn collar and production method thereof

The invention relates to a collar, in particular to a cotton coated yarn collar and a production method thereof. The collar is woven by adopting the following components in percentage by weight: 52 to 56 percent of cotton yarns, 27 to 31 percent of polyester yarns and 15 to 19 percent of polyurethane coated yarns. Compared with the prior art, the invention has the advantages that: the polyester yarns and the polyurethane coated yarns with low cost are adopted for greatly substituting cotton yarns to weave the collar, and the performance of the produced cotton coated yarn collar is even superior to that of a pure cotton collar, so that the production cost of the collar is greatly reduced, the collar is hardwearing and durable, and the market competitiveness of the collar is improved; and proved by detection, the produced collar keeps the original appearance of the pure cotton collar, is close to the skin and comfortable, has thermal insulation property and air permeability, is light, elastic, stiff and smooth, and is not easily deformed or pilled.

Owner:泉州市劲超针织实业有限公司

A kind of semi-impregnated prepreg preparation method and prepreg structure

The invention relates to the technical field of molding composite materials, in particular to a method for preparing a semi-impregnated prepreg and a prepreg structure. The method comprises the following steps: applying low-gram-weight glue to the first glue film; High grammage glue coating; attach the first glued film and the second glued film on both sides of the fiber layer, and perform hot pressing molding; attach the air-conducting layer to the hot-pressed first glued film. The present invention controls the gluing parameters when gluing the first adhesive film and the second adhesive film by improving the hot pressing process of the prepreg in the prior art, and forms the upper micro-wetting layer and the middle dry yarn layer And the structure of the bottom impregnated layer, and the micro-infiltrated layer has air permeability; compared with the existing technology, it retains the air-permeable continuity of the semi-impregnated prepreg base layer, and reduces the gas residue during the vacuum curing process of the thick product layup , and ensure the stability of the dry yarn in the semi-impregnated prepreg substrate, reducing the twisting, slipping and dispersion of the dry yarn during the laying process.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Method for preparing dermal transfer smearing

InactiveCN1321197CRetain softnessRetain breathabilityLiquid surface applicatorsSynthetic resin layered productsPlastic filmPolyresin

The invention relates to a manufacture method of coating for true leather transfering, which can be used in the leather precision work craft. The manufacture is: A, first use mending agent to scrape and mend the wound on the leather; B, the resin which can fuse below 130 DEG C is pressed on the thin film; C, spray the water resin fluid on the leather or the thin film coated with the resin in fog mode; D, between 100-110 DEG C temperature conditions, fold the thin film with the resin evenly on the leather, flat or roller press the resin layer with the pressure of 2 to 4 kilograms on to the leather and bond with it. Remove the plastic film to obtain the finished product.

Owner:邹恒余

Special fertilizer for Huangguan pears and application thereof

PendingCN109180227APromote absorptionIncrease peel thicknessAnimal corpse fertilisersClimate change adaptationFertilizerBeneficial bacteria

The invention relates to the technical field of fruit tree planting and particularly relates to special fertilizer for Huangguan pears and a preparation method and application thereof. The special fertilizer for Huangguan pears comprises, by weight, 5-10 parts of wood vinegar, 2-6 parts of animal bones, 2-6 parts of fulvic acid and 1-3 parts of beneficial bacteria. The synergistic effects of components can effectively prevent Jizhua disease of Huangguan pears and improve fruit quality. The fertilizer does not contain toxic substances, is harmless to the human body and can meet people's requirements on the health and safety of fruits.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT HEBEI ACADEMY OF AGRI & FORESTRY SCI

Glue for cloth glue dispenser and preparation method thereof

InactiveCN111040707AHigh bonding strengthImprove temperature resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer scienceAdhesive glue

The invention discloses glue for a cloth glue dispenser and a preparation method of the glue. The glue for the cloth dispenser is prepared from the following components in percentage by mass: 61.5 to62.0 percent of a polyurethane prepolymer, 26.0 to 26.5 percent of an ethylene vinyl acetate copolymer, 11.0 to 11.5 percent of tackifying resin, 0.2 to 0.4 percent of a filler and 0.1 to 0.3 percentof an auxiliary agent. The disclosed glue is suitable for an automatic cloth glue dispenser. The temperature and pressure needed in a mold pressing process are low, high temperature and high pressureare not needed, energy consumption can be further reduced, the production cost can be further reduced, damage to cloth is avoided, the problems that the cloth becomes hard and discolors due to high temperature do not exist, and the application range is wide. A whole garment product produced by the glue matched with an automatic cloth glue dispenser is free of any sewing stitches, more convenient to clean, comfortable, soft, good in hand feeling, good in air permeability, firm in bonding and good in stability, the overall production efficiency is improved, and then the production cost is reduced.

Owner:SUZHOU MEISHANZI GARMENTS CO LTD +1

Full-bio-based high-durability super-hydrophobic cotton fabric and preparation method thereof

ActiveCN114411416ASuperhydrophobicAchieve self-cleaningTextile/flexible product manufactureLiquid repellent fibresOil separationStearic acid

The invention discloses a full-bio-based high-durability super-hydrophobic cotton fabric and a preparation method thereof. The preparation method comprises the following steps: carrying out roughening pretreatment on a cotton fabric; dipping the pretreated cotton fabric into an ethanol solution containing epoxidized soybean oil, sebacic acid and DBU, and then carrying out a curing reaction through catalysis of DBU; the treated cotton fabric is soaked in an ethanol solution containing stearic acid for esterification reaction, drying is conducted after soaking is finished, and the full-bio-based high-durability super-hydrophobic cotton fabric can be obtained. The full-bio-based high-durability super-hydrophobic cotton fabric prepared by the method not only has efficient hydrophobic capacity, excellent water-oil separation capacity and excellent self-cleaning capacity, but also adopts a full-bio-based reagent in the whole modification process of the fabric, so that the wearing safety of the modified cotton fabric is ensured; and the biological environmental protection property is greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

A kind of high-strength waterproof breathable composite dressing and preparation method thereof

ActiveCN111513925BImprove breathabilityPromote absorptionNon-adhesive dressingsPlastersPolymer scienceWound.exudate

The invention discloses a high-strength waterproof and breathable composite dressing and a preparation method thereof, comprising an outer layer and an inner layer, the outer layer is a polytetrafluoroethylene film, the inner layer is a hydrogel, and the polytetrafluoroethylene film has a channel structure , the polytetrafluoroethylene film is compositely connected with the inner hydrogel by grafting a hydrophilic polymer compound. The composite dressing prepared by the present invention uses expanded polytetrafluoroethylene film as the outer layer structure, so that the dressing has good waterproof and antifouling properties, and its special pore structure can effectively prevent bacteria from penetrating into the wound and effectively prevent wound infection; at the same time, Wound exudate and sweat on the skin can also evaporate quickly through this special pore structure. This composite dressing retains the excellent properties of expanded polytetrafluoroethylene, making the dressing meet the needs of wound treatment under complex conditions on the battlefield and in the field.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

Genuine leather composite preparation method for fur and leather integrated fur product

InactiveCN106967852AImprove skin utilizationImprove yieldTanning treatmentComposite leathersDermisDyeing

The invention belongs to the technical field of leather product production, and specifically provides a fur and leather composite preparation method for fur products. The dyed fur and leather are repaired, spliced and stitched respectively to obtain stitched fur and stitched leather, the stitched fur and stitched leather are flattened, glue is applied to the leather surface of the flattened stitched fur, and glue is applied to the stitched fur. A composite fur is obtained by pasting the stretched suture leather on the surface, and pressing the obtained composite fur. In the composite preparation method of the present invention, composite fur products are finally prepared through the composite of fur and leather, which retains the good quality properties of the leather such as breathability, softness, and warmth retention. The skin surface with scratches, knife wounds and other defects on the surface after tanning is used as the bonding surface, and the top layer of leather is directly covered and bonded to cover the scratches and knife wounds, so as to improve the utilization rate of the skin and reduce the production cost.

Owner:张洪响

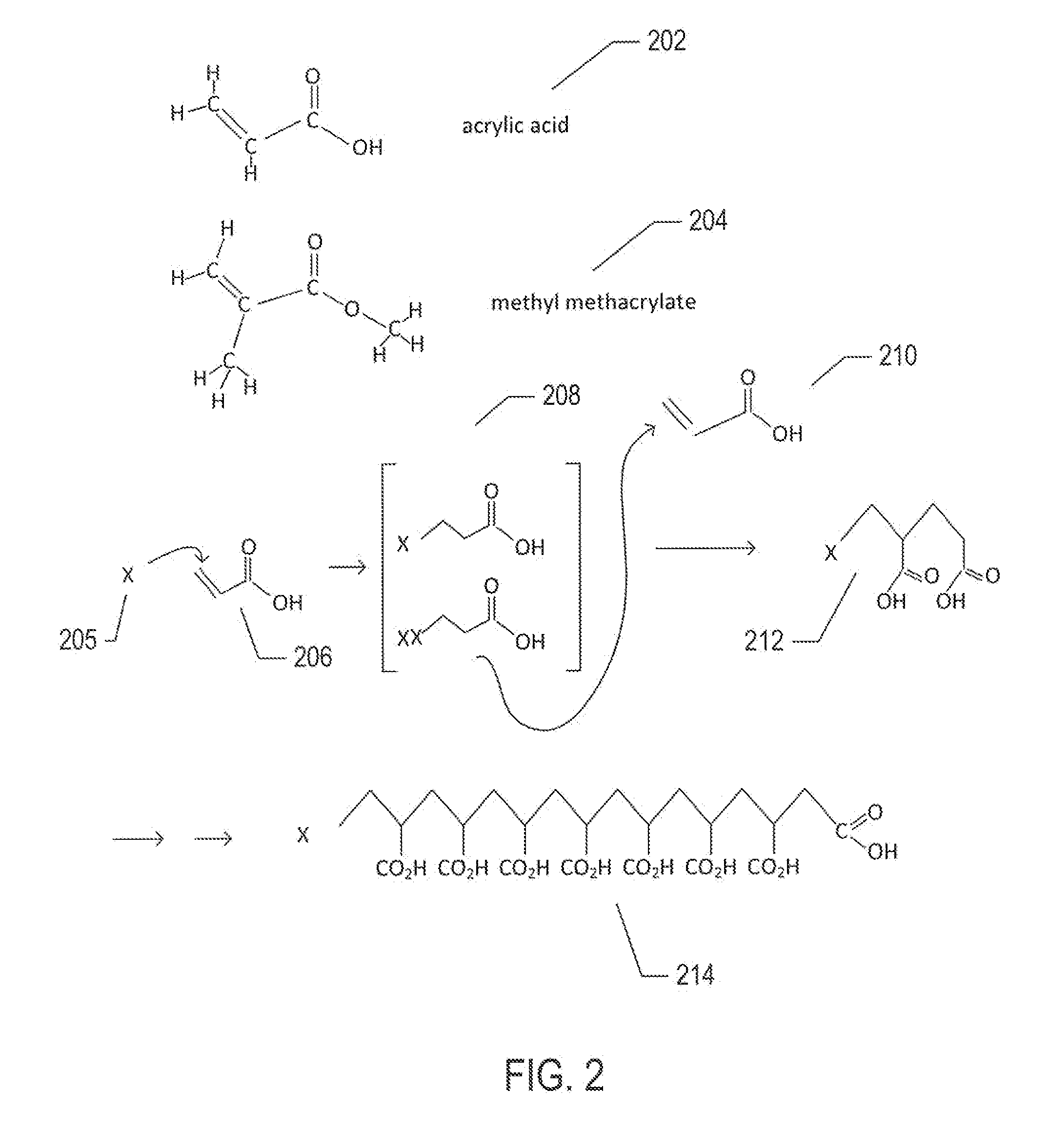

Waterproofing Compound and Waterproofing-Processing Method for Waterproofing a Wide Variety of Natual and Synthetic Fabrics and Materials

InactiveUS20110281483A1Retain breathabilityWaterproof, but breathableSynthetic resin layered productsPretreated surfacesWaterproofingEngineering

Embodiments of the present invention employ the perfluoroalkyl acrylic copolymerisate PD-1, produced by the Clariant Corporation, and certain other similar perfluoroalkyl acrylic copolymerisates, for waterproofing a wide variety of natural and synthetic fabrics and materials. In one embodiment of the present invention, fabrics and materials are passed through a bath of PD-1, or certain other perfluoroalkyl acrylic copolymerisates, and the material or fabric is then cured for a period of time within a range of periods of time specific to the type of material or fabric at a temperature within a range of temperatures specific to the type of material or fabric in order to create a remarkably waterproof, but breathable material or fabric with characteristics and properties identical or similar to those of the untreated fabric. Thus, embodiments of the present invention provide for remarkable degrees of waterproofing of natural and synthetic fabrics, while retaining the breathability characteristics of the natural and synthetic fabrics and materials as well as many other characteristics and properties, including texture, thickness, weight, and other characteristics and properties desirable to users of the materials and fabrics as well as products constructed from the materials and fabrics.

Owner:HIRSCHMANN FRANZ VON +1

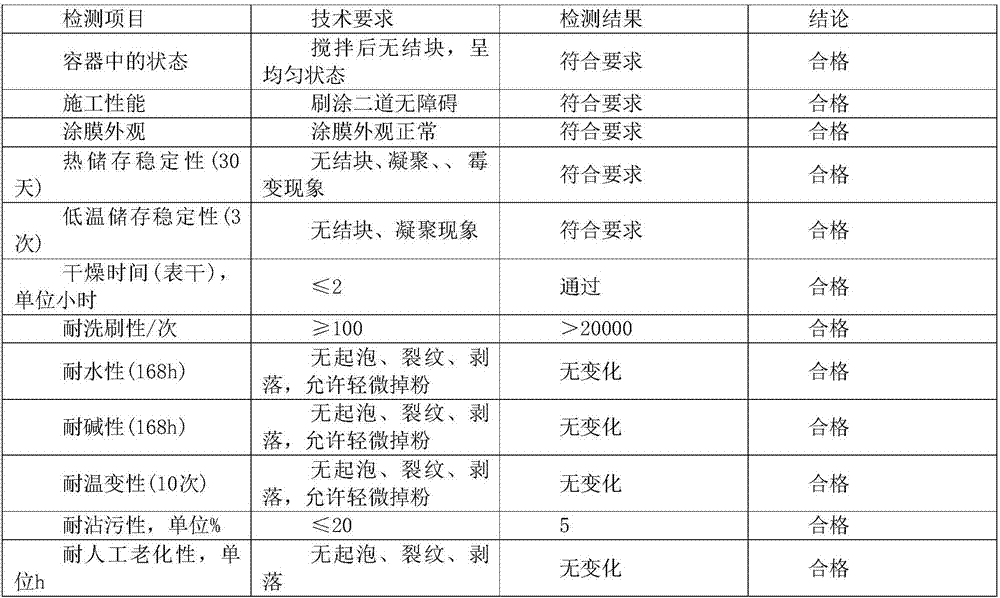

Novel colorful dry powder coating

The invention discloses a novel colorful dry powder coating. The novel colorful dry powder coating is prepared from, by weight, 400-500 parts of ordinary Portland cement, 200-300 parts of heavy calcium carbonate, 50-100 parts of talcum powder, 10-20 parts of titanium dioxide powder, 20-50 parts of iron oxide pigment, 2-3 parts of hydroxypropyl cellulose ether, 20-30 parts of modified redispersible polymer resin latex powder, 2-3 parts of sodium bentonite and 2-3 parts of ferrous sulfate. The colorful dry powder coating can be hardened under the condition of high humidity and rainfall, the adhesive power and washing resistant performance of a coating film are very excellent, the weatherability is good, and the novel colorful dry powder coating can be used for coating of internal and external wall veneers of new and old buildings.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

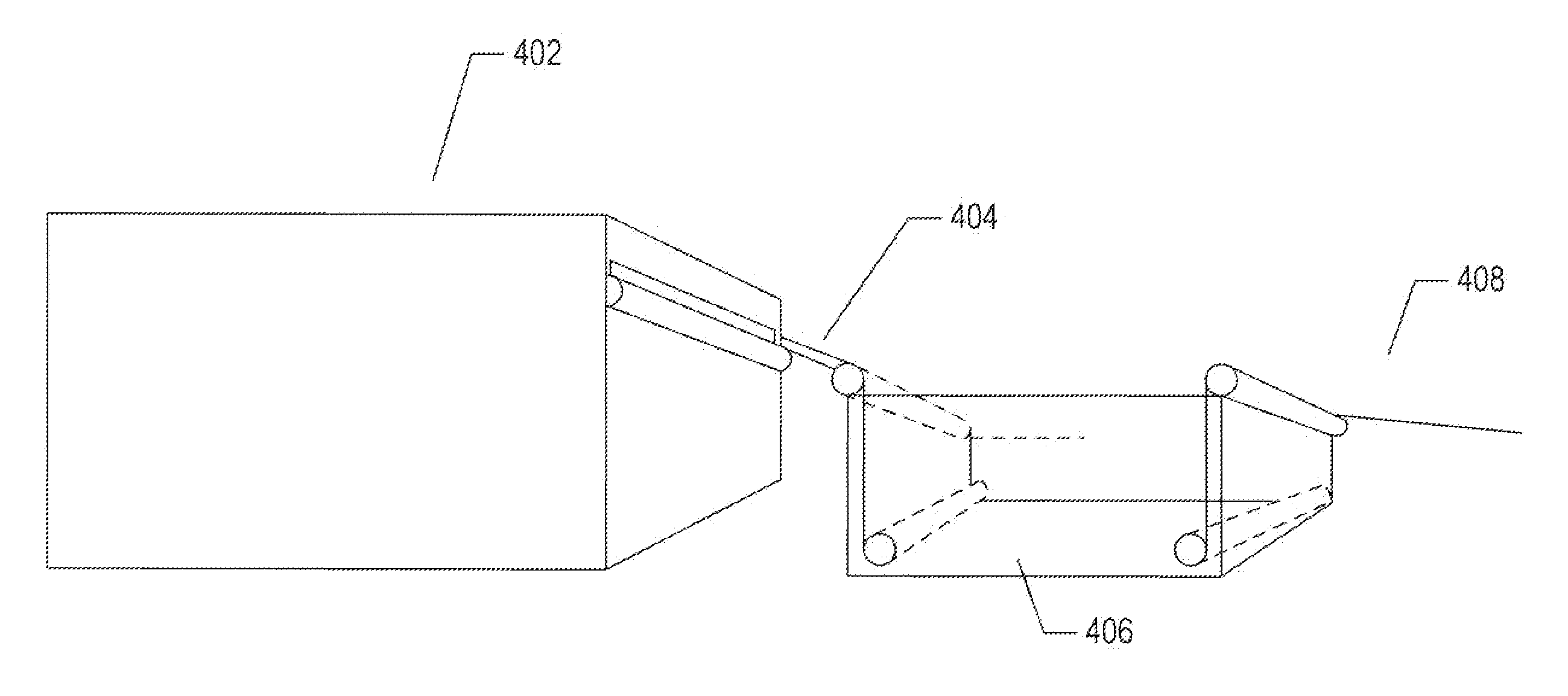

A kind of flame-retardant breathable fabric and preparation method thereof

ActiveCN112726181BRetain breathabilityLiquid surface applicatorsLaminationPolymer scienceAdhesive glue

The present invention relates to fabric processing, more specifically a flame-retardant breathable fabric and its preparation method, a preparation method of a flame-retardant breathable fabric, step 1: two flame-retardant fabrics I are wound on the feeding mechanism I, breathable The fabric is wound on the feeding mechanism Ⅱ, and the flame-retardant fabric Ⅱ is placed in the loading mechanism; Step 2: the smearing mechanism applies glue to the two flame-retardant fabrics Ⅰ, and the pushing mechanism pushes the end of the breathable fabric to the pressing mechanism On the lower side of Ⅰ, the shearing mechanism cuts it, and the pressing mechanism Ⅰ presses the cut breathable fabric between the two flame-retardant fabrics II; Step 3: The discharge mechanism pulls the gap between the two flame-retardant fabrics Ⅰ and The breathable fabric moves to the lower side of the pressing mechanism II, and the pressing mechanism II presses the flame-retardant fabric II in the charging mechanism between the two flame-retardant fabrics I and the front side of the breathable fabric; Step 4: pair the two The flame-retardant fabric I, the breathable fabric and the flame-retardant fabric II are stitched together to form a flame-retardant breathable fabric.

Owner:武汉长福亚太服饰股份有限公司

Method for coating surface of porous metal with film

ActiveCN112620625ASimple processNot easy to damageTransportation and packagingMetal-working apparatusPolyvinyl acetatePlasticizer

The invention discloses a method for coating the surface of porous metal with film. The method for coating the surface of the porous metal with the film comprises the following steps that 1, metal powder is mixed with a solvent, a plasticizer and a binder to form slurry A, and slurry B is prepared by using water and PVA (Polyvinyl Acetate); 2, a base band is coated with the slurry A, and after drying, the surface of the base band is coated with the slurry B; 3, a film blank is formed on the surface of the porous matrix through a cold isostatic press; and 4, demolding is conducted by using water-soluble treatment, and after drying, the porous metal film is prepared by adopting a vacuum degreasing-sintering process. According to the method for coating the surface of the porous metal with the film, the surface of a support body is directly coated with the film, the preparation process of a transition layer is omitted, the production cost is reduced, and the prepared porous film has consistent permeability with the support body, has the advantages of high precision, large flux and controllable film thickness, and can be widely applied to the fields of smoke dust removal, fine filtration and the like.

Owner:WESTERN BAODE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com